Number Determination of Successfully Packaged Dies Per Wafer Based on Machine Vision

Abstract

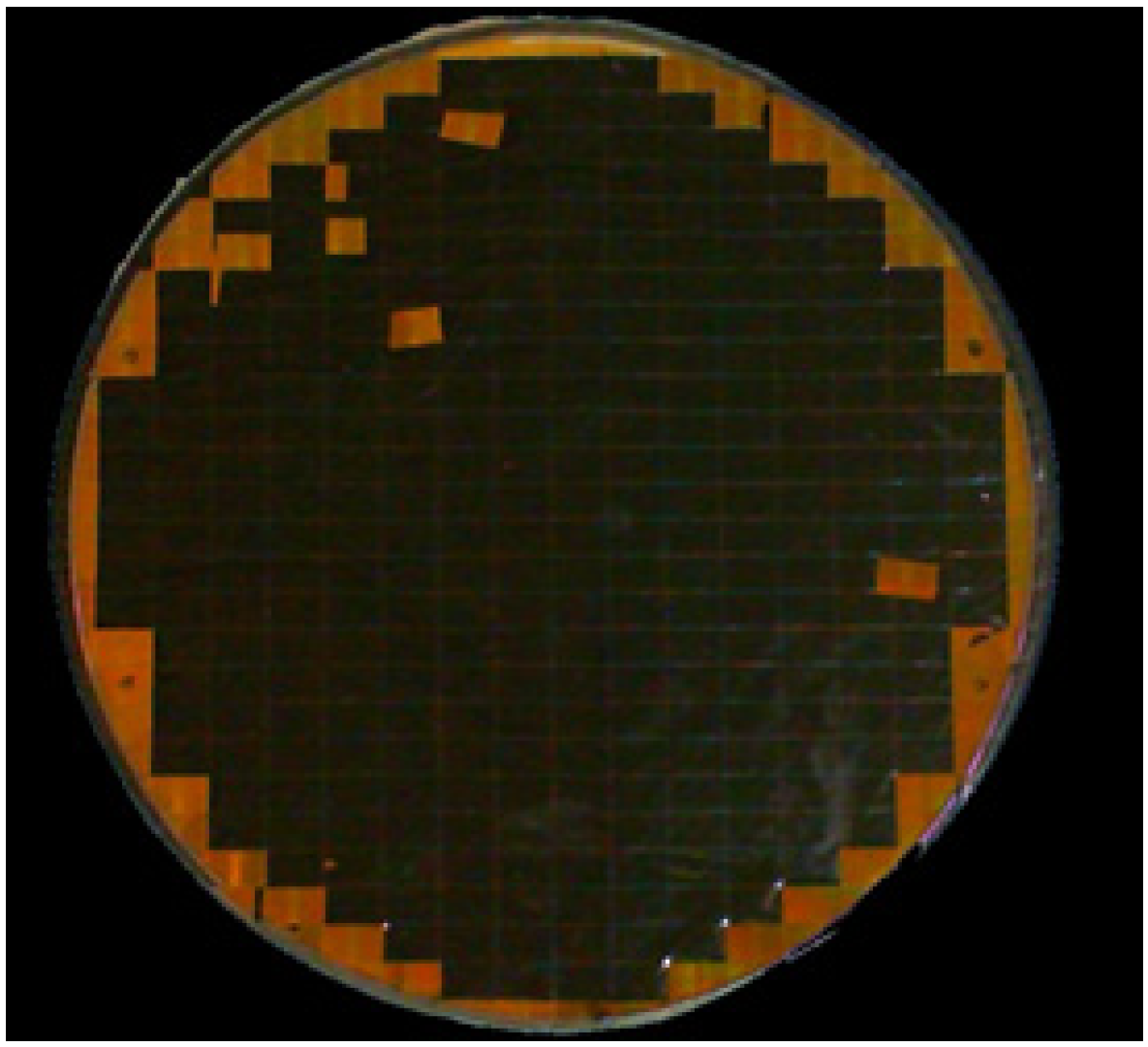

:1. Introduction

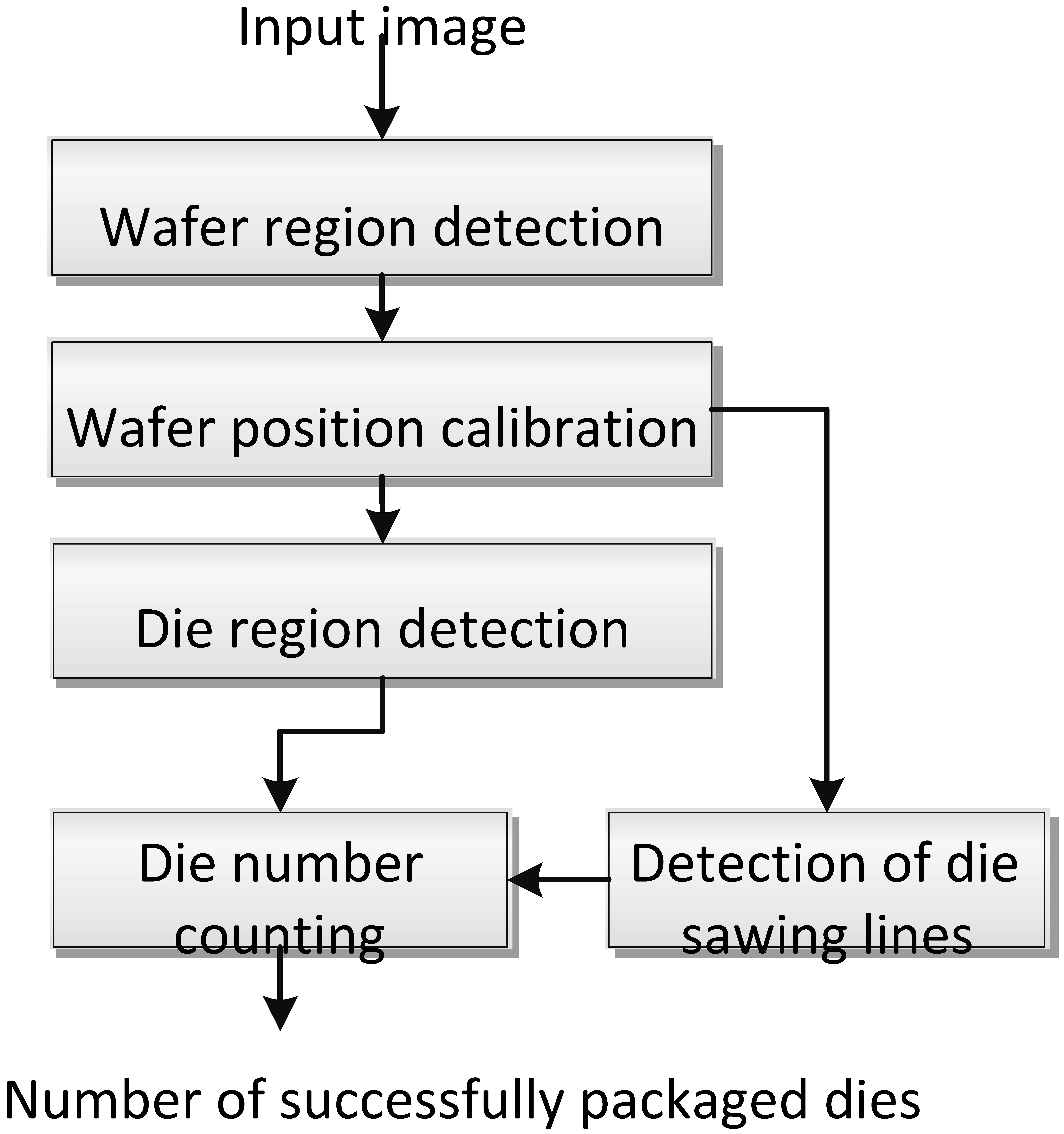

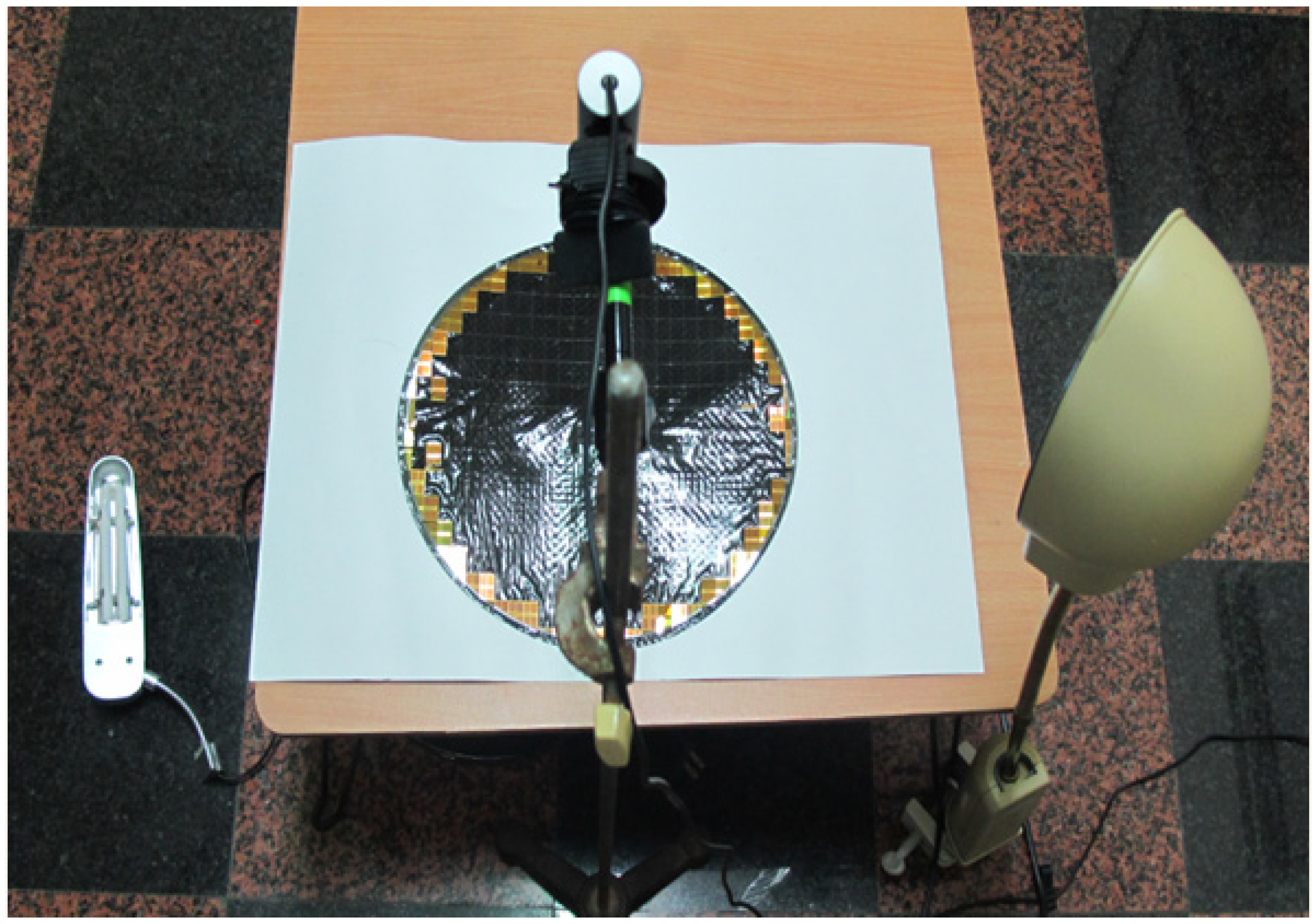

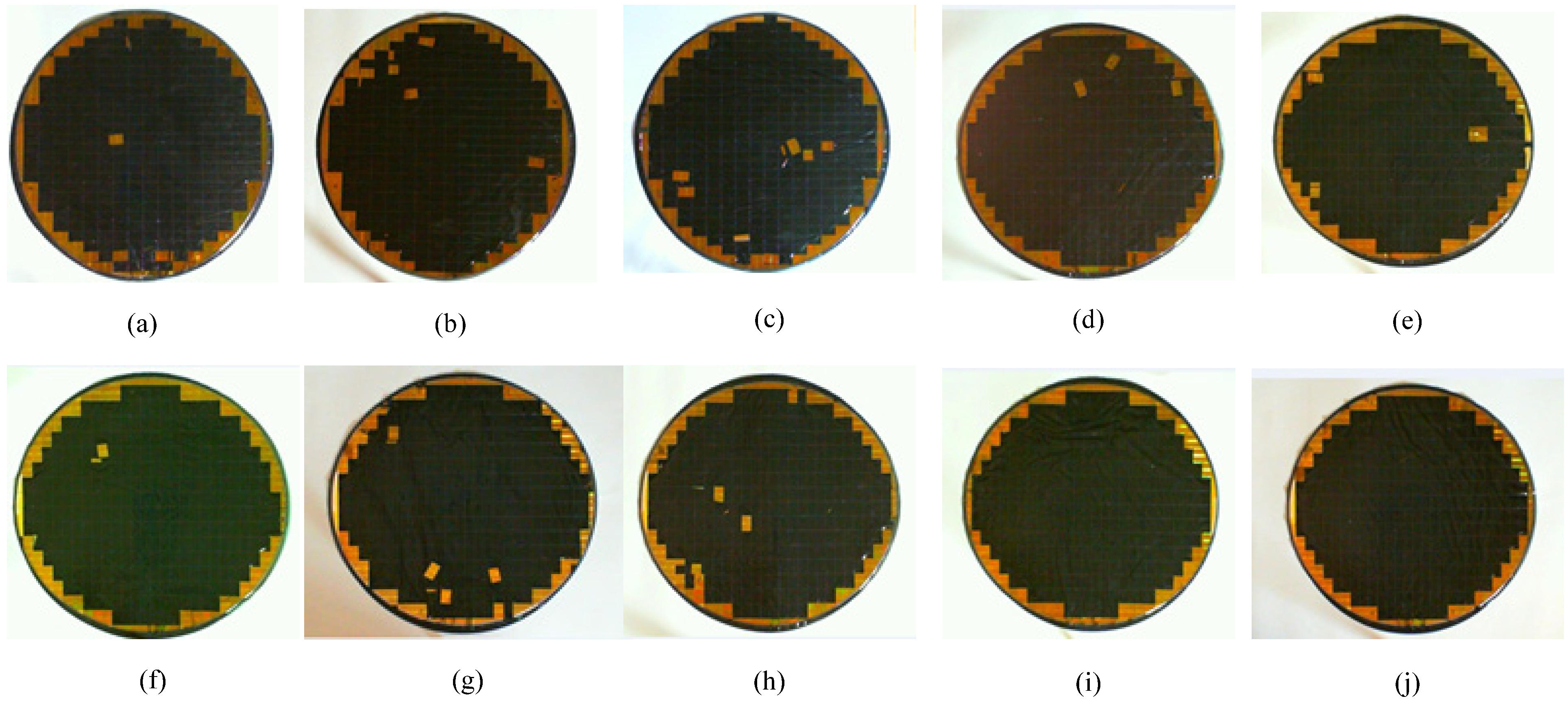

2. Method

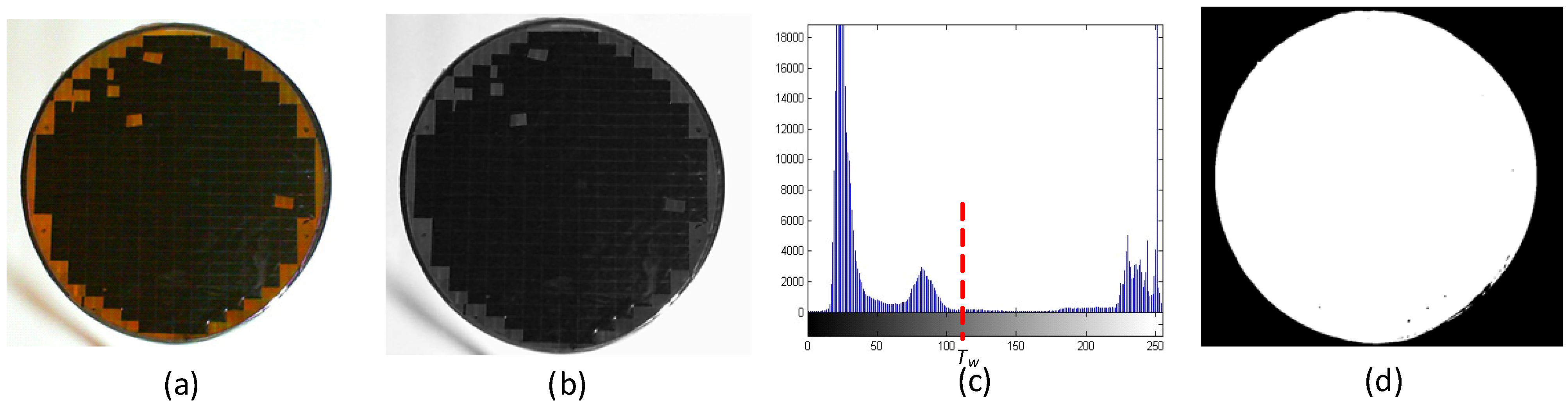

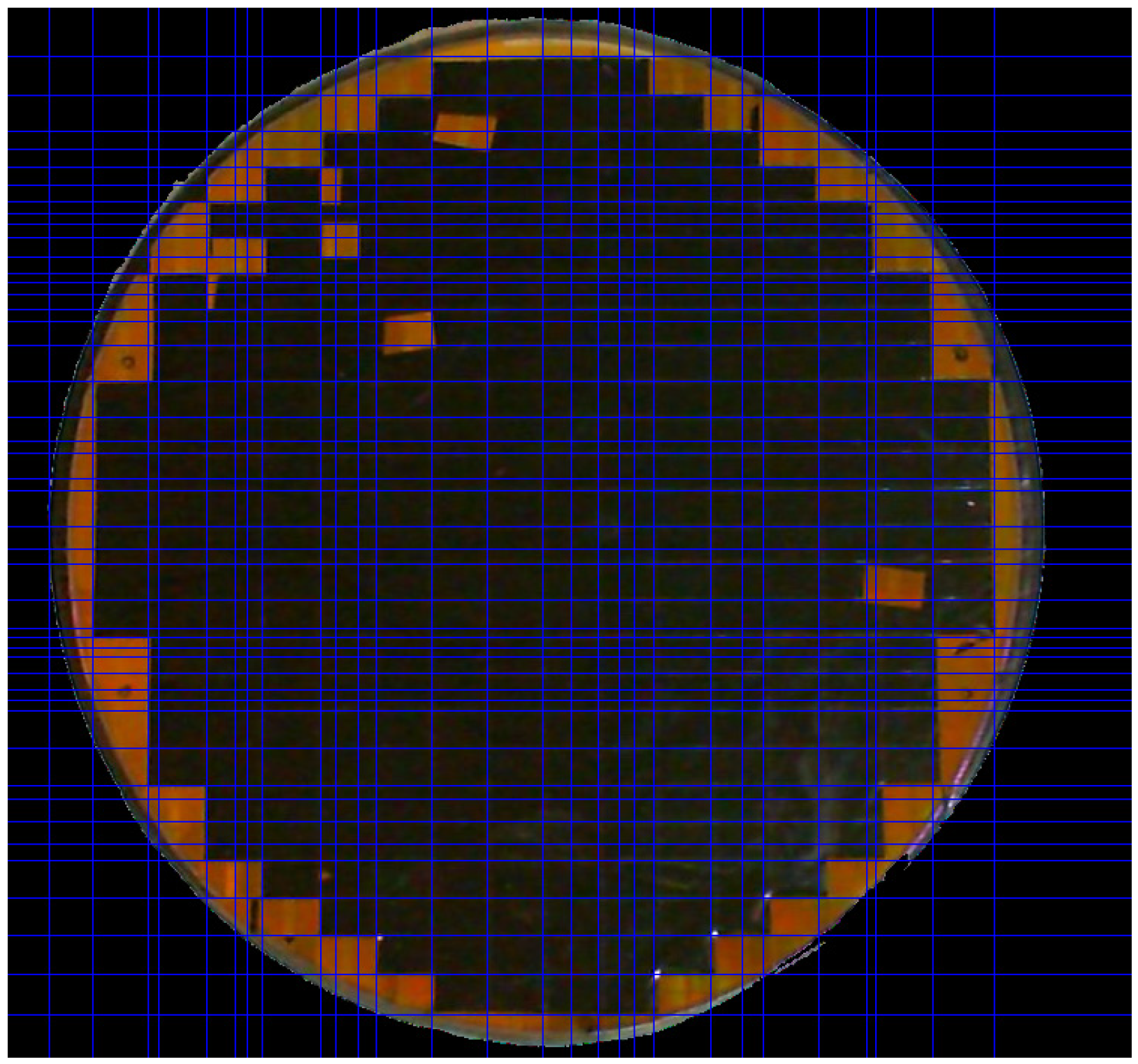

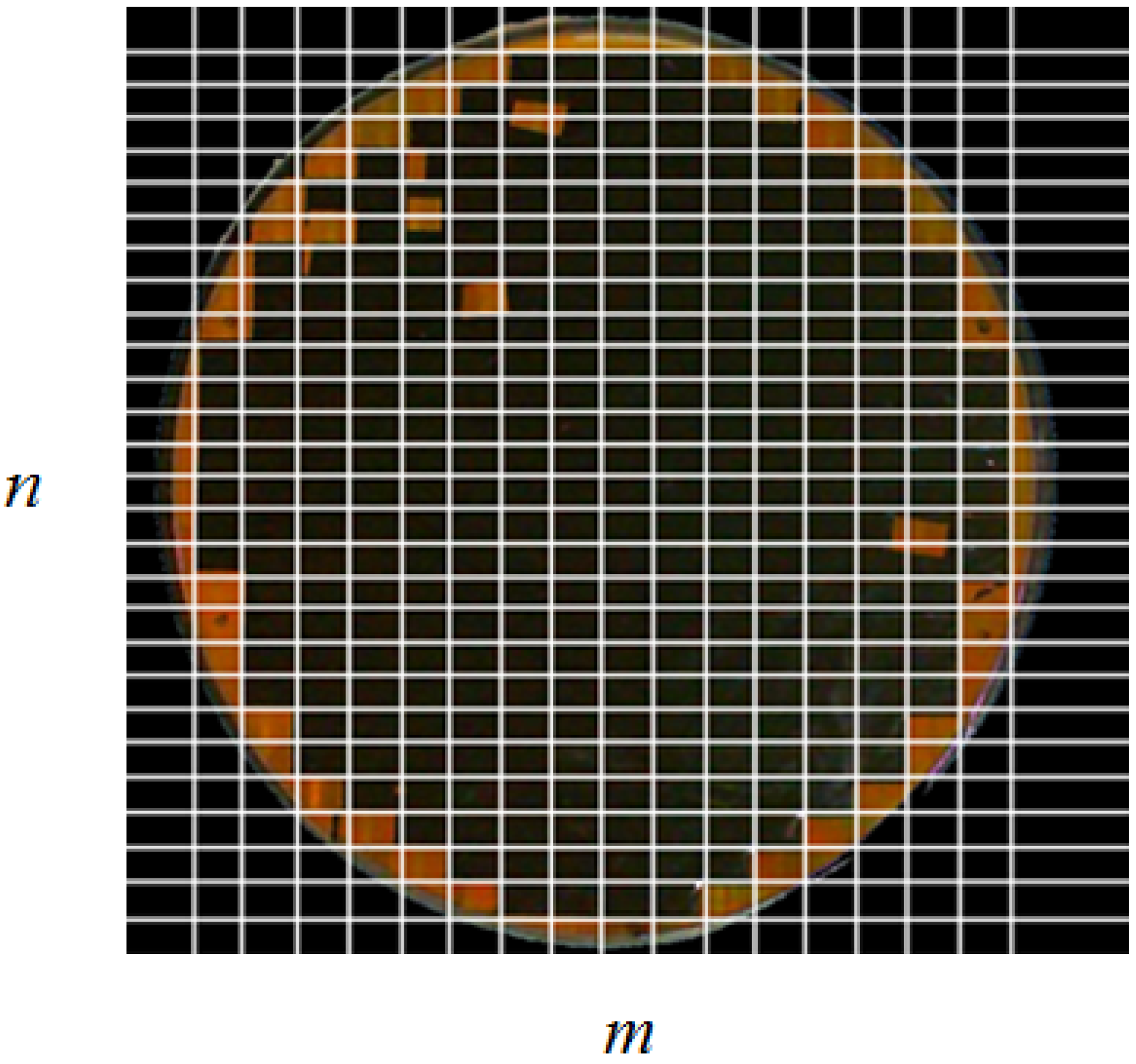

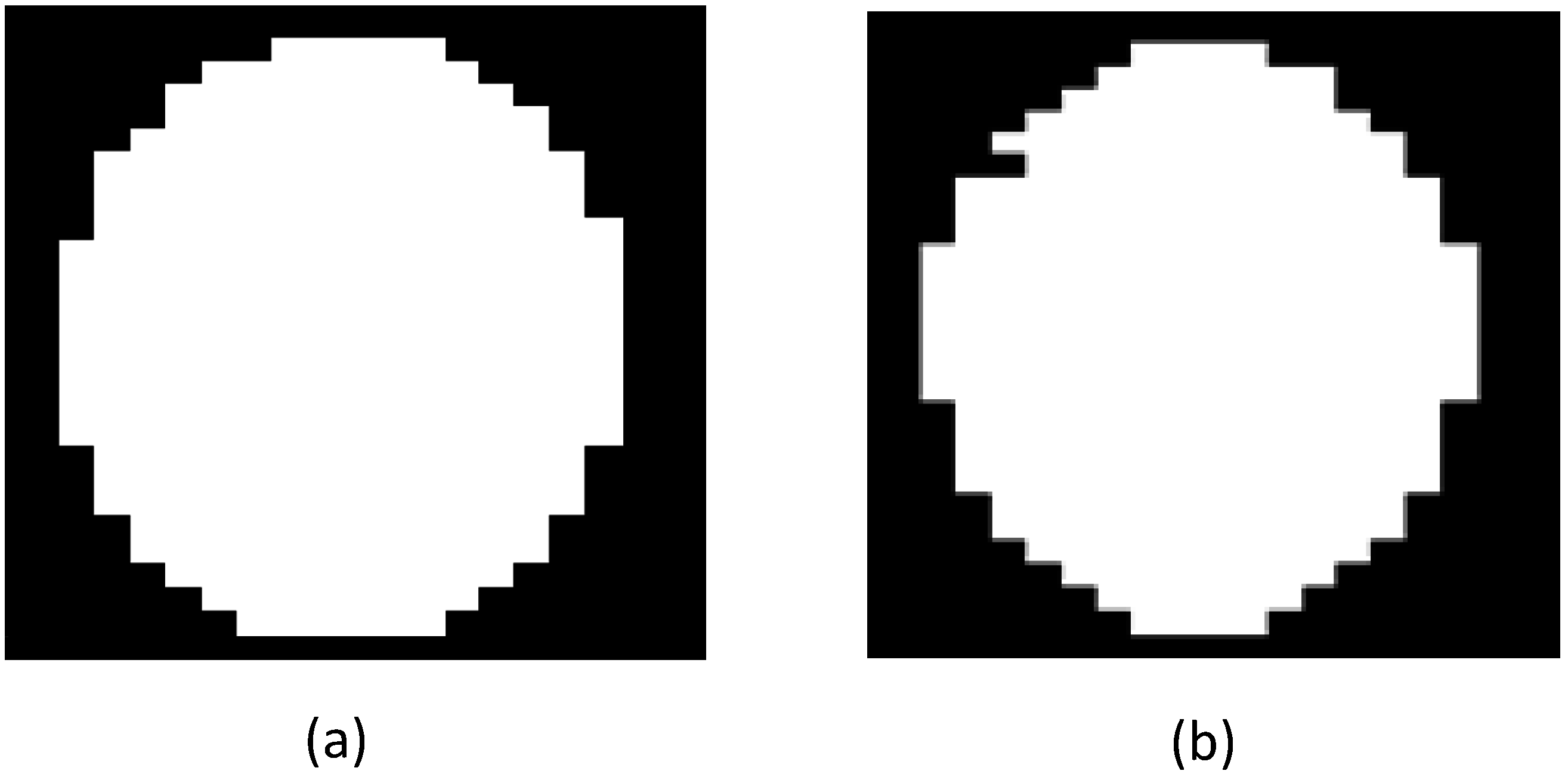

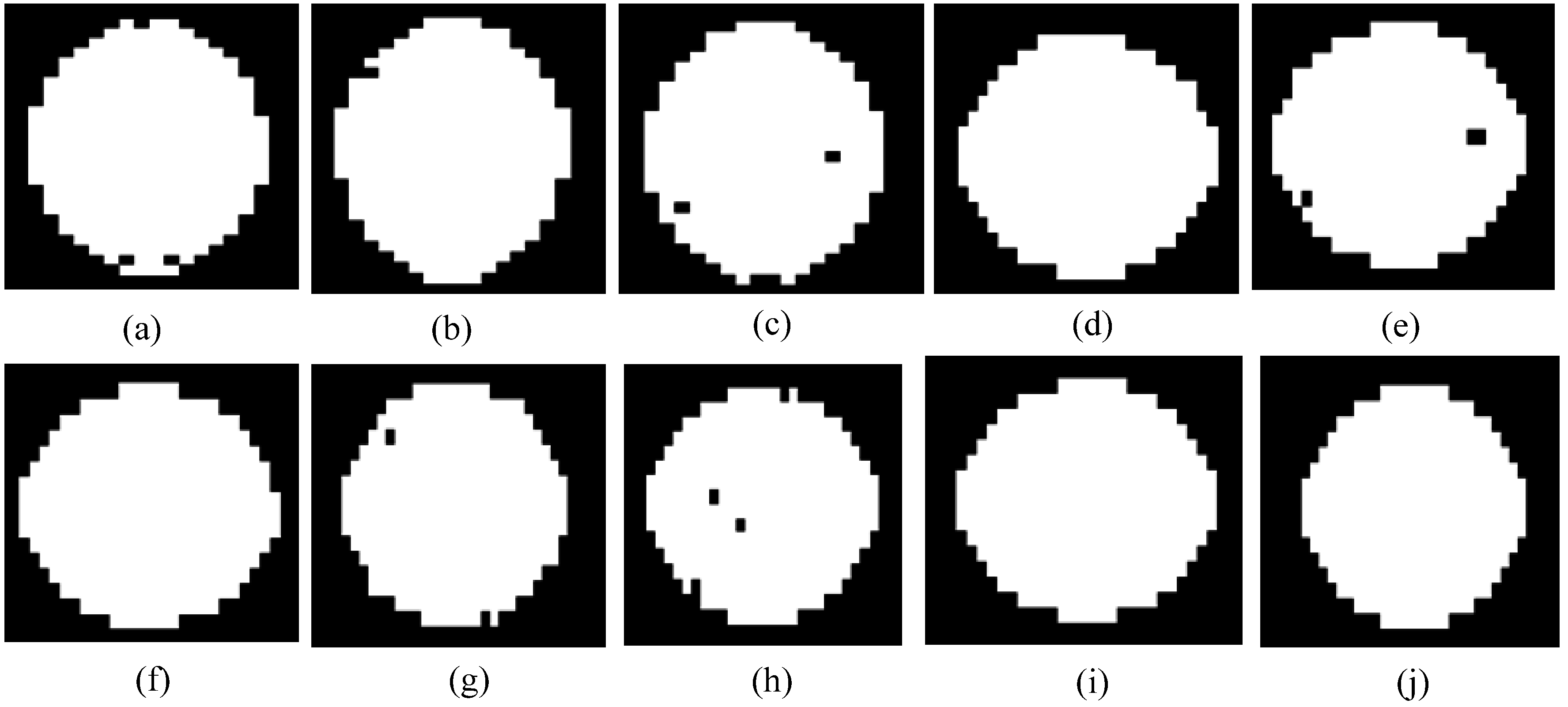

2.1. Wafer Region Detection

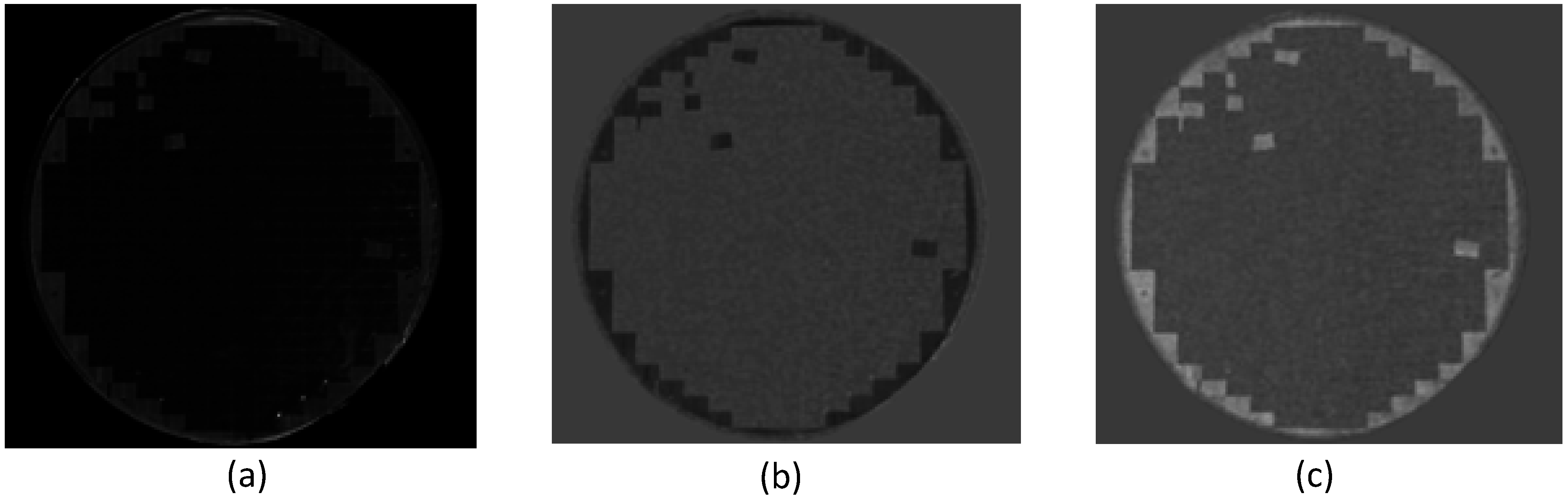

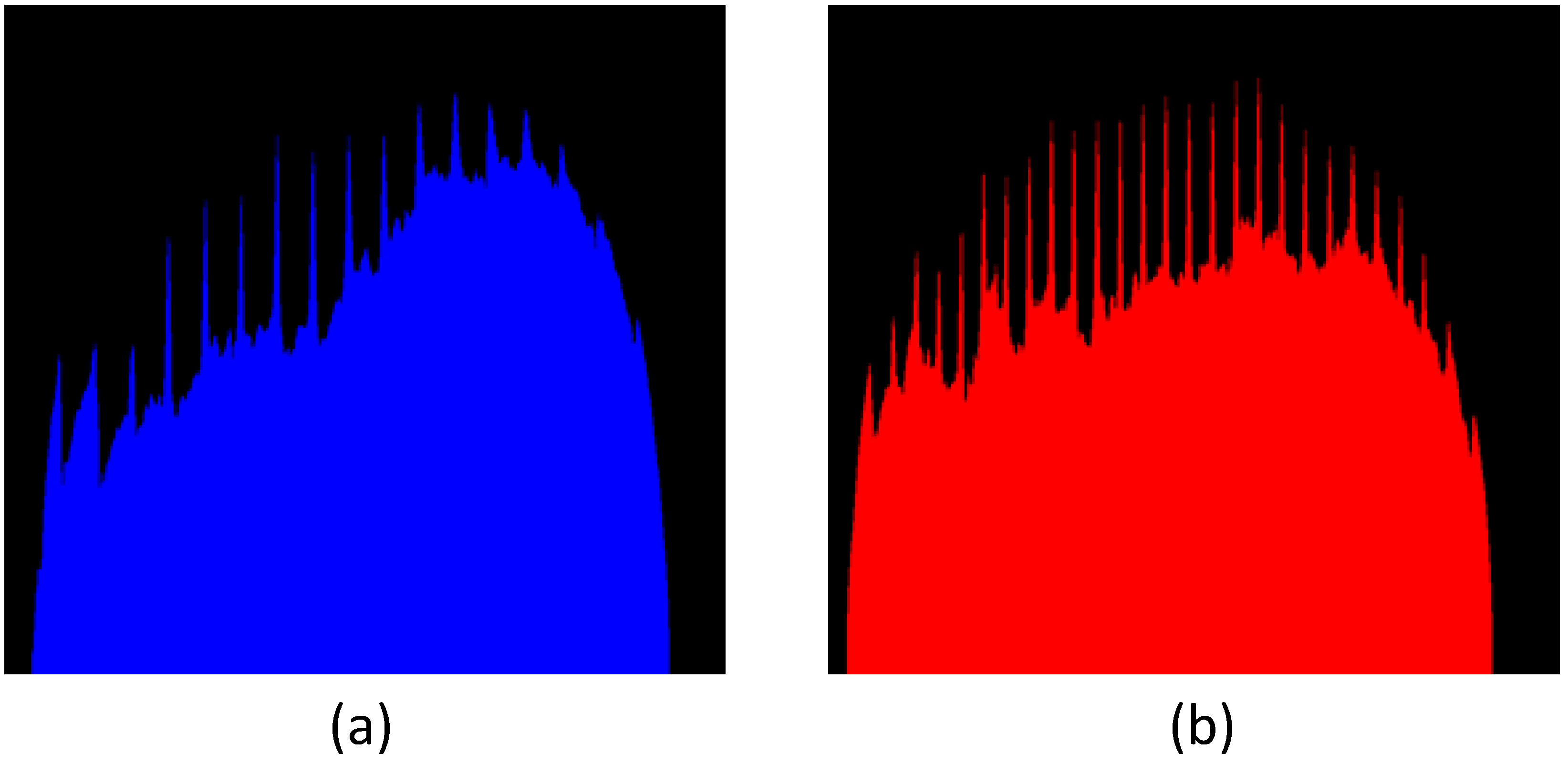

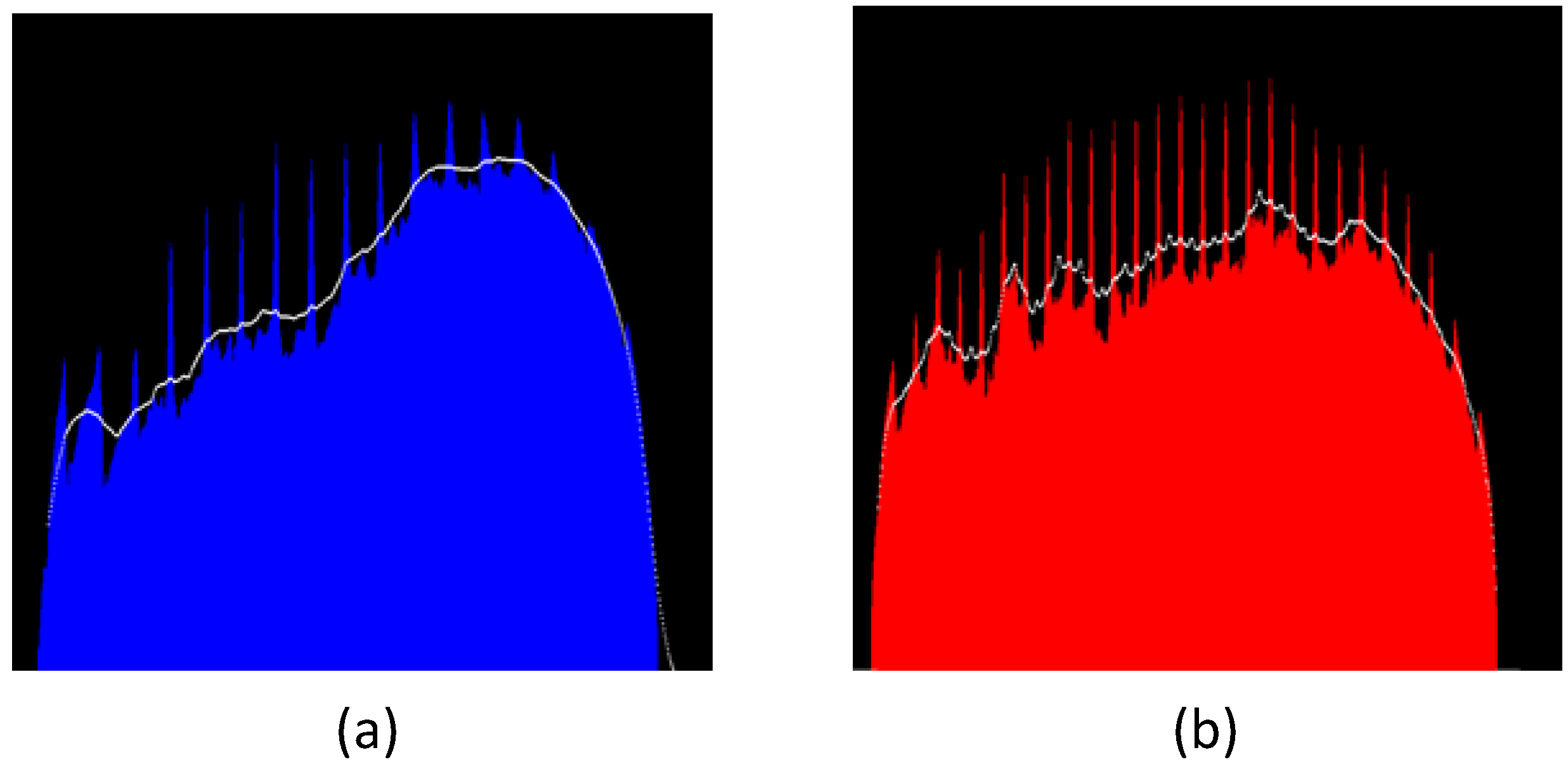

2.1.1. Color-to-Grayscale Transformation and Binarization

2.1.2. Region Labeling

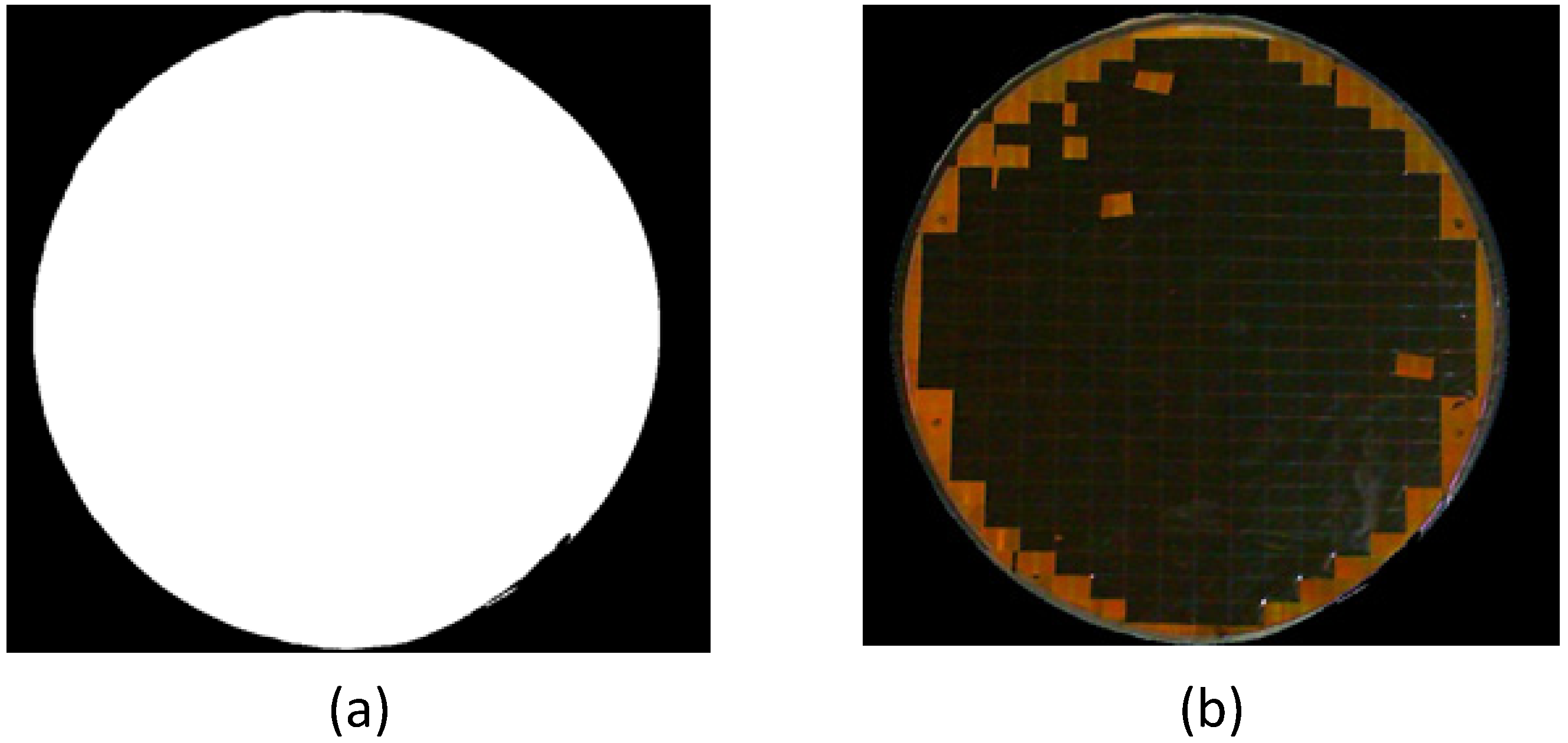

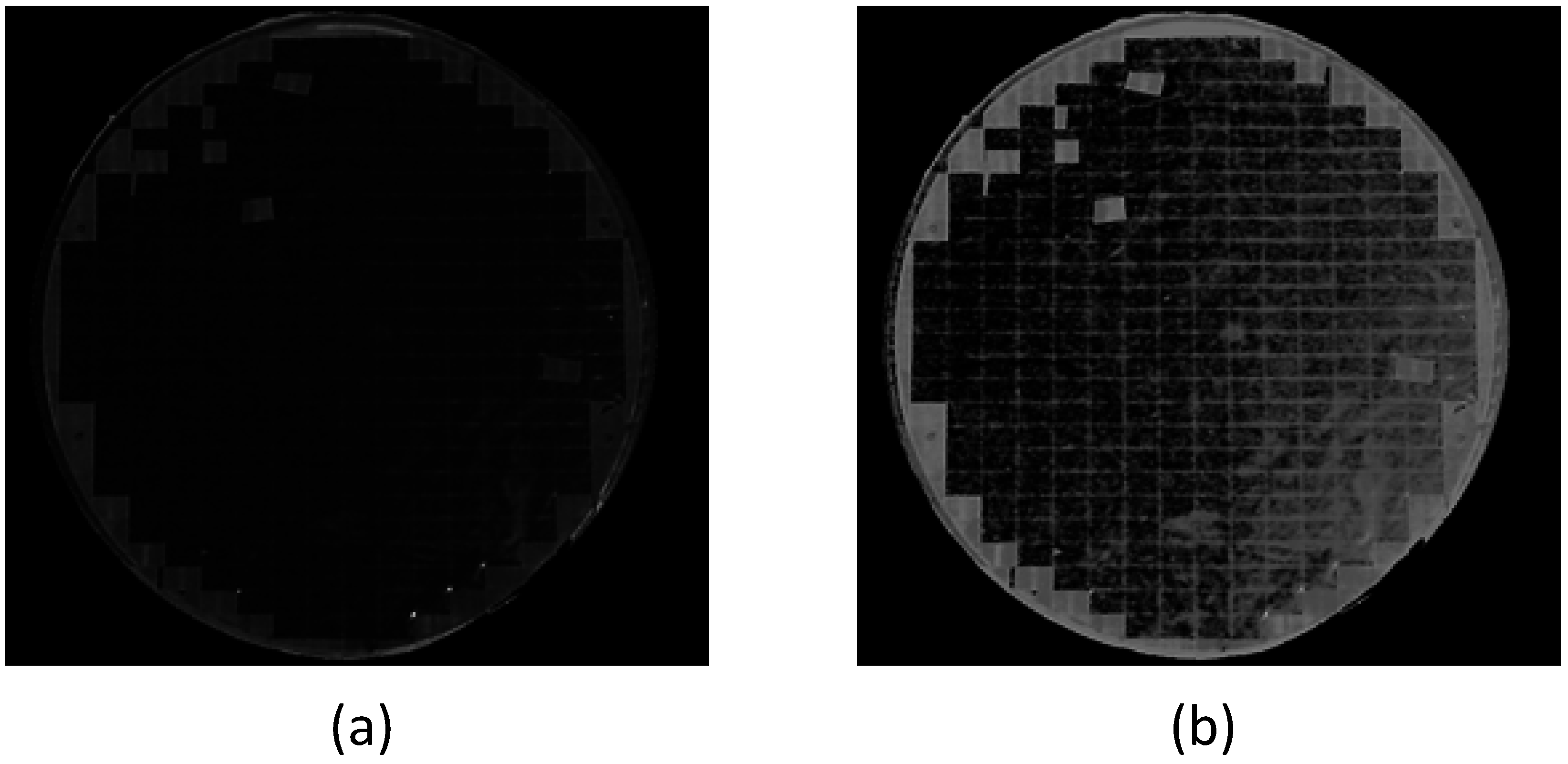

2.2. Wafer Position Calibration

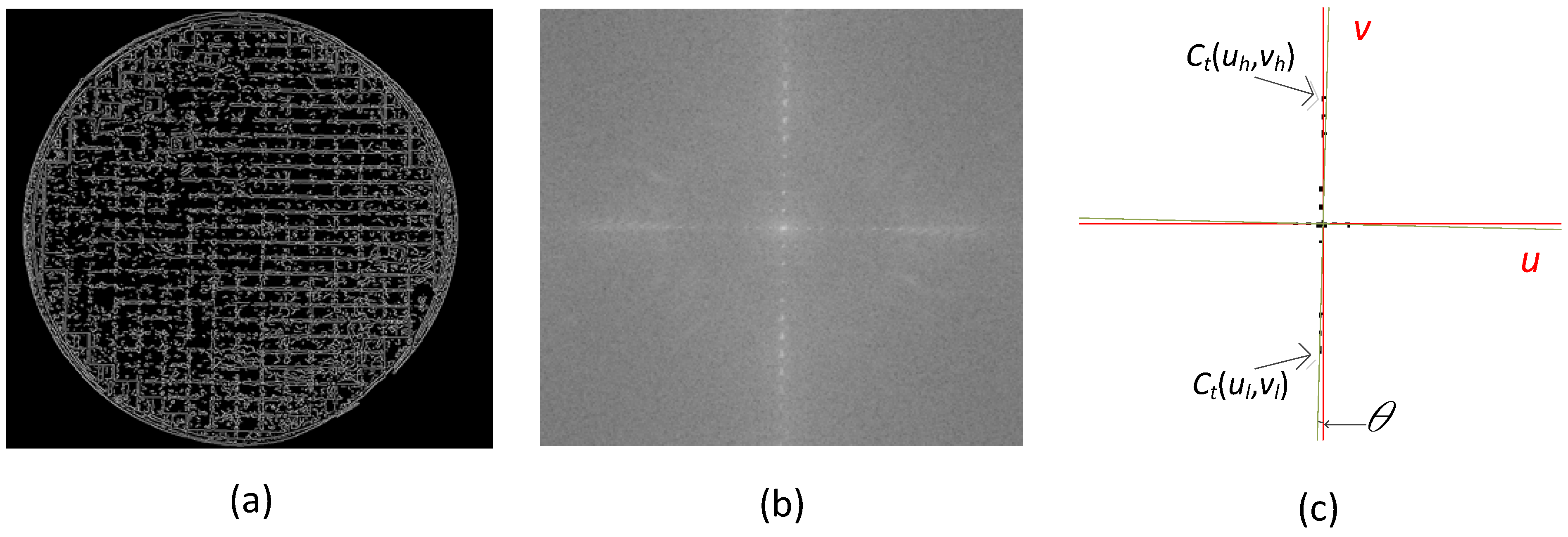

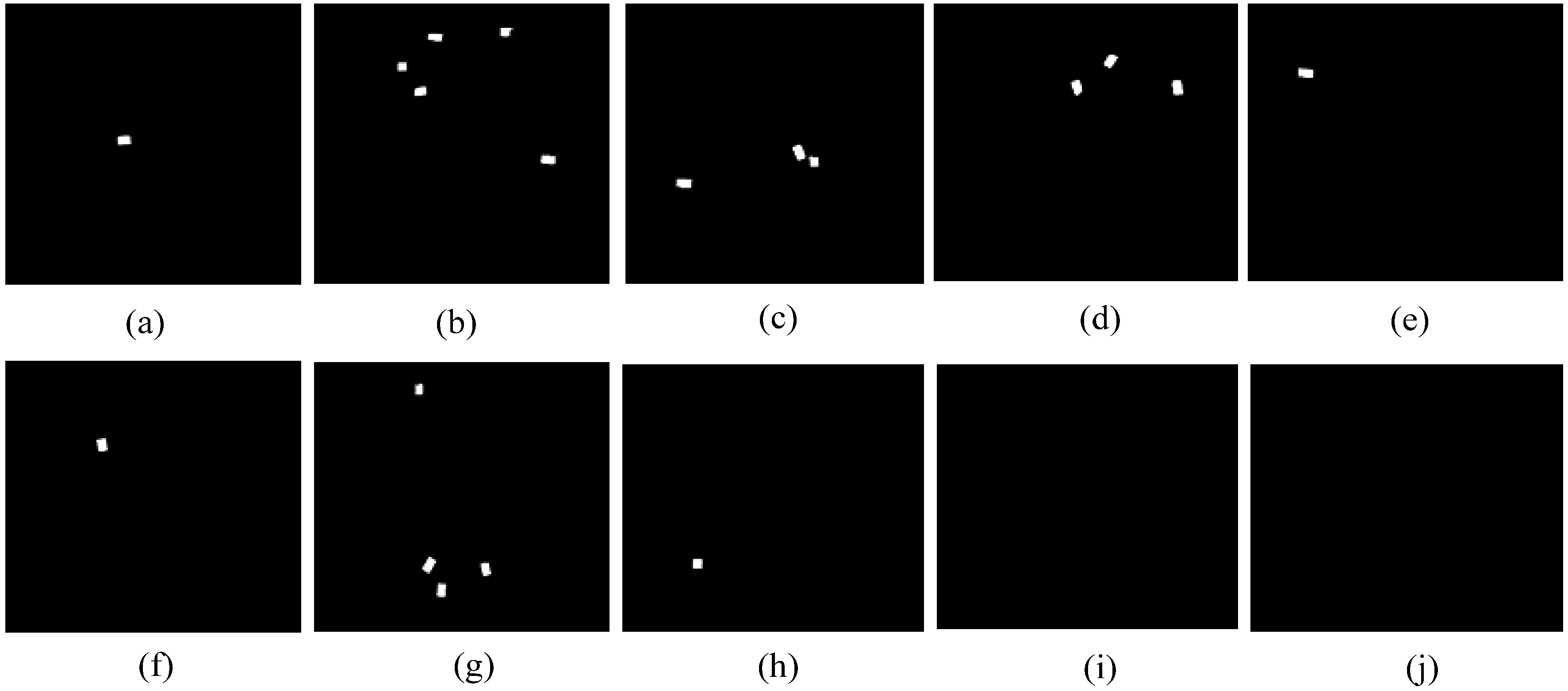

2.3. Die region Detection

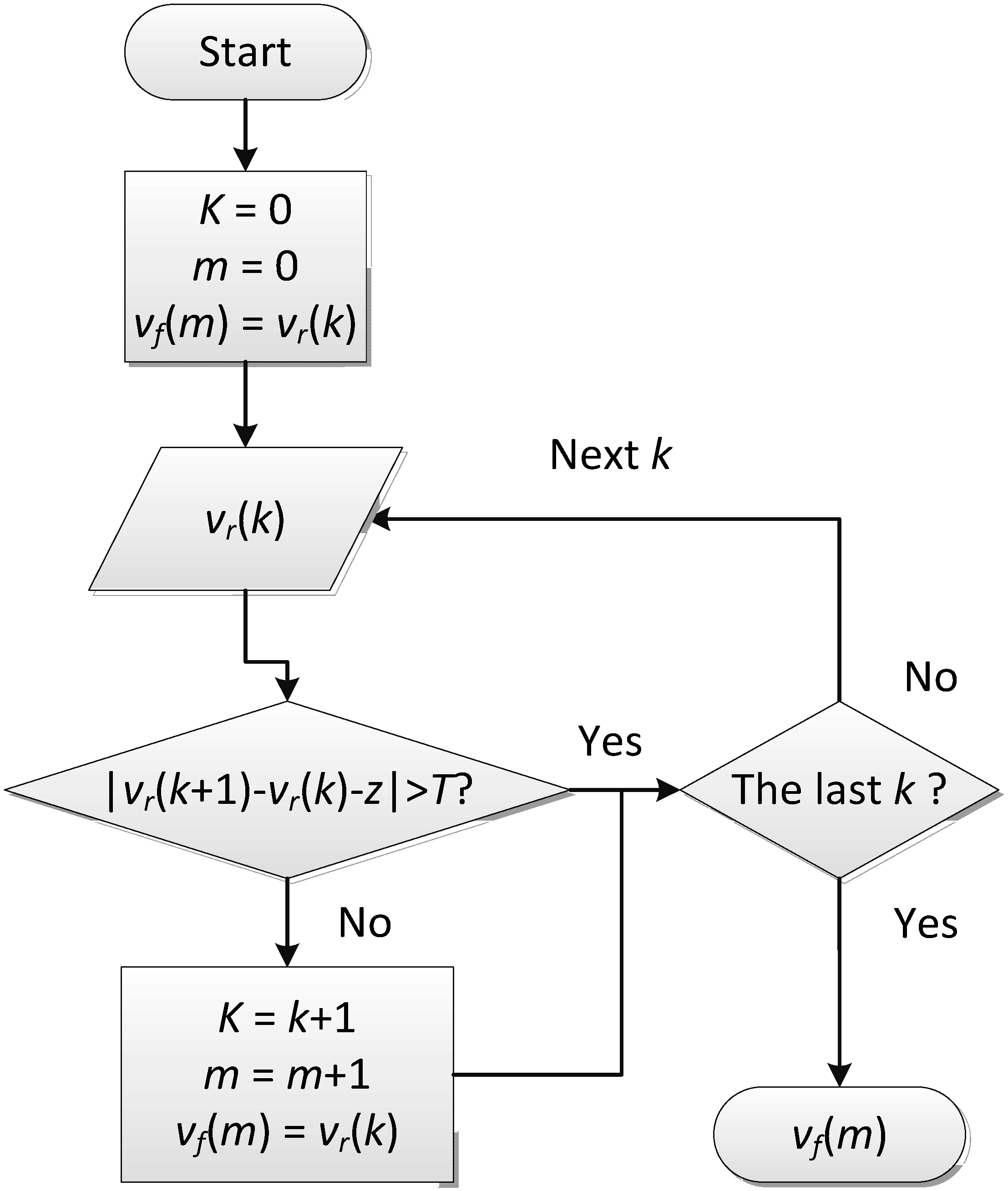

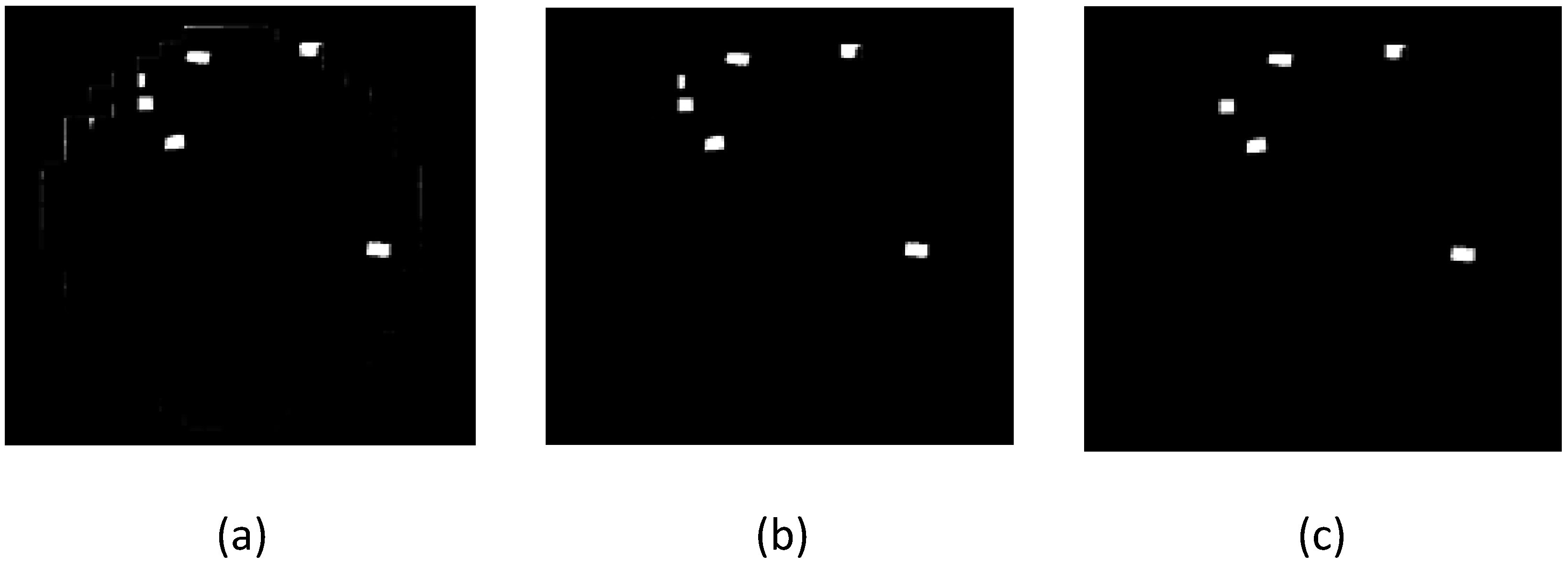

2.4. Detection of Die Sawing Lines

2.5. Counting the Packaged Dies Number

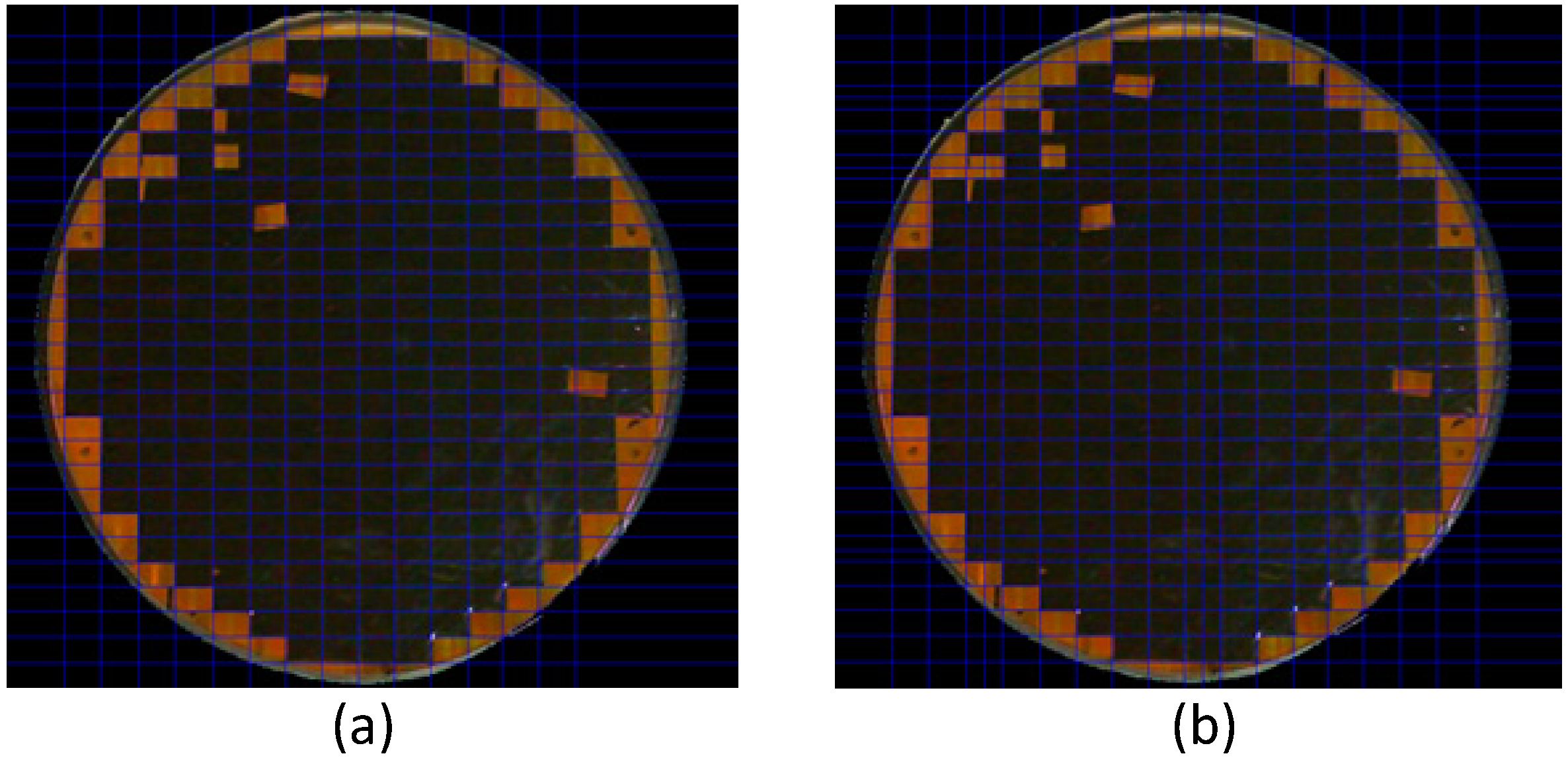

2.5.1. Normal Cases

2.5.2. Abnormal Cases

3. Experimental Results

| Wafer Image | Normal (N) | Abnormal (S) | Packaged (P) | Ground Truth (G) | Precision Rate | Recall Rate |

|---|---|---|---|---|---|---|

| 1 | 315 | 3 | 312 | 311 | 99.68% | 100.00% |

| 2 | 315 | 3 | 312 | 311 | 99.68% | 100.00% |

| 3 | 315 | 5 | 310 | 309 | 99.68% | 100.00% |

| 4 | 310 | 10 | 310 | 309 | 99.68% | 100.00% |

| 5 | 323 | 13 | 310 | 309 | 99.68% | 100.00% |

| 6 | 314 | 6 | 308 | 309 | 100.00% | 99.68% |

| 7 | 313 | 3 | 310 | 310 | 100.00% | 100.00% |

| 8 | 314 | 4 | 310 | 310 | 100.00% | 100.00% |

| 9 | 318 | 4 | 314 | 314 | 100.00% | 100.00% |

| 10 | 321 | 7 | 314 | 314 | 100.00% | 100.00% |

| 11 | 326 | 11 | 315 | 314 | 99.68% | 100.00% |

| 12 | 326 | 11 | 315 | 315 | 100.00% | 100.00% |

| 13 | 312 | 1 | 311 | 311 | 100.00% | 100.00% |

| 14 | 323 | 10 | 313 | 311 | 99.36% | 100.00% |

| 15 | 324 | 12 | 312 | 311 | 99.68% | 100.00% |

| 16 | 315 | 3 | 312 | 311 | 99.68% | 100.00% |

| 17 | 312 | 1 | 311 | 311 | 100.00% | 100.00% |

| 18 | 313 | 1 | 312 | 311 | 99.68% | 100.00% |

| 19 | 319 | 7 | 312 | 311 | 99.68% | 100.00% |

| 20 | 321 | 6 | 315 | 316 | 100.00% | 99.68% |

| 21 | 320 | 5 | 315 | 316 | 100.00% | 99.68% |

| 22 | 320 | 2 | 318 | 318 | 100.00% | 100.00% |

| 23 | 321 | 4 | 317 | 318 | 100.00% | 99.69% |

| 24 | 312 | 1 | 311 | 311 | 100.00% | 100.00% |

| 25 | 319 | 7 | 312 | 311 | 99.68% | 100.00% |

| 26 | 313 | 1 | 312 | 311 | 99.68% | 100.00% |

| 27 | 317 | 8 | 309 | 311 | 100.00% | 99.36% |

| 28 | 317 | 7 | 310 | 311 | 100.00% | 99.68% |

| 29 | 302 | 4 | 298 | 311 | 100.00% | 95.82% |

| 30 | 317 | 6 | 311 | 312 | 100.00% | 99.68% |

| 31 | 313 | 0 | 313 | 313 | 100.00% | 100.00% |

| 32 | 315 | 2 | 313 | 313 | 100.00% | 100.00% |

| 33 | 315 | 2 | 313 | 313 | 100.00% | 100.00% |

| 34 | 316 | 3 | 314 | 313 | 99.68% | 100.00% |

| 35 | 322 | 7 | 315 | 313 | 99.37% | 100.00% |

| 36 | 318 | 2 | 316 | 316 | 100.00% | 100.00% |

| 37 | 325 | 9 | 316 | 316 | 100.00% | 100.00% |

| 38 | 330 | 11 | 319 | 316 | 99.06% | 100.00% |

| 39 | 320 | 3 | 317 | 316 | 99.68% | 100.00% |

| 40 | 319 | 2 | 317 | 315 | 99.37% | 100.00% |

| 41 | 316 | 1 | 315 | 315 | 100.00% | 100.00% |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Driels, M.R.; Pathre, U.S. Vision-based automatic theodolite for robot calibration. IEEE Trans. Robot. Autom. 1991, 7, 351–360. [Google Scholar] [CrossRef]

- Madhvanath, S.; Govindaraju, V. The role of holistic paradigms in handwritten word recognition. IEEE Trans. Pattern Anal. Mach. Intell. 2001, 23, 149–164. [Google Scholar] [CrossRef]

- Kumar, A.; Yingbo, Z. Human Identification Using Finger Images. IEEE Trans. Image Process. 2012, 21, 2228–2244. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.S.; Lee, T.C.; Chang, H.T.; Peng, S.J.; Huang, J.W.; Wang, H.P.; Hung, C.W. A computer-aided method for automatic localization and thickness measurement of peritoneum in ultrasound images. In Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology Society, MA, USA, 30 August–3 September 2011; pp. 8005–8008.

- Gao, Y.S.; Leung, M.K.H. Face recognition using line edge map. IEEE Trans. Pattern Anal. Mach. Intell. 2002, 24, 764–779. [Google Scholar] [CrossRef]

- Hackenberg, G.; McCall, R.; Broll, W. Lightweight palm and finger tracking for real-time 3D gesture control. In Proceedings of the IEEE Virtual Reality Conference (VR), Singapore, Singapore, 19–23 March 2011; pp. 19–26.

- Zeng, Z.; Dai, S.; Mu, P.A. Wafer defects detecting and classifying system based on machine vision. In Proceedings of the International Conference on Electronic Measurement and Instruments, Xi’an, China, 16–18 August 2007; pp. 4-520–4-523.

- Wu, H.H.P.; Yang, J.G.; Hsu, M.M.; Wu, C.J. Automatic measurement and grading of LED dies on wafer by machine vision. In Proceedings of the IEEE International Conference on Mechatronics, Kumamoto, Japan, 8–10 May 2007; pp. 1–6.

- Wang, G.; Li, D.; Wu, L.; Deng, Y.; Liu, R. Machine vision recognition of disconnection failure of IC wafer. In Proceedings of the International Conference on Electronic Packaging Technology, Shanghai, China, 26–29 August 2006; pp. 1–4.

- Sharma, G.; Kumar, A.; Rao, V.S.; Soon, W.H.; Kripesh, V. Solutions strategies for die shift problem in wafer level compression molding. IEEE Trans. Compon. Packag. Manuf. Technol. 2011, 1, 502–509. [Google Scholar] [CrossRef]

- Croft, G.D.; Lomenick, R.L.; Youngblood, D.L.; Johnston, J.M. Die-counting algorithm for yield modeling and die-per-wafer optimization. SPIE 1997, 3216, 186–196. [Google Scholar]

- Cunningham, J.A. The use of evaluation of yield models in integrated circuit manufacturing. IEEE Trans. Semicond. Manuf. 1990, 3, 60–71. [Google Scholar] [CrossRef]

- De Vries, D.K. Investigation of gross die per wafer formulas. IEEE Trans. Semicond. Manuf. 2005, 18, 136–139. [Google Scholar]

- Magee, M.R.; Beer, M.D.; Erck, W.R. Computation of Die-Per-Wafer Considering Production Technology and Wafer Size. United States Patent US 6,529,790, 4 March 2003. [Google Scholar]

- Die Per Wafer Calculator 1.00. Available online: http://mrhackerott.org/semiconductor-informatics/informatics/toolz/DPWCalculator/Input.html (accessed on 6 April 2015).

- Die-per-Wafer Estimator. Available online: http://www.silicon-edge.co.uk/j/index.php/resources/die-per-wafer (accessed on 6 April 2015).

- Mital, D.P.; Teoh, E.K. Computer based wafer inspection system. In Proceedings of the 1991 International Conference on Industrial Electronics, Control and Instrumentation, 28 October–1 November 1991; pp. 2497–2503.

- Su, C.T.; Yang, T.; Ke, C.M. Neural-network approach for semiconductor wafer post-sawing inspection. IEEE Trans. Semicond. Manuf. 2002, 15, 260–266. [Google Scholar] [CrossRef]

- Chang, H.T.; Pan, R.J. Automatic counting of packaged wafer die based on machine vision. In Proceedings of the 2012 International Conference on Information Security and Intelligent Control (ISIC 2012), Douliu, Taiwan, 14–16 August 2012; pp. 274–277.

- Xu, S.; Cheng, Z.; Gao, Y.; Pan, Q. Visual wafer dies counting using geometrical characteristics. IET Image Process. 2014, 8, 280–288. [Google Scholar] [CrossRef]

- Wafer Chip Counter—IVC12. Available online: http://www.ivtech.com.tw/ (accessed on 6 April 2015).

- Fischler, M.A.; Bolles, R.C. Random sample consensus: A paradigm for model fitting with applications to image analysis and automated cartography. Commun. ACM 1981, 24, 381–395. [Google Scholar] [CrossRef]

- De la Fraga, L.G.; Dominguez, G.M.L. Robust detection of several circles or ellipses with heuristics. In Proceedings of the IEEE Congress Evolutionary Computation, New Orleans, LA, USA, 5–8 June 2011; pp. 484–490.

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Gonzalez, R.C.; Woods, R.E. Digital Image Processing, 2nd ed.; Prentice-Hall, Inc.: New Jersey, NJ, USA, 2002. [Google Scholar]

- Canny, J. A computational approach to edge detection. IEEE Trans. Pattern Anal. Mach. Intell. 1986, PAMI-8, 679–698. [Google Scholar] [CrossRef]

- Kim, Y.T. Contrast enhancement using brightness preserving bi-histogram equalization. IEEE Trans. Consum. Electron. 1997, 43, 1–8. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, H.-T.; Pan, R.-J.; Peng, H.-W. Number Determination of Successfully Packaged Dies Per Wafer Based on Machine Vision. Machines 2015, 3, 72-92. https://doi.org/10.3390/machines3020072

Chang H-T, Pan R-J, Peng H-W. Number Determination of Successfully Packaged Dies Per Wafer Based on Machine Vision. Machines. 2015; 3(2):72-92. https://doi.org/10.3390/machines3020072

Chicago/Turabian StyleChang, Hsuan-Ting, Ren-Jie Pan, and Hsiao-Wei Peng. 2015. "Number Determination of Successfully Packaged Dies Per Wafer Based on Machine Vision" Machines 3, no. 2: 72-92. https://doi.org/10.3390/machines3020072