Embedded Payload Solutions in UAVs for Medium and Small Package Delivery

Abstract

:1. Introduction

- (i)

- Embedded solution: the packaging must be hosted in the cargo bay within the drone fuselage;

- (ii)

- Medical transportation compatibility: the packaging must allow for the delivery of medical items; and

- (iii)

- User-oriented design: the packaging must make voluntary interaction with the user as simple as possible.

2. Materials and Methods

2.1. Requirements Identification

- (i)

- Embedded solution:

- a.

- The available volume within the drone fuselage that can be occupied by the package must be optimized;

- b.

- Access to the cargo bay should be as simple as possible for the user, but the package should be protected as much as possible from external undesired interactions and threats.

- (ii)

- Medical transportation compatibility:

- a.

- The package must have an adequate minimum internal volume and be composed of appropriate materials that do not cause danger or harm to the good or the user. The package must also allow for sensor integration for delivery tracking and monitoring of package conditions, with additional space to house dry ice units;

- b.

- The release system must work in emergency scenarios, with the user acting under potentially high-stress conditions. Therefore, access to the cargo bay by the user must be as simple and effective as possible.

- (iii)

- User-oriented design:

- a.

- The package must be easy to use, i.e., simple and quick to assemble and open. The box should include user instructions for assembly and opening operations;

- b.

- The release system must effectively ensure the safety and security of the good but be intuitive to use. Access to the cargo bay must be safe for the user and as inclusive as possible (e.g., wheelchair-friendly).

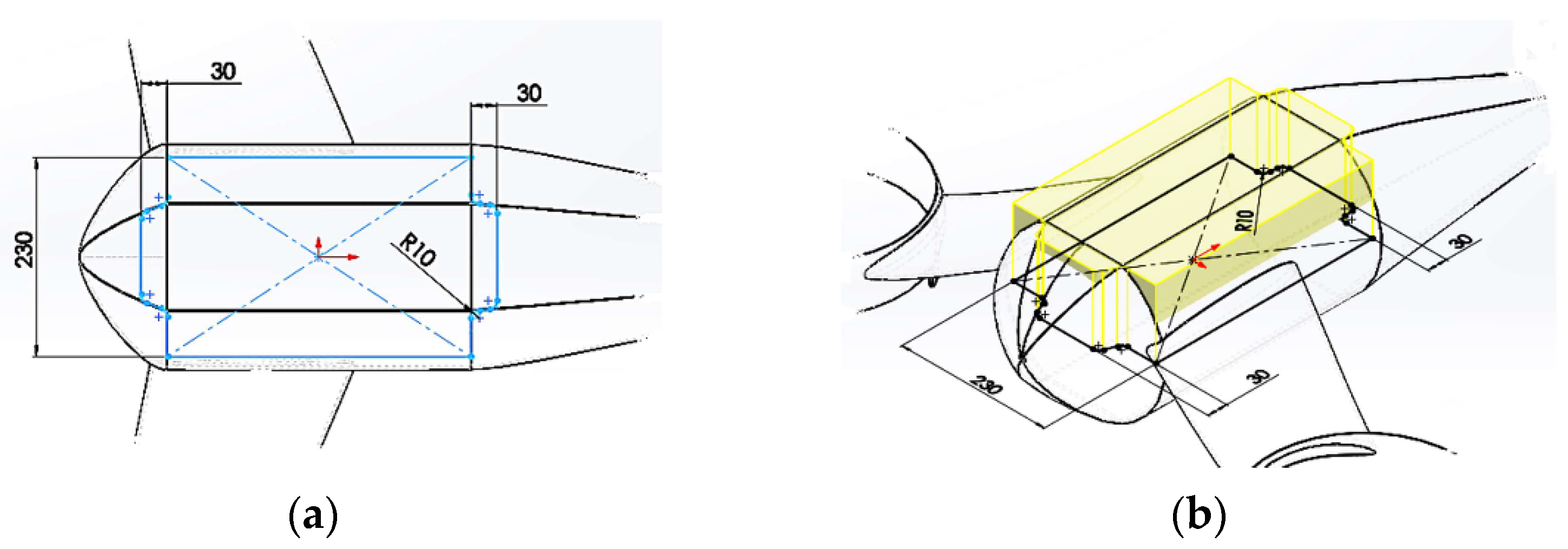

2.2. Packaging Geometry

2.3. Packaging Material

- (e.1)

- Outside liner: The external liner of the package must be made of virgin fiber paper, as it provides resistance to impacts and absorption of liquids. These characteristics can be assessed through burst tests and Cobb tests, respectively, as described in Test Standard DIN EN ISO 535; the former involves the use of a Mullen tester to measure the pressure force required to puncture or rupture the face of the corrugated board (in kPa), and the latter measures the amount of water absorbed by a defined area of cardboard within a defined amount of time (typically 60, 180, or 1800 s) resulting from one-sided contact with water (in g/m2). Holding other characteristics equal, the selected grade must maximize the results of the burst test and minimize those of the Cobb test;

- (e.2)

- ECT/cardboard density ratio: The edge compression test (ECT) measures the strength of corrugated board in response to edgewise compression. In the test, a small segment of cardboard is compressed on its edge between two rigid plates orthogonal to the direction of the flutes, and the force required to establish a peak load is measured (in kN per linear meter of load-bearing edge (kN/m), although often reported as an ECT value). The chosen grade must provide the best ECT result with equal mass;

- (e.3)

- ECTmin: for the selected grade, a minimum value of 7 kN/m is required.

- -

- KLW (white kraftliner ), a virgin fiber paper characterized by high resistance to humidity and high mechanical performance;

- -

- WS (Wellenstoff), a recycled paper typically used in flutes and middle-layer paper; and

- -

- TL (test liner), a recycled paper characterized by low cost and low performance.

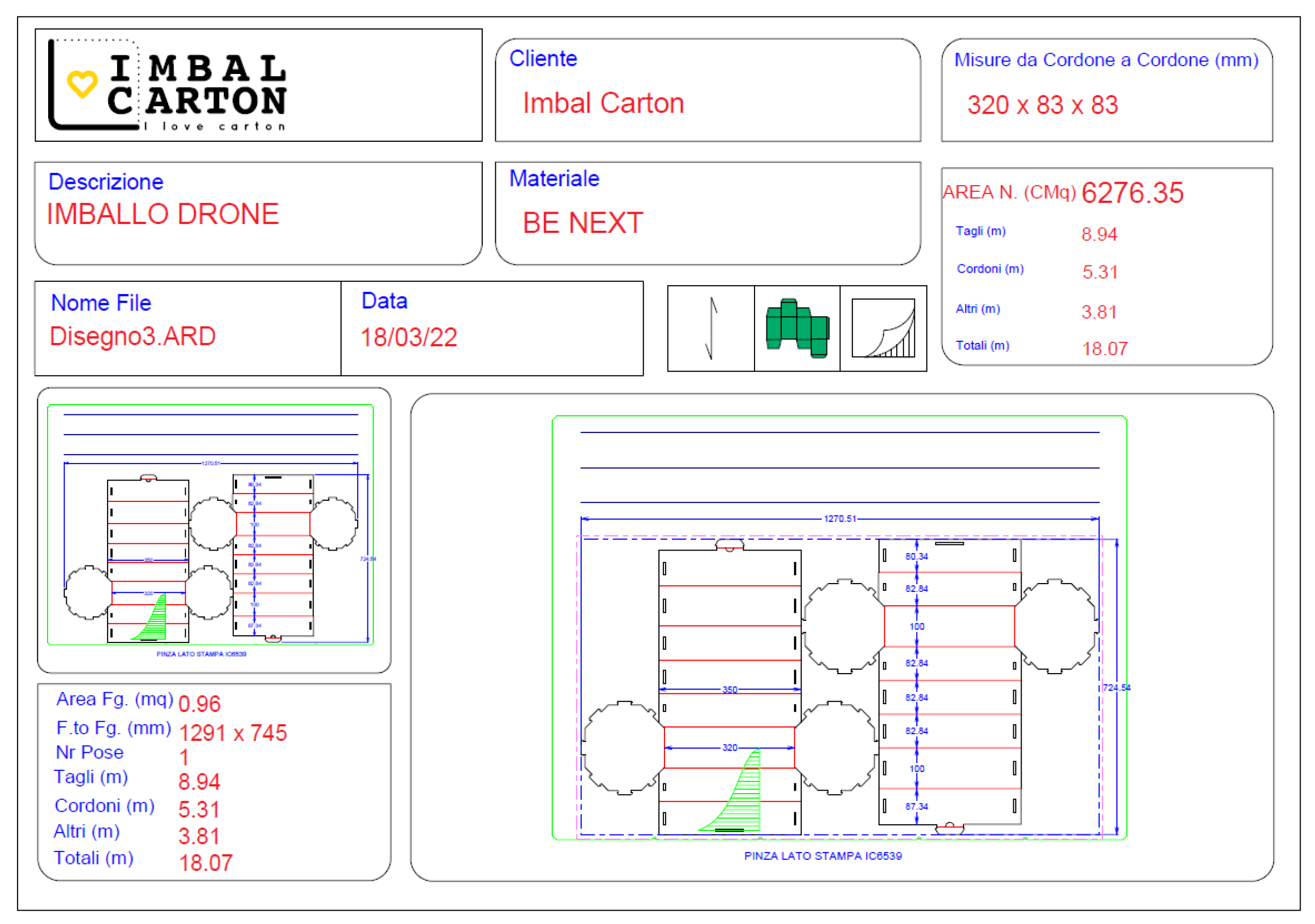

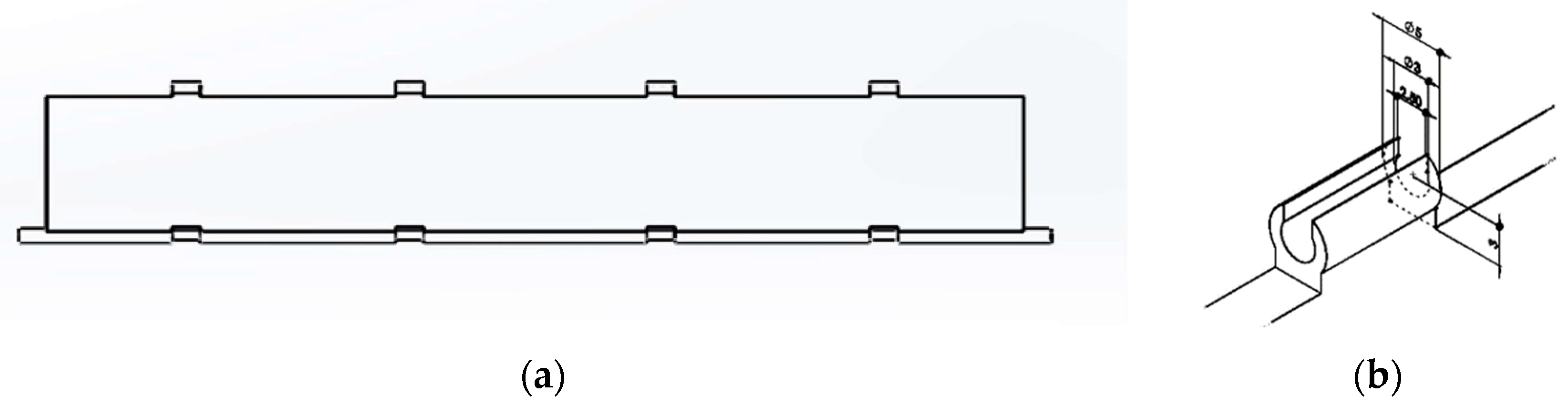

2.4. Industrialization Process

2.5. Quick-Release System

- (a.1)

- Mass: overall mass of the system (could be substituted by volume or material cost, as all the proposed solutions are intended to be realized with the same material);

- (a.2)

- Realization: quantification of the realization costs of the system; assessed in terms of the number of elements that require precision machining;

- (a.3)

- Accessibility: ease of use by the user during the release and detachment of the package; quantified in terms of the number of elementary operations required of the user to retrieve the package;

- (a.4)

- Locking: the ability of the system to constrain the package in terms of contact surfaces or redundancy; evaluated in terms of the area of the system at a minimum distance from the package;

- (a.5)

- Protection: provides an indication about the level of protection that the system can assure; is quantified as the area of the package free from fuselage protection, but covered by the system;

- (a.6)

- Resistance: the capacity of the system to provide functional support to the resistance of the fuselage; evaluated in terms of the minimum transversal section of the system along the package extension.

3. Results

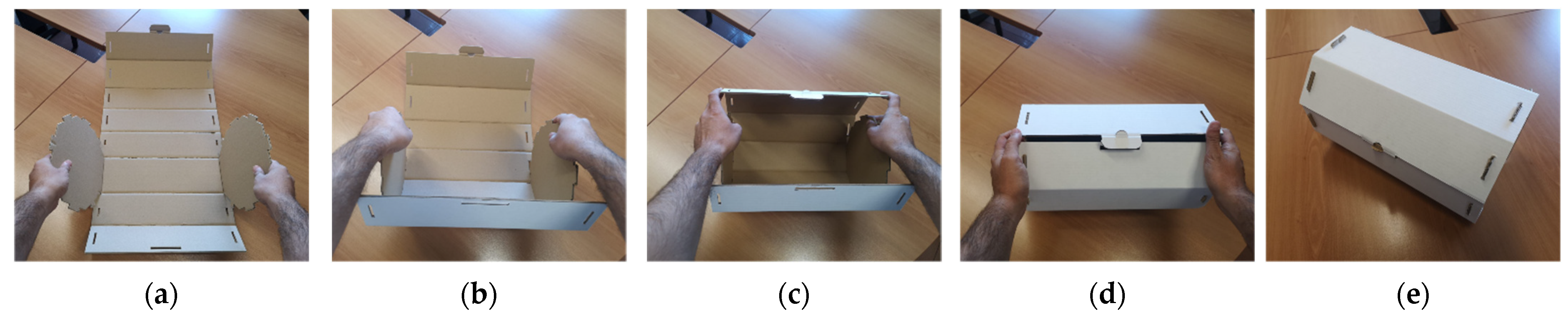

3.1. Industrialized Packaging

- (s.1)

- The good to be delivered, equipped with its standard box, if necessary, is positioned on the package rectangular face connected to the two lateral octagonal faces;

- (s.2)

- The octagonal faces are folded perpendicularly to the support surface toward the inner side of the box (see Figure 4a);

- (s.3)

- Grasping the box by the octagonal faces, the box is roto-translated on the support surface so that the lateral flaps of the octagonal face lock with the windows of each rectangular face (see Figure 4b);

- (s.4)

- Once all the rectangular faces are locked to the octagonal bases, the final flap on the longitudinal dimension of the last rectangular face is hook-locked to the corresponding window, closing the box (see Figure 4d);

- (s.5)

- Additional elements, such as a seal of warranty, can be affixed to the package, although not necessary for packaging functionality.

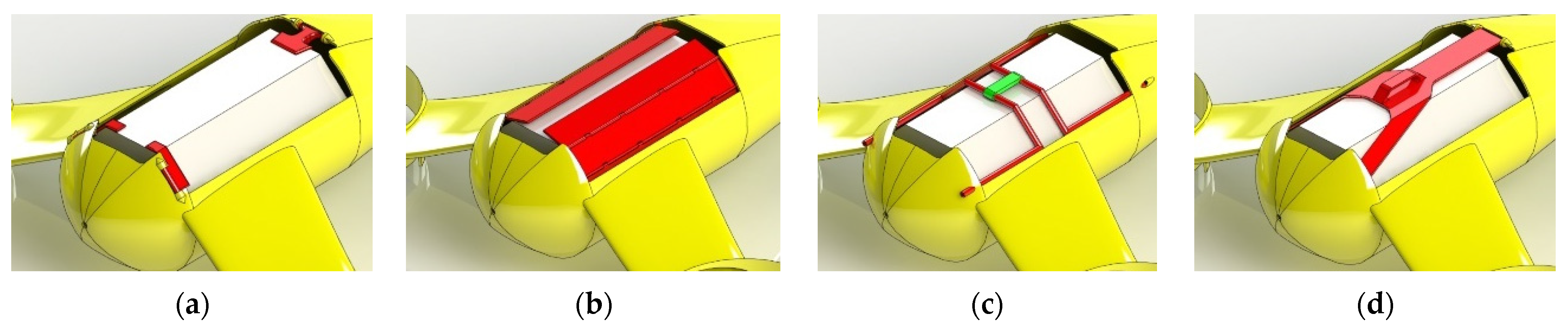

3.2. Quick-Release System

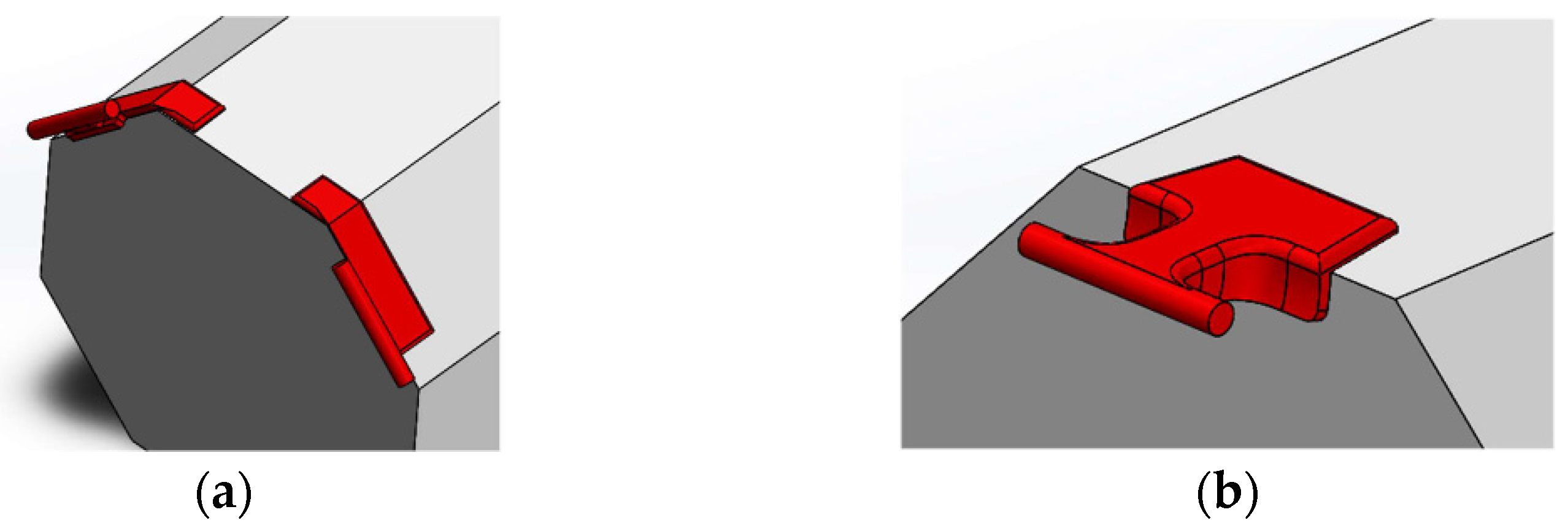

3.2.1. Clamps

- (c1)

- The clamps are directly connected to an electric actuator that manages opening and closing of the clamps and can be remotely controlled. The system is user-independent, as locking and unlocking operations do not require user action;

- (c2)

- Clamp-closing operations are performed automatically. Once the package is locked, the safety latch can be automatically closed and opened. To release the package, the user must wait for the remote opening of the safety latch, then manually open each clamp;

- (c3)

- Clamp closing and safety latch locking and unlocking managed as in (c2), but every clamp is provided with a spring that is compressed when the clamps are closed. Opening of the safety latch enables the automatic release of the clamps without action by the user.

3.2.2. Shutters

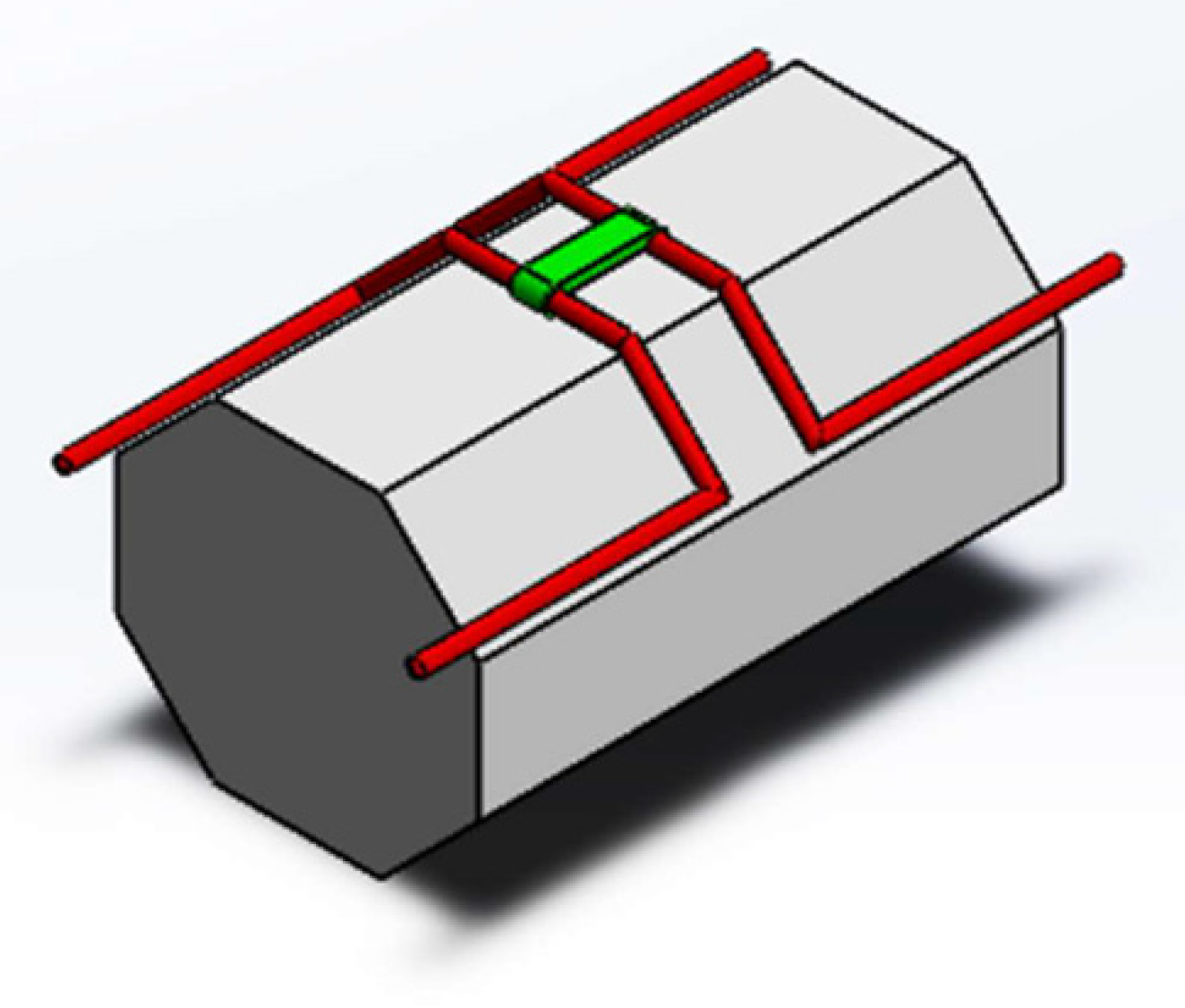

3.2.3. Cage

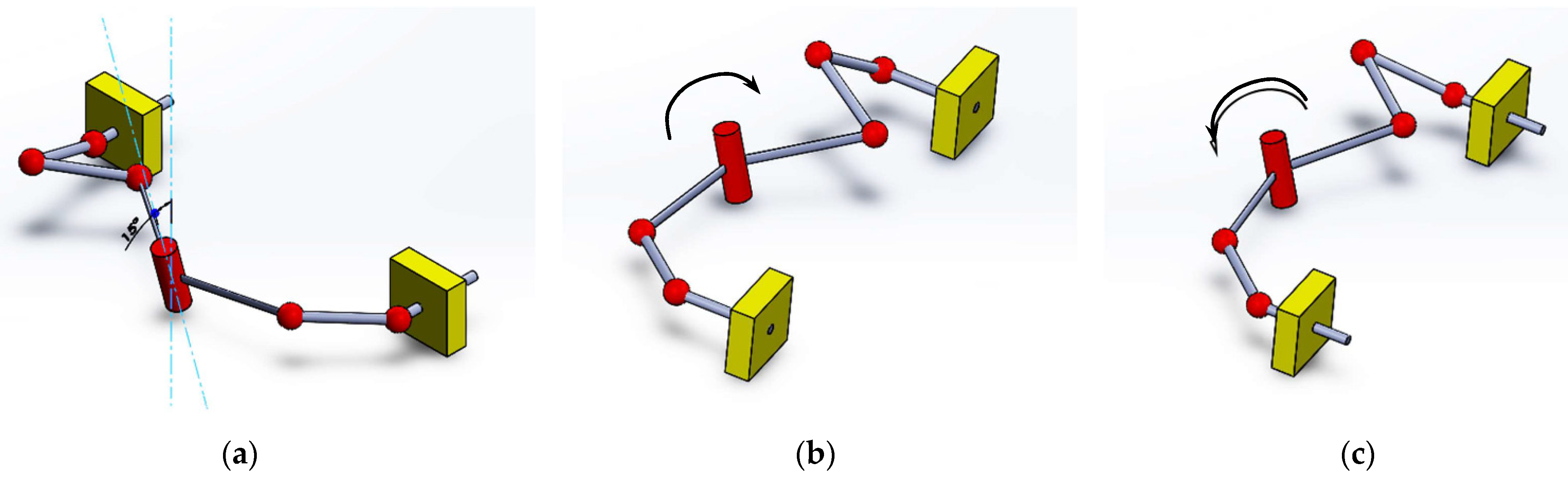

3.2.4. Y

3.2.5. Solution Comparison

4. Discussion

4.1. Packaging

4.2. Quick-Release System

4.3. Limitations of the Study

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Benarbia, T.; Kyamakya, K. A Literature Review of Drone-Based Package Delivery Logistics Systems and Their Implementation Feasibility. Sustainability 2021, 14, 360. [Google Scholar] [CrossRef]

- Amici, C.; Ceresoli, F.; Pasetti, M.; Saponi, M.; Tiboni, M.; Zanoni, S. Review of Propulsion System Design Strategies for Unmanned Aerial Vehicles. Appl. Sci. 2021, 11, 5209. [Google Scholar] [CrossRef]

- Amici, C.; Ceresoli, F.; Saponi, M.; Pasetti, M.; Zanoni, S.; Borboni, A.; Tiboni, M.; Faglia, R. Experimental Characterization of an Electrical Propulsion Unit for Service UAVs. In Proceedings of I4SDG Workshop 2021; Quaglia, G., Gasparetto, A., Petuya, V., Carbone, G., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 307–314. [Google Scholar] [CrossRef]

- Suzuki, K.A.O.; Filho, P.K.; Morrison, J.R. Automatic Battery Replacement System for UAVs: Analysis and Design. J. Intell. Robot. Syst. 2011, 65, 563–586. [Google Scholar] [CrossRef]

- Ranquist, E.A.; Steiner, M.; Argrow, B. Exploring the range of weather impacts on UAS operations. In Proceedings of the 18th Conference on Aviation, Range and Aerospace Meteorology, Seattle, WA, USA, 23 January 2017. [Google Scholar]

- Zailani, M.A.H.; Sabudin, R.Z.A.R.; Rahman, R.A.; Saiboon, I.M.; Ismail, A.; Mahdy, Z.A. Drone for medical products transportation in maternal healthcare: A systematic review and framework for future research. Medicine 2020, 99, e21967. [Google Scholar] [CrossRef]

- Asadi, A.; Pinkley, S.N.; Mes, M. A Markov decision process approach for managing medical drone deliveries. Expert Syst. Appl. 2022, 204, 117490. [Google Scholar] [CrossRef]

- Cheema, M.A.; Ansari, R.I.; Ashraf, N.; Hassan, S.A.; Qureshi, H.K.; Bashir, A.K.; Politis, C. Blockchain-based secure delivery of medical supplies using drones. Comput. Netw. 2022, 204, 108706. [Google Scholar] [CrossRef]

- Khan, S.I.; Qadir, Z.; Munawar, H.S.; Nayak, S.R.; Budati, A.K.; Verma, K.; Prakash, D. UAVs path planning architecture for effective medical emergency response in future networks. Phys. Commun. 2021, 47, 101337. [Google Scholar] [CrossRef]

- Glick, T.B.; Figliozzi, M.A.; Unnikrishnan, A. Case Study of Drone Delivery Reliability for Time-Sensitive Medical Supplies with Stochastic Demand and Meteorological Conditions. Transp. Res. Rec. J. Transp. Res. Board 2021, 2676, 242–255. [Google Scholar] [CrossRef]

- Purahong, B.; Anuwongpinit, T.; Juhong, A.; Kanjanasurat, I.; Pintaviooj, C. Medical Drone Managing System for Automated External Defibrillator Delivery Service. Drones 2022, 6, 93. [Google Scholar] [CrossRef]

- Bauer, J.; Moormann, D.; Strametz, R.; Groneberg, D.A. Development of unmanned aerial vehicle (UAV) networks delivering early defibrillation for out-of-hospital cardiac arrests (OHCA) in areas lacking timely access to emergency medical services (EMS) in Germany: A comparative economic study. BMJ Open 2021, 11, e043791. [Google Scholar] [CrossRef]

- Sigari, C.; Biberthaler, P. Medical drones: Disruptive technology makes the future happen [Medizinische Drohnen: Innovative Technologie eröffnet neue Horizonte der Unfallchirurgie]. Der Unf. 2021, 124, 974–976. [Google Scholar] [CrossRef]

- Nimilan, V.; Manohar, G.; Sudha, R.; Stanley, P. Drone-Aid: An Aerial Medical Assistance. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 1288–1292. [Google Scholar] [CrossRef]

- Claesson, A.; Bäckman, A.; Ringh, M.; Svensson, L.; Nordberg, P.; Djärv, T.; Hollenberg, J. Time to Delivery of an Automated External Defibrillator Using a Drone for Simulated Out-of-Hospital Cardiac Arrests vs Emergency Medical Services. JAMA 2017, 317, 2332–2334. [Google Scholar] [CrossRef] [PubMed]

- Baloola, M.O.; Ibrahim, F.; Mohktar, M.S. Optimization of Medication Delivery Drone with IoT-Guidance Landing System Based on Direction and Intensity of Light. Sensors 2022, 22, 4272. [Google Scholar] [CrossRef]

- Stephan, F.; Reinsperger, N.; Grünthal, M.; Paulicke, D.; Jahn, P. Human drone interaction in delivery of medical supplies: A scoping review of experimental studies. PLoS ONE 2022, 17, e0267664. [Google Scholar] [CrossRef]

- Sun, J.; Shen, Y.; Rosen, J. Sensor Reduction, Estimation, and Control of an Upper-Limb Exoskeleton. IEEE Robot. Autom. Lett. 2021, 6, 1012–1019. [Google Scholar] [CrossRef]

- Hii, M.; Courtney, P.; Royall, P. An Evaluation of the Delivery of Medicines Using Drones. Drones 2019, 3, 52. [Google Scholar] [CrossRef]

- Quek, S.G.; Selvachandran, G.; Sham, R.; Siau, C.S.; Ramli, M.H.M.; Ahmad, N. A Fuzzy Logic Based Optimal Network System for the Delivery of Medical Goods via Drones and Land Transport in Remote Areas. In Intelligent Systems Design and Applications; ISDA 2021. Lecture Notes in Networks and Systems; Abraham, A., Gandhi, N., Hanne, T., Hong, T.P., Nogueira Rios, T., Ding, W., Eds.; Springer: Cham, Switzerland, 2022; pp. 1306–1312. [Google Scholar] [CrossRef]

- Sham, R.; Siau, C.S.; Tan, S.; Kiu, D.C.; Sabhi, H.; Thew, H.Z.; Selvachandran, G.; Quek, S.G.; Ahmad, N.; Ramli, M.H.M. Drone Usage for Medicine and Vaccine Delivery during the COVID-19 Pandemic: Attitude of Health Care Workers in Rural Medical Centres. Drones 2022, 6, 109. [Google Scholar] [CrossRef]

- Ganesan, G.S.; Mokayef, M. Multi-Purpose Medical Drone for the Use in Pandemic Situation. In Proceedings of the 2021 IEEE Workshop on Microwave Theory and Techniques in Wireless Communications, MTTW 2021, Riga, Latvia, 7–8 October 2021; pp. 188–192. [Google Scholar] [CrossRef]

- Pavithran, R.; Lalith, V.; Naveen, C.; Sabari, S.P.; Kumar, M.A.; Hariprasad, V. A prototype of Fixed Wing UAV for delivery of Medical Supplies. IOP Conf. Series Mater. Sci. Eng. 2020, 995, 012015. [Google Scholar] [CrossRef]

- Mohd, S.A.; Gan, K.B.; Ihsan, A.K.A.M. Development of Medical Drone for Blood Product Delivery: A Technical Assessment. Int. J. Online Biomed. Eng. (iJOE) 2021, 17, 183–196. [Google Scholar] [CrossRef]

- Amicone, D.; Cannas, A.; Marci, A.; Tortora, G. A Smart Capsule Equipped with Artificial Intelligence for Autonomous Delivery of Medical Material through Drones. Appl. Sci. 2021, 11, 7976. [Google Scholar] [CrossRef]

- Jacob, B.; Kaushik, A.; Velavan, P.; Sharma, M. Autonomous Drones for Medical Assistance Using Reinforcement Learning. Stud. Comput. Intell. 2022, 998, 133–156. [Google Scholar] [CrossRef]

- Amukele, T.; Ness, P.M.; Tobian, A.A.; Boyd, J.; Street, J. Drone transportation of blood products. Transfusion 2016, 57, 582–588. [Google Scholar] [CrossRef] [PubMed]

- Yakushiji, F.; Yakushiji, K.; Murata, M.; Hiroi, N.; Takeda, K.; Fujita, H. The Quality of Blood is not Affected by Drone Transport: An Evidential Study of the Unmanned Aerial Vehicle Conveyance of Transfusion Material in Japan. Drones 2020, 4, 4. [Google Scholar] [CrossRef]

- Sharley, P.H.; Williams, I.; Hague, S. Blood transportation for medical retrieval services. Air Med J. 2003, 22, 24–27. [Google Scholar] [CrossRef]

- Maity, N.M. Lightweight Thermal Insulation Systems in Medical Delivery Drones. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 6–13 March 2021; Volume 2021-March. [Google Scholar] [CrossRef]

- Kostin, A.S.; Silin, Y.A. Development of an Insulated Container for the Implementation of the Delivery of Special Cargo Using an Unmanned Aerial System. In Proceedings of the 2022 Wave Electronics and its Application in Information and Telecommunication Systems (WECONF), St. Petersburg, Russia, 30 May 2022–3 June 2022; pp. 1–4. [Google Scholar] [CrossRef]

- United Nations. Agreement Concerning the International Carriage of Dangerous Goods by Road Vol. I; UNITED NATIONS PUBLICATIONS: New York, NY, USA, 2021.

- United Nations. Agreement Concerning the International Carriage of Dangerous Goods by Road Vol. II; UNITED NATIONS PUBLICATIONS: New York, NY, USA, 2021.

- Molina, B.D.M.; Oña, M.S. The Drone Sector in Europe. In Ethics and Civil Drones; Springer: Cham, Switzerland, 2018; pp. 7–33. [Google Scholar] [CrossRef]

- Chowdhury, S.; Emelogu, A.; Marufuzzaman, M.; Nurre, S.G.; Bian, L. Drones for disaster response and relief operations: A continuous approximation model. Int. J. Prod. Econ. 2017, 188, 167–184. [Google Scholar] [CrossRef]

- Restas, A. Drone Applications for Supporting Disaster Management. World J. Eng. Technol. 2015, 3, 316–321. [Google Scholar] [CrossRef]

- Sankey, T.; Donager, J.; McVay, J.; Sankey, J.B. UAV lidar and hyperspectral fusion for forest monitoring in the southwestern USA. Remote Sens. Environ. 2017, 195, 30–43. [Google Scholar] [CrossRef]

- Hodgson, A.; Peel, D.; Kelly, N. Unmanned aerial vehicles for surveying marine fauna: Assessing detection probability. Ecol. Appl. 2017, 27, 1253–1267. [Google Scholar] [CrossRef]

- Casella, E.; Collin, A.; Harris, D.; Ferse, S.; Bejarano, S.; Parravicini, V.; Hench, J.L.; Rovere, A. Mapping coral reefs using consumer-grade drones and structure from motion photogrammetry techniques. Coral Reefs 2017, 36, 269–275. [Google Scholar] [CrossRef]

- Szantoi, Z.; Smith, S.E.; Strona, G.; Koh, L.P.; Wich, S.A. Mapping orangutan habitat and agricultural areas using Landsat OLI imagery augmented with unmanned aircraft system aerial photography. Int. J. Remote Sens. 2017, 38, 2231–2245. [Google Scholar] [CrossRef]

- Rao, B.; Gopi, A.G.; Maione, R. The societal impact of commercial drones. Technol. Soc. 2016, 45, 83–90. [Google Scholar] [CrossRef]

- Formicola, R.; Ragni, F.; Mor, M.; Bissolotti, L.; Amici, C. Design Approach of Medical Devices for Regulation Compatibility: A Robotic Rehabilitation Case Study. In Proceedings of the 7th International Conference on Information and Communication Technologies for Ageing Well and e-Health, Prague, Czechia, 24–26 April 2021; pp. 146–153. [Google Scholar] [CrossRef]

- Amici, C.; Pellegrini, N.; Tiboni, M. The Robot Selection Problem for Mini-Parallel Kinematic Machines: A Task-Driven Approach to the Selection Attributes Identification. Micromachines 2020, 11, 711. [Google Scholar] [CrossRef] [PubMed]

| Flute Type | Flute Height Range (h, in mm) | Distinguishing Features |

|---|---|---|

| K—high flute | h ≥ 5 | Particularly suitable for heavy cardboards, with high flutes and double- or triple-wall boards |

| A—high flute | h ≥ 4.5 | High resistance to vertical compression and good dumping performance but low resistance to transversal compression and low linearity of the liners; therefore, low quality is expected for printings on liners |

| C—mean flute | 3.5 < h ≤ 4.4 | Good compromise between mechanical performance (resistance to external forces) and paper consumption |

| B—low flute | 2.5 < h ≤ 3.4 | High linearity of the liners, with a high quality expected for printings on liners, but high paper consumptionGood resistance to transversal compression but limited to vertical compression |

| E—micro flute | 1.2 < h ≤ 2.4 | |

| F—micro flute | 0.8 < h ≤ 0.9 | |

| G—micro flute | 0.5 < h ≤ 0.6 |

| Grade | Density (g/m2) | Thickness (mm) | Total Box Weight (kg) | Burst (kPa) | ECT (kN/m) | ECT/Density | External Paper | ECTmin Check | External Paper Check |

|---|---|---|---|---|---|---|---|---|---|

| 2.40 BE X6 | 595 | 3.7 | 0.246 | 892.6 | 8.8 | 14.790 | PLK 140 | x | |

| 1.24 B X2 | 379 | 2.8 | 0.157 | 841.0 | 5.4 | 14.248 | KLW 115 | x | |

| 1.22 E X6 | 319 | 1.5 | 0.132 | 874.8 | 4.5 | 14.107 | KL 115 | x | |

| 2.28 BC Q9 * | 624 | 5.7 | 0.258 | 1095.8 | 8.7 | 13.942 | KLW 115 | x | x |

| 2.28 BE X7 * | 583 | 3.7 | 0.241 | 984.0 | 8.1 | 13.894 | KLW 115 | x | x |

| 1.21 B Q7 | 411 | 2.3 | 0.170 | 746.0 | 5.7 | 13.869 | PLK 120 | ||

| 1.24 B Q7 | 411 | 2.3 | 0.170 | 856.6 | 5.7 | 13.869 | KLW 115 | x | |

| 2.47 BC N9 * | 694 | 5.8 | 0.287 | 1252.9 | 9.6 | 13.833 | KLW 135 | x | x |

| 1.40 C X2 | 502 | 3.8 | 0.208 | 1006.8 | 6.9 | 13.745 | PLK 175 | ||

| 2.32 BC N2 | 543 | 5.7 | 0.224 | 959.3 | 7.4 | 13.628 | PLK 120 | x |

| Layer | Material | Paper Density (g/m2) |

|---|---|---|

| Outside liner | KLW | 115 |

| Fluting | WS | 115 |

| Middle liner | WS | 90 |

| Fluting | WS | 80 |

| Inside liner | TL | 135 |

| Parameter | Clamps | Shutters | Cage | Y |

|---|---|---|---|---|

| Mass | 100 | 0 | 92 | 81 |

| Realization | 100 | 0 | 95 | 95 |

| Accessibility | 100 | 0 | 0 | 33 |

| Locking | 18 | 0 | 55 | 100 |

| Protection | 0 | 100 | 11 | 20 |

| Resistance | 0 | 72 | 90 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saponi, M.; Borboni, A.; Adamini, R.; Faglia, R.; Amici, C. Embedded Payload Solutions in UAVs for Medium and Small Package Delivery. Machines 2022, 10, 737. https://doi.org/10.3390/machines10090737

Saponi M, Borboni A, Adamini R, Faglia R, Amici C. Embedded Payload Solutions in UAVs for Medium and Small Package Delivery. Machines. 2022; 10(9):737. https://doi.org/10.3390/machines10090737

Chicago/Turabian StyleSaponi, Matteo, Alberto Borboni, Riccardo Adamini, Rodolfo Faglia, and Cinzia Amici. 2022. "Embedded Payload Solutions in UAVs for Medium and Small Package Delivery" Machines 10, no. 9: 737. https://doi.org/10.3390/machines10090737