Simulation Analysis of a Novel Digital Pump with Direct Recycling of Hydraulic Energy

Abstract

:1. Introduction

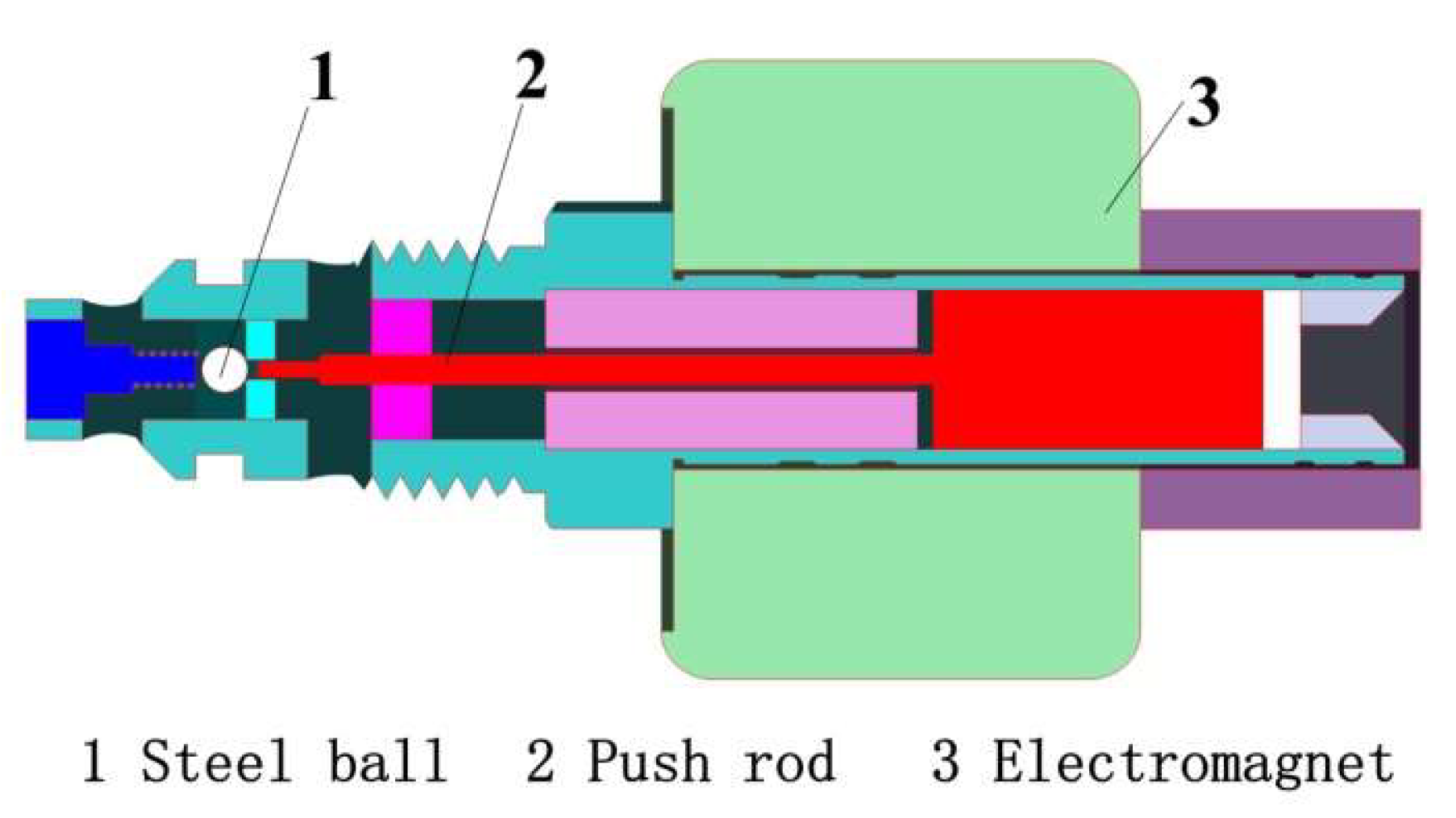

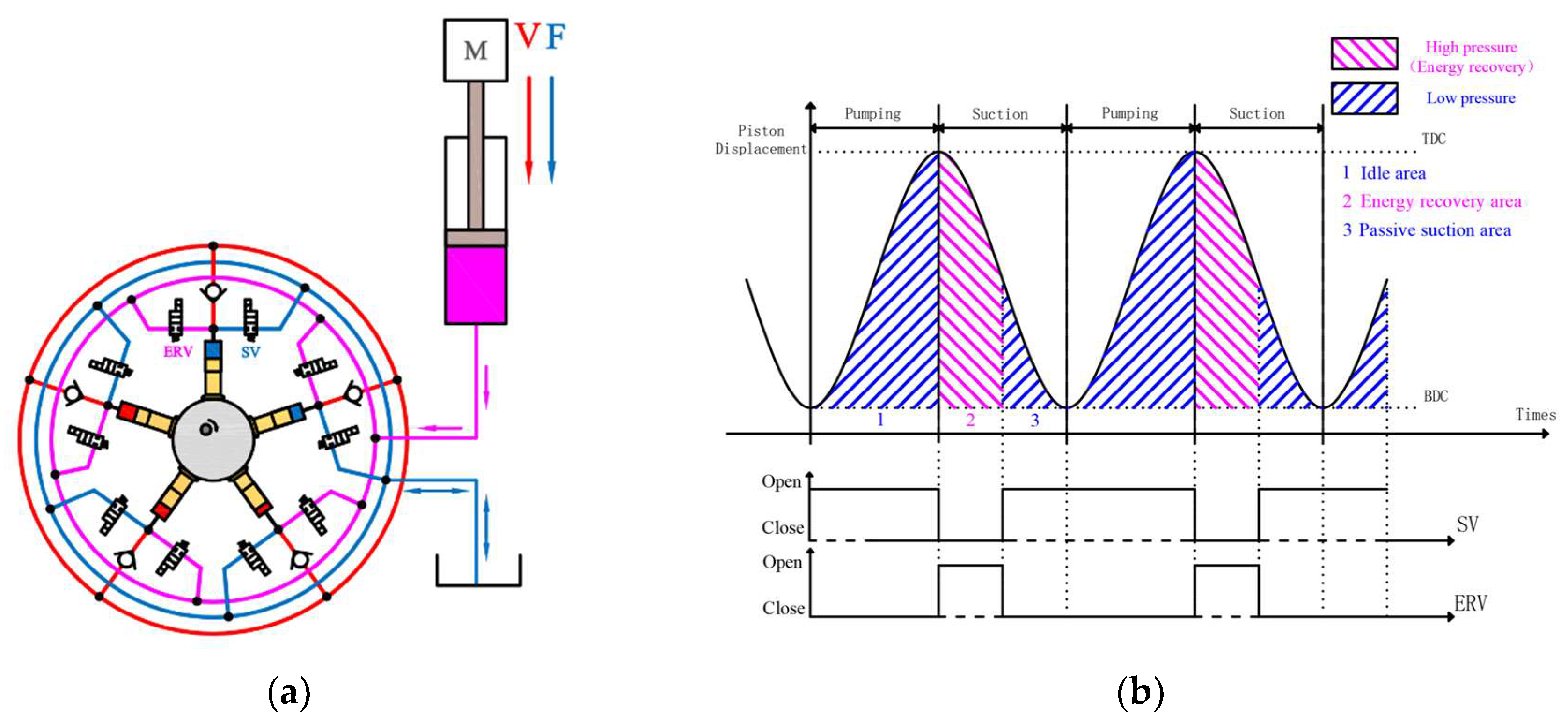

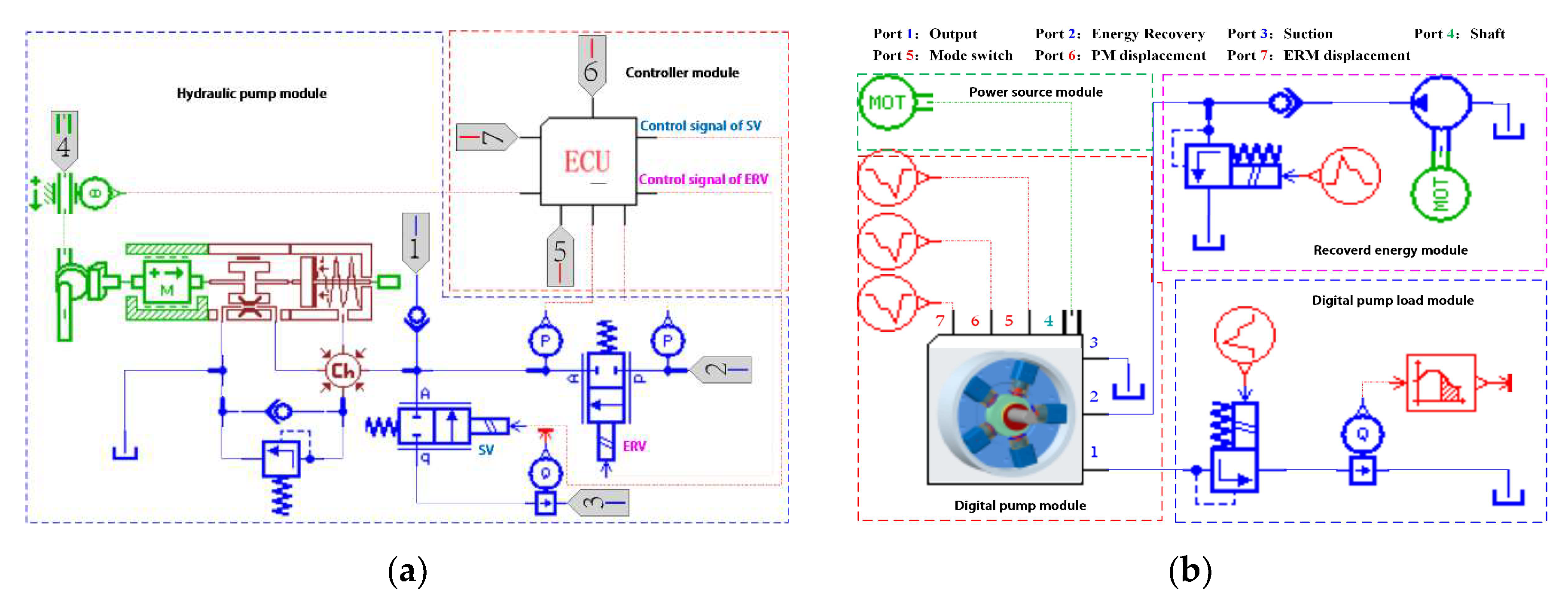

2. Structure and Mathematic Model of DERDP

2.1. Structure of DERDP

2.2. Mathematical Model of DERDP

2.2.1. Motion Characteristics of Radial Plunger Pump

2.2.2. Leakage Characteristics

2.2.3. Flow Distribution Valve

3. Working Modes of DERDP

3.1. Pump Mode (PM)

3.2. Energy Recycling Mode (ERM)

3.3. Direct Reuse Mode (DRM)

4. Simulation Modeling of DERDP

5. Simulation Analysis

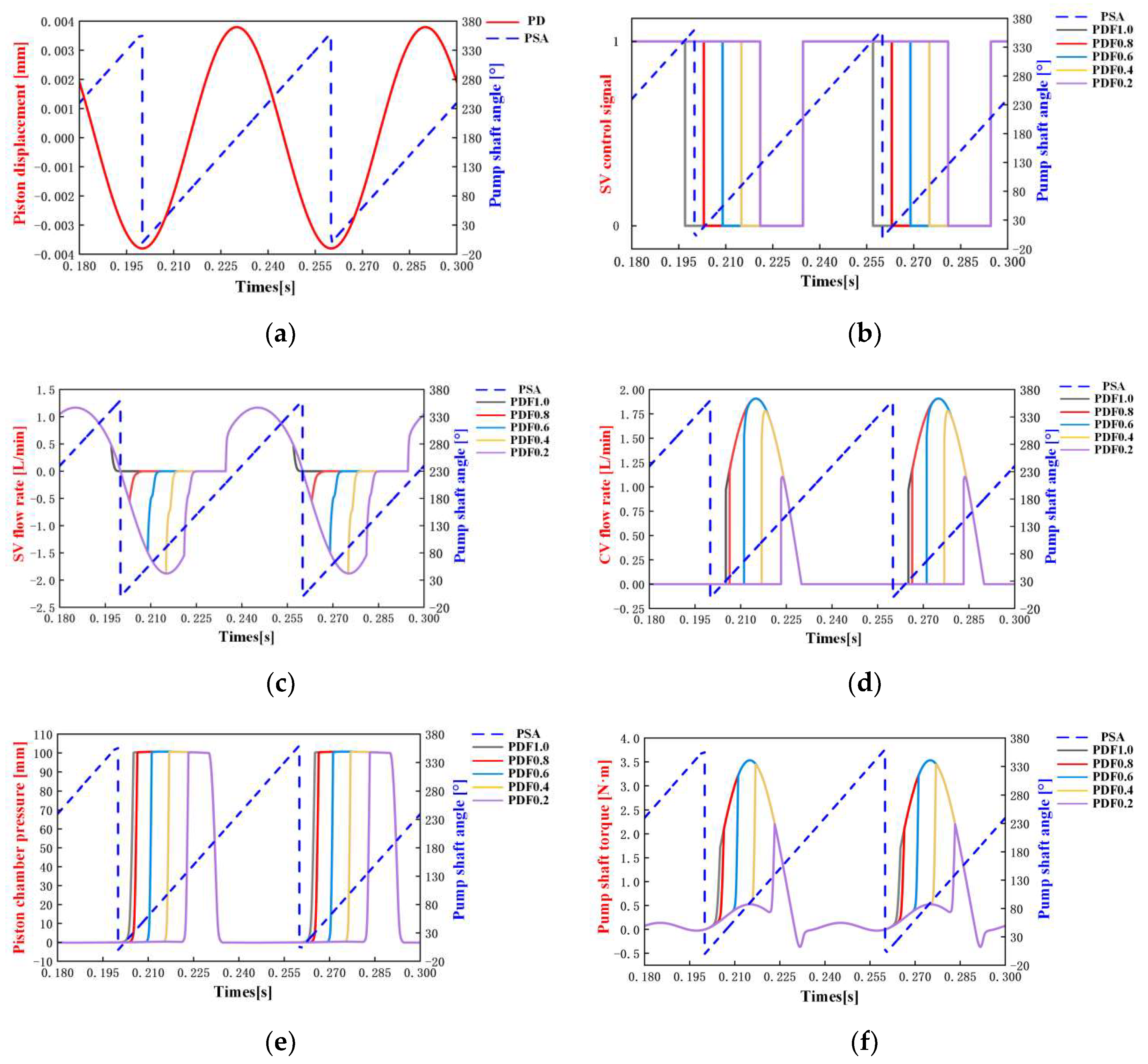

5.1. The Simulation of the DERDP in PM

5.2. The Simulation of the DERDP in ERM

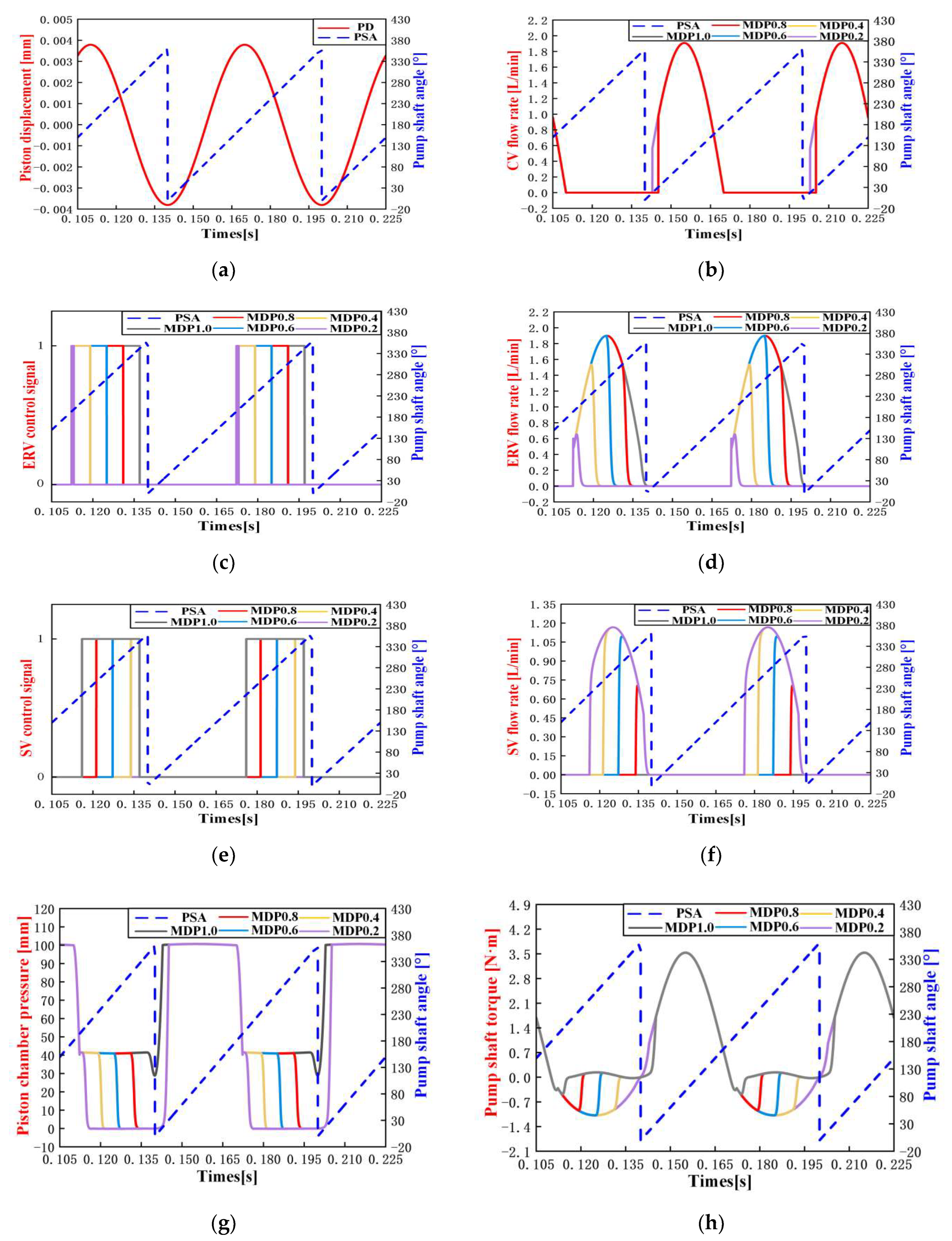

5.3. The Simulation of the DERDP in DRM

6. Conclusions

- When DERDP is in PM, only PDF can be controlled to realize the control of output flow and the control input energy of DERDP, which is used as a digital pump.

- As the DERDP is switched to ERM, the energy recovery function is activated. External hydraulic energy is allowed to be recovered and converted into mechanical energy. The period of the negative torque of DERDP expands proportionally to the MDF, i.e., increasing the MDF allows for more energy recovered.

- In the case that DERDP is in DRM, both PDF and MDF can be adjusted. The positive torque required to drive the DERDP decreases as the PDF reduces, and the operation of increasing the MDF also has this effect. The negative torque generated by the direct reuse process of DERDP can contribute to helping other plungers’ movement. Therefore, the energy required to drive the DERDP will be reduced.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Azzam, I.; Hwang, J.; Breidi, F.; Lumkes, J.; Salem, T. Automated method for selecting optimal digital pump operating strategy. Expert Syst. Appl. 2023, 232, 120509. [Google Scholar] [CrossRef]

- Sadiq, M.; Ali, S.W.; Terriche, Y.; Mutarraf, M.U.; Hassan, M.A.; Hamid, K.M.H.K.M.; Ali, Z.; Sze, J.Y.; Su, C.-L.; Guerrero, J.M.J.I.A. Future Greener Seaports: A Review of New Infrastructure, Challenges, and Energy Efficiency Measures. IEEE Access 2021, 9, 75568–75587. [Google Scholar] [CrossRef]

- Tabora, J.M.; Tostes, M.E.D.L.; Bezerra, U.H.; De Matos, E.O.; Pereira Filho, C.L.; Soares, T.M.; Rodrigues, C.E.M.J.I.A. Assessing energy efficiency and power quality impacts due to high-efficiency motors operating under nonideal energy supply. IEEE Access 2021, 9, 121871–121882. [Google Scholar] [CrossRef]

- Chen, M.; Chen, R.; Zheng, S.; Li, B. Green Investment, Technological Progress, and Green Industrial Development: Implications for Sustainable Development. Sustainability 2023, 15, 3808. [Google Scholar] [CrossRef]

- DOE/EIA. 2012. Available online: http://www.eia.gov/totalenergy/data/annual/ (accessed on 10 December 2022).

- Tian, H. Study of Active Valve Timing on Efficient Hydraulic Piston Motor Operations. Master’s Thesis, University of Minnesota, Minneapolis, MN, USA, 2016. [Google Scholar]

- Yang, H.-Y.; Pan, M. Engineering research in fluid power: A review. J. Zhejiang Univ. Sci. A 2015, 16, 427–442. [Google Scholar] [CrossRef] [Green Version]

- Chunying, H.; Haiquan, Y.; Guoyou, H.; Mingyang, L. Leakage of a Multistage Self-compensating Soft Plunger Pump under Different Methods. J. Eng. Sci. Technol. Rev. 2022, 15, 93–99. [Google Scholar] [CrossRef]

- Brazhenko, V.N.; Mochalin, E.V.; Jian-Cheng, C. Mechanical Admixture Influence in the Working Fluid on Wear and Jamming of Spool Pairs from Aircraft Hydraulic Drives. J. Frict. Wear 2020, 41, 526–530. [Google Scholar] [CrossRef]

- Zhang, D.; Zou, Y.; Zhang, P.; Song, Z.; Ding, M. Development of Full Hydraulic Marine Skimmer with Sweeping Arm. J. Navig. China 2017, 40, 16. [Google Scholar]

- Wang, H.; Shen, H.; Cao, S.; Xu, X.; Han, T.; Guo, H. Hydraulic System Design of Combined Harvester Header and Simulation of Header Lifting System. IOP Conf. Ser. Earth Environ. Sci. 2019, 233, 32012. [Google Scholar] [CrossRef]

- Zhao, P.; Chen, Y.; Zhou, H. Potential Energy Recovery System of Hydraulic Hybrid Excavator. In Proceedings of the BATH/ASME 2016 Symposium on Fluid Power and Motion Control, Bath, UK, 7–9 September 2016; American Society of Mechanical Engineers: New York, NY, USA, 2016. [Google Scholar]

- Geiger, C.; Geimer, M. Efficiency Optimisation of a Forestry Crane by Implement Hydraulics with Energy Recovery; Karlsruhe Institute of Technology: Karlsruhe, Germany, 2017. [Google Scholar]

- Sun, Z.; Wang, Y.; Zhang, H.; Li, J.; Xu, S. Parameter optimization and performance simulation evaluation of new swash plate-plunger energy recovery device. Desalination 2022, 528, 115598. [Google Scholar] [CrossRef]

- Liang, X.; Virvalo, T. An energy recovery system for a hydraulic crane. Part C J. Mech. Eng. Sci. 2001, 215, 737–744. [Google Scholar] [CrossRef]

- Ho, T.H.; Ahn, K.K.J.I.-S. Saving energy control of cylinder drive using hydraulic transformer combined with an assisted hydraulic circuit. In Proceedings of the 2009 ICCAS-SICE, Fukuoka, Japan, 18–21 August 2009; pp. 2115–2120. [Google Scholar]

- Lin, T.; Wang, Q.; Hu, B.; Gong, W. Research on the energy regeneration systems for hybrid hydraulic excavators. Autom. Constr. 2010, 19, 1016–1026. [Google Scholar] [CrossRef]

- Boehm, D.; Hollander, C.; Landmann, T. Hybrid drives in crawler excavators: Concepts and solutions. In Proceedings of the 3rd Symposium on Hybrid Drive Systems for Mobile Machinery, Karlsruhe, Germany, 28 February 2011; Karlsruhe Institute of Technology: Karlsruhe, Germany; pp. 117–124. [Google Scholar]

- Thompson, B.D.; Yoon, H.-S.; Kim, J.; Lee, J.Y. Swing Energy Recuperation Scheme for Hydraulic Excavators; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Winkler, B. Recent Advances in Digital Hydraulic Components and Applications. In Proceedings of the Ninth Workshop on Digital Fluid Power, Aalborg, Denmark, 7–8 September 2017. [Google Scholar]

- Breidi, F.E.; Garrity, J.; Lumkes, J. Design and Testing of Novel Hydraulic Pump/Motors to Improve the Efficiency of Agricultural Equipment. Trans. ASAB 2017, 60, 1809–1817. [Google Scholar] [CrossRef]

- Azzam, I.; Pate, K.; Garcia-Bravo, J.; Breidi, F. Energy Savings in Hydraulic Hybrid Transmissions through Digital Hydraulics Technology. Energies 2022, 15, 1348. [Google Scholar] [CrossRef]

- Minav, T.A.; Hänninen, H.; Sinkkonen, A.; Laurila, L.I.E.; Pyrhonen, J. Electric or Hydraulic Energy Recovery Systems in a Reach Truck—A Comparison. J. Mech. Eng. 2014, 60, 232–240. [Google Scholar] [CrossRef]

- Green, M.; Macpherson, J.; Caldwell, N.; Rampen, W.H.S. DEXTER: The Application of a Digital Displacement® Pump to a 16 Tonne Excavator. In Proceedings of the BATH/ASME 2018 Symposium on Fluid Power and Motion Control, Bath, UK, 12–14 September 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018; pp. 12–14. [Google Scholar]

- Hutcheson, J.; Abrahams, D.; Macpherson, J.; Caldwell, N.; Rampen, W. Demonstration of Efficient Energy Recovery Systems Using Digital Displacement® Hydraulics. In Proceedings of the BATH/ASME 2020 Symposium on Fluid Power and Motion Control, Virtual, 9–11 September 2020; American Society of Mechanical Engineers: New York, NY, USA, 2020. [Google Scholar]

- Macpherson, J.; Williamson, C.; Green, M.; Caldwell, N. Energy Efficient Excavator Hydraulic Systems with Digital Displacement® Pump-Motors and Digital Flow Distribution. In Proceedings of the BATH/ASME 2020 Symposium on Fluid Power and Motion Control, Virtual, 9–11 September 2020; American Society of Mechanical Engineers: New York, NY, USA, 2020. [Google Scholar]

- Pellegri, M.; Green, M.A.; Macpherson, J.; McKay, C.; Caldwell, N.J.J.V.-C. Applying a Multi-Service Digital Displacement® Pump to an Excavator to Reduce Valve Losses. In Proceedings of the 12th International Fluid Power Conference (IFK), Dresden, Germany, 12–14 October 2020. [Google Scholar]

- Merrill, K.J. Modeling and Analysis of Active Valve Control of a Digital Pump-Motor. Ph.D. Dissertation, Purdue University, West Lafayette, IN, USA, 2012. [Google Scholar]

- El-Breidi, F. Investigation of Digital Pump/Motor Control Strategies. Ph.D. Dissertation, Purdue University, West Lafayette, IN, USA, 2016. [Google Scholar]

- Noah, D.; Manring, R.C.F. Hydraulic Control Systems; Wiley Online Library, John Wiley & Sons: New York, NY, USA, 2019. [Google Scholar]

- Liu, Z.; Li, L.; Yue, D.; Wei, L.; Liu, C.; Zuo, X. Dynamic Performance Improvement of Solenoid Screw-In Cartridge Valve Using a New Hybrid Voltage Control. Machines 2022, 10, 106. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Pump angular speed | 1000 | rpm |

| Chamber length | 25.1 | mm |

| Eccentric radius | 31 | mm |

| Eccentricity | 3.8 | mm |

| Flow coefficient | 0.7 | |

| Piston diameter | 10 | mm |

| Dead volume of piston | 0.08 | cm3 |

| SV response time | 3 | ms |

| ERV response time | 3 | ms |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yue, D.; Zuo, X.; Liu, Z.; Liu, Y.; Wei, L.; Sun, J.; Gao, H. Simulation Analysis of a Novel Digital Pump with Direct Recycling of Hydraulic Energy. Axioms 2023, 12, 696. https://doi.org/10.3390/axioms12070696

Yue D, Zuo X, Liu Z, Liu Y, Wei L, Sun J, Gao H. Simulation Analysis of a Novel Digital Pump with Direct Recycling of Hydraulic Energy. Axioms. 2023; 12(7):696. https://doi.org/10.3390/axioms12070696

Chicago/Turabian StyleYue, Daling, Xiukun Zuo, Zengguang Liu, Yinshui Liu, Liejiang Wei, Jisu Sun, and Hongfei Gao. 2023. "Simulation Analysis of a Novel Digital Pump with Direct Recycling of Hydraulic Energy" Axioms 12, no. 7: 696. https://doi.org/10.3390/axioms12070696