Zeolite Synthesized from Coal Fly Ash Produced by a Gasification Process for Ni2+ Removal from Water

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Preparation

2.2. Zeolite Synthesis

2.3. Characterization of Samples

2.4. Adsorption Experiments

3. Results and Discussion

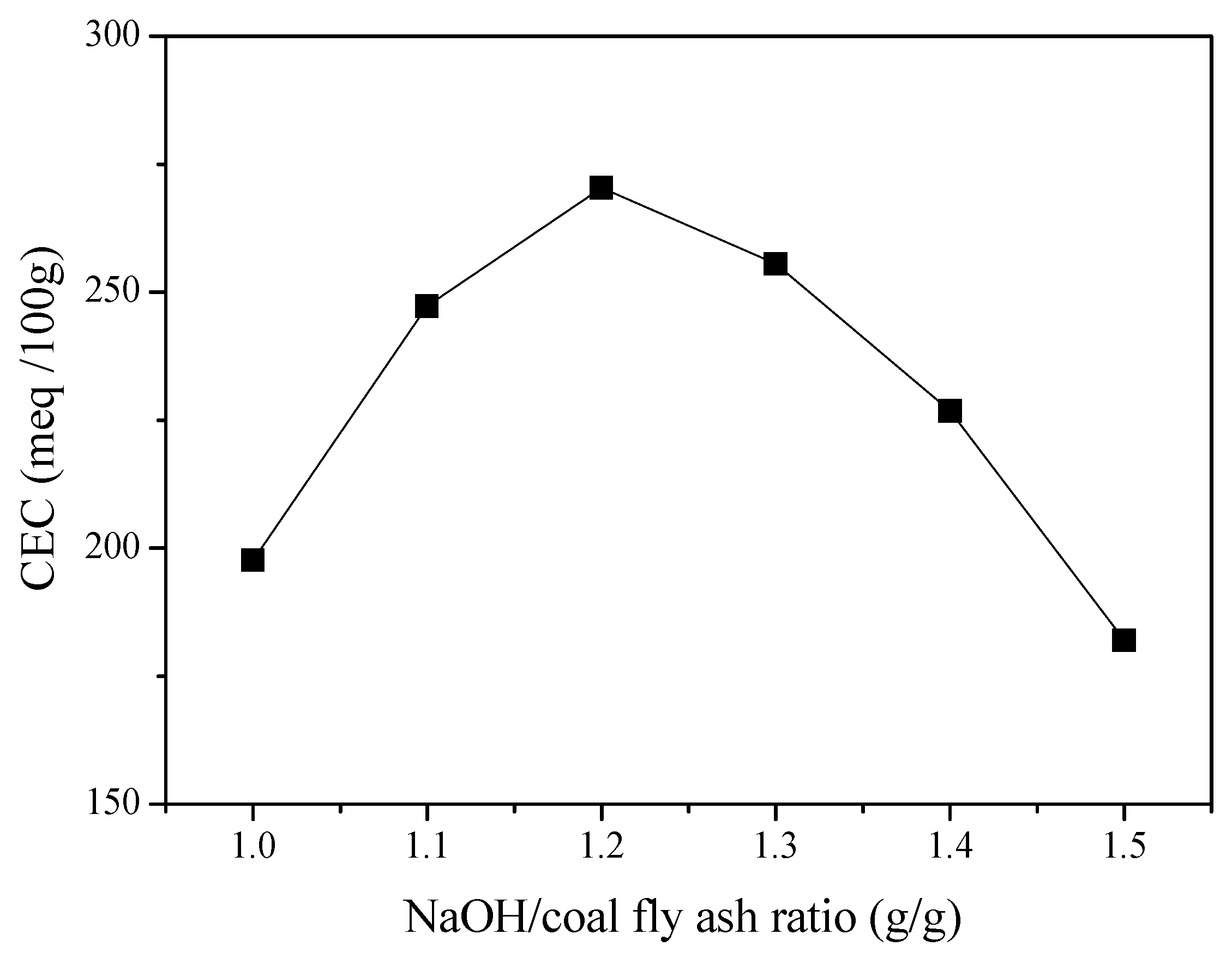

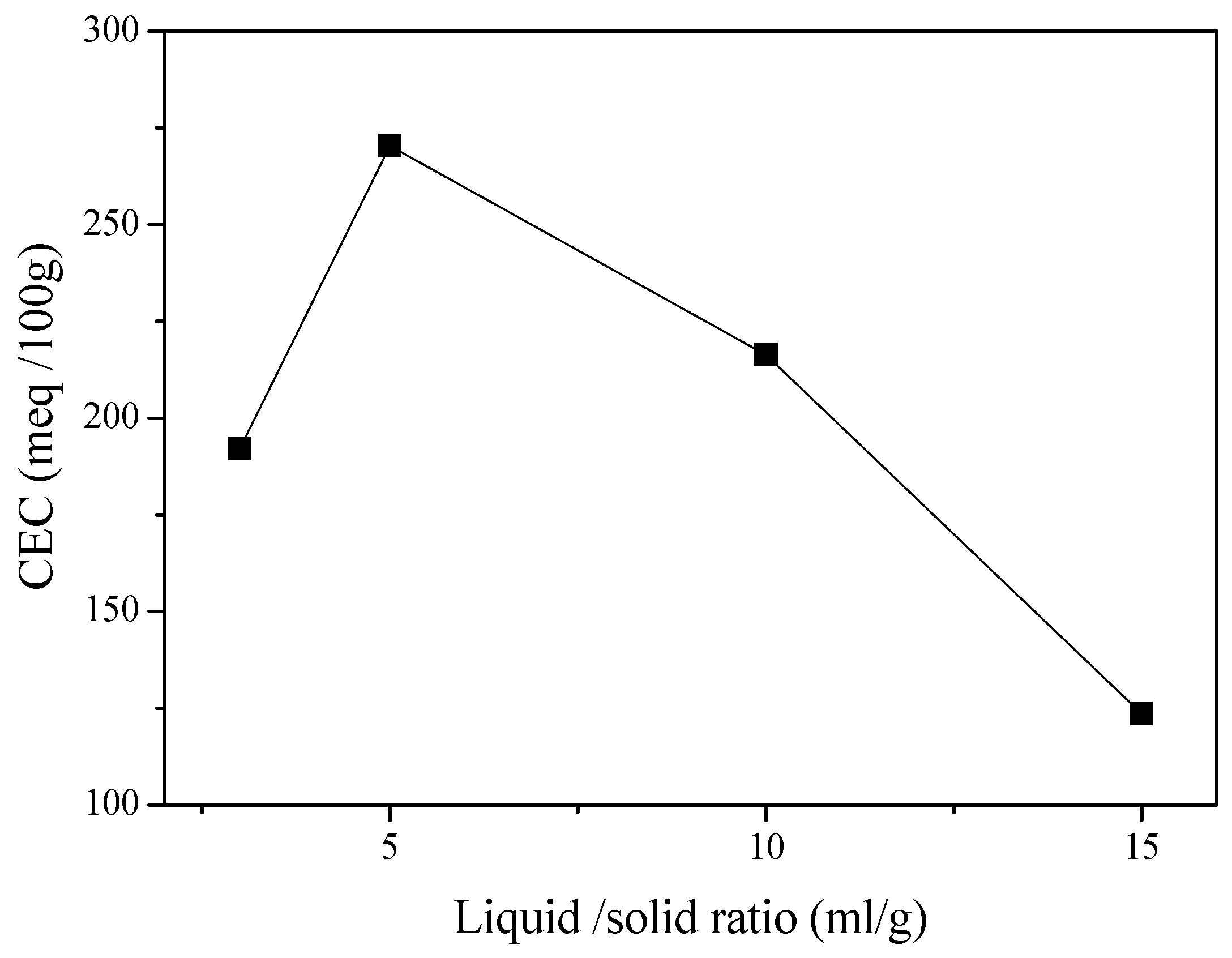

3.1. Effect of Operation Conditions on the Cation Exchange Capacity (CEC) of Synthesized Zeolite

3.1.1. Effect of NaOH/Fly Ash Ratio

3.1.2. Effect of Liquid/Solid Ratio

3.1.3. Effect of Alkali Fusion Conditions

3.1.4. Effect of Hydrothermal Treatment Conditions

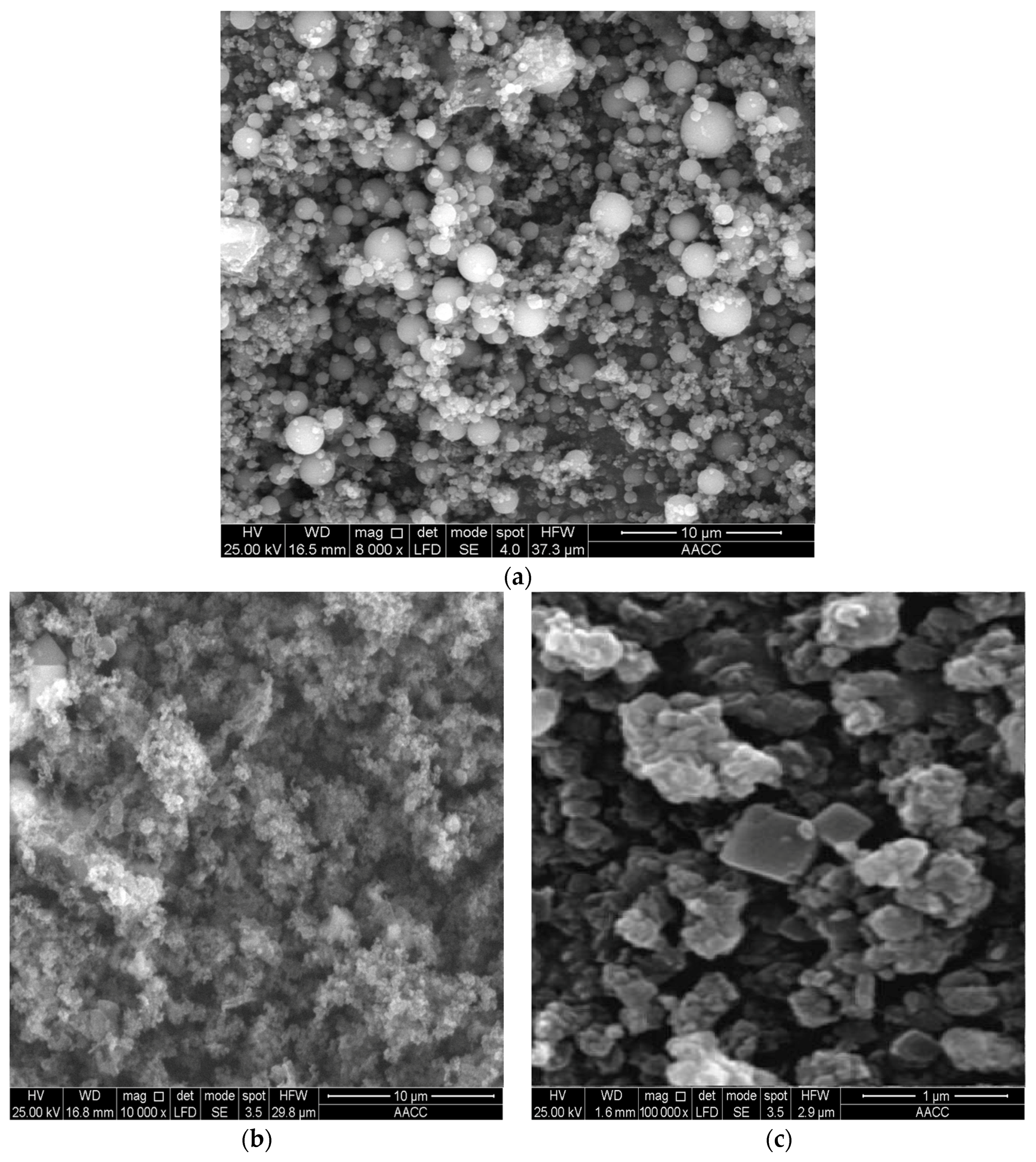

3.1.5. Mineralogical and Morphological Analysis

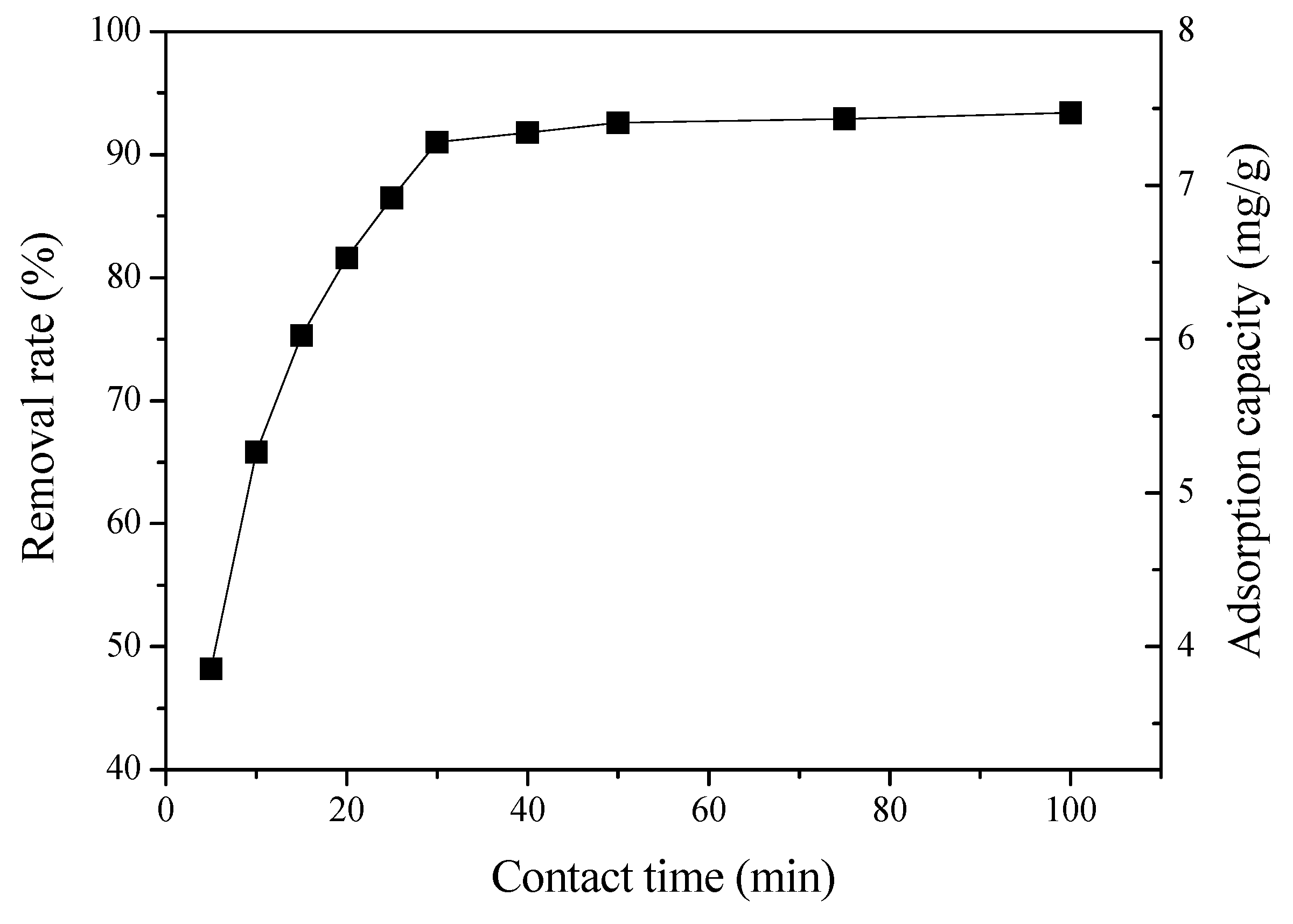

3.2. Adsorption of Ni2+ by Synthesized Zeolite

3.2.1. Effect of pH on Adsorption

3.2.2. Effect of Contact Time on Adsorption

3.2.3. Effect of Adsorbent Dose on Adsorption

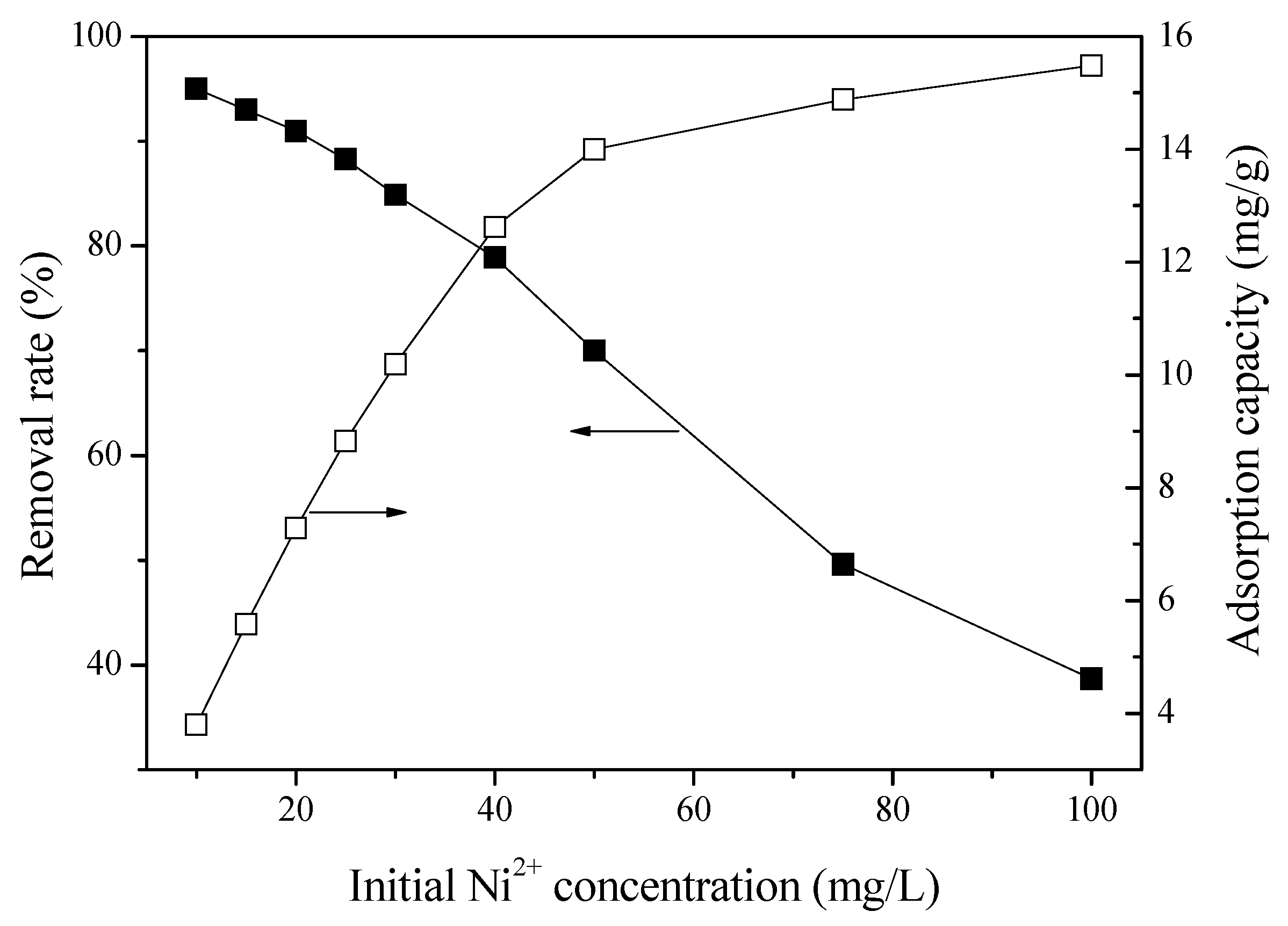

3.2.4. Effect of Initial Ni2+ Concentration on Adsorption

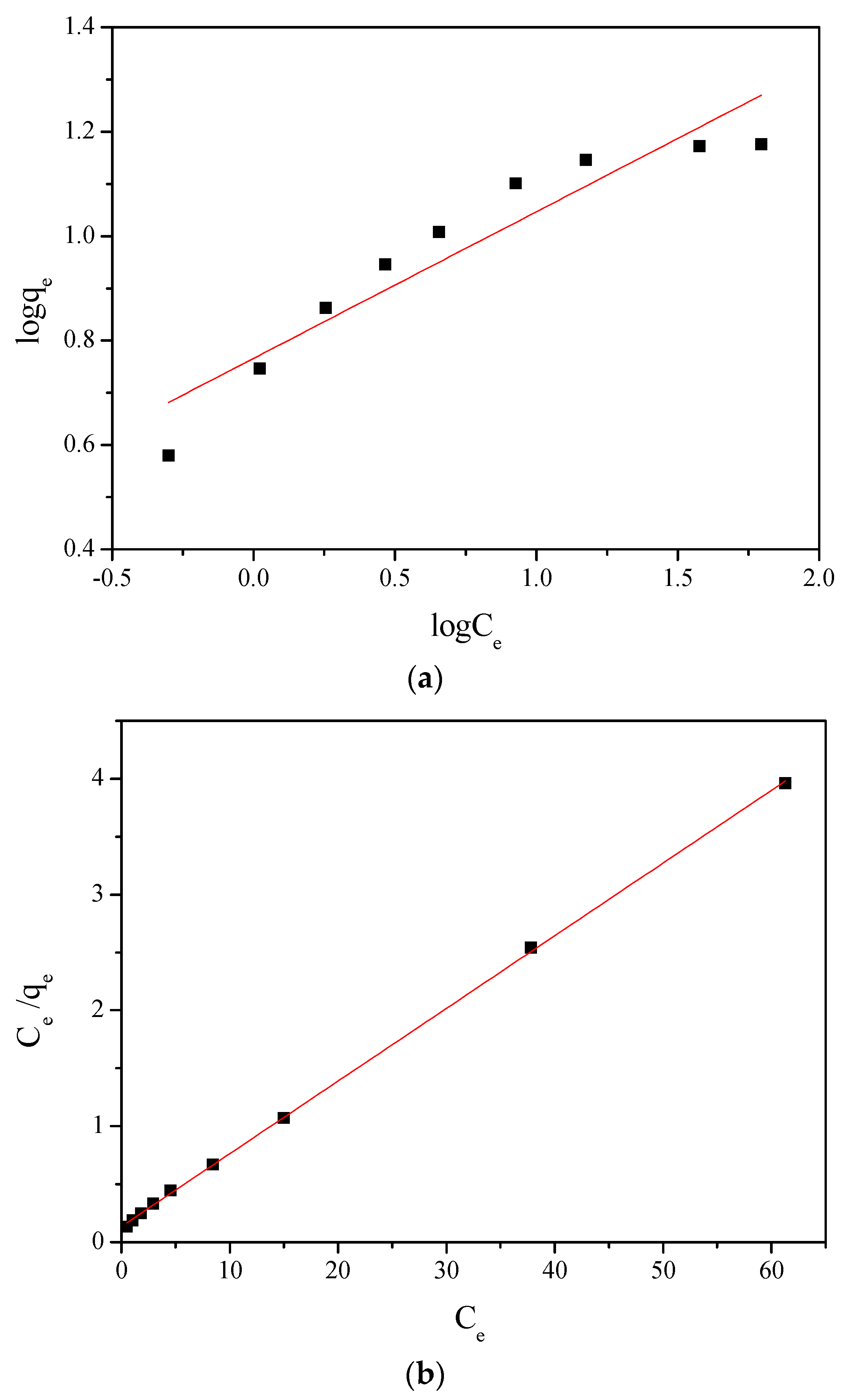

3.2.5. Adsorption Isotherm and Kinetics

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Benvenuti, T.; Krapf, R.S.; Rodrigues, M.A.S.; Bernardes, A.M.; Zoppas-Ferreira, J. Recovery of nickel and water from nickel electroplating wastewater by electrodialysis. Sep. Purif. Technol. 2014, 129, 106–112. [Google Scholar] [CrossRef]

- Borba, C.E.; Guirardello, R.; Silva, E.A.; Veit, M.T.; Tavares, C.R.G. Removal of nickel(II) ions from aqueous solution by biosorption in a fixed bed column: Experimental and theoretical breakthrough curves. Biochem. Eng. J. 2006, 30, 184–191. [Google Scholar] [CrossRef]

- Boujelben, N.; Bouzid, J.; Elouear, Z. Adsorption of nickel and copper onto natural iron oxide-coated sand from aqueous solutions: study in single and binary systems. J. Hazard. Mater. 2009, 163, 376–382. [Google Scholar] [CrossRef] [PubMed]

- Argun, M.E. Use of clinoptilolite for the removal of nickel ions from water: kinetics and thermodynamics. J. Hazard. Mater. 2008, 150, 587–595. [Google Scholar] [CrossRef] [PubMed]

- Peng, C.; Jin, R.; Li, G.; Li, F.; Gu, Q. Recovery of nickel and water from wastewater with electrochemical combination process. Sep. Purif. Technol. 2014, 136, 42–49. [Google Scholar] [CrossRef]

- Visa, M.; Chelaru, A.-M. Hydrothermally modified fly ash for heavy metals and dyes removal in advanced wastewater treatment. Appl. Surf. Sci. 2014, 303, 14–22. [Google Scholar] [CrossRef]

- Koukouzas, N.; Vasilatos, C.; Itskos, G.; Mitsis, I.; Moutsatsou, A. Removal of heavy metals from wastewater using CFB-coal fly ash zeolitic materials. J. Hazard. Mater. 2010, 173, 581–588. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.T.; Ji, X.S.; Sarker, P.K.; Tang, J.H.; Ge, L.Q.; Xia, M.S.; Xi, Y.Q. A comprehensive review on the applications of coal fly ash. Earth-Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef]

- Blissett, R.S.; Rowson, N.A. A review of the multi-component utilisation of coal fly ash. Fuel 2012, 97, 1–23. [Google Scholar] [CrossRef]

- Raoa, M.; Parwatea, A.V.; Bholeb, A.G. Removal of Cr6+ and Ni2+ from aqueous solution using bagasse and fly ash. Waste Manag. 2002, 22, 821–830. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Molina, A.; Poole, C. A comparative study using two methods to produce zeolites from fly ash. Miner. Eng. 2004, 17, 167–173. [Google Scholar] [CrossRef]

- Kunecki, P.; Panek, R.; Wdowin, M.; Franus, W. Synthesis of faujasite (FAU) and tschernichite (LTA) type zeolites as a potential direction of the development of lime Class C fly ash. Int. J. Miner. Process. 2017, 166, 69–78. [Google Scholar] [CrossRef]

- Wdowin, M.; Franus, M.; Panek, R.; Badura, L.; Franus, W. The conversion technology of fly ash into zeolites. Clean Technol. Environ. Policy 2014, 16, 1217–1223. [Google Scholar] [CrossRef]

- Querola, X.; UmanÄaa, J.C.; Planaa, F.; Alastueya, A.; Lopez-Solera, A.; Medinacelib, A.; Valerob, A.; Domingob, M.J.; Garcia-Rojo, E. Synthesis of zeolites from fly ash at pilot plant scale. Examples of potential applications. Fuel 2001, 80, 857–865. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, Z.H. Characterisation and environmental application of an Australian natural zeolite for basic dye removal from aqueous solution. J. Hazard. Mater. 2006, 136, 946–952. [Google Scholar] [CrossRef] [PubMed]

- Katsou, E.; Malamis, S.; Tzanoudaki, M.; Haralambous, K.J.; Loizidou, M. Regeneration of natural zeolite polluted by lead and zinc in wastewater treatment systems. J. Hazard. Mater. 2011, 189, 773–786. [Google Scholar] [CrossRef] [PubMed]

- Vyšvařil, M.; Bayer, P. Immobilization of Heavy Metals in Natural Zeolite-blended Cement Pastes. Procedia Eng. 2016, 151, 162–169. [Google Scholar] [CrossRef]

- Shanableh, A.; Kharabsheh, A. Stabilization of Cd, Ni and Pb in soil using natural zeolite. J. Hazard. Mater. 1996, 45, 207–217. [Google Scholar] [CrossRef]

- Kronbauer, M.A.; Izquierdo, M.; Dai, S.; Waanders, F.B.; Wagner, N.J.; Mastalerz, M.; Hower, J.C.; Oliveira, M.L.; Taffarel, S.R.; Bizani, D.; et al. Geochemistry of ultra-fine and nano-compounds in coal gasification ashes: a synoptic view. Sci. Total Environ. 2013, 456–457, 95–103. [Google Scholar] [CrossRef] [PubMed]

- Minchener, A.J. Coal gasification for advanced power generation. Fuel 2005, 84, 2222–2235. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, Y.; Li, L.; Xu, H.; Sun, Y.; Wang, Y. Novel synthesis of cyano-functionalized mesoporous silica nanospheres (MSN) from coal fly ash for removal of toxic metals from wastewater. J. Hazard. Mater. 2018, 345, 76–86. [Google Scholar] [CrossRef] [PubMed]

- He, K.; Chen, Y.; Tang, Z.; Hu, Y. Removal of heavy metal ions from aqueous solution by zeolite synthesized from fly ash. Environ. Sci. Pollut. Res. Int. 2016, 23, 2778–2788. [Google Scholar] [CrossRef] [PubMed]

- Bai, J.; Li, W.; Li, B. Characterization of low-temperature coal ash behaviors at high temperatures under reducing atmosphere. Fuel 2008, 87, 583–591. [Google Scholar] [CrossRef]

- Huffman, G.P.; Huggins, F.E.; Dunmyre, G.R. Investigation of the high-temperature behaviour of coal ash in reducing and oxidizing atmospheres. Fuel 1981, 60, 585–597. [Google Scholar] [CrossRef]

- Ojha, K.; Pradhan, N.C.; Samanta, A.N. Zeolite from fly ash synthesis and characterization. Bull. Mater. Sci. 2004, 27, 555–564. [Google Scholar] [CrossRef]

- Rujiwatra, A.; Phueadpho, M.; Grudpan, K. Selective synthesis of zeolitic phillipsite and hibschite hydrogarnet from lignite ash employing calcium hydroxide under mild conditions. J. Phys. Chem. Solids 2005, 66, 1085–1090. [Google Scholar] [CrossRef]

- Shigemoto, N.; Hayashi, H. Selective formation of Na-X zeolite from coal fly ash by fusion with sodium hydroxide prior to hydrothermal reaction. J. Mater. Sci. 1993, 28, 4781–4786. [Google Scholar] [CrossRef]

- Murayama, N.; Yamamoto, H.; Shibata, J. Mechanism of zeolite synthesis from coal fly ash by alkali hydrothermal reaction. Int. J. Miner. Process. 2002, 64, 1–17. [Google Scholar] [CrossRef]

- Rayalu, S.; Meshram, S.U.; Hasan, M.Z. Highly crystalline faujasitic zeolites from fly ash. J. Hazard. Mater. 2000, 77, 123–131. [Google Scholar] [CrossRef]

- Kalyani, S.; Srinivasa Rao, P.; Krishnaiah, A. Removal of nickel (II) from aqueous solutions using marine macroalgae as the sorbing biomass. Chemosphere 2004, 57, 1225–1229. [Google Scholar] [CrossRef] [PubMed]

- Onundi, Y.B.; Mamun, A.A.; Khatib, M.F.A.; Ahmed, Y.M. Adsorption of copper, nickel and lead ions from synthetic semiconductor industrial wastewater by palm shell activated carbon. Int. J. Environ. Sci. Technol. 2010, 7, 751–758. [Google Scholar] [CrossRef]

- Panneerselvam, P.; Bala, V.S.S.; Thinakaran, N.; Baskaralingam, P.; Palanichamy, M.; Sivanesan, S. Removal of nickel(II) from aqueous solutions by adsorption with modified ZSM-5 zeolites. J. Chem. 2009, 6, 729–736. [Google Scholar] [CrossRef]

- Kocaoba, S.; Orhan, Y.; Akyüz, T. Kinetics and equilibrium studies of heavy metal ions removalby use of natural zeolite. Desalination 2007, 214, 1–10. [Google Scholar] [CrossRef]

- Abdel Salam, O.E.; Reiad, N.A.; ElShafei, M.M. A study of the removal characteristics of heavy metals from wastewater by low-cost adsorbents. J. Adv. Res. 2011, 2, 297–303. [Google Scholar] [CrossRef]

- Hui, K.S.; Chao, C.Y.; Kot, S.C. Removal of mixed heavy metal ions in wastewater by zeolite 4A and residual products from recycled coal fly ash. J. Hazard. Mater. 2005, 127, 89–101. [Google Scholar] [CrossRef] [PubMed]

| Compound | SiO2 | Al2O3 | CaO | Fe2O3 | K2O | Unburnt Carbon | Others |

|---|---|---|---|---|---|---|---|

| Content (%) | 39.84 | 22.42 | 6.12 | 5.91 | 1.47 | 15.20 | 9.04 |

| Mineral | Coal Fly Ash | Synthesized Zeolite |

|---|---|---|

| Quartz | Y | Y |

| Calcite | Y | N |

| Mullite | Y | Y |

| Illite | Y | N |

| Magnetite | Y | N |

| Hematite | Y | N |

| Zeolite X | N | Y |

| Zeolite A | N | Y |

| Freundlich Constants | Langmuir Constants | ||||

|---|---|---|---|---|---|

| (mg/g) | |||||

| 5.833 | 3.562 | 0.883 | 0.465 | 15.936 | 0.999 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Dong, J.; Guo, F.; Shao, Z.; Wu, J. Zeolite Synthesized from Coal Fly Ash Produced by a Gasification Process for Ni2+ Removal from Water. Minerals 2018, 8, 116. https://doi.org/10.3390/min8030116

Zhang Y, Dong J, Guo F, Shao Z, Wu J. Zeolite Synthesized from Coal Fly Ash Produced by a Gasification Process for Ni2+ Removal from Water. Minerals. 2018; 8(3):116. https://doi.org/10.3390/min8030116

Chicago/Turabian StyleZhang, Yixin, Jixiang Dong, Fanhui Guo, Zhongye Shao, and Jianjun Wu. 2018. "Zeolite Synthesized from Coal Fly Ash Produced by a Gasification Process for Ni2+ Removal from Water" Minerals 8, no. 3: 116. https://doi.org/10.3390/min8030116