3.2.1. Effect of Temperature

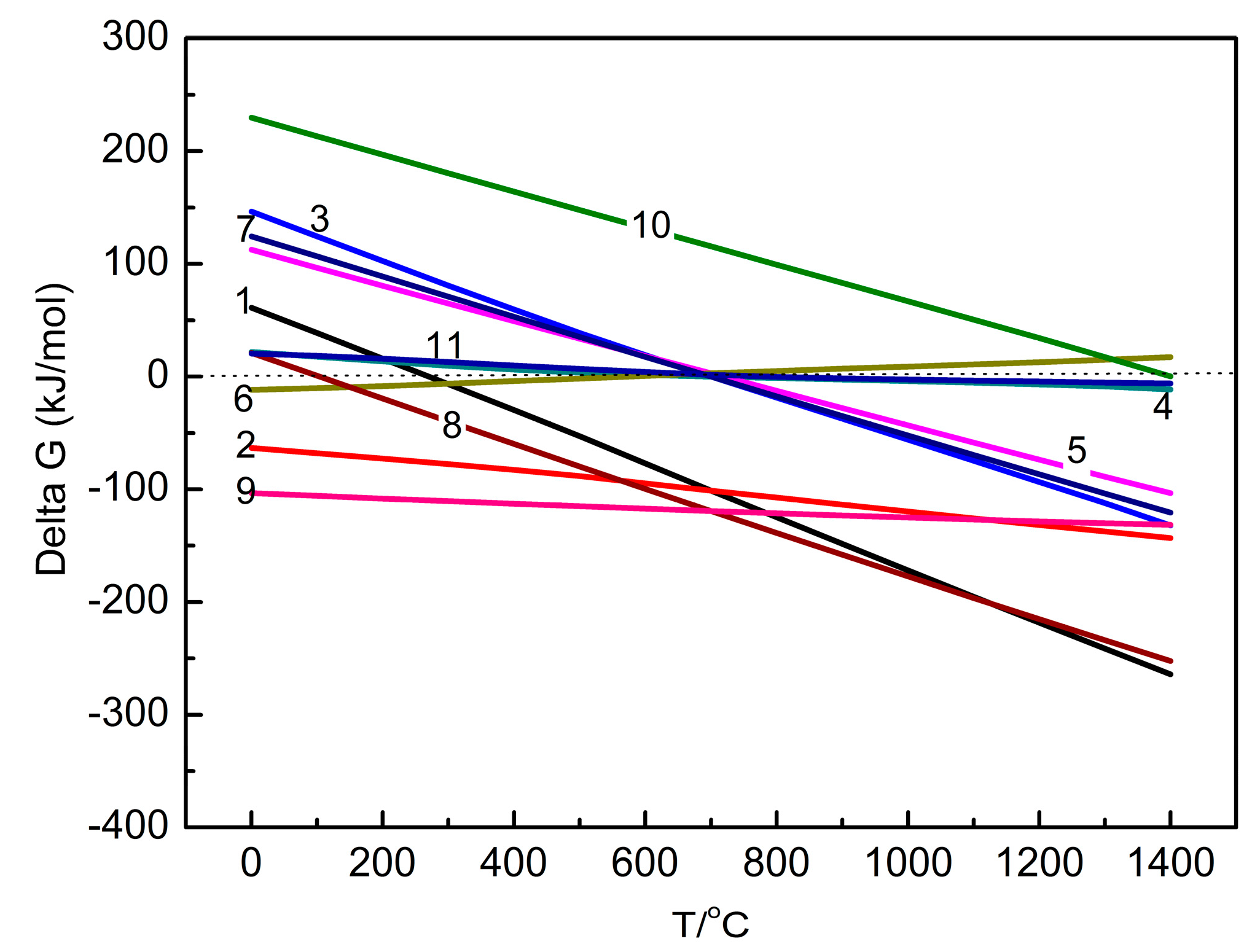

Chemical reactions that may take place during the carbothermic reduction process in the experimental temperature range (600–1200 °C) are listed in

Table 4. An Ellingham diagram for these key reactions is shown in

Figure 3.

As is known from

Figure 3, iron oxides can be reduced to metallic iron above 800 °C. Iron carbide also forms at temperatures higher than 800 °C. The Mn

2O

3 transforms to MnO spontaneously at this experimental condition. However, elemental manganese forms until the temperature reaches higher than 1400 °C. Therefore, except for reaction 10, the others listed in

Table 4 are actually taking place in the carbothermic reduction process.

The metallization ratio of reduced samples obtained at different temperatures is given in

Figure 4. It can be seen from the line chart that, as ferruginous manganese ore is roasted at 600 °C, almost no reduction occurred. Then, the reduction improves greatly with the temperature rising up to 1000 °C. The improvement showed a prominent increase in the metallization ratio of reduced samples. This value reached 75.7% at 1000 °C and increased by 75%, as compared to 600 °C. A further temperature rise only led to a slight increase of the metallization ratio. It finally attained 90.4% at 1200 °C and topped within experimental range in this paper.

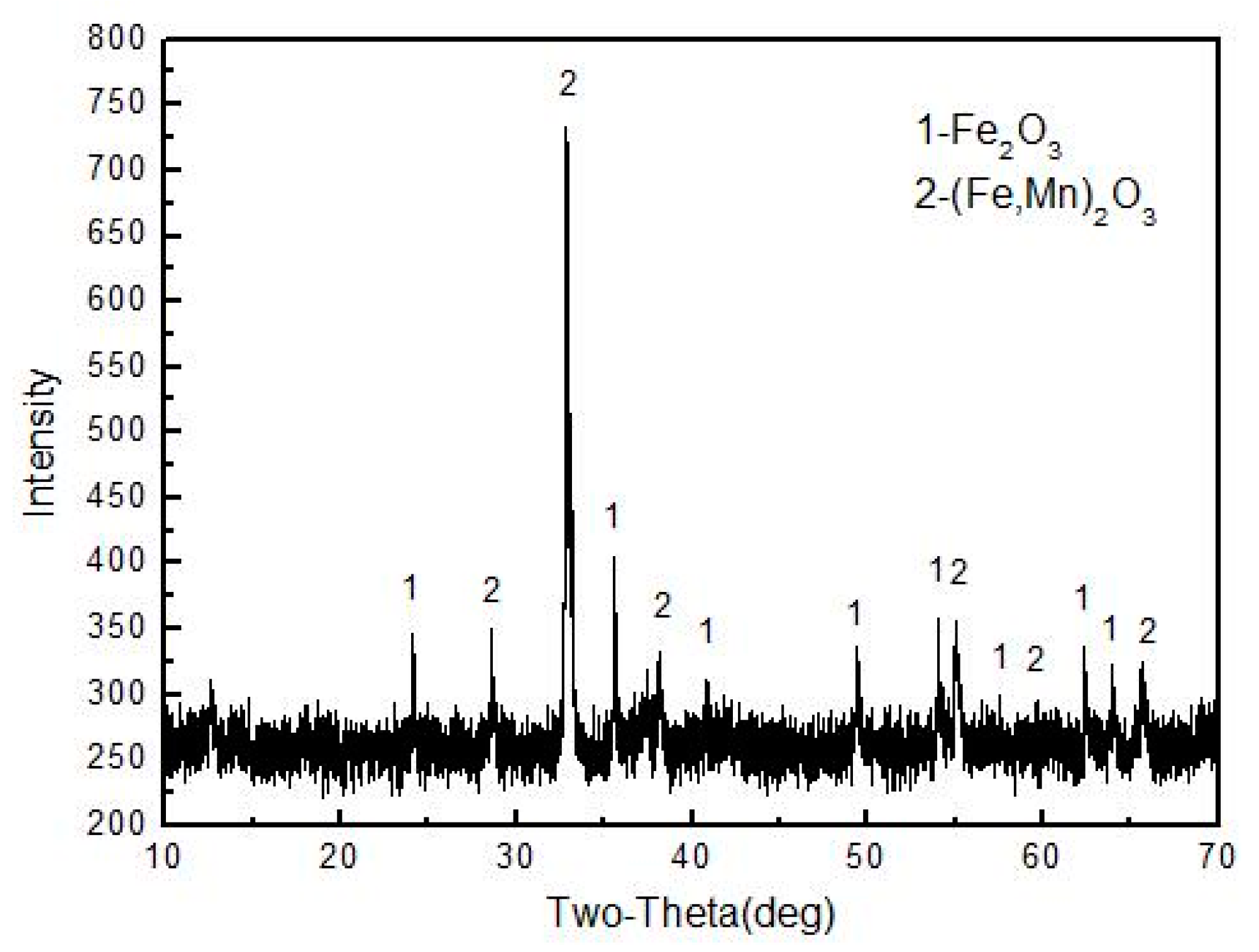

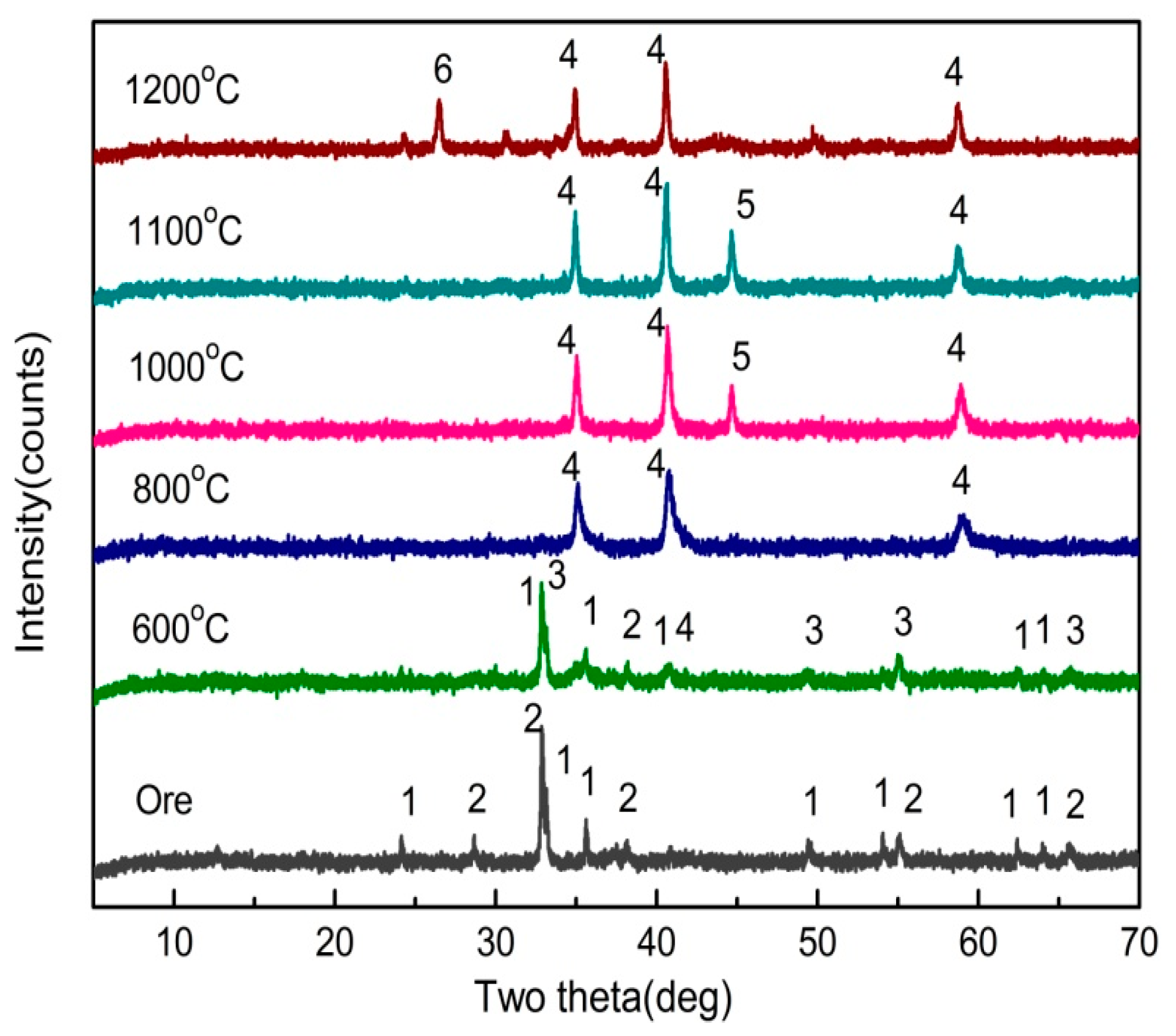

Samples reduced at different temperatures for 100 min were characterized by X-ray diffraction, as presented in

Figure 5, to understand the phase transformation law with temperature. The XRD pattern showed the major phase Fe

2O

3 and Mn

2O

3 coexisted with minor (Mn, Fe)

2O

3 and MnO in sample reduced at 600 °C indicating that the decomposition of (Mn, Fe)

2O

3 (main phase in raw ore) occurred at this temperature. Meanwhile, a very small amount of MnO was also identified due to the reduction of Mn

2O

3. Temperature rise improved this reduction as an obvious increase of MnO was identified in samples reduced between 800 °C and 1200 °C. The diffraction peak corresponding to iron phase was observed in sample obtained between 1000 °C and 1100 °C. It can be inferred that the reduction of iron oxide to metallic iron occurred at this temperature range. A further temperature rise to 1200 °C led to the formation of carbide (Fe

2.7Mn

0.3C), which inevitably hindered the separation for Fe and Mn elements. Thus, the phase transformation of ferruginous manganese ore reduction with temperature could be summarized as follows: Fe-Mn symbiotic phase decomposition → reduction of manganese oxides with high valence → reduction of iron oxides → MnO reduction → carbide (Fe

2.7Mn

0.3C) formation.

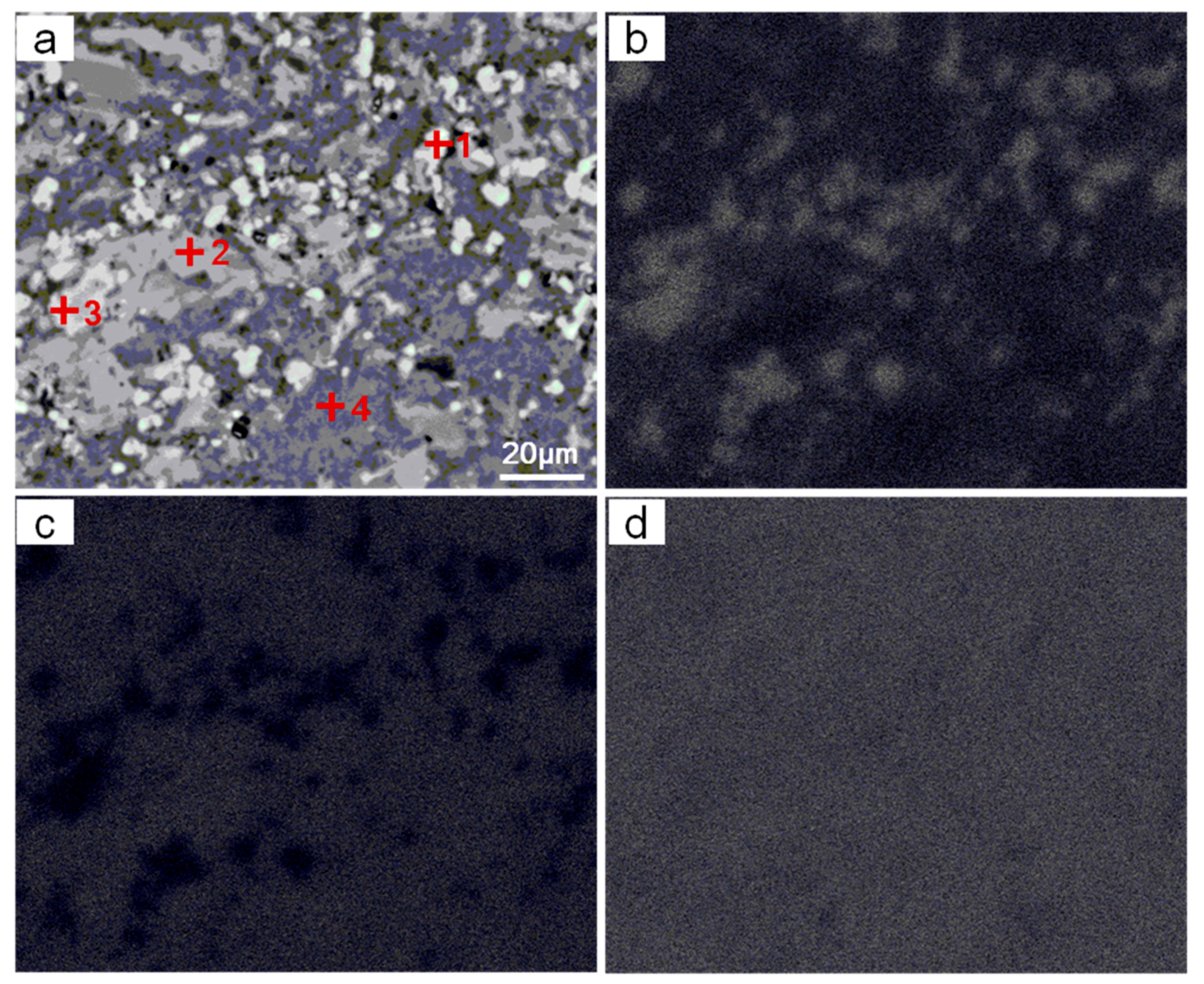

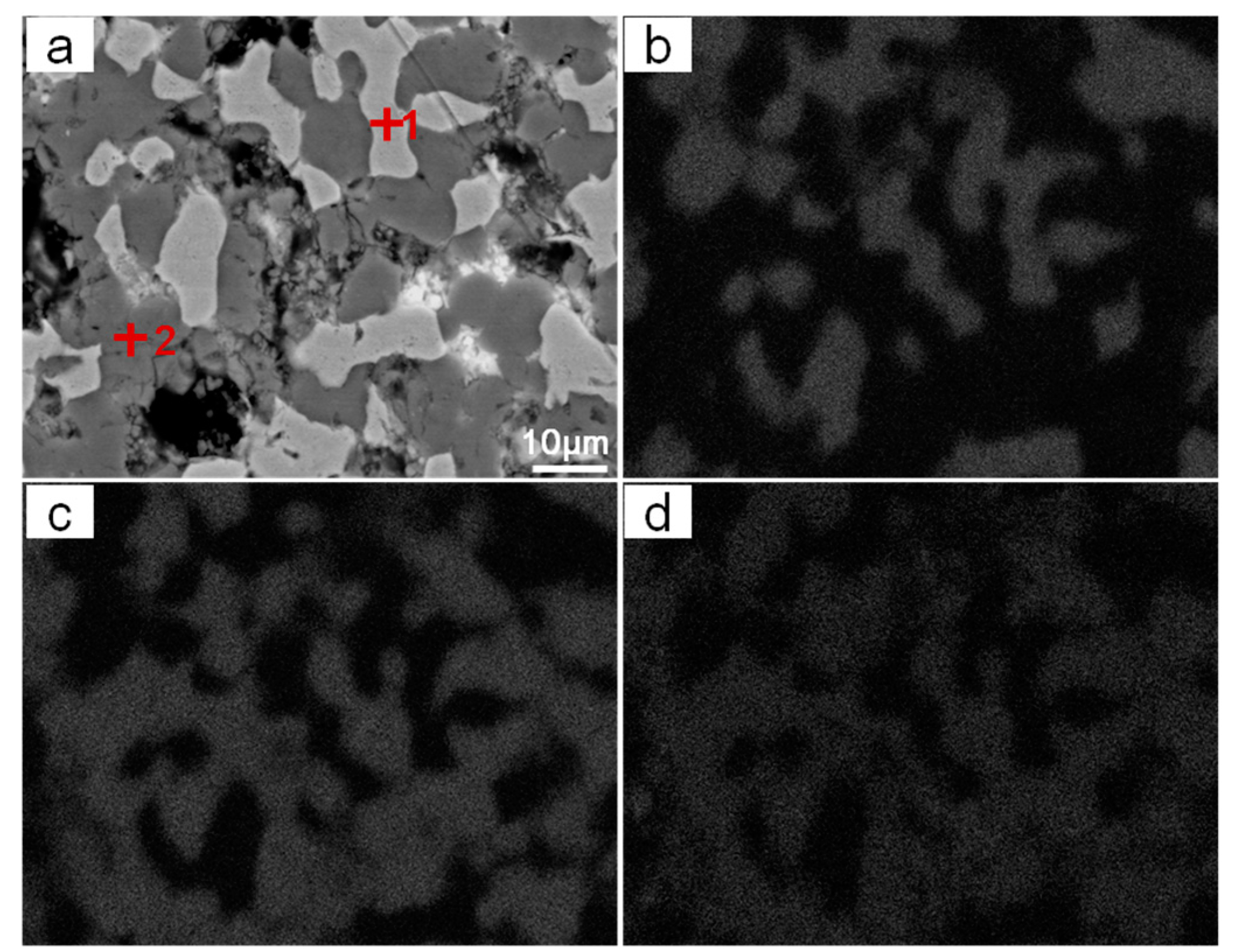

The microstructure (cross-section) of raw ore and samples reduced at 600 °C to 1200 °C (for 100 min) were characterized, as shown in

Figure 6, to reveal the intrinsic morphology evolution. A compact platy structure could be widely observed in unroasted ore, as presented in

Figure 6a. It was mainly composed of iron or manganese-rich minerals identified by EDX. Then, the fragmentary structure generated as a sample was reduced at 600 °C (shown in

Figure 6b). Decomposition of the (Fe, Mn)

2O

3 phase (as discussed in

Figure 5) at this temperature may be the inducement. At 800 °C the fragmentation became more and more apparent. It was accompanied by the reduction of high-valence manganese oxides to the MnO phase according to EDX (spot 3), which also coincided well with the XRD analysis. From

Figure 6d fine iron particles began to form, but still dispersed in the substrate of the MnO phase as the sample was reduced at 1000 °C. Then, much more iron formed and aggregated as the temperature further rose to 1100 °C and 1200 °C. The iron phase gradually separated from the manganese-rich phase and eventually formed a distinct boundary between metallic iron, MnO, and the manganese-rich slag phase, as shown in

Figure 6e,f. Especially for samples roasted at 1200 °C, there was evidence of a liquid phase formation, which would have enhanced the aggregation of the metallic iron-based phase (

Figure 6f). From the XRD analysis result presented in

Figure 5, low eutectic carbide generated at 1200 °C may be the main inducement for liquid phase formation and the distinct boundary development, consequently. Thus, the morphology evolution of ferruginous manganese ore reduction with temperature could be probably summarized as follows: plate-like structure fragment → granular MnO phase formation → fine metallic iron formation → aggregation of metallic iron → boundary development between phases.

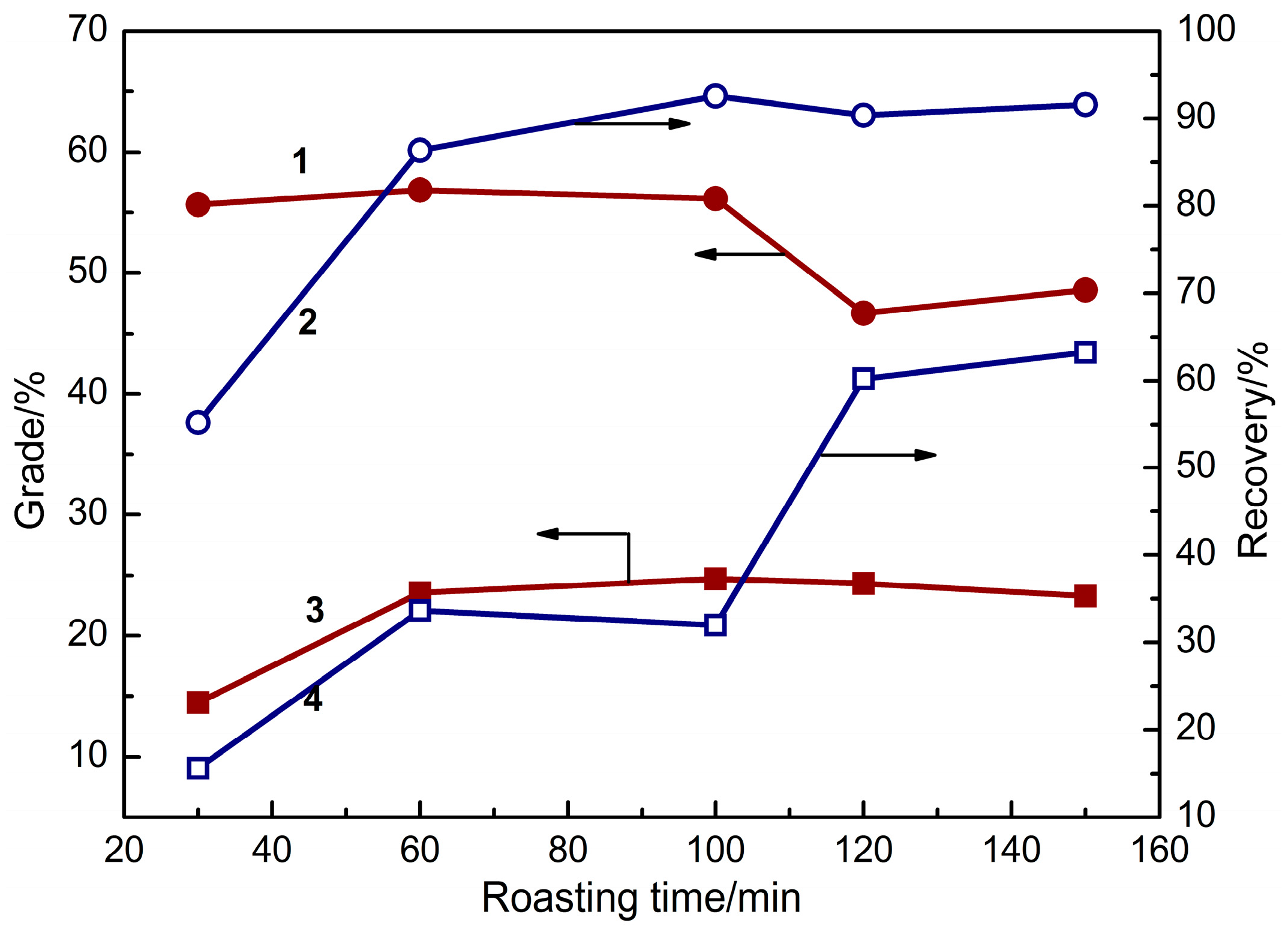

3.2.2. Effect of Roasting Time

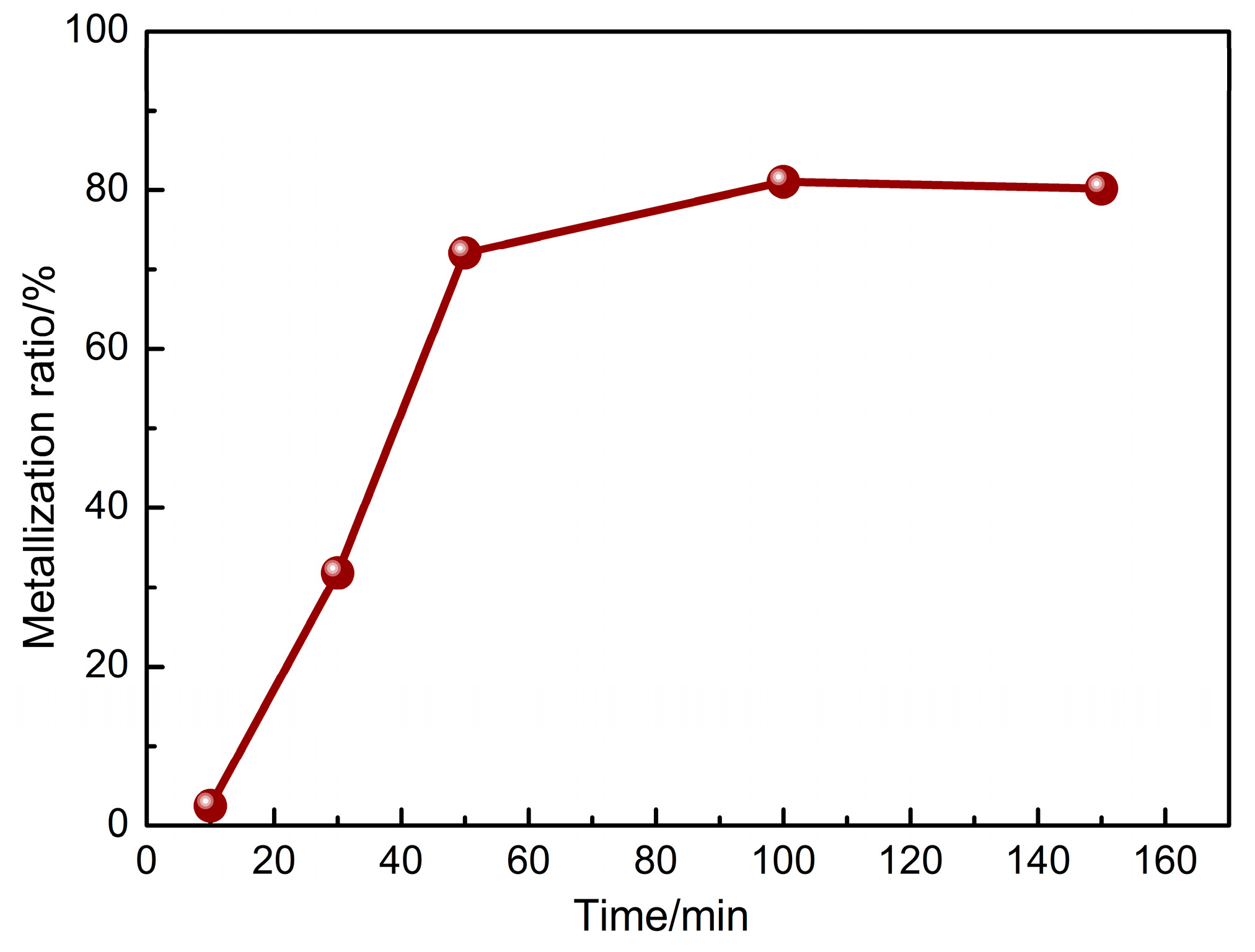

The metallization ratio of samples reduced (1100 °C) for different times is presented in

Figure 7. It can be seen from the line chart that the metallization ratio showed an obvious increase with prolonged time. As ferruginous manganese ore was roasted for 10 min only 2.5% of metallization ratio could be obtained. However, this value sharply rose to 72.1% as the roasting time lengthened to 50 min. After this, the upward trend gradually slowed down and the metallization ratio stabilized at 80.2% as the sample was reduced for 100 min. Thus, it can be inferred that the drastic reduction occurred within 50 min, but about 100 min was required for maximum reduction.

Samples reduced for different times were characterized by X-ray diffraction, as presented in

Figure 8, to understand the phase transformation law with roasting time.

The XRD pattern shows that the major phase (Mn, Fe)

2O

3 in raw ore almost disappeared when reduced for 10 min. Instead, the new phases Mn

2O

3 and MnO were identified, which indicate that decomposition of (Mn, Fe)

2O

3 and fractional reduction of Mn

2O

3 had completed within 10 min. After 30 min of reduction, the characteristic diffraction peaks that represent Mn

2O

3 faded away, while peaks of MnO intensified correspondingly. The new iron phase began to form as well. It can be inferred that the transformation of manganese oxides with high valence to MnO had mainly accomplished within 30 min. Lengthening the time further brought about an obvious increase of metallic iron without any other phase extinction or regeneration. From the iron phase transformation aspect, it showed good agreement with the metallization ratio trend, as displayed in

Figure 7. Thus, the phase transformation of ferruginous manganese ore reduction with time could be summarized as follows: Fe-Mn symbiotic phase decomposition → reduction of manganese oxides with high valence to MnO → reduction of iron oxides to metallic iron.

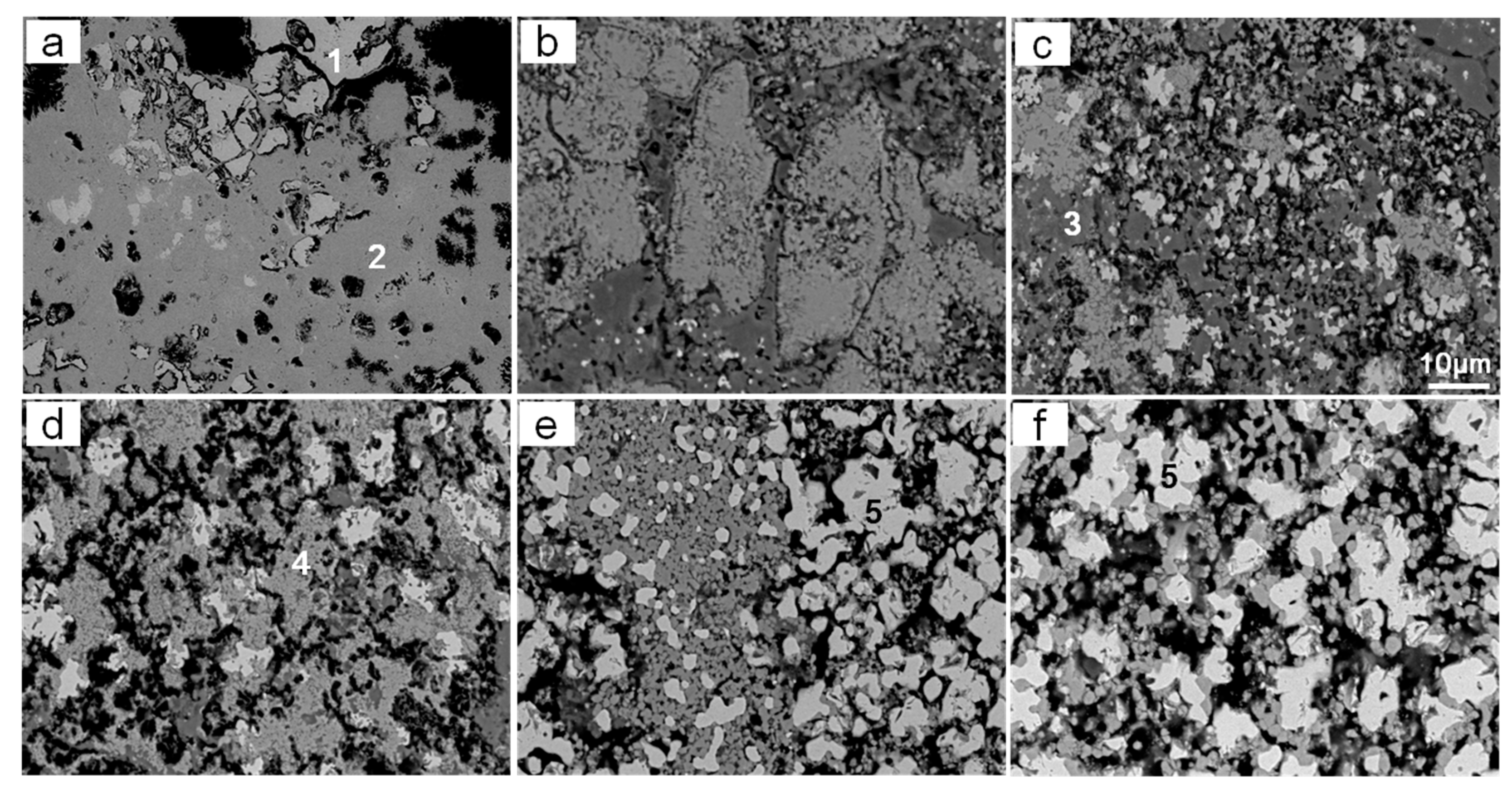

The microstructure (cross-section) of raw ore and samples reduced for 10 min to 150 min (at 1100 °C) were characterized, as shown in

Figure 9, to reveal the intrinsic morphology evolution. It can be observed that the compact platy structure in raw ore had fragmented to be several bulky cakes when the sample was reduced for 10 min. Decomposition of Mn-Fe associated minerals may have caused this variation as compared with its phase transformation (as discussed in

Figure 8). This fragmentation appeared to be more serious with time prolonged to 30 min and 50 min for its drastic reduction in the meantime. A fine iron phase began to form beside the cracks and pores at 30 min, as shown in

Figure 9c, which coincided well with the XRD analysis. Then, more iron formed and aggregated as the time was further lengthened to 100 min, and even to 150 min. Iron oxides dispersed in the MnO phase were also fully reduced to iron and separated with the manganese phase gradually. Thus, the morphology evolution with time could be probably summarized as follows: plate-like structure fragment → granular MnO phase formation → fine metallic iron formation → aggregation of metallic iron → separation of iron and manganese phase.

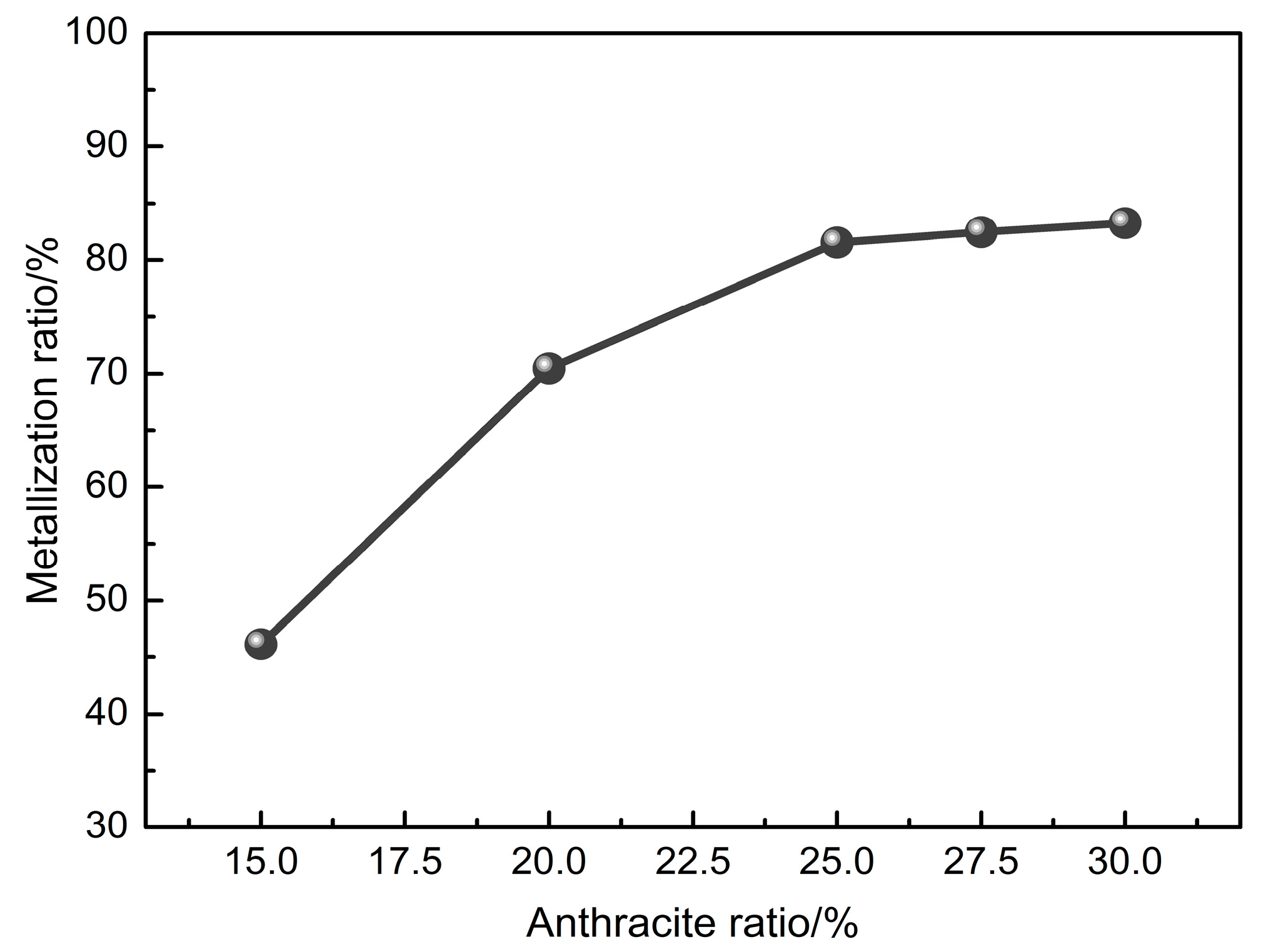

3.2.3. Effect of the Reducing Agent

In this part, anthracite with relatively high fixed carbon was chosen to study the effect of reductant dosage as presented in

Figure 10. As can be seen from the line chart, the metallization ratio gradually rose to be stable with reductant dosage. The metallization ratio of the reduced sample reached 45.2% with 15 wt % of anthracite addition. This was the stoichiometric amount that was required for a complete reaction (Fe

2O

3 → Fe and Mn

2O

3 → MnO) of this ferruginous manganese ore. An obvious upward trend as anthracite dosage increased to 25% was observed. Further anthracite dosage increased to 30% had little effect on the reduction degree. The metallization ratio of the reduced sample still remained at about 82% as 25% of anthracite was added. On one hand, the reductant increase could enhance the reduction potential in the reaction system and, therefore, promoted the metallization ratio. On the other hand, too much may turn into a barrier for full reduction because of its obstruction effect on the aggregation of newly-formed iron grains. Thus, anthracite dosage of 25% was appropriate for this reduction process.

From the metallization ratio, phase evolution aspects of reduced samples discussed above, and also from a cost perspective, the optimal temperature of 1100 °C, a roasting time of 100 min, and anthracite addition of 25% were selected for the ferruginous manganese ore reduction process.