Porosity and Permeability of Round Top Mountain Rhyolite (Texas, USA) Favor Coarse Crush Size for Rare Earth Element Heap Leach

Abstract

:1. Introduction

2. Materials and Methods

2.1. Rhyolite Samples

2.2. Porosity Measurements

2.3. Permeability Measurements

3. Results

3.1. Pre-Acid-Leach Porosity

3.2. Post-Acid-Leach Porosity

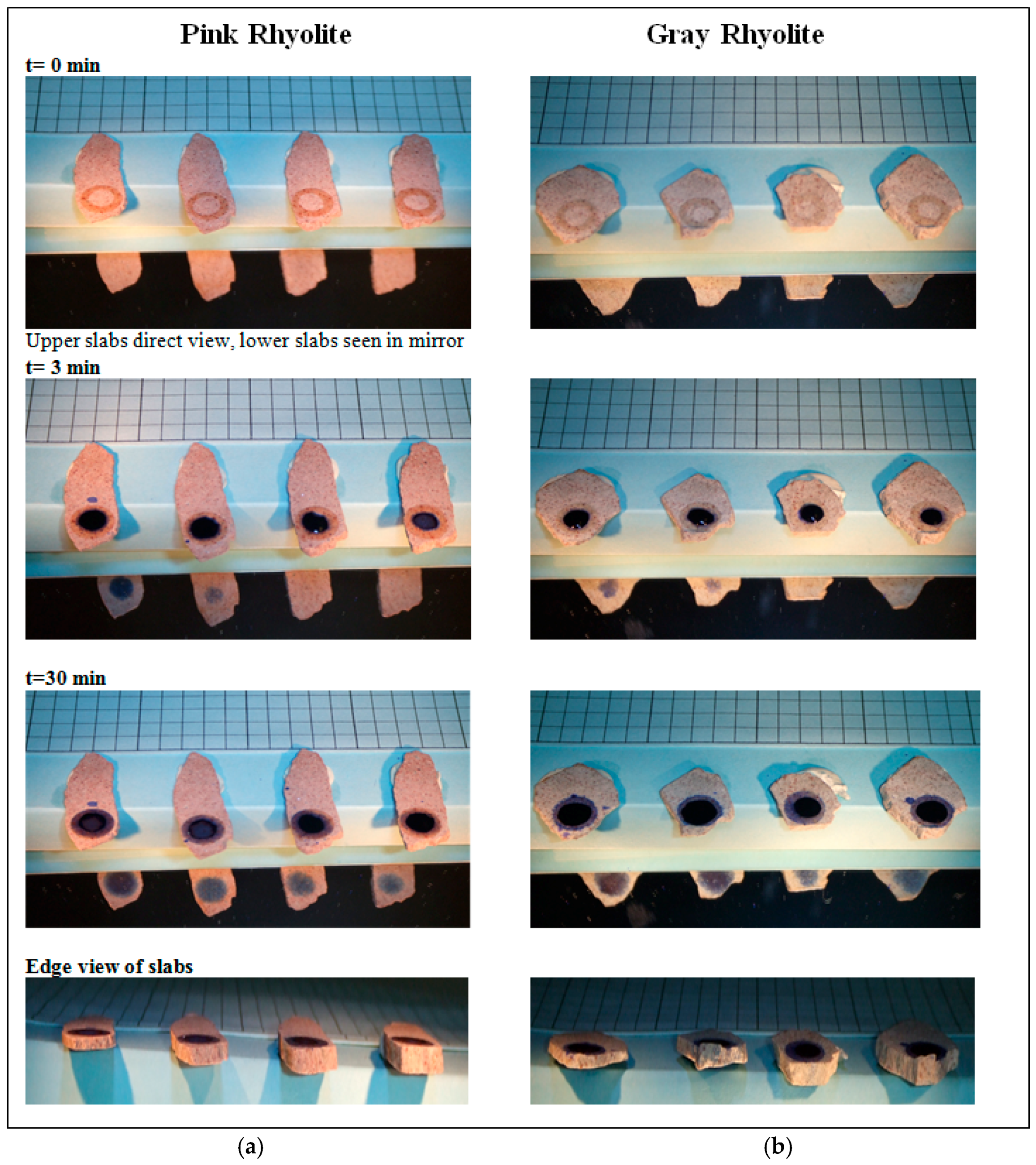

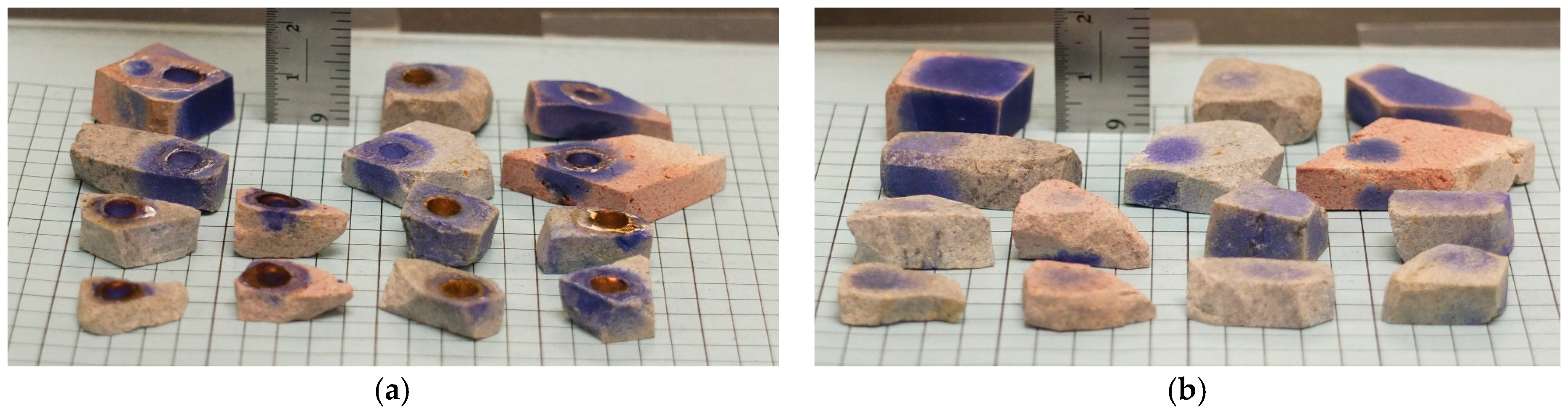

3.3. Permeability

4. Discussion

4.1. Significance of Round Top Rhyolite Porosity and Permeability

4.2. Heap Leach Efficiency: Pink vs. Gray Rhyolite Varieties

4.3. Ionic Diffusion: Rate-Limiting Step for Round Top Heap Leach

4.4. Unconventional Opportunity to Heap Leach Coarse-Crushed Crystalline Rock

5. Conclusions

- (1)

- Water-saturation porosity of Round Top rhyolite ranged from 1%–10%, with the pink variety consistently higher than the gray variety.

- (2)

- Water penetration and saturation was rapid, with most occurring within one day, and nearly complete in two to three days.

- (3)

- Porosity increased 15% (pinks) to 50% (grays) after a three-week dilute sulfuric acid leach.

- (4)

- Ink-penetration permeability was rapid (minutes to hours) for slabs up to 2.5 mm. Thicker slabs, to 10 mm, took as much as several days. Pink rhyolite was consistently more permeable than gray rhyolite.

- (5)

- The rate-limiting step for YHREE recovery in the anticipated heap leach is expected to be diffusion of fresh acid from the dripping heap leach solution into the solution-saturated micropores, and back-diffusion of dissolved elements out of the pores.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| YHREEs: yttrium and heavy rare earth elements; |

| REEs: rare earth elements; |

| LREEs: light rare earth elements; |

| HREEs: heavy rare earth elements; |

| TRER: Texas Rare Earth Resources. |

References

- Chakmouradian, A.R.; Wall, F. Rare earth elements: Minerals, mines, magnets (and more). Elements 2012, 8, 333–340. [Google Scholar] [CrossRef]

- Peishan, Z.; Zhuming, Y.; Kejie, T.; Xueming, Y. Mineralogy and Geology of Rare Earths in China; Science Press: Beijing, China, 1995; p. 209. [Google Scholar]

- Mariano, A.N. Economic geology of rare earth elements. In Geochemistry and Mineralogy of Rare Earth Elements. Reviews in Mineralogy 21; Lipin, B.R., McKay, G.A., Eds.; Mineralogical Society of America: Washington, DC, USA, 1989; pp. 309–337. [Google Scholar]

- Mariano, A.N.; Mariano, A., Jr. Rare earth mining and exploration in North America. Elements 2012, 8, 369–376. [Google Scholar] [CrossRef]

- Price, J.G.; Rubin, J.N.; Henry, C.D.; Pinkston, T.L.; Tweedy, S.W.; Koppenaal, D.W. Rare-metal enriched peraluminous rhyolites in a continental arc, Sierra Blanca Area, Trans-Pecos Texas; chemical modification by vapor-phase crystallization. In Ore Bearing Granite Systems; Petrogenesis and Mineralizing Processes (Special Paper (Geological Society of America)); Stein, H.J., Hannah, J.L., Eds.; Geological Society of America: Boulder, CO, USA, 1990; pp. 103–120. [Google Scholar]

- Henry, C.D.; McDowell, F.W.; Price, J.G.; Smyth, R.C. Compilation of Potassium-Argon Ages of Tertiary Igneous Rocks, Trans-Pecos, Texas; University of Texas, Bureau of Economic Geology: Austin, TX, USA, 1986; pp. 1–34. [Google Scholar]

- Pingitore, N., Jr.; Clague, J.; Gorski, D. Round Top Mountain (Texas, USA), a massive, unique Y-bearing-fluorite-hosted heavy rare earth element (HREE) deposit. J. Rare Earths 2012, 32, 90–96. [Google Scholar] [CrossRef]

- Yttrofluorite, Mindat.org. Available online: http://www.mindat.org/gallery.php?min=4371 (accessed on 27 December 2015).

- Rubin, J.N.; Price, J.G.; Henry, C.D.; Koppenaal, D.W. Cryolite-bearing and rare metal-enriched rhyolite, Sierra Blanca Peaks, Hudspeth County, Texas. Am. Mineral. 1987, 72, 1122–1130. [Google Scholar]

- O’Neill, L.C. REE-Be-U-F Mineralization of the Round Top Laccolith, Sierra Blanca Peaks, Trans-Pecos, Texas. Master’s Thesis, University of Texas, Austin, TX, USA, 2014. [Google Scholar]

- Crawford, J. Solubility Data on 646 Common and Not so Common Minerals, 2009. Available online: http://www.mindat.org/article.php/553/Solubility+Data+on+646+Common+and+Not+So+Common+Minerals (accessed on 27 December 2015).

- Texas Rare Earth Resources. Available online: http://www.trer.com (accessed on 27 December 2015).

- Gustavson Associates. NI 43–101 Preliminary Economic Assessment, Round Top Project, Sierra Blanca, Texas. 2012. Available online: http://trer.com/wp-content/uploads/2012/06/TRER_NI%2043-101%20PEA_KLG_037.pdf (accessed on 27 December 2015).

- Dhawan, J.; Safarzadeh, M.S.; Miller, J.D.; Rajamani, R.K.; Moats, M.S. Insights into heap leach technology. In Proceedings of the 2012 SME Annual Meeting and Exhibit 2012, Washington, DC, USA, 19–22 February 2012; pp. 560–567.

- Akinyemi, O.A.; Alabi, A.A.; Ojo, A.I.; Adewusi, O.E. Characterization of density and porosity of rocks samples from Ogun State of Nigeria. Earth Sci. Res. 2012, 1, 137–146. [Google Scholar] [CrossRef]

- Bongiolo, E.M.; Bongiolo, D.E.; Sardini, P.; Mexias, A.S.; Siitari-Kauppi, M.; Gomes, M.E.B.; Formoso, M.L. Quantification of porosity evolution from unaltered to propylitic-altered granites: The 14C-PMMA method applied on the hydrothermal system of Lavras do Sul, Brazil. Ann. Acad. Bras. Ciênc. 2007, 79, 503–517. [Google Scholar] [CrossRef]

- Takarli, M.; Prince-Agbodjan, W. Temperature effects on physical properties and mechanical behavior of granite: Experimental investigation of material damage. J. ASTM Int. 2008, 5, 1–13. [Google Scholar]

- Petford, N. Controls on primary porosity and permeability development in igneous rocks. In Hydrocarbons in Crystalline Rocks; Petford, N., McCaffrey, K.J.W., Eds.; Geological Society Publishing House: Bath, UK, 2003; pp. 93–107. [Google Scholar]

- Brace, W.F. Permeability of crystalline rocks: New in situ measurements. J. Geophys. Res. 1984, 89, 4327–4330. [Google Scholar] [CrossRef]

- Ilankoon, I.; Neethling, S. The effect of particle porosity on liquid holdup in heap leaching. Miner. Eng. 2013, 45, 73–80. [Google Scholar] [CrossRef]

- Sausse, J.; Genter, A. Types of permeable fractures in granite. In Petrophysical Properties of Crystalline Rocks; Harvey, P.K., Brewer, T.S., Pezard, P.A., Petrov, V.A., Eds.; Geological Society Publishing House: Bath, UK, 2005; pp. 1–14. [Google Scholar]

- Monicard, R.P. Properties of Reservoir Rocks: Core Analysis; Éditions Technip: Paris, France, 1980; pp. 1–168. [Google Scholar]

- Pingitore, N.; Clague, J.; Gorski, D. Uniform distribution of yttrium and heavy rare earth elements in Round Top Mountain rhyolite deposit, Sierra Blanca Texas, USA: Data, significance, and origin. In Proceedings of the American Geophysical Union, Fall Meeting, San Francisco, CA, USA, 15–19 December 2014.

- Pingitore, N. The role of diffusion during carbonate diagenesis. J. Sed. Petrol. 1982, 52, 27–29. [Google Scholar]

- Bannerman Resources. Available online: http://32uo991mljzg3wrz8dkq0et1.wpengine.netdna-cdn.com/wp-content/uploads/2015/07/Etango-Heap-Leach-Demonstration-Program-Phase-1-Report.pdf (accessed on 12 December 2015).

- Bartlett, R. Solution Mining: Leaching and Fluid Recovery of Materials, 2nd ed.; Gordon and Breach: Amsterdam, The Netherlands, 1998; p. 470. [Google Scholar]

- De Andrade Lima, L. Liquid axial dispersion and holdup in column leaching. Miner. Eng. 2006, 19, 37–47. [Google Scholar] [CrossRef]

- Petersen, J.; Dixon, D. Modelling zinc heap bioleaching. Hydrometallurgy 2007, 85, 127–143. [Google Scholar] [CrossRef]

- Ilankoon, I.; Neethling, S. Hysteresis in unsaturated flow in packed beds and heaps. Miner. Eng. 2012, 35, 1–8. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Negron, L.; Pingitore, N.; Gorski, D. Porosity and Permeability of Round Top Mountain Rhyolite (Texas, USA) Favor Coarse Crush Size for Rare Earth Element Heap Leach. Minerals 2016, 6, 16. https://doi.org/10.3390/min6010016

Negron L, Pingitore N, Gorski D. Porosity and Permeability of Round Top Mountain Rhyolite (Texas, USA) Favor Coarse Crush Size for Rare Earth Element Heap Leach. Minerals. 2016; 6(1):16. https://doi.org/10.3390/min6010016

Chicago/Turabian StyleNegron, Lorraine, Nicholas Pingitore, and Daniel Gorski. 2016. "Porosity and Permeability of Round Top Mountain Rhyolite (Texas, USA) Favor Coarse Crush Size for Rare Earth Element Heap Leach" Minerals 6, no. 1: 16. https://doi.org/10.3390/min6010016

APA StyleNegron, L., Pingitore, N., & Gorski, D. (2016). Porosity and Permeability of Round Top Mountain Rhyolite (Texas, USA) Favor Coarse Crush Size for Rare Earth Element Heap Leach. Minerals, 6(1), 16. https://doi.org/10.3390/min6010016