Rapid Removal of Cr(VI) from Aqueous Solution Using Polycationic/Di-Metallic Adsorbent Synthesized Using Fe3+/Al3+ Recovered from Real Acid Mine Drainage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Collection and Preparation of Working Solution

2.2. Synthesis of PDFe/Al from Authentic AMD

2.3. Optimisation Studies

2.4. Characterisation of the Feedstock and Product Minerals

2.5. Point of Zero Charge (PZC)

2.6. PDFe/Al Adsorption Capacity and Removal Efficiency

2.6.1. Adsorption Capacity

2.6.2. Percentage Removal

2.7. Regeneration Study

3. Results

3.1. Characterisation of PDFe/Al before and after Cr(VI) Adsorption

3.1.1. FTIR Analysis

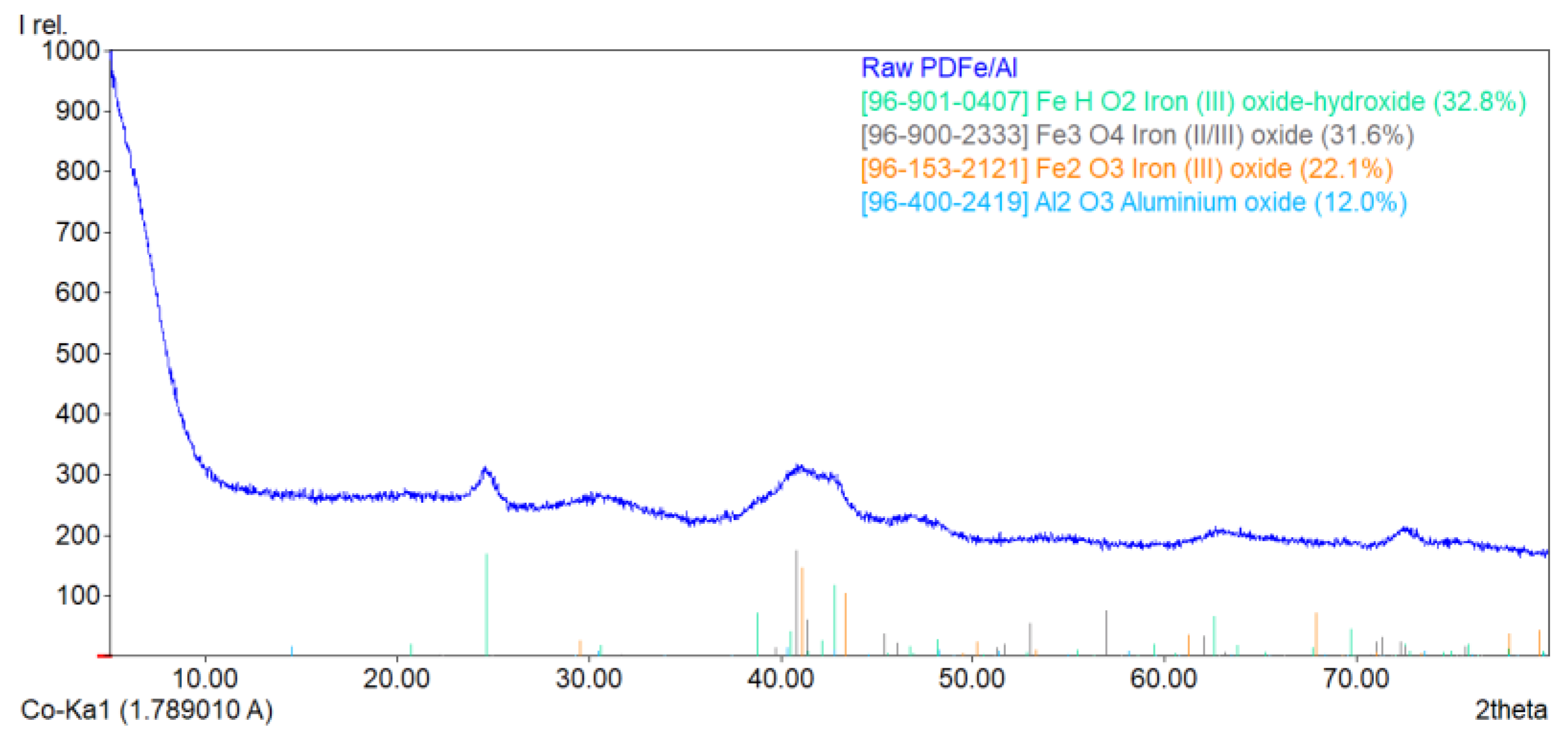

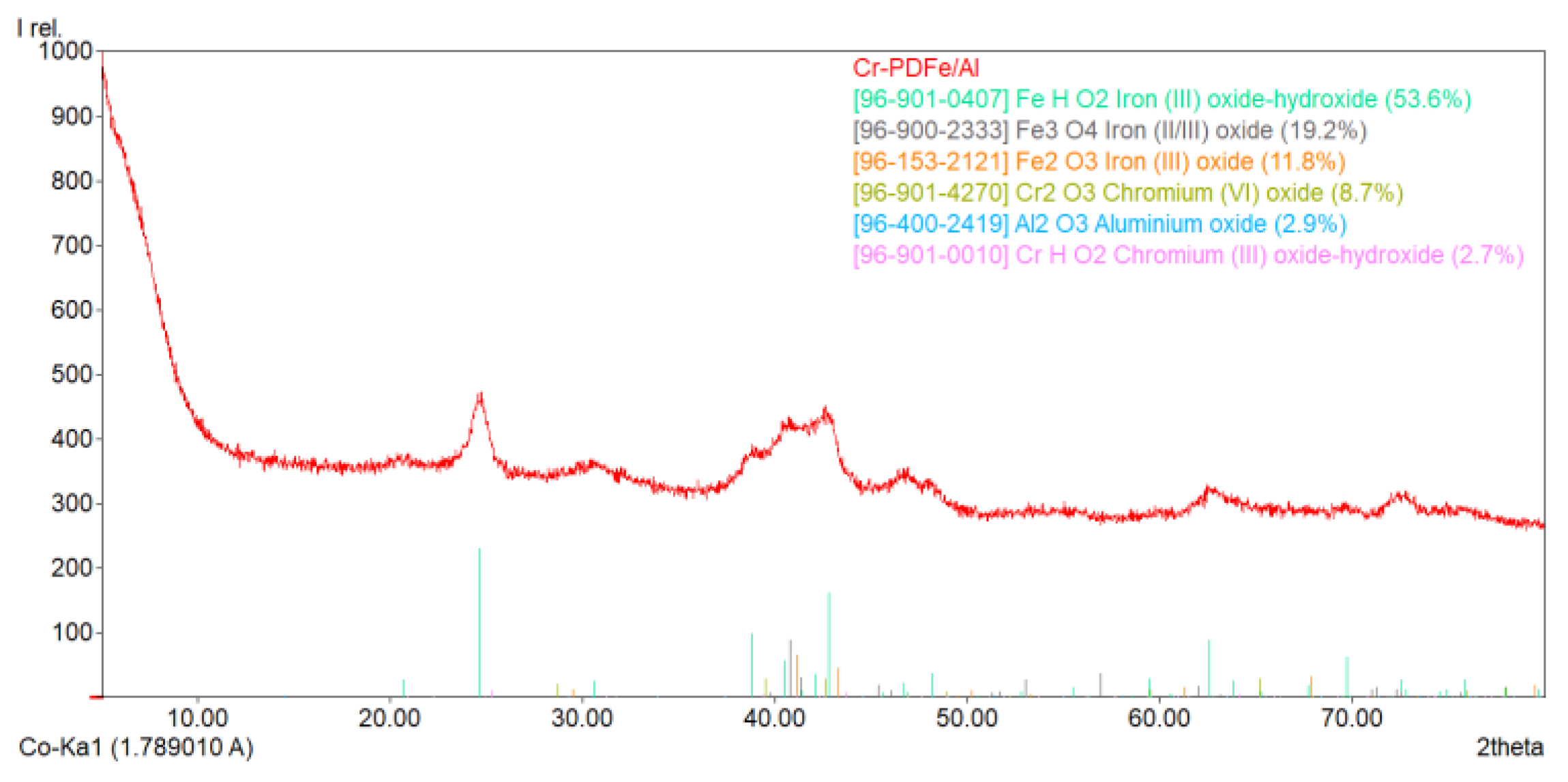

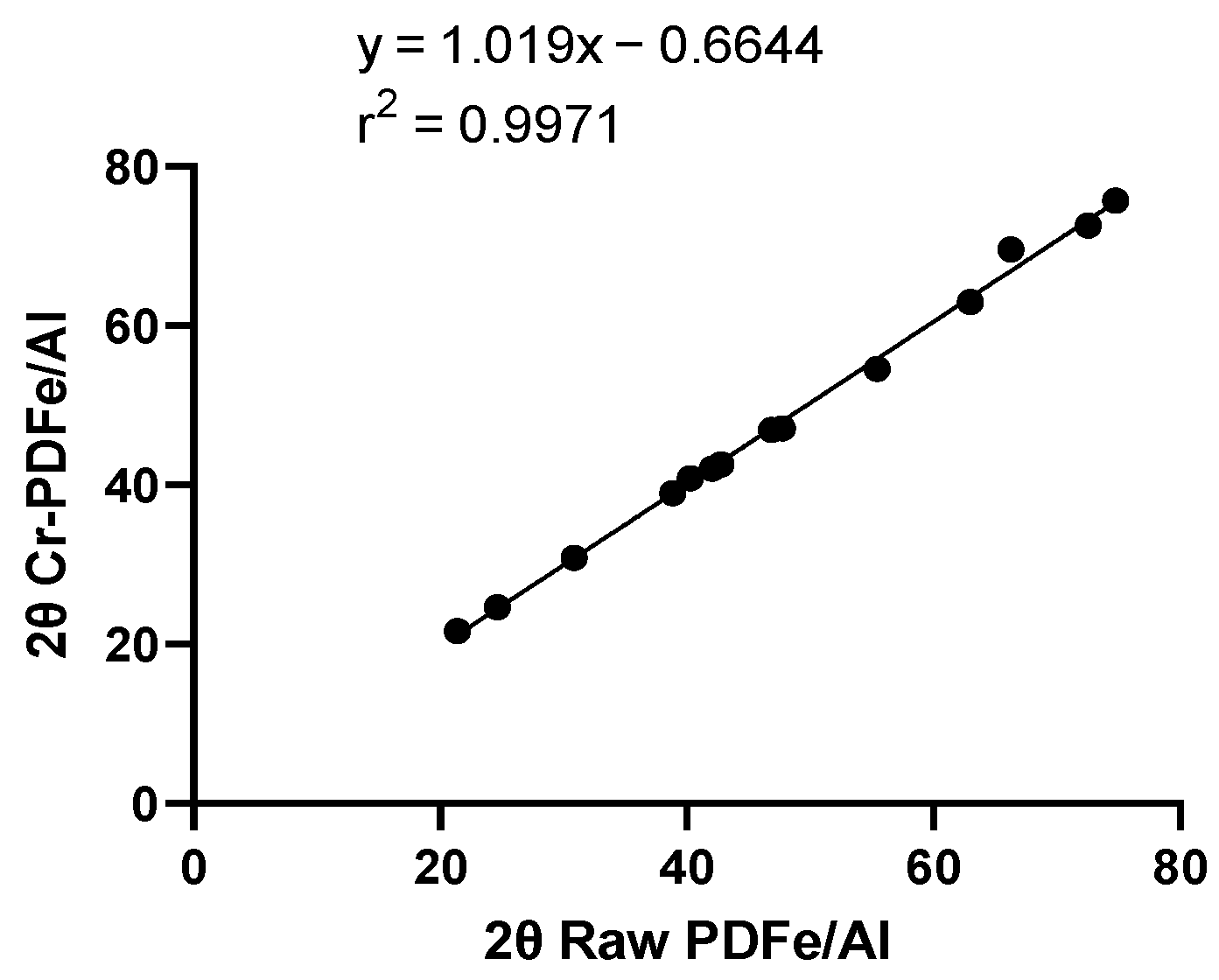

3.1.2. XRD Mineralogical Composition

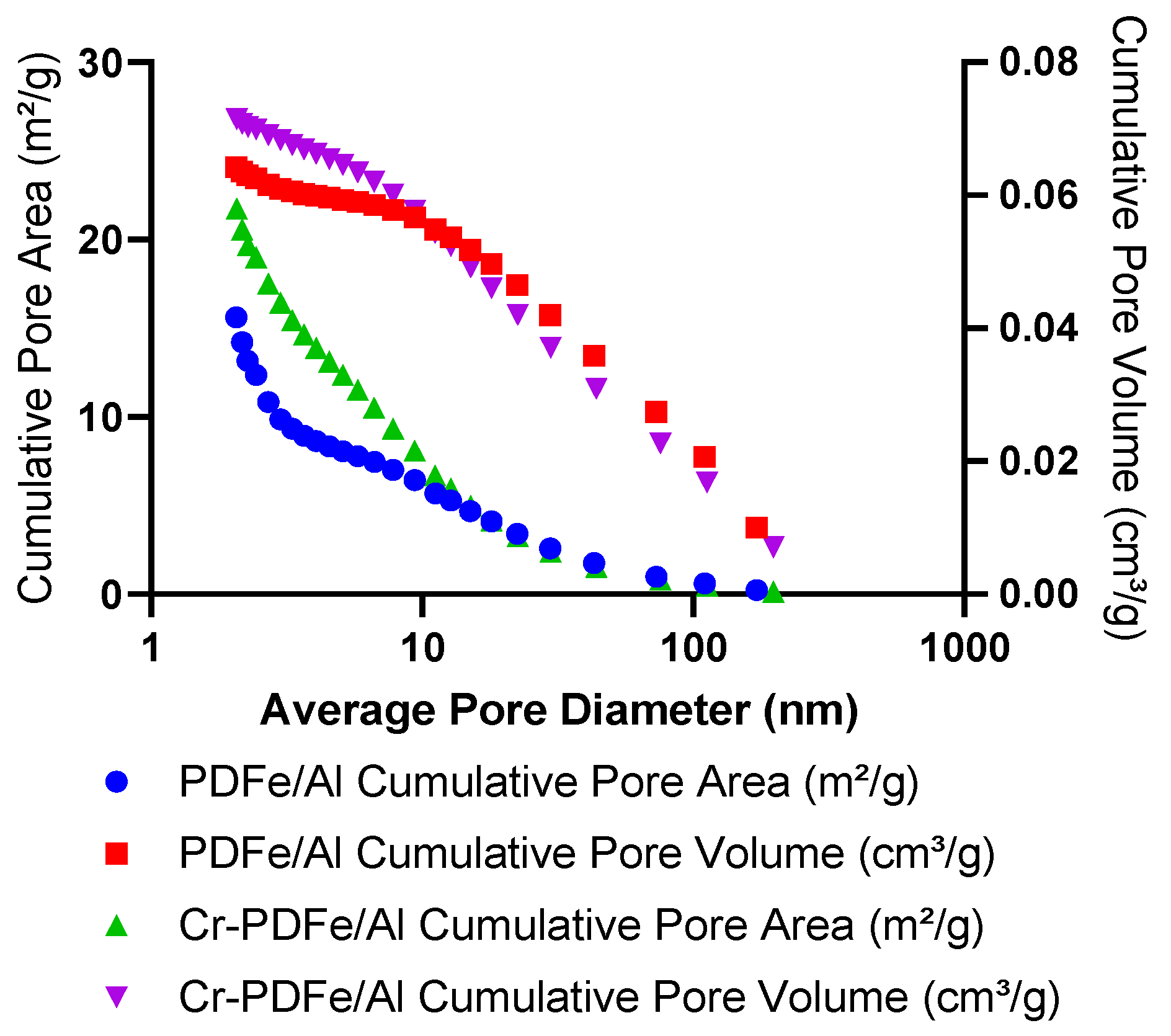

3.1.3. BET Surface and Porosity Analysis

3.1.4. SEM Morphology

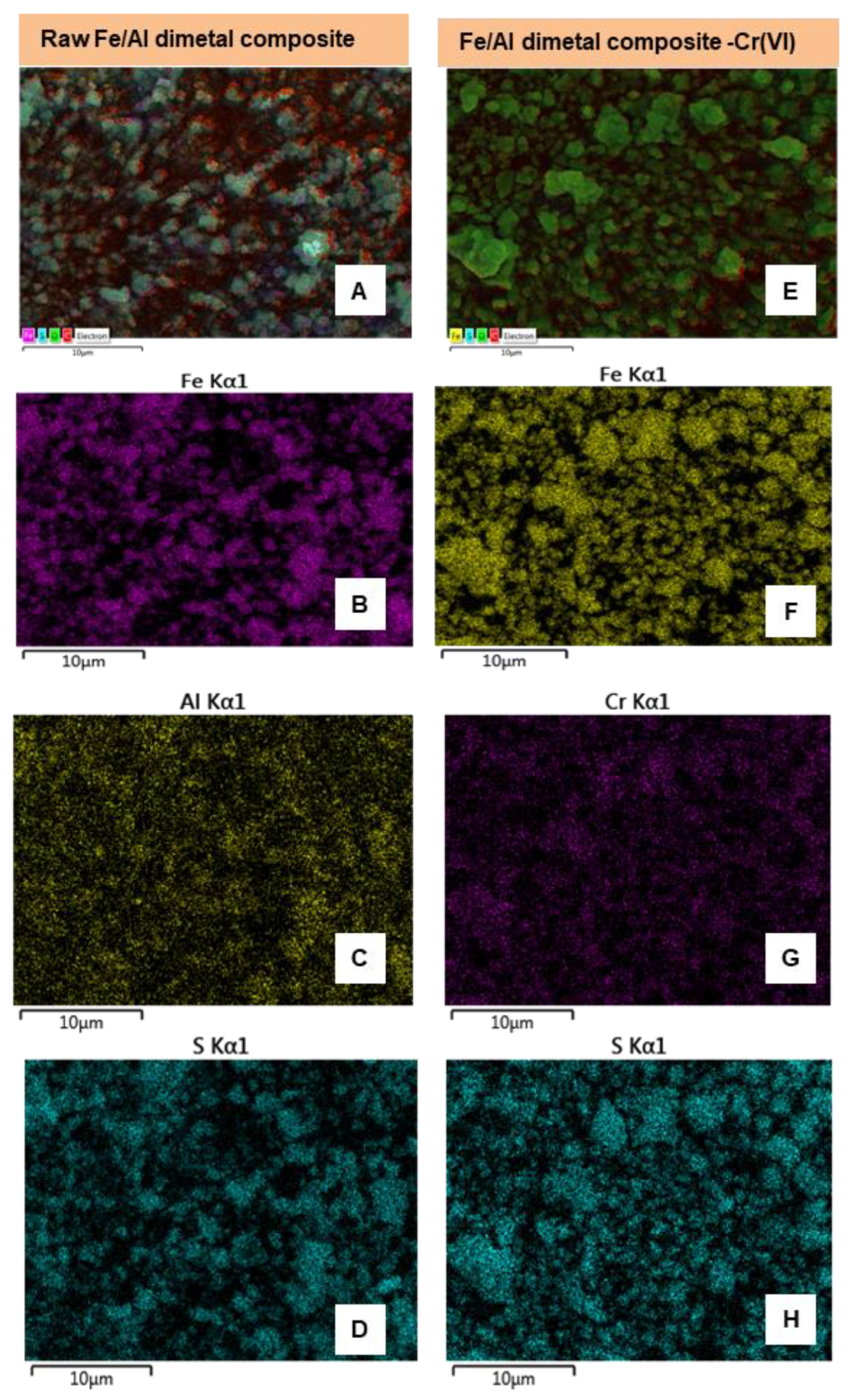

3.1.5. EDX Elemental Mapping

3.1.6. TGA Thermal Stability

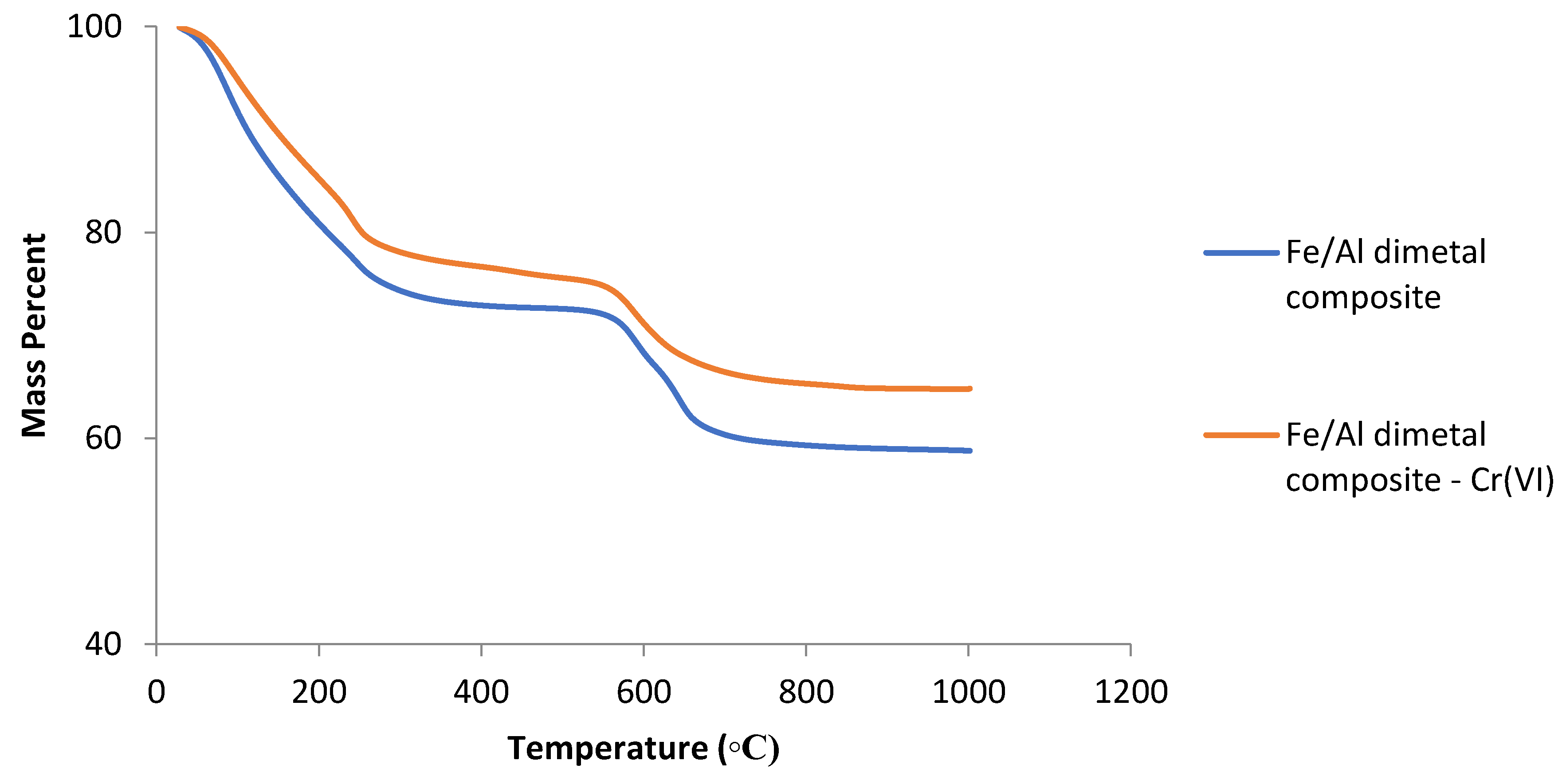

3.2. Batch Adsorption Experiments

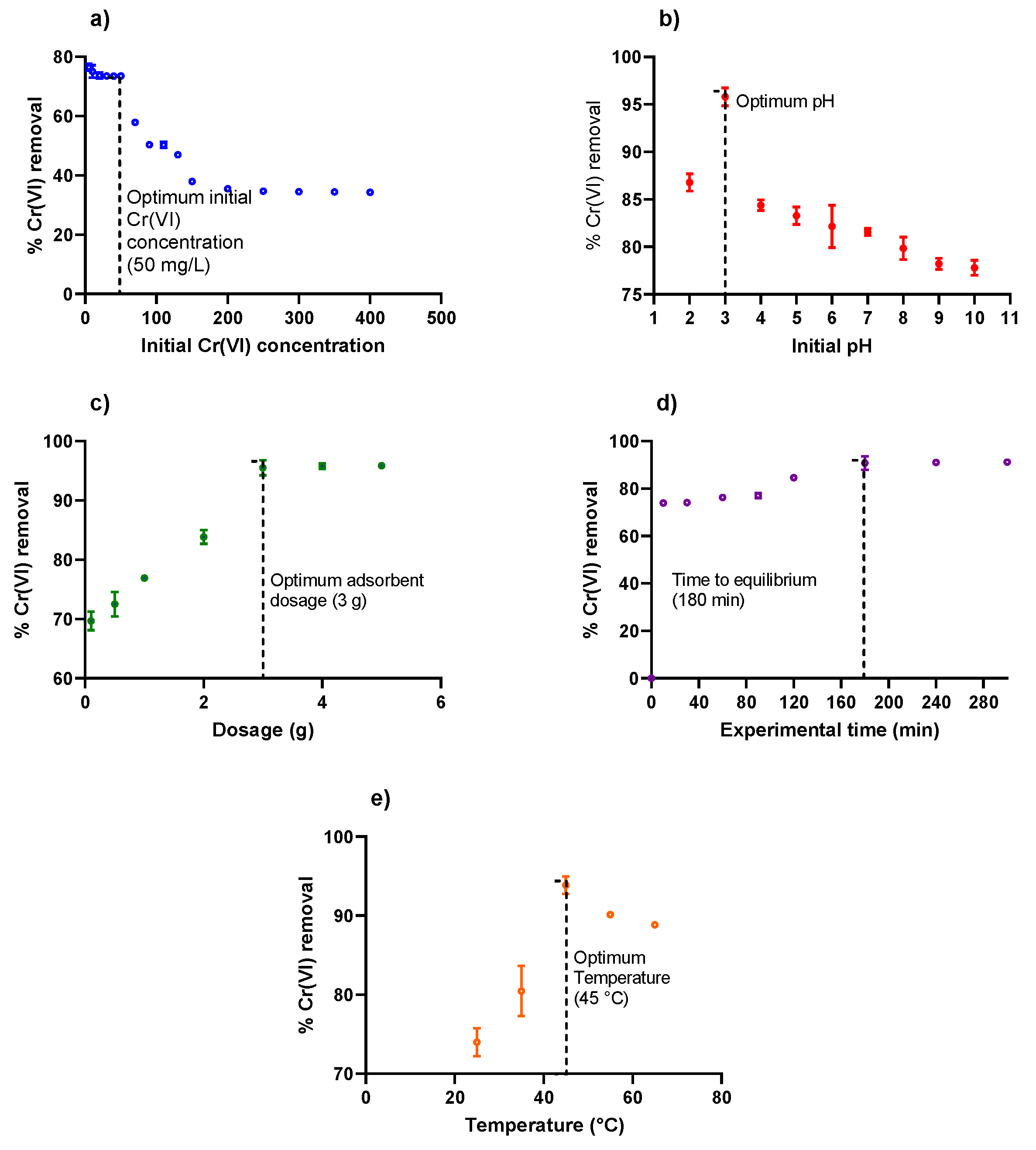

3.2.1. Effect of Concentration

3.2.2. Effect of Initial Solution pH

3.2.3. Effect of Adsorbent Dosage

3.2.4. Effect of Agitation Time

3.2.5. Effect of Temperature

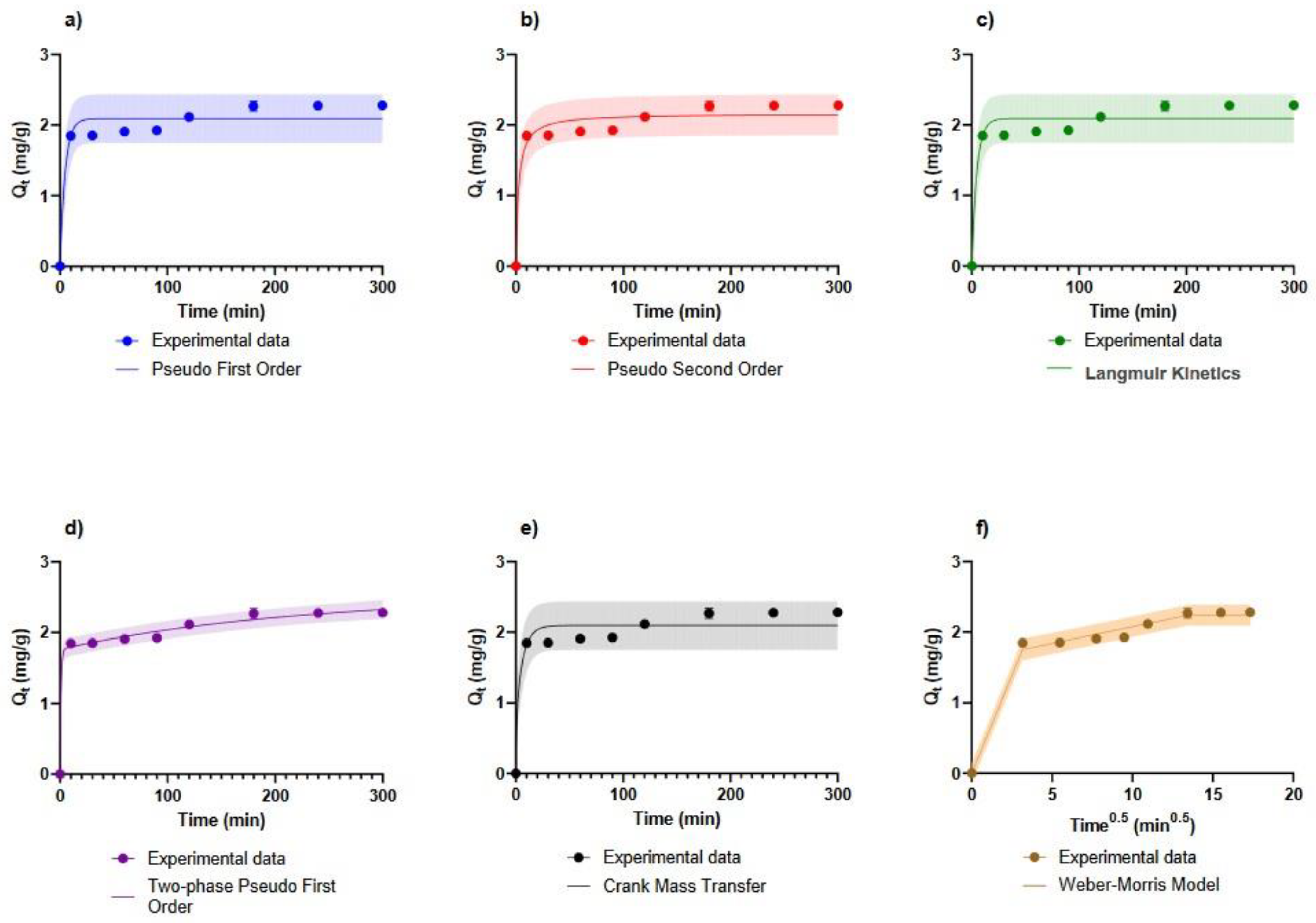

3.3. Adsorption Kinetics

| Kinetic Law | Differential Form | Analytical Form | Fitted Parameters | R2/RMSE |

|---|---|---|---|---|

| Pseudo first order [50] | Qe = 2.092 mg·g−1 k1 = 0.211 min−1 | 0.945/ 0.1604 mg·g−1 | ||

| Pseudo second order [50] | Qe = 2.165 mg·g−1 k2 = 0.188 L2·mg−2·min−1 | 0.962/ 0.1336 mg·g−1 | ||

| Langmuir adsorption [51] | | kad = 0.00491 L·mg−1·min−1 obtained from Langmuir isotherm | 0.945/ 0.1603 mg·g−1 | |

| Two phase adsorption [52,53,54] | | kfast = 1.11 min−1 Qfast = 1.77 mg/g kslow = 0.00444min−1 Qslow = 0.77 mg/g | 0.993/ 0.0563 mg·g−1 | |

| Crank internal mass transfer model [50] | | | De = 2.61× 10−13 m2·s−1 r = 32 μm | 0.946/ 0.159 mg·g−1 |

| Weber and Morris [50,55] | | De1 = 4.59× 10−13 m2·s−1 r = 32 μm De2 = 3.30 × 10−15 m2·s−1 De3 = 0 m2·s−1 | 0.991/ 0.0665 mg·g−1 |

3.4. Adsorption Isotherms

| Kinetic Law | Differential Form | Fitted Parameters | R2/RMSE |

|---|---|---|---|

| Langmuir [50,58,59] | 0.9717/0.3412 mg·g−1 | ||

| Freundlich [58] | 0.959/0.410 mg·g−1 | ||

| Two-surface Langmuir [59] | 0.975/0.320 mg·g−1 |

3.5. Regeneration Study

4. Discussion

4.1. Summary of Results

4.2. Comparison of Fe/Al Dimetal Nanocomposite for Removal of Cr(VI) from an Aqueous System

4.3. Proposed Mechanism

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Muedi, K.L.; Brink, H.G.; Masindi, V.; Maree, J.P. Effective removal of arsenate from wastewater using aluminium enriched ferric oxide-hydroxide recovered from authentic acid mine drainage. J. Hazard. Mater. 2021, 414, 125491. [Google Scholar] [CrossRef] [PubMed]

- Muedi, K.L.; Masindi, V.; Maree, J.P.; Haneklaus, N.; Brink, H.G. Effective Adsorption of Congo Red from Aqueous Solution Using Fe/Al Di-Metal Nanostructured Composite Synthesised from Fe(III) and Al(III) Recovered from Real Acid Mine Drainage. Nanomaterials 2022, 12, 776. [Google Scholar] [CrossRef] [PubMed]

- Baker, B.J.; Banfield, J.F. Microbial communities in acid mine drainage. FEMS Microbiol. Ecol. 2003, 44, 139–152. [Google Scholar] [CrossRef] [Green Version]

- Amos, R.T.; Blowes, D.W.; Bailey, B.L.; Sego, D.C.; Smith, L.; Ritchie, A.I.M. Waste-rock hydrogeology and geochemistry. Appl. Geochem. 2015, 57, 140–156. [Google Scholar] [CrossRef]

- Sheoran, V.; Sheoran, A.; Choudhary, R.P. Biogeochemistry of acid mine drainage formation: A review. In Mine Drainage and Related Problems; Nova Science Publishers Inc.: Hauppauge, NY, USA, 2011; pp. 119–154. [Google Scholar]

- Sheoran, A.; Sheoran, V.; Choudhary, R.P. Geochemistry of acid mine drainage: A review. Perspect. Environ. Res. 2011, 4, 217–243. [Google Scholar]

- Naidu, G.; Ryu, S.; Thiruvenkatachari, R.; Choi, Y.; Jeong, S.; Vigneswaran, S. A critical review on remediation, reuse, and resource recovery from acid mine drainage. Environ. Pollut. 2019, 247, 1110–1124. [Google Scholar] [CrossRef]

- Cheng, H.; Hu, Y.; Luo, J.; Xu, B.; Zhao, J. Geochemical processes controlling fate and transport of arsenic in acid mine drainage (AMD) and natural systems. J. Haz. Mat 2009, 165, 13–26. [Google Scholar] [CrossRef]

- Masindi, V.; Foteinis, S.; Chatzisymeon, E. Co-treatment of acid mine drainage and municipal wastewater effluents: Emphasis on the fate and partitioning of chemical contaminants. J. Haz. Mat 2022, 421, 126677. [Google Scholar] [CrossRef]

- Masindi, V.; Fosso-Kankeu, E.; Mamakoa, E.; Nkambule, T.T.I.; Mamba, B.B.; Naushad, M.; Pandey, S. Emerging remediation potentiality of struvite developed from municipal wastewater for the treatment of acid mine drainage. Environ. Res. 2022, 210, 112944. [Google Scholar] [CrossRef]

- Dhal, B.; Thatoi, H.N.; Das, N.N.; Pandey, B.D. Chemical and microbial remediation of hexavalent chromium from contaminated soil and mining/metallurgical solid waste: A review. J. Hazard. Mater. 2013, 250–251, 272–291. [Google Scholar] [CrossRef]

- Papp, J.F. Mineral Commodity Summaries; U.S. Geological Survey: Reston, VA, USA, 2017. [Google Scholar]

- Zhang, Y.K.; Qi, S.; Chen, H.H. A review of remediation of chromium contaminated soil by washing with chelants. Adv. Mater. Res. 2014, 838–841, 2625–2629. [Google Scholar] [CrossRef]

- Sultana, M.Y.; Akratos, C.S.; Pavlou, S.; Vayenas, D.V. Chromium removal in constructed wetlands: A review. Int. Biodeterior. Biodegrad. 2014, 96, 181–190. [Google Scholar] [CrossRef]

- Jobby, R.; Jha, P.; Yadav, A.K.; Desai, N. Biosorption and biotransformation of hexavalent chromium [Cr(VI)]: A comprehensive review. Chemosphere 2018, 207, 255–266. [Google Scholar] [CrossRef]

- Shahid, M.; Shamshad, S.; Rafiq, M.; Khalid, S.; Bibi, I.; Niazi, N.K.; Dumat, C.; Rashid, M.I. Chromium speciation, bioavailability, uptake, toxicity and detoxification in soil-plant system: A review. Chemosphere 2017, 178, 513–533. [Google Scholar] [CrossRef] [PubMed]

- WHO. Guidelines for drinking-water quality. In Fourth Edition Incorporating the First Addendum; WHO: Geneva, Switzerland, 2017. [Google Scholar]

- Wang, Z.; Shen, Q.; Xue, J.; Guan, R.; Li, Q.; Liu, X.; Jia, H.; Wu, Y. 3D hierarchically porous NiO/NF electrode for the removal of chromium(VI) from wastewater by electrocoagulation. Chem. Eng. J. 2020, 402, 126151. [Google Scholar] [CrossRef]

- Giagnorio, M.; Steffenino, S.; Meucci, L.; Zanetti, M.C.; Tiraferri, A. Design and performance of a nanofiltration plant for the removal of chromium aimed at the production of safe potable water. J. Environ. Chem. Eng. 2018, 6, 4467–4475. [Google Scholar] [CrossRef]

- Melak, F.; Du Laing, G.; Ambelu, A.; Alemayehu, E. Application of freeze desalination for chromium (VI) removal from water. Desalination 2016, 377, 23–27. [Google Scholar] [CrossRef]

- Shao, Z.; Huang, C.; Wu, Q.; Zhao, Y.; Xu, W.; Liu, Y.; Dang, J.; Hou, H. Ion exchange collaborating coordination substitution: More efficient Cr(VI) removal performance of a water-stable CuII-MOF material. J. Hazard. Mater. 2019, 378, 120719. [Google Scholar] [CrossRef]

- Kretschmer, I.; Senn, A.M.; Meichtry, J.M.; Custo, G.; Halac, E.B.; Dillert, R.; Bahnemann, D.W.; Litter, M.I. Photocatalytic reduction of Cr(VI) on hematite nanoparticles in the presence of oxalate and citrate. Appl. Catal. B Environ. 2019, 242, 218–226. [Google Scholar] [CrossRef]

- Kalita, E.; Baruah, J. 16—Environmental remediation. In Colloidal Metal Oxide Nanoparticles; Thomas, S., Tresa Sunny, A., Velayudhan, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 525–576. [Google Scholar] [CrossRef]

- Islam, M.A.; Angove, M.J.; Morton, D.W. Recent innovative research on chromium (VI) adsorption mechanism. Environ. Nanotechnol. Monit. Manag. 2019, 12, 100267. [Google Scholar] [CrossRef]

- Dimos, V.; Haralambous, K.J.; Malamis, S. A review on the recent studies for chromium species adsorption on raw and modified natural minerals. Crit. Rev. Environ. Sci. Technol. 2012, 42, 1977–2016. [Google Scholar] [CrossRef]

- Alvarez-Ayuso, E.; Garcia-Sanchez, A.; Querol, X. Adsorption of Cr(VI) from synthetic solutions and electroplating wastewaters on amorphous aluminium oxide. J. Hazard. Mater. 2007, 142, 191–198. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Liu, D.; Lu, J.; Huang, J. Enhanced adsorption of hexavalent chromium from aqueous solutions on facilely synthesized mesoporous iron-zirconium bimetal oxide. Colloids Surf. A-Physicochem. Eng. Asp. 2015, 481, 133–142. [Google Scholar] [CrossRef]

- Rathinam, K.; Atchudan, R.; Edison, T. Zirconium oxide intercalated sodium montmorillonite scaffold as an effective adsorbent for the elimination of phosphate and hexavalent chromium ions. J. Environ. Chem. Eng. 2021, 9, 106053. [Google Scholar] [CrossRef]

- Adegoke, H.; Adekola, F. Equilibrium sorption of hexavalent chromium from aqueous solution using synthetic hematite. Colloid J. 2012, 74, 420–426. [Google Scholar] [CrossRef]

- Dim, P.; Mustapha, L.; Termtanun, M.; Okafor, J. Adsorption of chromium (VI) and iron (III) ions onto acid-modified kaolinite: Isotherm, kinetics and thermodynamics studies. Arab. J. Chem. 2021, 14, 103064. [Google Scholar] [CrossRef]

- Smičiklas, I.; Milonjić, S.K.; Pfendt, P.; Raičević, S. The point of zero charge and sorption of cadmium (II) and strontium (II) ions on synthetic hydroxyapatite. Sep. Purif. Technol. 2000, 18, 185–194. [Google Scholar] [CrossRef]

- Kumari, P.; Sharma, P.; Srivastava, S.; Srivastava, M.M. Biosorption studies on shelled Moringa oleifera Lamarck seed powder: Removal and recovery of arsenic from aqueous system. Int. J. Miner. Process. 2006, 78, 131–139. [Google Scholar] [CrossRef]

- Bordoloi, S.; Nath, S.K.; Gogoi, S.; Dutta, R.K. Arsenic and iron removal from groundwater by oxidation–coagulation at optimized pH: Laboratory and field studies. J. Hazard. Mater. 2013, 260, 618–626. [Google Scholar] [CrossRef]

- Naiya, T.K.; Singha, B.; Das, S.K. FTIR Study for the Cr(VI) Removal from Aqueous Solution Using Rice Waste. In Proceedings of the International Conference on Chemistry and Chemical Process, Singapore, 25–28 February 2019. [Google Scholar]

- Tang, B.; Ge, J.; Zhuo, L.; Wang, G.; Niu, J.; Shi, Z.; Dong, Y. A facile and controllable synthesis of gamma-Al2O3 nanostructures without a surfactant. Eur. J. Inorg. Chem. 2005, 2005, 4366–4369. [Google Scholar] [CrossRef]

- Prabakaran, E.; Pillay, K.; Brink, H. Hydrothermal synthesis of magnetic-biochar nanocomposite derived from avocado peel and its performance as an adsorbent for the removal of methylene blue from wastewater. Mater. Today Sustain. 2022, 18, 100123. [Google Scholar] [CrossRef]

- Hwang, S.; Umar, A.; Dar, G.; Kim, S.; RI, B. Synthesis and characterization of iron oxide nanoparticles for phenyl hydrazine sensor applications. Sens. Lett. 2014, 12, 97–101. [Google Scholar] [CrossRef]

- Bhatt, R.; Sreedhar, B.; Padmaja, P. Chitosan supramolecularly cross linked with trimesic acid—Facile synthesis, characterization and evaluation of adsorption potential for chromium(VI). Int. J. Biol. Macromol. 2017, 104, 1254–1266. [Google Scholar] [CrossRef] [PubMed]

- Ablouh, E.; Hanani, Z.; Eladlani, N.; Rhazi, M.; Taourirte, M. Chitosan microspheres/sodium alginate hybrid beads: An efficient green adsorbent for heavy metals removal from aqueous solutions. Sustain. Environ. Res. 2019, 29, 1–11. [Google Scholar] [CrossRef]

- Xia, Z.; Baird, L.; Zimmerman, N.; Yeager, M. Heavy metal ion removal by thiol functionalized aluminum oxide hydroxide nanowhiskers. Appl. Surf. Sci. 2017, 416, 565–573. [Google Scholar] [CrossRef]

- Peak, D.; Ford, R.G.; Sparks, D.L. An in situ ATR-FTIR investigation of sulfate bonding mechanisms on goethite. J. Colloid Interface Sci. 1999, 218, 289–299. [Google Scholar] [CrossRef] [Green Version]

- Ou, J.; Sheu, Y.; Tsang, D.; Sun, Y.; Kao, C. Application of iron/aluminum bimetallic nanoparticle system for chromium-contaminated groundwater remediation. Chemosphere 2020, 256, 127158. [Google Scholar] [CrossRef]

- Gallios, G.P.; Vaclavikova, M. Removal of chromium (VI) from water streams: A thermodynamic study. Environ. Chem. Lett. 2008, 6, 235–240. [Google Scholar] [CrossRef]

- Yang, J.; Yu, M.; Chen, W. Adsorption of hexavalent chromium from aqueous solution by activated carbon prepared from longan seed: Kinetics, equilibrium and thermodynamics. J. Ind. Eng. Chem. 2015, 21, 414–422. [Google Scholar] [CrossRef]

- Gürü, M.; Venedik, D.; Murathan, A. Removal of trivalent chromium from water using low-cost natural diatomite. J. Hazard. Mater. 2008, 160, 318–323. [Google Scholar] [CrossRef]

- Hu, C.-Y.; Lo, S.-L.; Liou, Y.-H.; Hsu, Y.-W.; Shih, K.; Lin, C.-J. Hexavalent chromium removal from near natural water by copper–iron bimetallic particles. Water Res. 2010, 44, 3101–3108. [Google Scholar] [CrossRef] [PubMed]

- Gaffer, A.; Al Kahlawy, A.A.; Aman, D. Magnetic zeolite-natural polymer composite for adsorption of chromium (VI). Egypt. J. Pet. 2017, 26, 995–999. [Google Scholar] [CrossRef]

- Enniya, I.; Rghioui, L.; Jourani, A. Adsorption of hexavalent chromium in aqueous solution on activated carbon prepared from apple peels. Sustain. Chem. Pharm. 2018, 7, 9–16. [Google Scholar] [CrossRef]

- Iadicicco, N.; Paduano, L.; Vitagliano, V. Diffusion coefficients for the system potassium chromate water at 25 degrees C. J. Chem. Eng. Data 1996, 41, 529–533. [Google Scholar] [CrossRef]

- Largitte, L.; Pasquier, R. A review of the kinetics adsorption models and their application to the adsorption of lead by an activated carbon. Chem. Eng. Res. Des. 2016, 109, 495–504. [Google Scholar] [CrossRef]

- Chu, K.H. Fixed bed sorption: Setting the record straight on the Bohart-Adams and Thomas models. J. Hazard. Mater. 2010, 177, 1006–1012. [Google Scholar] [CrossRef]

- Brusseau, M.L.; Jessup, R.E.; Suresh, P.; Rao, C. Nonequilibrium Sorption of Organic Chemicals: Elucidation of Rate-Limiting Processes. Environ. Sci. Technol. 1991, 25, 134–142. [Google Scholar] [CrossRef]

- Cornelissen, G.; VanNoort, P.; Parsons, J.; Govers, H. Temperature dependence of slow adsorption and desorption kinetics of organic compounds in sediments. Environ. Sci. Technol. 1997, 31, 454–460. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Zhao, J.; Song, L.; Mashayekhi, H.; Chefetz, B.; Xing, B. Adsorption and desorption of phenanthrene on carbon nanotubes in simulated gastrointestinal fluids. Environ. Sci. Technol. 2011, 45, 6018–6024. [Google Scholar] [CrossRef]

- Weber, W.J.; Morris, J.C. Kinetics of Adsorption on Carbon from Solution. J. Sanit. Eng. Div. 1963, 89, 31–60. [Google Scholar] [CrossRef]

- Alemu, A.; Lemma, B.; Gabbiye, N.; Alula, M.; Desta, M. Removal of chromium (VI) from aqueous solution using vesicular basalt: A potential low cost wastewater treatment system. Heliyon 2018, 4, e00682. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Panda, H.; Tiadi, N.; Mohanty, M.; Mohanty, C.R. Studies on adsorption behavior of an industrial waste for removal of chromium from aqueous solution. S. Afr. J. Chem. Eng. 2017, 23, 132–138. [Google Scholar] [CrossRef]

- Girods, P.; Dufour, A.; Fierro, V.; Rogaume, Y.; Rogaume, C.; Zoulalian, A.; Celzard, A. Activated carbons prepared from wood particleboard wastes: Characterisation and phenol adsorption capacities. J. Hazard. Mater. 2009, 166, 491–501. [Google Scholar] [CrossRef] [PubMed]

- Langmuir, I. The adsorption of gases on plane surfaces of glass, mica and platinum. J. Am. Chem. Soc. 1918, 40, 1361–1403. [Google Scholar] [CrossRef] [Green Version]

- Chang, J.; Wang, H.; Zhang, J.; Xue, Q.; Chen, H. New insight into adsorption and reduction of hexavalent chromium by magnetite: Multi-step reaction mechanism and kinetic model developing. Colloids Surf. A-Physicochem. Eng. Asp. 2021, 611, 125784. [Google Scholar] [CrossRef]

- Vansek, P. Corrosion: Materials; Electrochemical Series; CRC Press: London, UK, 2018; pp. 665–671. [Google Scholar]

| Experiment No | Initial Cr(VI) Concentration (mg/L) | Initial pH | Adsorbent Dose (g) | Agitation Time (min) | Temperature (°C) |

|---|---|---|---|---|---|

| 1 | 1; 5; 10; 20; 30; 40; 50; 100; 150; 200 | 4–5 | 1 | 180 | 25 |

| 2 | 10 | 2, 3, 4, 5, 6, 7, 8, 9, 10 (±0.2) | 1 | 180 | 25 |

| 3 | 10 | 4–5 | 0.1; 0.5; 1; 2; 3; 4; 5 (±0.0005) | 180 | 25 |

| 4 | 10 | 4–5 | 1 | 10; 30; 60; 90; 120; 180; 240; 300 | 25 |

| 5 | 10 | 4–5 | 1 | 180 | 25; 35; 45; 55; 65 |

| Raw PDFe/Al | Cr-PDFe/Al | Likely Attributable Source |

|---|---|---|

| 535.5 | 532.8 | AlOOH [35], Si-O-Al [28] |

| 606.4 | 604.4 | Fe-O [36,37], O-Al-O [36] |

| - | 610.9 | O-Cr-O [38,39] |

| 705.2 | 704.9 | AlOOH [36] |

| 795.3 | 796.2 | Fe-O [36], Silica [28] |

| 976.4 | 976.9 | Si-O [40] |

| 1096.3 | 1103.2 | HOH stretching [33], S-O groups [41], Si-O-Al linkages [40] |

| 1629.9 | 1630.2 | HOH stretching [28,33] |

| 3197.3 | 3200.0 | O-H [1,2] |

| PDFe/Al | Cr-PDFe/Al | Fe/Al vs. Cr-PDFe/Al | |||||

|---|---|---|---|---|---|---|---|

| Element | EDS | XRF | p-Value 1 | EDS | XRF | p-Value 2 | p-Value 3 |

| Fe | 21.11 ± 10.42 | 37.51 | 0.22 | 32.38 ± 15.39 | 38.91 | 0.72 | 0.21 |

| O | 67.99 ± 2.53 | 59.83 | 0.042 | 59.75 ± 19.51 | 60.07 | 0.99 | 0.38 |

| S | 7.34 ± 3.72 | 0.24 | 0.16 | 4.59 ± 2.52 | 0.07 | 0.18 | 0.21 |

| Cr 4 | 0 ± 0 | 0.00 | - | 1.46 ± 0.57 | 0.08 | 0.091 | 0.00043 |

| Al | 0.83 ± 0.38 | 1.15 | 0.49 | 1.02 ± 0.47 | 0.62 | 0.48 | 0.51 |

| Si | 0.19 ± 0.32 | 0.14 | 0.90 | 0.07 ± 0.11 | 0.13 | 0.65 | 0.46 |

| K | 0 ± 0 | 0.00 | - | 0.15 ± 0.1 | 0.00 | 0.24 | 0.01 |

| Ca | 1.75 ± 3.74 | 0.15 | 0.72 | 0 ± 0 | 0.00 | - | 0.33 |

| Cl | 0.51 ± 1.13 | 0.00 | 0.70 | 0 ± 0 | 0.00 | - | 0.35 |

| Na | 0.18 ± 0.4 | 0.62 | 0.37 | 0.3 ± 0.31 | 0.00 | 0.43 | 0.61 |

| Mg | 0.11 ± 0.25 | 0.29 | 0.56 | 0.2 ± 0.32 | 0.00 | 0.59 | 0.63 |

| Ti | 0 ± 0 | 0.00 | 0.22 | 0.06 ± 0.13 | 0.00 | 0.70 | 0.35 |

| Total | 100.00 ± 0.00 | 99.94 | - | 100.00 ± 0.00 | 99.89 | - | - |

| Material | Parameter | Value |

|---|---|---|

| PDFe/Al | Total Surface Area (BET): | 37.5841 m2/g |

| Micropore Volume: | 0.003066 cm3/g | |

| Micropore Area: | 13.6686 m2/g | |

| External Surface Area: | 23.9156 m2/g | |

| Cr-PDFe/Al | Total Surface Area (BET): | 95.5269 m2/g |

| Micropore Volume: | 0.020797 cm3/g | |

| Micropore Area: | 52.9926 m2/g | |

| External Surface Area: | 42.5343 m2/g |

| Adsorbent | Qmax (mg·g−1) | Qe (mg·g−1) | k2 | t2,99 (min) [36] | References |

|---|---|---|---|---|---|

| PDFe/Al nanocomposite | 6.67 | 2.165 | 0.188 g·mg−2 min−1 | 279 | This study |

| Aluminium Oxide | 78.1 | 72.5 | 6.9 × 10−4 g·mg−2 min−1 | 1978 | [26] |

| Mesoporous iron–zirconium bimetal oxide | 59.88 | 52.46 | 0.02 g·mg−2 min−1 | 2619 | [27] |

| Zirconium oxide intercalated sodium montmorillonite scaffold | 52.46 | 44.46 | 0.0023 g·mg−2 min−1 | 2277 | [28] |

| Hematite | 2.299 | 0.5 | 0.0088 g·mg−2 min−1 | 5952 | [29] |

| Hydrochloric acid-modified kaolinite | 18.15 | 0.34 | 0.089 g·mg−2 min−1 | 2631 | [30] |

| Acetic acid-modified kaolinite | 10.42 | 0.38 | 0.66 g·mg−2 min−1 | 513 | [30] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muedi, K.L.; Masindi, V.; Maree, J.P.; Brink, H.G. Rapid Removal of Cr(VI) from Aqueous Solution Using Polycationic/Di-Metallic Adsorbent Synthesized Using Fe3+/Al3+ Recovered from Real Acid Mine Drainage. Minerals 2022, 12, 1318. https://doi.org/10.3390/min12101318

Muedi KL, Masindi V, Maree JP, Brink HG. Rapid Removal of Cr(VI) from Aqueous Solution Using Polycationic/Di-Metallic Adsorbent Synthesized Using Fe3+/Al3+ Recovered from Real Acid Mine Drainage. Minerals. 2022; 12(10):1318. https://doi.org/10.3390/min12101318

Chicago/Turabian StyleMuedi, Khathutshelo Lilith, Vhahangwele Masindi, Johannes Philippus Maree, and Hendrik Gideon Brink. 2022. "Rapid Removal of Cr(VI) from Aqueous Solution Using Polycationic/Di-Metallic Adsorbent Synthesized Using Fe3+/Al3+ Recovered from Real Acid Mine Drainage" Minerals 12, no. 10: 1318. https://doi.org/10.3390/min12101318

APA StyleMuedi, K. L., Masindi, V., Maree, J. P., & Brink, H. G. (2022). Rapid Removal of Cr(VI) from Aqueous Solution Using Polycationic/Di-Metallic Adsorbent Synthesized Using Fe3+/Al3+ Recovered from Real Acid Mine Drainage. Minerals, 12(10), 1318. https://doi.org/10.3390/min12101318