Bioleaching Process for Copper Extraction from Waste in Alkaline and Acid Medium

Abstract

:1. Introduction

2. Materials and Methods

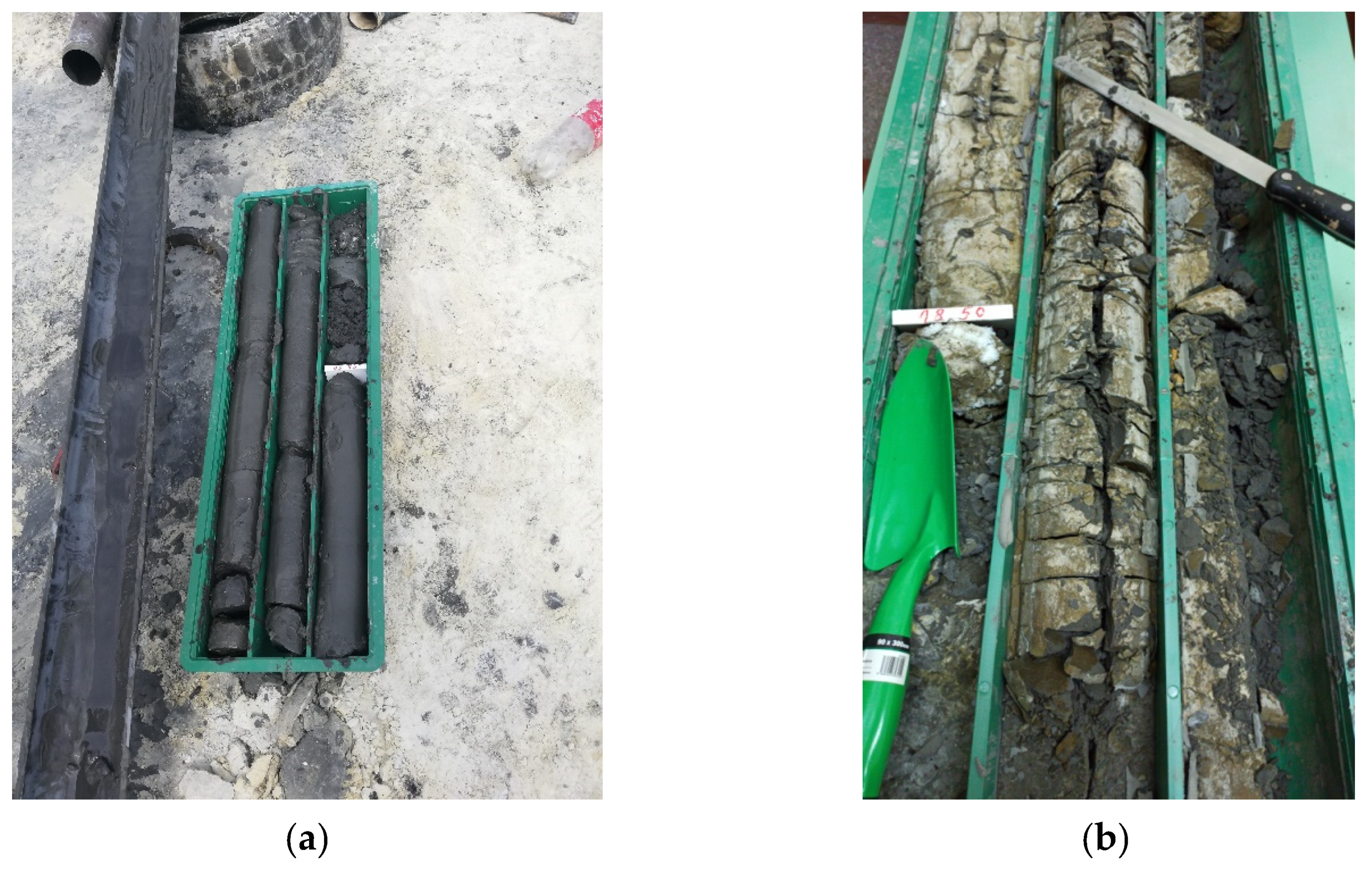

2.1. Materials

- Well B—1 21.50 m;

- Well B—2 18.50 m;

- Well B—3 30.00 m;

- Well B—4 33.50 m.

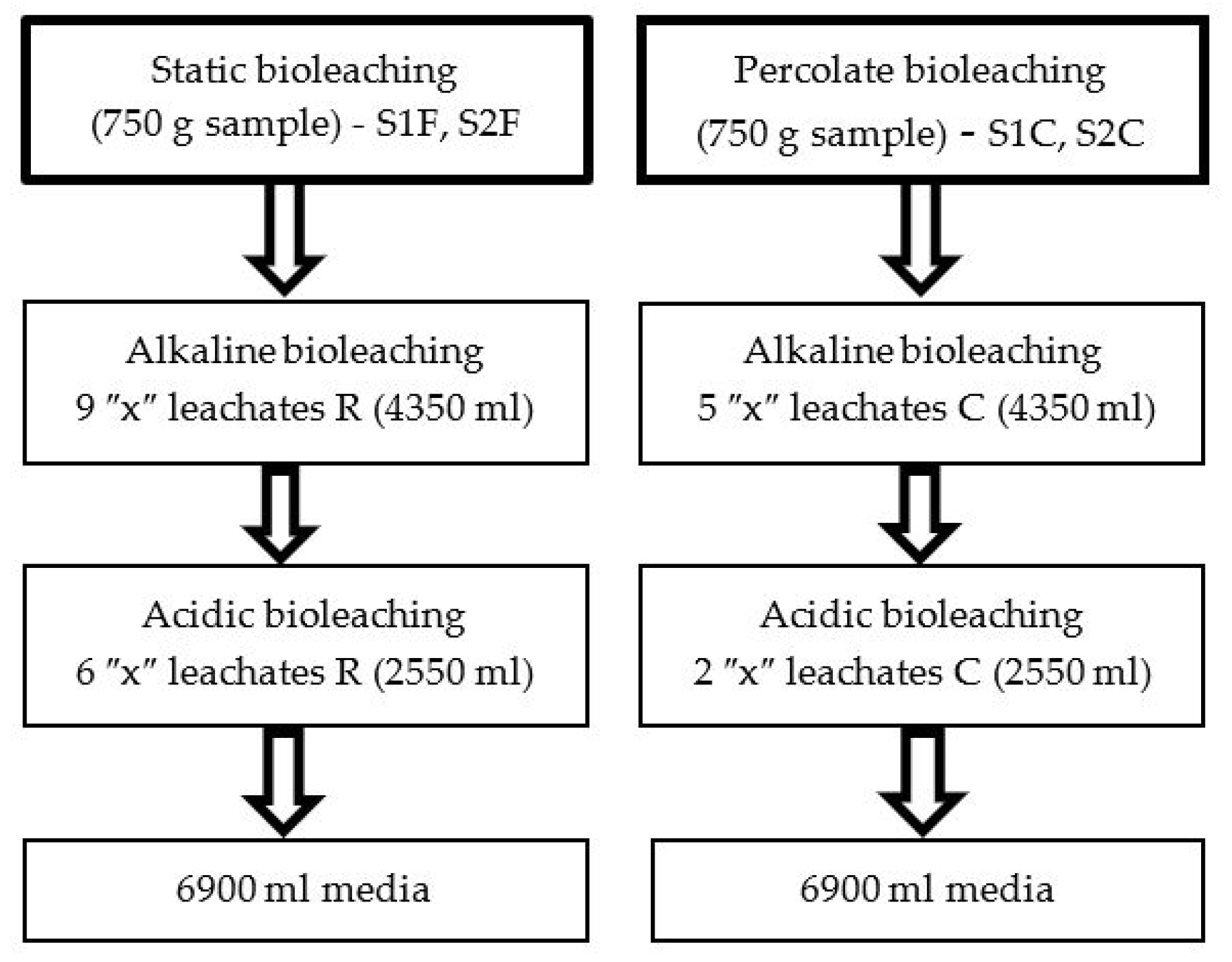

2.2. Experimental Procedures

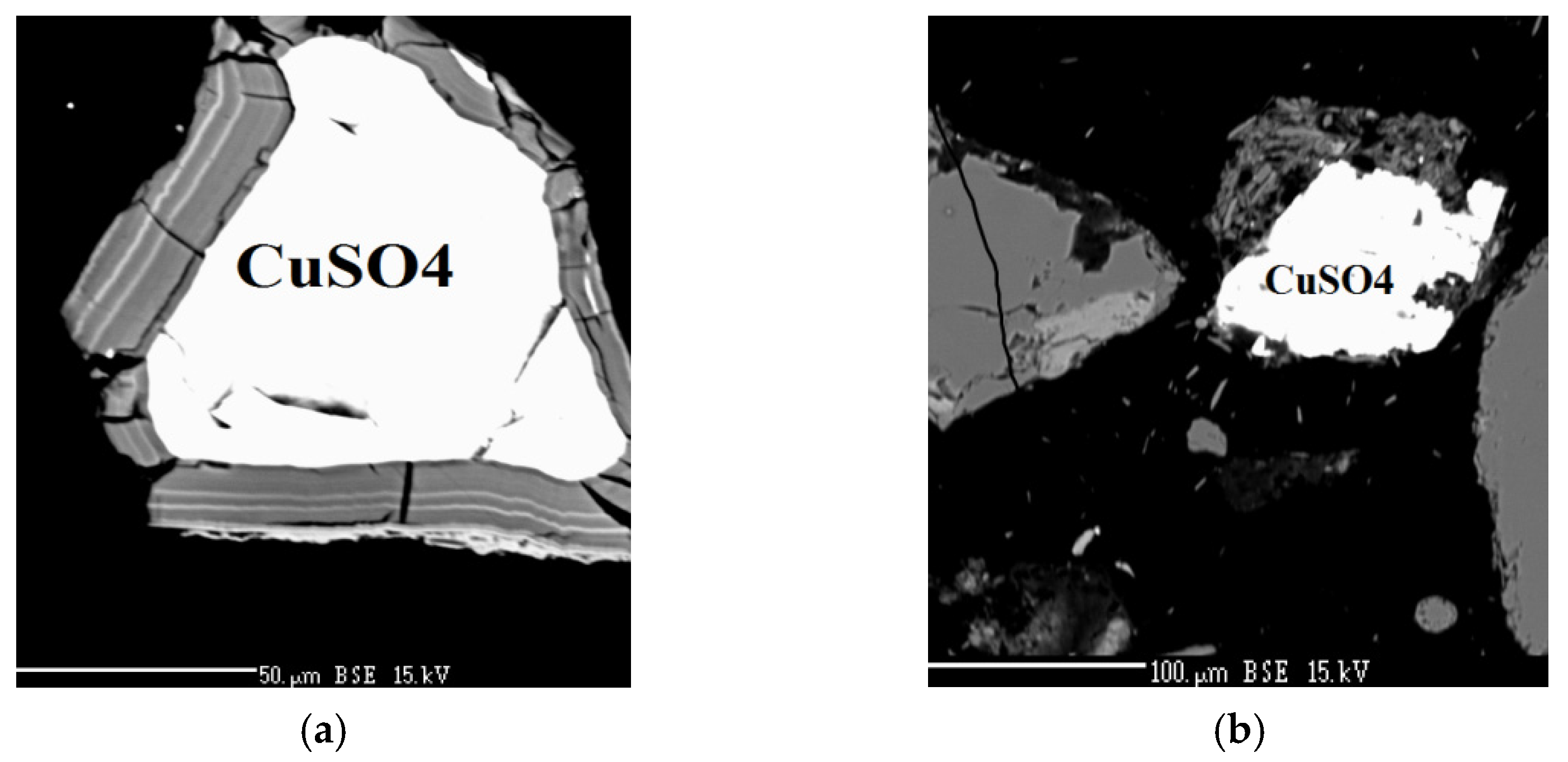

3. Results and Discussion

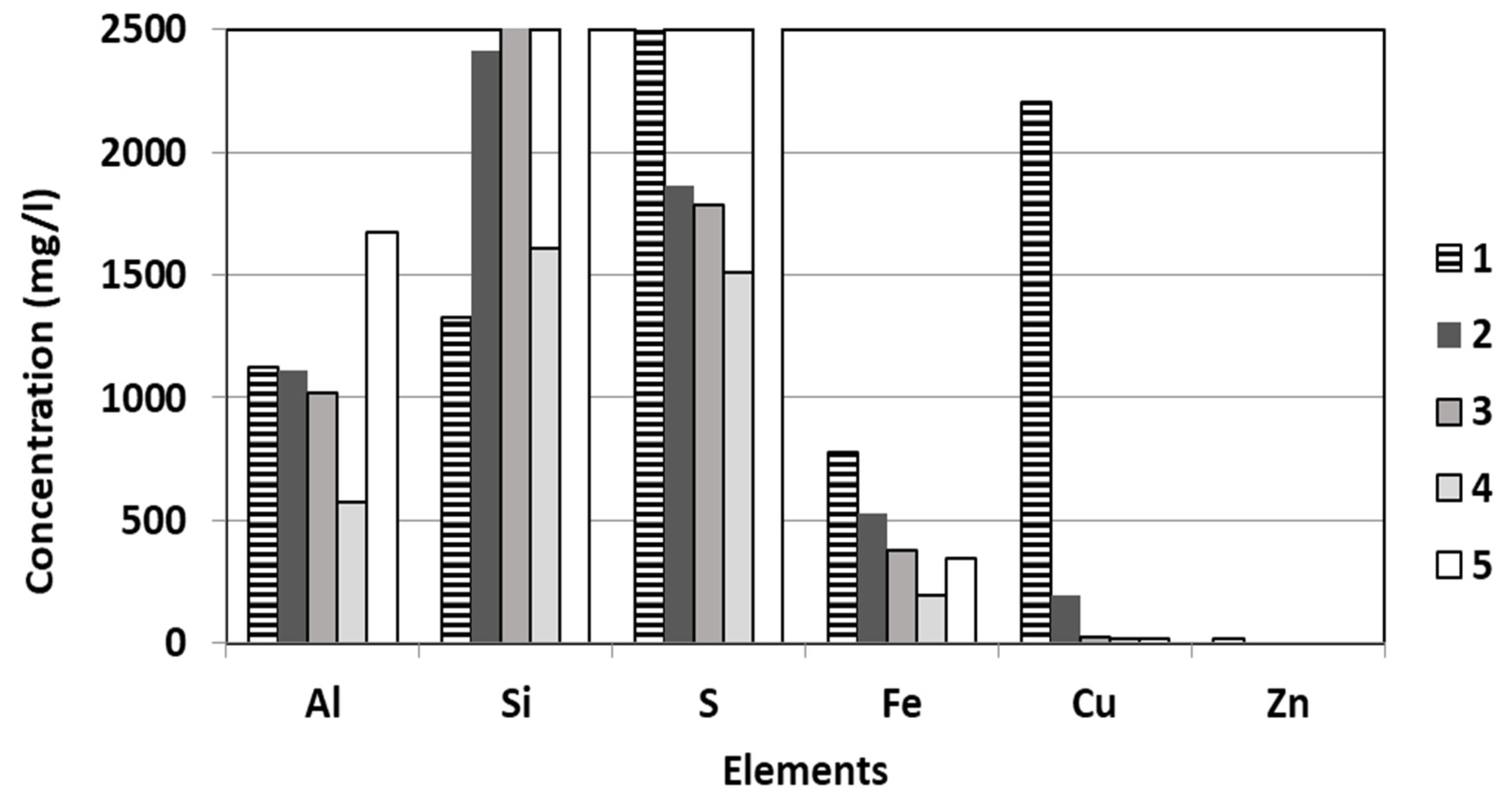

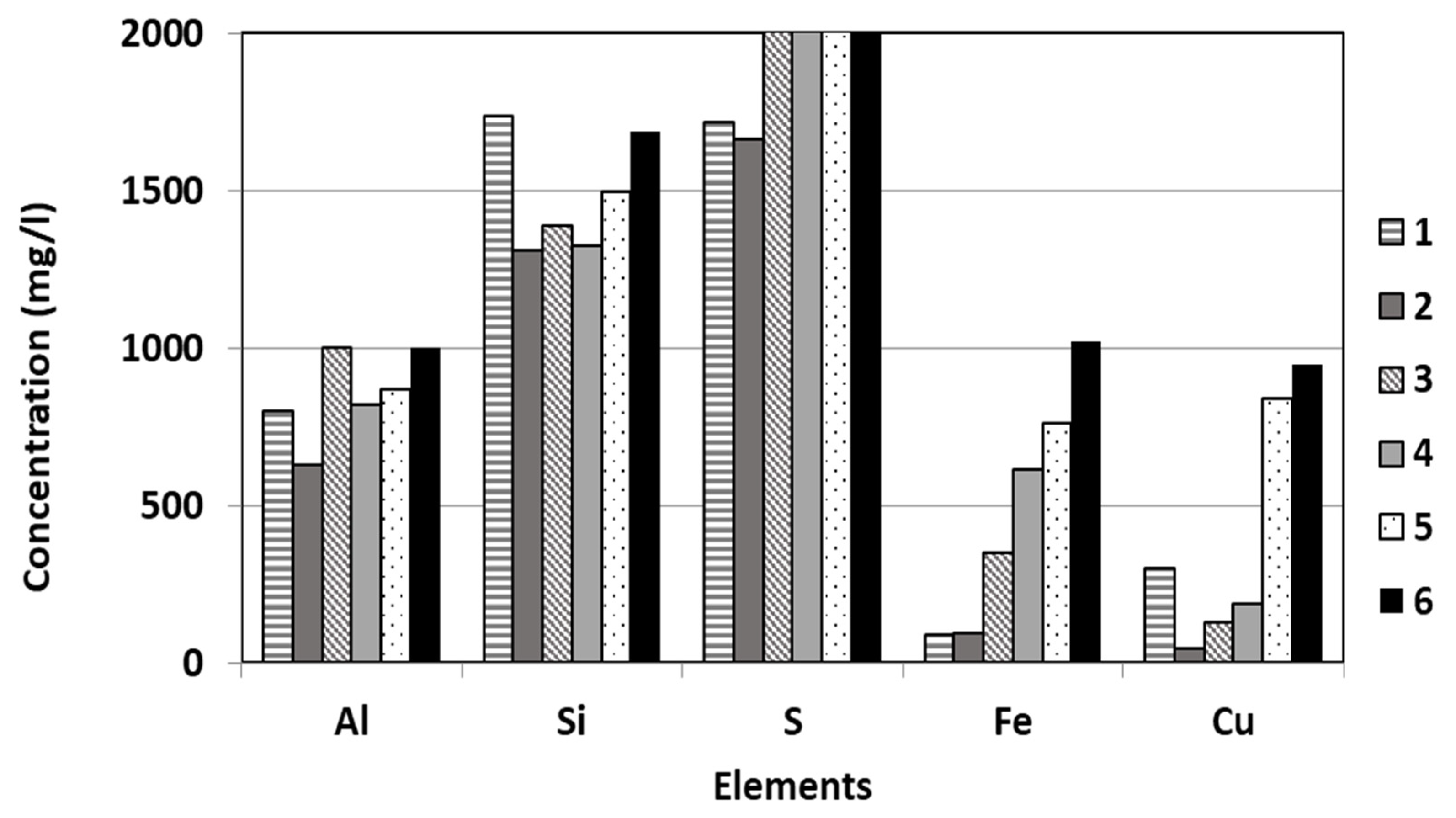

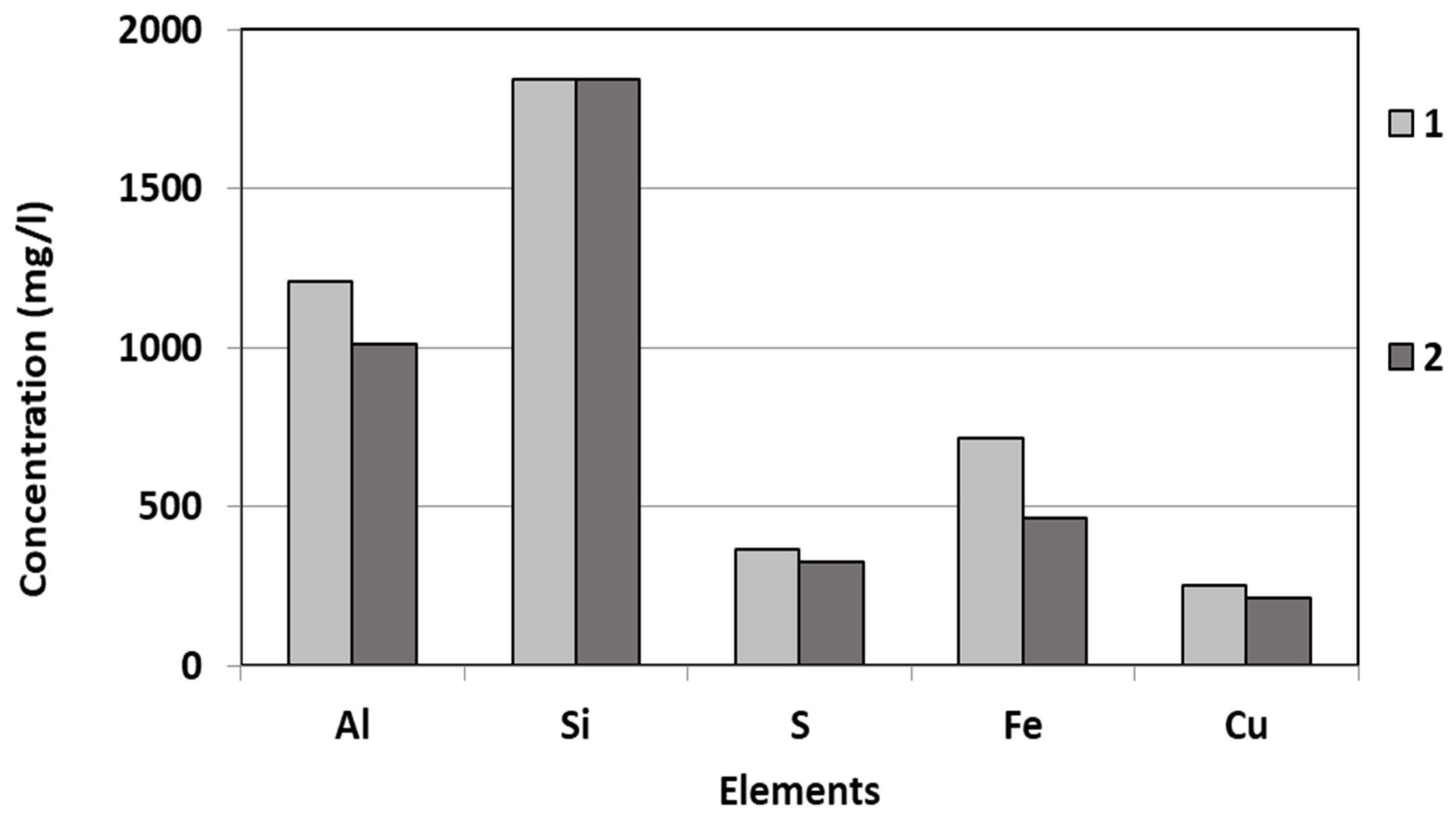

3.1. Alkaline Bioleaching

3.2. Acidic Bioleaching

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prospectus of RTB Bor for the tender for the selection of a strategic partner for Bor Mining and Metallurgical Basin, Serbia, Company documentation. 2018.

- Žikić, M.; Mihajlović, B.; Živković, M.; Stojadinović, S.; Pantović, R.; Kržanović, D. Analysis of the copper losses in all the production phases and their recycling potential on the example of Veliki Krivelj open pit. Reciklaža Održivi Razvoj 2013, 6, 35–40. [Google Scholar]

- Antonijevic, M.M.; Dimitirijevic, M.D.; Stevanovic, Z.O.; Serbula, S.M.; Bogdanovic, G.D. Investigation of the possibility of copper recovery from the flotation tailings by acid leaching. J. Hazard. Mater. 2008, 158, 23–34. [Google Scholar] [CrossRef] [PubMed]

- Stevanovic, Z. Kinetics of Copper and Gold Leaching from the Flotation Tailings. Master’s Thesis, University of Belgrade, Technical Faculty, Bor, Belgrade, Serbia, 2001. [Google Scholar]

- Stevanovic, Z.; Antonijevic, M.; Bogdanovic, G.; Bugarin, M.; Trujic, V.; Markovic, R.; Nedeljkovic, D. The effect of oxidants through a tailing dump depth and the leaching of copper. Carpathian J. Earth Environ. Sci. 2013, 8, 29–38. [Google Scholar]

- Holmes, D.S.; Debus, K.A. Biological opportunities for metal recovery. In Proceedings of the International Symposium on Biotechnology for Energy, Faisalabad, Pakistan, 16–21 December 1989; Malik, K.A., Naqvi, S.H.M., Aleem, M.I.H., Eds.; NIAB/NIBGE: Faisalabad, Pakistan, 1991; pp. 341–358. [Google Scholar]

- Falagán, C.; Grail, B.M.; Johnson, D.B. New approaches for extracting and recovering metals from mine tailings. Miner. Eng. 2017, 106, 71–78. [Google Scholar] [CrossRef]

- Hu, K.J.; Wu, A.X.; Wang, H.J.; Wang, S.Y. A new heterotrophic strain for bioleaching of low-grade complex copper ore. Minerals 2016, 6, 12. [Google Scholar] [CrossRef] [Green Version]

- Eksteen, J.J.; Oraby, E.A.; Tanda, B.C. A conceptual process for copper extraction from chalcopyrite in alkaline glycinate solutions. Miner. Eng. 2017, 108, 53–66. [Google Scholar] [CrossRef]

- Yin, S.; Wang, L.; Wu, A.; Kabwe, E.; Chen, X.; Yan, R. Copper recycle from sulfide tailings using combined leaching of ammonia solution and alkaline bacteria. J. Clean. Prod. 2018, 189, 746–753. [Google Scholar] [CrossRef]

- Cabrol, L.; Quéméneur, M.; Misson, B. Inhibitory effects of sodium azide on microbial growth in experimental resuspension of marine sediment. J. Microbiol. Methods 2017, 133, 62–65. [Google Scholar] [CrossRef] [PubMed]

- Dew, D.W.; van Buuren, C.; McEwan, K.; Bowker, C. Bioleaching of base metal sulphide concentrates: A comparison of mesophilic and thermophilic bacterial cultures. In Proceedings of the International Biohydrometallurgy Symposium, Madrid, Spain, 20–23 June 1999; Amils, R., Ballester, A., Eds.; Part A. Elsevier: Amsterdam, The Netherlands, 1999; pp. 229–238. [Google Scholar]

- Sokic, M.; Radovanovic, D.; Marković, B.; Stojanovic, J.; Kamberovic, Z.; Petronijevic, N.; Stanković, S. Treatment of the acidic effluent from a copper smelter by flotation tailings. Chem. Ind. 2019, 73, 115–124. [Google Scholar] [CrossRef]

- Rawlings, D.E. Characteristics and adaptability of iron- and sulfur-oxidizing microorganisms used for the recovery of metals from minerals and their concentrates. Microb. Cell Fact. 2005, 4, 13. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Astudillo, C.; Acevedo, F. Adaptation of Sulfolobus metallicus to high pulp densities in the biooxidation of a flotation gold concentrate. Hydrometallurgy 2008, 92, 11–15. [Google Scholar] [CrossRef]

- Mahmoud, A.; Cézac, P.; Hoadley, A.F.; Contamine, F.; d’Hugues, P. A review of sulfide minerals microbially assisted leaching in stirred tank reactors. Int. Biodeterior. Biodegrad. 2017, 119, 118–146. [Google Scholar] [CrossRef]

- Conić, V.; Stanković, S.; Marković, B.; Božić, D.; Stojanović, J.; Sokić, M. Investigation of the optimal technology for copper leaching from old flotation tailings of the copper mine Bor (Serbia). Metall. Mater. Eng. 2020, 26, 209–222. [Google Scholar] [CrossRef]

- Han, B.; Altansukh, B.; Kazutoshi, H.; Stevanovic, Z.; Jonovic, R.; Avramovic, L.; Uroševic, D.; Takasaki, Z.; Masuda, N.; Ishiyama, D.; et al. Development of copper recovery process from flotation tailings by a combined method of high-pressure leaching-solvent extraction. J. Hazard. Mater. 2018, 352, 192–203. [Google Scholar] [CrossRef] [PubMed]

- Das, A.; Modak, J.M.; Natarajan, K.A. Studies on multi-metal ion tolerance of Thiobacillus ferrooxidans. Miner. Eng. 1997, 10, 743–749. [Google Scholar] [CrossRef]

- Dopson, M.; Baker-Austin, C.; Koppineedi, P.R.; Bond, P.L. Growth in sulfidic mineral environments: Metal resistance mechanisms in acidophilic micro-organisms. Microbiology 2003, 149, 1959–1970. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Readett, D.; Sylwestrzak, L.; Franzmann, P.D.; Plumb, J.J.; Robertson, W.R.; Gibson, J.A.E.; Watling, H. The life cycle of a chalcocite heap bioleach system. In Hydrometallurgy 2003; Young, C.A., Alfantazi, A.M., Anderson, C.G., Dreisinger, D.B., Harris, B., James, A., Eds.; TMS: Warrendale, PA, USA, 2003; pp. 365–374. [Google Scholar]

| Location | Tailings (t) | Cu (%) | Au(g/t) | Ag (g/t) |

|---|---|---|---|---|

| Old Flotation Tailing Dump | 28,000,000 | 0.245 | 0.395 | 1.700 |

| Tailing Dump RTH | 50,000,000 | 0.200 | 0.100 | 0.500 |

| Veliki Krivelj | 160,000,000 | 0.100 | 0.050 | 0.500 |

| Majdanpek | 350,000,000 | 0.079 | 0.154 | 1.071 |

| Σ All flotation tailings | 588,000,000 | 0.103 | 0.133 | 0.897 |

| Concentration (%) | Al | Si | S | Mn | Fe | Cu | Zn | As | Ag | Hg | Pb |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Input | 4.73 | 21.57 | 9.6 | 0.01 | 8.19 | 0.43 | 0.004 | 0.012 | 0.015 | 0.0008 | 0.008 |

| S1 F | 4.54 | 25.35 | 10.82 | 0.01 | 8.52 | 0.14 | 0.002 | 0.011 | 0.016 | 0.0007 | 0.006 |

| S2 F | 5.04 | 24.98 | 10.79 | 0.01 | 8.38 | 0.16 | 0.002 | 0.014 | 0.016 | 0.0011 | 0.006 |

| S1 C | 5.71 | 24.95 | 10.32 | 0.09 | 9.14 | 0.14 | 0.002 | 0.013 | 0.017 | 0.0009 | 0.007 |

| S2 C | 5.79 | 25.17 | 10.02 | 0.09 | 8.98 | 0.15 | 0.002 | 0.013 | 0.017 | 0.0009 | 0.007 |

| Concentration (%) | Al | Si | S | Mn | Fe | Cu | Zn | As | Ag | Hg | Pb |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe precipitates | 1.75 | 8.36 | 9.28 | 0.002 | 15.41 | 0.21 | 0.002 | 0.02 | 0.02 | 0 | 0.019 |

| Concentration (%) | Al | Si | S | Mn | Fe | Cu | Zn | As | Ag | Hg | Pb |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Input | 4.7 | 21.6 | 9.60 | 0.01 | 8.19 | 0.43 | 0.004 | 0.012 | 0.015 | 0.0008 | 0.008 |

| S1 F | 4.2 | 22.9 | 10.28 | 0.008 | 7.21 | 0.11 | 0.002 | 0.012 | 0.013 | 0.0009 | 0.008 |

| S2 F | 4.6 | 25.8 | 10.92 | 0.01 | 8.03 | 0.12 | 0.002 | 0.016 | 0.017 | 0.0011 | 0.014 |

| S1 C | 4.5 | 19.4 | 7.40 | 0.009 | 8.12 | 0.10 | 0.003 | 0.022 | 0.014 | 0.0008 | 0.027 |

| S2 C | 4.2 | 19.5 | 8.43 | 0.008 | 9.40 | 0.13 | 0.005 | 0.027 | 0.017 | 0.0009 | 0.034 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ristović, I.; Štyriaková, D.; Štyriaková, I.; Šuba, J.; Širadović, E. Bioleaching Process for Copper Extraction from Waste in Alkaline and Acid Medium. Minerals 2022, 12, 100. https://doi.org/10.3390/min12010100

Ristović I, Štyriaková D, Štyriaková I, Šuba J, Širadović E. Bioleaching Process for Copper Extraction from Waste in Alkaline and Acid Medium. Minerals. 2022; 12(1):100. https://doi.org/10.3390/min12010100

Chicago/Turabian StyleRistović, Ivica, Darina Štyriaková, Iveta Štyriaková, Jaroslav Šuba, and Emilija Širadović. 2022. "Bioleaching Process for Copper Extraction from Waste in Alkaline and Acid Medium" Minerals 12, no. 1: 100. https://doi.org/10.3390/min12010100

APA StyleRistović, I., Štyriaková, D., Štyriaková, I., Šuba, J., & Širadović, E. (2022). Bioleaching Process for Copper Extraction from Waste in Alkaline and Acid Medium. Minerals, 12(1), 100. https://doi.org/10.3390/min12010100