Down to the Crust: Chemical and Mineralogical Analysis of Ceramic Surface Encrustations on Bronze Age Ceramics from Békés 103, Eastern Hungary

Abstract

:1. Introduction

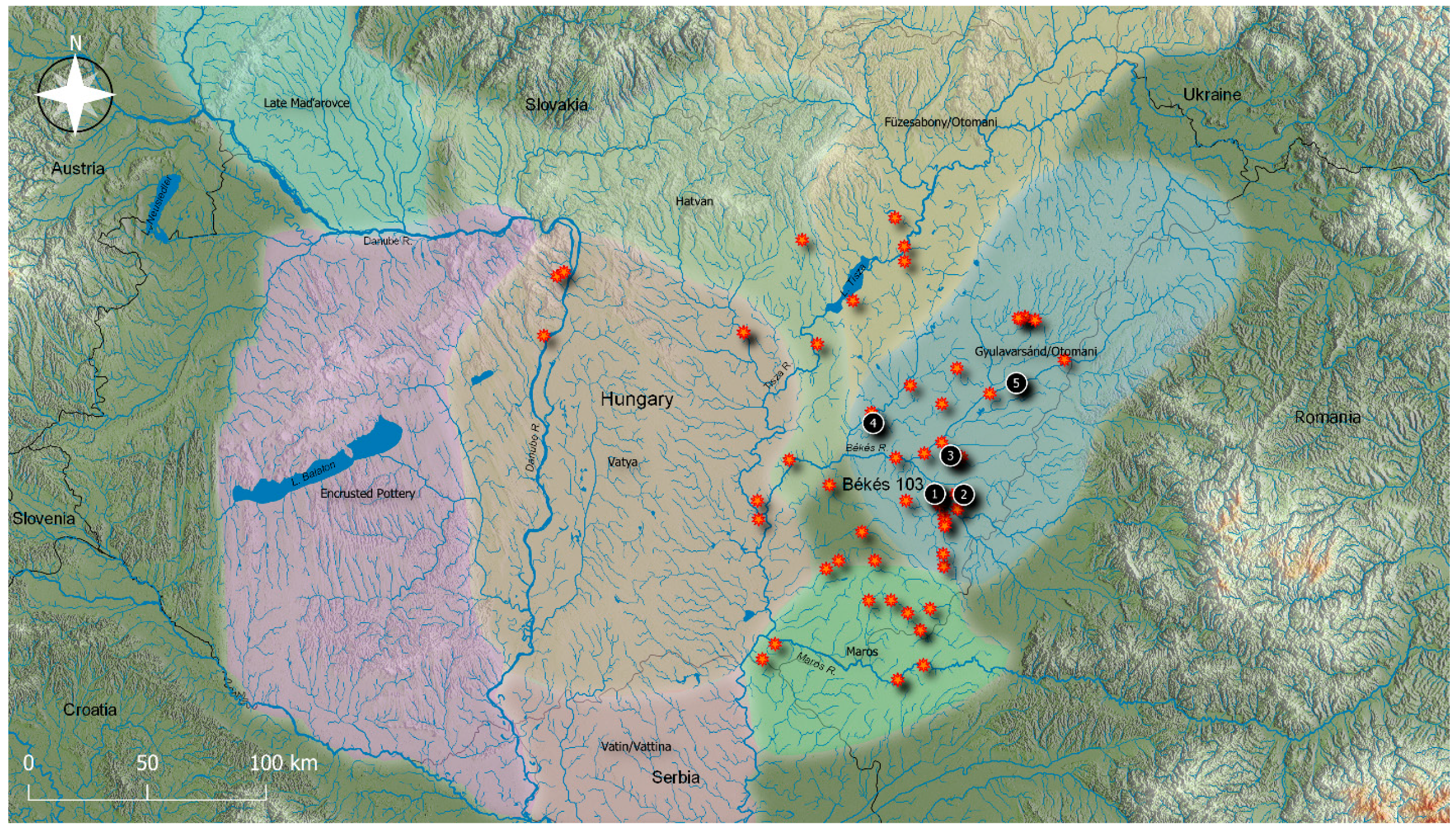

The Békés 103 “Jégvermi-Kert” Cemetery Ceramic Assemblage

2. Materials and Methods

2.1. Sample

2.2. Methods

3. Results

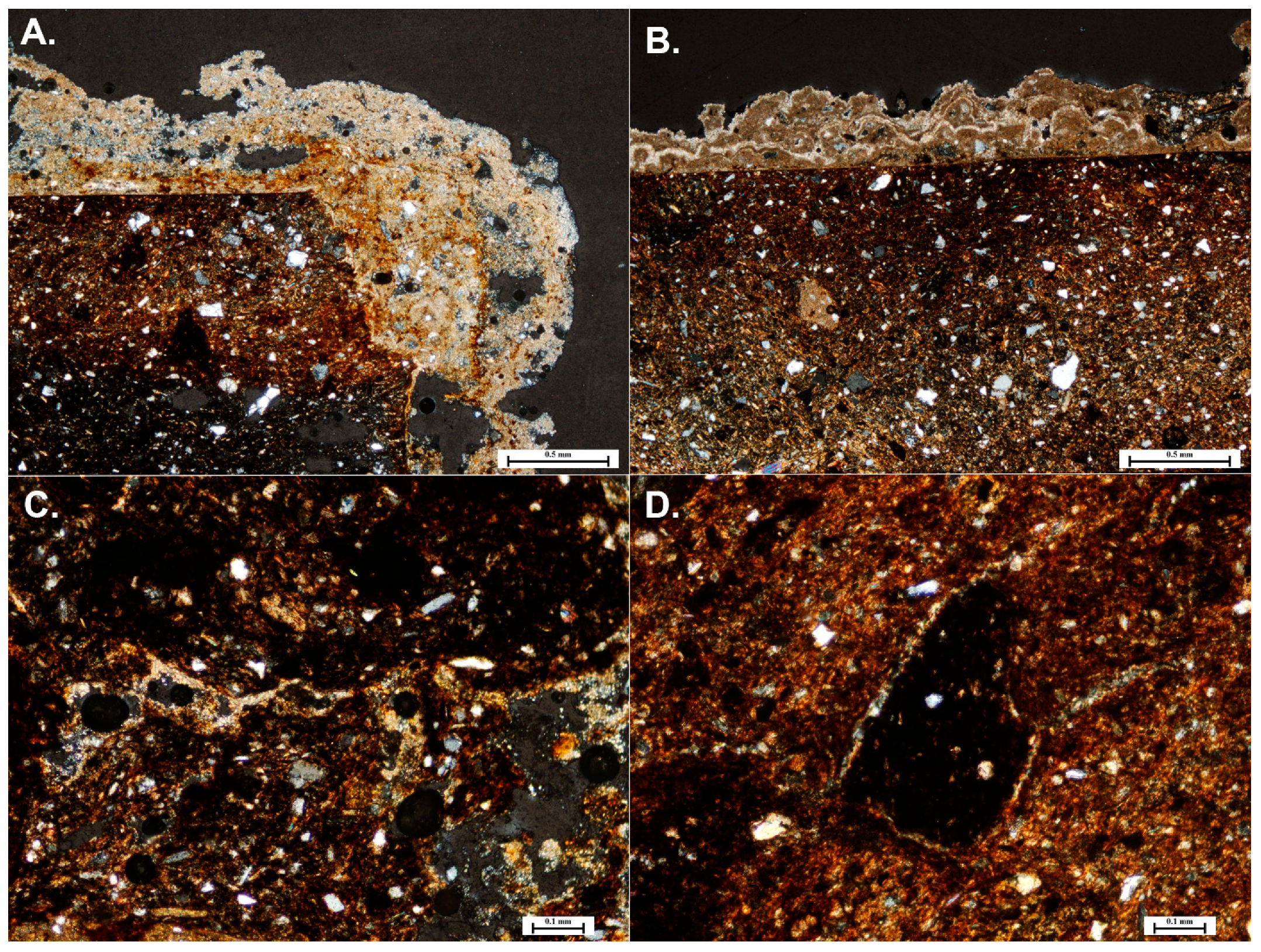

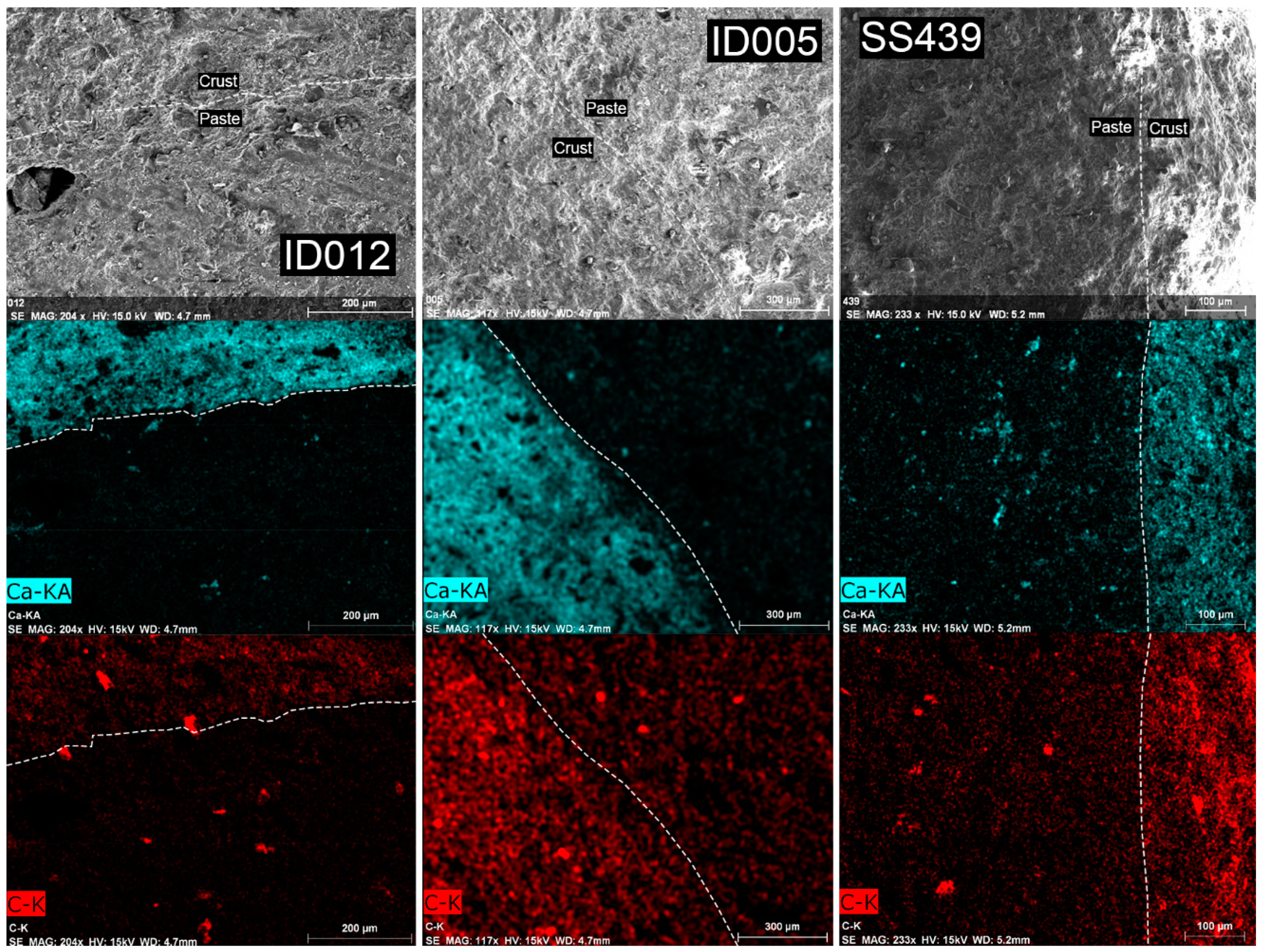

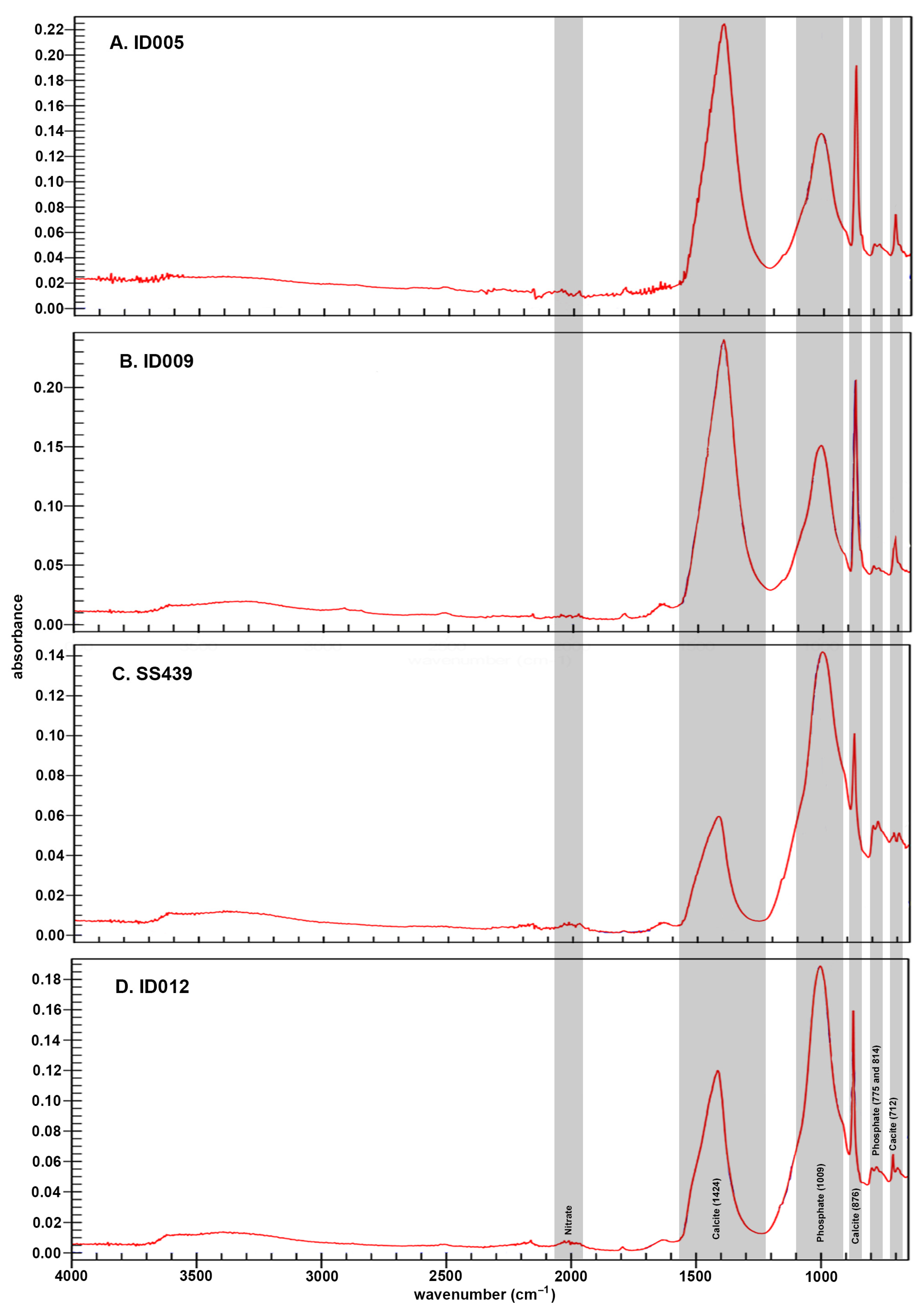

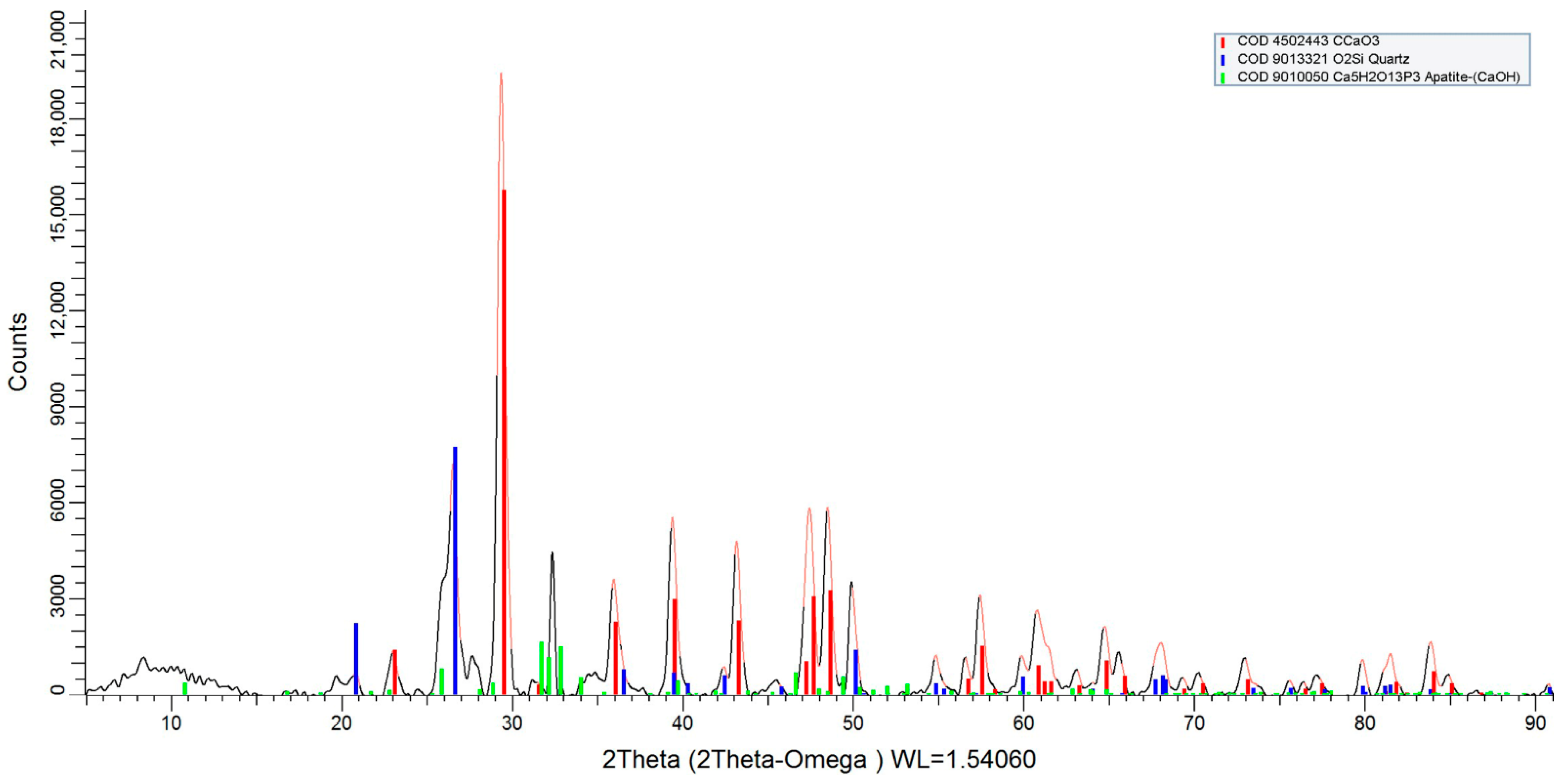

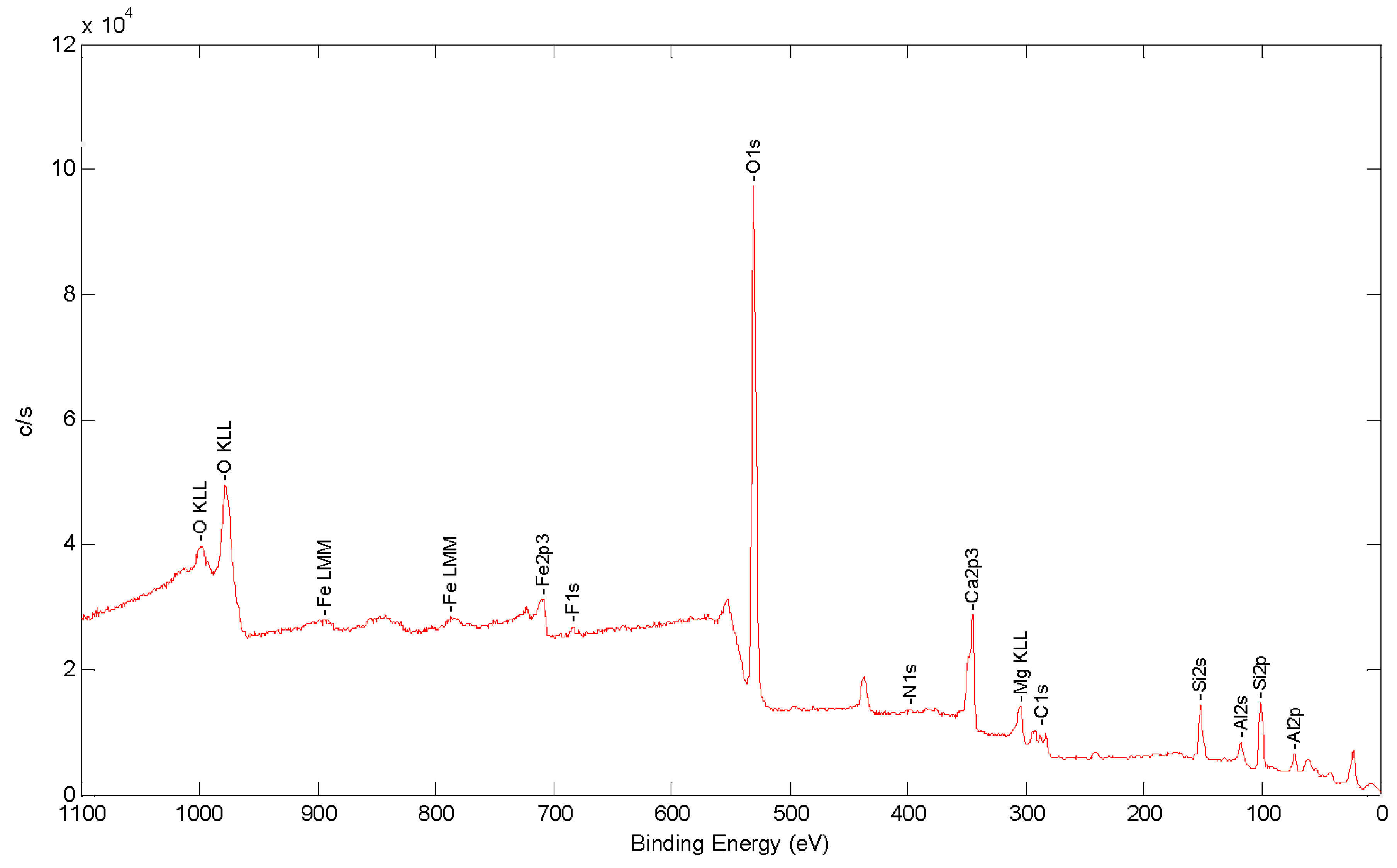

3.1. Crust Composition

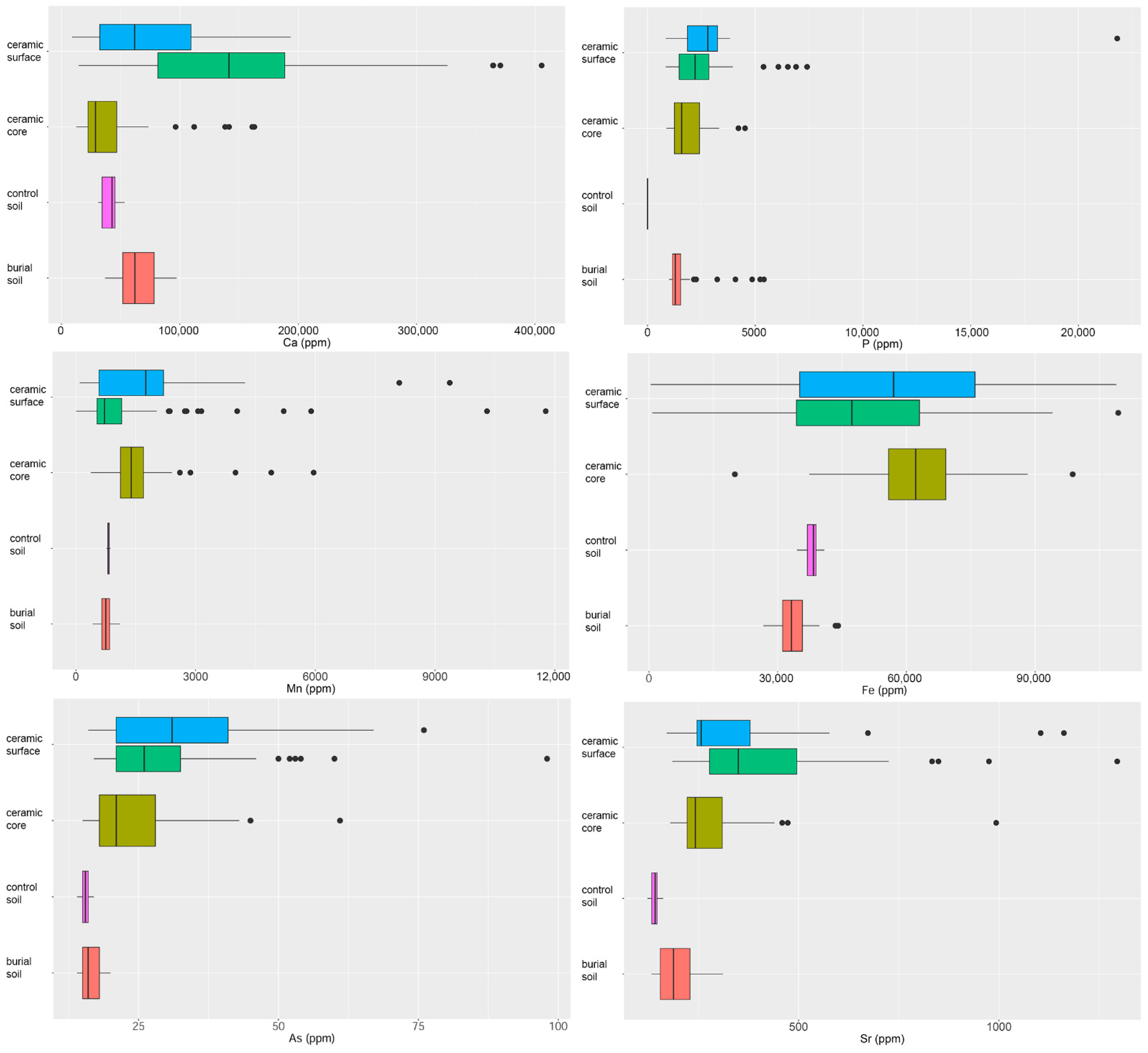

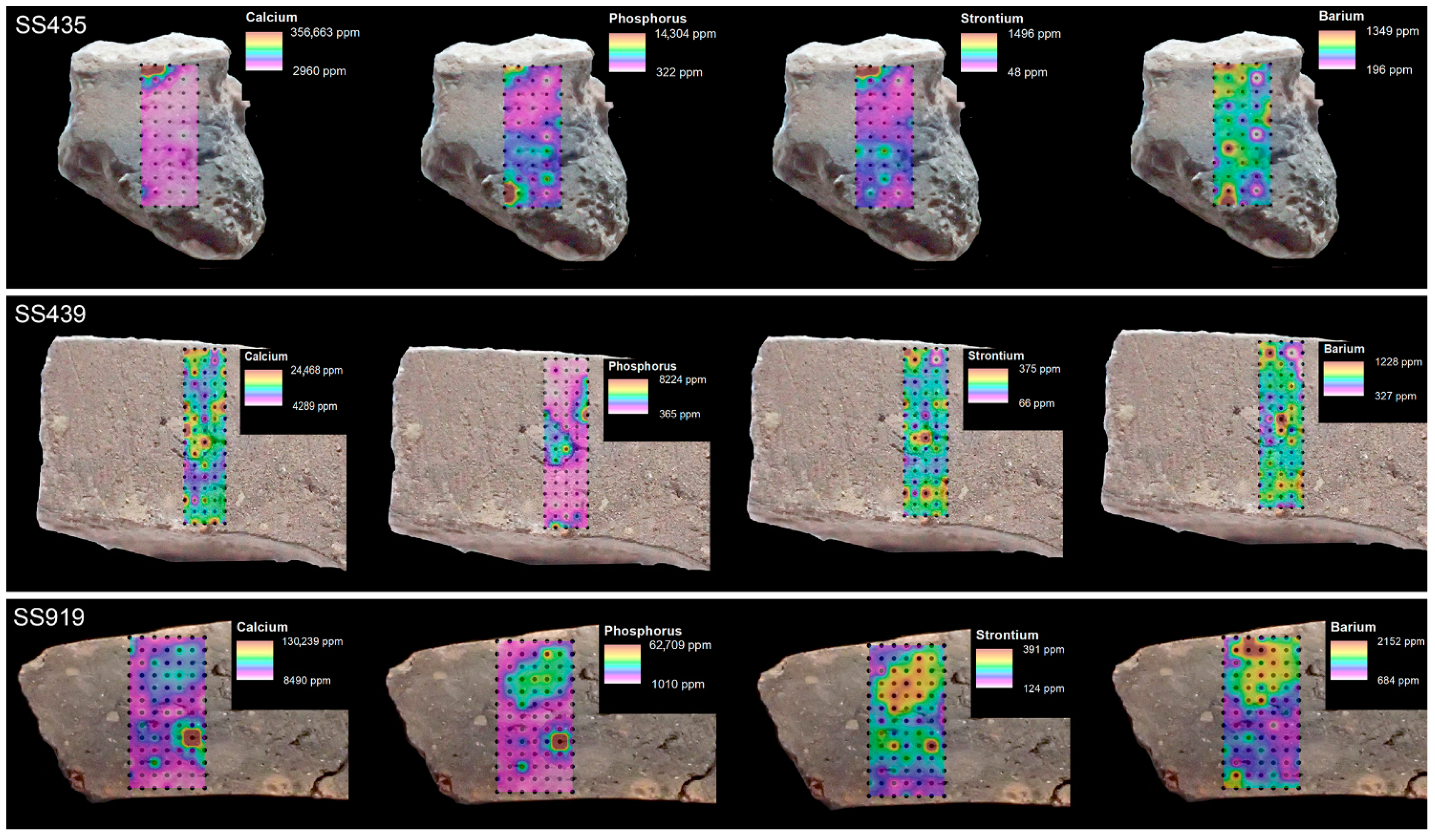

3.2. Identification of Elemental Leaching

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Neff, H.; Cogswell, J.W.; Ross, L.M.J. Supplementing bulk chemistry in archaeological provenience investigations. In Patterns and Process: A Festschrift in Honor of Dr. Edward V. Sayre; van Zelst, L., Ed.; Smithsonian Center for Materials Research and Education: Suitland, MD, USA, 2003; pp. 200–224. [Google Scholar]

- Duffy, P.R.; Parditka, G.M.; Giblin, J.I.; Paja, L. The problem with tells: Lessons learned from absolute dating of Bronze Age mortuary ceramics in Hungary. Antiquity 2019, 93, 63–79. [Google Scholar] [CrossRef]

- Duffy, P.R. River networks and funerary metal in the Bronze Age of the Carpathian Basin. PLoS ONE 2020, 15, e0238526. [Google Scholar] [CrossRef] [PubMed]

- Duffy, P.R.; Paja, L.; Parditka, G.M.; Giblin, J.I. Modelling mortuary populations at local and regional levels. J Anthr. Archaeol. 2019, 53, 240–261. [Google Scholar] [CrossRef]

- Duffy, P.R.; Parditka, G.M.; Giblin, J.I.; Paja, L.; Salisbury, R.B. Discovering Mortuary Practices in the Körös River Basin, Hungary. Hung. Archaeol. E-J. Magy. Régészet Online Mag. 2014, Autumn, 1–5. [Google Scholar]

- Paja, L.; Duffy, P.R.; Parditka, G.M.; Giblin, J.I. Bioanthropological analysis of Békés 103 (Jégvermi-kert, Lipscei-tanya), a Bronze Age cemetery from southeastern Hungary. Acta Biol. Szeged. 2016, 60, 183–192. [Google Scholar]

- O’Shea, J.M. Villagers of the Maros: A Portrait of an Early Bronze Age Society; Plenum Press: New York, NY, USA, 1996. [Google Scholar]

- Riebe, D.J.; Duffy, P.R. Baroque by whose hand? Detailing the regional production of finewares in Middle Bronze Age Hungary. Paper Presented at the 79th Annual Meeting of the Society for American Archaeology, Austin, TX, USA, 23—27 April 2014. [Google Scholar]

- Parkinson, W.A.; Palmer, R.A.; Xia, Y.; Carlock, B.; Gyucha, A.; Yerkes, R.W.; Galaty, M.L. Elemental analysis of ceramic incrustation indicates long-term cultural continuity in the prehistoric Carpathian Basin. Archaeol. Ethnol. Anthropol. Eurasia 2010, 201038, 64–70. [Google Scholar] [CrossRef]

- Odriozola, C.P.; Hurtado Pérez, V.M. The manufacturing process of 3rd millennium BC bone based incrusted pottery decoration from the Middle Guadiana river basin (Badajoz, Spain). J. Archaeol. Sci. 2007, 34, 1794–1803. [Google Scholar] [CrossRef]

- Všianský, D.; Kolář, J.; Petřík, J. Continuity and changes of manufacturing traditions of Bell Beaker and Bronze Age encrusted pottery in the Morava river catchment (Czech Republic). J. Archaeol. Sci. 2014, 49, 414–422. [Google Scholar] [CrossRef]

- Hajdu, T.; György-Toronyi, A.; Pap, I.; Rosendahl, W.; Szabó, G. The chronology and meaning of the Transdanubian encrusted pottery decoration. Praehist. Z. 2016, 91, 353–368. [Google Scholar] [CrossRef]

- Kiss, V. Middle Bronze Age Encrusted Pottery in Western Hungary; Archaeolingua: Budapest, Hungary, 2012. [Google Scholar]

- Roberts, S.; Sofaer, J.; Kiss, V. Characterization and textural analysis of Middle Bronze Age Transdanubian inlaid wares of the Encrusted Pottery Culture, Hungary: A preliminary study. J. Archaeol. Sci. 2008, 35, 322–330. [Google Scholar] [CrossRef] [Green Version]

- Sofaer, J.; Mihelić, S. Pattern, colour, and texture in encrusted ceramics in the Carpathian Basin. In Creativity in the Bronze Age: Understanding Innovation in Pottery, Textile, and Metalwork Production; Jørgensen, L.B., Sofaer, J., Stig Sørensen, M.L., Eds.; Cambridge University Press: Cambridge, UK, 2018; pp. 263–274. [Google Scholar]

- Sziki, G.A.; Biró, K.T.; Uzonyi, I.; Dobos, E.; Kiss, A.Z. Investigation of incrusted pottery found in the territory of Hungary by micro-PIXE method. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2004, 210, 478–482. [Google Scholar] [CrossRef]

- Stig Sørensen, M.L.; Rebay-Salisbury, K. Landscapes of the Body: Burials of the Middle Bronze Age in Hungary. Eur. J. Archaeol. 2009, 11, 49–74. [Google Scholar] [CrossRef]

- Fischl, K.P.; Kiss, V.; Kulcsár, G.; Szeverényi, V. Transformations in the Carpathian Basin around 1600 B.C. In 1600—Cultural Change in the Shadow of the Thera-Eruption? Tagungen des Landesmuseums für Vorgeschichte Halle (9); Meller, H., Bertemes, F., Bork, H.-R., Risch, R., Eds.; Landesamt für Denkmalpflege und Archäologie Sachsen-Anhalt - Landesmuseum für Vorgeschichte, Halle: Halle (Saale), Germany, 2013; Volume 9, pp. 355–370. [Google Scholar]

- Sofaer, J. Cosmologies in clay: Swedish Helmet Bowls in the Middle Bronze Age of the Carpathian Basin. In Counterpoint: Essays in archaeology and heritage studies in honour of Professor Kristian Kristiansen; Bergerbrant, S., Sabatini, S., Eds.; BAR International Series 2508; Archaeopress: Oxford, UK, 2013; pp. 361–365. [Google Scholar]

- Casaletto, M.P.; Ingo, G.M.; Riccucci, C.; De Caro, T.; Bultrini, G.; Fragalà, I.; Leoni, M. Chemical cleaning of encrustations on archaeological ceramic artefacts found in different Italian sites. Appl. Phys. A 2008, 92, 35–42. [Google Scholar] [CrossRef]

- Gyucha, A.; Duffy, P.R.; Frolking, T.A. The Körös Basin from the Neolithic to the Hapsburgs: Linking Settlement Distributions with Pre-Regulation Hydrology through Multiple Data Set Overlay. Geoarchaeology 2011, 26, 392–419. [Google Scholar] [CrossRef]

- Duffy, P.R. Complexity and Autonomy in Bronze Age Europe: Assessing Cultural Developments in Eastern Hungary. Prehistoric Research in the Körös Region; Archaeolingua: Budapest, Hungary, 2014. [Google Scholar]

- Dunnell, R.C.; Hunt, T.L. Elemental composition and inference of ceramic vessel function. Curr. Anthropol. 1990, 31, 330–336. [Google Scholar] [CrossRef]

- Franklin, U.M.; Vitali, V. The environmental stability of ancient ceramics. Archaeometry 1985, 27, 3–15. [Google Scholar] [CrossRef]

- Freestone, I.C.; Meeks, N.D.; Middleton, A.P. Retention of phosphate in buried ceramics: An electron microbeam approach. Archaeometry 1985, 27, 161–177. [Google Scholar] [CrossRef]

- Golitko, M.; Dudgeon, J.V.; Neff, H.; Terrell, J.E. Identification of post-depositional chemical alteration of ceramics from the north coast of Papua New Guinea (Sanduan Province) by time-of-flight-laser ablation-inductively coupled plasma-mass spectrometry (TOF-LA-ICP-MS). Archaeometry 2012, 54, 80–100. [Google Scholar] [CrossRef]

- Heinmann, R.B. Firing technologies and their possible assessment by modern analytical methods. In Archaeological Ceramics; Olin, J.S., Franklin, J.D., Eds.; Smithsonian Institution: Washington, DC, USA, 1982; pp. 86–96. [Google Scholar]

- Maggetti, M. Phase analysis and its significance for technology and origin. In Archaeological Ceramics; Olin, J.S., Franklin, J.D., Eds.; Smithsonian Institution: Washington, DC, USA, 1982; pp. 121–134. [Google Scholar]

- Picon, M. Quelques observations complémentaires sur les alterations de composition des céramiques au cours du temps: Cas de quelques alcalins et alcalino-terreux. ArchéoSciences revue d’Archéométrie 1991, 11, 41–47. [Google Scholar] [CrossRef]

- Hedges, R.E.M.; McLellan, M. On the cation exchange capacity of fired clays and its effects on the chemical and radiometric analysis of pottery. Archaeometry 1976, 18, 203–207. [Google Scholar] [CrossRef]

- Kreiter, A. Technological choices and material meanings: Analyses of Early and Middle Bronze Age ceramics from Hungary; BAR International Series 1604; Archaeopress: Oxford, UK, 2007. [Google Scholar]

- Kreiter, A.; Bajnóczi, B.; Sipos, P.; Szakmány, G.Y.; Tóth, M. Archaeometric examination of Early and Middle Bronze Age ceramics from Százhalombatta-Földvár, Hungary. Archeometriai Műhely 2007, 2007, 33–47. [Google Scholar]

- Maniatis, Y.; Tite, M.S. Technological examination of Neolithic-Bronze Age pottery from Central and Southeastern Europe and from the Near East. J. Archaeol. Sci. 1981, 8, 59–76. [Google Scholar] [CrossRef]

- Michelaki, K. Making Pots and Potters in the Bronze Age Maros Villages of Kiszombor-Új-Élet and Klárafalva-Hajdova. Camb. Archaeol. J. 2008, 18, 355–380. [Google Scholar] [CrossRef]

- Maritan, L. Ceramic abandonment. How to recognise post-depositional transformations. Archaeol. Anthrop. Sci. 2020, 12, 199. [Google Scholar] [CrossRef]

- Shoval, S. Fourier Transform Infrared Spectroscopy (FT-IR) in Archaeological Ceramic Analysis. In The Oxford Handbook of Archaeological Ceramic Analysis; Hunt, A.M.W., Ed.; Oxford University Press: Oxford, UK, 2017; pp. 509–530. [Google Scholar]

- Golitko, M. LBK Realpolitik: An Archaeometric Study of Conflict and Social Structure in the Belgian Early Neolithic; Archaeopress: Oxford, UK, 2015. [Google Scholar]

- Maritan, L.; Mazzoli, C. Phosphates in archaeological finds: Implications for environmental conditions of burial. Archaeometry 2004, 46, 673–683. [Google Scholar] [CrossRef]

- Bosch Reig, F.; Gimeno Adelantado, J.V.; Moya Moreno, M.C.M. FTIR quantitative analysis of calcium carbonate (calcite) and silica (quartz) mixtures using the constant ratio method. Applications to geological samples. Talanta 2002, 58, 811–821. [Google Scholar]

- Neff, H.; Bigney, S.J.; Sakai, S.; Burger, P.R.; Garfin, T.; George, R.G.; Cullteon, B.J.; Kennett, D.J. Characterization of Archaeological Sediments Using Fourier Transform Infrared (FT-IR) and Portable X-ray Fluoresence (pXRF): An Application to Formative Period Pyro-Industrial Sites in Pacific Coastal Southern Chiapas, Mexico. Appl. Spectrosc. 2016, 70, 110–127. [Google Scholar] [CrossRef]

- Regev, L.; Poduska, K.M.; Addadi, L.; Weiner, S.; Boaretto, E. Distinguishing between calcites formed by different mechanisms using infrared spectrometry: Archaeological applications. J. Archaeol. Sci. 2010, 37, 3022–3029. [Google Scholar] [CrossRef] [Green Version]

- De La Fuente, G.A. Post-Depositional Chemical Alterations in Archaeological Ceramics: A critical review and implications for their conservation. Boletín del Laboratorio de Petrología y Conservación Cerámica 2008, 1, 21–37. [Google Scholar]

- Hedges, R.E.M. Bone diagenesis: An overview of processes. Archaeometry 2002, 44, 319–328. [Google Scholar] [CrossRef]

- Kendall, C.; Høier Eriksen, A.M.; Kontopoulos, I.; Collins, M.J.; Turner-Walker, G. Diagenesis of archaeological bone and tooth. Palaeogeogr. Palaeocl. 2008, 491, 21–37. [Google Scholar] [CrossRef] [Green Version]

- Nielsen-Marsh, C.M.; Hedges, R.E.M. Patterns of diagenesis in bone I: The effects of site environments. J. Archaeol. Sci. 2000, 27, 1139–1150. [Google Scholar] [CrossRef]

- Rottländer, R.C.A. Über die Veränderungen von Elementkonzentrationen in keramischen Scherben während der Bodenlagerung (Teil 1). Sprechsaal 1981, 114, 742–745. [Google Scholar]

- Aoyama, H.; Yamagiwa, K.; Fujimoto, S.; Izumi, J.; Ganeko, S.; Kameshima, S. Non-destructive elemental analysis of prehistoric potsherds in the southern Ryukyu Islands, Japan: Consideration of the pottery surface processing technique in the boundary region between the Japanese Jōmon and Neolithic Taiwan. J. Archaeol. Sci. Rep. 2020, 33, 102512. [Google Scholar] [CrossRef]

- Snoeck, C.; Lee-Thorp, J.A.; Schulting, R.J. From bone to ash: Compositional and structural changes in burned modern and archaeological bone. Palaeogeogr. Palaeocl. 2014, 416, 55–68. [Google Scholar] [CrossRef]

- Snoeck, C.; Lee-Thorp, J.; Schulting, R.; de Jong, J.; Debouge, W.; Mattielli, N. Calcined bone provides a reliable substrate for strontium isotope ratios as shown by an enrichment experiment. Rapid Commun. Mass Spectrom. 2015, 29, 107–114. [Google Scholar] [CrossRef] [Green Version]

- Snoeck, C.; Staff, R.A.; Brock, F. A reassessment of the routine pretreatment protocol for radiocarbon dating cremated bones. Radiocarbon 2016, 58, 1–8. [Google Scholar] [CrossRef]

- Quarato, E.; Giblin, J.I. Burning Questions about Preservation: An Investigation of Cremated Bone Crystallinity at a Bronze Age Cemetery. Poster Presented at the 82nd Annual Meeting of the Society for American Archaeology, Vancouver, CO, Canada, 29 March–2 April 2017. [Google Scholar]

- Salminen, R.; Batista, M.J.; Bidovec, M.; Demetriades, A.; De Vivo, B.; De Vos, W.; Duris, M.; Gilucis, A.; Gregorauskiene, V.; Halamic, J.; et al. FOREGS Geochemical Atlas of Europe; Geological Survey of Finland: Espoo, Finland, 2005.

- Salisbury, R.B. Sediments, Settlements, and Space: A practice approach to Late Neolithic communities on the Great Hungarian Plain. Ph.D. Thesis, State University of New York at Buffalo, Buffalo, NY, USA, 2010. [Google Scholar]

- Giblin, J.I.; Knudson, K.J.; Bereczki, Z.; Pálfi, G.; Pap, I. Strontium isotope analysis and human mobility during the Neolithic and Copper Age: A case study from the Great Hungarian Plain. J. Archaeol. Sci. 2013, 40, 227–239. [Google Scholar] [CrossRef]

| Sample | Context | Phase | Vessel Type | TS | PXRF | LA-ICP-MS | SEM-EDS | FT-IR |

|---|---|---|---|---|---|---|---|---|

| ID001 | Cemetery | x | ||||||

| ID002 | Cemetery | x | ||||||

| ID003 | Cemetery | x | ||||||

| ID004 | Cemetery | x | ||||||

| ID005 | Cemetery | x | x | |||||

| ID006 | Cemetery | x | ||||||

| ID007 | Cemetery | x | ||||||

| ID008 | Cemetery | x | ||||||

| ID009 | Cemetery | x | x | x | ||||

| ID010 | Cemetery | x | ||||||

| ID011 | Settlement | x | ||||||

| ID012 | Cemetery | x | x | x | ||||

| ID013 | Settlement | x | ||||||

| j29 | Burial 6 | 4 | jar/urn | x | ||||

| j37 | Burial 2 | 4 | jar/urn | x | ||||

| SS1071 | Burial 70 | jar/urn | x | |||||

| SS306 | Burial 10 | 4 | jar/urn | x | ||||

| SS325 | Burial 20 | 4 | jar/urn | x | ||||

| SS328 | Burial 18 | 4 | jar/urn | x | ||||

| SS407 | Burial 24 | 4 | pitcher/jug | x | ||||

| SS410 | Burial 26 | 4 | pitcher/jug | x | ||||

| SS416 | Burial 34 | 4 | cup/mug | x | ||||

| SS429 | Burial 37 | 4 | jar/urn | x | ||||

| SS435 | Burial 23 | 4 | jar/urn | x | x | |||

| SS439 | Burial 22 | 4 | jar/urn | x | x | x | x | x |

| SS452 | Burial 26 | 4 | jar/urn | x | ||||

| SS471 | Burial 34 | 4 | jar/urn | x | x | |||

| SS486 | Burial 31 | jar/urn | x | |||||

| SS511 | Burial 28 | 4 | jar/urn | x | ||||

| SS547 | Burial 21 | 3 | jar/urn | x | ||||

| SS555 | Burial 31 | pitcher/jug | x | |||||

| SS558 | Burial 28 | 4 | pitcher/jug | x | ||||

| SS572 | Burial 13 | 4 | jar/urn | x | ||||

| SS592/593 | Burial 8 | 4 | urn | x | x | |||

| SS597 | Burial 15 | 4 | bowl | x | ||||

| SS601 | Burial 8 | 4 | bowl | x | ||||

| SS604 | Burial 13 | 4 | lid | x | ||||

| SS605 | Burial 11 | 4 | lid | x | ||||

| SS610 | Burial 13 | 4 | pitcher/jug | x | ||||

| SS614 | Burial 14 | 3 | bowl | x | ||||

| SS616 | Burial 43 | 4 | cup/mug | x | ||||

| SS618 | Burial 28 | 4 | bowl | x | ||||

| SS620 | Burial 28 | 4 | bowl | x | ||||

| SS692 | Burial 52 | 3 | cup/mug | x | ||||

| SS762 | Burial 55 | 1 | cup/mug | x | ||||

| SS782 | Burial 57 | 5 | cup/mug | x | ||||

| SS784 | Burial 57 | 5 | jar/urn | x | ||||

| SS815 | Burial 59 | 5 | pot/storage | x | ||||

| SS817 | Burial 59 | 5 | pot/storage | x | ||||

| SS818 | Burial 59 | 5 | cup/mug | x | ||||

| SS819 | Burial 59 | 5 | cup/mug | x | ||||

| SS919 | Burial 33 | 4 | bowl | x | x | x | ||

| SS952 | Burial 62 | 1 | jar/urn | x | ||||

| SS955 | Burial 66 | 4 | jar/urn | x |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golitko, M.; McGrath, A.; Kreiter, A.; Lightcap, I.V.; Duffy, P.R.; Parditka, G.M.; Giblin, J.I. Down to the Crust: Chemical and Mineralogical Analysis of Ceramic Surface Encrustations on Bronze Age Ceramics from Békés 103, Eastern Hungary. Minerals 2021, 11, 436. https://doi.org/10.3390/min11040436

Golitko M, McGrath A, Kreiter A, Lightcap IV, Duffy PR, Parditka GM, Giblin JI. Down to the Crust: Chemical and Mineralogical Analysis of Ceramic Surface Encrustations on Bronze Age Ceramics from Békés 103, Eastern Hungary. Minerals. 2021; 11(4):436. https://doi.org/10.3390/min11040436

Chicago/Turabian StyleGolitko, Mark, Alyssa McGrath, Attila Kreiter, Ian V. Lightcap, Paul R. Duffy, Györgyi M. Parditka, and Julia I. Giblin. 2021. "Down to the Crust: Chemical and Mineralogical Analysis of Ceramic Surface Encrustations on Bronze Age Ceramics from Békés 103, Eastern Hungary" Minerals 11, no. 4: 436. https://doi.org/10.3390/min11040436