Morphometric Analysis through 3D Modelling of Bronze Age Stone Moulds from Central Sardinia

Abstract

:1. Introduction

2. Materials and Methods

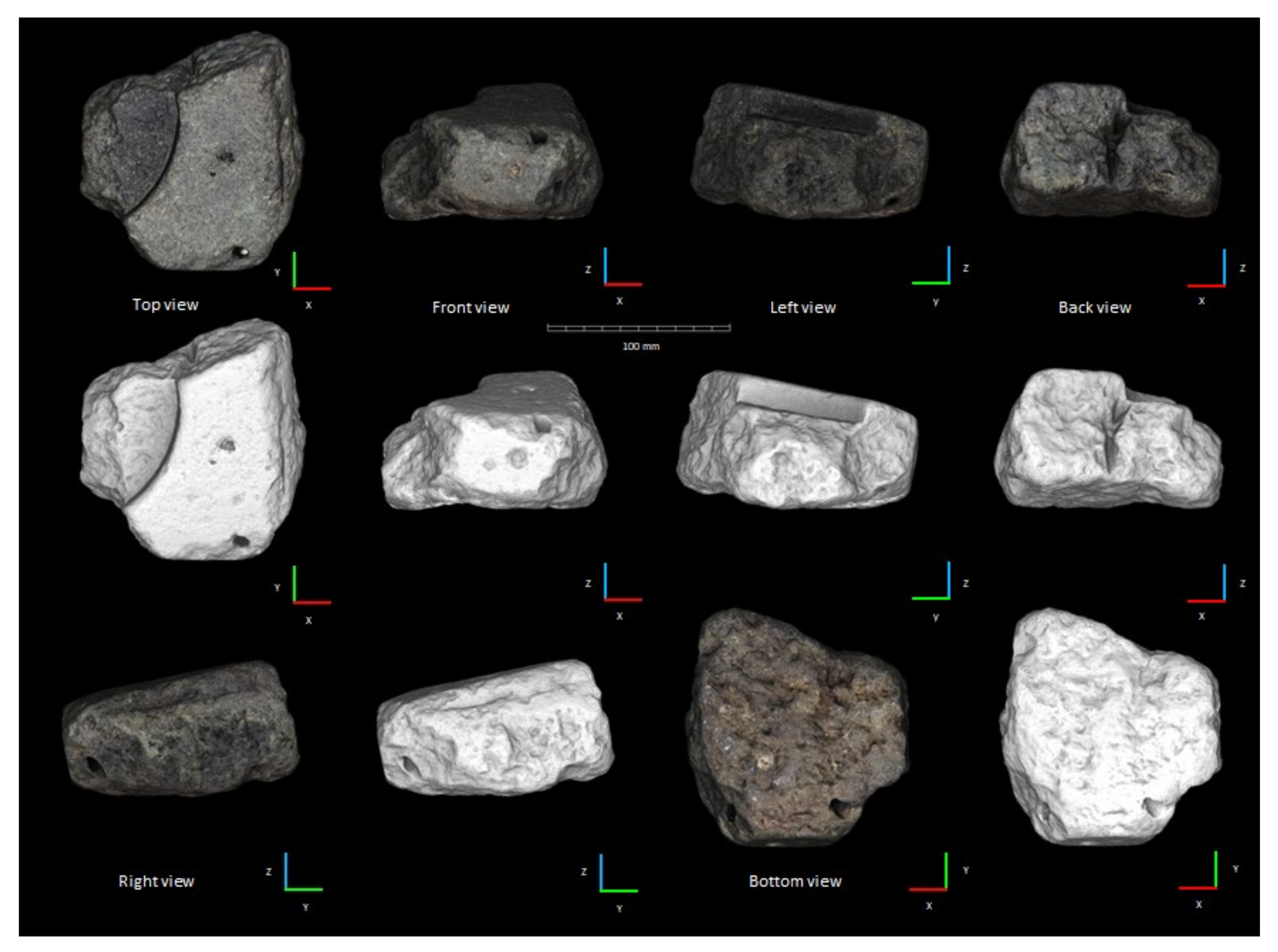

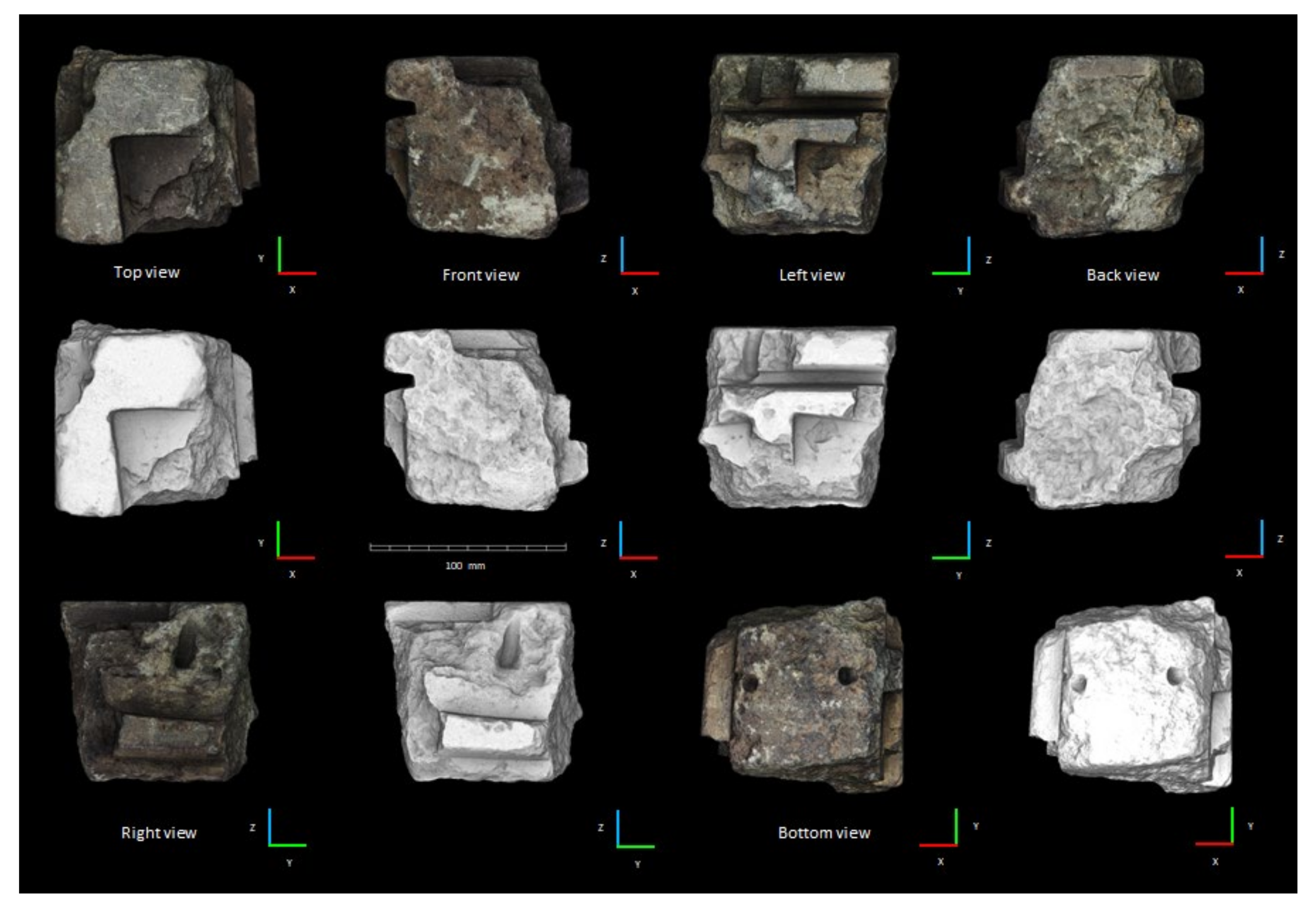

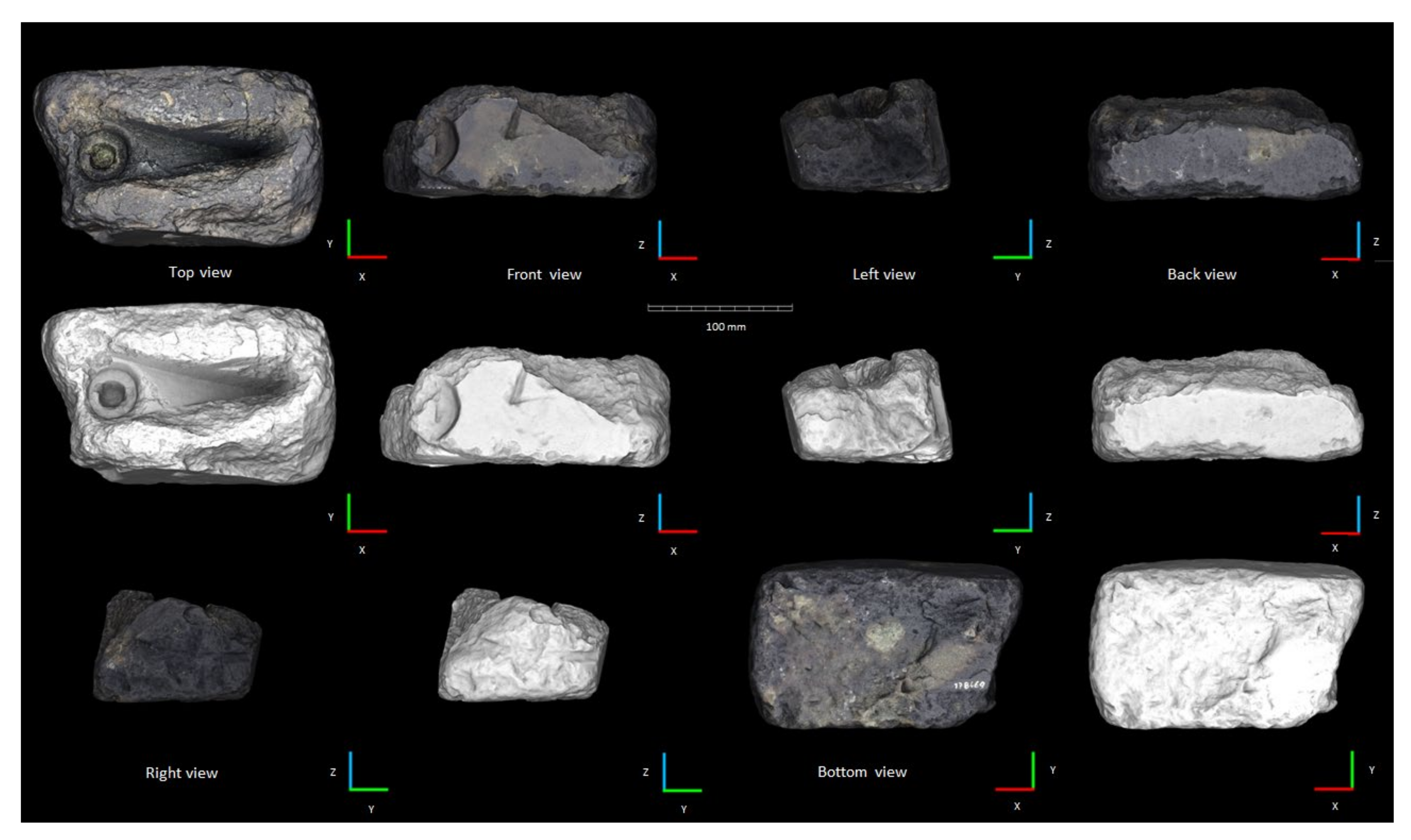

2.1. The Stone Moulds

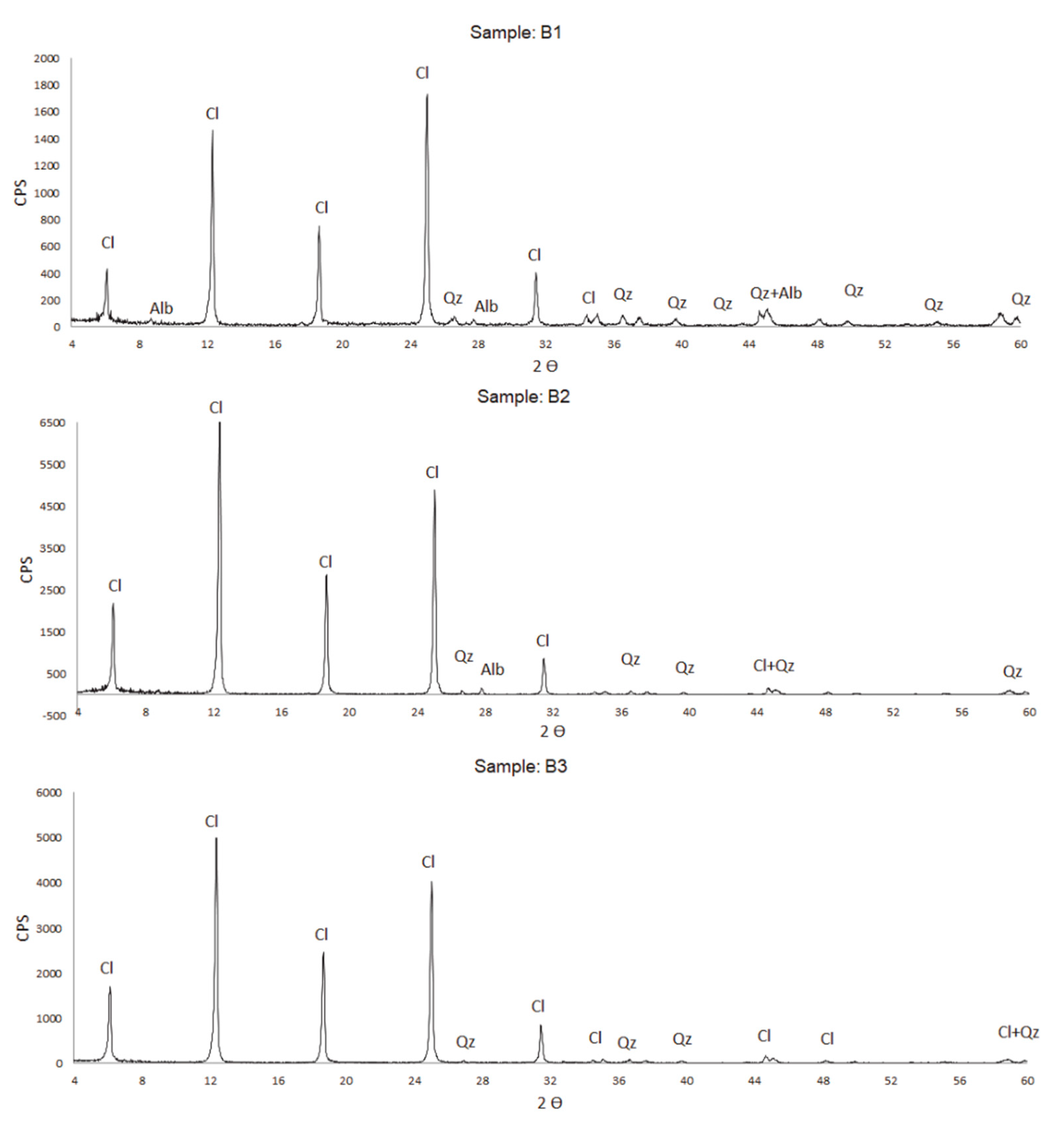

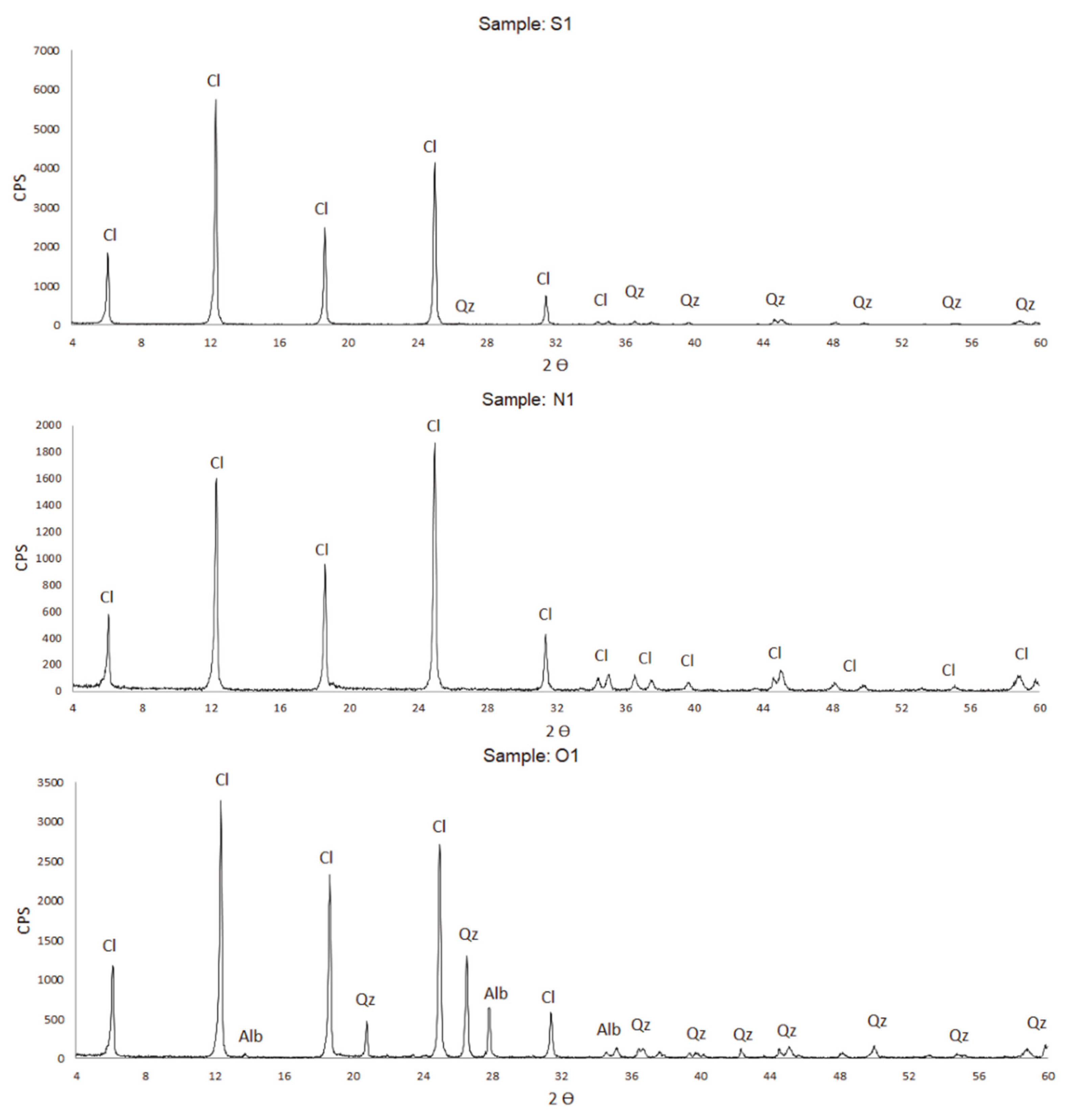

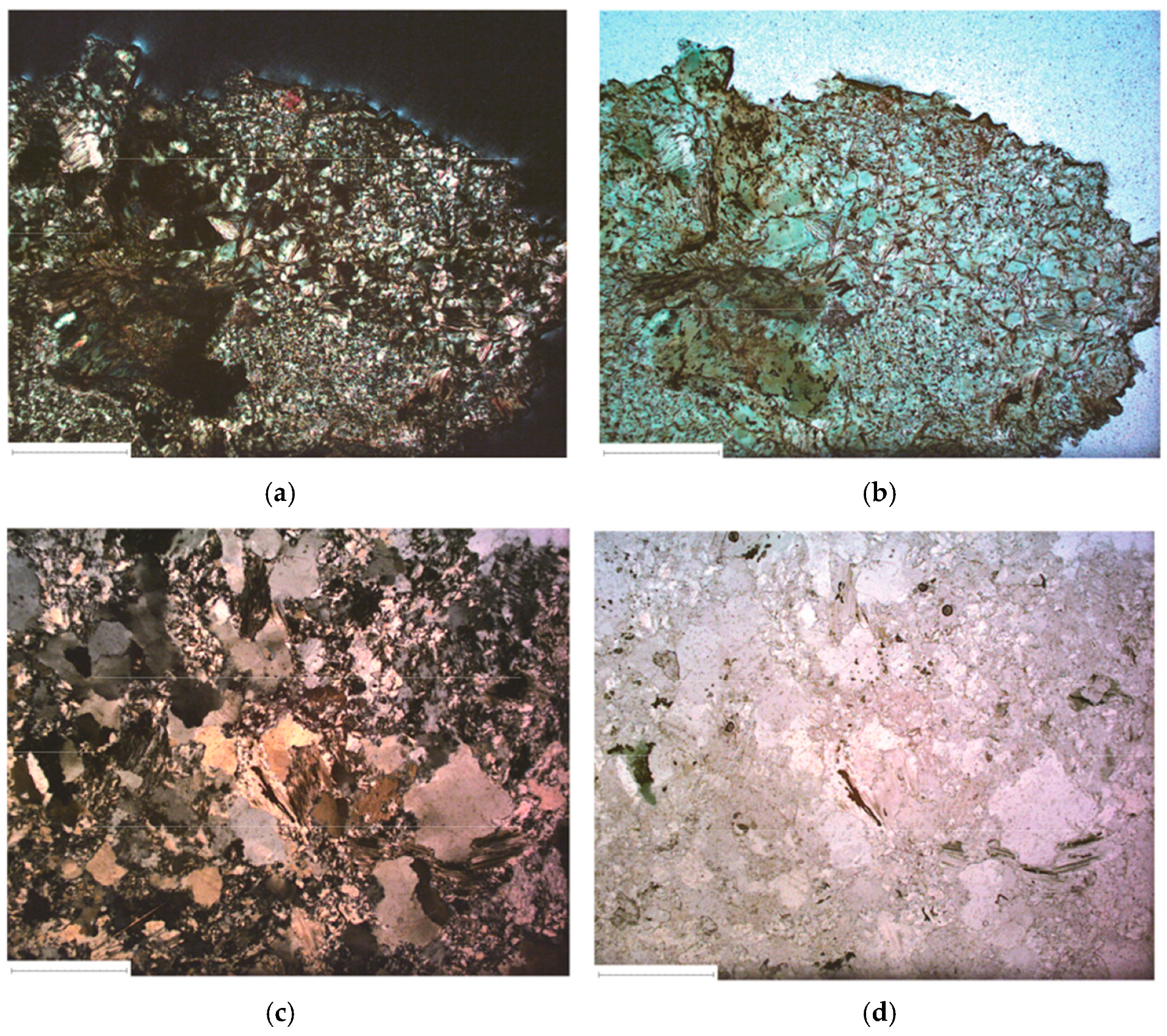

2.2. Mineralogical and Petrographic Characterization of the Stone Moulds

2.3. Photogrammetric Method and 3D Modeling

2.4. Pre-Acquisition Procedure and High-Precision Positioning

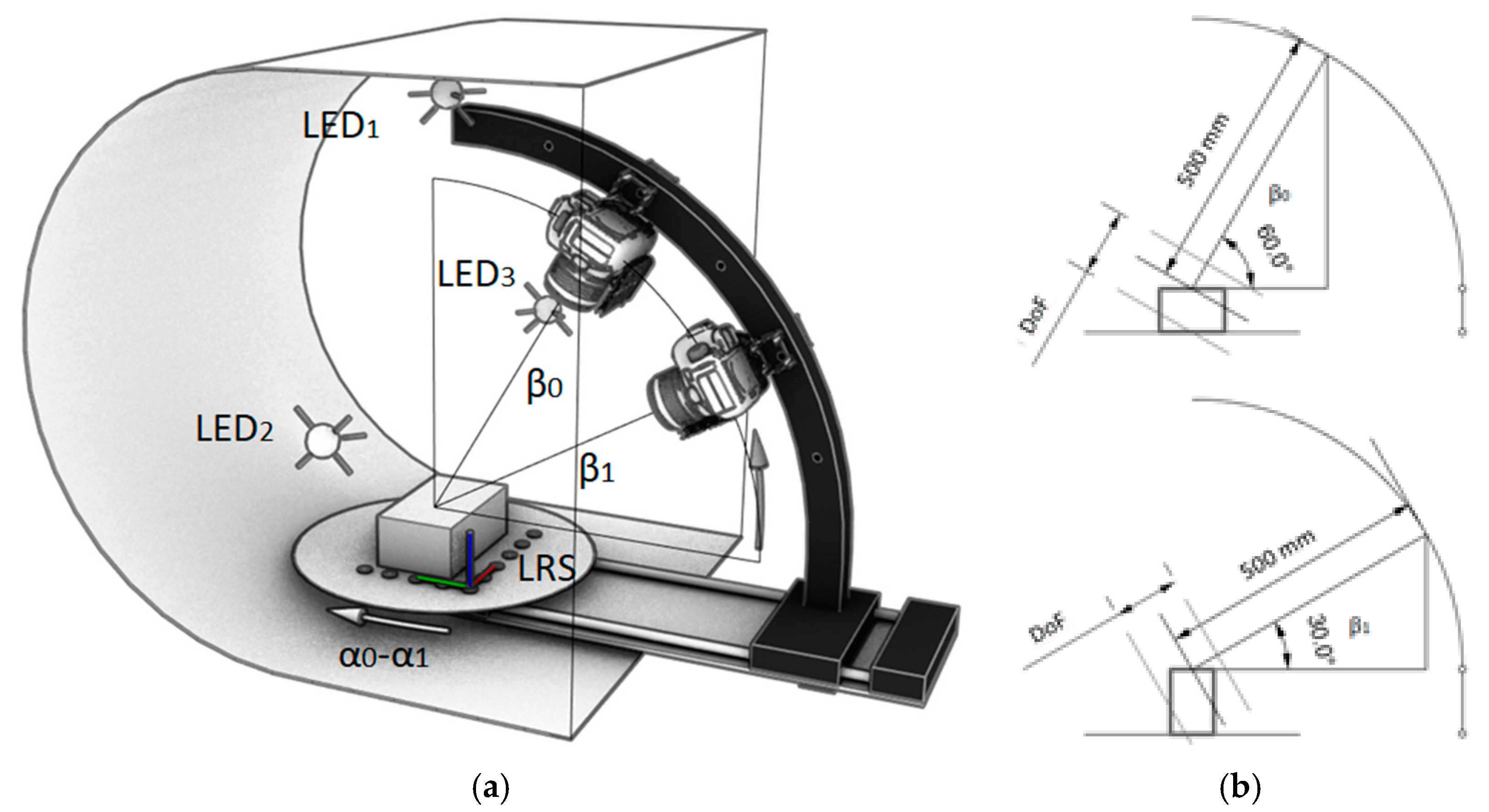

2.5. Acquisition

2.6. Image Pre-Processing

2.7. Alignment Procedure

2.8. Point Cloud Reconstruction

2.9. Texturing Procedure

2.10. Evaluation of Reconstruction Accuracy

2.11. Morphometric Analysis Procedure

3. Results and Discussion

3.1. Mineralogical-Petrographic Analysis and Provenance of Stone Materials

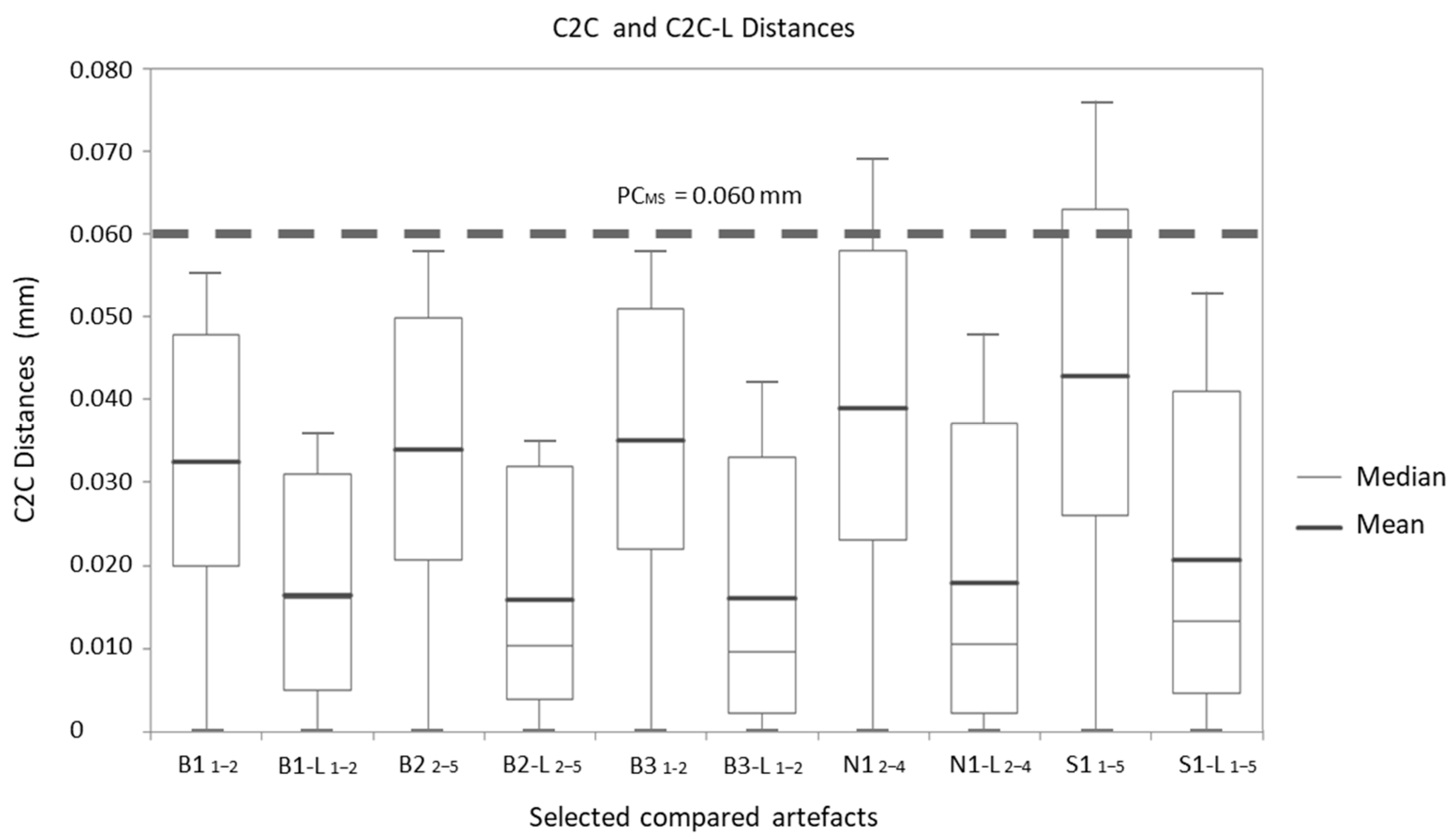

3.2. Accuracy of the Photogrammetric Models

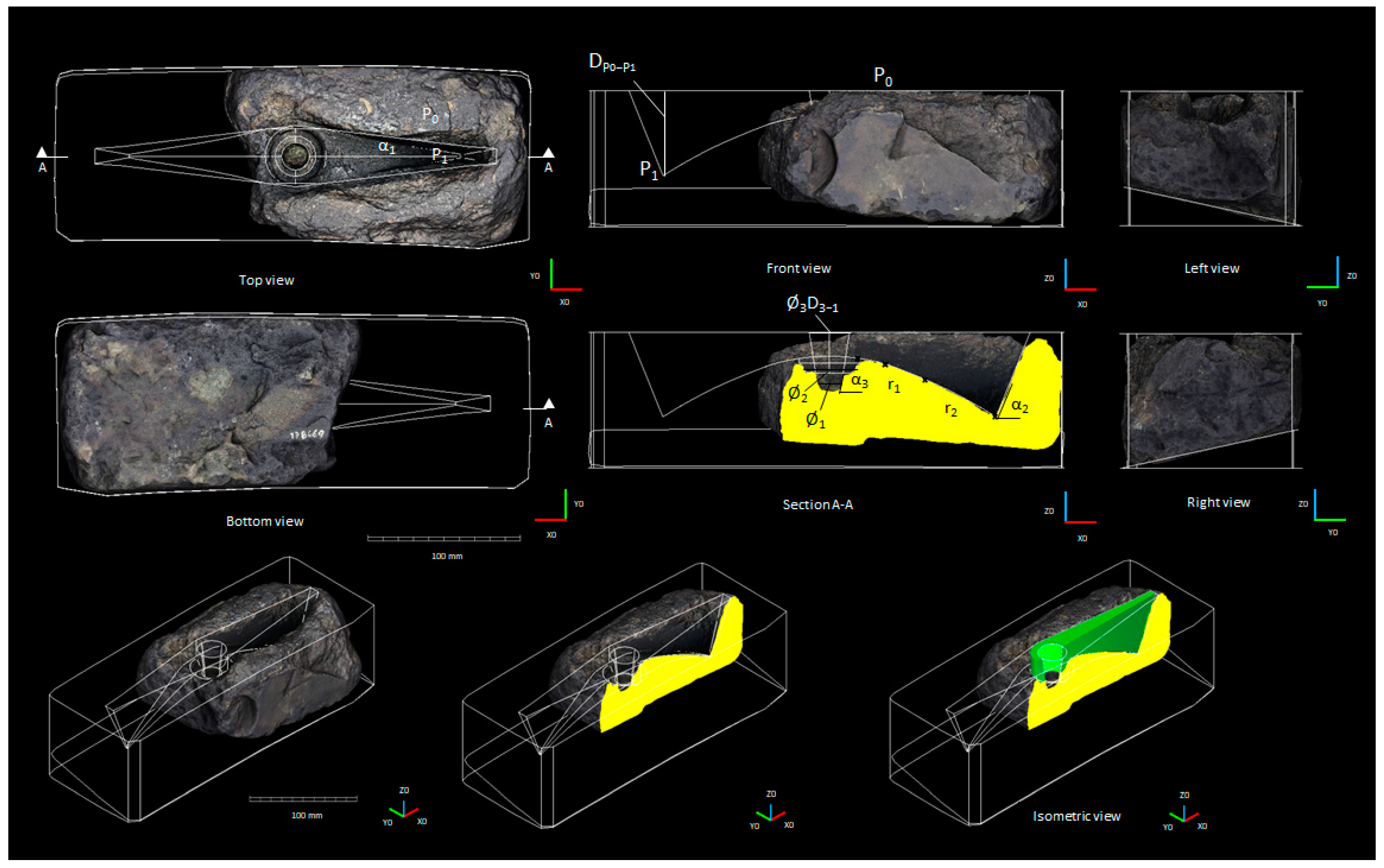

Dimensional Analysis of Archaeological Finds from 3D Models

- maximum dimension in the three axis directions (X, Y, Z);

- worked surface characteristics and orientation in space;

- angles, arches and curves characteristics of the hollows;

- minimum and maximum thicknesses of the mould area;

- reciprocal orientation of the multiple moulds with respect to the shape of the stone;

- examples of virtual reconstruction of the possible casting artefact;

- weight, volume and apparent specific weight of the stone artefact.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Usai, A. A proposito di alcune matrici nuragiche da Bidonì, Sorradile e Narbolia (OR). In Bronze Age Metallurgy on Mediterranean Islands: Volume in Honor of Robert Maddin and Vassos Karageorgis; Giumilia-Mair, A., Lo Schiavo, F., Eds.; Monographies instrumentum, 56; Editions Mergoil: Drémil-Lafage, France, 2018; pp. 377–391. ISBN 978-2-35518-083-5. [Google Scholar]

- Usai, A. Testimonianze Prenuragiche e Nuragiche nel Territorio di Narbolia. In Nurabolia-Narbolia; Zucca, R., Ed.; Una Villa di Frontiera del Giudicato di Arborea: Narbolia, Italy, 2005; pp. 21–57. [Google Scholar]

- Lo Schiavo, F. Le matrici e i crogioli della Sardegna nuragica. In Bronze Age Metallurgy on Mediterranean Islands: Volume in Honor of Robert Maddin and Vassos Karageorgis; Giumilia-Mair, A., Lo Schiavo, F., Eds.; Monographies instrumentum, 56; Editions Mergoil: Drémil-Lafage, France, 2018; pp. 195–238. ISBN 978-2-35518-083-5. [Google Scholar]

- Koutsoudis, A.; Vidmar, B.; Arnaoutoglou, F. Performance evaluation of a multi-image 3D reconstruction software on a low-feature artefact. J. Archaeol. Sci. 2013, 40, 4450–4456. [Google Scholar] [CrossRef]

- Sapirstein, P. A high-precision photogrammetric recording system for small artifacts. J. Cult. Herit. 2018, 31, 33–45. [Google Scholar] [CrossRef]

- Sapirstein, P. Accurate measurement with photogrammetry at large sites. J. Archaeol. Sci. 2016, 66, 137–145. [Google Scholar] [CrossRef]

- Jancosek, M.; Pajdla, T. Multi-view reconstruction preserving weakly-supported surface. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Colorado Springs, CO, USA, 20–25 June 2011. [Google Scholar] [CrossRef]

- RealityCapture Software, Version 1.20.16813 Tarasque [CLI Software]. Epic Game Slovakia s.r.o., Slovakia. Available online: https://www.capturingreality.com (accessed on 30 September 2021).

- Schneider, C.T.; Sinnreich, K. Optical 3-D measurement systems for quality control in industry. Int. Arch. Photogramm. Remote Sens. 1992, 29, 56–59. [Google Scholar]

- Jin, T.; Dong, X. Designing and decoding algorithm of circular coded target. Appl. Res. Comput. 2019, 36, 263–267. [Google Scholar]

- Gajski, D.; Gasparovic, M. Applications of macro photogrammetry in archaeology. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2016, XLI-B5, 263–266. [Google Scholar] [CrossRef] [Green Version]

- Brown, D.C. Close-range camera calibration. Photogramm. Eng. 1971, 37, 855–866. [Google Scholar]

- Besl, P.J.; MacKay, N.D. A method fo registration of 3-D shapes. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 239–256. [Google Scholar] [CrossRef]

- CloudCompare, Version 2.11.3 [GNU GPL Software]. 2021. Available online: http://www.cloudcompare.org (accessed on 30 September 2021).

- Lerma, J.L.; Muir, C. Evaluating the 3D documentation of an early Christian upright stone with carvings from Scotland with multiples images. J. Archaeol. Sci. 2014, 46, 311–318. [Google Scholar] [CrossRef]

- Lague, D.; Brodu, N.; Leroux, J. Accurate 3D comparison of complex topography with terrestrial laser scanner: Application to the Rangitikei canyon (N-Z). ISPRS J. Photogramm. Remote Sens. 2013, 82, 10–26. [Google Scholar] [CrossRef] [Green Version]

- Henrikson, J. Completeness and total boundedness of the hausdorff metric. MIT Undergrad. J. Math. 1999, 1, 69–80. [Google Scholar]

- Tarini, M.; Cignoni, P.; Scopigno, R. Visibility based methods and assessment for detail-recovery. In Proceedings of the IEEE Visualization, 2003. VIS 2003, Seattle, WA, USA, 19–24 October 2003; pp. 457–464. [Google Scholar] [CrossRef] [Green Version]

- Fiori, C.; Grillo, S.M. Albite-chlorite and talc-chlorite deposits in metasedimentary and granitoid rocks of central Sardinia (Italy). Boletim Paranaense de Geociências 2002, 50, 51–57. [Google Scholar] [CrossRef] [Green Version]

- Delaunay, B. Sur la sphere vide. Bull. Acad. Sci. USSR Classe Sci. Mat. Nat. 1934, 7, 793–800. [Google Scholar]

- Galantucci, L.M.; Pesce, M.; Lavecchia, F. A stereo photogrammetry scanning methodology, for precise and accurate 3D digitization of small parts with sub-millimeter sized features. CIRP Ann. Manuf. Technol. 2015, 64, 507–510. [Google Scholar] [CrossRef]

- Galantucci, L.M.; Pesce, M.; Lavecchia, F. A powerful scanning methodology for 3D measurements of small parts with complex surfaces and sub millimeter-sized features, based on close range photogrammetry. Precis. Eng. 2016, 43, 211–219. [Google Scholar] [CrossRef]

| Artefact | Length Max | Width Max | Height Max | External Color (RGB) | Mould Color (RGB) |

|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | |||

| B1 | 100.8 | 75.7 | 48.1 | 61–59–56 | 68–60–54 |

| B2 | 95.0 | 114.7 | 65.1 | 53–54–52 | 45–45–43 |

| B3 | 124.6 | 133.2 | 76.2 | 88–89–93 | 35–36–34 |

| N1 | 111.7 | 104.5 | 95.3 | 85–76–62 | 104–91–71 |

| S1 | 201.9 | 125.5 | 83.8 | 109–109–113 | 60–59–64 |

| Artefact | Focal Length | Camera Tilt | Step Angle | Object Side | D | DoF | Aperture | n. Images |

|---|---|---|---|---|---|---|---|---|

| (mm) | (β) | (α) | (n) | (mm) | (mm) | ≥6 | ||

| B 1 * | 50 | 60 | 12 | 1 | 500 | 87 | f/16 | 10 |

| B 2 * | 50 | 60 | 12 | 1 | 500 | 87 | f/16 | 10 |

| B 3 * | 50 | 60 | 12 | 1 | 500 | 87 | f/16 | 10 |

| N1 * | 50 | 60 | 12 | 1 | 500 | 124 | f/22 | 10 |

| S1 * | 50 | 60 | 12 | 1 | 500 | 124 | f/22 | 10 |

| B 1 | 50 | 60 | 12 | 6 | 500 | 87 | f/16 | 180 |

| B 2 | 50 | 60 | 12 | 6 | 500 | 87 | f/16 | 180 |

| B 3 | 50 | 60 | 12 | 6 | 500 | 87 | f/16 | 180 |

| N1 | 50 | 60 | 12 | 6 | 500 | 124 | f/22 | 180 |

| S1 | 50 | 30 | 12 | 2 | 500 | 124 | f/22 | 60 |

| S1 | 50 | 30/60 | 7/12 | 2 | 500 | 124 | f/22 | 162 |

| Artefact | Camera’s Count | Triangle’s Count | Point’s Count | Max Error (pix) | Median Error (pix) | Mean Error (pix) |

|---|---|---|---|---|---|---|

| B1 | 190 | 5.6 M | 2.8 M | 0.623999 | 0.185081 | 0.217189 |

| B2 | 190 | 8.7 M | 4.4 M | 0.623997 | 0.198011 | 0.229245 |

| B3 | 190 | 11.2 M | 5.6 M | 0.623962 | 0.195791 | 0.226403 |

| N1 | 190 | 15.2 M | 7.6 M | 0.623998 | 0.195359 | 0.226753 |

| S1 | 232 | 21.5 M | 10.8 M | 0.561598 | 0.184055 | 0.211238 |

| Compared | B1 | B2 | B3 | N1 | S1 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| C2C Distance | M (mm) | SD (mm) | M (mm) | SD (mm) | M (mm) | SD (mm) | M (mm) | SD (mm) | M (mm) | SD (mm) |

| 1–2 | 0.032 | 0.012 | 0.034 | 0.014 | 0.035 | 0.013 | 0.039 | 0.016 | 0.04 | 0.018 |

| 1–3 | 0.036 | 0.012 | 0.034 | 0.014 | 0.035 | 0.013 | 0.042 | 0.015 | 0.046 | 0.017 |

| 1–4 | 0.034 | 0.011 | 0.037 | 0.013 | 0.038 | 0.014 | 0.042 | 0.015 | 0.045 | 0.018 |

| 1–5 | 0.036 | 0.011 | 0.035 | 0.012 | 0.036 | 0.015 | 0.039 | 0.017 | 0.043 | 0.017 |

| 2–3 | 0.031 | 0.013 | 0.031 | 0.015 | 0.033 | 0.015 | 0.036 | 0.016 | 0.043 | 0.017 |

| 2–4 | 0.030 | 0.014 | 0.032 | 0.013 | 0.038 | 0.012 | 0.039 | 0.016 | 0.041 | 0.018 |

| 2–5 | 0.030 | 0.014 | 0.034 | 0.013 | 0.037 | 0.012 | 0.039 | 0.016 | 0.045 | 0.017 |

| 3–4 | 0.031 | 0.013 | 0.032 | 0.012 | 0.035 | 0.013 | 0.037 | 0.017 | 0.042 | 0.018 |

| 3–5 | 0.032 | 0.012 | 0.033 | 0.013 | 0.033 | 0.014 | 0.035 | 0.018 | 0.044 | 0.015 |

| 4–5 | 0.032 | 0.012 | 0.036 | 0.012 | 0.034 | 0.013 | 0.041 | 0.016 | 0.042 | 0.018 |

| Compared | C2C Distance | C2C Q95 | C2C-L Distance | C2C-L Q95 | ||

|---|---|---|---|---|---|---|

| M (mm) | SD (mm) | (mm) | M (mm) | SD (mm) | (mm) | |

| B1 1–2 | 0.032 | 0.012 | 0.055 | 0.016 | 0.011 | 0.036 |

| B2 2–5 | 0.034 | 0.013 | 0.058 | 0.016 | 0.011 | 0.035 |

| B3 1–2 | 0.035 | 0.013 | 0.058 | 0.016 | 0.012 | 0.042 |

| N1 2–4 | 0.039 | 0.016 | 0.069 | 0.018 | 0.017 | 0.048 |

| S1 1–5 | 0.043 | 0.017 | 0.076 | 0.021 | 0.018 | 0.053 |

| Compared | C2C-X | M ± 2SD | C2C-Y | M ± 2SD | C2C-Z | M ± 2SD | |||

|---|---|---|---|---|---|---|---|---|---|

| M (mm) | SD (mm) | (mm) | M (mm) | SD (mm) | (mm) | M (mm) | SD (mm) | (mm) | |

| B1 1–2 | 0.001 | 0.022 | 0.001 ± 0.044 | 0.003 | 0.023 | 0.003 ± 0.046 | 0.001 | 0.021 | 0.001 ± 0.042 |

| B2 2–5 | 0.001 | 0.022 | 0.001 ± 0.044 | 0.002 | 0.023 | 0.002 ± 0.046 | −0.003 | 0.020 | −0.003 ± 0.040 |

| B3 1–2 | 0.002 | 0.023 | 0.002 ± 0.046 | 0.003 | 0.022 | 0.006 ± 0.044 | 0.002 | 0.019 | 0.002 ± 0.038 |

| N1 2–4 | −0.003 | 0.025 | −0.003 ± 0.050 | −0.003 | 0.024 | −0.003 ± 0.048 | 0.001 | 0.024 | 0.001 ± 0.048 |

| S1 1–5 | 0.003 | 0.028 | 0.003 ± 0.056 | 0.004 | 0.028 | 0.004 ± 0.056 | 0.002 | 0.026 | 0.002 ± 0.052 |

| Artefact | X Length Max | Y Width Max | Z Height Max | Faces | Casting | Holes |

|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | num. | num. | num. | |

| B1 | 100.696 ± 0.044 | 75.584 ± 0.046 | 47.976 ± 0.056 | 6 | 1 | 2 |

| B2 | 95.021 ± 0.044 | 114.746 ± 0.046 | 65.005 ± 0.040 | 6 | 3 | 0 |

| B3 | 124.507 ± 0.046 | 133.235 ± 0.044 | 76.102 ± 0.038 | 6 | 1 | 1 |

| N1 | 111.677 ± 0.050 | 104.586 ± 0.048 | 95.201 ± 0.056 | 6 | 7 | 3 |

| S1 | 201.938 ± 0.058 | 125.468 ± 0.056 | 83.905 ± 0.052 | 6 | 1 | 0 |

| Artefact | Weight (g) | Mean Volume (cm3) | Mean Volumetric Error (%) | Mean Specific Weight * (g/cm3) | Mean Specific Weight * (Kg/m3) |

|---|---|---|---|---|---|

| B1 | 469.38 | 176.85 | 0.070 | 2.654129 | 2654.13 |

| B2 | 1079.59 | 389.68 | 0.065 | 2.770460 | 2770.46 |

| B3 | 1660.46 | 601.14 | 0.062 | 2.762190 | 2762.19 |

| N1 | 1563.70 | 572.93 | 0.068 | 2.729289 | 2729.29 |

| S1 | 3066.95 | 1123.01 | 0.070 | 2.731021 | 2731.02 |

| Artefact | X Length Max | Y Width Max | Z Height Max | Faces | Casting | Holes | Weight | Mean Volume |

|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | num. | num. | num. | (g) | (cm3) | |

| S1 | 200.25 | 119.932 | 87.855 | 6 | 1 | 0 | 3066.95 | 1123.01 |

| Casting Mould | DP0−P1 | Øm1/D1 | Øm2/D2 | α1 | α2 | α3 | r1 (3pts.) | r2 (3pts.) |

| (mm) | (mm) | (mm) | (°) | (°) | (°) | (mm) | (mm) | |

| S1 | 55.38 | 16.32/13.01 | 34.43/5.89 | 80.9 | 68.4 | 81.3 | 146.6 | 336.25 |

| Cast Axe | X/2 Length max | Y Width max | Z Height max | X/2 Length min | Y Width min | Z Height min | Øm1 | Ø3/D1-3 |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | |

| S1 | 131.84 | 40.51 | 55.57 | 109.44 | 9.98 | 26.58 | 18.11 | 26.33/26.58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cara, S.; Valera, P.; Matzuzzi, C. Morphometric Analysis through 3D Modelling of Bronze Age Stone Moulds from Central Sardinia. Minerals 2021, 11, 1192. https://doi.org/10.3390/min11111192

Cara S, Valera P, Matzuzzi C. Morphometric Analysis through 3D Modelling of Bronze Age Stone Moulds from Central Sardinia. Minerals. 2021; 11(11):1192. https://doi.org/10.3390/min11111192

Chicago/Turabian StyleCara, Stefano, Paolo Valera, and Carlo Matzuzzi. 2021. "Morphometric Analysis through 3D Modelling of Bronze Age Stone Moulds from Central Sardinia" Minerals 11, no. 11: 1192. https://doi.org/10.3390/min11111192