Analytical Model of a Multi-Step Straightening Process for Linear Guideways Considering Neutral Axis Deviation

Abstract

:1. Introduction

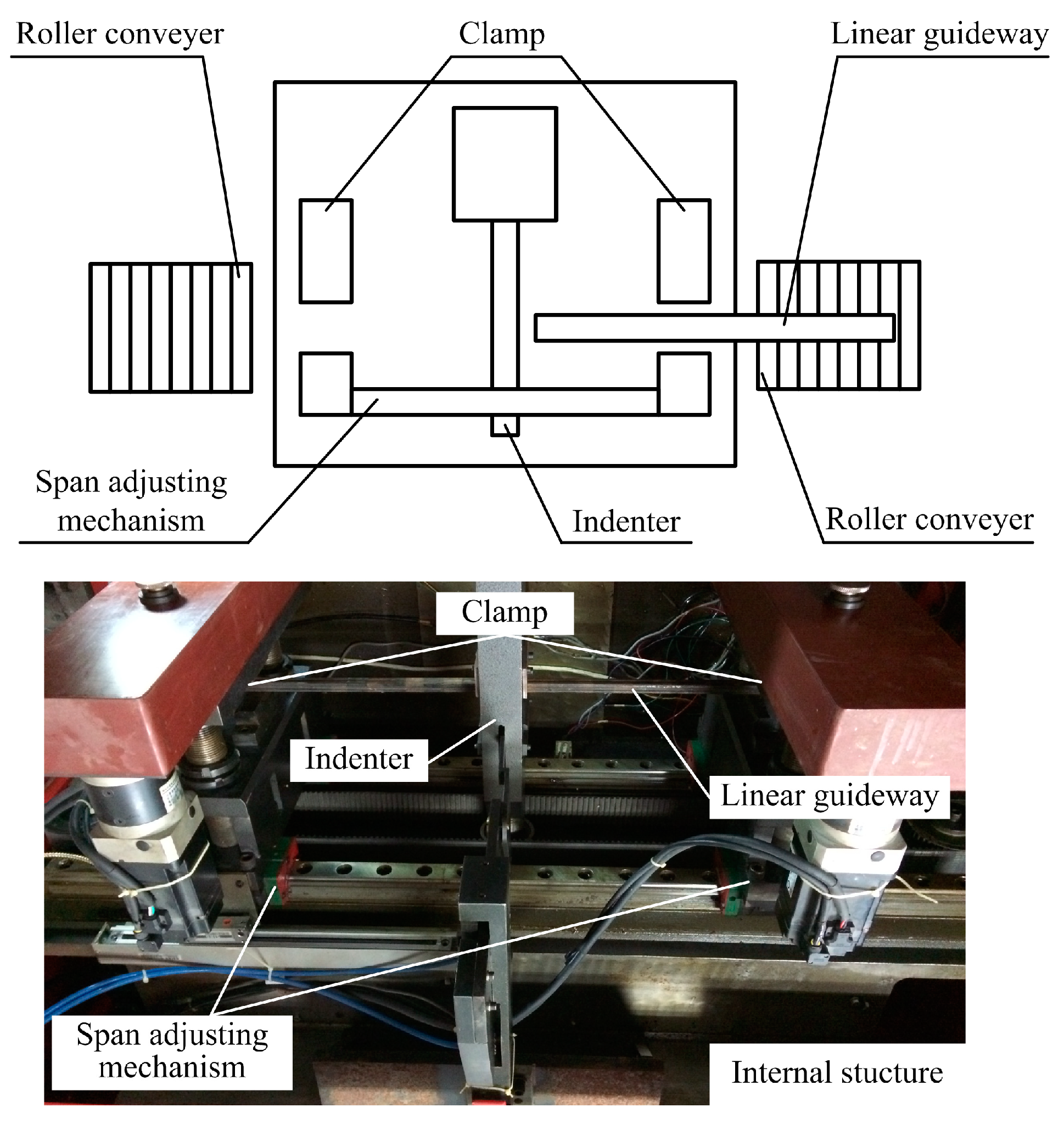

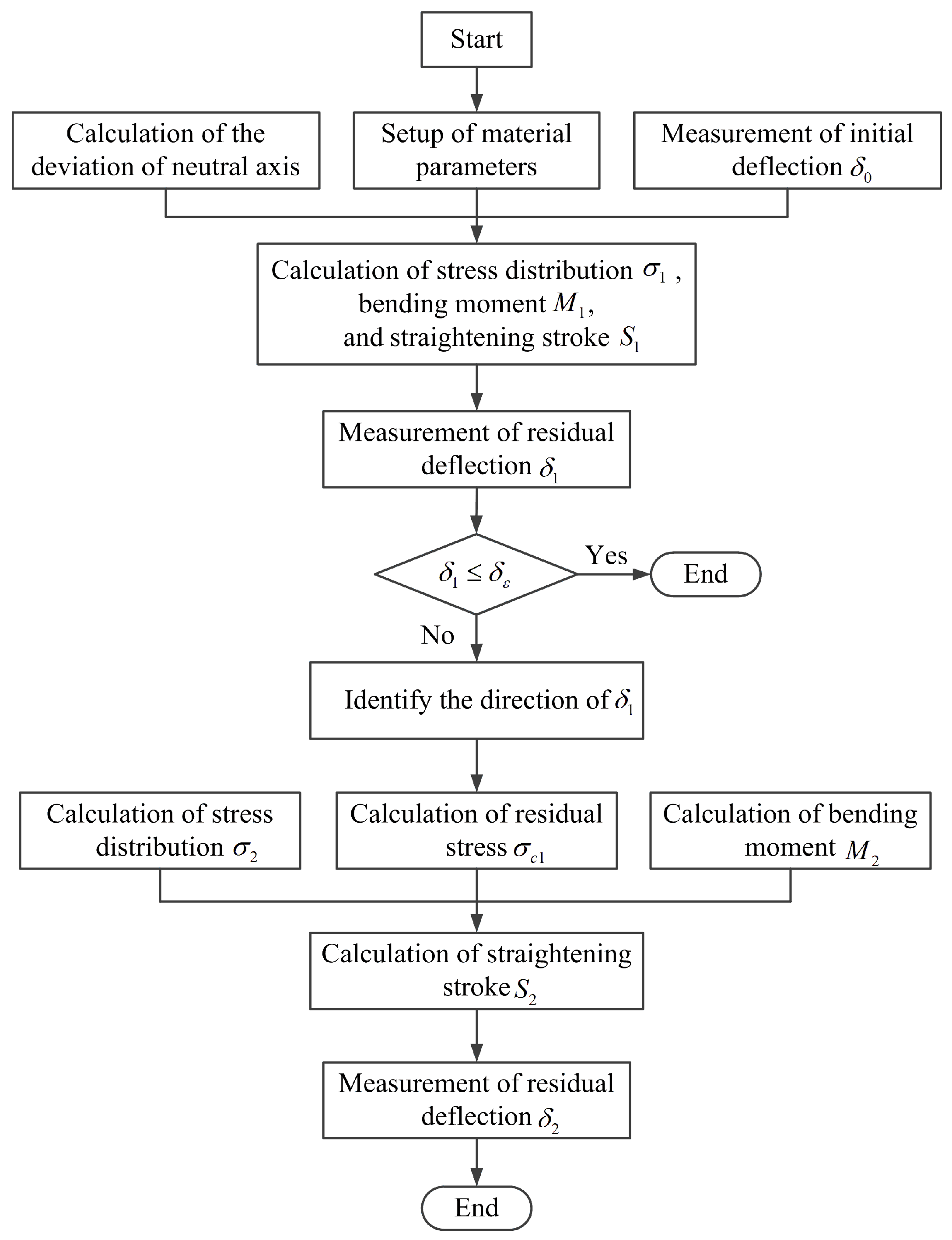

2. Straightening System of Linear Guideway

2.1. Straightening Principle

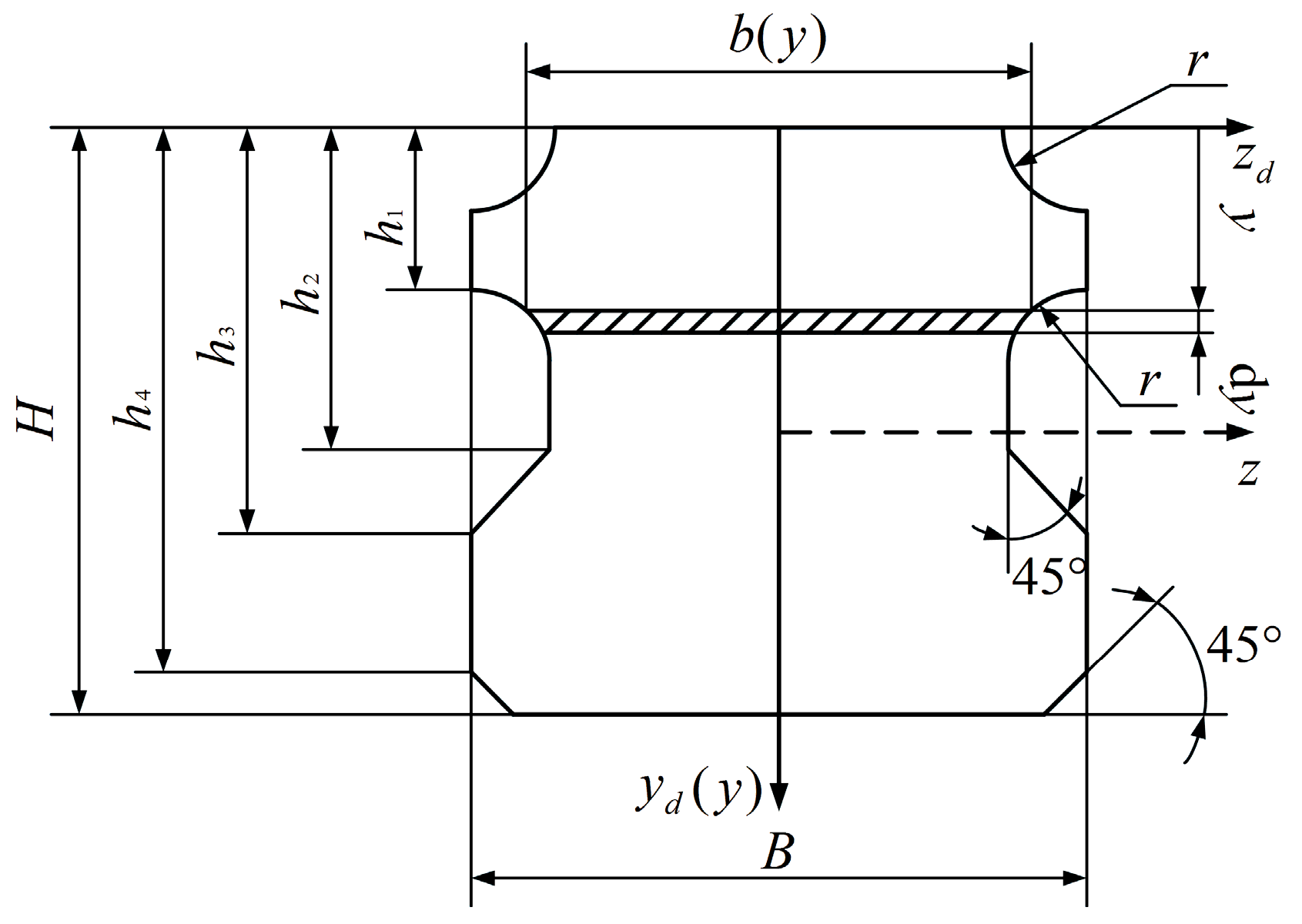

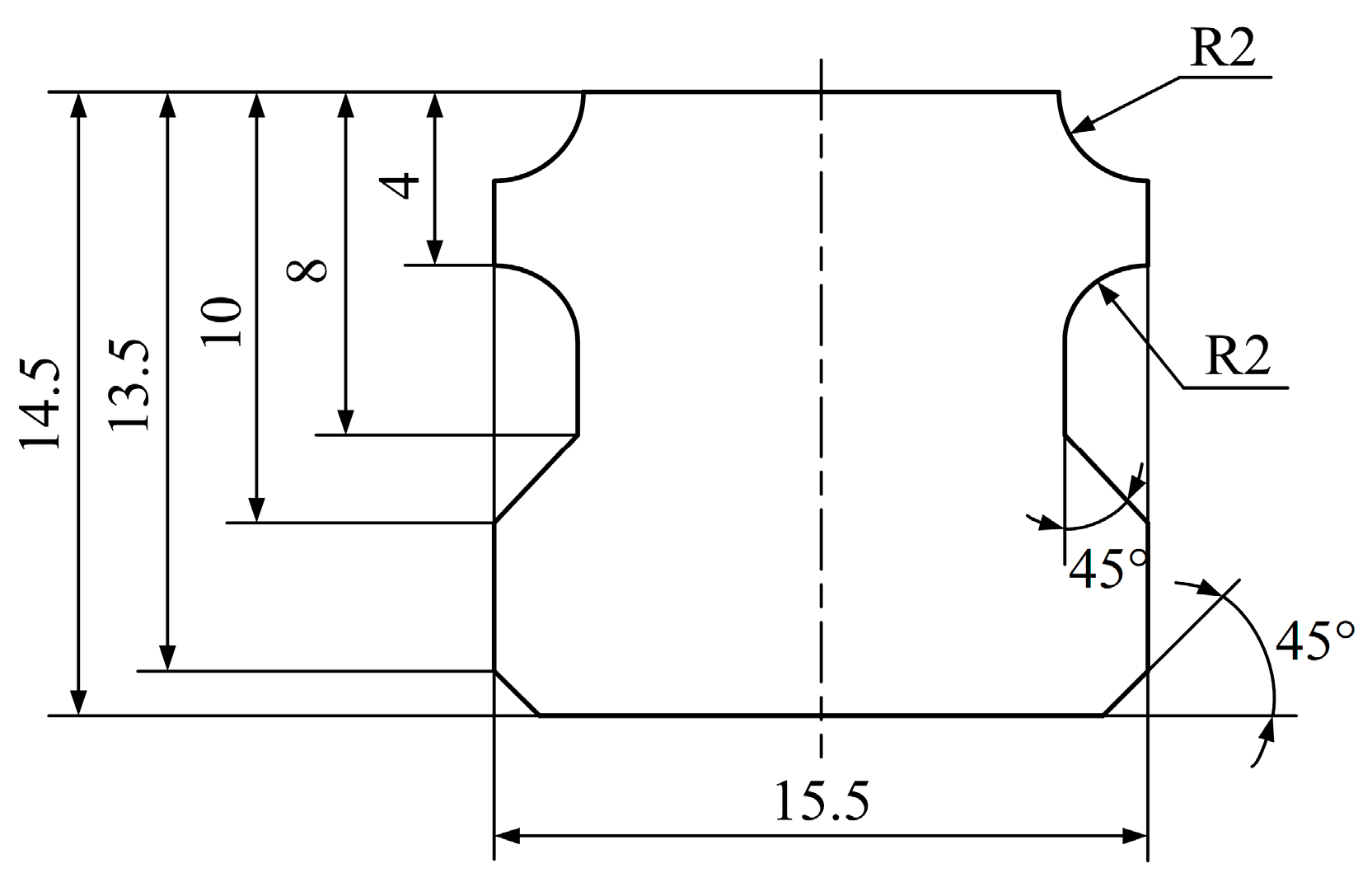

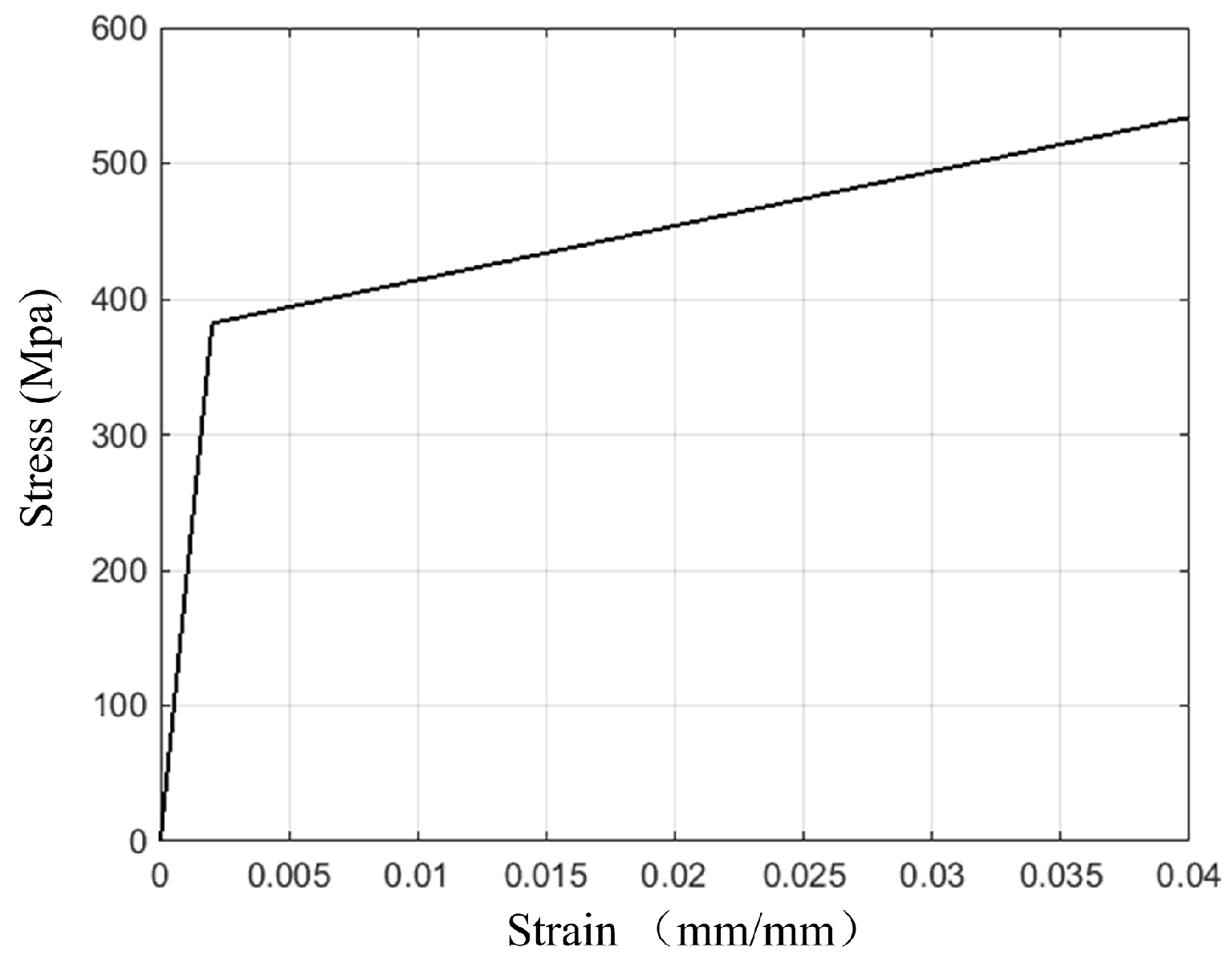

2.2. Geometrical and Material Models

3. Analytical Model of Multi-Step Straightening Process

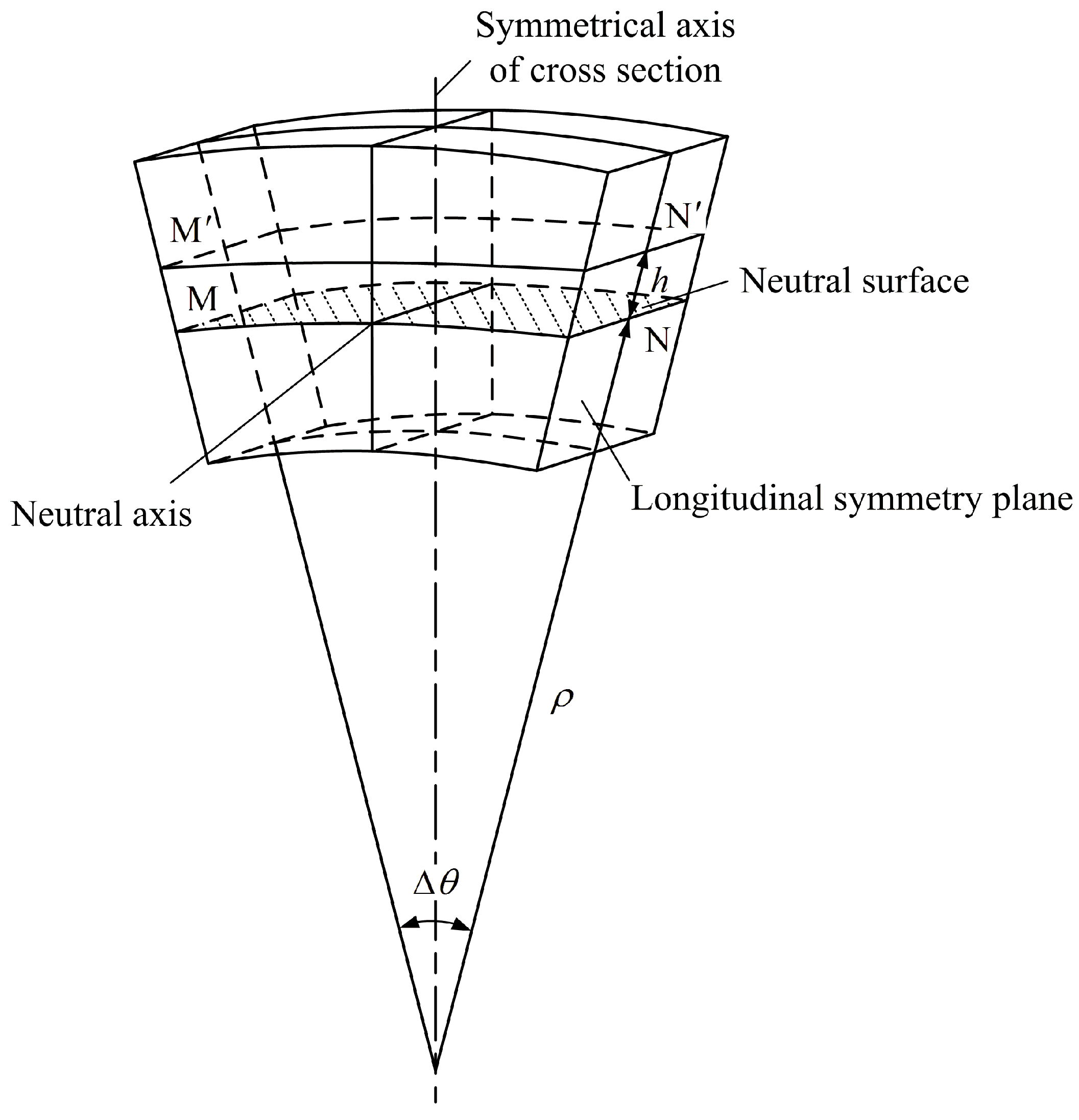

3.1. Straightening Moment

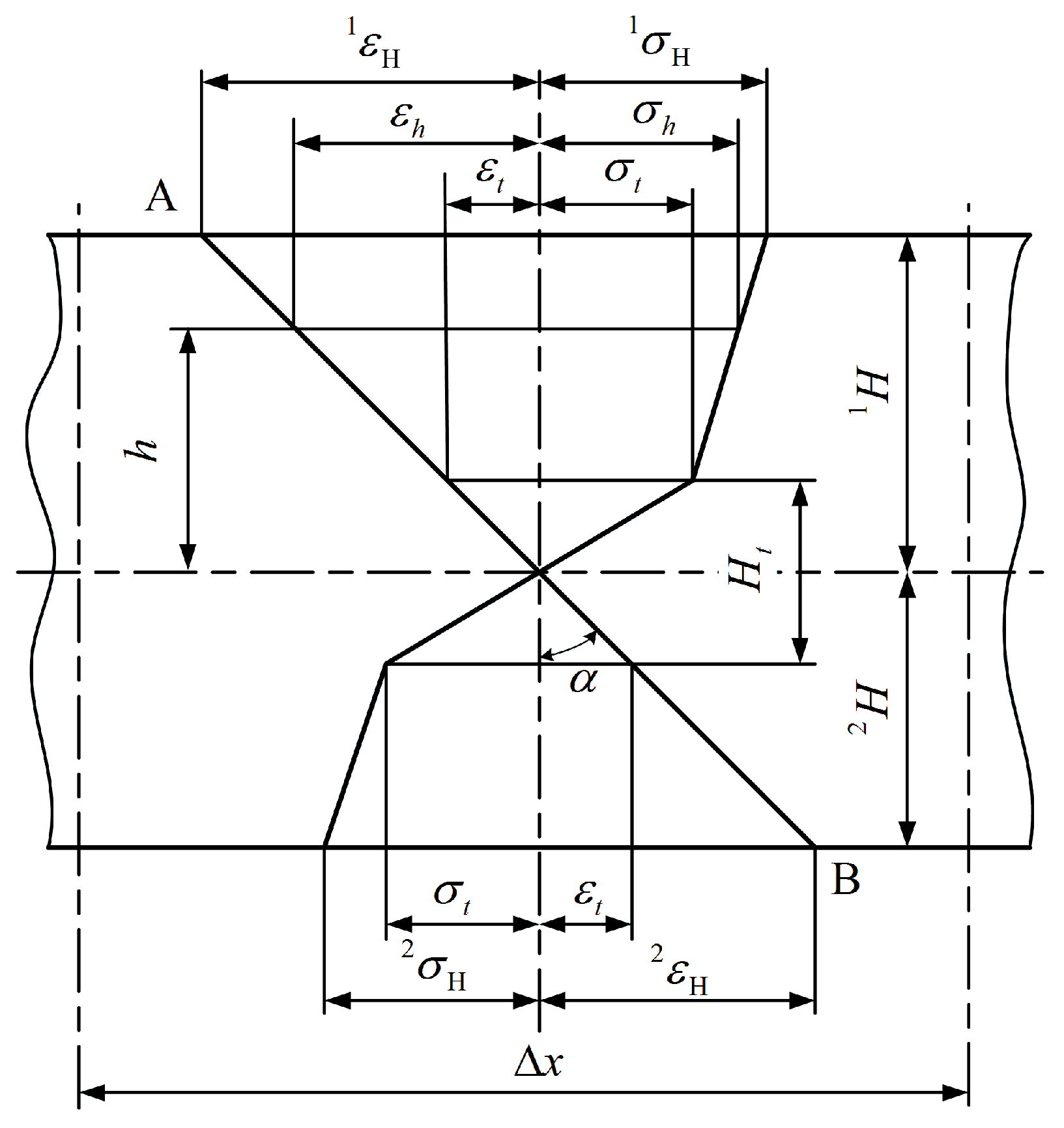

3.2. Mechanism of Residual Stress and Strain

3.3. Analytical Model of the Second Straightening Process

4. Numerical Simulation of the Multi-Step Straightening Process

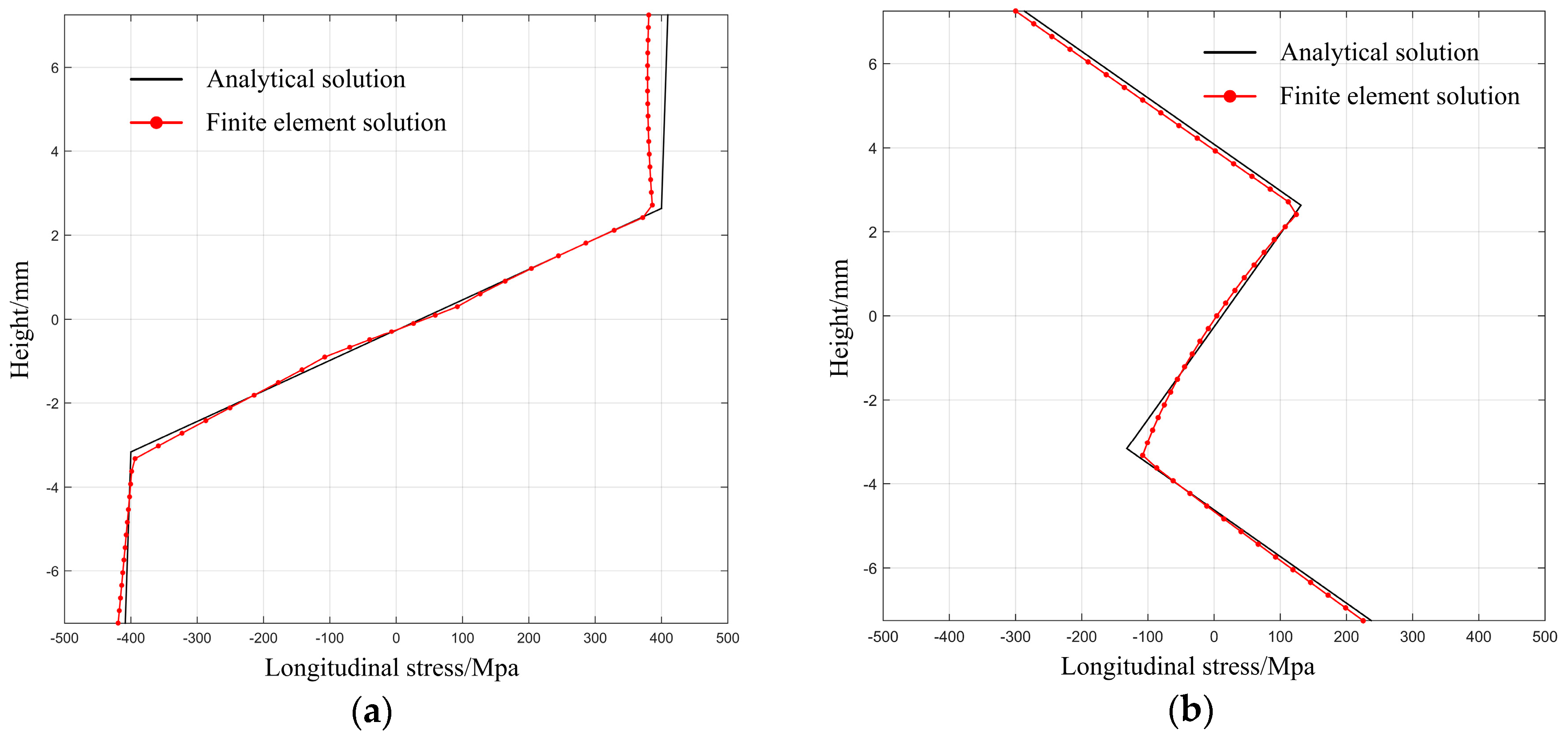

4.1. Analytical Model of the Straightening Process

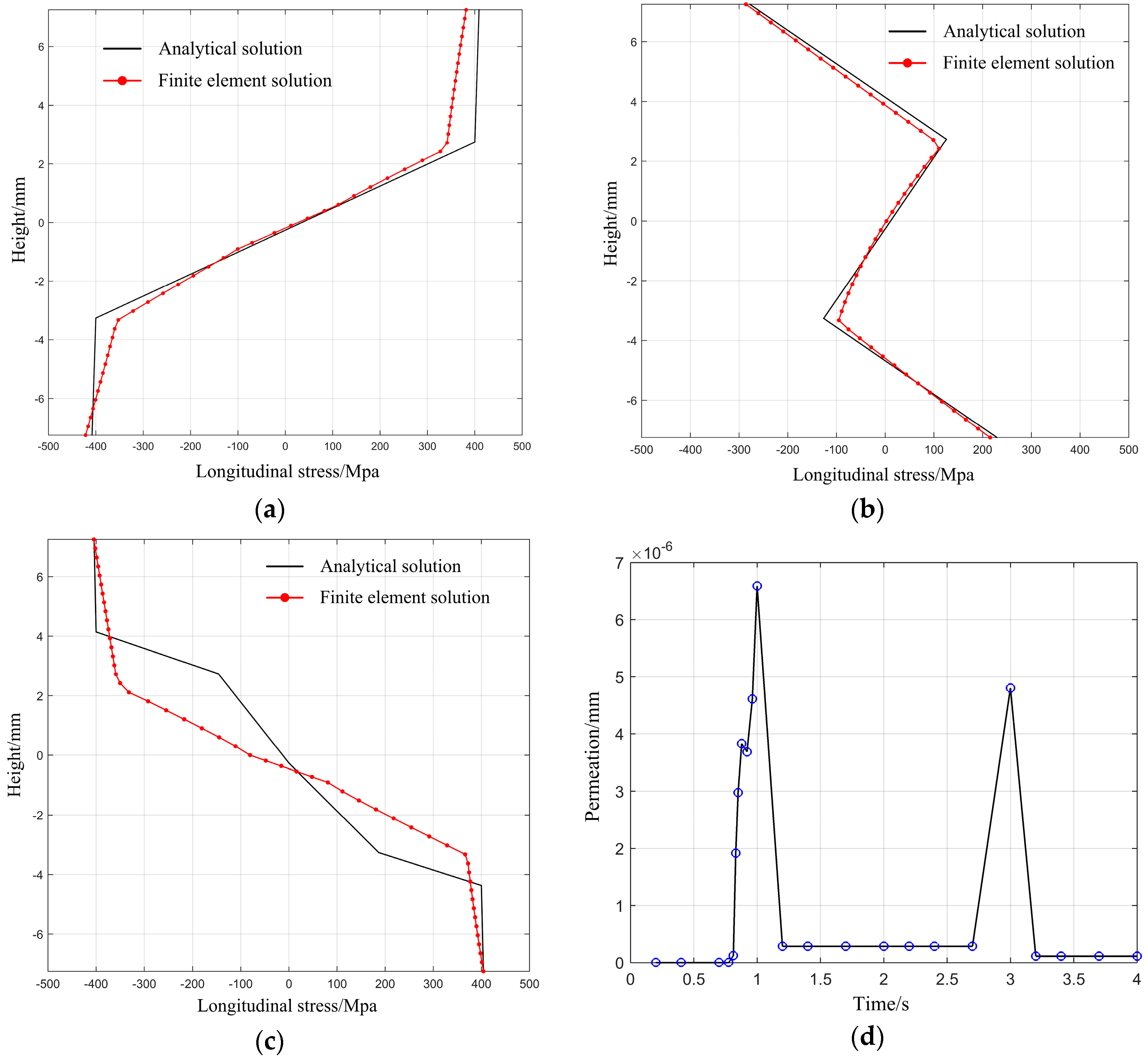

4.2. Finite Element (FE) Simulation of the Multi-Step Straightening Process

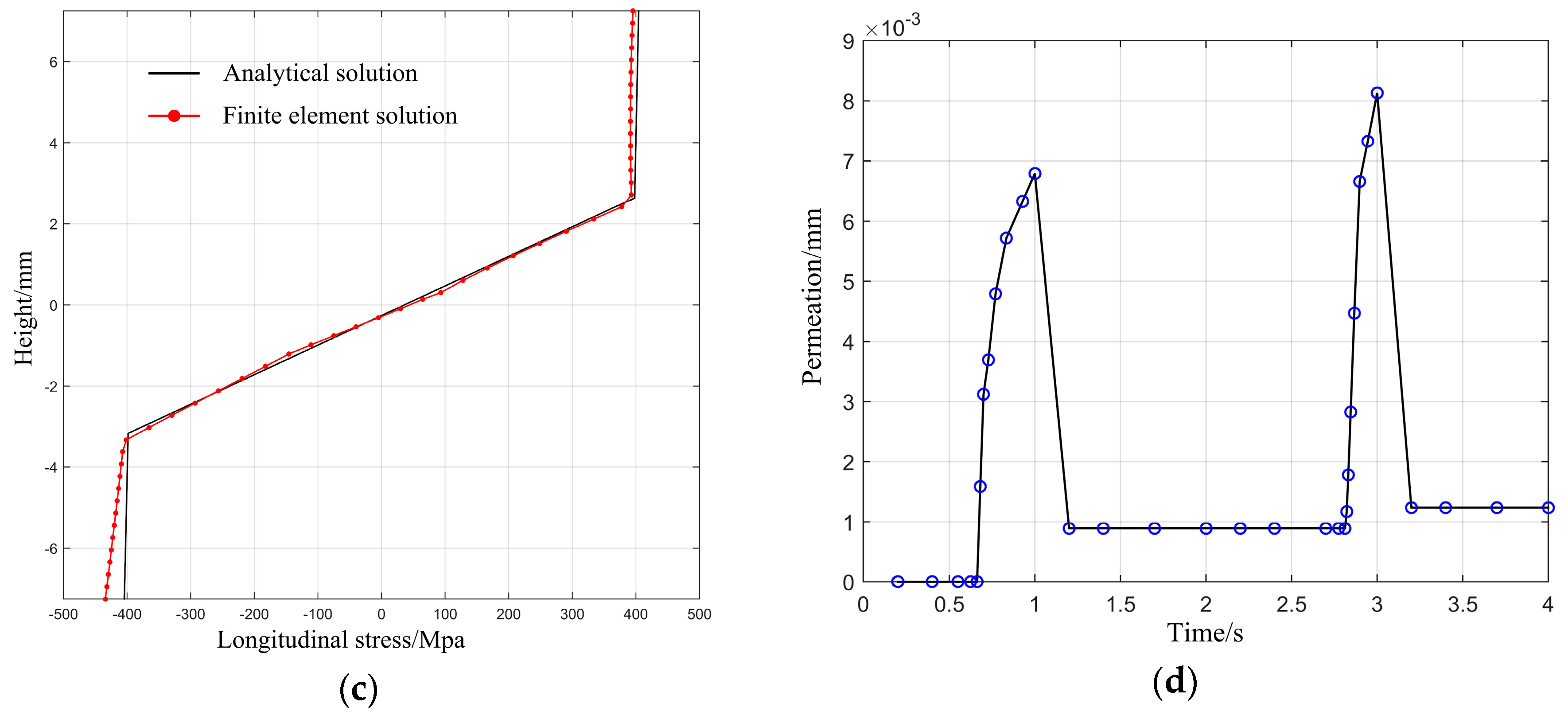

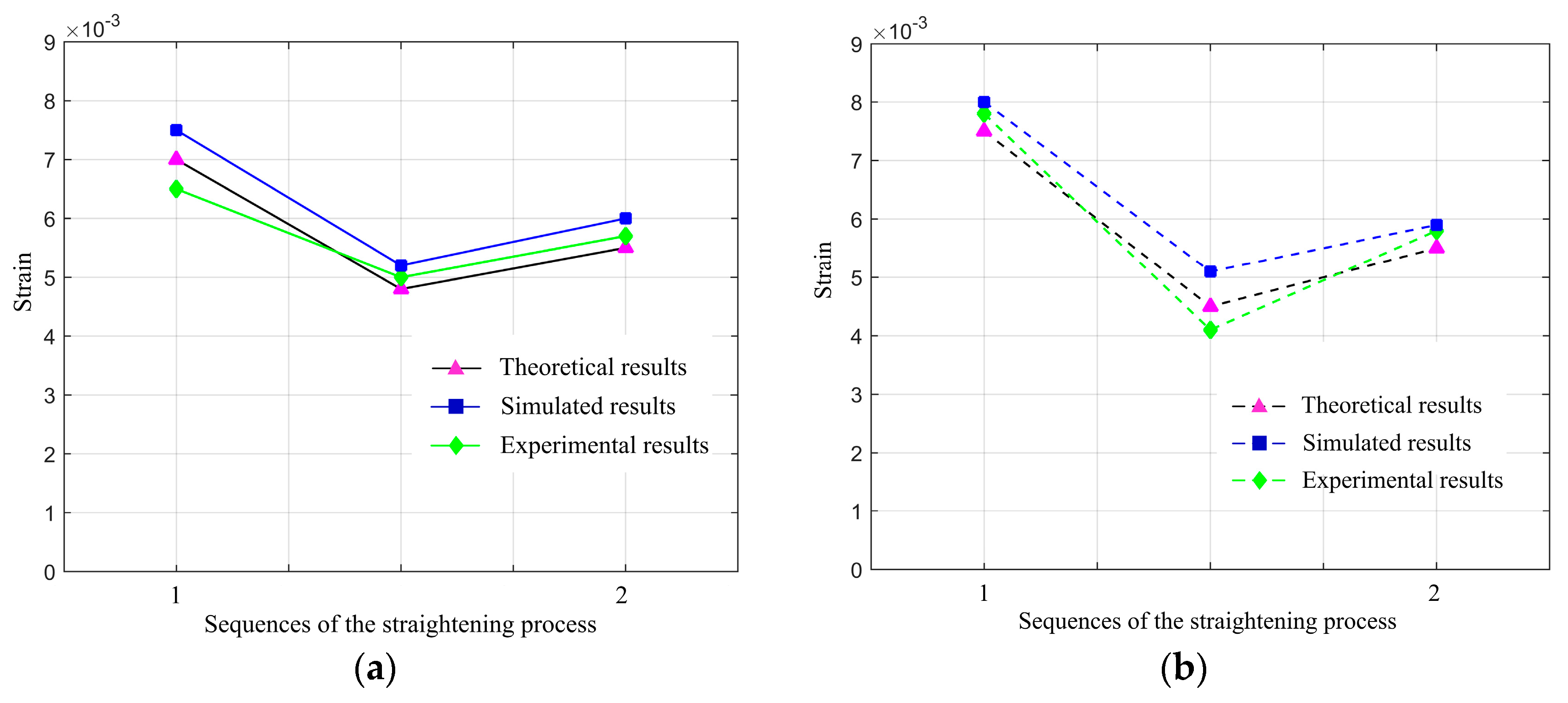

5. Results

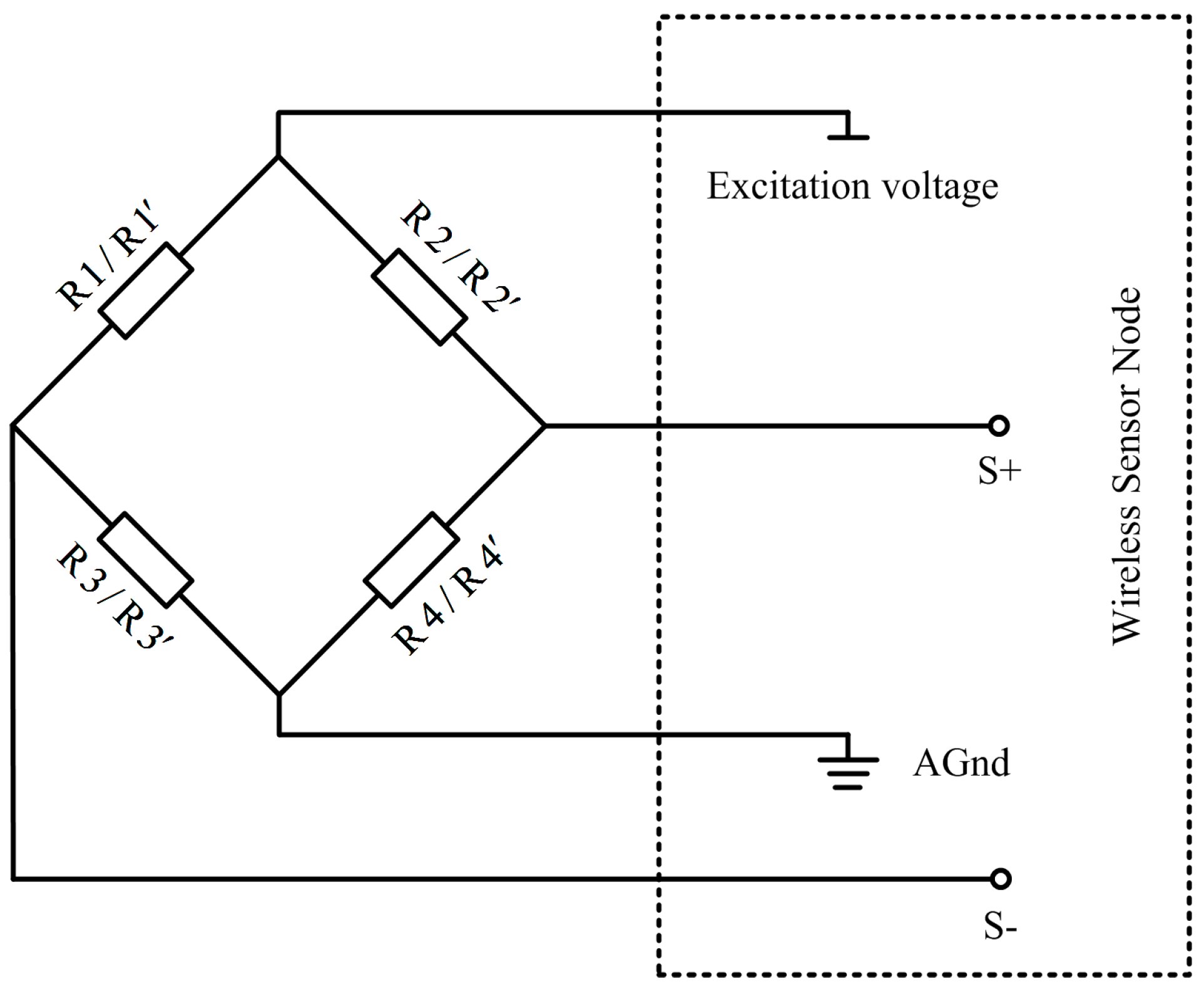

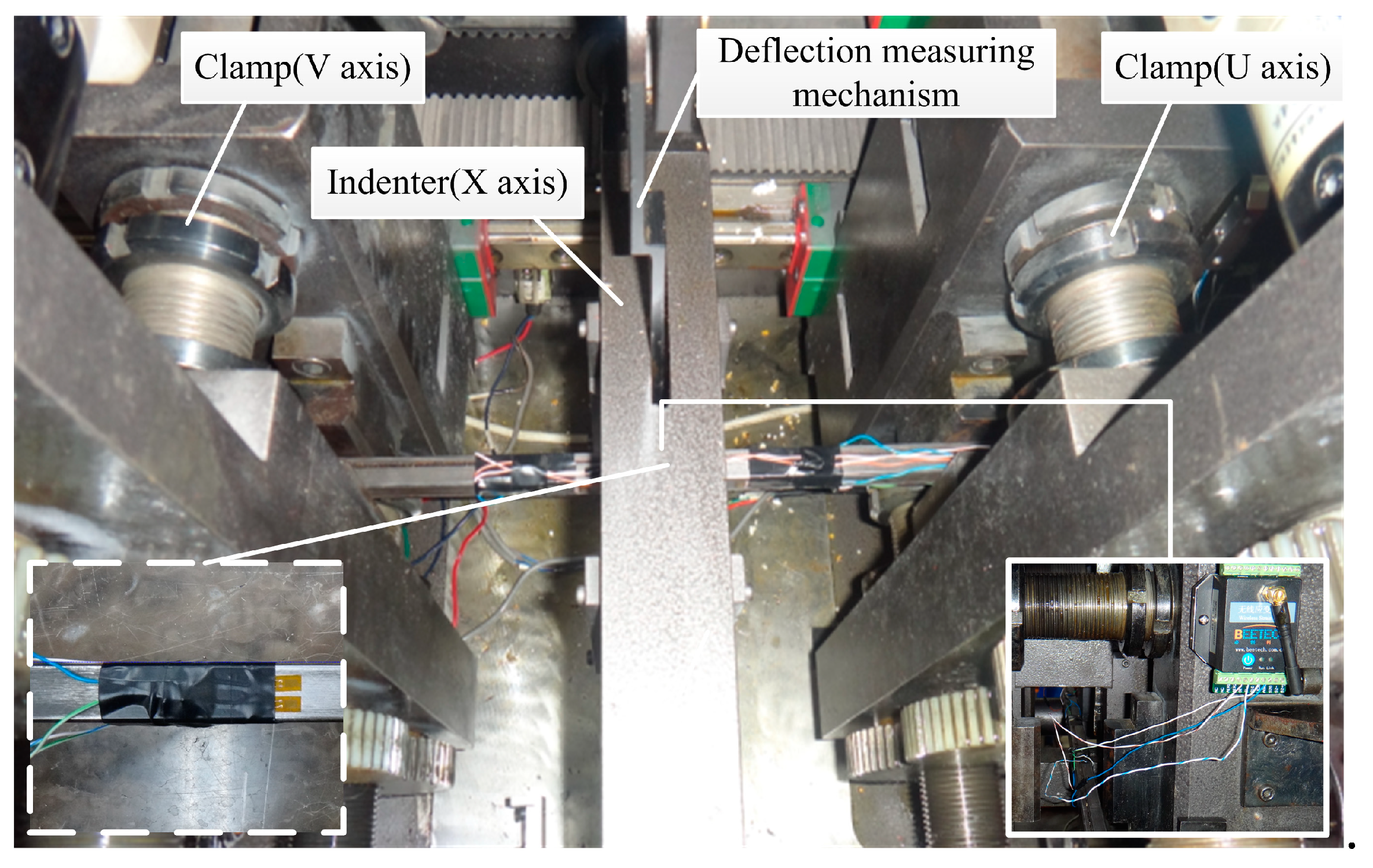

5.1. Experimental Schemes of Straightening Process and Deflection Measurement

5.2. Results

6. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Gergess, A.N.; Sen, R. Curving structural steel girders by two-point bending. J. Constr. Steel Res. 2016, 122, 511–519. [Google Scholar] [CrossRef]

- Gergess, A.N.; Sen, R. Cambering structural steel I girders using cold bending. J. Constr. Steel Res. 2008, 64, 407–417. [Google Scholar] [CrossRef]

- Mujika, F.; Arrese, A.; Adarraga, I.; Oses, U. New correction terms concerning three-point and four-point bending tests. Polym. Test. 2016, 55, 25–37. [Google Scholar] [CrossRef]

- Seo, Y.H.; Park, J.W.; Song, W.J.; Kang, B.S.; Kim, J. Flexible die design and springback compensation based on modified displacement adjustment method. Adv. Mech. Eng. 2014, 6, 1–15. [Google Scholar] [CrossRef]

- Eggertsen, P.A.; Mattiasson, K. On the modeling of the bending–unbending behavior for accurate springback predictions. Int. J. Mech. Sci. 2009, 51, 547–563. [Google Scholar] [CrossRef]

- Eggertsen, P.A.; Mattiasson, K. On the identification of kinematic hardening material parameters for accurate springback predictions. Int. J. Mater. Form. 2011, 4, 103–120. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, J. Springback prediction of three-dimensional variable curvature tube bending. Adv. Mech. Eng. 2016, 8, 1–13. [Google Scholar] [CrossRef]

- Pernía, A.; Martínez-de-Pisón, F.J.; Ordieres, J.; Alba, F.; Blanco, J. Fine tuning straightening process using genetic algorithms and finite element methods. Ironmak. Steelmak. 2010, 37, 119–125. [Google Scholar] [CrossRef]

- Biempica, C.B.; Díaz, J.J.D.C.; Nieto, P.J.G.; Sánchez, I.P. Nonlinear analysis of residual stresses in a rail manufacturing process by FEM. Appl. Math. Model. 2009, 33, 34–53. [Google Scholar] [CrossRef]

- Guan, B.; Zang, Y.; Pang, X.N.; Lu, Z.Y.; Liu, F.N.; Feng, W. Study on residual stresses evolution mechanism of H-beam during straightening process. J. China Univ. Pet. (Ed. Nat. Sci.) 2012, 36, 122–135. [Google Scholar]

- Tsai, S.H.; Kan, H.C. The exact solution of the load-deflection model of a uniformly loaded rectangular cross-section cantilever beam. J. Phys. D Appl. Phys. 2008, 41. [Google Scholar] [CrossRef]

- Tsai, S.H.; Wang, Y.T.; Kan, H.C. Analysis on the uniformly loaded rectangular cross-section cantilever by a modified load-deflection model. J. Phys. D Appl. Phys. 2009, 42. [Google Scholar] [CrossRef]

- Kazan, R.; Fırat, M.; Tiryaki, A.E. Prediction of springback in wipe-bending process of sheet metal using neural network. Mater. Des. 2009, 30, 418–423. [Google Scholar] [CrossRef]

- Panthi, S.K.; Ramakrishnan, N.; Ahmed, M.; Singh, S.S.; Goel, M.D. Finite Element Analysis of sheet metal bending process to predict the springback. Mater. Des. 2010, 31, 657–662. [Google Scholar] [CrossRef]

- Baseri, H.; Bakhshi-Jooybari, M.; Rahmani, B. Modeling of spring-back in V-die bending process by using fuzzy learning back-propagation algorithm. Expert Syst. Appl. 2011, 38, 8894–8900. [Google Scholar] [CrossRef]

- Yin, J.; Zhao, S.; Wang, S.; Li, Y. Multiroller straightening analytical model of H-beam. Ironmak. Steelmak. 2014, 41, 521–528. [Google Scholar] [CrossRef]

- Kato, M.; Hasegawa, A.; Sugyo, S.; Nakamura, H.; Kobayashi, M.; Morimoto, Y. Straightening technology of round bars using 2-roll rotary straightener. Procedia Eng. 2014, 81, 233–238. [Google Scholar] [CrossRef]

- Spoorenberg, R.C.; Snijder, H.; Hoenderkamp, J.C.D. Experimental investigation of residual stresses in roller bent wide flange steel sections. J. Constr. Steel Res. 2011, 66, 737–747. [Google Scholar] [CrossRef]

- Xiao, B.; Li, K.; Rong, Y. Automatic determination and evaluation of residual stress calibration coefficients for hole-drilling strain gauge integral method. Sratin 2011, 47, 525–534. [Google Scholar] [CrossRef]

- Joseph, J.; Martell, C.; Richard, L.; Jing, S. Experimental investigation on variation of machined residual stresses by turning and grinding of hardened AISI 1053 steel. Int. J. Adv. Manuf. Technol. 2014, 74, 1381–1392. [Google Scholar] [CrossRef]

- Sasaki, T.; Yaguchi, O.; Suzuki, H. Neutron residual stress measurement of railway rails using image plate. Mate. Sci. Forum 2010, 652, 260–265. [Google Scholar] [CrossRef]

- Kosel, F.; Videnic, T.; Kosel, T.; Brojan, M. Elasto-plastic springback of beams subjected to repeated bending/unbending histories. J. Mater. Eng. Perform. 2011, 20, 846–854. [Google Scholar] [CrossRef]

- Song, Y.S.; Yu, Z.H. Springback after the lateral bending of T-section rails of work-hardening materials. J. Mater. Eng. Perform. 2013, 22, 3539–3549. [Google Scholar] [CrossRef]

- Zhao, J.; Zhai, R.; Ma, R.; Zhan, P.; Song, X. Springback theory of plane bending and the progress of study on its engineering application. Steel Res. Int. 2013, 84, 1230–1240. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, Y.Q.; Valentine, O.T.; Gao, S. A straightening stroke-deflection modeling and simulation approach based on online measurement. In Proceedings of the 8th ASME 2014 Manufacturing Science and Engineering Conference 2014 (MSEC 2014), Detroit, MI, USA, 9–13 June 2014. [Google Scholar]

| Material | GCr15 |

|---|---|

| Density (kg/m3) | 7810 |

| Young’s modulus (E/Mpa) | 190,089 |

| Hardening modulus (/Mpa) | 3800 |

| Poison’s ratio | 0.3 |

| Yield stress (/Mpa) | 402 |

| Elastic-limit strain () | 0.004 |

| Specifications (mm) | LG15.5 × 14.5 × 400 |

| Distance between two clamps (/mm) | 300 |

| Initial deflection (/mm) | 1.581 |

| Measurement range | ±3 mm |

| Measurement accuracy | 1/1024 mm |

| Linear error | ±1% |

| Repeatability error | 0.2 μm |

| First Straightening Step | First Unloading | Second Straightening Step | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Theor. | FEA | Expt. | Theor. | FEA | Expt. | Theor. | FEA | Expt. | ||

| Tensile region | Strain (10−3) | 7.0 | 6.5 | 7.5 | 4.8 | 5.0 | 5.2 | 5.5 | 5.7 | 6.0 |

| Stress (Mpa) | 408 | 382 | ─ | 278 | 286 | ─ | 405 | 407 | ─ | |

| Compressive region | Strain (10−3) | 7.5 | 7.8 | 8.0 | 4.5 | 4.1 | 5.1 | 5.5 | 5.8 | 5.9 |

| Stress (Mpa) | 409 | 421 | ─ | 230 | 216 | ─ | 405 | 408 | ─ | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Lu, H.; Ling, H.; Lian, Y.; Ma, M. Analytical Model of a Multi-Step Straightening Process for Linear Guideways Considering Neutral Axis Deviation. Symmetry 2018, 10, 316. https://doi.org/10.3390/sym10080316

Zhang Y, Lu H, Ling H, Lian Y, Ma M. Analytical Model of a Multi-Step Straightening Process for Linear Guideways Considering Neutral Axis Deviation. Symmetry. 2018; 10(8):316. https://doi.org/10.3390/sym10080316

Chicago/Turabian StyleZhang, Yongquan, Hong Lu, He Ling, Yang Lian, and Mingtian Ma. 2018. "Analytical Model of a Multi-Step Straightening Process for Linear Guideways Considering Neutral Axis Deviation" Symmetry 10, no. 8: 316. https://doi.org/10.3390/sym10080316