Ex-Ante Eco-Efficiency Assessment of Dendromass Production: Conception and Experiences of an Innovation Project

Abstract

:1. Introduction

2. Material and Methods

2.1. Eco-Efficiency Theory and Application

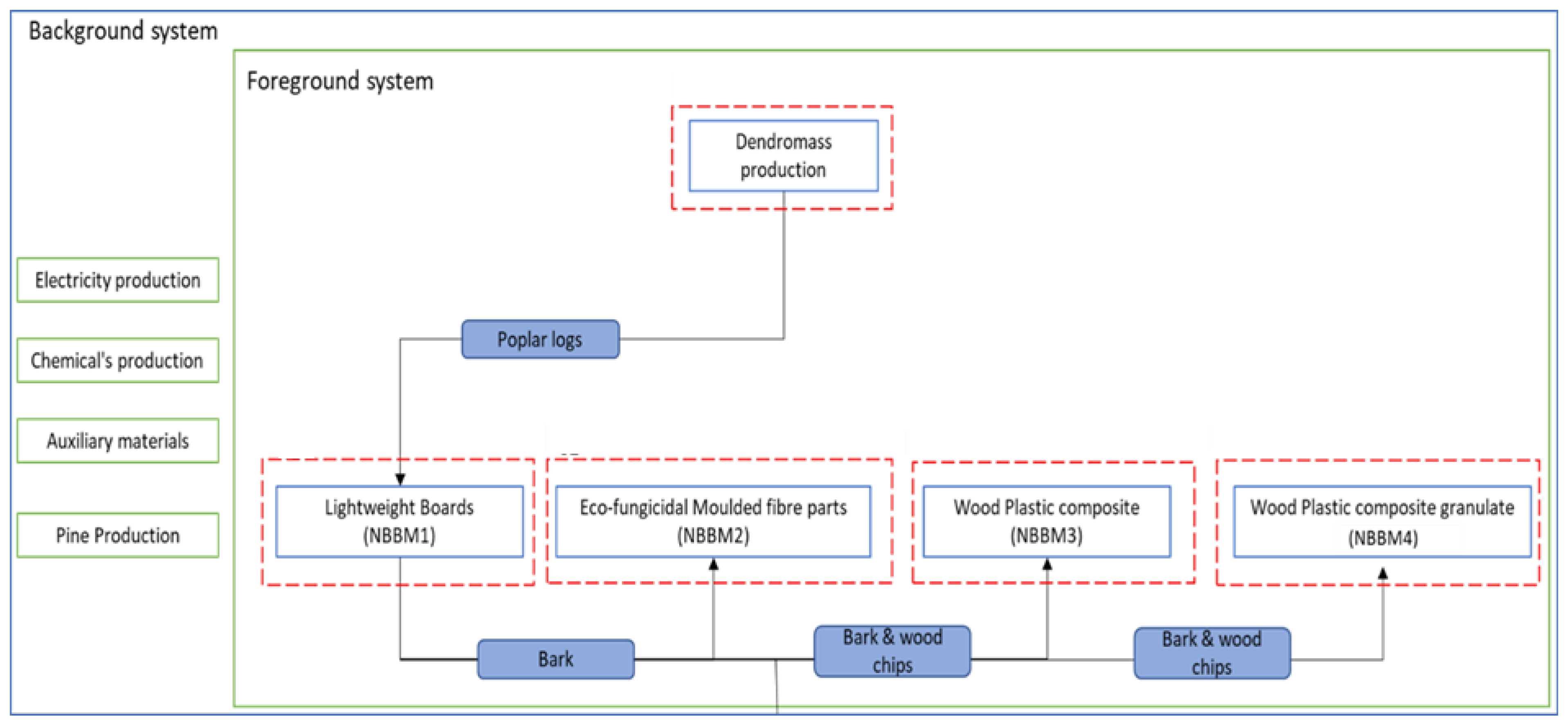

2.2. Demonstration Project and System Definition

- 1 ton of bone dry (bdt) dendromass,

- 1 m3 of finished NBBM1,

- 1 ton of NBBM2,

- 1 ton of NBBM3,

- 1 ton of finished NBBM4, and

- 1 ton of dendromass and the maximum of NBBMs that can be made from it, as the D4EU value chain.

2.3. Life Cycle Assessment/Environmental Performance

2.4. Product System Value

3. Results

3.1. Eco-Efficiency of Each Product

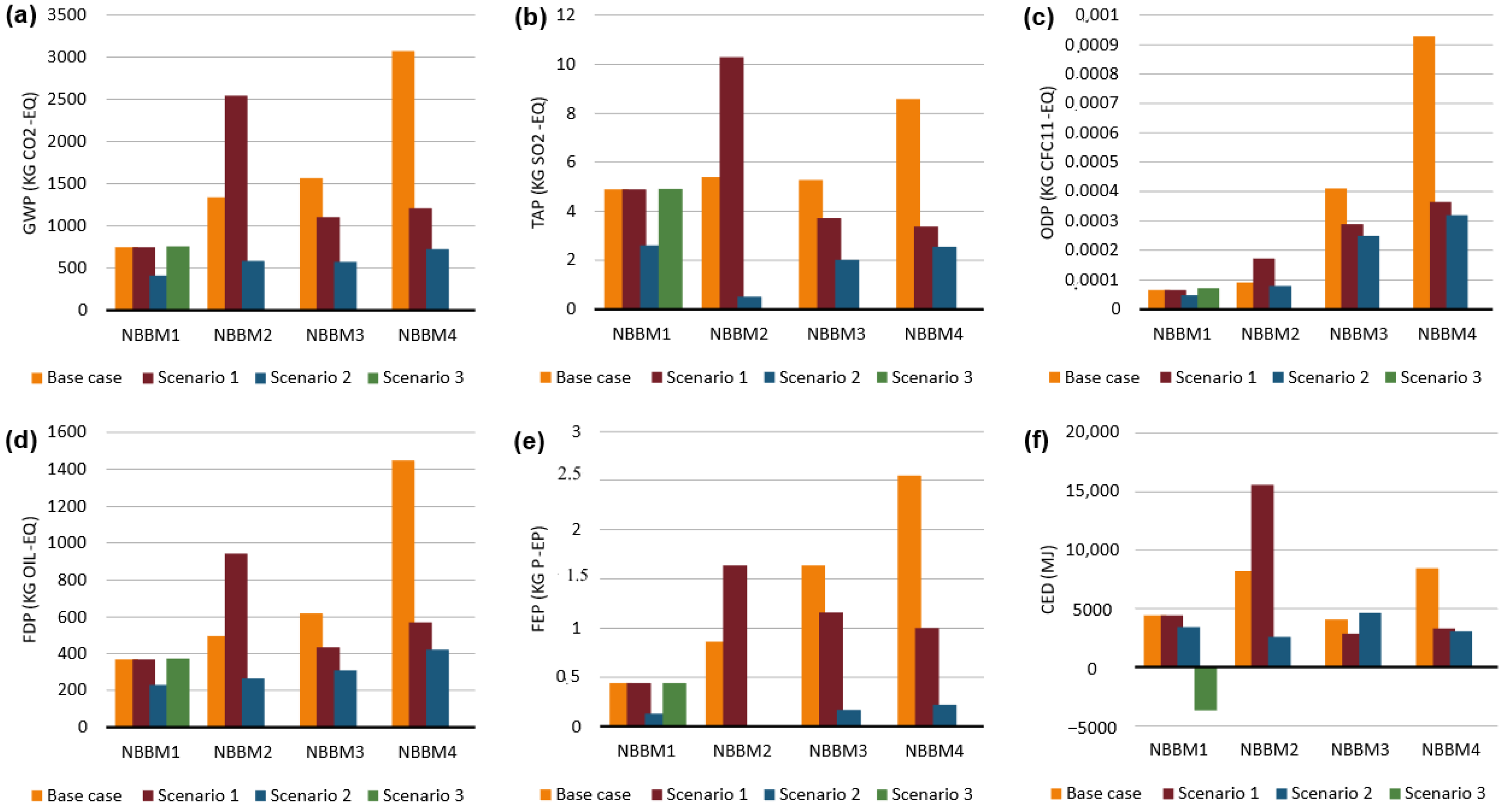

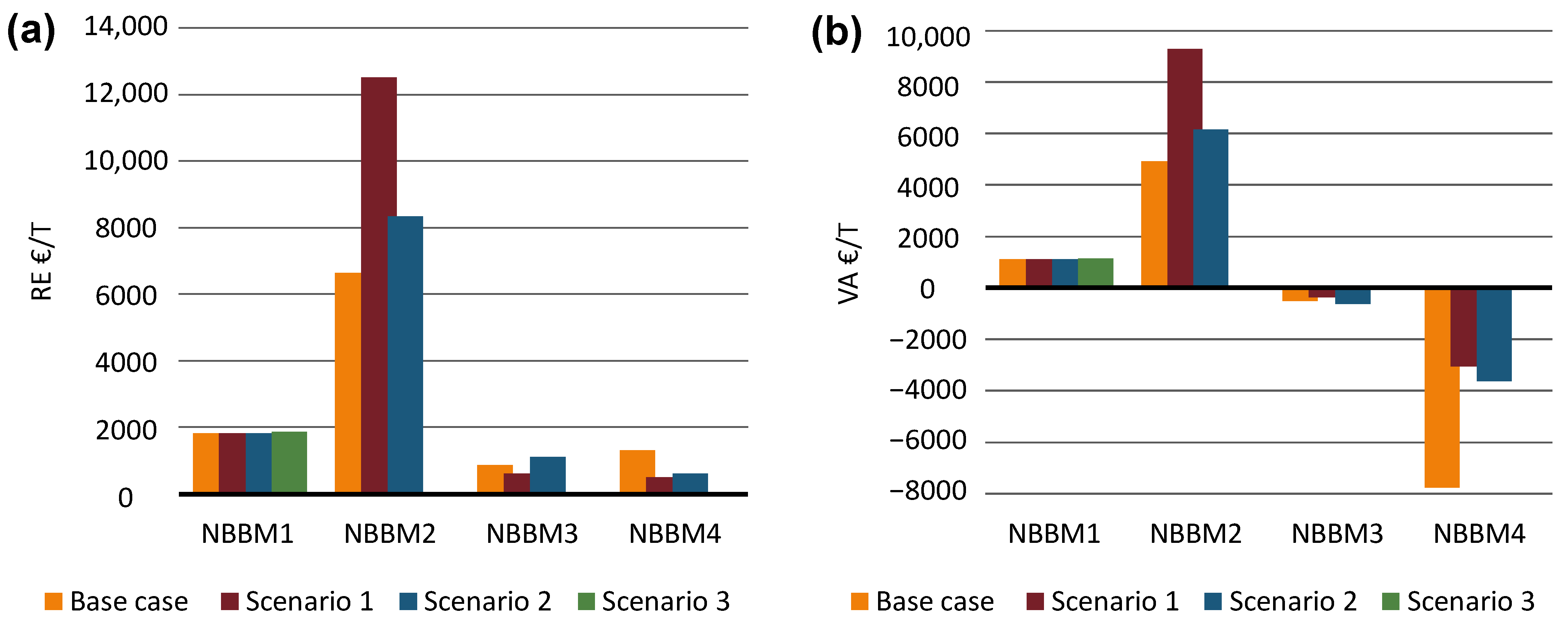

3.2. Environmental Performance and Product System Values of Scenarios

3.3. Eco-Efficiency of the Total Product System

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission (EC). A Sustainable Bioeconomy for Europe: Strengthening the Con-Nection between Economy, Society and the Environment; COM(2018) 673 final; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- D’Amato, D.; Droste, N.; Allen, B.; Kettunen, M.; Lähtinen, K.; Korhonen, J.; Leskinen, P.; Matthies, B.D.; Toppinen, A. Green, circular, bio economy: A comparative analysis of sustainability avenues. J. Clean. Prod. 2017, 168, 716–734. [Google Scholar] [CrossRef]

- Imbert, E.; Ladu, L.; Morone, P.; Quitzow, R. Comparing policy strategies for a transition to a bioeconomy in Europe: The case of Italy and Germany. Energy Res. Soc. Sci. 2017, 33, 70–81. [Google Scholar] [CrossRef]

- De Besi, M.; Mccormick, K. Towards a bioeconomy in Europe: National, regional and industrial strategies. Sustainability 2015, 7, 10461–10478. [Google Scholar] [CrossRef] [Green Version]

- Gawel, E.; Pannicke, N.; Hagemann, N. A Path Transition Towards a Bioeconomy—The Crucial Role of Sustainability. Sustainability 2019, 11, 3005. [Google Scholar] [CrossRef] [Green Version]

- Ranacher, L.; Pollakova, B.; Schwarzbauer, P.; Liebal, S.; Weber, N.; Hesser, F. Farmers’ Willingness to Adopt Short Rotation Plantations on Marginal Lands: Qualitative Study About Incentives and Barriers in Slovakia. BioEnergy Res. 2021, 14, 357–373. [Google Scholar] [CrossRef]

- Fürtner, D.; Ranacher, L.; Perdomo Echenique, E.A.; Schwarzbauer, P.; Hesser, F. Locating Hotspots for the Social Life Cycle Assessment of Bio-Based Products from Short Rotation Coppice. BioEnergy Res. 2021, 14, 510–533. [Google Scholar] [CrossRef]

- Perdomo, E.A.; Schwarzbauer, P.; Fürtner, D.; Hesser, F. Life Cycle Assessment of Agricultural Wood Production—Methodological Options: A Literature Review. BioEnergy Res. 2021, 14, 492–509. [Google Scholar] [CrossRef]

- Karvonen, J.; Halder, P.; Kangas, J.; Leskinen, P. Indicators and tools for assessing sustaina-bility impacts of the forest bioeconomy. For. Ecosyst. 2017, 4, 2. [Google Scholar] [CrossRef] [Green Version]

- Mair-Bauernfeind, C. The Sustainability of Bioeconomic Innovations: Tools and Indicators for a Substitution Assessment. Ph.D. Thesis, Karl-Franzens-Universität Graz, Graz, Austria, 2020. [Google Scholar]

- Sandin, G.; Clancy, G.; Heimersson, S.; Peters, G.M.; Svanström, M.; Ten Hoeve, M. Making the most of LCA in technical inter-organisational R&D projects. J. Clean. Prod. 2014, 70, 97–104. [Google Scholar]

- McAloone, T.C.; Bey, N. Environmental Improvement through Product Development: A Guide; Danish Environmental Protection Agency: Copenhagen, Denmark, 2009. [Google Scholar]

- Lettner, M. Rethinking Technology and Product Development in the Context of the Emerging Bioeconomy: The Concept of Sustainable Innovation Readiness Level (Sirl). Ph.D. Thesis, Institut für Marketing und Innovation, BOKU-Universität für Bodenkultur Vienna, Vienna, Austria, 2018; p. 220. [Google Scholar]

- Ichimura, M.; Nam, S.; Bonjour, S.; Rankine, H.; Carisma, B.; Qiu, Y.; Khrueachot-Ikul, R. Eco-Efficiency Indicators: Measuring Resource-Use Efficiency and the Impact of Economic Activities on the Environment; United Nations Escap—Economic and SoCial Commission for Asia and the Pacific, Issue: Bangkok, Thailand, 2009. [Google Scholar]

- Schaltegger, S.; Sturm, A. Ökologie Induzierte Entscheidungsprobleme des Managements. Ansatzpunkte zur Ausgestaltung von Instrumenten; WWZ-Discussion PaperNo. 8914; Inst. f. Betriebswirtschaft: Basel, Switzerland, 1989. [Google Scholar]

- ISO 14045; Environmental Management—Eco-Efficiency Assessment of Product Systems—Principles, Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2012.

- Arceo, A.; Biswas, W.K.; John, M. Eco-efficiency improvement of Western Australian remote area power supply. J. Clean. Prod. 2019, 230, 820–834. [Google Scholar] [CrossRef]

- Molina-Besch, K.; Pålsson, H. A simplified environmental evaluation tool for food packaging to support decision-making in packaging development. Packag. Technol. Sci. 2020, 33, 141–157. [Google Scholar] [CrossRef]

- Mehmeti, A.; Santoni, F.; Della Pietra, M.; Mcphail, S.J. Life cycle assessment of molten carbonate fuel cells: State of the art and strategies for the future. J. Power Sources 2016, 308, 97–108. [Google Scholar] [CrossRef]

- Muradin, M.; Joachimiak-Lechman, K.; Foltynowicz, Z. Evaluation of eco-efficiency of two alternative agricultural biogas plants. Appl. Sci. 2018, 8, 2083. [Google Scholar] [CrossRef] [Green Version]

- Silalertruksa, T.; Gheewala, S.H.; Pongpat, P. Sustainability assessment of sugarcane biorefinery and molasses ethanol production in Thailand using eco-efficiency indicator. Appl. Energy 2015, 160, 603–609. [Google Scholar] [CrossRef]

- Schweier, J.; Schnitzler, J.P.; Becker, G. Selected environmental impacts of the tech-nical production of wood chips from poplar short rotation coppice on marginal land. Biomass Bioenergy 2016, 85, 235–242. [Google Scholar] [CrossRef]

- Yang, Y.-H.; Lin, S.-J.; Lewis, C. Reduction of acidification from electricity—Generating industries in Taiwan by Life Cycle Assessment and Monte Carlo optimization. Ecol. Econ. 2009, 68, 1575–1582. [Google Scholar] [CrossRef]

- Ferreira, M.B.; Salvador, R.; Barros, M.V.; De Souza, J.T.; Rabelo TG, L.; De Fran-Cisco, A.C.; Coelho, R.; Piekarski, C.M. Eco-efficiency of the differential ratio change in a heavy-duty vehicle and implications for the automotive industry. Sustain. Prod. Consum. 2020, 21, 145–155. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Afshar, S. Eco-efficiency of electric vehicles in the United States: A life cycle assessment based principal component analysis. J. Clean. Prod. 2019, 212, 515–526. [Google Scholar] [CrossRef]

- Al-Lami, A.; Hilmer, P.; Sinapius, M. Eco-efficiency assessment of manufacturing carbon fiber reinforced polymers (CFRP) in aerospace industry. Aerosp. Sci. Technol. 2018, 79, 669–678. [Google Scholar] [CrossRef]

- Changwichan, K.; Silalertruksa, T.; Gheewala, S.H. Eco-efficiency assessment of bioplastics production systems and end-of-life options. Sustainability 2018, 10, 952. [Google Scholar] [CrossRef] [Green Version]

- De Oliveira, S.A.; Nunes de Macedo, J.R.; Rosa, D.D.S. Eco-efficiency of poly (lactic acid)-Starch-Cotton composite with high natural cotton fiber content: Environmental and functional value. J. Clean. Prod. 2019, 217, 32–41. [Google Scholar] [CrossRef]

- Leejarkpai, T.; Mungcharoen, T.; Suwanmanee, U. Comparative assessment of global warming impact and eco-efficiency of PS (polystyrene), PET (polyethylene terephthalate) and PLA (pol-ylactic acid) boxes. J. Clean. Prod. 2006, 125, 95–107. [Google Scholar] [CrossRef]

- Mendoza, J.M.F.; D’Aponte, F.; Gualtieri, D.; Azapagic, A. Disposable baby diapers: Life cycle costs, eco-efficiency and circular economy. J. Clean. Prod. 2019, 211, 455–467. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Stanchev, P.; Katsou, E.; Awad, S.; Fan, M. A circular economy use of recov-ered sludge cellulose in wood plastic composite production: Recycling and eco-efficiency assessment. Waste Manag. 2020, 99, 42–48. [Google Scholar] [CrossRef]

- Czaplicka-Kolarz, K.; Burchart-Korol, D.; Turek, M.; Borkowski, W. Model of Eco-Efficiency Assessment of Mining Production Processes. Arch. Min. Sci. 2015, 60, 477–486. [Google Scholar] [CrossRef] [Green Version]

- Foulet, A.; Bouchez, T.; Desmond-Le Quéméner, E.; Giard, L.; Renvoisé, L.; Aissani, L. Eco-design of microbial electrochemical technologies for the production of waste-based succinic acid thanks to a life cycle assessment. J. Clean. Prod. 2019, 225, 1155–1168. [Google Scholar] [CrossRef] [Green Version]

- Joachimiak-Lechman, K.; Selech, J.; Kasprzak, J. Eco-efficiency analysis of an inno-vative packaging production: Case study. Clean Technol. Environ. Policy 2019, 21, 339–350. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.; Dale, B.E. Comparing alternative cellulosic biomass biorefining systems: Centralized versus distributed processing systems. Biomass Bioenergy 2015, 74, 135–147. [Google Scholar] [CrossRef] [Green Version]

- Niero, M.; Hauschild, M.Z.; Hoffmeyer, S.B.; Olsen, S.I. Combining Eco-Efficiency and Eco-Effectiveness for Continuous Loop Beverage Packaging Systems: Lessons from the Carlsberg Circular Community. J. Ind. Ecol. 2017, 21, 742–753. [Google Scholar] [CrossRef] [Green Version]

- Rönnlund, I.; Reuter, M.; Horn, S.; Aho, J.; Aho, M.; Päällysaho, M.; Ylimäki, L.; Pur-Sula, T. Eco-efficiency indicator framework implemented in the metallurgical industry: Part 1—A comprehensive view and benchmark. Int. J. Life Cycle Assess. 2016, 21, 1473–1500. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, C. Eco-efficiency evaluation indicator of plantation harvesting system and its improvement based on material flow analysis. In Proceedings of the Asia-Pacific Power and Energy Engineering Conference, APPEEC, Wuhan, China, 25–28 March 2011. [Google Scholar]

- Berglund, L.; Breedveld, L.; Oksman, K. Toward eco-efficient production of natural nanofibers from industrial residue: Eco-design and quality assessment. J. Clean. Prod. 2020, 255, 120274. [Google Scholar] [CrossRef]

- Risse, M.; Weber-Blaschke, G.; Richter, K. Eco-efficiency analysis of recycling recovered solid wood from construction into laminated timber products. Sci. Total Environ. 2019, 661, 107–119. [Google Scholar] [CrossRef] [PubMed]

- Burchart-Korol, D.; Krawczyk, P.; Czaplicka-Kolarz, K.; Smoliński, A. Eco-efficiency of underground coal gasification (UCG) for electricity production. Fuel 2016, 173, 239–246. [Google Scholar] [CrossRef]

- Silalertruksa, T.; Gheewala, S.H. Competitive use of sugarcane for food, fuel, and biochemical through the environmental and economic factors. Int. J. Life Cycle Assess. 2020, 25, 1343–1355. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Gálvez-Martos, J.-L.; Dufour, J. Robust eco-efficiency assessment of hydrogen from biomass gasification as an alternative to conventional hydrogen: A life-cycle study with and without external costs. Sci. Total Environ. 2019, 650, 1465–1475. [Google Scholar] [CrossRef] [PubMed]

- Valdivia, C.; Seth, A.; Gilles, J.L.; García, M.; Jiménez, E.; Cusicanqui, J.; Navia, F. Adapting to Climate Change in Andean Ecosystems: Landscapes, Capitals, and Perceptions Shaping Rural Livelihood Strategies and Linking Knowledge Systems and Edwin Yucra. In Geography of Climate Change; Routledge: Abingdon, UK, 2013; pp. 111–127. [Google Scholar]

- Ehrenfeld, J.R. Eco-efficiency: Philosophy, Theory, and Tools. J. Ind. Ecol. 2005, 9, 6–8. [Google Scholar] [CrossRef]

- Huppes, G.; Ishikawa, M. A Framework for quantified eco-efficiency analysis. J. Ind. Ecol. 2005, 9, 25–41. [Google Scholar] [CrossRef]

- WBCSD: World Business Council for Sustainable Development. Eco-Efficiency: Learning Module; WBCSD World Business Council for Sustainable Development: Geneva, Switzerland, 2006. [Google Scholar]

- Knust, C. Kurzumtriebsplantagen–Stand des Wissens. Anbau und Nutzung von Bäumen auf landwirtschaftlichen Flächen. In Anbau und Nutzung von Bäumen auf landwirtschaftlichen Flächen; Reeg, T., Bemmann, A., Konold, W., Murach, D., Spiecker, H., Eds.; WILEY-VCH Verlag GmbH & Co. KgaA: Weinheim, Germany, 2009; pp. 1–9. ISBN 978-3-527-32417-0. [Google Scholar]

- Klöpffer, W.; Grahl, B. Life Cycle Assessment (LCA): A Guide to Best Practice; Wiley-VHC: Weinheim, Germany, 2009. [Google Scholar]

- Arzoumanidis, I.; D’eusanio, M.; Petti, L.; Traverso, M. Functional Unit Definition Criteria in Life Cycle Assessment and Social Life Cycle Assessment: A Discussion; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Van der Giesen, C.; Cucurachi, J.; Kramer, G.; Tukker, A. A critical view on the current application of lca for new technologies and recommendations for improved practice. J. Clean. Prod. 2020, 259, 120904. [Google Scholar] [CrossRef]

- Lettner, M.; Hesser, F. Asking instead of telling-Recommendations for developing Life Cycle Assessment within technical R&D Projects. In Sustainable Production, Life Cycle Engineering and Management; Albrecht, S., Fischer, M., Leistner, P., Schebek, L., Eds.; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Rombouts, L.J.A.; Hellweg, S.; Frischknecht, R.; Hendriks, A.J.; van de Meent, D.; Ragas, A.M.J.; Reijnders, L.; Struijs, J. Is cumulative fossil energy demand a useful Indicator for the environmental performance of products? Environ. Sci. Technol. 2006, 40, 641–648. [Google Scholar] [CrossRef] [Green Version]

- Turnock, D. Rural diversification in Eastern Europe: Introduction. GeoJournal 1999, 46, 171–181. [Google Scholar] [CrossRef]

- Van Staden, C. The relevance of theories of political economy to the understanding of financial reporting in South Africa: The case of value-added statements. Account. Forum 2003, 27, 224–245. [Google Scholar] [CrossRef]

- Hoffmann, D. Creation of regional added value by regional bioenergy resources. Renew. Sustain. Energy Rev. 2009, 13, 2419–2429. [Google Scholar] [CrossRef]

- Haller, A.; Staden, C.J.V.; Landis, C. Value Added as part of Sustainability Reporting: Report-ing on Distributional Fairness or Obfuscation? J. Bus. Ethics 2018, 152, 763–781. [Google Scholar] [CrossRef]

| Scenario | Allocation Key | NBBM1 | NBBM2 | NBBM3 | NBBM4 |

|---|---|---|---|---|---|

| Base Case | Quantity produced (t) | 2.58 | 0.40 | 0.71 | 1.27 |

| Dendromass content (t) | 0.76 | 0.08 | 0.08 | 0.08 | |

| Scenario 1 (economic best case) | Quantity produced (t) | 2.58 | 0.75 | 0.50 | 0.50 |

| Dendromass content (t) | 0.76 | 0.15 | 0.06 | 0.03 | |

| Scenario 2 (environmental best case) | Quantity produced (t) | 2.58 | 0.50 | 0.90 | 0.60 |

| Dendromass content (t) | 0.76 | 0.10 | 0.10 | 0.04 | |

| Scenario 3 (NBBM1 only) | Quantity produced (t) | 2.58 | 0 | 0 | 0 |

| Dendromass content (t) | 1.00 | 0 | 0 | 0 |

| Environmental Performance | Value/1 ton Bone Dry Dendromass | Value/1 ton NBBM1 | Value/1 ton NBBM2 | Value/1 ton NBBM3 | Value/1 ton NBBM4 |

|---|---|---|---|---|---|

| GWP (kg CO2-eq) | 4.19 × 10 | 2.79 × 10² | 3.39 × 10³ | 2.21 × 10³ | 2.42 × 10³ |

| TAP (kg SO2-eq) | 5.90 × 10−2 | 1.52 | 1.37 × 10 | 7.43 | 6.75 |

| ODP (kg CFC11-eq) | 8.27 × 10−6 | 2.56 × 10−5 | 2.30 × 10−4 | 5.80 × 10−4 | 7.30 × 10−4 |

| FEP (kg P-ep) | 4.00 × 10−4 | 1.60 × 10−1 | 2.18 | 2.31 | 2.01 |

| FDP (kg oil-eq) | 1.59 × 10 | 1.40 × 10² | 1.25 × 10³ | 8.71 × 10² | 1.14 × 10³ |

| CED (MJ) | 4.79 × 10² | 1.58 × 10³ | 2.07 × 104 | 5.68 × 10³ | 6.63 × 10³ |

| Economic Performance | Value/1 bdt Dendromass | Value/1 ton NBBM1 | Value/1 ton NBBM2 | Value/1 ton NBBM3 | Value/1 ton NBBM4 |

|---|---|---|---|---|---|

| VA €/t | 24 | 430 | 12,348 | −707 | −6071 |

| RE €/t | 24 | 711 | 16,667 | 1220 | 1027 |

| Eco-Efficiency (Base Case) | Value/1 bdt Dendromass | Value/1 ton NBBM1 | Value/1 ton NBBM2 | Value/1 ton NBBM3 | Value/1 ton NBBM4 |

|---|---|---|---|---|---|

| VA (€)/GWP (kg CO2-eq) | 5.70 × 10−1 | 1.54 | 3.64 | ||

| VA (€)/TAP (kg SO2-eq) | 4.02 × 10² | 2.83 × 10² | 9.02 × 10² | ||

| VA (€)/ODP (kg CFC11-eq) | 2.87 × 106 | 1.68 × 107 | 5.37 × 107 | ||

| VA (€)/FEP (kg P-ep) | 5.93 × 104 | 2.69 × 103 | 5.66 × 103 | ||

| VA (€)/FDP (kg oil-eq) | 1.49 | 3.07 | 9.84 | ||

| VA (€)/CED (MJ) | 5.00 × 10−2 | 2.70 × 10−1 | 6.00 × 10−1 |

| Eco-Efficiency (Base Case) | Value/1 bdt Dendromass | Value/1 ton NBBM1 | Value/1 ton NBBM2 | Value/1 ton NBBM3 | Value/1 ton NBBM4 |

|---|---|---|---|---|---|

| RE (€)/GWP (kg CO2-eq) | 5.70 × 10−1 | 2.55 | 4.92 | 5.50 × 10−1 | 4.20 × 10−1 |

| RE (€)/TAP (kg SO2-eq) | 4.02 × 102 | 4.68 × 102 | 1.22 × 103 | 1.64 × 102 | 1.52 × 102 |

| RE (€)/ODP (kg CFC11-eq) | 2.87 × 106 | 2.78 × 107 | 7.25 × 107 | 2.10 × 106 | 1.41 × 106 |

| RE (€)/FEP (kg P-ep) | 5.93 × 104 | 4.44 × 103 | 7.65 × 103 | 5.28 × 102 | 5.11 × 102 |

| RE (€)/FDP (kg oil-eq) | 1.49 | 5.07 | 1.33 × 10 | 1.40 | 9.00 × 10−1 |

| RE (€)/CED (MJ) | 5.00 × 10−2 | 4.50 × 10−1 | 8.10 × 10−1 | 2.10 × 10−1 | 1.50 × 10−1 |

| Eco-Efficiency (VA) | Base Case | Scenario 1 | Scenario 2 | Scenario 3 |

|---|---|---|---|---|

| VA (€)/GWP (kg CO2-Eq | n. a. | 1.25 | 1.33 | 1.50 |

| VA (€)/TAP (kg SO2-Eq) | n. a. | 315.27 | 397.40 | 230.35 |

| VA (€)/ODP (kg CFC11-Eq) | n. a. | 7,888,764.04 | 4,360,000.00 | 15,796,089.39 |

| VA (€)/FEP (kg P-Ep) | n. a. | 1655.90 | 5869.23 | 2570.45 |

| VA (€)/FDP (kg oil-Eq) | n. a. | 3.03 | 2.49 | 3.04 |

| VA (€)/CED (MJ) | n. a. | 0.27 | 0.13 | −0.31 |

| Eco-Efficiency (RE) | Base Case | Scenario 1 | Scenario 2 | Scenario 3 |

|---|---|---|---|---|

| RE (€)/GWP (kg CO2-Eq) | 1.59 | 2.76 | 5.20 | 2.45 |

| RE (€)/TAP (kg SO2-Eq) | 442.38 | 696.09 | 1548.96 | 377.80 |

| RE (€)/ODP (kg CFC11-Eq) | 7,119,333.33 | 17,417,977.53 | 16,994,285.71 | 25,907,821.23 |

| RE (€)/FEP (kg P-Ep) | 1945.17 | 3656.13 | 22,876.92 | 4215.91 |

| RE (€)/FDP (kg oil-Eq) | 3.64 | 6.69 | 9.70 | 4.98 |

| RE (€)/CED (MJ) | 0.42 | 0.59 | 0.51 | −0.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hesser, F.; Groiß-Fürtner, D.; Woitsch, L.; Mair-Bauernfeind, C. Ex-Ante Eco-Efficiency Assessment of Dendromass Production: Conception and Experiences of an Innovation Project. Land 2023, 12, 839. https://doi.org/10.3390/land12040839

Hesser F, Groiß-Fürtner D, Woitsch L, Mair-Bauernfeind C. Ex-Ante Eco-Efficiency Assessment of Dendromass Production: Conception and Experiences of an Innovation Project. Land. 2023; 12(4):839. https://doi.org/10.3390/land12040839

Chicago/Turabian StyleHesser, Franziska, Daniela Groiß-Fürtner, Leona Woitsch, and Claudia Mair-Bauernfeind. 2023. "Ex-Ante Eco-Efficiency Assessment of Dendromass Production: Conception and Experiences of an Innovation Project" Land 12, no. 4: 839. https://doi.org/10.3390/land12040839