Simulation of Miniature PDMA for Ultrafine-Particle Measurement

Abstract

:1. Introduction

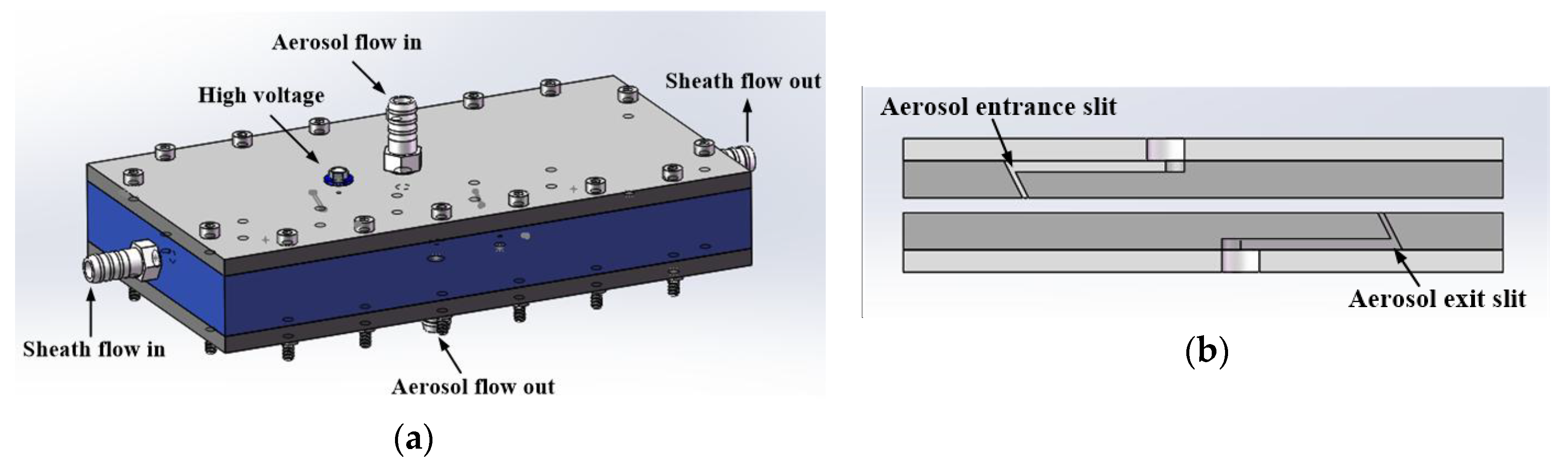

2. PDMA Simulation Model

2.1. Working Principle

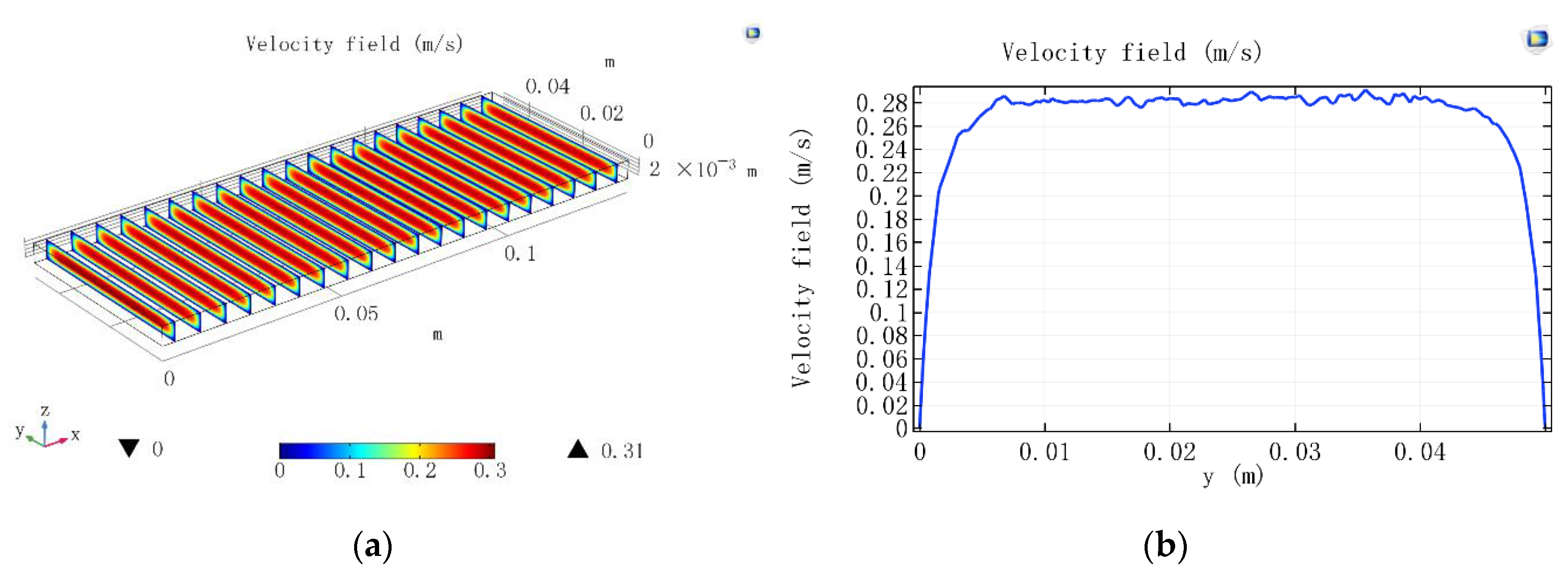

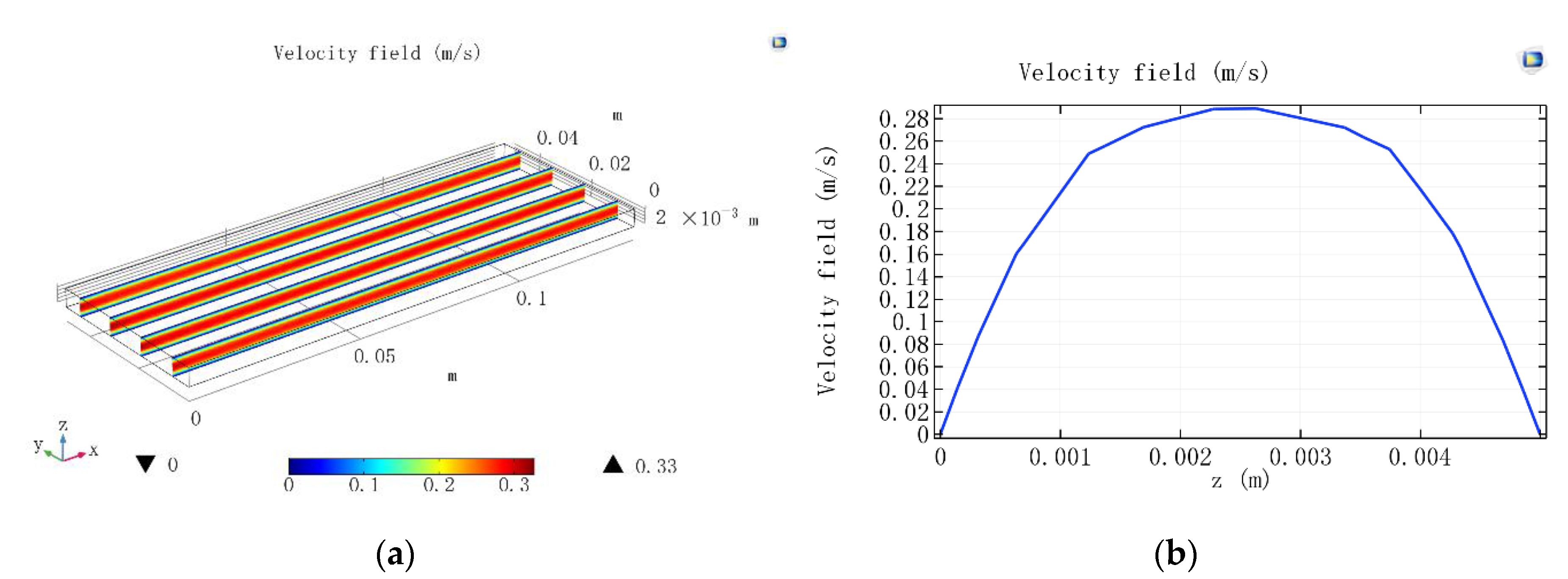

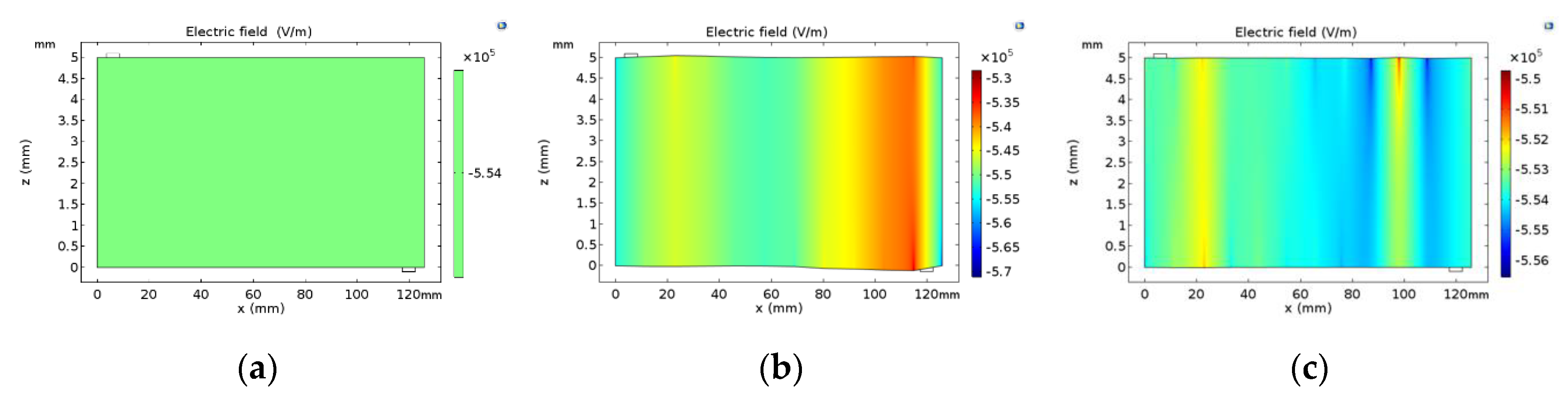

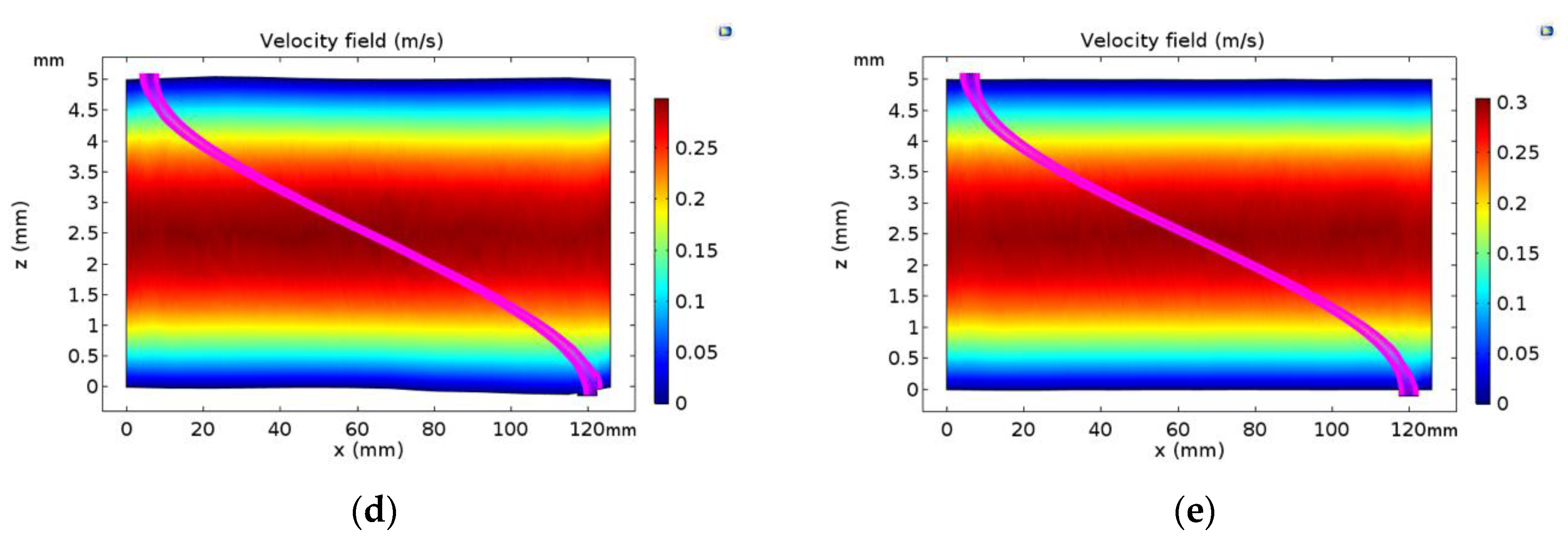

2.2. Simulation Model

2.3. Validation Setup

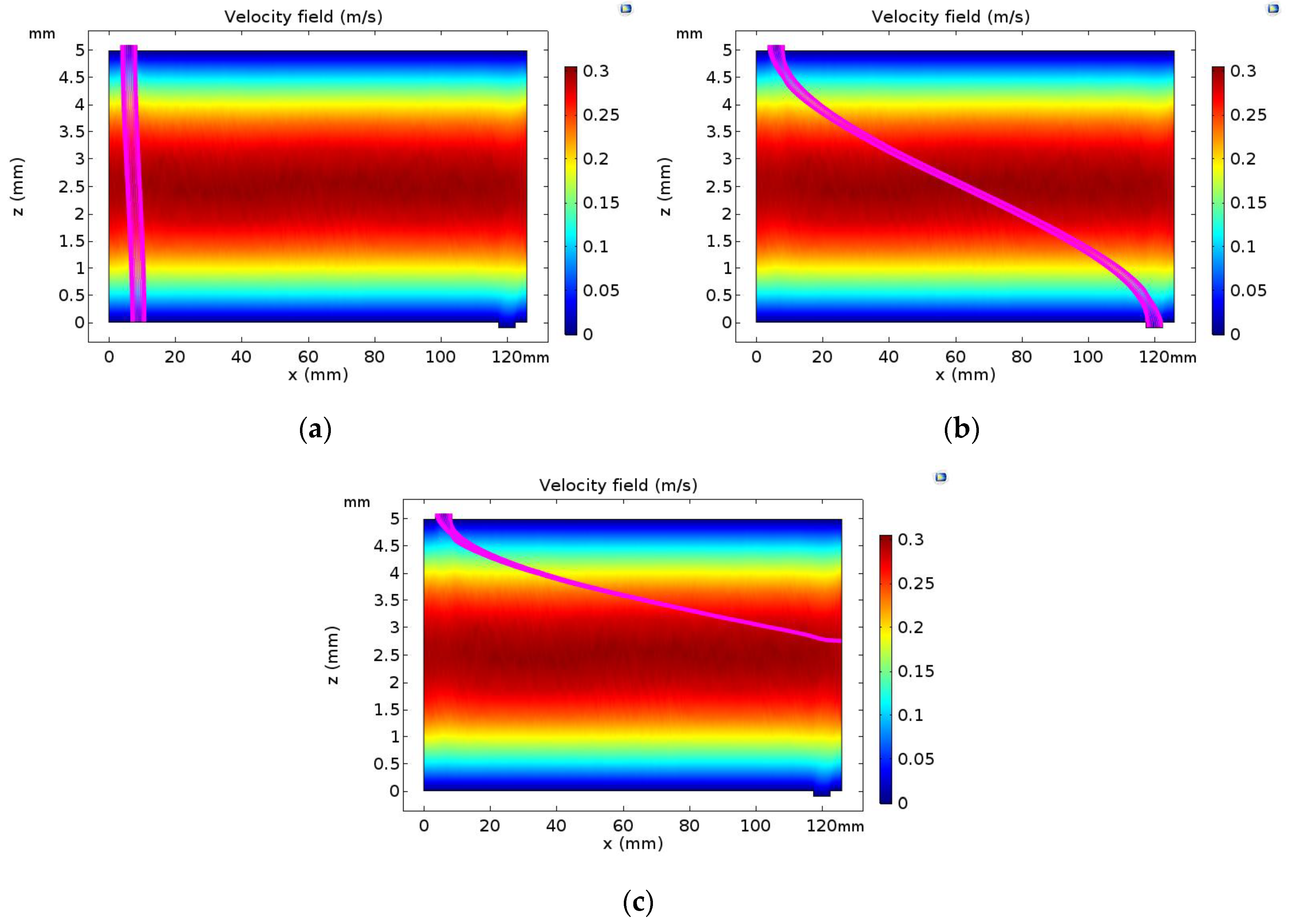

3. Results and Discussion

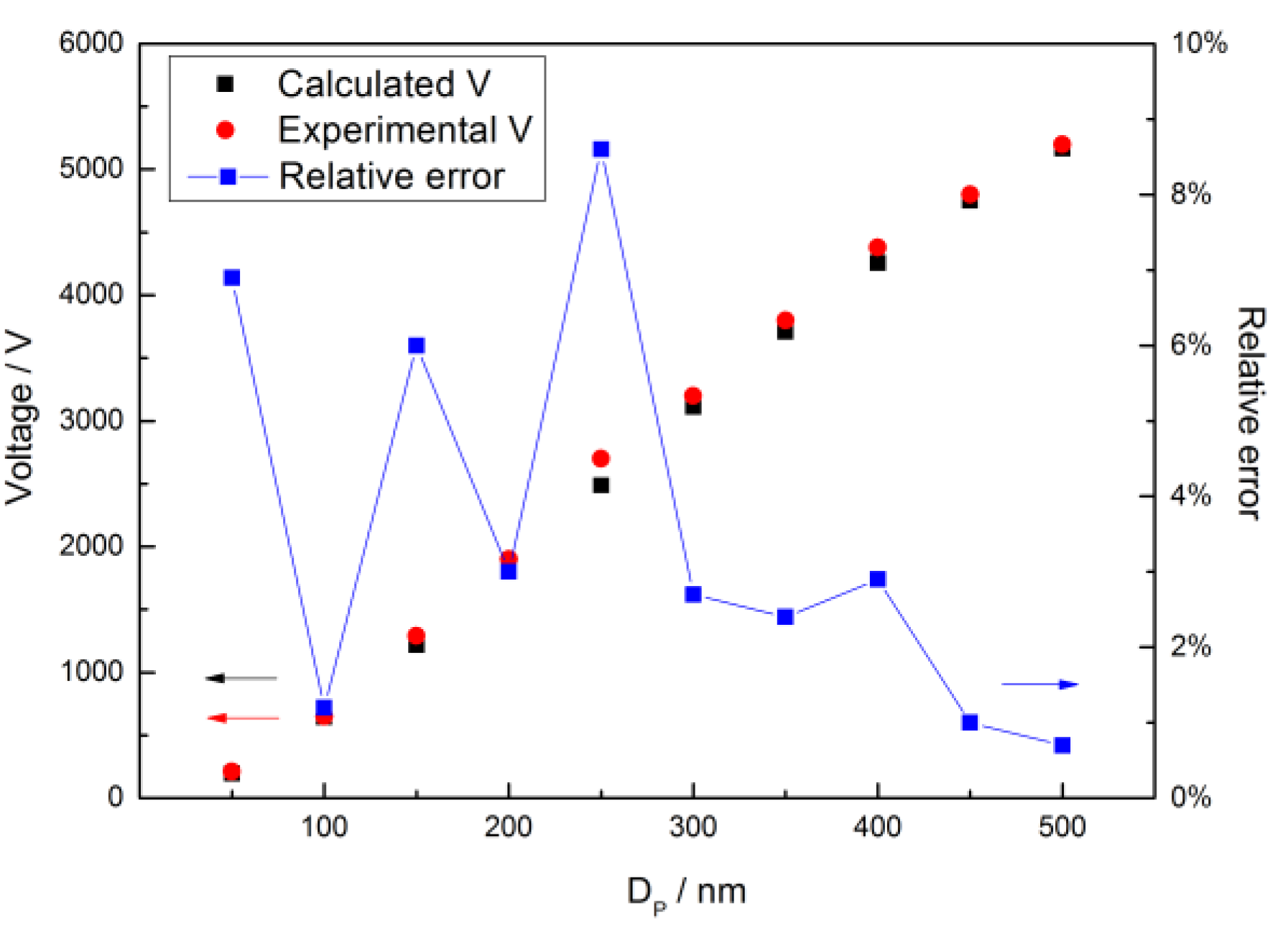

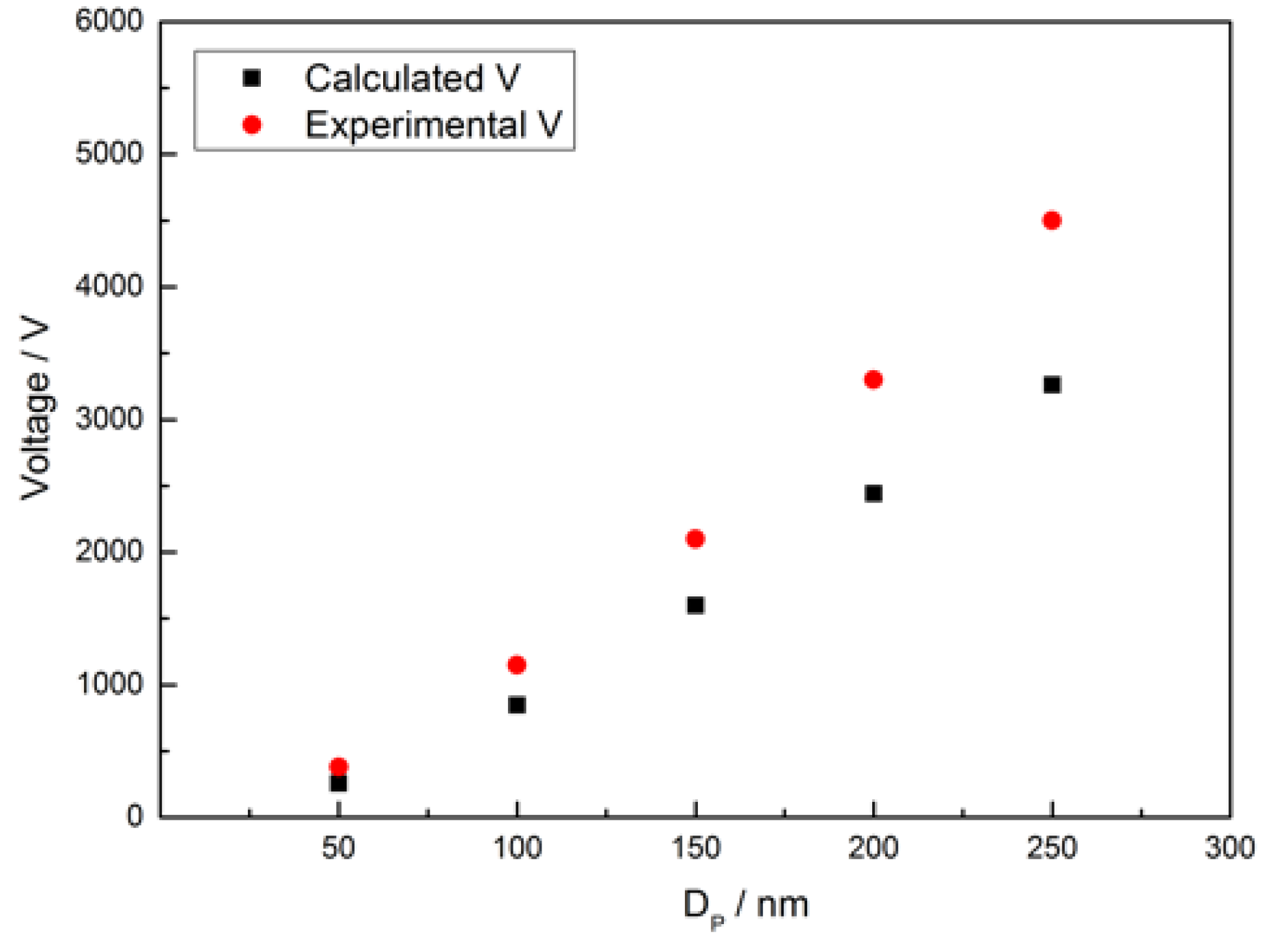

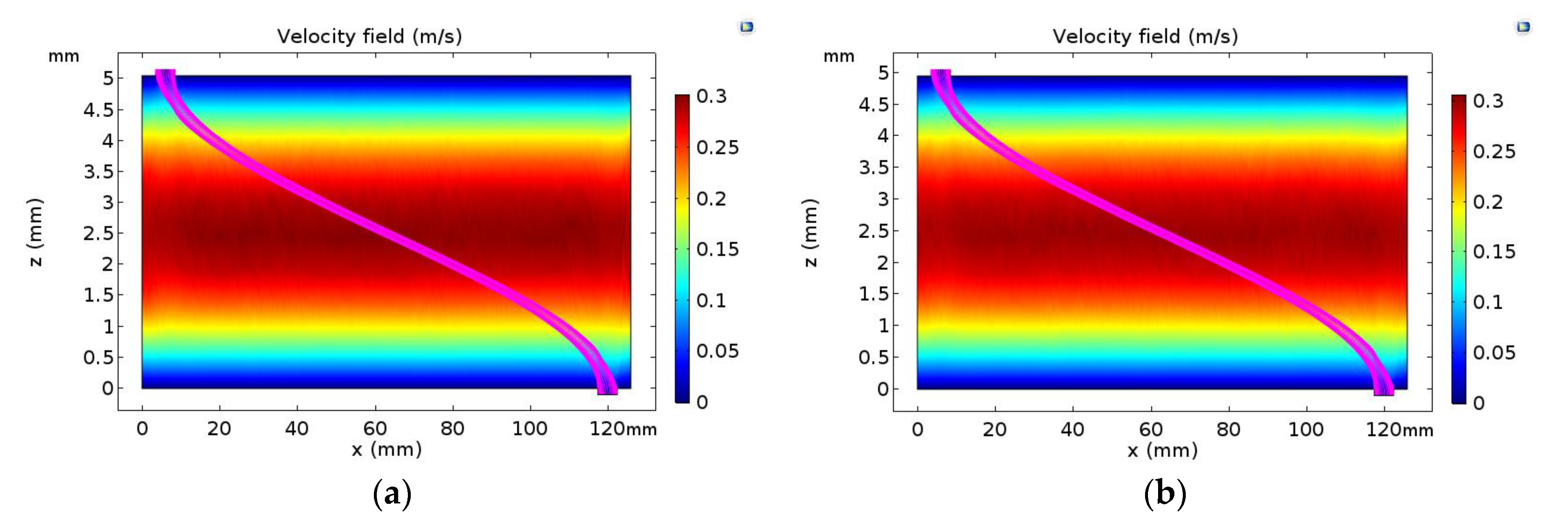

3.1. Simulation-Model Validation

3.2. Effect of Classification-Zone Dimensions

3.3. Process-Parameter Effects

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Maher, B.A.; Ahmed, I.A.; Karloukovski, V.; MacLaren, D.A.; Foulds, P.G.; Allsop, D.; Mann, D.M.A.; Torres-Jardón, R.; Calderon-Garciduenas, L. Magnetite pollution nanoparticles in the human brain. Proc. Natl. Acad. Sci. USA 2016, 13, 10797–10801. [Google Scholar] [CrossRef] [PubMed]

- Mills, H. The Ecology of Infancy and Early Childhood in Rural Senegal; A Five Year Old Can Boot but not Foot, an Exploration of Where Biology Meets Culture. Philos. Trans. R. Soc. Lond. 2014, 358, 2673–2682. [Google Scholar]

- Stolcpartova, J.; Pechout, M.; Dittrich, L.; Mazac, M.; Fenkl, M.; Vrbova, K.; Ondracek, J.; Vojtisek-Lom, M. Internal Combustion Engines as the Main Source of Ultrafine Particles in Residential Neighborhoods: Field Measurements in the Czech Republic. Atmosphere 2015, 6, 1714–1735. [Google Scholar] [CrossRef]

- Stabile, L. Ultrafine Particle Generation through Atomization Technique: The Influence of the Solution. Aerosol Air Qual. Res. 2013, 13, 1667–1677. [Google Scholar] [CrossRef]

- Xiang, S.; Hu, Z.; Zhai, W.; Wen, W.; Noll, K.E. Concentration of Ultrafine Particles near Roadways in An Urban Area in Chicago, Illinois. Aerosol Air Qual. Res. 2018, 18, 895–903. [Google Scholar] [CrossRef]

- Flagan, R.C. History of electrical aerosol measurements. Aerosol Sci. Technol. 1998, 28, 301–380. [Google Scholar] [CrossRef]

- Intra, P.; Tippayawong, N. An overview of differential mobility analyzers for size classification of nanometer-sized aerosol particles. Songklanakarin J. Sci. Technol. 2008, 30, 243–256. [Google Scholar]

- Hewitt, G.W. The Charging of Small Particles for Electrostatic Precipitation. Am. Inst. Electron. Eng. Trans. 1957, 76, 300–306. [Google Scholar] [CrossRef]

- Knutson, E.O.; Whitby, K.T. Aerosol classification by electric mobility: Apparatus, theory, and applications. J. Aerosol Sci. 1975, 6, 443–451. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, D.R. Experimental evaluation of miniature plate DMAs (mini-plate DMAs) for future ultrafine particle (UFP) sensor network. Aerosol Sci. Technol. 2016, 50, 297–307. [Google Scholar] [CrossRef]

- Zhang, S.H.; Akutsu, Y.; Russell, L.M.; Flagan, R.C. Radial Differential Mobility Analyzer. Aerosol Sci. Technol. 1995, 23, 357–372. [Google Scholar] [CrossRef]

- Russell, L.M.; Stolzenburg, M.R.; Zhang, S.H.; Caldow, R.; Flagan, R.C.; Seinfeld, J.H. Radially Classified Aerosol Detector for Aircraft Based Submicron Aerosol Measurements. J. Atmos. Ocean. Technol. 1996, 13, 598–609. [Google Scholar] [CrossRef]

- Ranjan, M.; Dhaniyala, S. Theory and design of a new miniature electrical-mobility aerosol spectrometer. J. Aerosol Sci. 2007, 38, 950–963. [Google Scholar] [CrossRef]

- Steer, B.; Gorbunov, B.; Muir, R.; Ghimire, A.; Rowles, J. Portable Planar DMA: Development and Tests. Aerosol Sci. Technol. 2014, 48, 251–260. [Google Scholar] [CrossRef]

- Alonso, M.; Endo, Y. Dispersion of aerosol particles undergoing Brownian motion. J. Phys. A Math. Gen. 2001, 34, 10745–10755. [Google Scholar] [CrossRef]

- Rus, J.; Moro, D.; Sillero, J.A.; Royuela, J.; Casado, A.; Estevez-Molinero, F.; Fernández de la Mora, J. IMS-MS studies based on coupling a differential mobility analyzer (DMA) to commercial API-MS systems. Int. J. Mass Spectrom. 2010, 298, 30–40. [Google Scholar] [CrossRef]

- Santos, J.P. Performance evaluation of a high-resolution parallel-plate differential mobility analyzer. Atmos. Chem. Phys. 2009, 8, 2419–2429. [Google Scholar] [CrossRef]

- Wang, S.C.; Flagan, R. Scanning Electrical Mobility Spectrometer. Aerosol Sci. Technol. 1989, 13, 230–240. [Google Scholar] [CrossRef]

- Zhang, M.; Wexler, A.S. Cross flow ion mobility spectrometry: Theory and initial prototype testing. Int. J. Mass Spectrom. 2006, 258, 13–20. [Google Scholar] [CrossRef]

- Zhou, G.J.; Yan, Z.Y.; Xu, S.X.; Zhang, K.B. Fluid Mechanics, 2nd ed.; Higher Education Press: Beijing, China, 2011; Volume 2, pp. 150–350. [Google Scholar]

| Length (mm) | Width (mm) | Height (mm) | H/WL |

|---|---|---|---|

| 126 | 50 | 5 | 0.794 |

| Upper Electrode Plate (mm) | Lower Electrode Plate (mm) |

|---|---|

| 0.028 | 0.116 |

| 0.053 | 0.102 |

| 0.043 | 0.077 |

| 0.023 | 0.064 |

| 0.010 | 0.019 |

| 0.060 | 0.006 |

| 0.008 | 0.003 |

| 0.015 | 0.010 |

| 0.026 | 0.017 |

| 0.033 | 0.015 |

| Upper Electrode Plate (mm) | Lower Electrode Plate (mm) |

|---|---|

| −0.004 | 0.008 |

| −0.002 | 0.003 |

| 0.000 | 0.001 |

| −0.001 | 0.000 |

| 0.000 | −0.001 |

| −0.005 | 0.001 |

| −0.007 | 0.001 |

| −0.009 | 0.000 |

| −0.009 | 0.001 |

| −0.009 | 0.000 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, M.; Wang, H.; Sun, Q.; Yu, F.; Wang, Y.; Wan, W.; Wang, C.; Gui, H.; Liu, J.; Lü, L. Simulation of Miniature PDMA for Ultrafine-Particle Measurement. Atmosphere 2019, 10, 116. https://doi.org/10.3390/atmos10030116

Chen M, Wang H, Sun Q, Yu F, Wang Y, Wan W, Wang C, Gui H, Liu J, Lü L. Simulation of Miniature PDMA for Ultrafine-Particle Measurement. Atmosphere. 2019; 10(3):116. https://doi.org/10.3390/atmos10030116

Chicago/Turabian StyleChen, Mingjie, Huanqin Wang, Qiang Sun, Fajun Yu, Yuzhong Wang, Wei Wan, Chengpeng Wang, Huaqiao Gui, Jianguo Liu, and Liang Lü. 2019. "Simulation of Miniature PDMA for Ultrafine-Particle Measurement" Atmosphere 10, no. 3: 116. https://doi.org/10.3390/atmos10030116

APA StyleChen, M., Wang, H., Sun, Q., Yu, F., Wang, Y., Wan, W., Wang, C., Gui, H., Liu, J., & Lü, L. (2019). Simulation of Miniature PDMA for Ultrafine-Particle Measurement. Atmosphere, 10(3), 116. https://doi.org/10.3390/atmos10030116