Cross-Sectional Unification on the Stress-Strain Model of Concrete Subjected to High Passive Confinement by Fiber-Reinforced Polymer

Abstract

:1. Introduction

2. Existing Stress-Strain Models

2.1. Models by Teng’s Group

2.2. Model by Youssef et al.

2.3. Model by Hu and Wang

2.4. Model by Wei and Wu

3. Experimental Database

4. Stress-Strain Modeling

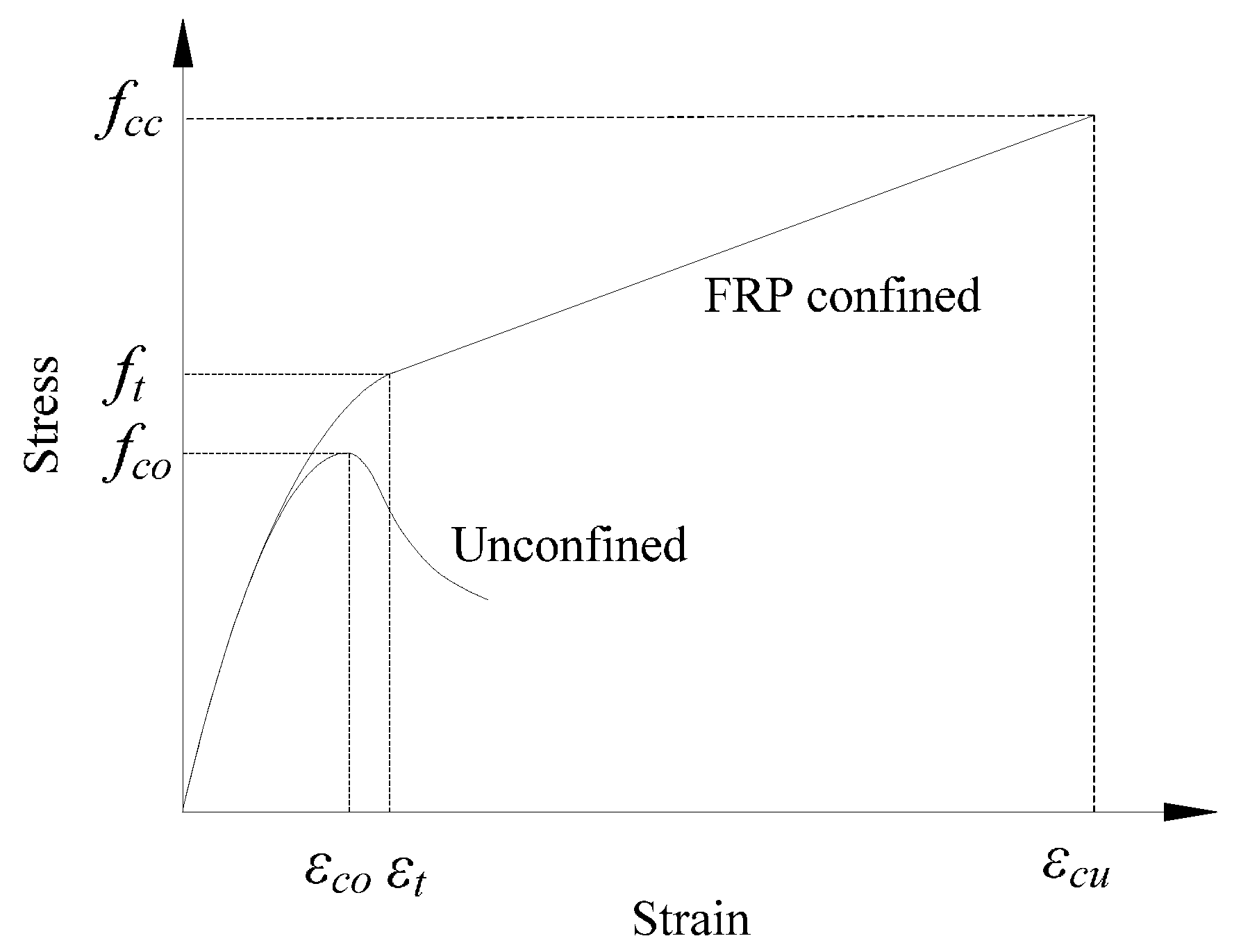

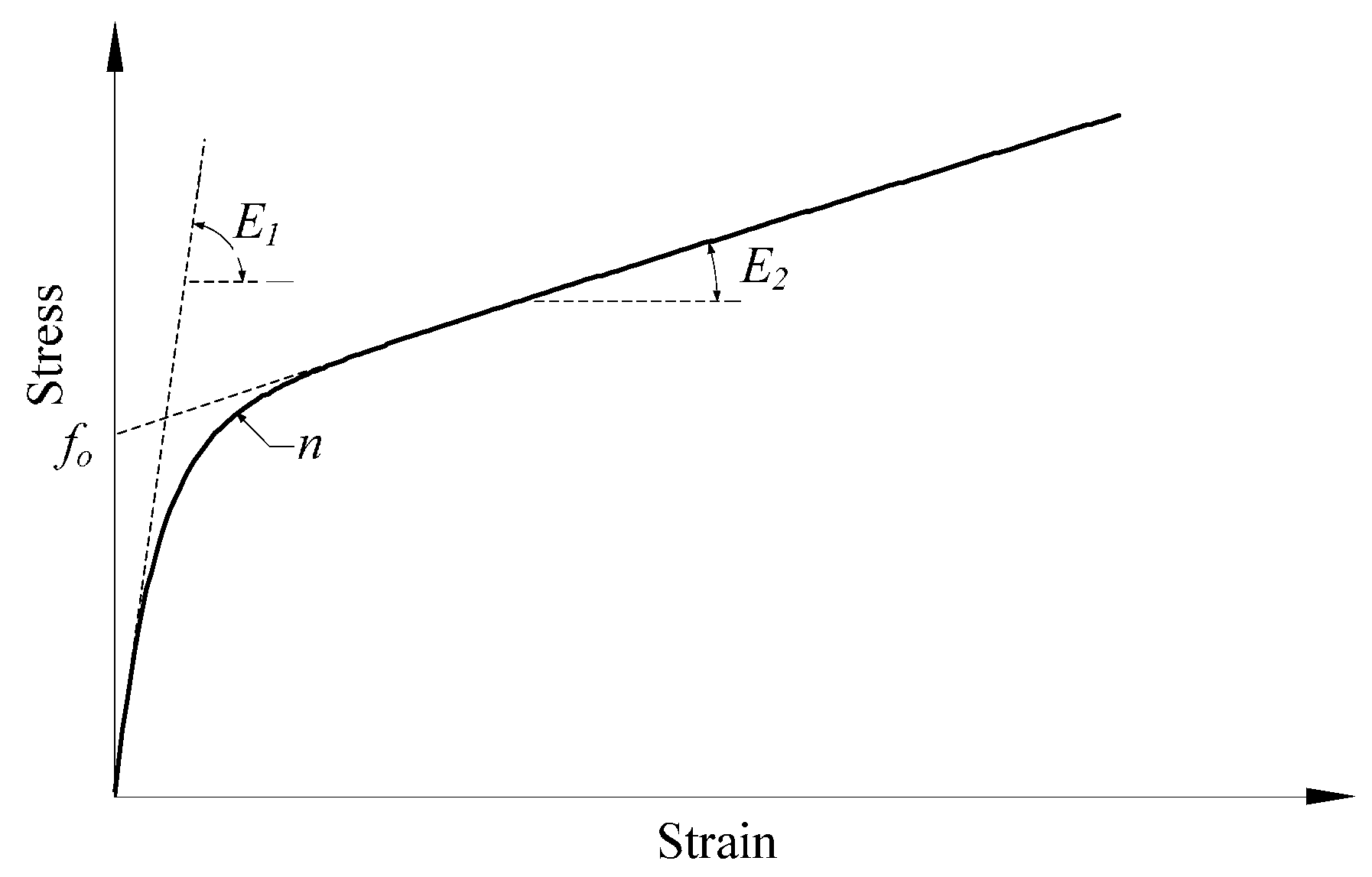

4.1. General Mathematical Model

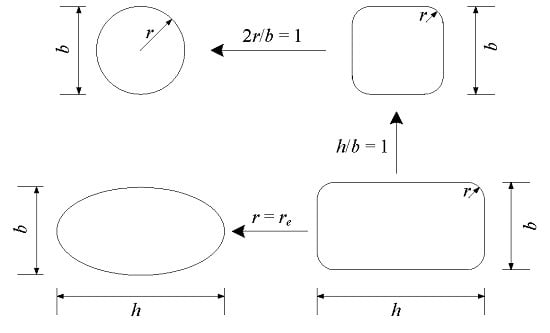

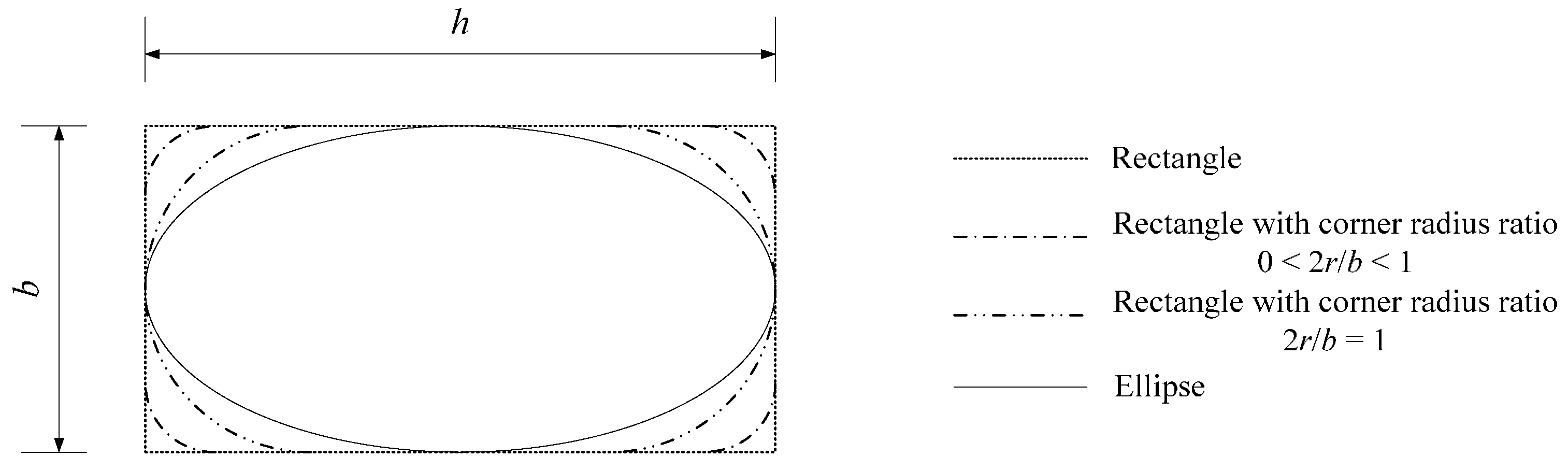

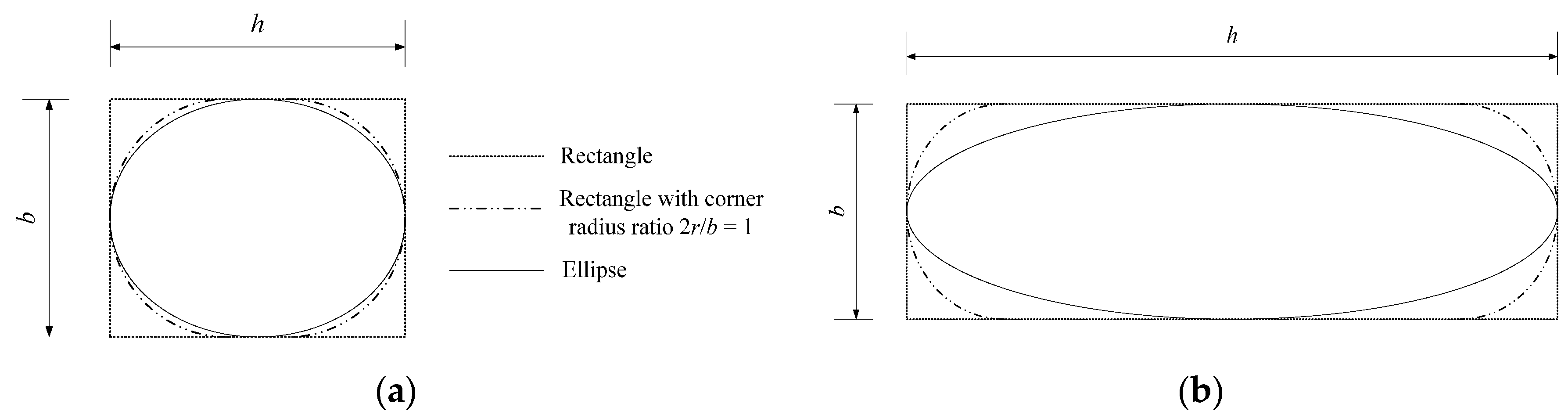

4.2. Cross-Sectional Analysis

4.3. Parameters in Modeling

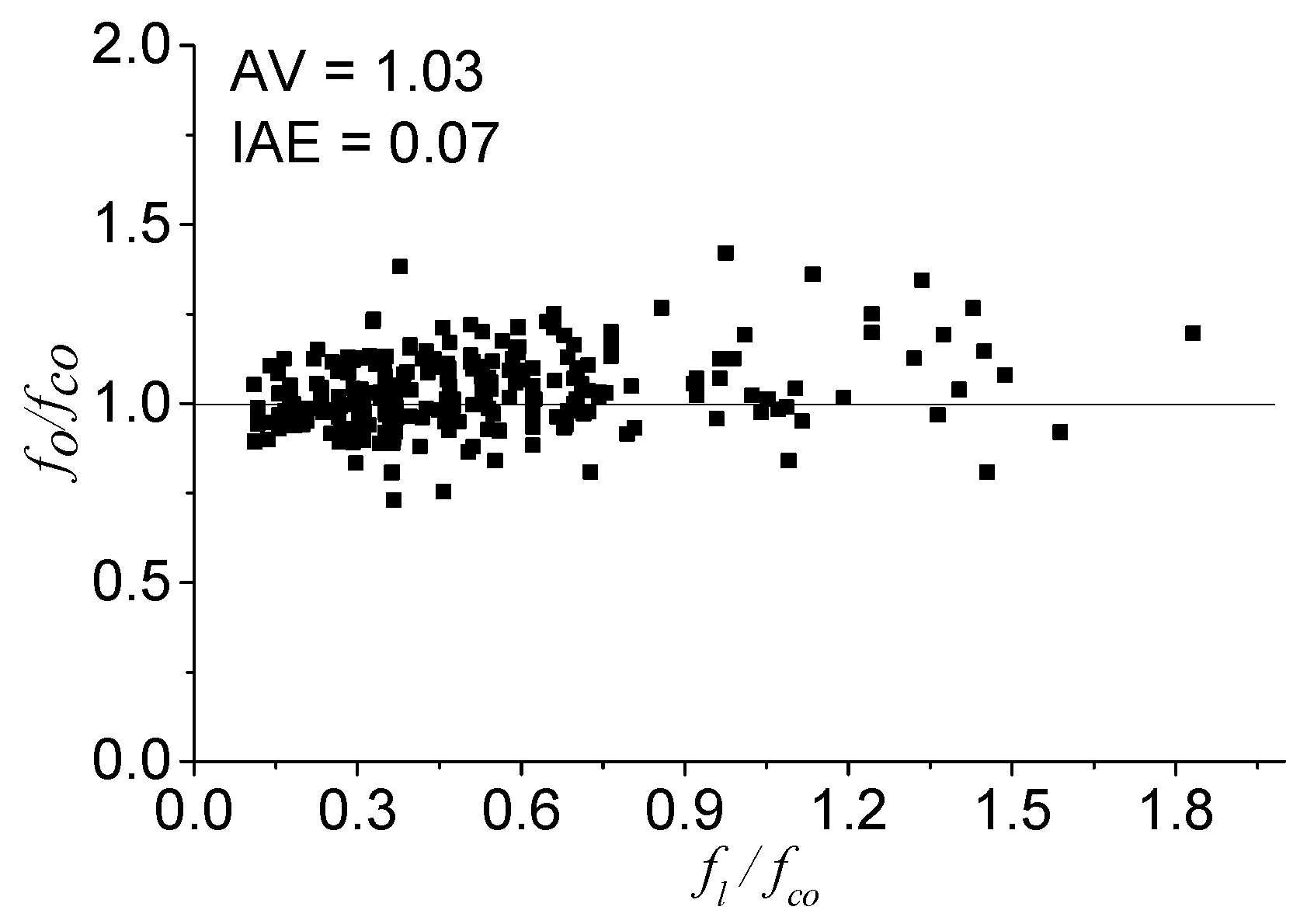

4.3.1. Elastic limit fo

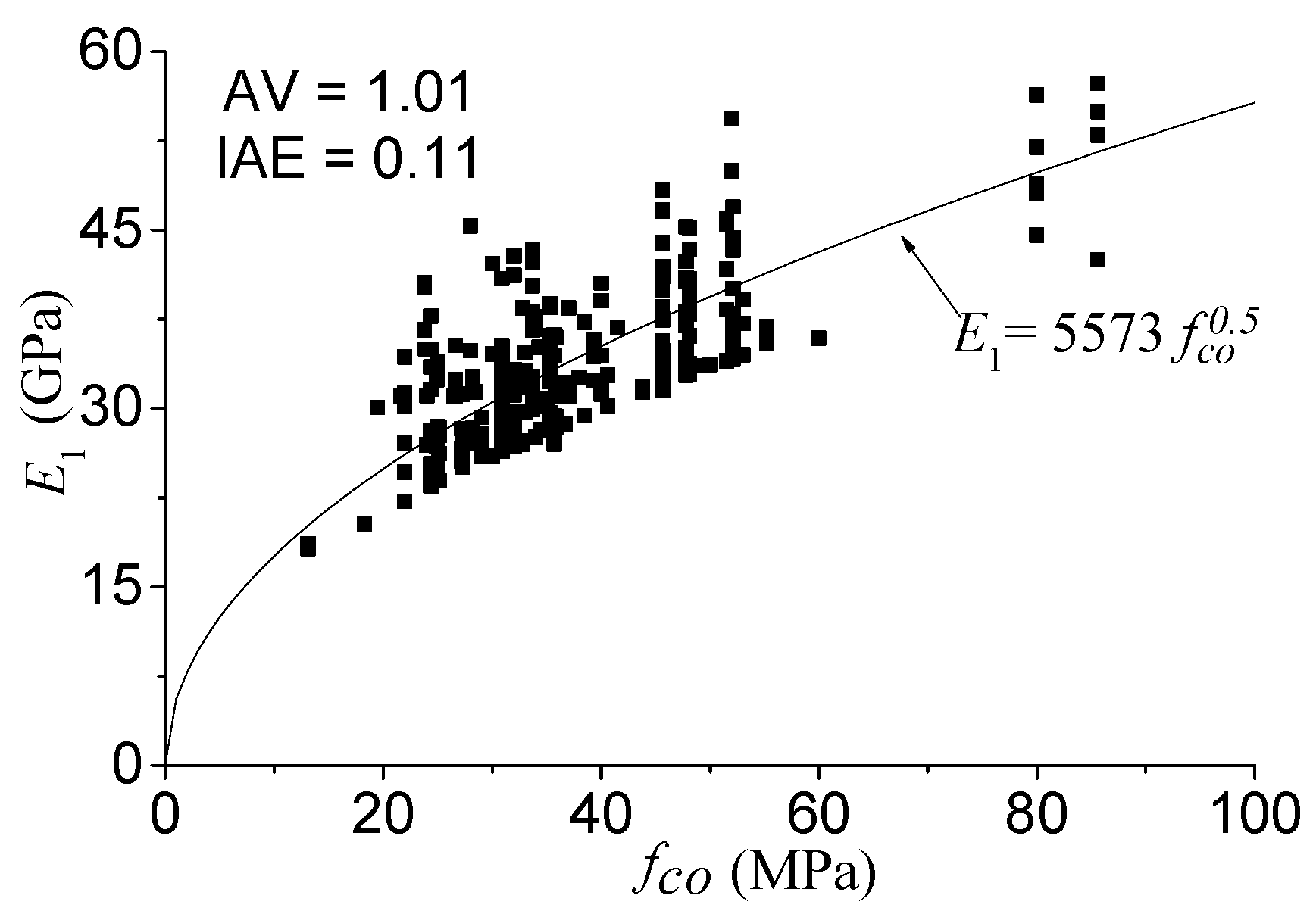

4.3.2. Initial modulus E1

4.3.3. Parameter n

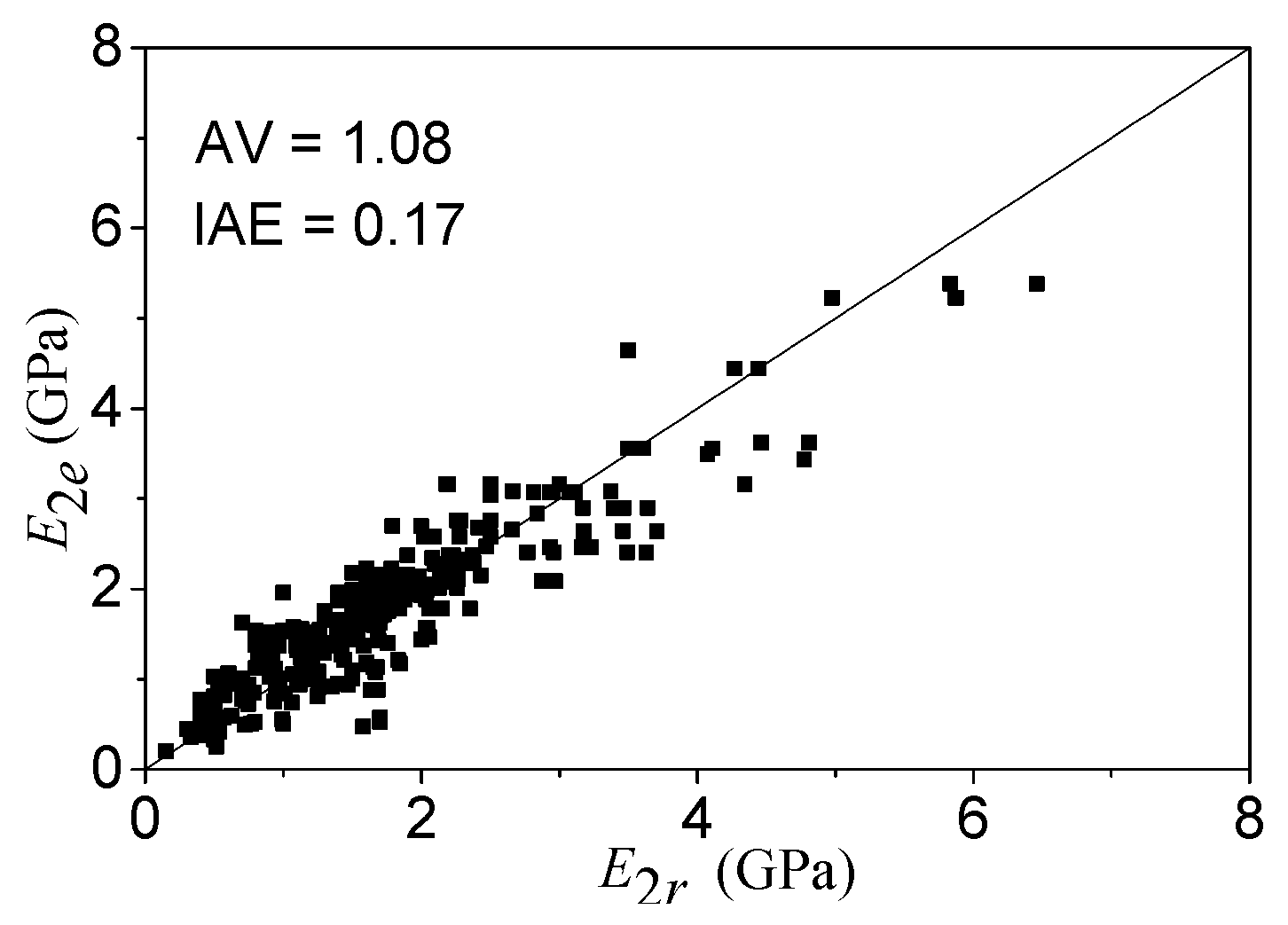

4.3.4. Hardening modulus E2

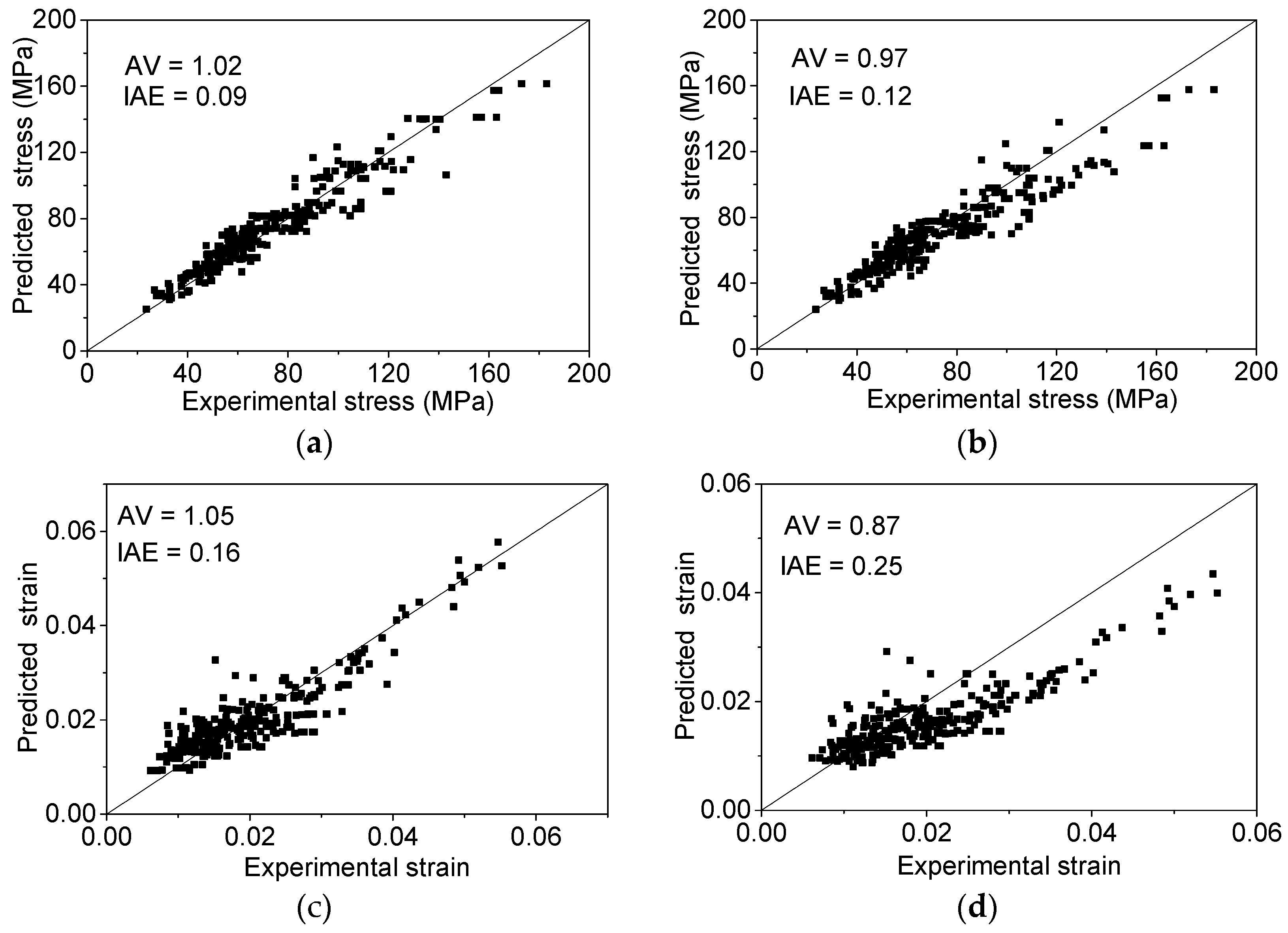

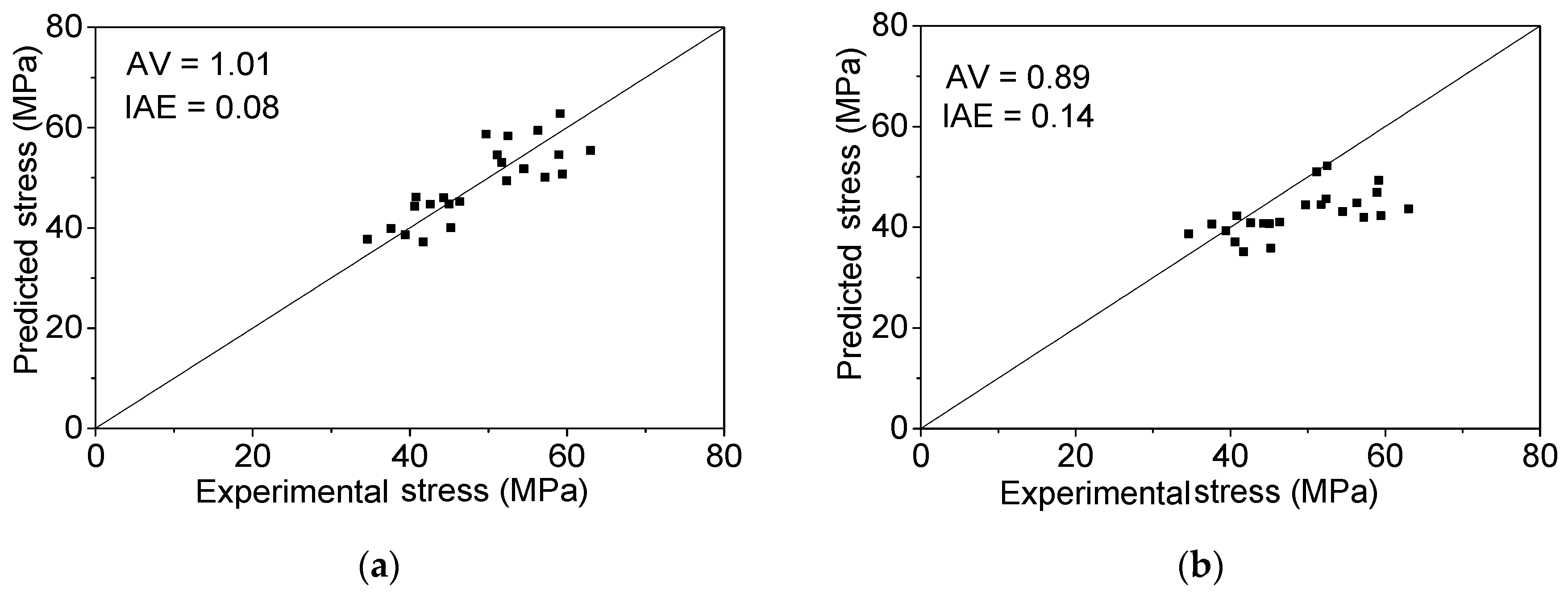

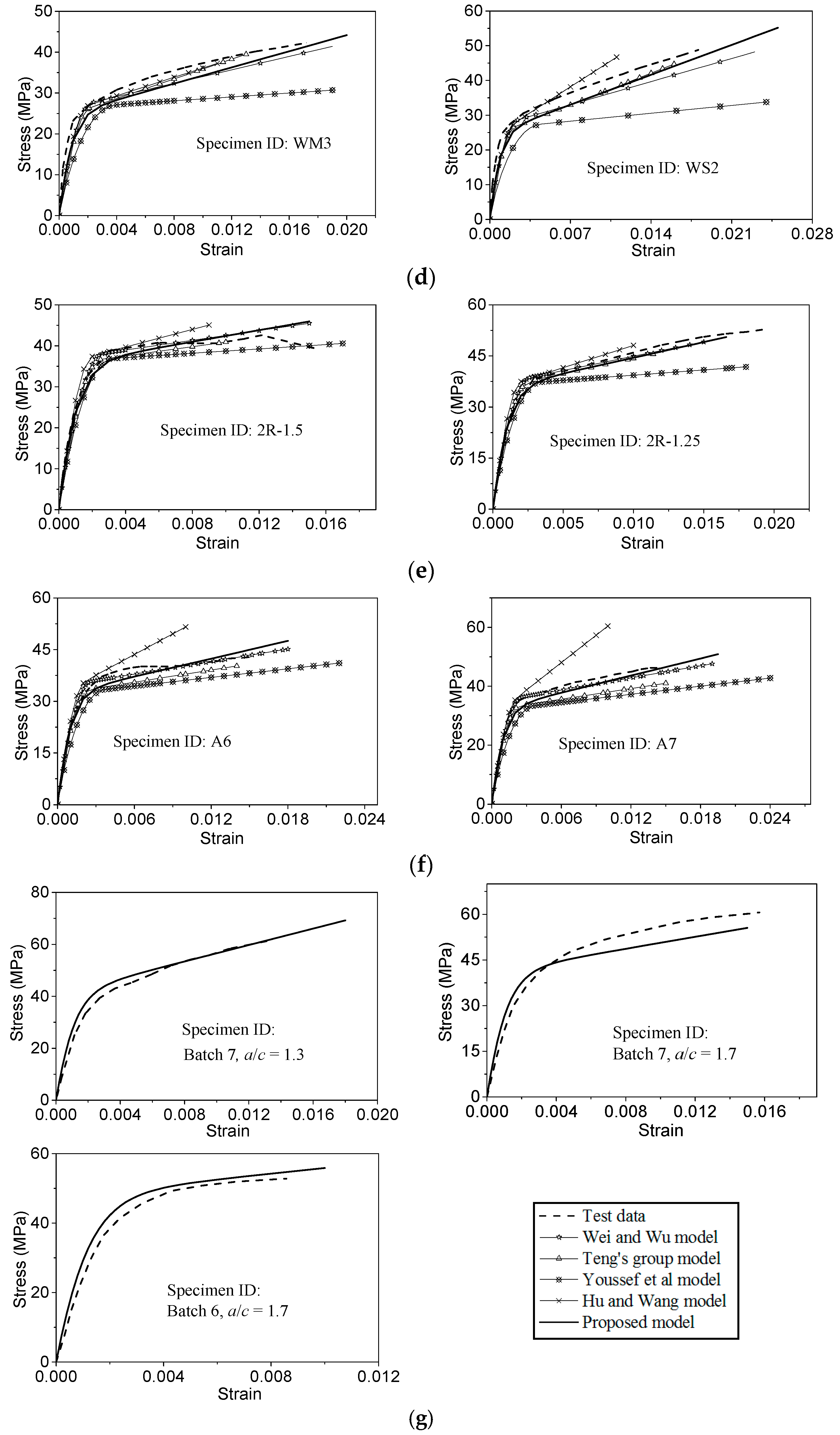

5. Model Performance

5.1. Performance of the Ultimate Strain and Stress Model

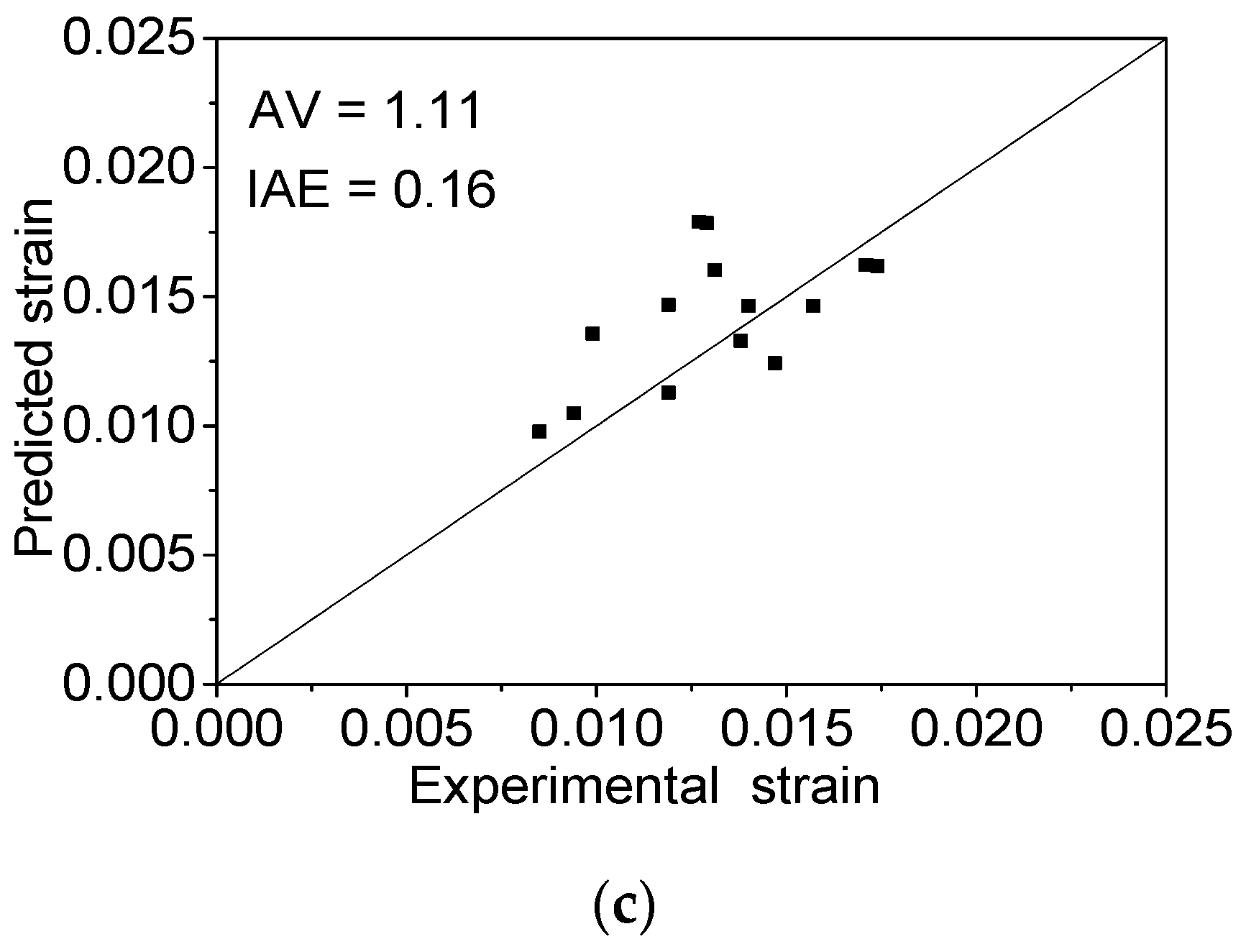

5.2. Performance of the Stress-Strain Relationship Model

6. Conclusions

- (1)

- The equivalent corner radius ratio (2re/b) was introduced to transform the elliptical cross-section into a rectangular cross-section. The elliptical cross-section can be considered as a rectangular cross-section with a special corner radius ratio.

- (2)

- Based on the equivalent confinement efficiency, the relationship between the ellipse and rectangle is obtained. A simple model of the equivalent corner radius ratio for the ellipse is proposed.

- (3)

- Compared to other models and test data, the proposed model has better performance of ultimate stress and strain.

- (4)

- According to the database, a unified stress-strain model is proposed for the FRP-confined different cross-sectional concrete columns. The advantage of this model is that it can predict the stress-strain relationship for FRP-confined circular, square, rectangular and elliptical columns. Compared to other models and experimental data, the proposed models in this paper show better agreement with the experimental data.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bakis, C.; Bank, L.; Brown, V.; Cosenza, E.; Davalos, J.; Lesko, J.; Machida, A.; Rizkalla, S.; Triantafillou, T. Fiber-reinforced polymer composites for construction—State-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, Y.F.; Wu, G. Plastic hinge length of FRP-confined square RC columns. J. Compos. Constr. 2014, 18, 04014003. [Google Scholar] [CrossRef]

- Aram, M.R.; Czaderski, C.; Motavalli, M. Debonding failure modes of flexural FRP-strengthened RC beams. Compos. Part B 2008, 39, 826–841. [Google Scholar] [CrossRef]

- Yu, Q.Q.; Chen, T.; Gu, X.L.; Zhao, X.L.; Xiao, Z.G. Fatigue behaviour of CFRP strengthened steel plates with different degrees of damage. Thin Wall. Struct. 2013, 69, 10–17. [Google Scholar] [CrossRef]

- Wu, Y.F.; Xu, X.S.; Sun, J.B.; Jiang, C. Analytical solution for the bond strength of externally bonded reinforcement. Compos. Struct. 2012, 94, 3232–3239. [Google Scholar] [CrossRef]

- Abbasnia, R.; Hosseinpour, F.; Rostamian, M.; Ziaadiny, H. Cyclic and monotonic behavior of FRP confined concrete rectangular prisms with different aspect ratios. Constr. Build. Mater. 2013, 40, 118–125. [Google Scholar] [CrossRef]

- Benzaid, R.; Mesbah, H.; Chikh, N.E. FRP-confined concrete cylinders: Axial compression experiments and strength model. J. Reinf. Plast. Comp. 2010, 29, 2469–2488. [Google Scholar] [CrossRef]

- Berthet, J.; Ferrier, E.; Hamelin, P. Compressive behavior of concrete externally confined by composite jackets: Part B: Modeling. Constr. Build. Mater. 2006, 20, 338–347. [Google Scholar] [CrossRef]

- Cui, C.; Sheikh, S. Analytical model for circular normal-and high-strength concrete columns confined with FRP. J. Compos. Constr. 2010, 14, 562–572. [Google Scholar] [CrossRef]

- Cusson, D.; Paultre, P. Stress-strain model for confined high-strength concrete. J. Struct. Eng. 1995, 121, 468–477. [Google Scholar] [CrossRef]

- Harajli, M.H. Axial stress–strain relationship for FRP confined circular and rectangular concrete columns. Cem. Concr. Comp. 2006, 28, 938–948. [Google Scholar] [CrossRef]

- Harajli, M.H.; Hantouche, E.; Soudki, K. Stress-strain model for fiber-reinforced polymer jacketed concrete columns. ACI Struct. J. 2006, 103, 672–682. [Google Scholar]

- Hu, B.; Wang, J.G. Unified model for calculating stress-strain relationship of circular and rectangular concrete columns confined with FRP. J. Xi’an Univ. Arch. Tech. 2010, 4, 394–406. (In Chinese) [Google Scholar]

- Lam, L.; Teng, J.G. Design-oriented stress-strain model for FRP-confined concrete. Constr. Build. Mater. 2003, 17, 471–489. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-oriented stress-strain model for FRP-confined concrete in rectangular columns. J. Reinf. Plast. Comp. 2003, 22, 1149–1186. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Stress-strain model for FRP-confined concrete under cyclic axial compression. Eng. Struct. 2009, 31, 308–321. [Google Scholar] [CrossRef]

- Matthys, S.; Toutanji, H.; Taerwe, L. Stress–strain behavior of large-scale circular columns confined with FRP composites. J. Struct. Eng. 2006, 132, 123–133. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Lim, J.C. Axial compressive behavior of FRP-confined concrete: Experimental test database and a new design-oriented model. Compos. Part B 2013, 55, 607–634. [Google Scholar] [CrossRef] [Green Version]

- Wei, Y.Y.; Wu, Y.F. Unified stress-strain model of concrete for FRP-confined columns. Constr. Build. Mater. 2012, 26, 381–392. [Google Scholar] [CrossRef]

- Wu, G.; Wu, Z.S.; Lü, Z.T. Design-oriented stress–strain model for concrete prisms confined with FRP composites. Constr. Build. Mater. 2007, 21, 1107–1121. [Google Scholar] [CrossRef]

- Wu, Y.F.; Jiang, C. Effect of load eccentricity on the stress–strain relationship of FRP-confined concrete columns. Compos. Struct. 2013, 98, 228–241. [Google Scholar] [CrossRef]

- Wu, Y.F.; Wang, L.M. Unified strength model for square and circular concrete columns confined by external jacket. J. Struct. Eng. 2009, 135, 253–261. [Google Scholar] [CrossRef]

- Wu, Y.F.; Wei, Y. General Stress-Strain Model for Steel-and FRP-Confined Concrete. J. Compos. Constr. 2014, 19, 04014069. [Google Scholar] [CrossRef]

- Wu, Y.F.; Zhou, Y.W. Unified strength model based on Hoek-Brown failure criterion for circular and square concrete columns confined by FRP. J. Compos. Constr. 2010, 14, 175–184. [Google Scholar] [CrossRef]

- Cao, Y.G.; Wu, Y.F.; Li, X.Q. Unified model for evaluating ultimate strain of FRP confined concrete based on energy method. Constr. Build. Mater. 2016, 103, 23–35. [Google Scholar] [CrossRef]

- Ilki, A.; Kumbasar, N. Behavior of damaged and undamaged concrete strengthened by carbon fiber composite sheets. Struct. Eng. Mech. 2002, 13, 75–90. [Google Scholar] [CrossRef]

- Ilki, A.; Kumbasar, N. Compressive behaviour of carbon fibre composite jacketed concrete with circular and non-circular cross-sections. J. Earthq. Eng. 2003, 7, 381–406. [Google Scholar] [CrossRef]

- Youssef, M.N.; Feng, M.Q.; Mosallam, A.S. Stress–strain model for concrete confined by FRP composites. Compos. Part B 2007, 38, 614–628. [Google Scholar] [CrossRef]

- Yan, Z.; Pantelides, C.P.; Reaveley, L.D. Fiber-reinforced polymer jacketed and shape-modified compression members: I-experimental behavior. ACI Struct. J. 2006, 103, 885–893. [Google Scholar]

- Ozbakkaloglu, T.; Lim, J.C.; Vincent, T. FRP-confined concrete in circular sections: Review and assessment of stress–strain models. Eng. Struct. 2013, 49, 1068–1088. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T. Behavior of square and rectangular ultra high-strength concrete-filled FRP tubes under axial compression. Compos. Part B 2013, 54, 97–111. [Google Scholar] [CrossRef]

- Teng, J.G.; Lam, L. Compressive behavior of carbon fiber reinforced polymer-confined concrete in elliptical columns. J. Struct. Eng. 2002, 128, 1535–1543. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Strength models for fiber-reinforced plastic-confined concrete. J. Struct. Eng. 2002, 128, 612–623. [Google Scholar] [CrossRef]

- Richart, F.E.; Brandtzaeg, A.; Brown, R.L. A study of the failure of concrete under combined compressive stresses. University of Illinois Bulletin: Champaign, IL, USA, 1928. [Google Scholar]

- Xiao, Y.; Wu, H. Compressive behavior of concrete confined by carbon fiber composite jackets. J. Mater. Civ. Eng. 2000, 12, 139–146. [Google Scholar] [CrossRef]

- Karabinis, A.; Rousakis, T. Concrete confined by FRP material: A plasticity approach. Eng. Struct. 2002, 24, 923–932. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Ultimate condition of fiber reinforced polymer-confined concrete. J. Compos. Constr. 2004, 8, 539–548. [Google Scholar] [CrossRef]

- Almusallam, T.H. Behavior of normal and high-strength concrete cylinders confined with E-glass/epoxy composite laminates. Compos. Part B 2007, 38, 629–639. [Google Scholar] [CrossRef]

- Stefano, C. Experimental Study on Carbon FRP-Confined Elliptical Concrete Columns. Master’s Thesis, University of Bologna, Bologna, Italy, 2011. [Google Scholar]

- Wang, L.M. Effect of corner radius on the performance of CFRP-confined square concrete columns. Master’s Thesis, City University of Hong Kong, Hongkong, China, 2007. [Google Scholar]

- Cui, C.; Sheikh, S. Experimental study of normal-and high-strength concrete confined with fiber-reinforced polymers. J. Compos. Constr. 2010, 14, 553–561. [Google Scholar] [CrossRef]

- Akogbe, R.K.; Liang, M.; Wu, Z.M. Size effect of axial compressive strength of CFRP confined concrete cylinders. Int. J. Concr. Struct. Mater. 2011, 5, 49–55. [Google Scholar] [CrossRef]

- Wu, Y.F.; Yun, Y.C.; Wei, Y.Y.; Zhou, Y.W. Effect of predamage on the stress-strain relationship of confined concrete under monotonic loading. J. Struct. Eng. 2014, 140, 04014093. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G.; Cheung, C.; Xiao, Y. FRP-confined concrete under axial cyclic compression. Cem. Concr. Comp. 2006, 28, 949–958. [Google Scholar] [CrossRef]

- Wu, Y.F.; Jiang, J.F. Effective strain of FRP for confined circular concrete columns. Compos. Struct. 2013, 95, 479–491. [Google Scholar] [CrossRef]

- Masia, M.J.; Gale, T.N.; Shrive, N.G. Size effects in axially loaded square-section concrete prisms strengthened using carbon fibre reinforced polymer wrapping. Can. J. Civ. Eng. 2004, 31, 1–13. [Google Scholar] [CrossRef]

- Tao, Z.; Yu, Q.; Zhong, Y.Z. Compressive behaviour of CFRP-confined rectangular concrete columns. Mag. Concr. Res. 2008, 60, 735–745. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Wang, D.Y.; Smith, S.T. Size effect of square concrete columns confined with CFRP wraps. In Proceedings of the 3rd Asia-Pacific Conference on FRP in Structures, Hokkaido University, Sapporo, Japan, 2–4 February 2012.

- Wei, Y.Y. Stress-Strain Behavior of FRP-Confined Concrete Column. Ph.D. Thesis, City University of Hong Kong, Hong Kong, China, 2014. [Google Scholar]

- Abbasnia, R.; Ziaadiny, H. Experimental investigation and strength modeling of CFRP-confined concrete rectangular prisms under axial monotonic compression. Mater. Struct. 2015, 48, 485–500. [Google Scholar] [CrossRef]

- Rochette, P.; Labossiere, P. Axial testing of rectangular column models confined with composites. J. Compos. Constr. 2000, 4, 129–136. [Google Scholar] [CrossRef]

- Chaallal, O.; Shahawy, M.; Hassan, M. Performance of axially loaded short rectangular columns strengthened with carbon fiber-reinforced polymer wrapping. J. Compos. Constr. 2003, 7, 200–208. [Google Scholar] [CrossRef]

- Girgin, Z.C.; Arioglu, N.; Arioglu, E. Evaluation of strength criteria for very high strength concretes under triaxial compression. ACI Struct. J. 2007, 104, 278–284. [Google Scholar]

- Wu, Y.F.; Jiang, C. Quantification of bond-slip relationship for externally bonded FRP-to-concrete joints. J. Compos. Constr. 2013, 17, 673–686. [Google Scholar] [CrossRef]

- Zhou, Y.W.; Wu, Y.F. General model for constitutive relationships of concrete and its composite structures. Compos. Struct. 2012, 94, 580–592. [Google Scholar] [CrossRef]

- Popovics, S. A numerical approach to the complete stress-strain curve of concrete. Cem. Concr. Res. 1973, 3, 583–599. [Google Scholar] [CrossRef]

- Fahmy, M.F.; Wu, Z.S. Evaluating and proposing models of circular concrete columns confined with different FRP composites. Compos. Part B 2010, 41, 199–213. [Google Scholar] [CrossRef]

- Ilki, A.; Kumbasar, N.; Koc, V. Low strength concrete members externally confined with FRP sheets. Struct. Eng. Mech. 2004, 18, 167–194. [Google Scholar] [CrossRef]

- Ilki, A.; Peker, O.; Karamuk, E.; Demir, C.; Kumbasar, N. FRP retrofit of low and medium strength circular and rectangular reinforced concrete columns. J. Mater. Civ. Eng. 2008, 20, 169–188. [Google Scholar] [CrossRef]

- Nisticò, N.; Pallini, F.; Rousakis, T.; Wu, Y.F.; Karabinis, A. Peak strength and ultimate strain prediction for FRP confined square and circular concrete sections. Compos. Part B 2014, 67, 543–554. [Google Scholar] [CrossRef]

- Campione, G.; Fossetti, M. Compressive behaviour of concrete elliptical columns confined by single hoops. Eng. Struct. 2007, 29, 408–417. [Google Scholar] [CrossRef]

- Wang, L.M.; Wu, Y.F. Effect of corner radius on the performance of CFRP-confined square concrete columns: Test. Eng. Struct. 2008, 30, 493–505. [Google Scholar] [CrossRef]

- Wu, Y.F.; Wei, Y.Y. Effect of cross-sectional aspect ratio on the strength of CFRP-confined rectangular concrete columns. Eng. Struct. 2010, 32, 32–45. [Google Scholar] [CrossRef]

| Ref. | Model | Cross-section # | Supplementary notation |

|---|---|---|---|

| Teng’s group [14,15,32,33] | ; | C | k = 2 in [33] and 3.3 in [14]; εf is the ultimate strain of FRP; εco is the peak strain of plain concrete; fl is the confinement pressure; r is the corner radius; h is the length of the longer side of the rectangle; b is the length of the shorter side of the rectangle or the side of the square; a and c are the lengths of major and minor axis, respectively. |

| ; ; ; | R | ||

| E | |||

| Youssef et al. [28] | ; ; ; | C | ρf is the volume ratio of the FRP; Ef is the elastic modulus of the FRP; εjt is the FRP strain at the transition from the first to the second region, which is equal to 0.002; and ffrp is the tensile strength of FRP. |

| ; ; ; | R | ||

| Hu and Wang [13] | ; ; ; ; ; | C&R | νct is Poisson’s ratio for the turning point; t is the thickness of FRP; Ef is the tensile elastic modulus of FRP; νf is Poisson’s ratio for FRP; b is the diameter of the circular cross-section or the width of the rectangular and or square cross-section; Af and Ac are the areas of the FRP and concrete, respectively. |

| Wei and Wu [19]. | ; ; ; ; | C&R | fo and εo are the transitional stress and strain of confined concrete, respectively; fcc and εcu are the ultimate stress and ultimate strain of confined concrete, respectively; and f30 is the concrete strength of unconfined grade C30 concrete, which is equal to 30 MPa. |

| Reference | Specimen No. | Section | Specimen size | fco (MPa) | FRP type | ffrp (MPa) | tfrp (mm) |

|---|---|---|---|---|---|---|---|

| Type # | (mm) ^ | ||||||

| Xiao and Wu [35] | 17 | C | 152 × 305 | 33.7–55.2 | CFRP | 1,577 | 0.38–1.14 |

| Karabinis and Rousakis [36] | 7 | C | 200 × 320 | 35.7–38.5 | CFRP | 3,720 | 0.117–0.351 |

| Lam and Teng [37] | 13 | C | 152 × 305 | 34.3–38.5 | CFRP, | 4,203 | 0.165–0.495 |

| GFRP | 490 | 1.27–2.54 | |||||

| Almusallam [38] | 5 | C | 150 × 300 | 48–60 | GFRP | 540 | 1.3–1.9 |

| Lam et al. [44] | 6 | C | 152 × 305 | 39, 41 | CFRP | 3,754; 3,800 | 0.165, 0.33 |

| Stefano Casalboni [39] | 5 | C | 200 × 400 | 32.6–47.8 | CFRP | 3800 | 0.171–0.342 |

| Wang [40] | 12 | C | 150 × 300 | 30.9, 52.1 | CFRP | 3,788; 4,364 | 0.165–0.33 |

| Cui and Sheikh [41] | 58 | C | 150 × 300 | 45.6–85.6 | CFRP, GFRP | 849–3,648 | 0.111–3 |

| Akogbe et al. [42] | 2 | C | 100 × 200; 200 × 400 | 33.8 | CFRP | 3,248 | 0.167–0.334 |

| Cao et al. [25] | 11 | C | 150 × 300 | 25–60 | CFRP | 4,192 | 0.0495–0.33 |

| Wu and Jiang [45] | 33 | C | 150 × 300 | 20.6–36.7 | CFRP | 4,441 | 0.167–0.835 |

| Wu et al. [43] | 12 | C | 150 × 300 | 32–53 | CFRP | 4,192 | 0.167–0.334 |

| Teng and Lam [32] | 9 | E | 168 × 132 × 600, 195 × 115 × 600, 238 × 95 × 600 | 36.6–39.0 | CFRP | 3,983; 3,824 | 0.165, 0.22 |

| Stefano Casalboni [39] | 14 | E | 200 × 100 × 400, 200 × 120 × 400, 200 × 155 × 400. | 32.6–47.8 | CFRP | 3,800 | 0.171–0.342 |

| Rochette and Labossiere [51] | 2 | S | 152 × 152 × 500, r: 25,38 | 35.8, 42 | CFRP | 1,265 | 0.9, 1.2 |

| Lam and Teng [15] | 6 | S | 150 × 150 × 600, r: 15, 25 | 24, 33.7 | CFRP | 4,519 | 0.165–0.495 |

| Masia et al. [46] | 6 | S | (100–1500) × (100–150) × (300–450) r: 25 | 23.8–24 | CFRP | 3,500 | 0.26 |

| Wang [40] | 27 | S | 150 × 150 × 300, r: 30–60 | 30.9, 52.1 | CFRP | 3,788; 4,364 | 0.165–0.33 |

| Tao et al. [47] | 4 | S | 150 × 150 × 450, r: 20, 35 | 22, 49.5 | CFRP | 4,200; 4,470 | 0.17, 0.34 |

| Abbasnia et al. [6] | 1 | S | 150 × 150 × 300, r: 42 | 30 | CFRP | 3,943.5 | 0.489 |

| Wang et al. [48] | 10 | S | (100–400) × (100–400) × (300–1200) r: 10–45 | 24.4 | CFRP | 4,340 | 0.167–0.668 |

| Wei [49] | 5 | S | 150 × 300 × 300, r: 30 | 35.3 | CFRP | 4,192 | 0.167–0.334 |

| Abbasnia and Ziaadiny [50] | 7 | S | 150 × 150 × 300, r: 13.6–42 | 32–51.5 | CFRP | 3,943.5 | 0.352 |

| Lam and Teng [15] | 1 | R | 150 × 225 × 600, r: 25 | 41.5 | CFRP | 4,519 | 0.66 |

| Chaallal et al. [52] | 4 | R | 108 × 165, r: 25.4 | 25.1 | CFRP | 3,650 | 0.17 |

| Tao et al. [47] | 4 | R | 150 × 230 × 450, | 19.5, 22 | CFRP | 4,470 | 0.34 |

| 150 × 300 × 450, r: 20–50 | |||||||

| Abbasnia et al. [6] | 2 | R | (90, 120) × 180 × 300, r: 25.2–33.6 | 30 | CFRP | 3,943.5 | 0.489 |

| Wei [49] | 6 | R | 150 × 188 × 300, | 35.3 | CFRP | 4,192 | 0.167–0.335 |

| 150 × 225 × 300, r: 30 | |||||||

| Abbasnia and Ziaadiny [50] | 7 | R | 90 × 180 × 300, 120 × 180 × 300, r: 18.1–34.5 | 32–51.6 | CFRP | 3,943.5 | 0.352 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Y.-G.; Jiang, C.; Wu, Y.-F. Cross-Sectional Unification on the Stress-Strain Model of Concrete Subjected to High Passive Confinement by Fiber-Reinforced Polymer. Polymers 2016, 8, 186. https://doi.org/10.3390/polym8050186

Cao Y-G, Jiang C, Wu Y-F. Cross-Sectional Unification on the Stress-Strain Model of Concrete Subjected to High Passive Confinement by Fiber-Reinforced Polymer. Polymers. 2016; 8(5):186. https://doi.org/10.3390/polym8050186

Chicago/Turabian StyleCao, Yu-Gui, Cheng Jiang, and Yu-Fei Wu. 2016. "Cross-Sectional Unification on the Stress-Strain Model of Concrete Subjected to High Passive Confinement by Fiber-Reinforced Polymer" Polymers 8, no. 5: 186. https://doi.org/10.3390/polym8050186