Interlaminar Fracture Toughness of CFRP Laminates Incorporating Multi-Walled Carbon Nanotubes

Abstract

:1. Introduction

2. Experimental Methods

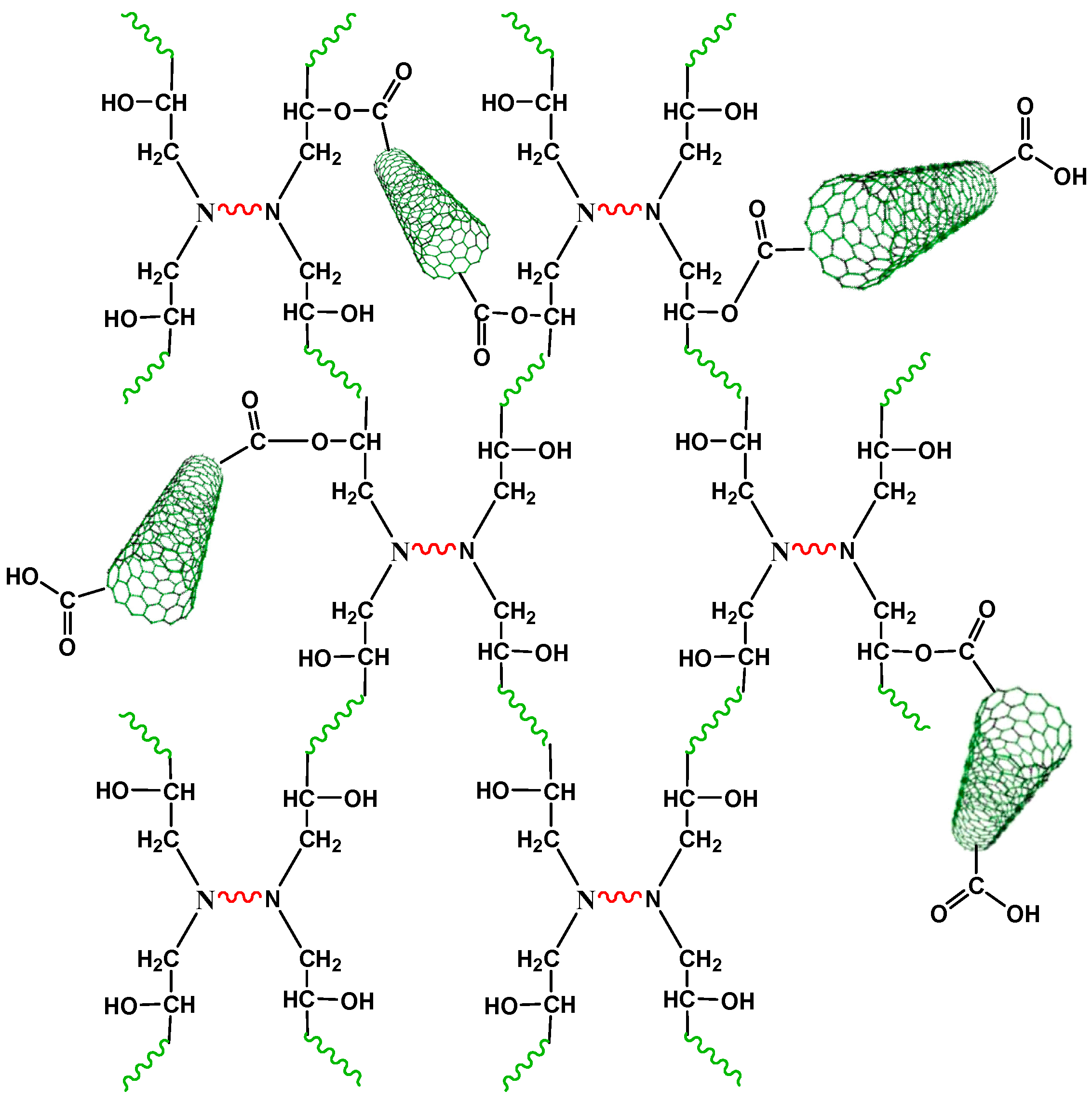

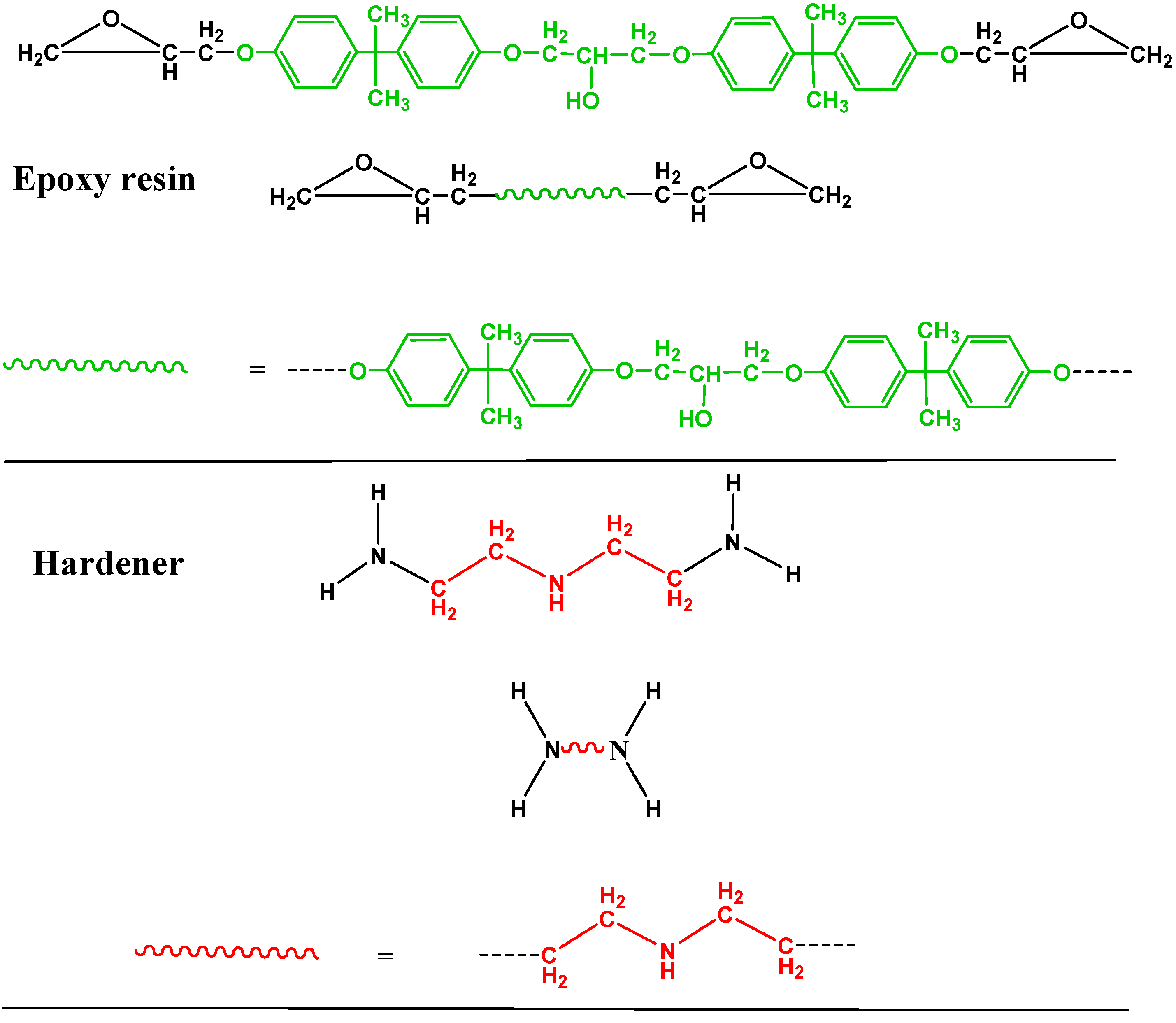

2.1. Materials

2.2. Dispersion of COOH–MWCNTs in Epoxy

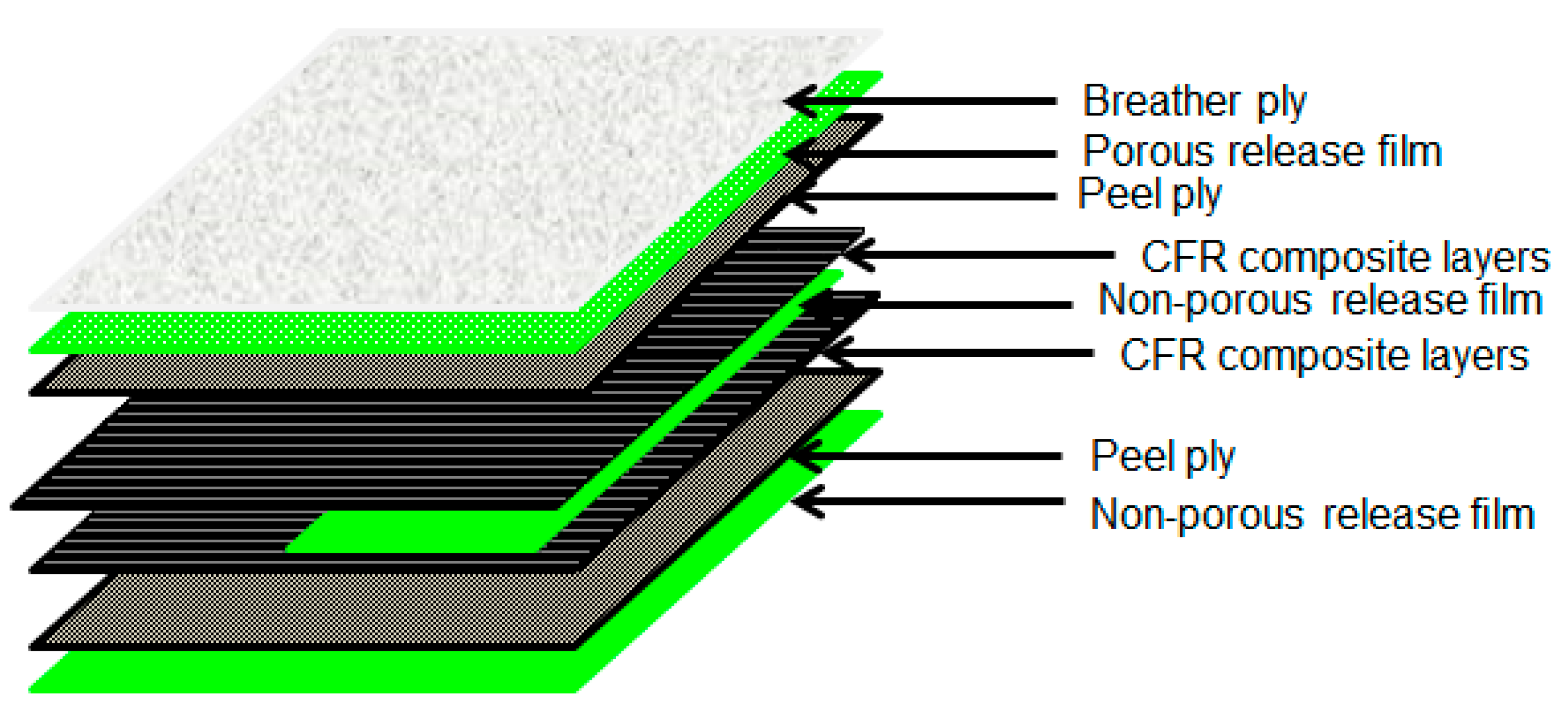

2.3. Laminate Fabrication

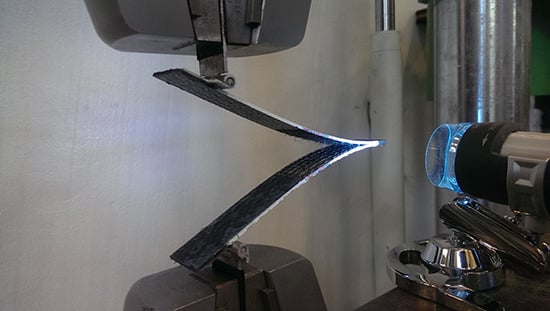

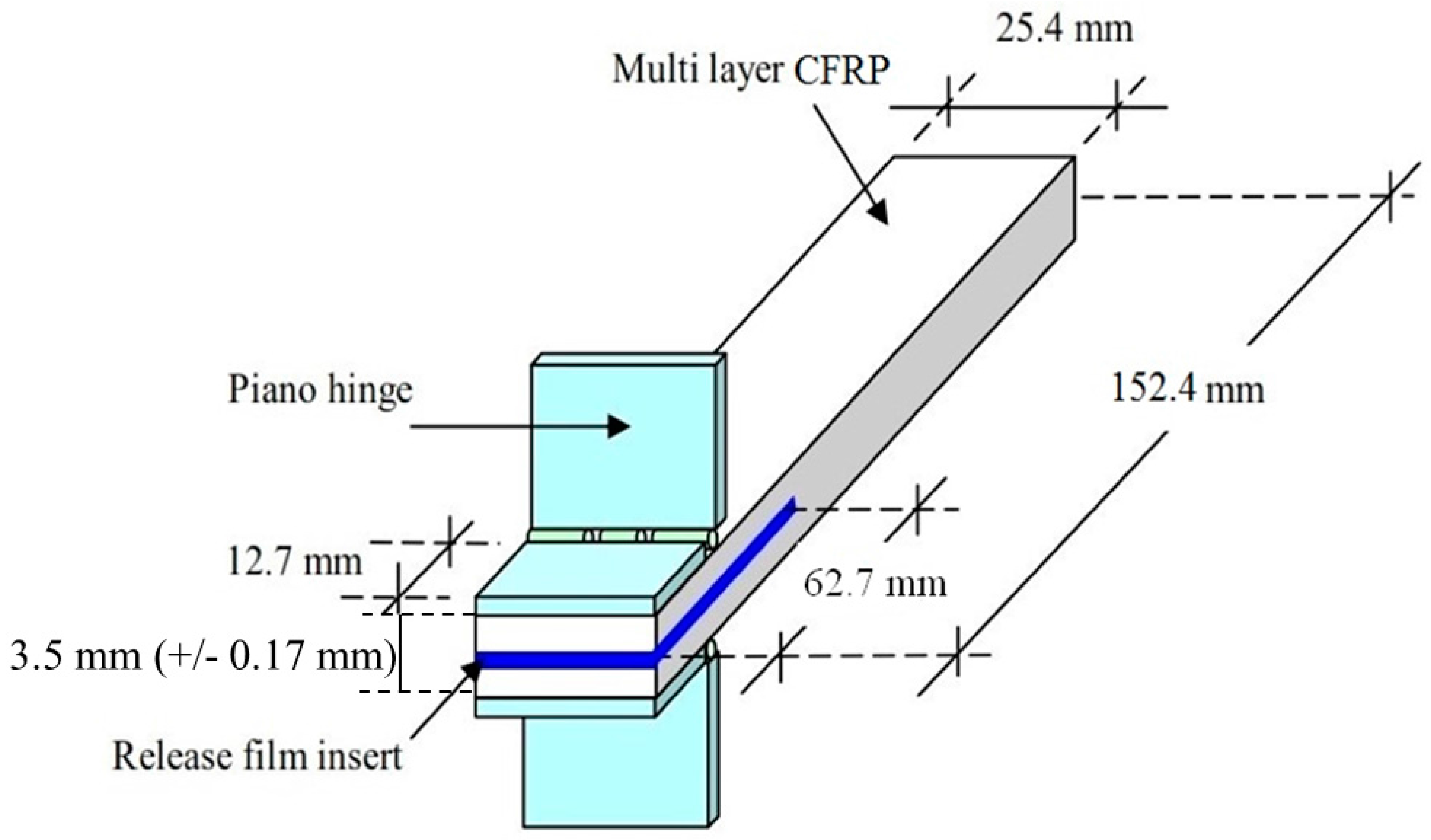

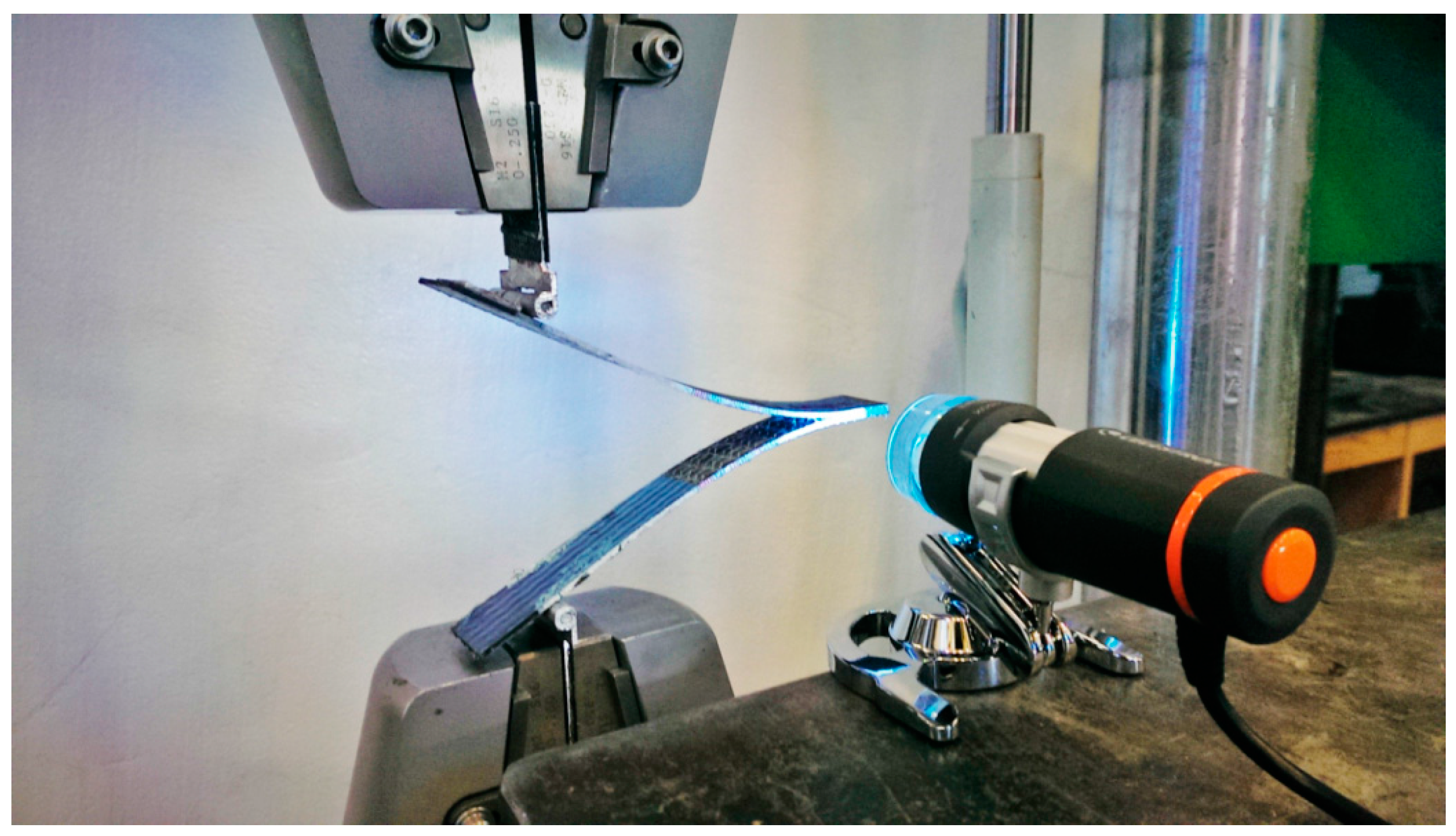

2.4. Mode I Fracture Testing Setup

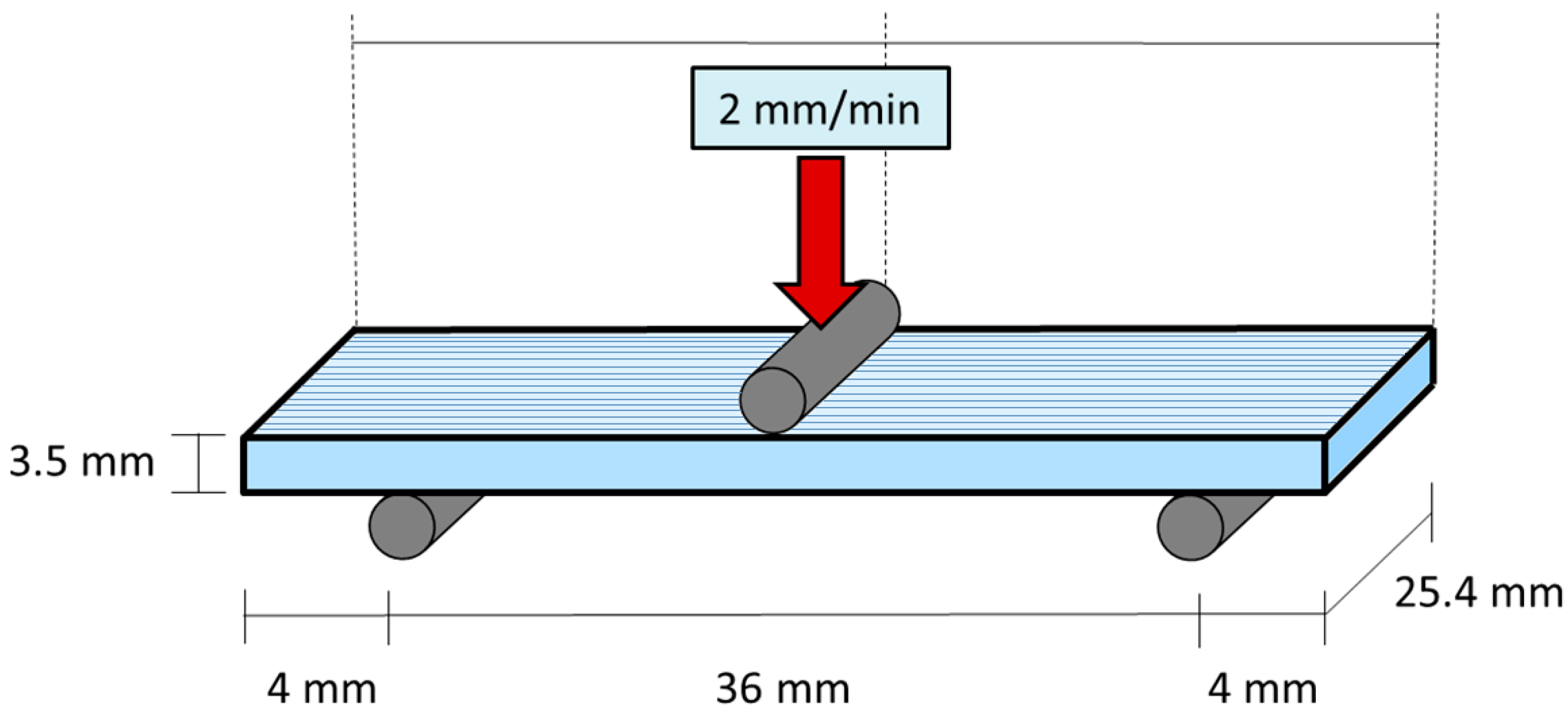

2.5. Flexural Testing

2.6. Spectroscopic Analysis

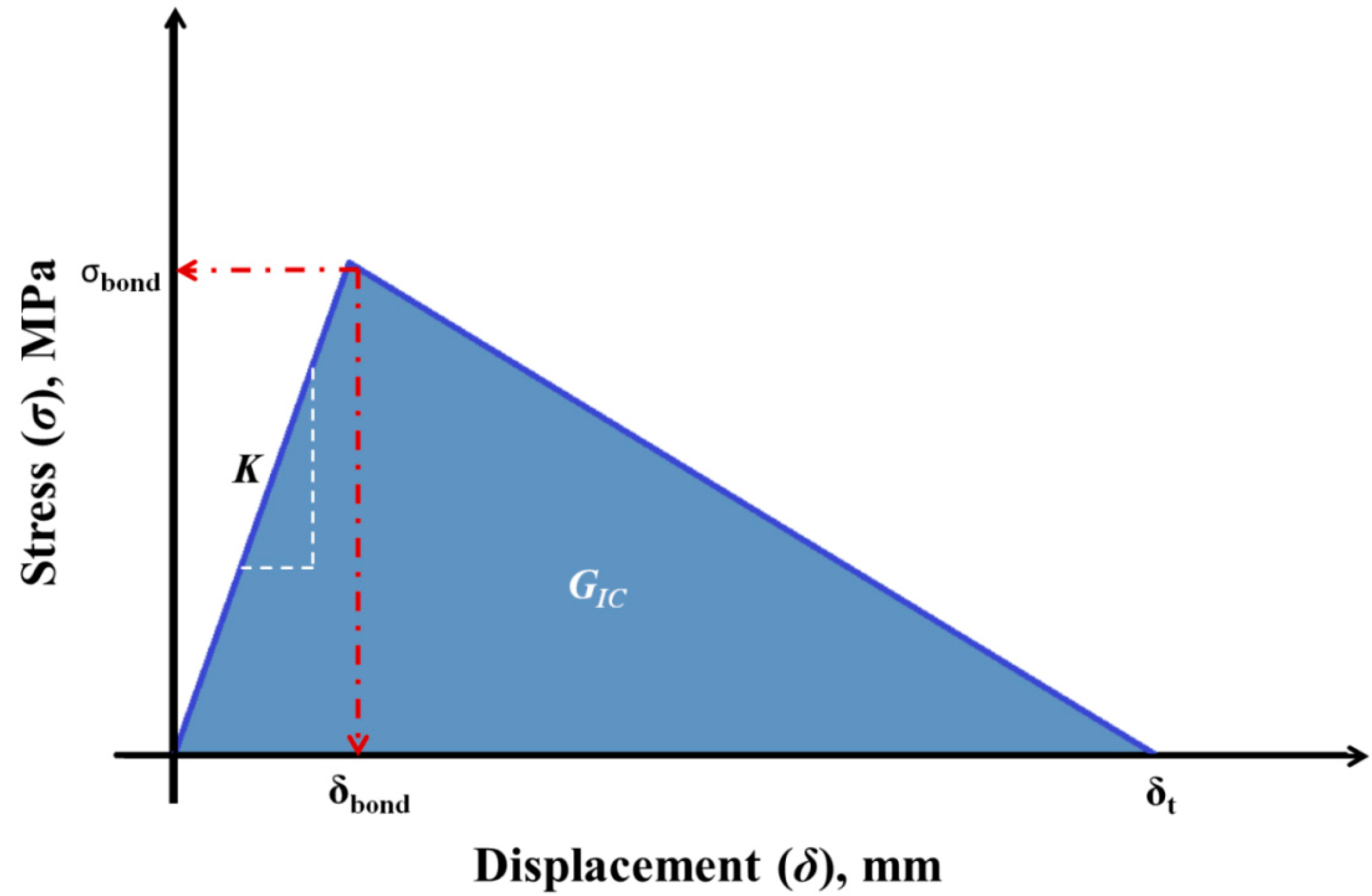

2.7. Finite Element Modeling

| wt% MWCNTs | 0.0% | 0.5% | 1.0% | 1.5% |

|---|---|---|---|---|

| E1 (GPa) | 32.1 | 30.3 | 32.9 | 36.5 |

3. Results and Discussion

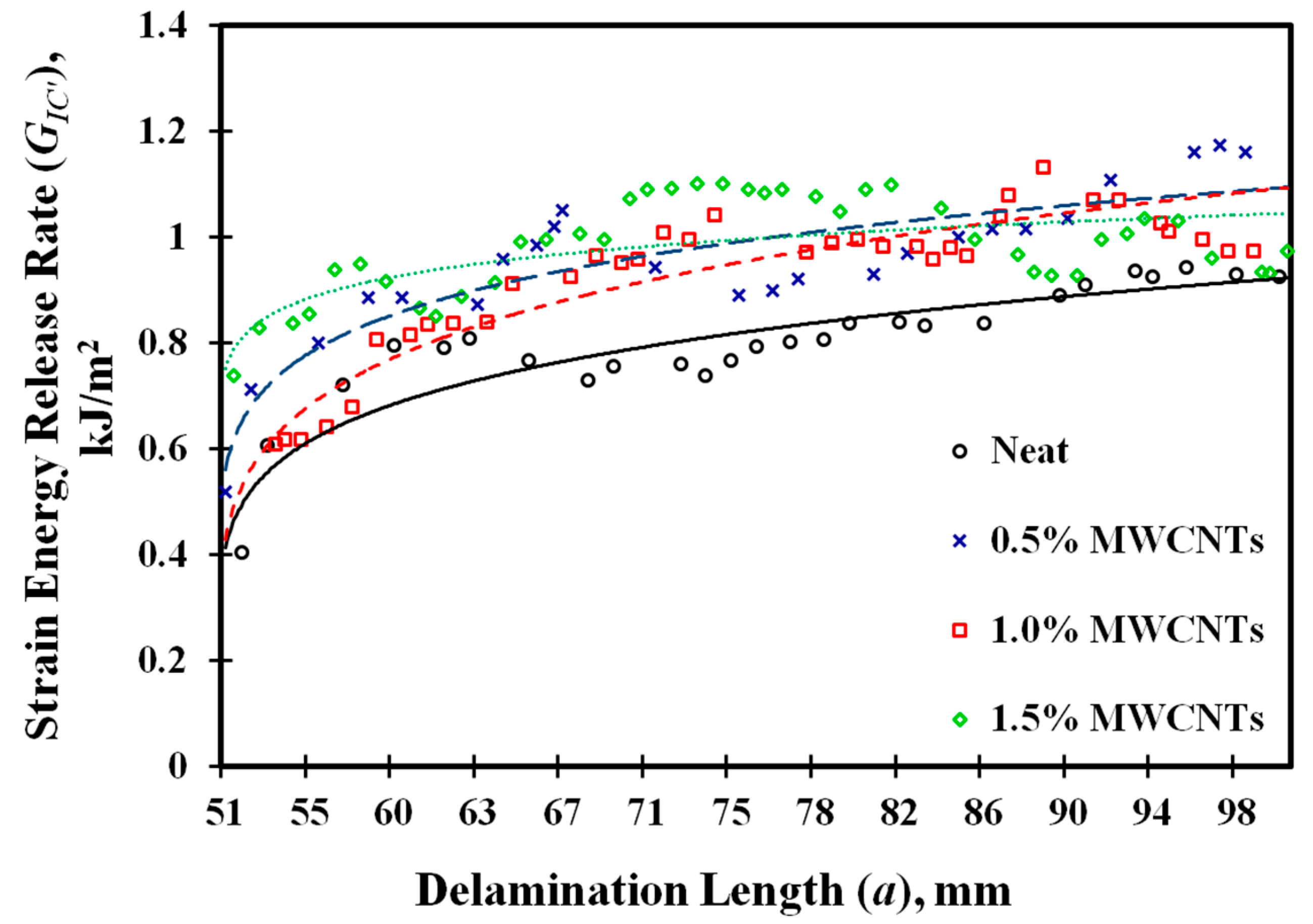

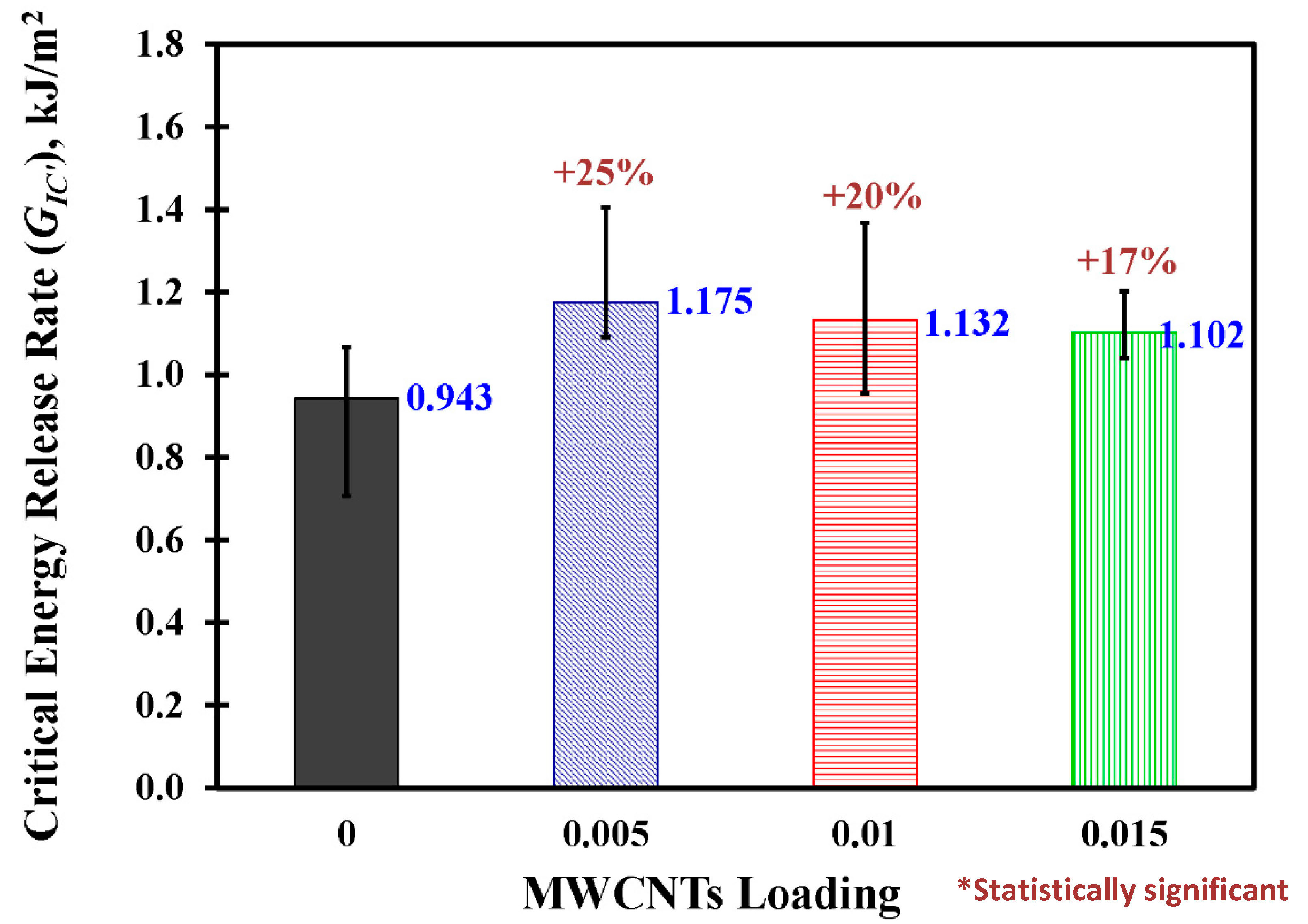

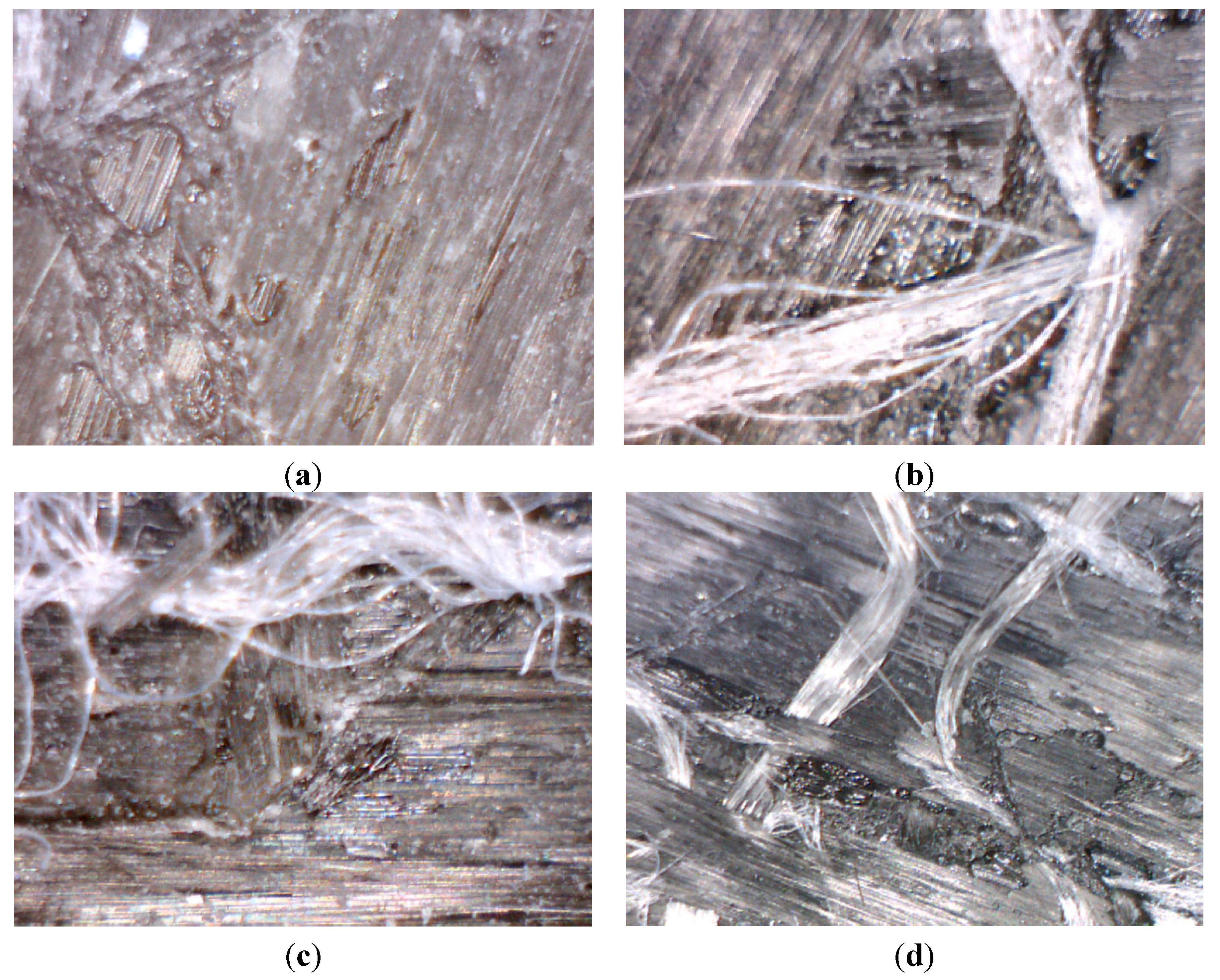

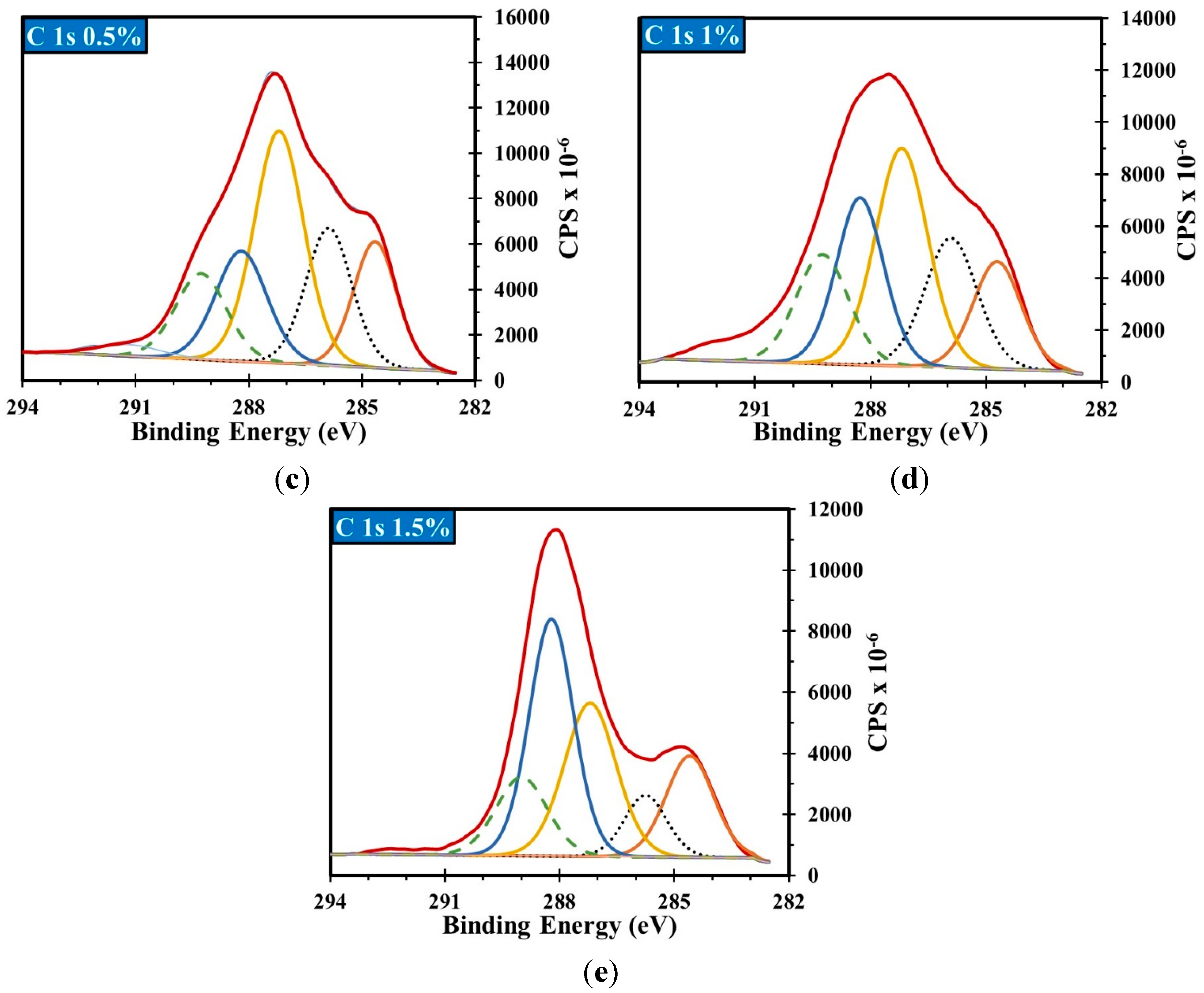

3.1. Experimental Fracture Tests

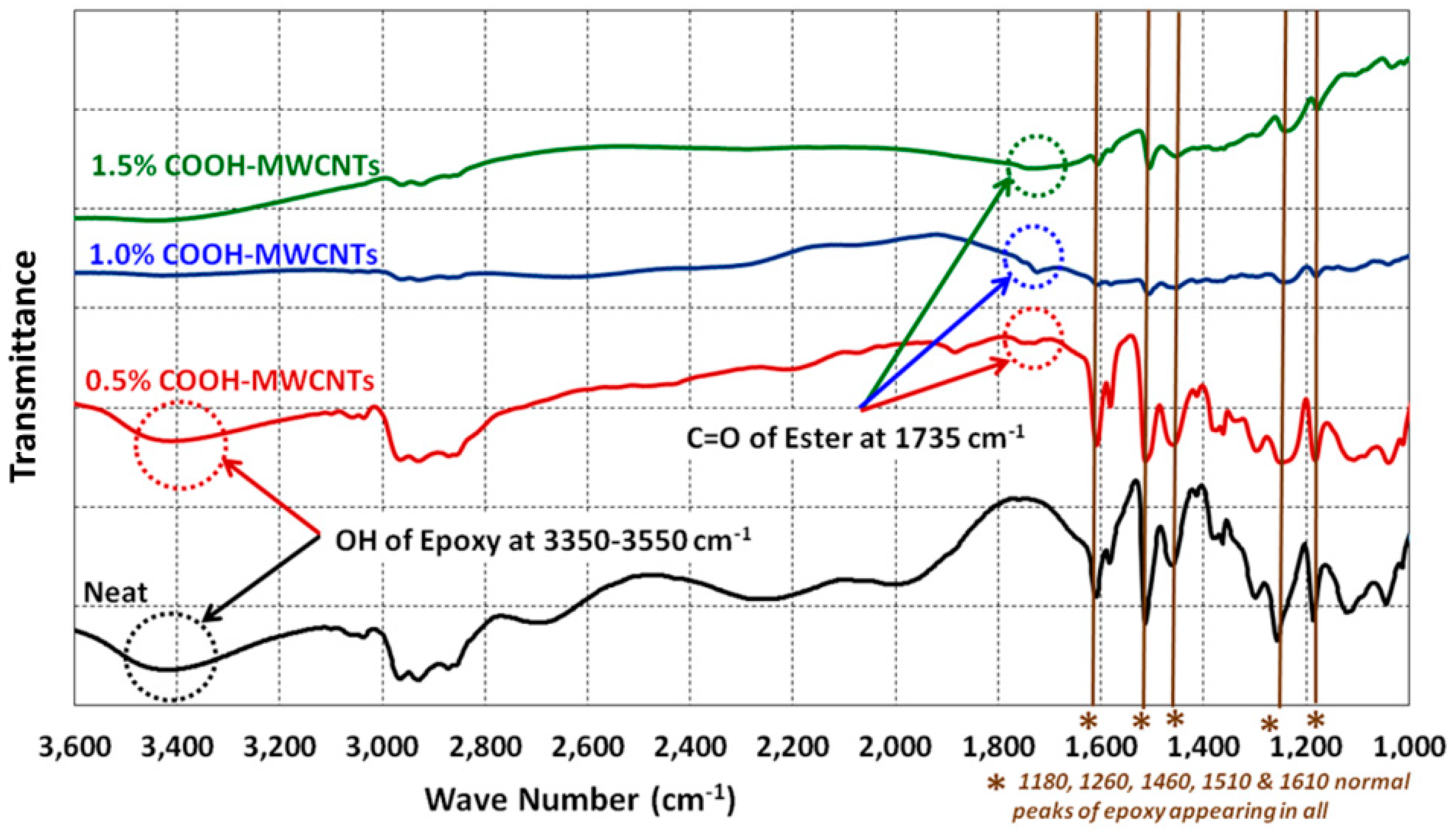

3.2. Fourier Transform Infrared Measurements

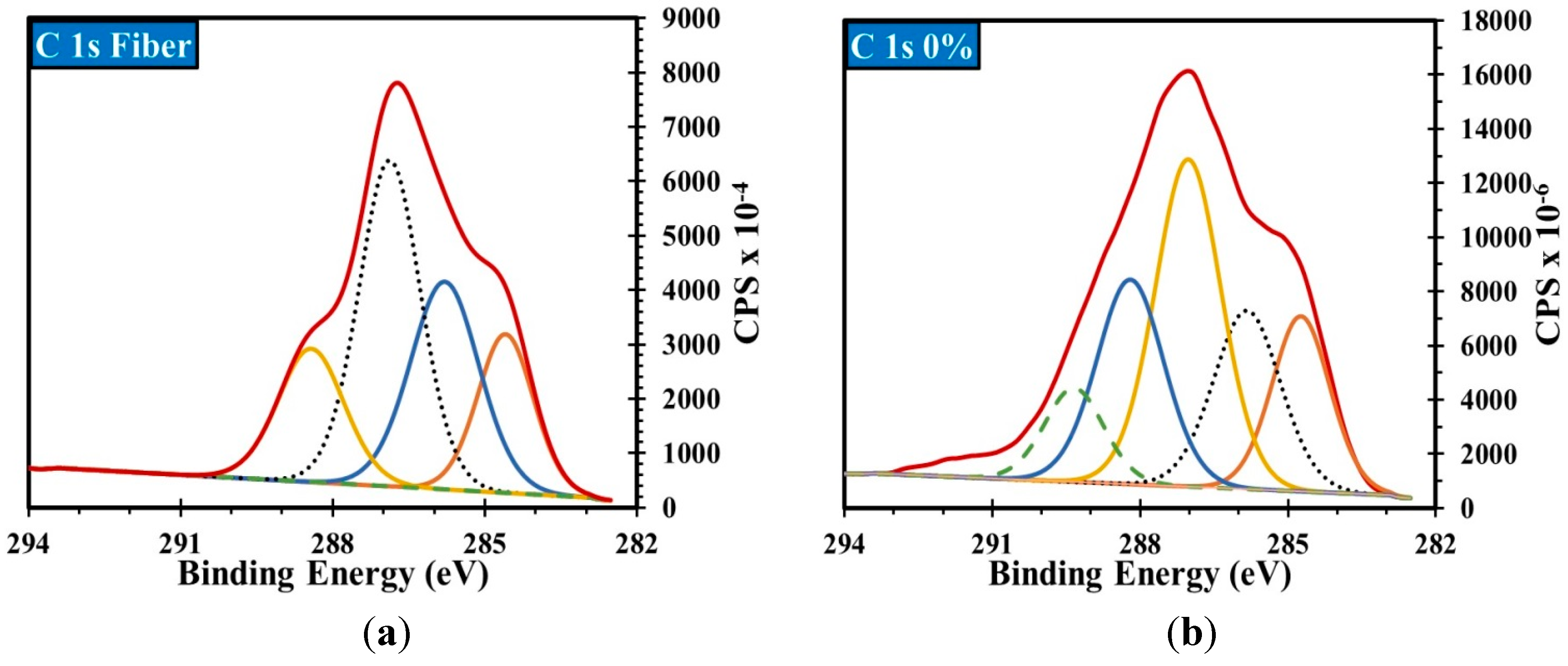

3.3. X-ray Photoelectron Spectroscopy

| Chemical bond/group | C–C% | C–O% & C–N% | C–O–C% Epoxy group | C=O% | COOH% | |

|---|---|---|---|---|---|---|

| Binding energy (eV) | 284.6 | 285.8 | 287.1 | 288.3 | 289.2 | |

| Specimen | Fibers | 14.3 | 22.7 | 44.5 | 18.5 | - |

| Neat Epoxy | 18.1 | 21.0 | 33.7 | 16.3 | 8.7 | |

| 0.5% COOH–MWCNTs | 14.9 | 21.2 | 33.4 | 15.4 | 12.5 | |

| 1.0% COOH–MWCNTs | 13.6 | 18.0 | 32.7 | 19.7 | 15.7 | |

| 1.5% COOH–MWCNTs | 13.5 | 7.3 | 20.4 | 39.2 | 16.8 | |

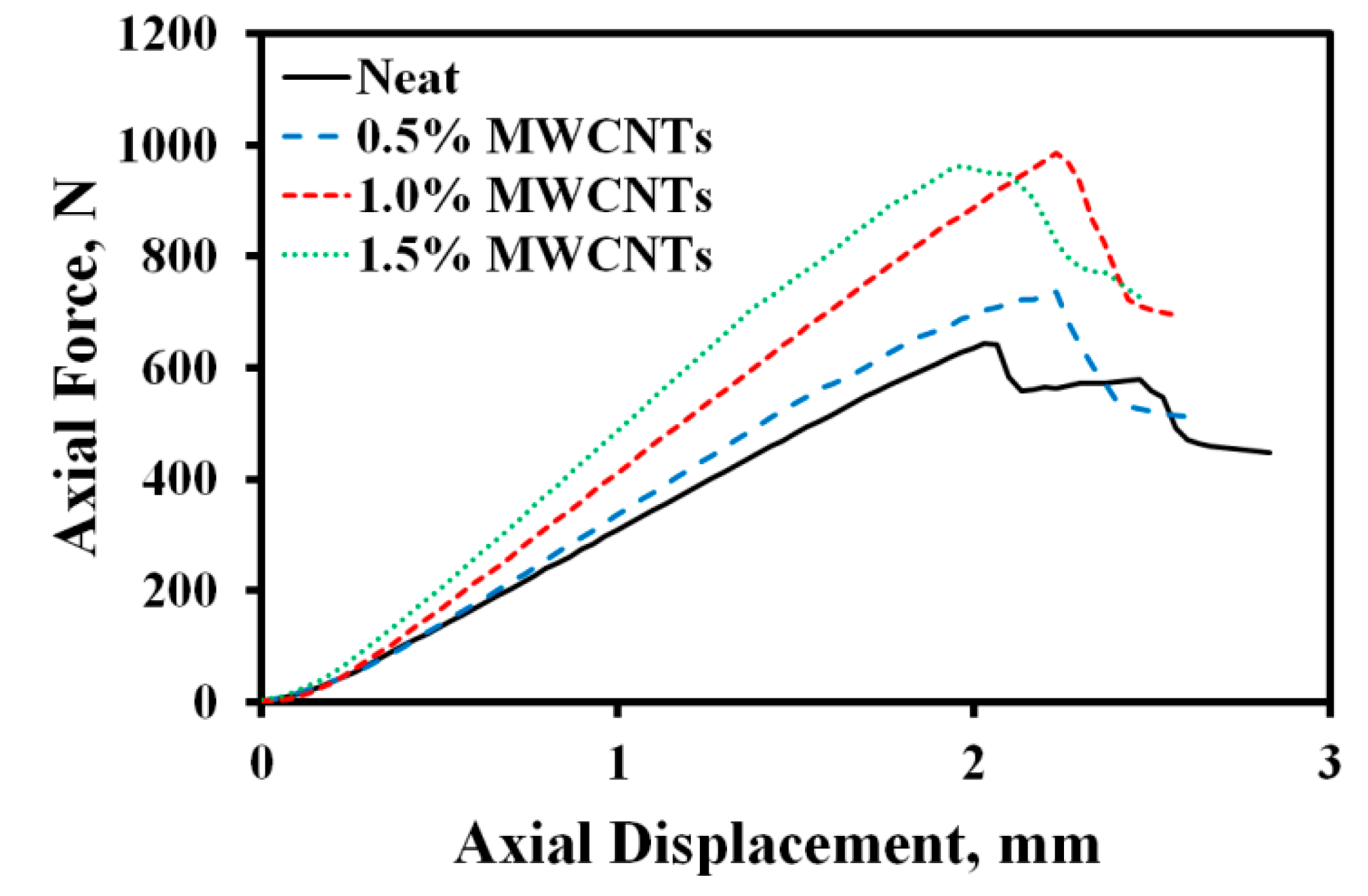

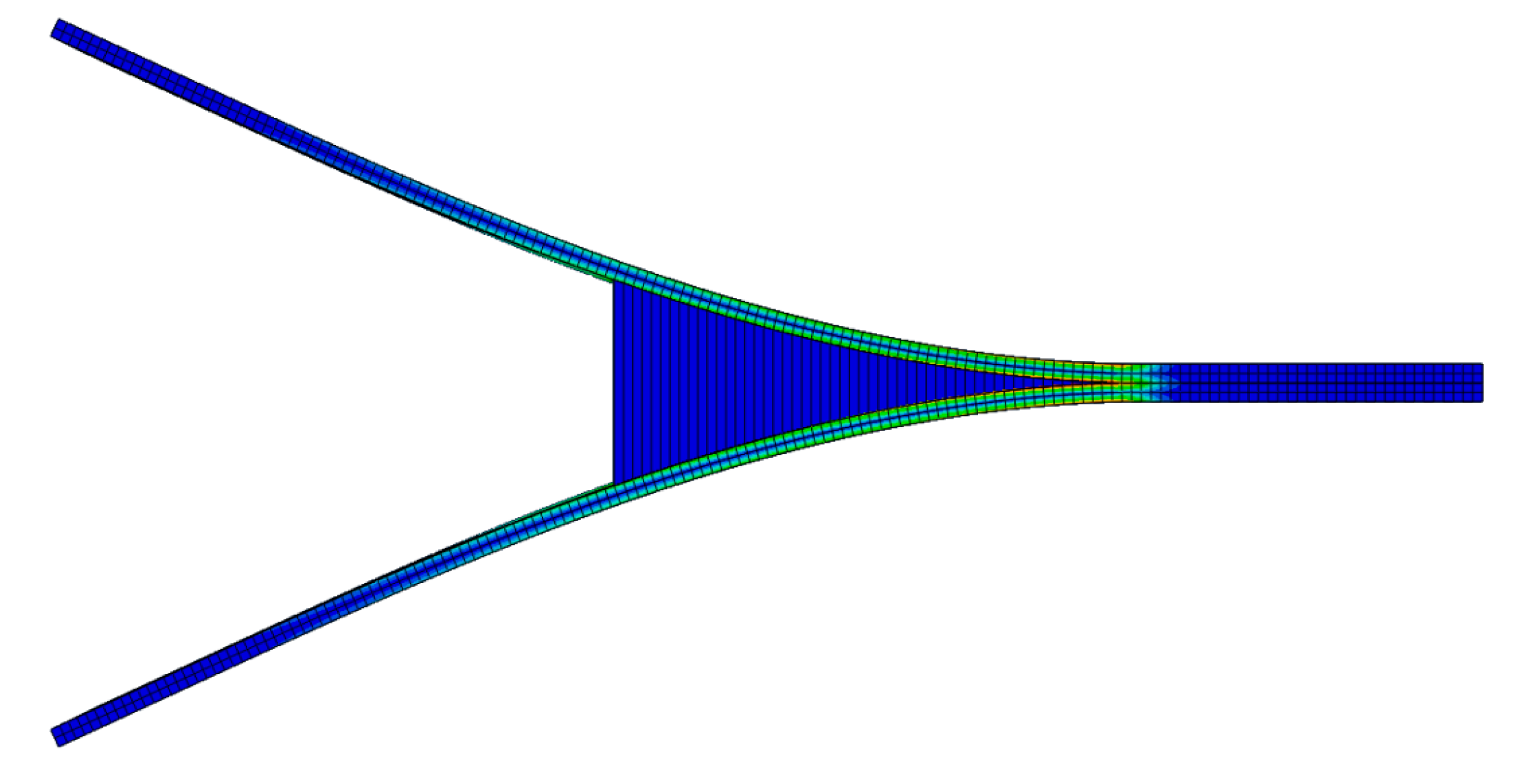

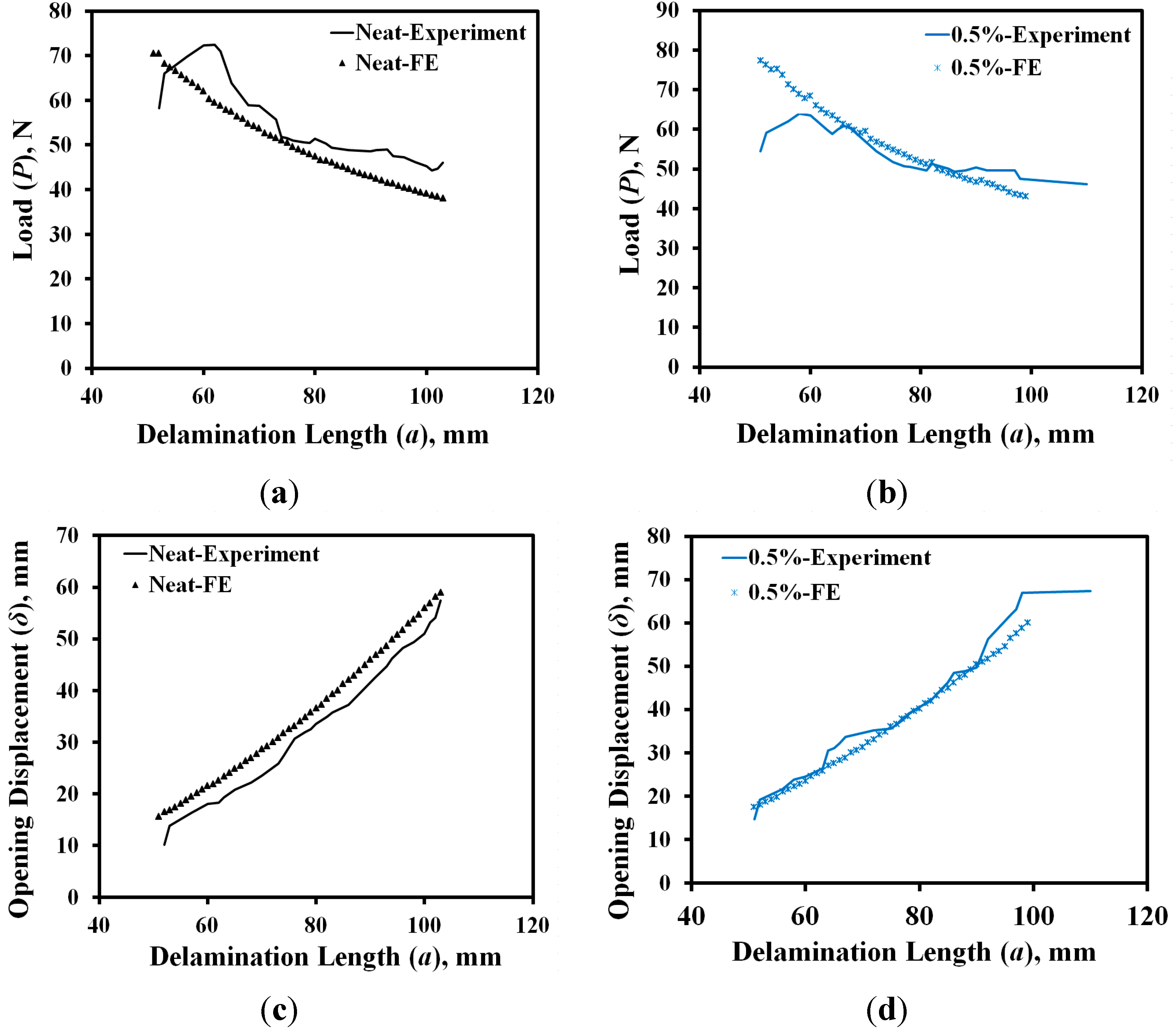

3.4. Finite Element Validation

4. Conclusions

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Tsai, J.L.; Huang, H.B.; Cheng, Y.L. Enhancing fracture toughness of glass/epoxy composites for wind blades using silica nanoparticles and rubber particles. Procedia Eng. 2011, 14, 1982–1987. [Google Scholar] [CrossRef]

- Tseng, C.H.; Wang, C.C.; Chen, C.Y. Functionalizing carbon nanotubes by plasma modification for the preparation of covalent-integrated epoxy composites. Chem. Mater. 2007, 19, 308–315. [Google Scholar] [CrossRef]

- Seyhan, A.T.; Tanoglu, M.; Schulte, K. Mode I and mode II fracture toughness of E-glass non-crimp fabric/carbon nanotube (CNT) modified polymer based composites. Eng. Fract. Mech. 2008, 75, 5151–5162. [Google Scholar] [CrossRef]

- Tehrani, M.; Yari Boroujeni, A.; Luhrs, C.; Phillips, J.; Al-Haik, M. Hybrid composites based on carbon fiber/carbon nanofilament reinforcement. Materials 2014, 7, 4182–4195. [Google Scholar] [CrossRef] [Green Version]

- Davis, D.C.; Whelan, B.D. An experimental study of interlaminar shear fracture toughness of a nanotube reinforced composite. Compos. B Eng. 2011, 42, 105–116. [Google Scholar] [CrossRef]

- Tamuzs, V.; Tarasovs, S.; Vilks, U. Delamination properties of translaminar-reinforced composites. Compos. Sci. Technol. 2003, 63, 1423–1431. [Google Scholar] [CrossRef]

- Lubineau, G.; Rahaman, A. A review of strategies for improving the degradation properties of laminated continuous-fiber/epoxy composites with carbon-based nanoreinforcements. Carbon 2012, 50, 2377–2395. [Google Scholar] [CrossRef]

- Shu, D.; Mai, Y.W. Effect of stitching on interlaminar delamination extension in composites laminates. Compos. Sci. Technol. 1993, 49, 165–171. [Google Scholar] [CrossRef]

- Chen, L.; Ifju, P.G.; Sankar, B.V. A novel double cantilever beam test for stitched composite laminates. J. Compos. Mater. 2001, 35, 1137–1149. [Google Scholar] [CrossRef]

- Liu, H.Y.; Mai, Y.W. Delamination fracture mechanics of composite laminates with through-thickness pinning. Strength Fract. Complex 2003, 1, 139–146. [Google Scholar]

- Lenzi, F.; Riccio, A.; Clarke, A.; Creemers, R. Coupon tests on z-pinned and unpinned composite samples for damage resistant applications. Macromol. Sympos. Times Polym. Compos. 2007, 27, 230–237. [Google Scholar] [CrossRef]

- Woo, E.M.; Bravenec, L.D.; Sefefus, J.C. Morphology and properties of an epoxy alloy system containing thermoplastics and a reactive rubber. Polym. Eng. Sci. 1993, 34, 1664–1673. [Google Scholar] [CrossRef]

- Arai, M.; Noro, Y.; Sugimoto, K.I.; Endo, M. Mode I and mode II interlaminar fracture toughness of CFRP laminates toughened by carbon nanofiber interlayer. Compos. Sci. Technol. 2008, 68, 516–525. [Google Scholar] [CrossRef]

- Hojo, M.; Ando, T.; Tanaka, M.; Adachi, T.; Ochiai, S.; Endo, Y. Modes I and II interlaminar fracture toughness and fatigue delamination of CF/epoxy laminates with self-same epoxy interleaf. Int. J. Fatigue 2006, 28, 1154–1165. [Google Scholar] [CrossRef]

- Li, M.; Gu, Y.; Liu, Y.; Li, Y.; Zhang, Z. Interfacial improvement of carbon fiber/epoxy composites using a simple process for depositing commercially functionalized carbon nanotubes on the fibers. Carbon 2013, 52, 109–121. [Google Scholar] [CrossRef]

- Sharma, K.; Shukla, M. Three-phase carbon fiber amine functionalized carbon nanotubes epoxy composite: Processing, characterization, and multiscale modeling. J. Nanomater. 2014, 2014, 1–10. [Google Scholar] [CrossRef]

- Park, J.M.; Kim, D.S.; Lee, J.R.; Kim, T.W. Nondestructive damage sensitivity and reinforcing effect of carbon nanotube/epoxy composites using electro-micromechanical technique. Mater. Sci. Eng. C 2003, 23, 971–975. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Shadlou, S.; Shokrieh, M.M. Mixed mode brittle fracture in epoxy/multi-walled carbon nanotube nanocomposites. Eng. Fract. Mech. 2011, 78, 2620–2632. [Google Scholar] [CrossRef]

- Inam, F.; Wong, D.W.; Kuwata, M.; Peijs, T. Multiscale hybrid micro-nanocomposites based on carbon nanotubes and carbon fibers. J. Nanomater. 2010, 2010, 1–12. [Google Scholar] [CrossRef]

- Soliman, E.; Al-Haik, M.; Taha, M.R. On and off-axis tension behavior of fiber reinforced polymer (FRP) composites incorporating multiwalled carbon nanotubes. J. Compos. Mater. 2012, 46, 1661–1675. [Google Scholar] [CrossRef]

- Patra, A.; Mitra, N. Interface fracture of sandwich composites: Influence of MWCNT sonicated epoxy resin. Compos. Sci. Technol. 2014, 101, 94–101. [Google Scholar] [CrossRef]

- Cui, L.; Wang, Y.; Xiu, W.; Wang, W.; Xu, L.; Xu, X.; Meng, Y.; Li, L.; Gao, J.; Chen, L.; et al. Effect of functionalization of multi-walled carbon nanotube on the curing behavior and mechanical property of multi-walled carbon nanotube/epoxy composites. Mater. Des. 2013, 49, 279–284. [Google Scholar] [CrossRef]

- Zhu, J.; Kim, J.; Peng, H.Q.; Margrave, J.L.; Khabashesku, V.N.; Barrera, E.V. Improving the dispersion and integration of single-walled carbon nanotubes in epoxy composites through functionalization. Nano Lett. 2003, 3, 1107–1113. [Google Scholar] [CrossRef]

- Tang, L.C.; Zhang, H.; Han, J.H.; Wu, X.P.; Zhang, Z. Fracture mechanisms of epoxy filled with ozone functionalized multi-wall carbon nanotubes. Compos. Sci. Technol. 2011, 72, 7–13. [Google Scholar] [CrossRef]

- Esposito, L.H.; Ramos, J.A.; Kortaberria, G. Dispersion of carbon nanotubes in nanostructured epoxy systems for coating application. Prog. Org. Coat. 2014, 77, 1452–1458. [Google Scholar] [CrossRef]

- Fang, C.; Wang, J.; Zhang, T. Interlaminar improvement of carbon fiber/epoxy composites via depositing mixture of carbon nanotubes and sizing agent. Appl. Surf. Sci. 2014, 321, 1–9. [Google Scholar] [CrossRef]

- Kim, W.; Kang, S.; Ah, C.; Lee, Y.; Ha, D.; Choi, I.; Yun, W. Functionalization of shortened SWCNTs using esterification. Bull. Korean Chem. Soc. 2004, 25, 1301–1302. [Google Scholar]

- Mujika, F.; Vargas, G.; Ibarretxe, J.; de Garcia, J.; Arrese, A. Influence of the modification with MWCNT on the interlaminar fracture properties of long carbon fiber composites. Compos. B 2012, 43, 1336–1340. [Google Scholar] [CrossRef]

- Romhany, G.; Szebenyi, G. Interlaminar crack propagation in MWCNT/fiber reinforced hybrid composites. Express Polym. Lett. 2009, 3, 145–151. [Google Scholar] [CrossRef]

- Almuhammadi, K.; Alfano, M.; Yang, Y.; Lubineau, G. Analysis of interlaminar fracture toughness and damage mechanisms in composite laminates reinforced with sprayed multi-walled carbon nanotubes. Mater. Des. 2014, 53, 921–927. [Google Scholar] [CrossRef]

- Soliman, E.; Sheyka, M.; Taha, M.R. Low-velocity impact of thin woven carbon fabric composites incorporating multi-walled carbon nanotubes. Int. J. Impact Eng. 2012, 47, 39–47. [Google Scholar] [CrossRef]

- Standard Guide for Preparation of Flat Composite Panels with Processing Guidelines for Specimen Preparation; ASTM D5687/D5687M–95; ASTM International: West Conshohocken, PA, USA, 2007.

- Standard Test Methods for Constituent Content of Composite Materials; ASTM D3171–06; ASTM International: West Conshohocken, PA, USA, 2006.

- Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites; ASTM D5528–13; ASTM International: West Conshohocken, PA, USA, 2013.

- Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials; ASTM D790–10; ASTM International: West Conshohocken, PA, USA, 2010.

- Hsu, A.; Mcpheeters, B. Nastran Cohesive Zone Modeling of Composite Bonded Joints; Society for the Advancement of Material and Process Engineering (SAMPE): Covina, CA, USA, 2012. [Google Scholar]

- Barenblatt, G.I. The mathematical theory of equilibrium cracks in brittle fracture. Adv. Appl. Mech. 1962, 7, 55–129. [Google Scholar]

- Zou, W.; Du, Z.; Liu, Y.; Yang, X.; Li, H.; Zhang, C. Functionalization of MWNTs using polyacryloyl chloride and the properties of CNT-epoxy matrix nanocomposites. Compos. Sci. Technol. 2008, 68, 3259–3264. [Google Scholar] [CrossRef]

- Yang, J., III. Part I: Synthesis of Aromatic Polyketones via Soluble Precursors Derived from Bis(A-Amininitrile)S Part II: Modifications of Epoxy Resins with Functional Hyperbranched Poly(Arylene Ester)S. Ph.D. Thesis, Virginia Institute and State University, Blacksburg, VA, USA, 1998. [Google Scholar]

- Soliman, E.; Kandil, U.; Taha, M. Improved strength and toughness of carbon woven fabric composites with functionalized MWCNTs. Materials 2014, 7, 4640–4657. [Google Scholar] [CrossRef]

- Ma, P.; Mo, S.; Tang, B.; Kim, J. Dispersion, interfacial interaction and re-agglomeration of functionalized carbon nanotubes in epoxy composites. Carbon 2010, 48, 1824–1834. [Google Scholar] [CrossRef]

- Dai, Z.; Zhang, B.; Shi, F.; Li, M.; Zhang, Z.; Gu, Y. Effect of heat treatment on carbon fiber surface properties and fibers/epoxy interfacial adhesion. Appl. Surf. Sci. 2011, 257, 8457–8461. [Google Scholar] [CrossRef]

- Zhao, W. Mode I Delamination Fracture Characterization of Polymeric Composites under Elevated Temperature. PhD Thesis, Syracuse University, Syracuse, NY, USA, 2011. [Google Scholar]

- Biel, A.; Stigh, U. An analysis of the evaluation of the fracture energy using the DCB-specimen. Arch. Mech. 2007, 59, 311–327. [Google Scholar]

- Blackman, B.R.K.; Hadavinia, H.; Kinloch, A.J.; Paraschi, M.; Williams, J.G. The calculation of adhesive fracture energies in mode I: revisiting the tapered double cantilever beam (TDCB) test. Eng. Fract. Mech. 2003, 70, 233–248. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borowski, E.; Soliman, E.; Kandil, U.F.; Taha, M.R. Interlaminar Fracture Toughness of CFRP Laminates Incorporating Multi-Walled Carbon Nanotubes. Polymers 2015, 7, 1020-1045. https://doi.org/10.3390/polym7061020

Borowski E, Soliman E, Kandil UF, Taha MR. Interlaminar Fracture Toughness of CFRP Laminates Incorporating Multi-Walled Carbon Nanotubes. Polymers. 2015; 7(6):1020-1045. https://doi.org/10.3390/polym7061020

Chicago/Turabian StyleBorowski, Elisa, Eslam Soliman, Usama F. Kandil, and Mahmoud Reda Taha. 2015. "Interlaminar Fracture Toughness of CFRP Laminates Incorporating Multi-Walled Carbon Nanotubes" Polymers 7, no. 6: 1020-1045. https://doi.org/10.3390/polym7061020