Biopolymer Blends Based on Poly (lactic acid): Shear and Elongation Rheology/Structure/Blowing Process Relationships

Abstract

:1. Introduction

2. Experimental Section

2.1. Polymers Used

| Notations | Composition |

|---|---|

| PLA | 100 wt% PLA |

| PBAT | 100 wt% PBAT |

| PLA-0.7 | 99.3 wt% PLA + 0.7 wt% Joncryl |

| PBAT-0.7 | 99.3 wt% PBAT + 0.7 wt% Joncryl |

| 80–20 | 80 wt% PLA + 20 wt% PBAT |

| 80–20–0.25 | 79.8 wt% PLA+ 19.95 wt% PBAT + 0.25 wt% Joncryl |

| 80–20–0.5 | 79.6 wt% PLA + 19.9 wt% PBAT + 0.5 wt% Joncryl |

| 80–20–0.7 | 79.44 wt% PLA + 19.86 wt% PBAT + 0.7 wt% Joncryl |

| 80–20–1 | 79.2 wt% PLA + 19.8 wt% PBAT + 1 wt% Joncryl |

2.2. Sample Preparation and Preliminary Work

2.2.1. Blends Preparation

2.2.2. Validation of Reaction Completion with Multifunctional Epoxide

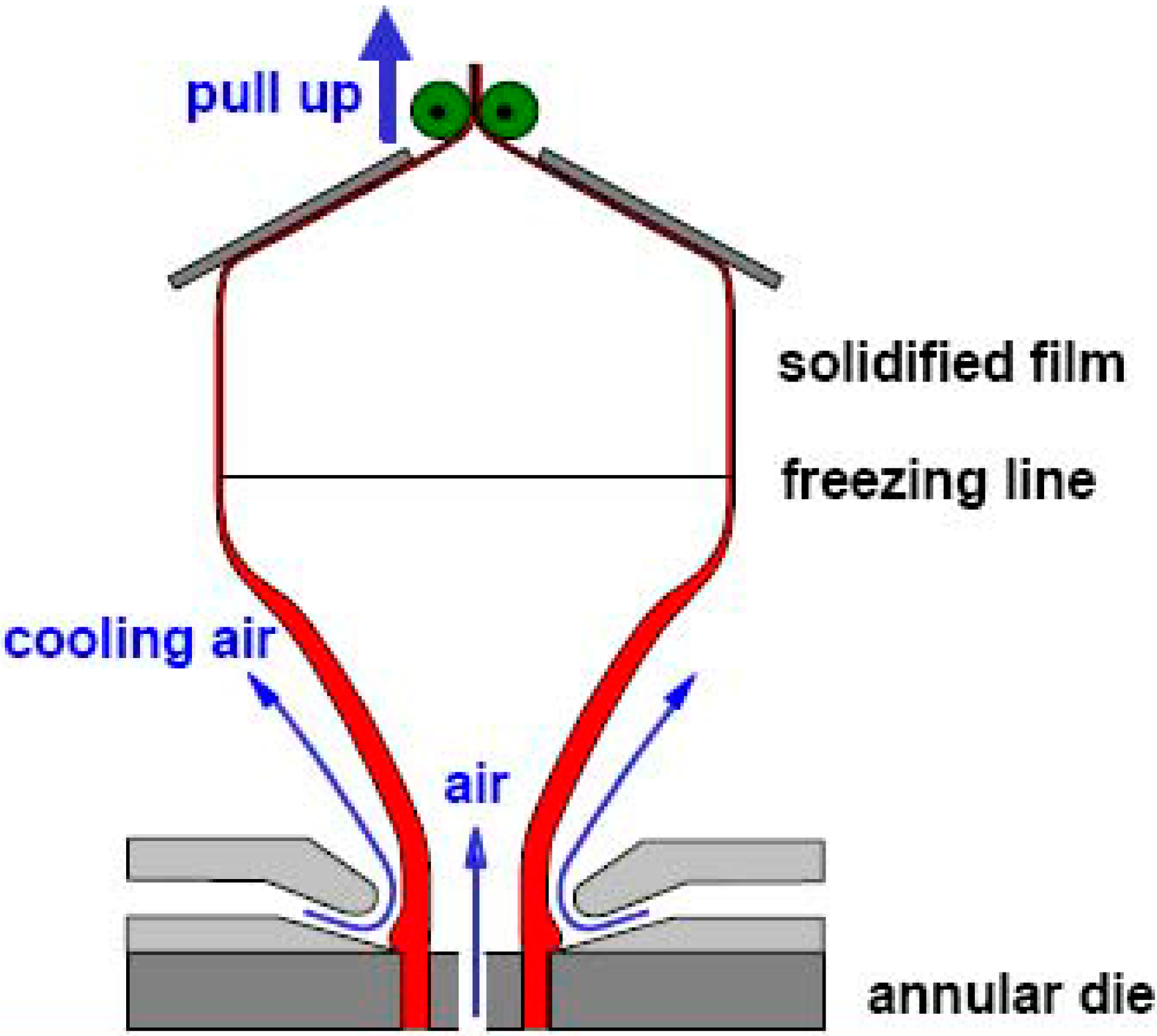

2.2.3. Blown Film Extrusion

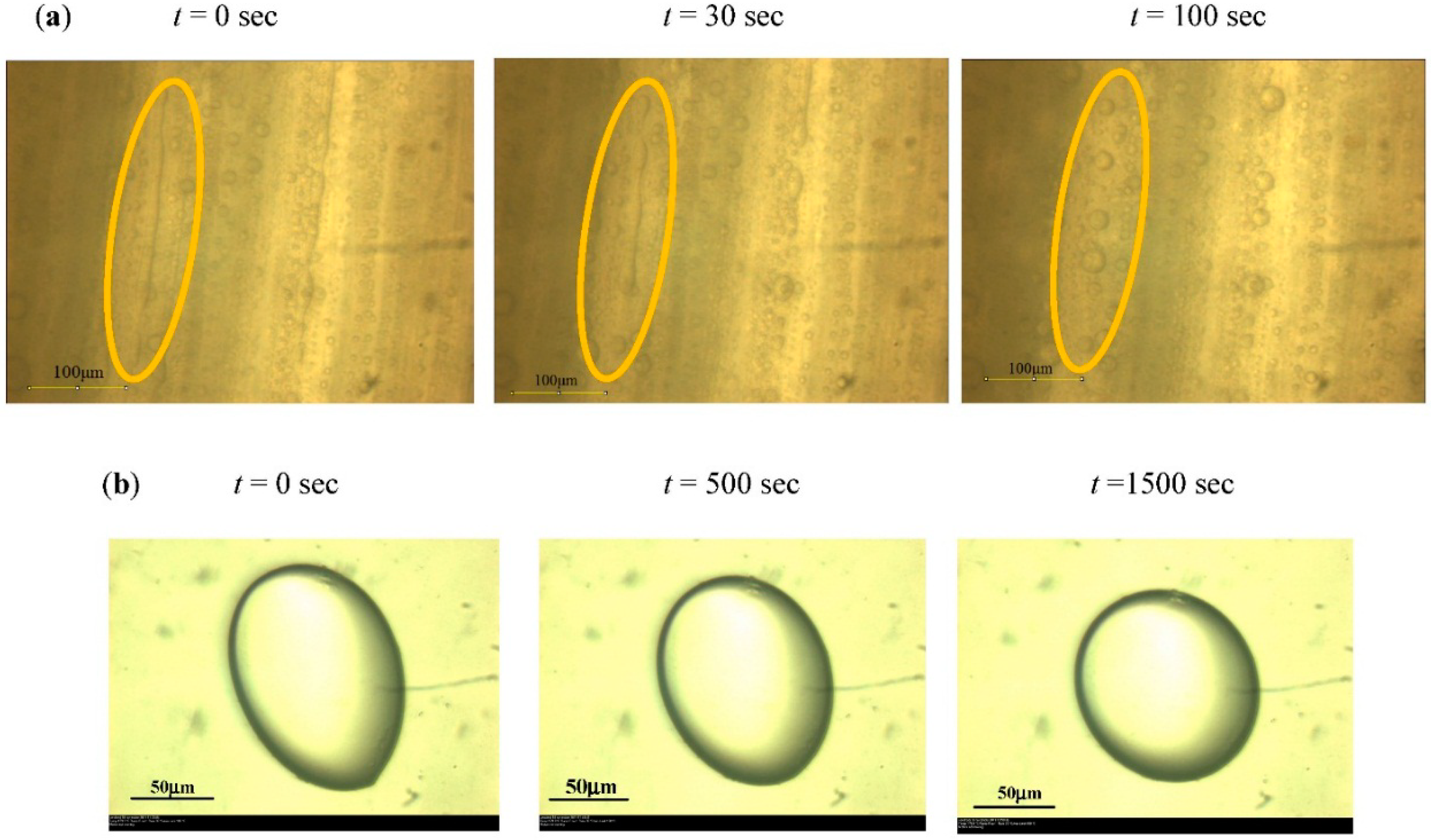

2.3. Interfacial Tension Measurements

- -

- Model A: it is used as a reference where neat PBAT is dispersed into PLA matrix;

- -

- Model B: it represents the more complicated systems where Joncryl reacts with both PLA and PBAT at the same time.

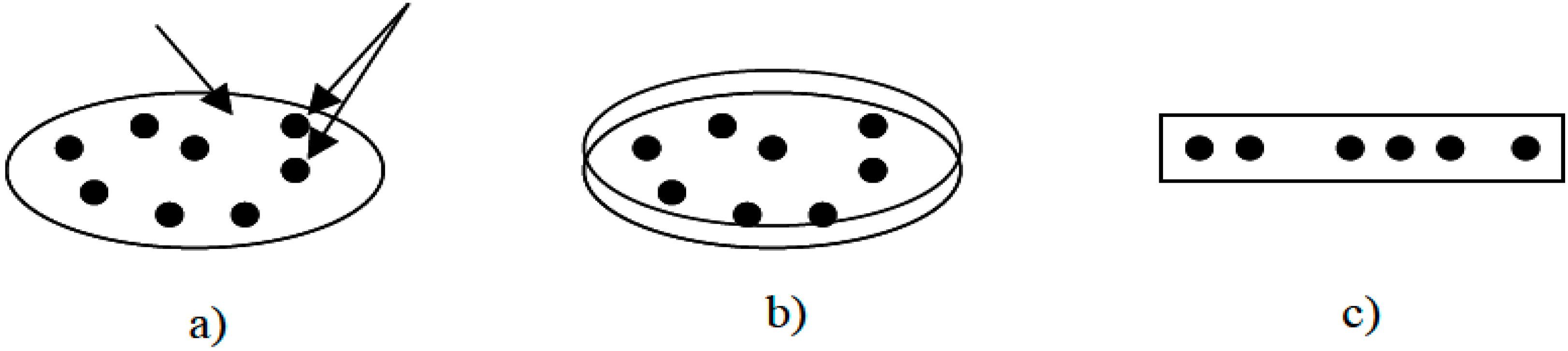

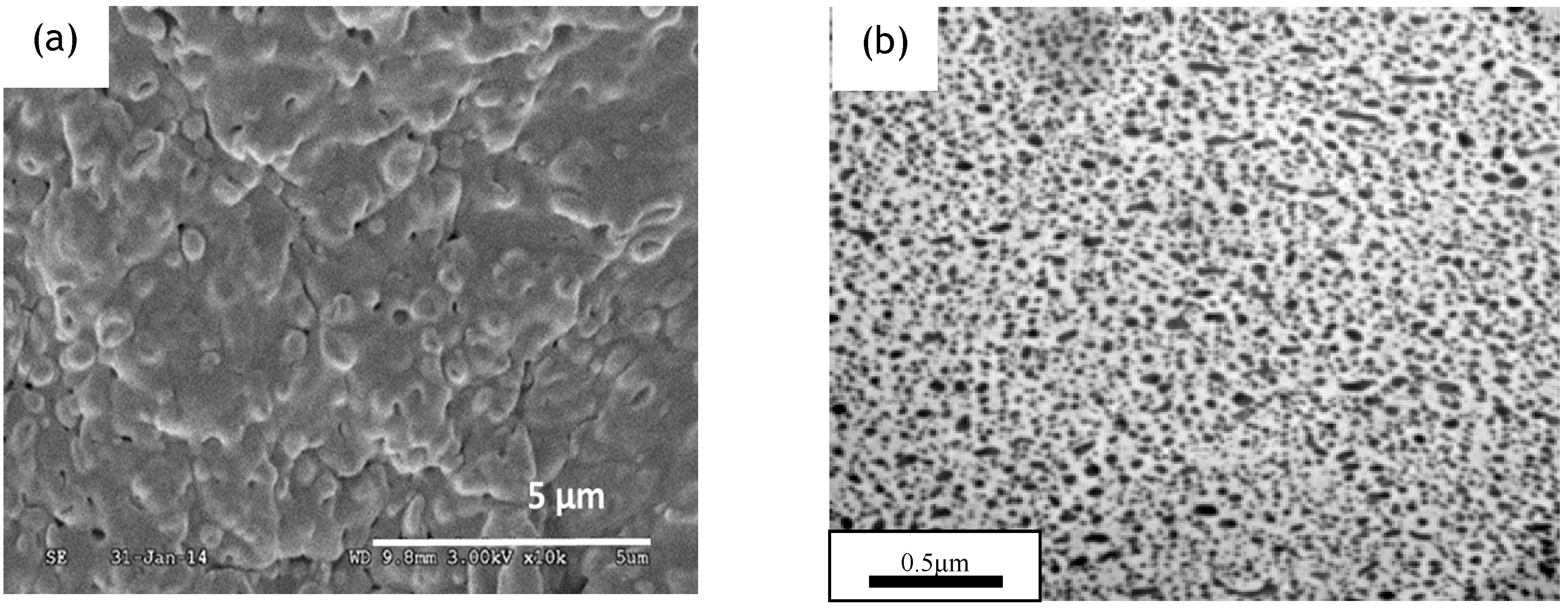

2.4. Morphological Study

2.5. Shear and Elongation Rheological Properties

2.5.1. Small-Amplitude Oscillatory Shear (SAOS) Measurements

2.5.2. Capillary Flow Rheology

2.5.3. Uniaxial Elongational Measurements

2.5.4. Start-up Shear Experiments (Transient Step Shear Rate Experiments)

2.6. Non-Isothermal Characterization

2.7. Thermo-Mechanical Properties

3. Results and Discussion

3.1. Interfacial Tension Measurements and Morphological Properties

3.2. Linear Viscoelastic and Shear Capillary Flow Properties of Neat and Modified PLA, PBAT Polymers and Their Respective Blends

3.3. Elongation Properties of Neat and Modified PLA, PBAT Polymers and Their Respective Stable Blends

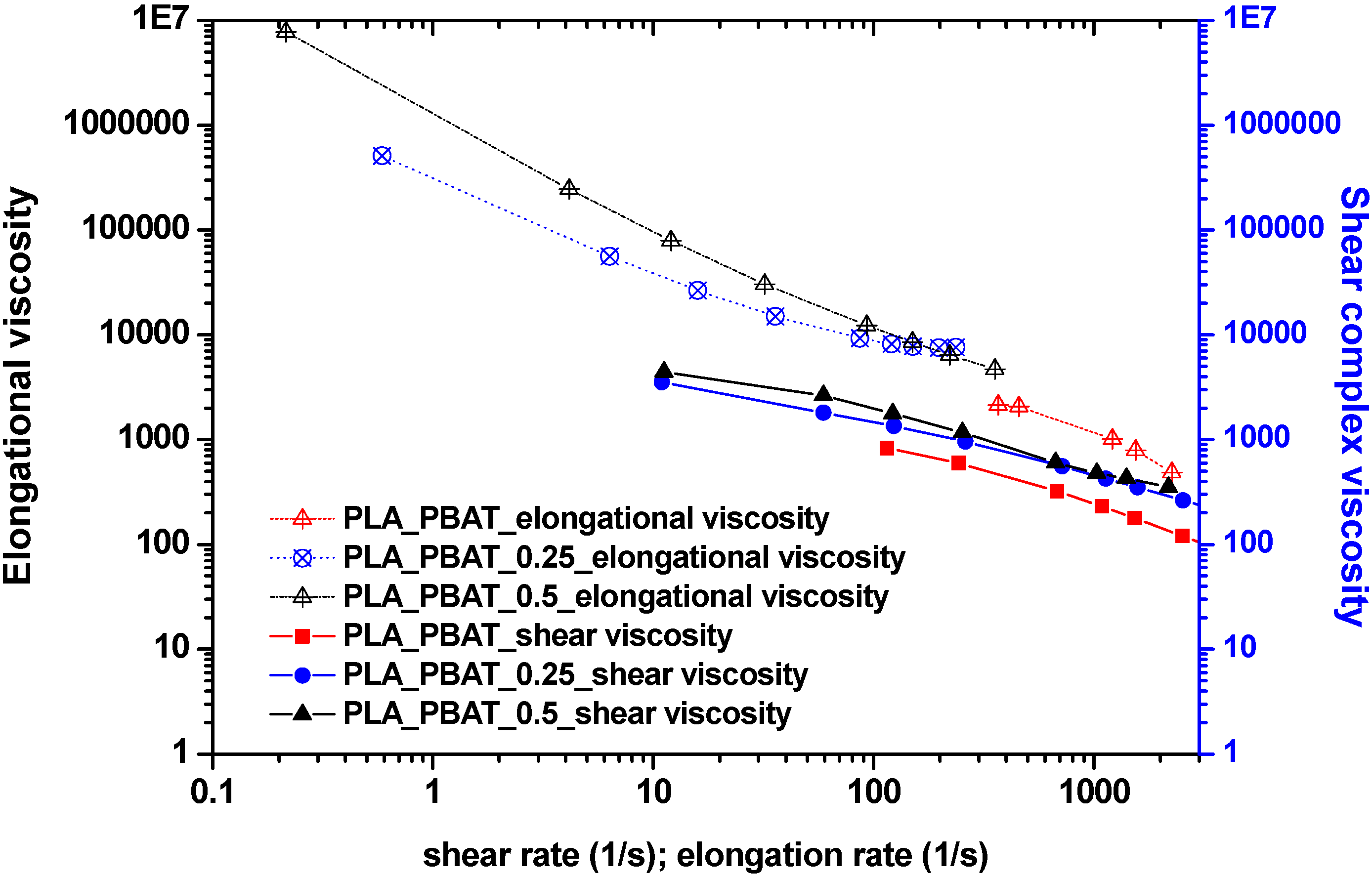

3.3.1. Indirect Method of Determining the Elongation Viscosity—Cogswell Elongation Viscosity

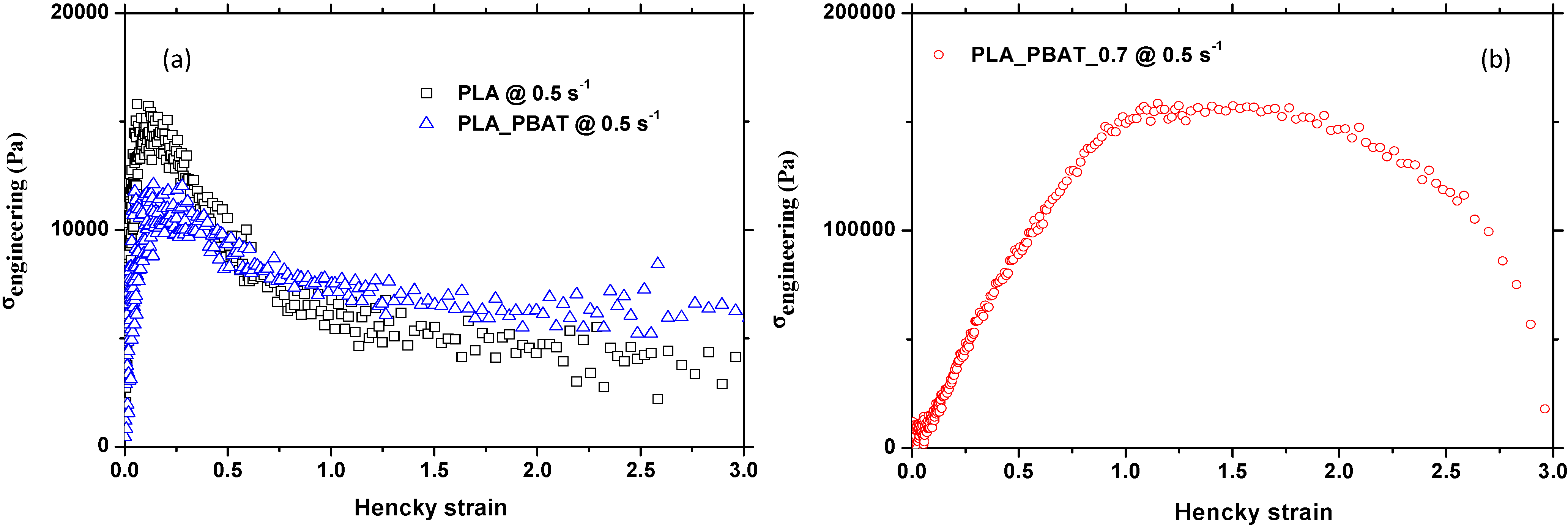

3.3.2. Uniaxial Extensional Experiments

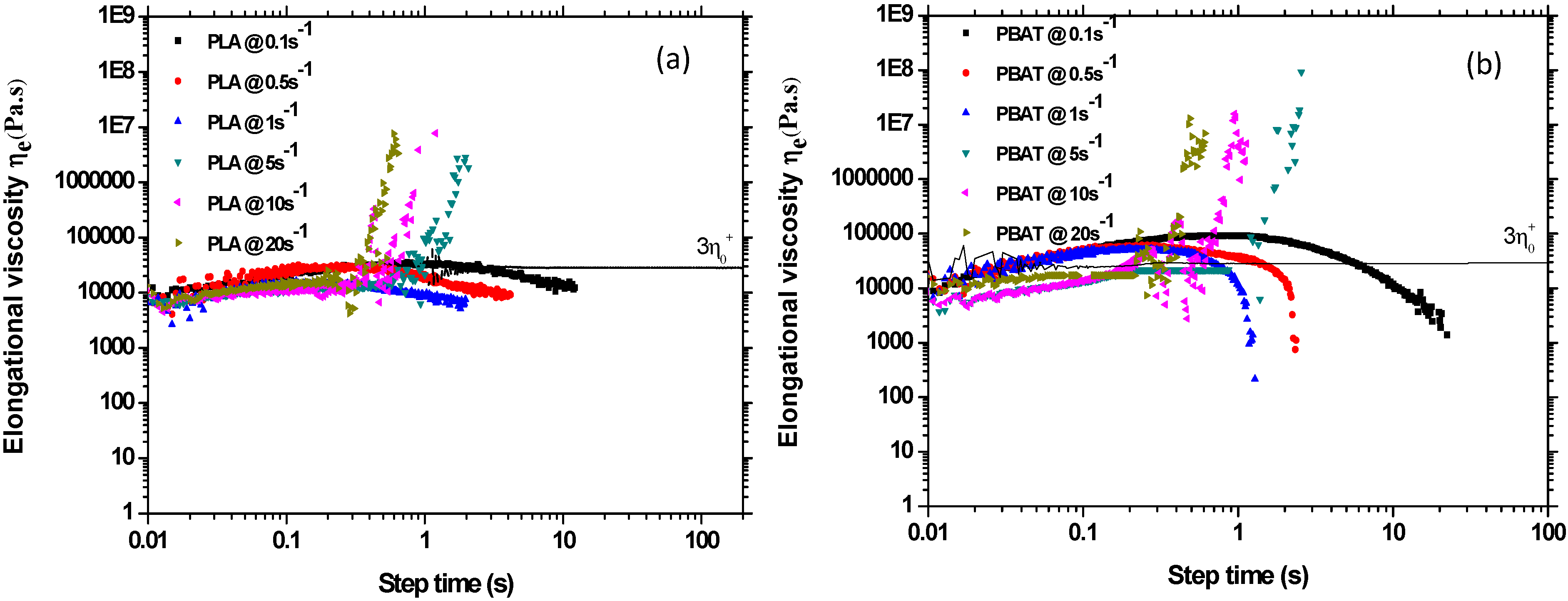

Neat PLA and PBAT Polymers

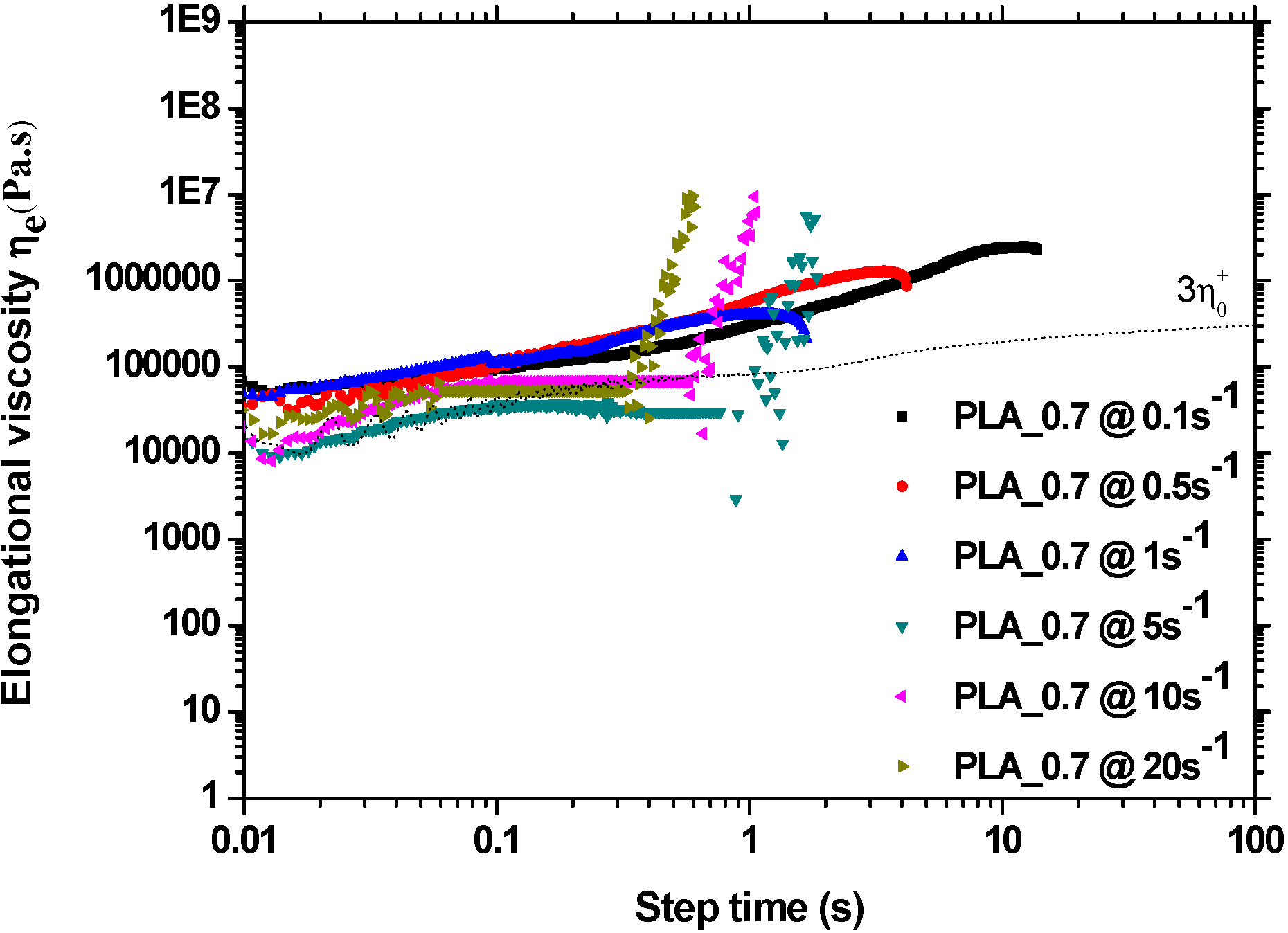

Modified PLA System

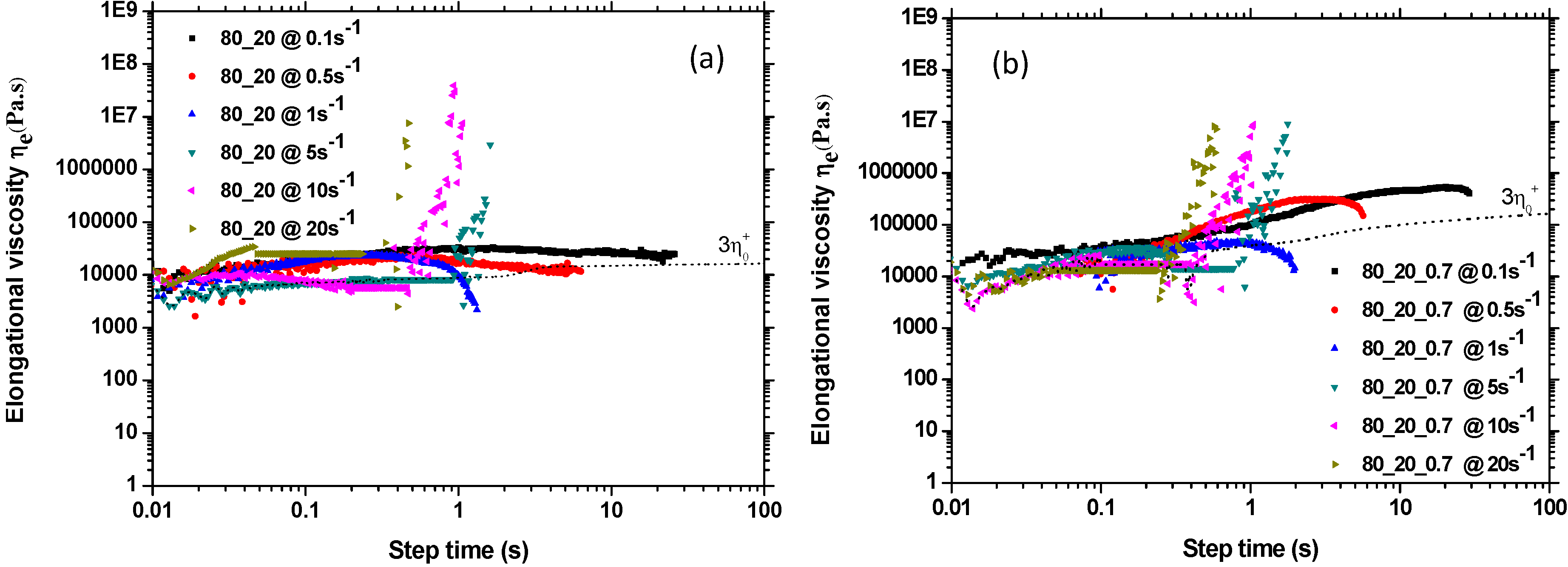

PLA-PBAT Blends

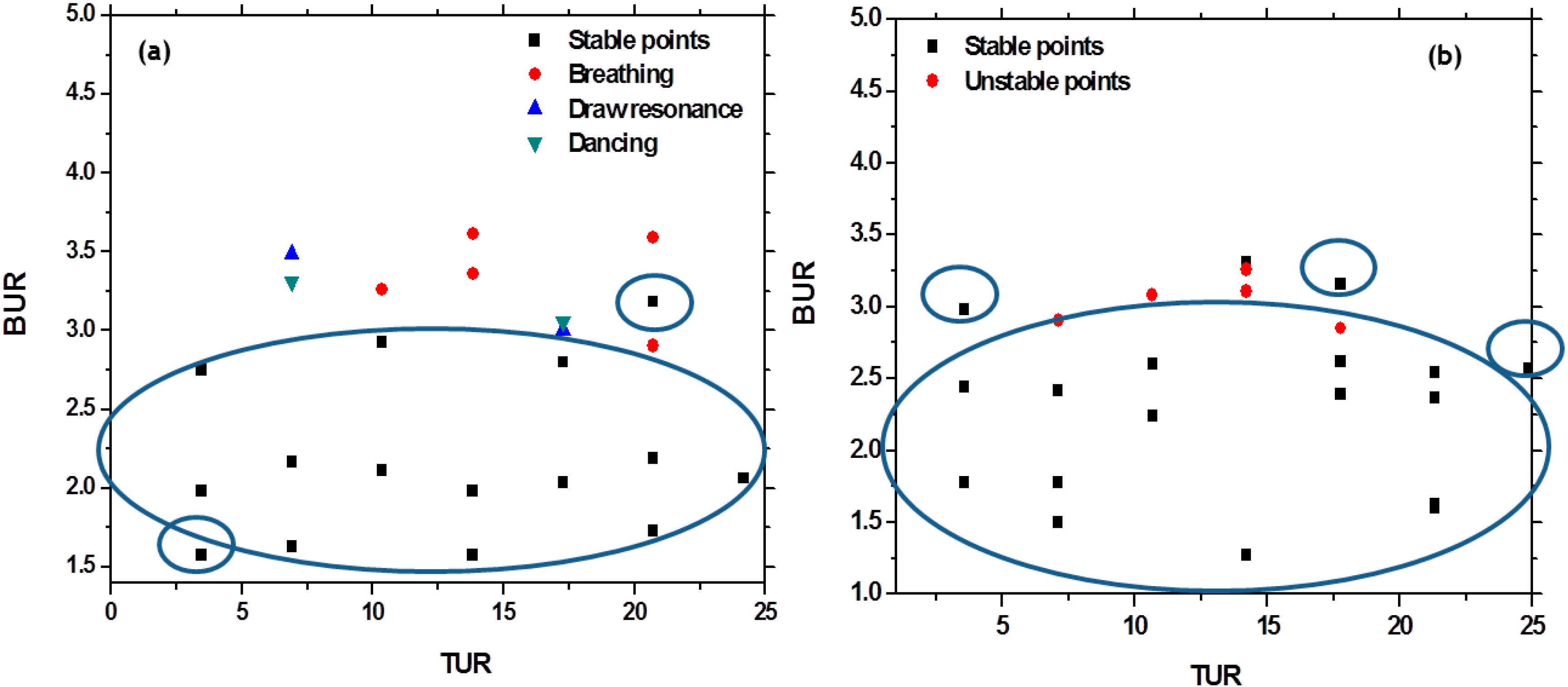

3.4. Application to Blown Film Extrusion: Investigation of the Stability Processing of Neat/Modified Polymers and Their Blends

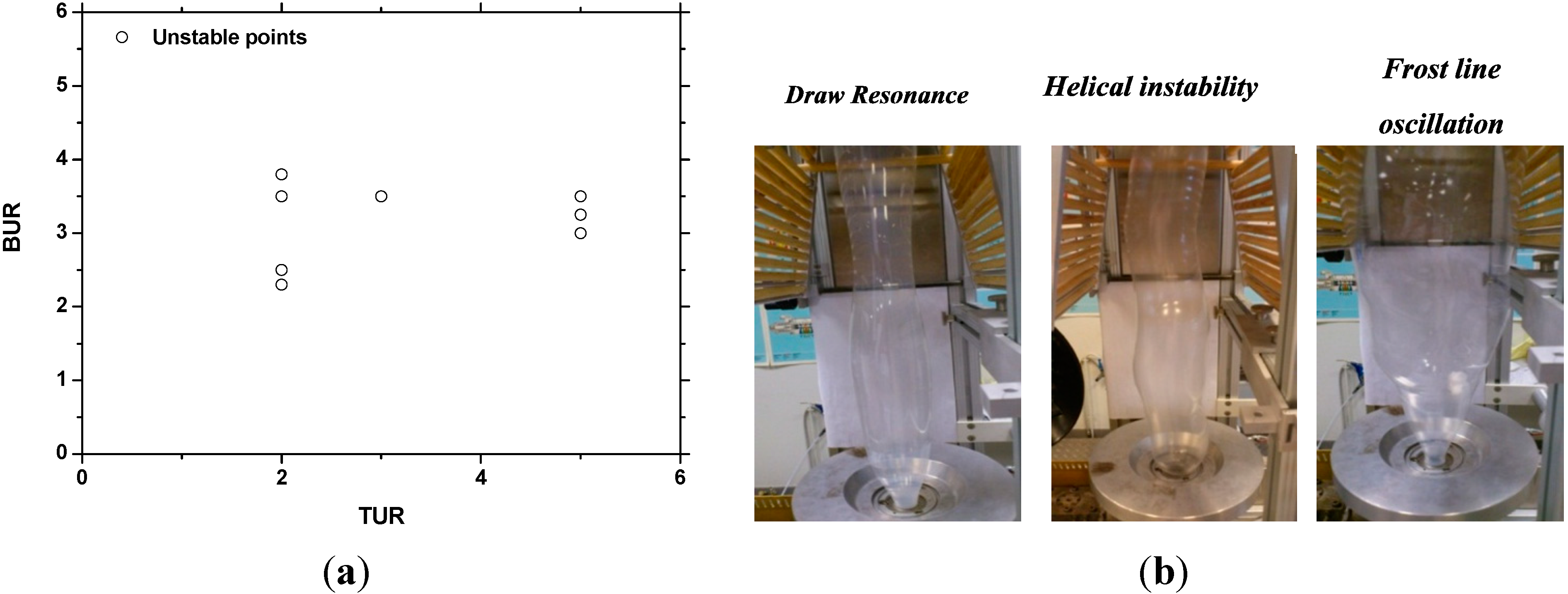

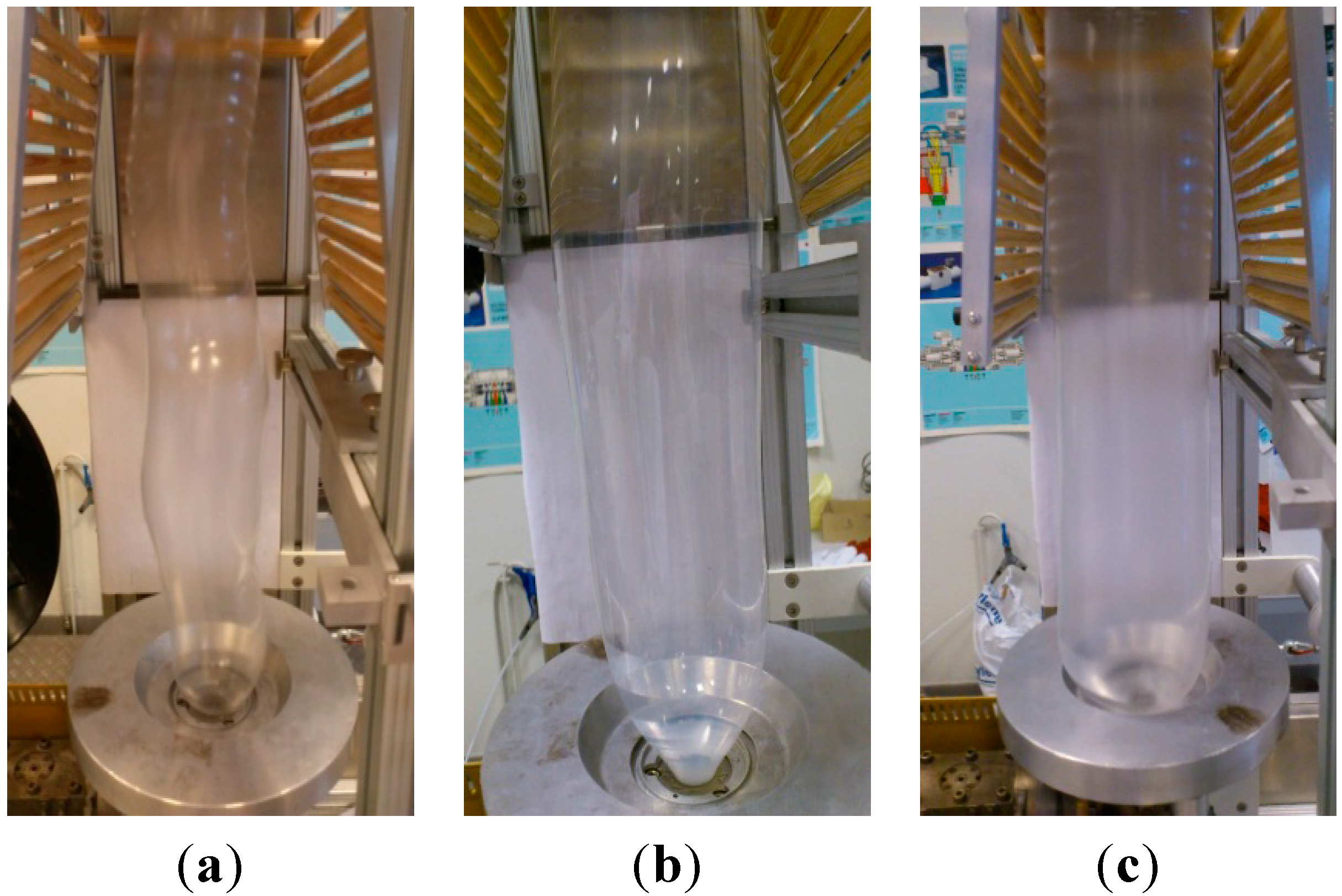

3.4.1. Stability Processing of Neat PLA and PBAT Polymers

3.4.2. Stability Processing of Chain Extended/Branched PLA Polymers

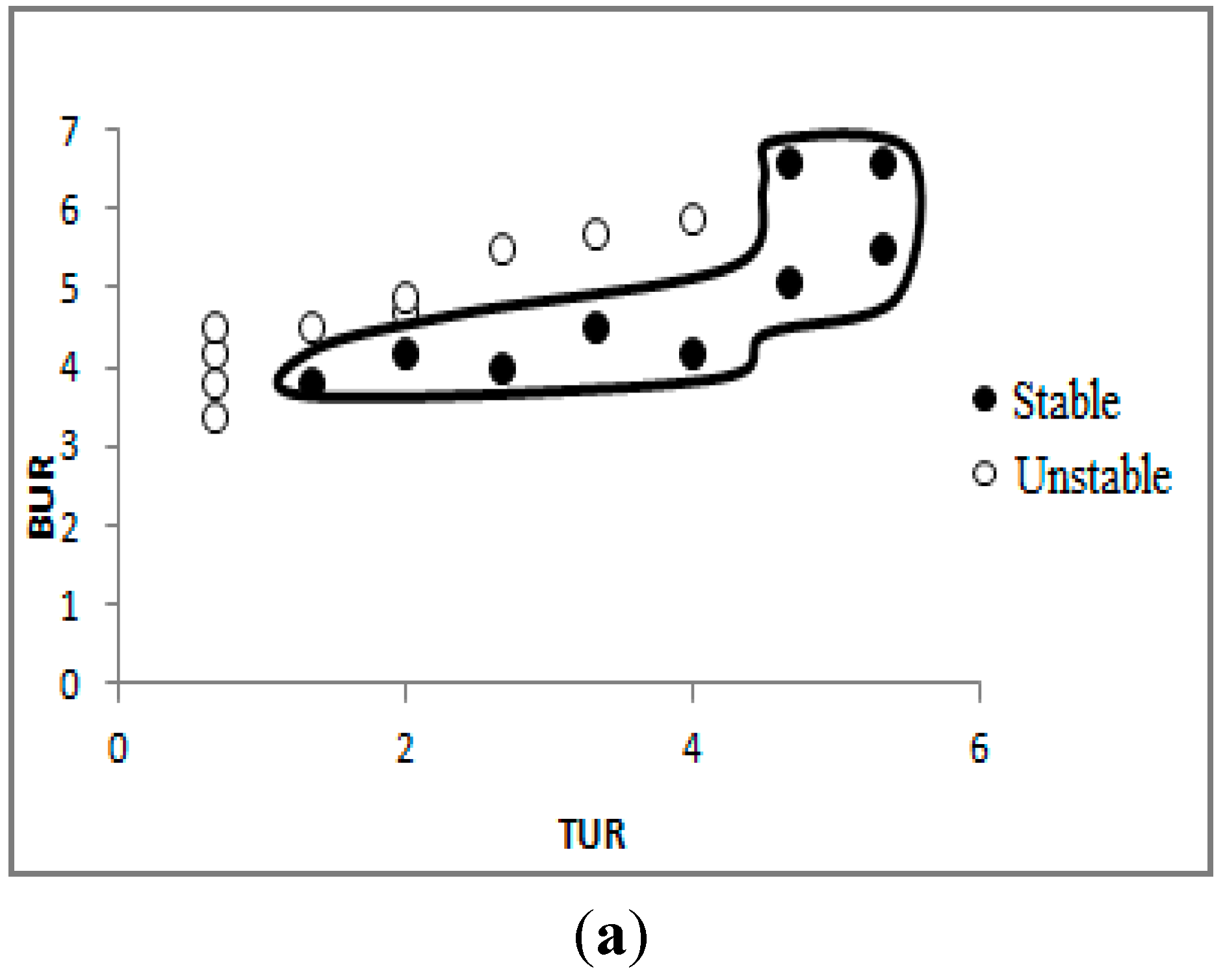

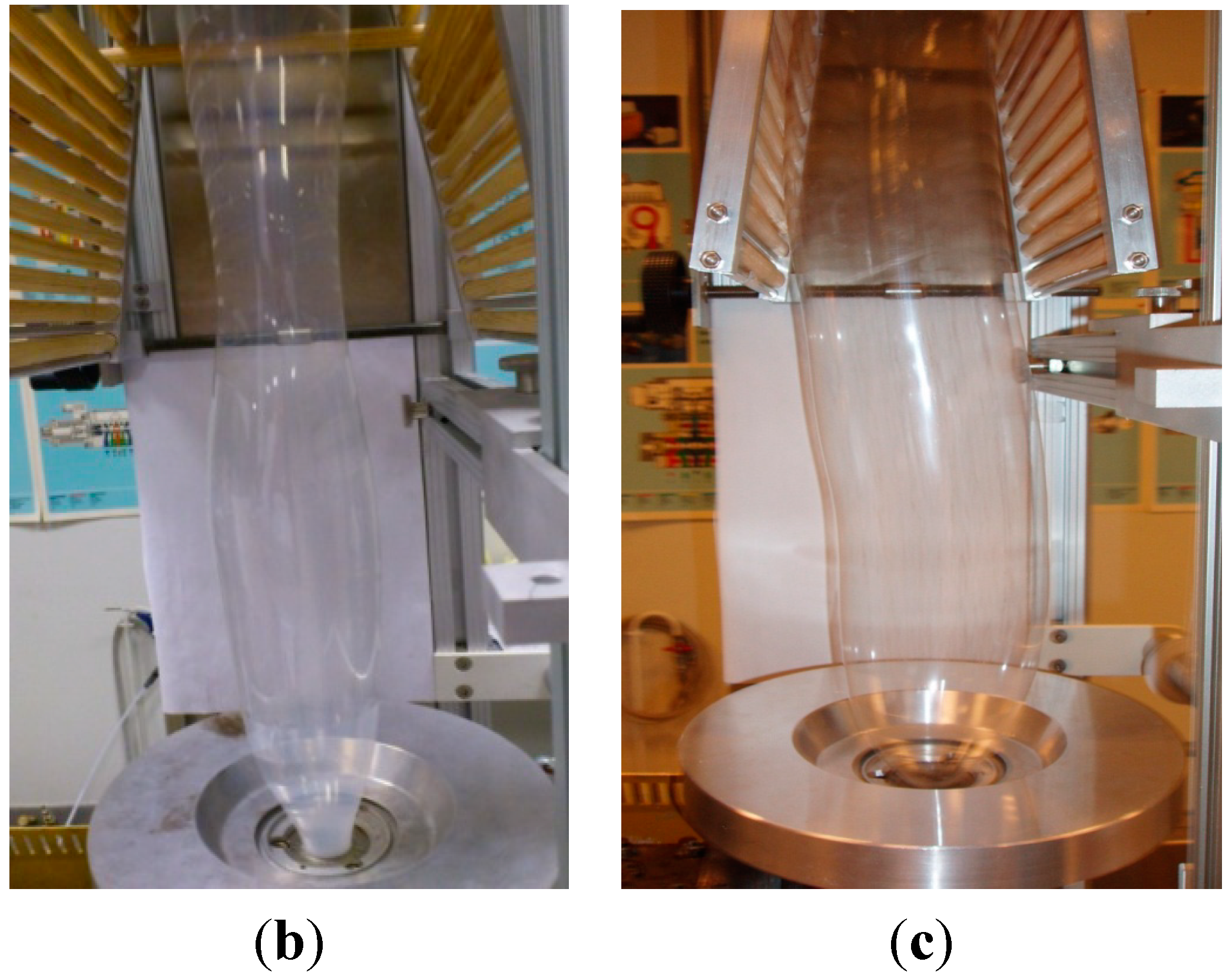

3.4.3. Stability Processing of PLA–PBAT Blends

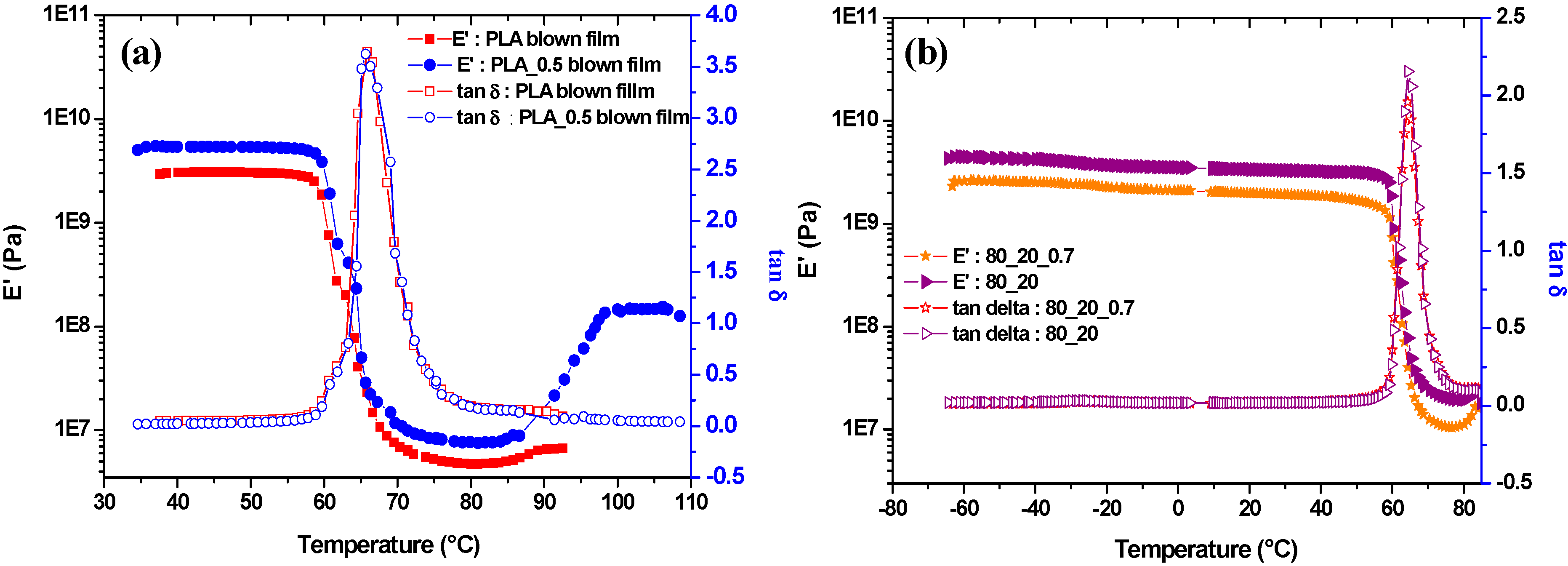

3.5. Thermo-Mechanical and Crystalline Properties of the Blown Films

| Films | Tg (°C) | Tcc (°C) | ΔHcc (J/g) | Tm (°C) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|---|---|

| PLA before blowing | 60 | 115 | 24 | 170 | 25 | 4 |

| PLA–0.7 before blowing | 59 | 111 | 33 | 169 | 38 | 5.5 |

| 80–20 before blowing | −31/62 | 98 | 20.5 | 169 | 28 | 11 |

| 80–20–0.7 before blowing | −30/62 | 108 | 20 | 167.5 | 25 | 7 |

| PLA after blowing | 61.5 | 110 | 27 | 170 | 33 | 6.5 |

| PLA–0.7 after blowing | 63 | 98 | 28 | 170 | 40 | 13 |

| 80–20 after blowing | −29/64 | 103 | 11 | 171 | 29 | 24 |

| 80–20–0.7 after blowing | −29/63 | 95 | 13 | 169 | 19 | 9 |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kanai, T.; Campbell, G.A. Film Processing; Carl Hanser Verlag: Munich, Germany, 1999. [Google Scholar]

- Lim, L.T.; Auras, R.; Rubino, M. Processing technologies for poly (lactic acid). Progr. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Jung, H.W.; Hyun, J.C. Instabilities in extensional deformation polymer processing. Rheol. Rev. 2006, 2006, 131–164. [Google Scholar]

- Arraiza, A.L.; Sarasua, J.R.; Verdu, J.; Colin, X. Rheological behavior and modeling of thermal degradation of poly(ε-caprolactone) and poly(l-lactide). Int. Polym. Process. XXII 2007, 22, 389–394. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym. Degrad. Stab. 2012, 97, 1898–1914. [Google Scholar] [CrossRef]

- Baird, D.J. The role of extensional rheology in polymer processing. Korea-Aust. Rheol. J. 1999, 11, 305–311. [Google Scholar]

- Mihai, M.; Huneault, M.; Favis, B.D. Rheology and extrusion foaming of chain-branched poly(lactic acid). Polym. Eng. Sci. 2010, 50, 629–642. [Google Scholar] [CrossRef]

- Japon, S.; Luciani, A.; Nguyen, Q.T.; Leterrier, Y.; Manson, J.A.E. Molecular characterization and rheological properties of modified poly(ethylene terephthalate) obtained by reactive extrusion. Polym. Eng. Sci. 2001, 41, 1299–1309. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Rheological, morphological, and interfacial properties of compatibilized PLA/PBAT blends. Rheol. Acta 2014, 53, 501–517. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Valenza, A.; Scargiali, F. Non isothermal elongational behavior of blends with liquid crystalline polymers. Polym. Eng. Sci. 1994, 34, 799–803. [Google Scholar] [CrossRef]

- Al-Itry, R.; Lamnawar, K.; Maazouz, A. Reactive extrusion of PLA, PBAT with a multi-functional epoxide: Physico-chemical and rheological properties. Eur. Polym. J. 2014, 58, 90–102. [Google Scholar] [CrossRef]

- Corre, Y.M.; Duchet, J.; Maazouz, A.; Reignier, J. Melt strengthening of poly (lactic acid) through reactive extrusion with epoxy-functionalized chains. Rheol. Acta 2011, 50, 612–629. [Google Scholar]

- Mallet, B.; Lamnawar, K.; Maazouz, A. Improvement of blown film extrusion, of poly (lactic acid): Structure-processing properties relationships. Polym. Eng. Sci. 2014, 54, 840–857. [Google Scholar] [CrossRef]

- Liu, J.; Lou, L.; Yu, W.; Liao, R.; Li, R.; Zhou, C. Long chain branching polylactide: Structures and properties. Polymer 2010, 51, 5186–5197. [Google Scholar] [CrossRef]

- Palade, L.L.; Lehermeier, H.J.; Dorgan, J.R. Melt rheology of high l-content poly(lactic sacid). Macromolecules 2001, 34, 1384–1390. [Google Scholar] [CrossRef]

- Corre, Y.M.; Maazouz, A.; Duchet, J.; Reignier, J. Batch foaming of chain extended PLA with supercritical CO2: Influence of the rheological properties and the process parameters on the cellular structure. J. Supercrit. Fluids 2001, 58, 177–188. [Google Scholar] [CrossRef]

- Zhu, W.L.; Wang, J.; Park, C.B.; Pop-Iliev, R.; Randall, J. Effects of chain branching on the foamability of polylactide. In Proceedings of 67th Annual Technical Conference of the Society of Plastics Engineers (SPE-ANTEC), Chicago, IL, USA, 22–24 June 2009; Volume 1, pp. 41–45.

- Eslami, H.; Kamal, M.R. Effect of a chain extender on the rheological and mechanical properties of biodegradable poly(lactic acid)/poly(butylene succinate-co-adipate) blends. J. Appl. Polym. Sci. 2013, 129, 2418–2428. [Google Scholar] [CrossRef]

- Kim, Y.M.; Park, J.K. Effect of short chain branching on the blown film properties of linear low density polyethylene. J. Appl. Polym. Sci. 1996, 61, 2315–2324. [Google Scholar] [CrossRef]

- Majumder, K.K.; Hobbs, G.; Bhattacharya, S.N. Molecular, rheological, and crystalline properties of low-density polyethylene in blown film extrusion. Polym. Eng. Sci. 2007, 47, 1983–1991. [Google Scholar] [CrossRef]

- Cogswell, F.N. Converging flow of polymer melts in extrusion dies. Polym. Eng. Sci. 1972, 12, 64–73. [Google Scholar] [CrossRef]

- Lehermeier, H.J.; Dorgan, J.R. Melt rheology of poly (lactic acid): Consequences of blending chain architectures. Polym. Eng. Sci. 2001, 41, 2172–2184. [Google Scholar] [CrossRef]

- Han, C.D.; Park, J.Y. Studies on blown film extrusion. III. Bubble instability. J. Appl. Polym. Sci. 1975, 19, 3291–3297. [Google Scholar] [CrossRef]

- Han, C.D.; Shetty, R. Flow instability in tubular film blowing. 1. Experimental study. Ind. Eng. Chem. Fundam. 1977, 16, 49–56. [Google Scholar] [CrossRef]

- Kanai, T.; White, J.L. Kinematics, dynamics and stability of tubular film extrusion of various polyethylenes. Polym. Eng. Sci. 1984, 24, 1185–1201. [Google Scholar] [CrossRef]

- Minoshima, W.; White, J.L. Instability phenomena in tubular film and melt spinning of rheological characterized high density, low density and linear low density polyethylenes. J. Non-Newton. Fluid Mech. 1986, 19, 275–302. [Google Scholar] [CrossRef]

- Yamane, H.; Sasai, K.; Takano, M. Poly(d-lactic acid) as a rheological modifier of poly(l-lactic acid): Shear and biaxial extensional flow behavior. J. Rheol. 2004, 48, 599–609. [Google Scholar] [CrossRef]

- Mekhilef, N.; Hedhli, L.; Moyses, S. Effect of rheological strain hardening on extrusion blown film of polyvinylidene fluoride. J. Plast. Film Sheeting 2007, 23, 203–219. [Google Scholar] [CrossRef]

- Stange, J.; Uhl, C.; Münstedt, H. Rheological behavior of blends from a linear and a long-chain branched polypropylene. J. Rheol. 2005, 49, 1059–1080. [Google Scholar] [CrossRef]

- Kasehagen, L.J.; Macosko, C.W. Nonlinear shear and extensional rheology of long-chain randomly branched polybutadiene. J. Rheol. 1998, 42, 1303–1327. [Google Scholar] [CrossRef]

- Raffa, P.; Coltelli, M.B.; Savi, S.; Bianch, S.; Castelvetro, V. Chain extension and branching of poly(ethylene terephthalate) (PET) with di- and multifunctional epoxy or isocyanate additives: An experimental and modelling study. React. Funct. Polym. 2012, 72, 50–60. [Google Scholar] [CrossRef]

- Henton, D.E.; Gruber, P.; Lunt, J.; Randall, J. Polylactic acid technology. In Natural Fibers, Biopolymers, and Biocomposites; Mohanty, A.K., Misra, M., Drzal, L.T., Eds.; Taylor & Francis: Boca Raton, FL, USA, 2005; pp. 527–577. [Google Scholar]

- Huda, M.S.; Yasui, M.; Mohri, N.; Fujimura, T.; Kimura, Y. Dynamic mechanical properties of solution-cast poly(l-lactide) films. Mater. Sci. Eng. A 2002, 333, 98–105. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Itry, R.; Lamnawar, K.; Maazouz, A. Biopolymer Blends Based on Poly (lactic acid): Shear and Elongation Rheology/Structure/Blowing Process Relationships. Polymers 2015, 7, 939-962. https://doi.org/10.3390/polym7050939

Al-Itry R, Lamnawar K, Maazouz A. Biopolymer Blends Based on Poly (lactic acid): Shear and Elongation Rheology/Structure/Blowing Process Relationships. Polymers. 2015; 7(5):939-962. https://doi.org/10.3390/polym7050939

Chicago/Turabian StyleAl-Itry, Racha, Khalid Lamnawar, and Abderrahim Maazouz. 2015. "Biopolymer Blends Based on Poly (lactic acid): Shear and Elongation Rheology/Structure/Blowing Process Relationships" Polymers 7, no. 5: 939-962. https://doi.org/10.3390/polym7050939