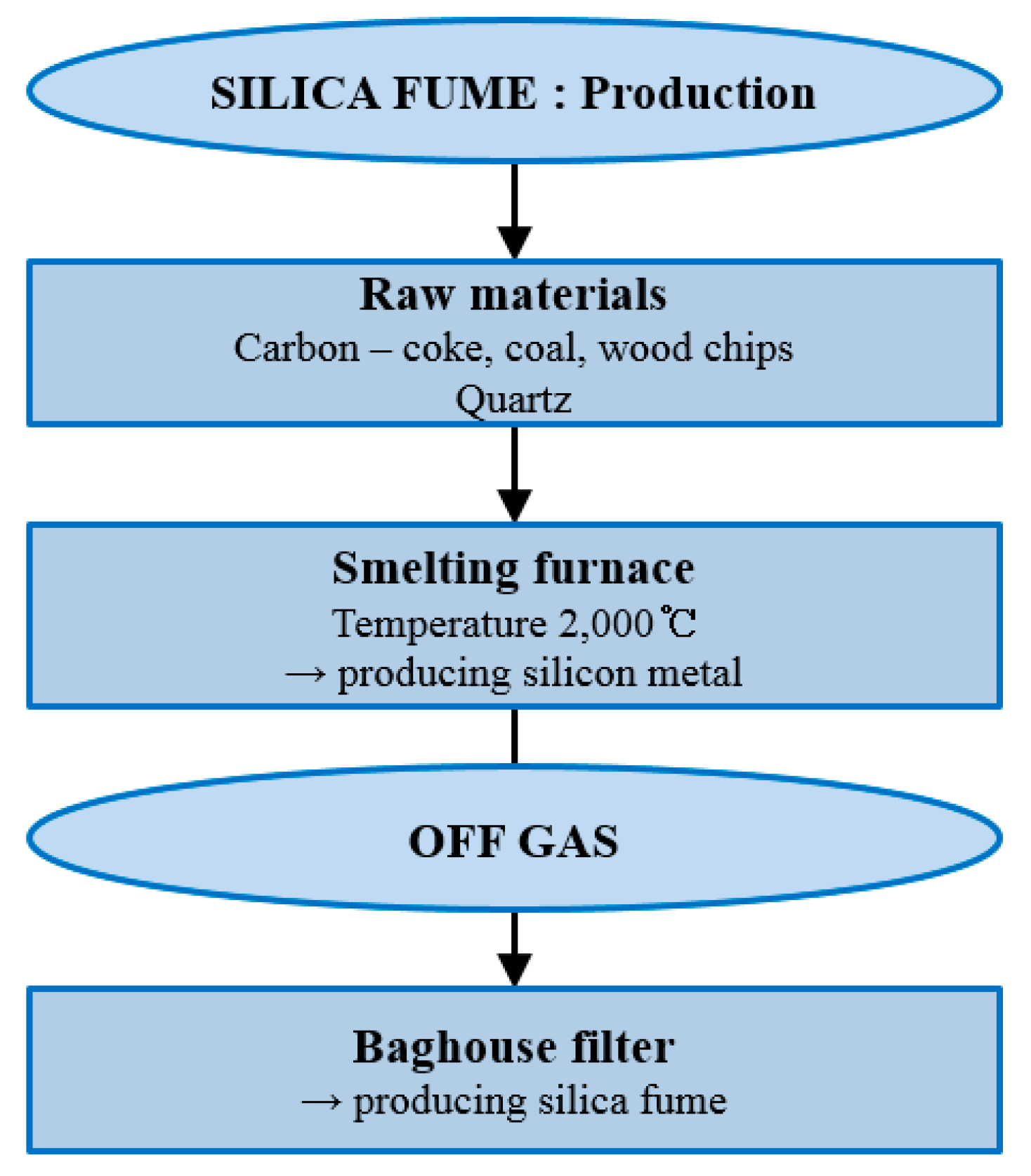

4.1. Plain Concrete MSAE Bond Performance Discussion

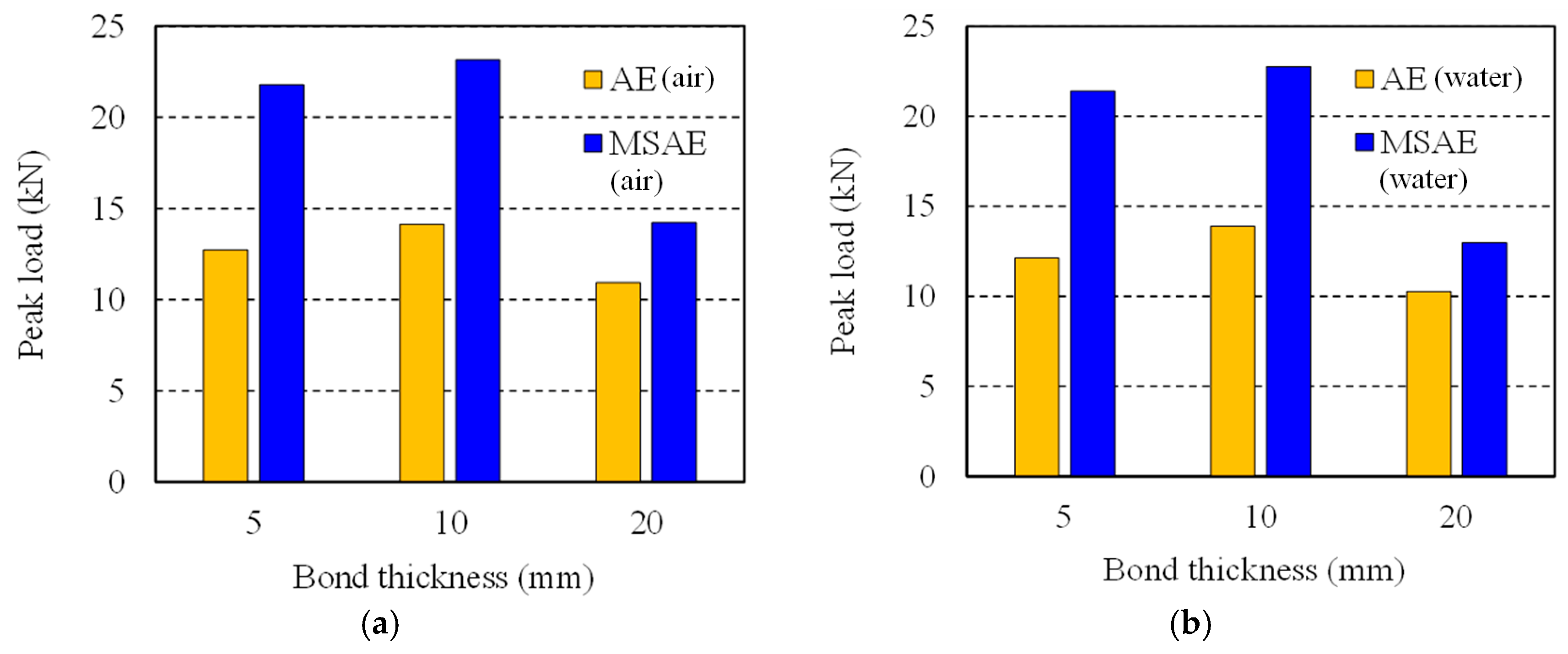

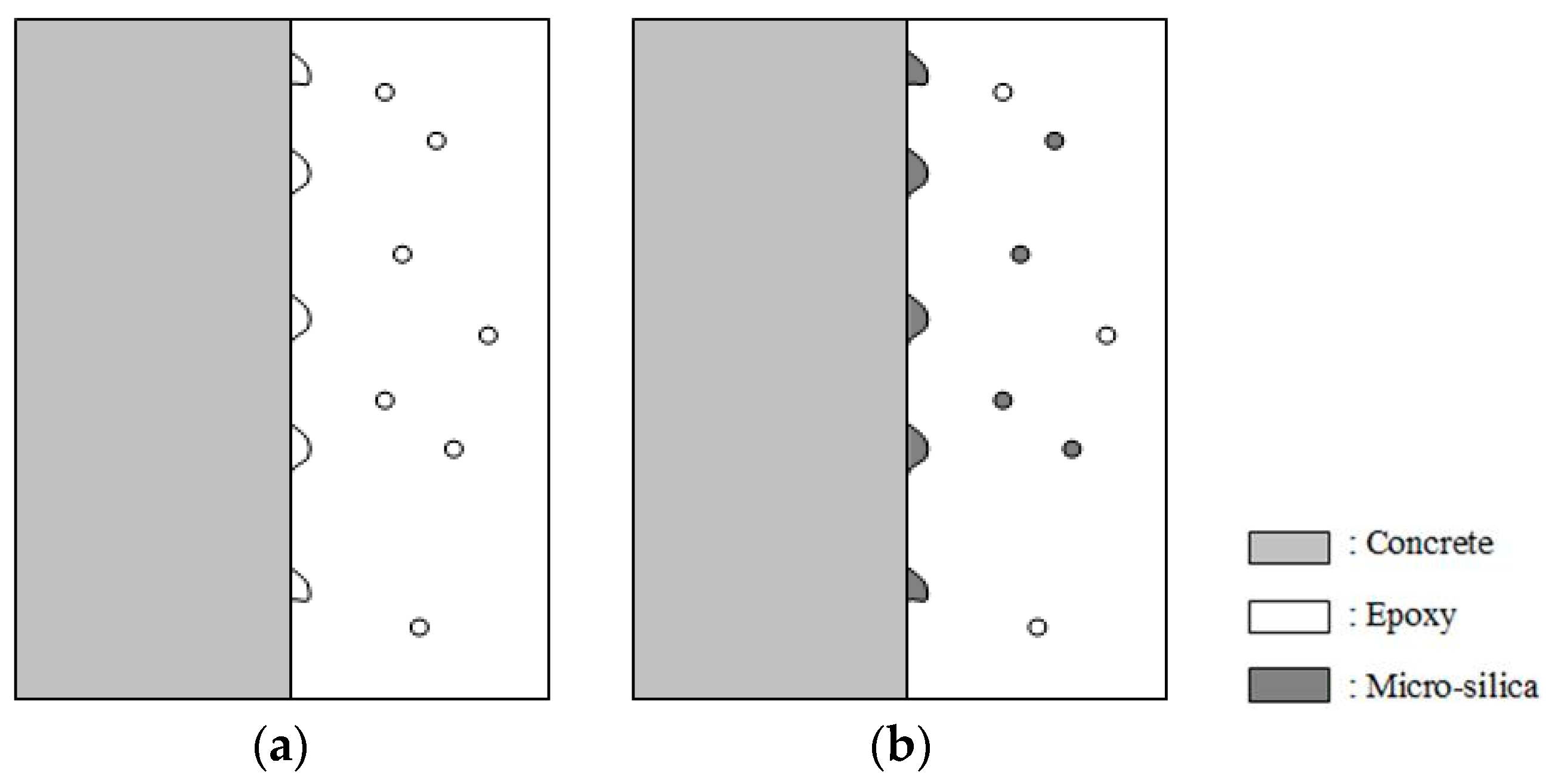

When the load-carrying capacity of the specimens with MSAE was compared to those with AE, the peak loads of the MSAE specimens were greater than the AE specimens. The increased peak loads can be attributed to the addition of micro-silica in increasing the bonding surface area of the interface. Since the AE is a highly viscous material, it is hard to consistently apply the AE to the concrete interfacial surface because this application inherently creates micro-pores at the concrete-epoxy interface as shown in

Figure 18. These micro-pores are the main reason for the decrease in bond strength because the net bond strength at the interface is dictated by the surface area of the bonded interface. Therefore, if no surface treatment is performed on the concrete surface, the pores decrease the bond capacity of the member. Also, the pores would decrease homogeneity of the bonded interface, so the peak load of the member should decrease. However, the addition of micro-silica would fill the existing pores in an epoxy matrix and at the interface, which would maintain the integrity of the bonded region.

Figure 18.

Pore reduction by MSAE; (a) non-MS; and (b) MSAE.

Figure 18.

Pore reduction by MSAE; (a) non-MS; and (b) MSAE.

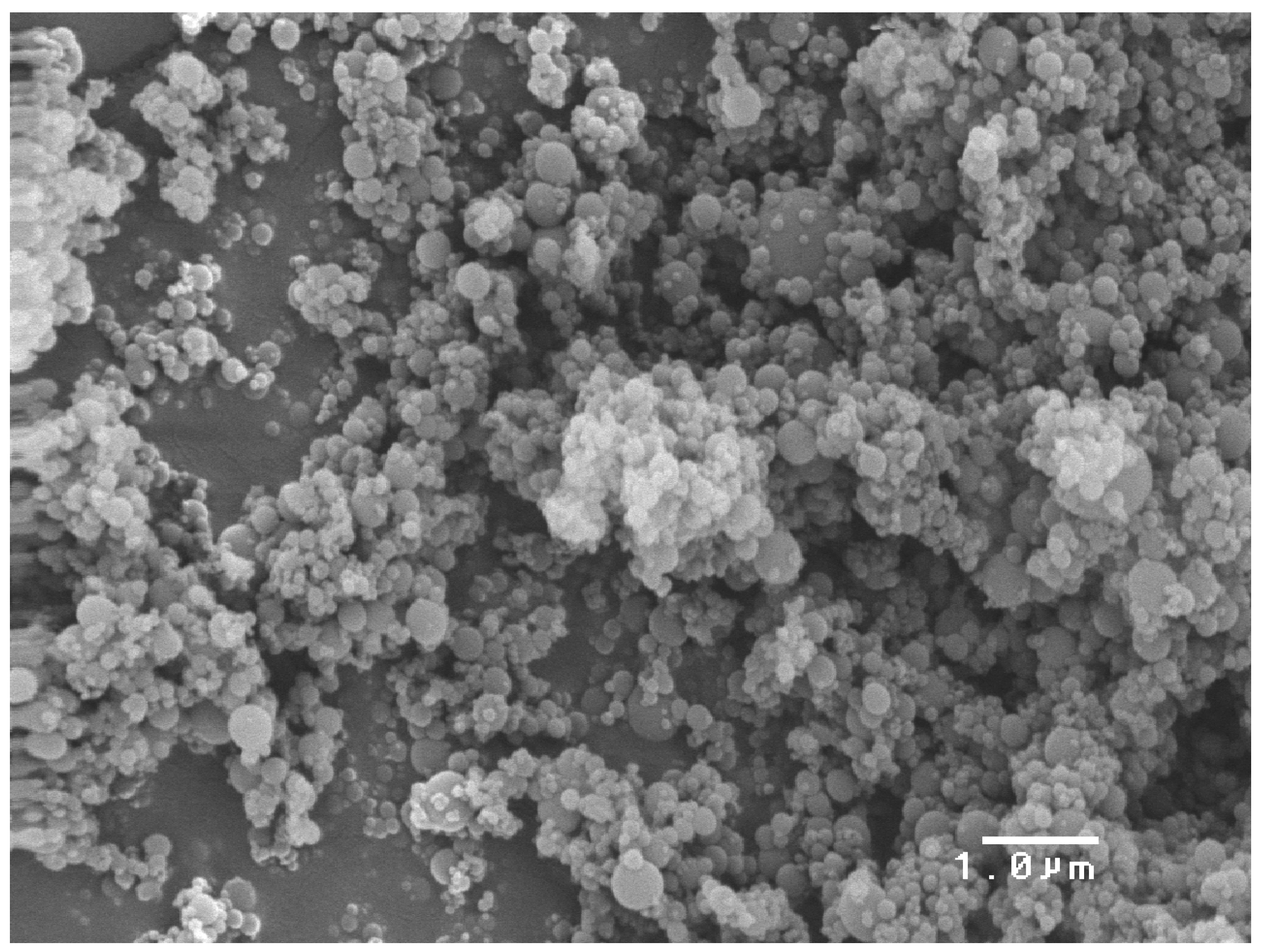

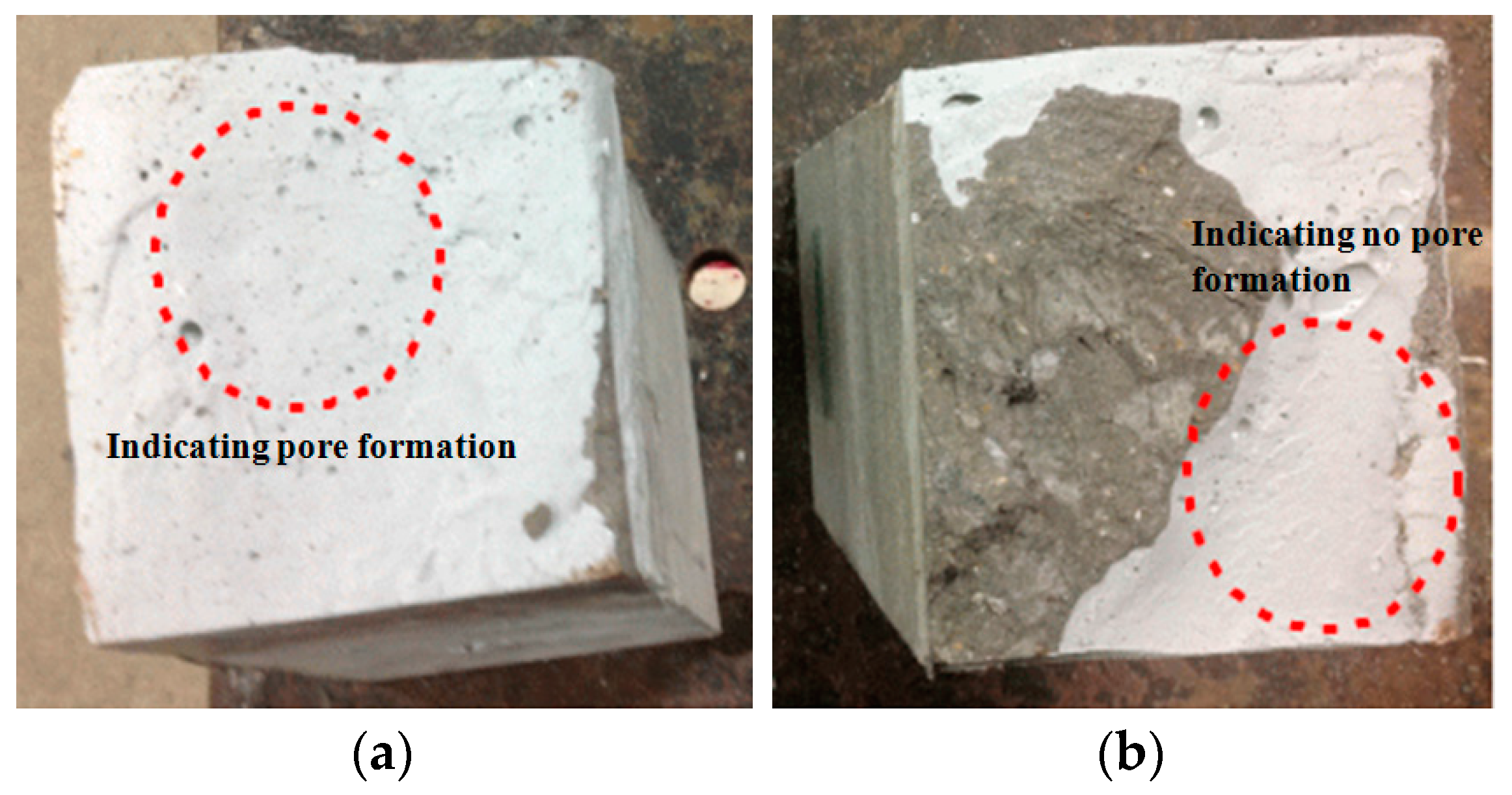

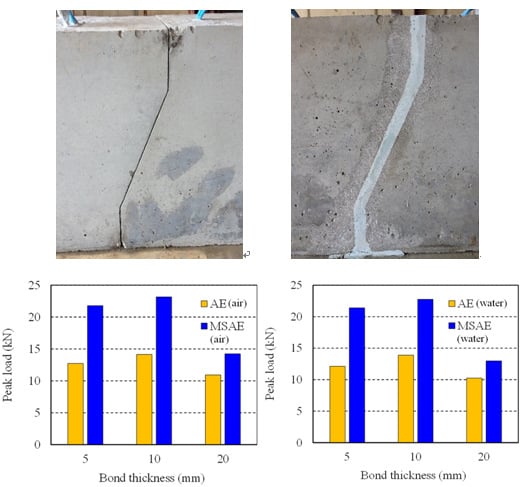

The proofs to the hypothesis of micro-silica filling of pores can be partly observed in the failure surface as shown in

Figure 19. The failure section shown in

Figure 19a,b show the existence of pores in AE without micro-silica and the reduction of pores with micro-silica, respectively. Of course, since the micro-pores are formed irregularly and inconsistently for each specimen, the reduction of micro-pores shown in

Figure 19b may not be a direct visible proof of filling of pores by micro-silica. A more trustworthy proof might be obtained from the failure surface. As shown in

Figure 19b, a portion of the concrete surface is visible due to MSAE spalling off (left gray part in

Figure 19b) while the module attached with AE shows a full AE surface. This means that specimens connected with AE failed by detachment while specimens connected with MSAE failed by partial concrete spalling, resulting in an increased bonding capacity by 64% irrespective of the curing condition.

Figure 19.

Interfacial fracture section and pore reduction (10 mm thickness); (a) non-MS; and (b) MSAE.

Figure 19.

Interfacial fracture section and pore reduction (10 mm thickness); (a) non-MS; and (b) MSAE.

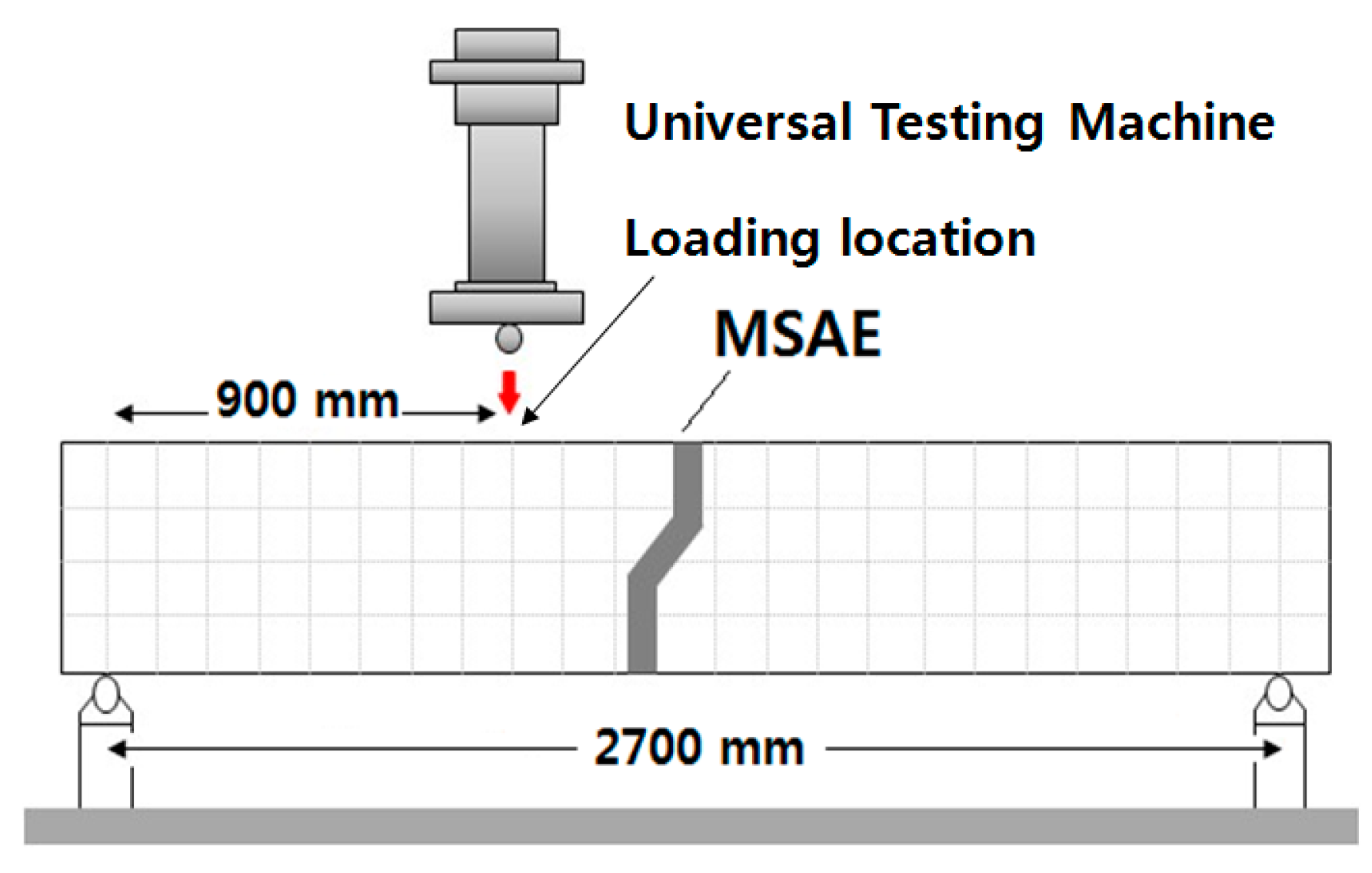

Figure 13b shows the test results for specimens bonded and cured underwater. Specimens plastered with MSAE and cured underwater showed higher capacities than the specimens bonded with AE. Even though the bonding capacities of specimens from the underwater condition decreased compared to the specimens formed in air, the reduction was only 4% on average for both specimens with and without micro-silica. Consequently, the results showed that the MASE can be applied successfully in sea conditions. Eliminating pores in a bonding material is very important when a structure is constructed and used at sea. If water particles in the pores undergo freeze-thawing action, cracking could occur in the epoxy matrix. Therefore, the reduction of micro-pores by adding micro-silica would significantly reduce the potential for cracking.

The bond thickness experiments showed that the maximum strength was obtained when the thickness was 10 mm. When the thickness was 5 mm, the load-carrying capacity was lower than that at 10 mm. The lowest load was obtained when the thickness was 20 mm. This phenomenon does not seem to be a material issue, but a structural issue. When the epoxy thickness is higher, shear and flexural stresses are generated on the interface due to the fact that a greater thickness translates into a larger weak zone in the middle of the specimen because the strength of the interface is independent of the interface thickness. However, this result is insignificant, because the capacity for bond thickness in a bonded concrete block will change depending on specimen size, loading scheme, etc. Also, since PS was applied to connect the modulus, the bond thickness does not directly dictate the overall bond behavior of the structure. The test results showed that the load-carrying capacity of the specimens with MSAE was enhance due to overall improvement in the integrity of the bonded interface increased by adding micro-silica in AE.

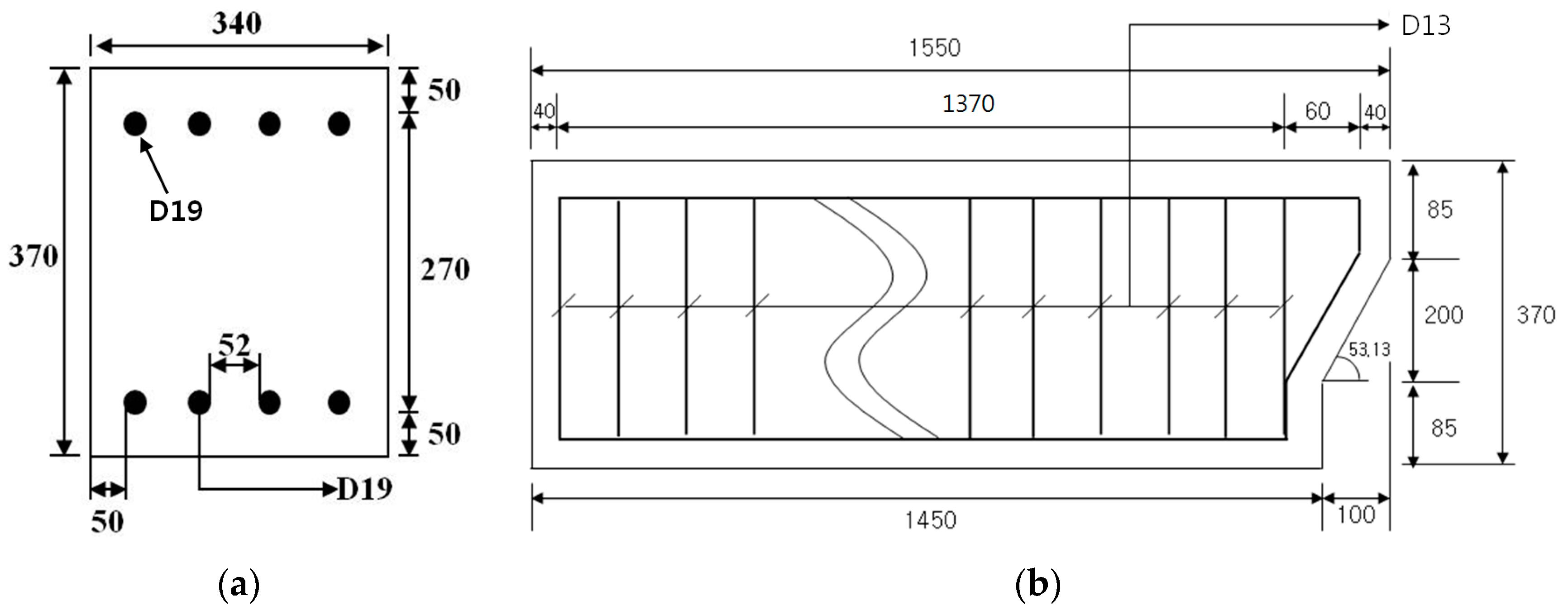

4.2. PSC Structural MSAE Bond Performance Discussion

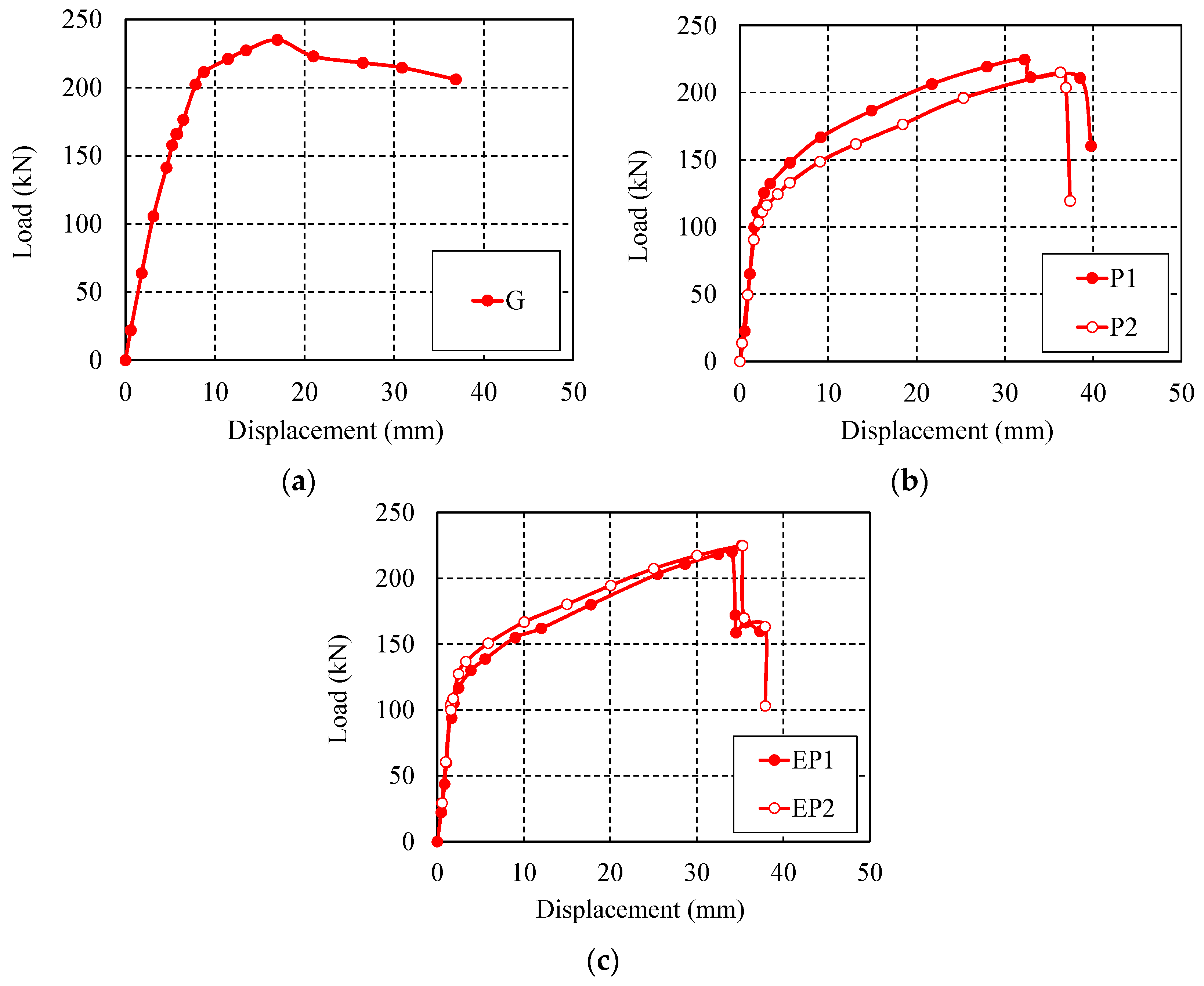

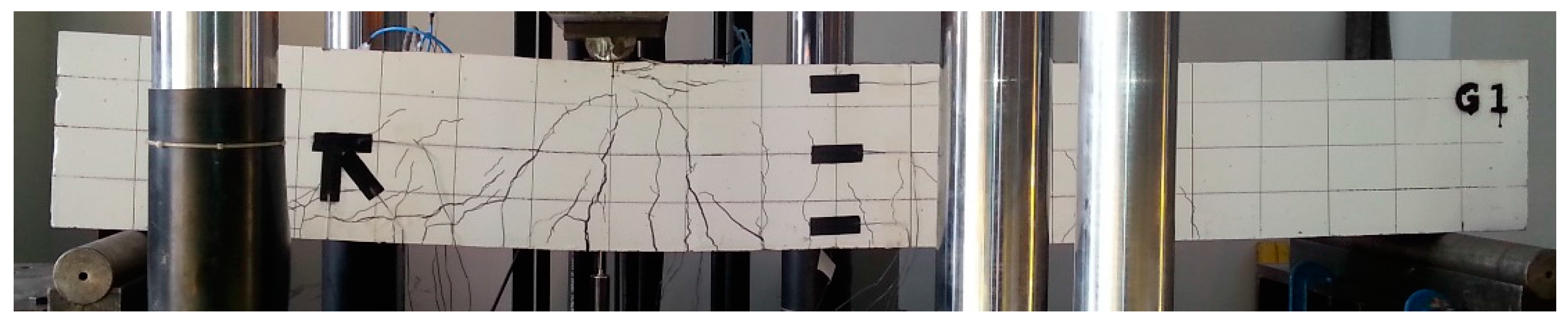

A comparison of the test results of P and EP specimens with those of the G (control) specimen showed that P and EP specimens had very similar load-carrying capacities of the G specimens. The maximum deflections of P and EP were different from that of the G specimens due to the difference in structural rigidity of RC and PSC. Since the specimens with splicing do not have continuity along the span, P and EP showed a large deflection. However, a relatively larger deflection could be better for a very large concrete module structure floating on the sea because it can absorb larger wave-induced energy. With respect to load-carrying capacity, the results showed that a spliced beam connected by PS could have the same structural capacity as that of a continuous beam.

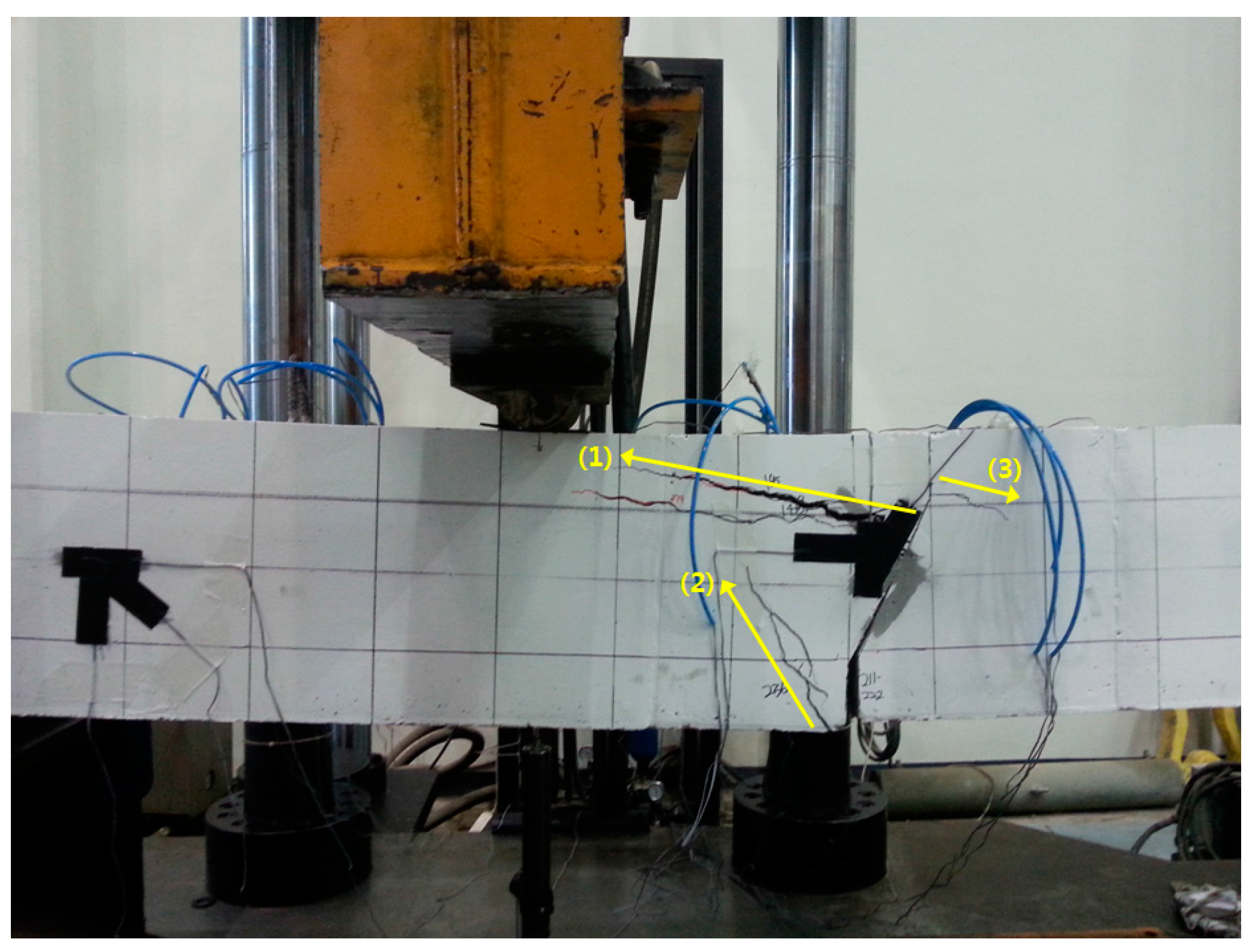

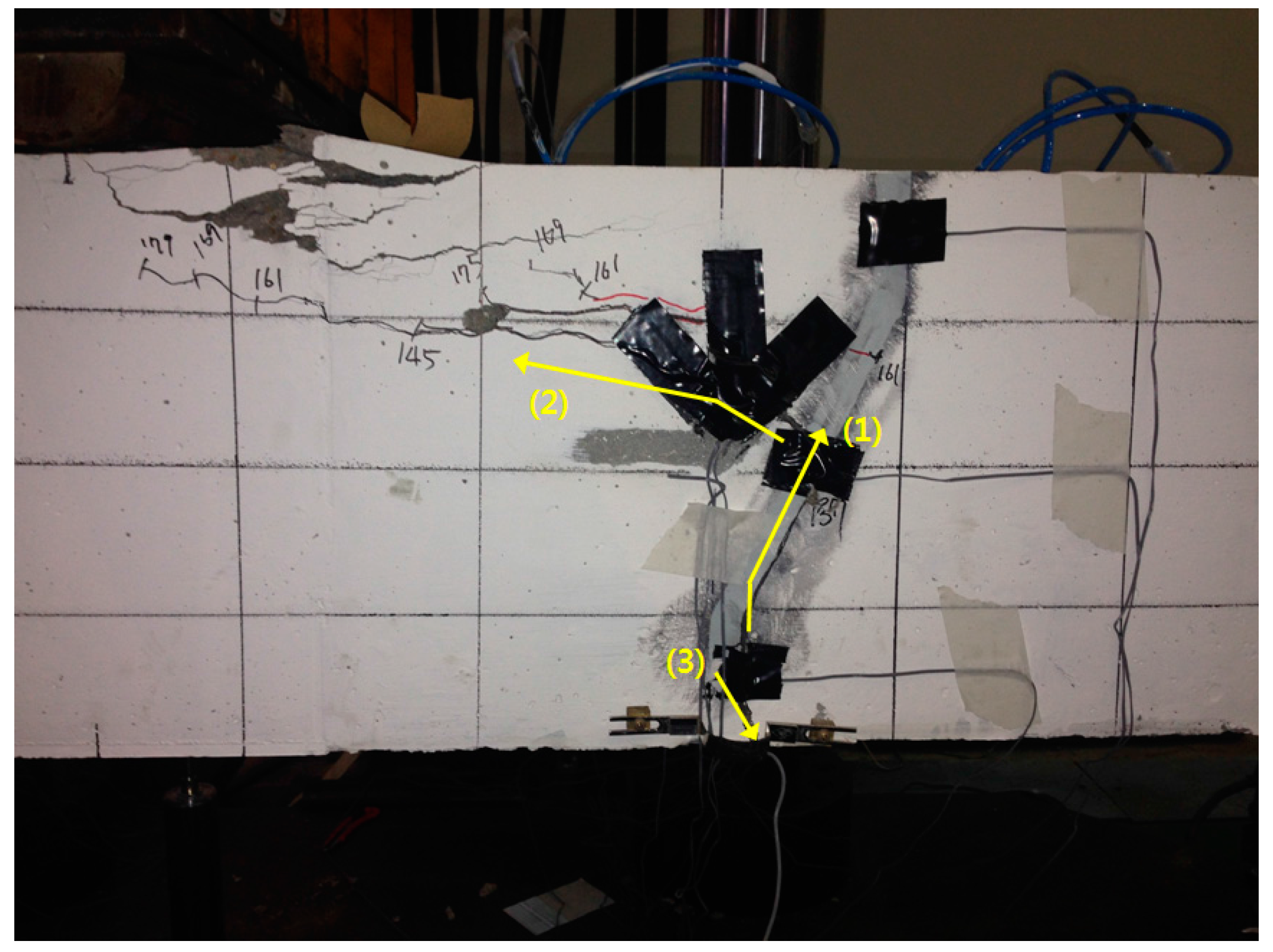

The effect of MSAE can be estimated by comparing P and EP series. We anticipated that MSAE would significantly contribute to stress distribution at the interface because it has a higher, stronger tensile strength than that of concrete. As the load increased, the interface opening was wider in P specimens than in EP specimens because the interface was not bonded. When the unbonded opening increased in P specimens, initial cracking occurred at the apex due to the stress concentration at the location. As the load increased, the inclined section below the apex shifted upward and interlocked with the right module. These movements caused the bottom interface to open and crack (2) to develop. Due to stress release at the inclined section away from crack (2), the stress concentration shifted to the top part of the beam and crack (3) occurred. Even though this stress concentration can be eliminated by securing a perfect fit at the interface of two concrete modules, it is practically impossible to create a perfect interface due to the material characteristics of concrete.

For the EP specimens bonded by MSAE, the interface opening did not start before initial cracking. As the load increased, debonding at the bottom region and sliding occurred at the middle of the inclined section of the interface, which led to cracking on the left-hand side as shown in

Figure 17. Even though the final crack patterns of P and EP specimens seemed to be similar, the location of the main cracks was different. It is important to note that the main crack location is critical to structural safety and durability.

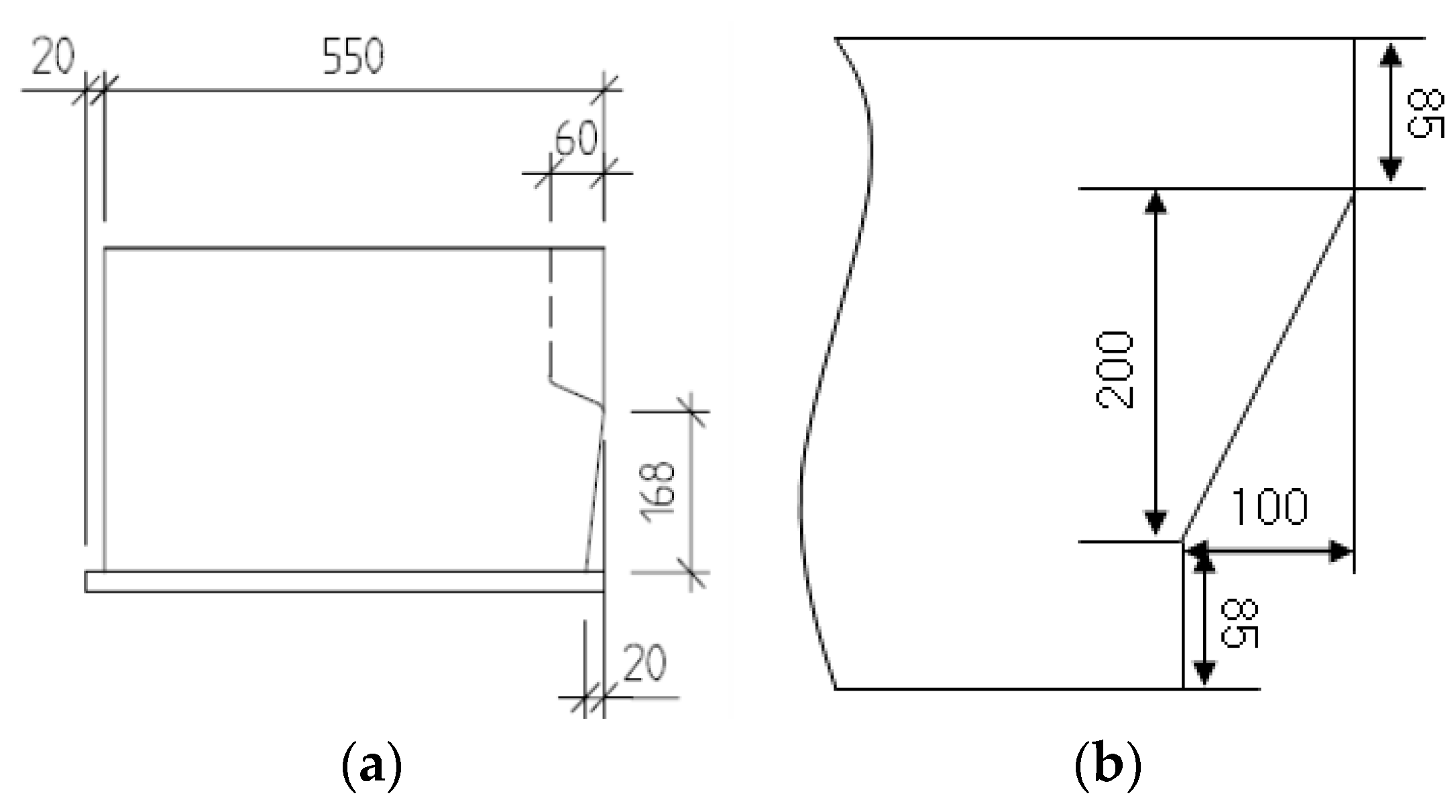

In

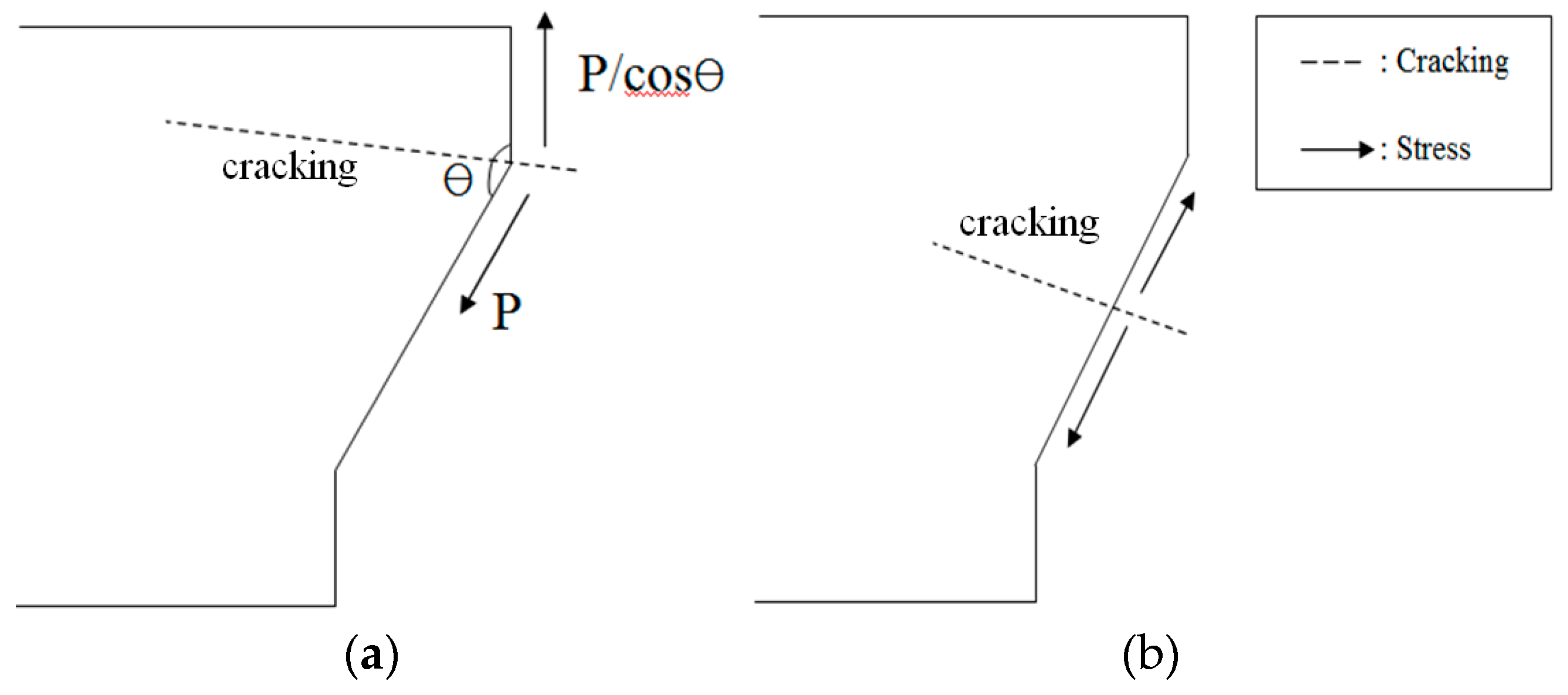

Table 12 and

Figure 20, the stress transmission processes of the P and EP series were compared. This comparison showed that the application of MSAE dictated the location of the cracking, and the stress transfer magnitude across the rebars was reduced from P to Pcosθ. Also, MSAE bonding prevented slip behavior from occurring at the interface, so the transmission of the stress was maintained.

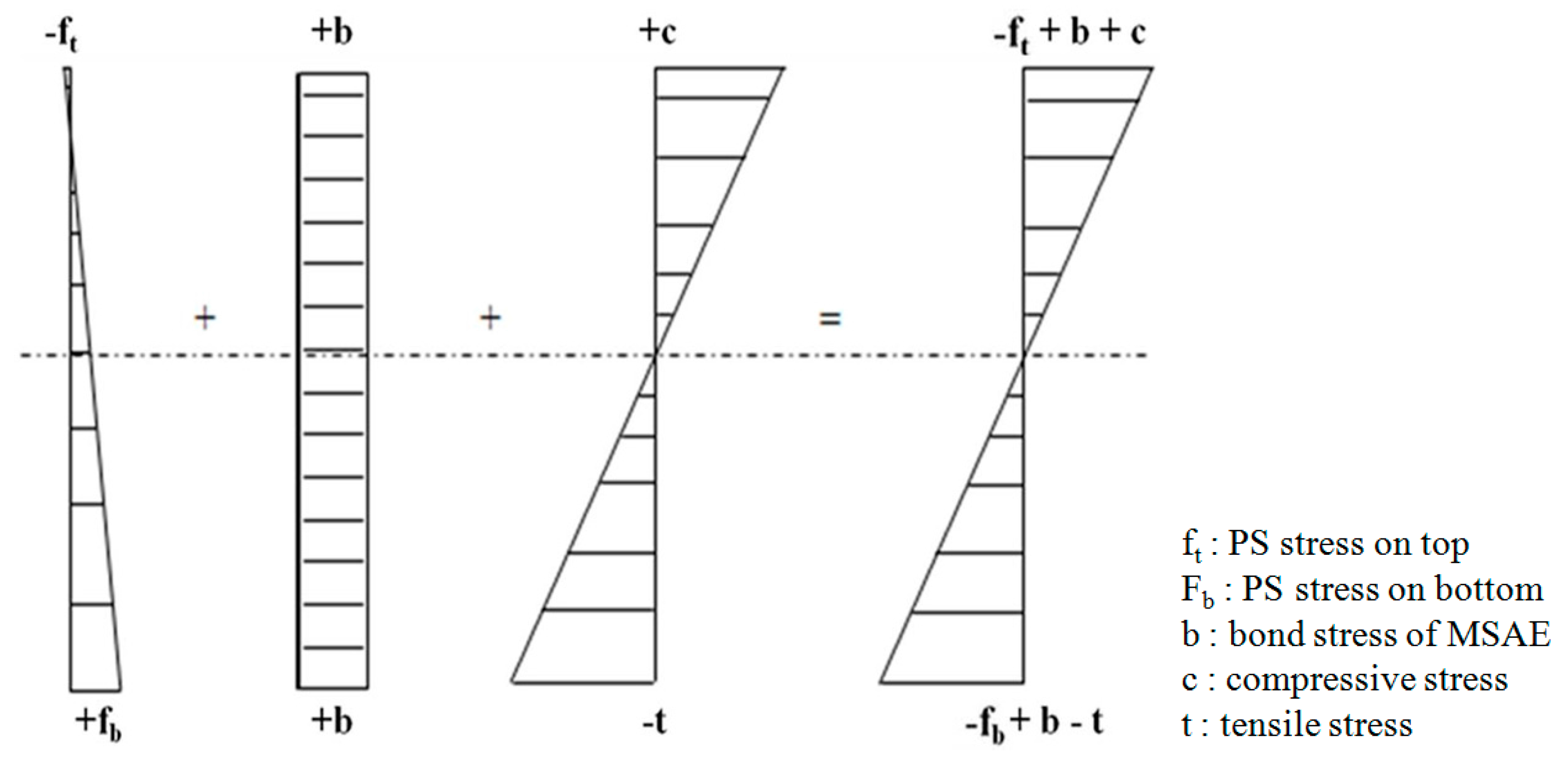

Figure 21 shows the interfacial stress profile across the cross-section. Before the application of load, the only stress applied to the cross-section was from the PS force and bond stress with top, bottom, and bond stress magnitudes of

ft = −0.94 MPa,

fb = 7.3 MPa, and

b = 4.8 MPa, respectively. After the start of loading, the stress generated by the bending moment was 20 MPa on the top and bottom sections when the load was approximately 220 kN. The top and bottom surfaces had final compressive and tensile stresses of 24 and 8 MPa, respectively. The stress profile of the interface should not have failed due to the stress. However, crack (2) was observed in P specimens without MSAE and this resulted from the stress concentration and transfer described previously. In the case of the EP specimen with MSAE, there were no cracks at the bottom of the specimens. The interfacial behavior after MSAE application seemed to be adequate for maintaining continuity across the concrete module interface. When concrete floating structures are constructed by module connection, pre-bonding of modules by MSAE before PS has the advantage of maintaining continuity over the interface until ultimate failure [

21]. Also, MSAE application at the interface allows continuous load transmission and stress distribution between the attached modules, allowing them to behave as one unit.

Figure 20.

Stress distribution in rebars. (a) P series; and (b) EP series.

Figure 20.

Stress distribution in rebars. (a) P series; and (b) EP series.

Table 12.

Change of stress transmission area.

Figure 21.

Stress diagram at interface.

Figure 21.

Stress diagram at interface.

In concrete structures, cracks are very important because they lead to the corrosion of steel reinforcing bars and the deterioration of load-carrying capacity. If a structure is constructed in sea water, the cracks are the most critical issue in the design of the structure. The results of the MSAE structural tests showed that MSAE helped in stress distribution along the interface. The interface experienced crack formation at the middle inclined section, while cracks formed at the bottom main tensile reinforcing bars were located in P specimens. Consequently, stress distribution of the MSAE increased the service life and durability of the concrete structures.