Evaluation of the Thermal Stability and Micro-Modification Mechanism of SBR/PP-Modified Asphalt

Abstract

:1. Introduction

2. Materials and Laboratory Test

2.1. Materials

2.2. Preparation of SBR/PP Composite-Modified Asphalt

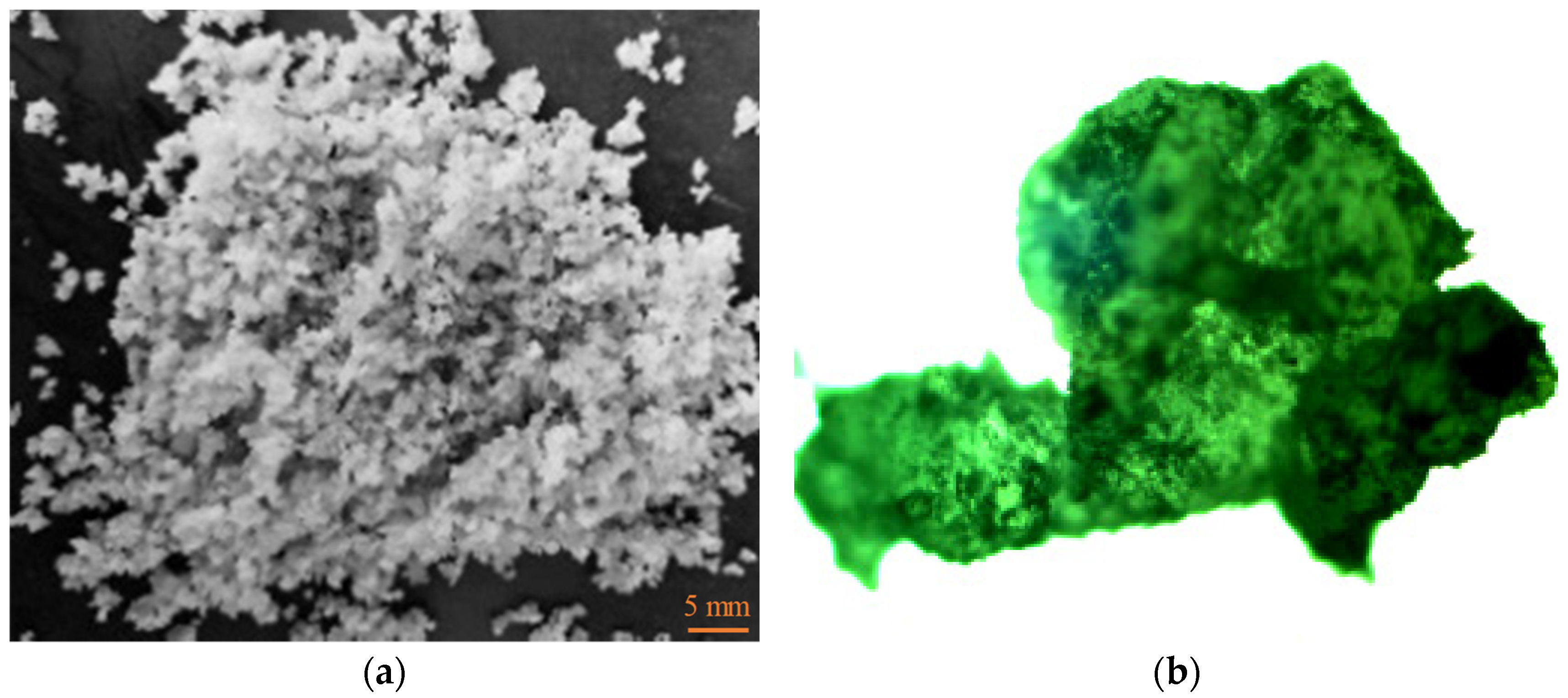

- The SBR powder and PP granules were weighed according to the proportioning design, respectively, mixed in a mixer for 1 min, and then added to an appropriate amount of compatibilizer, a crosslinking agent and an auxiliary agent for blending; finally, the blend was added to a screw extruder for extrusion. The temperature of the extruder feeding port was set to 180 °C, the temperature of the die head was set to 190 °C, and the rotational speed of the screw was 150 r/min to obtain the SBR/PP thermoplastic elastomer. In order to improve the dispersion and swelling of SBR/PP thermoplastic elastomer in asphalt, it is ground by a rubber pulverizer [19]. The effect is shown in Figure 1. It can be observed through the general optical micrograph microscope that the surface of the SBR/PP thermoplastic elastomer particles is rough, the shape is irregular, and the SBR and PP are evenly mixed. SBR/PP elastomers are not white, but off-white (shown in Figure 1a). It looks off-white mainly due to the use of auxiliary lighting during the shooting process, making the overall color bright (or off-white). In this study, the average particle size of SBR particles is approximately 20 mesh. According to some relevant studies [20,21,22], PP was calculated and revealed to exhibit isotactic configuration, with a molecular weight of 40,000 g/mol; this constitutes over 95% of the entire polymer content.

- 2.

- The SK 70 base asphalt was heated to a hot-melt state, and then the SBR/PP thermoplastic elastomer was slowly added to the asphalt. Then the modified asphalt was heated to 170~180 °C and mechanically stirred for 20 min, so that the SBR/PP thermoplastic elastomer body was fully swollen in asphalt. Then, the modified asphalt was sheared with a high-speed shearer at the speed of 5000 R/min for 40 min [23]. Finally, SBR/PP composite-modified asphalt was obtained. The proportion design of SBR/PP thermoplastic elastomer is shown in Table 2, in which the content of SBR/PP thermoplastic elastomer is 4% of the mass of asphalt.

2.3. Analysis and Testing

3. Results and Discussion

3.1. Technical Indicators of SBR/PP Composite-Modified Asphalt

3.2. PG Analysis of SBR/PP Composite-Modified Asphalt

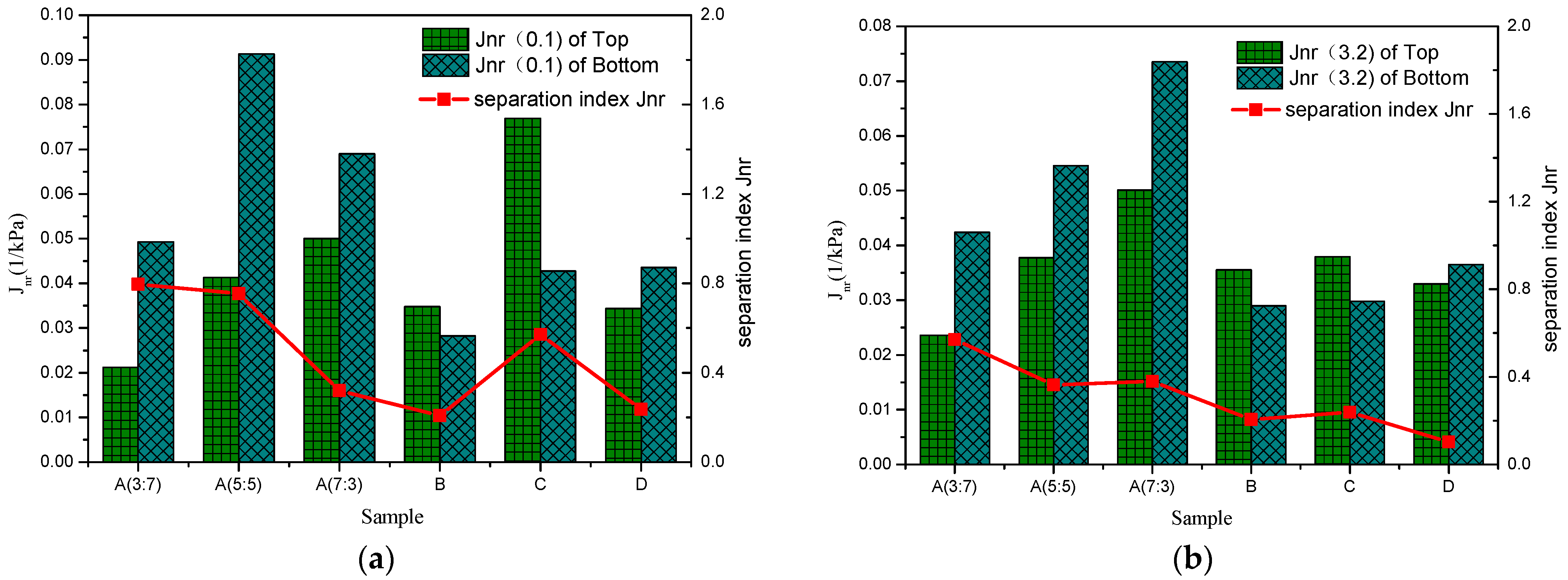

3.3. Stability Analysis of SBR/PP Composite-Modified Asphalt

3.4. Analysis of Compatibility Mechanism of SBR/PP Composite-Modified Asphalt

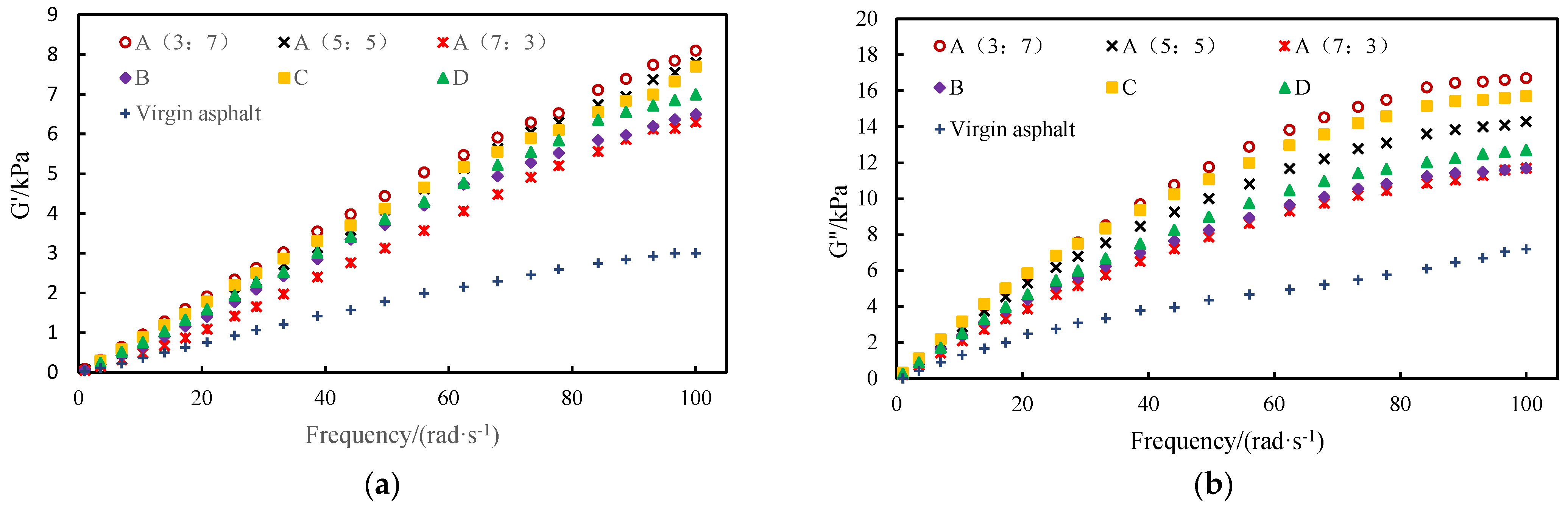

3.4.1. Frequency Sweep

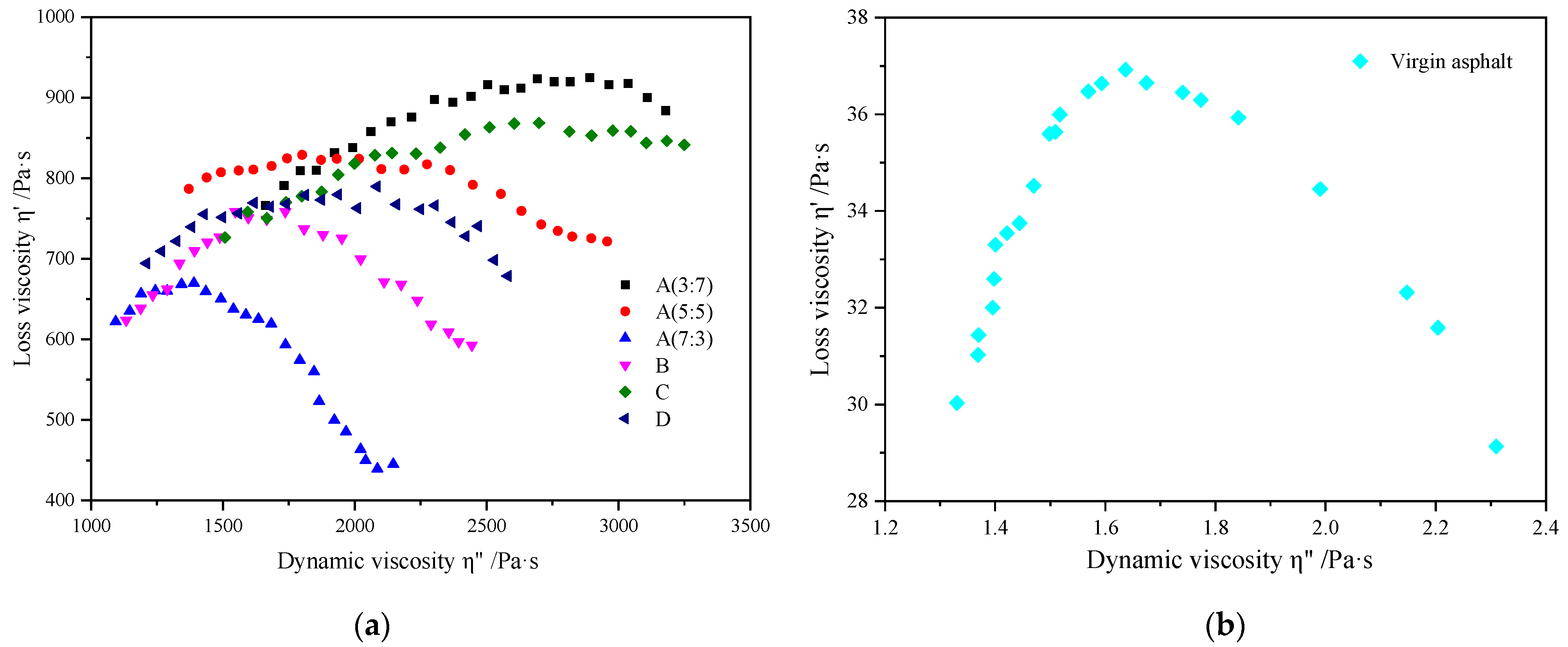

3.4.2. Cole–Cole Diagram Analysis

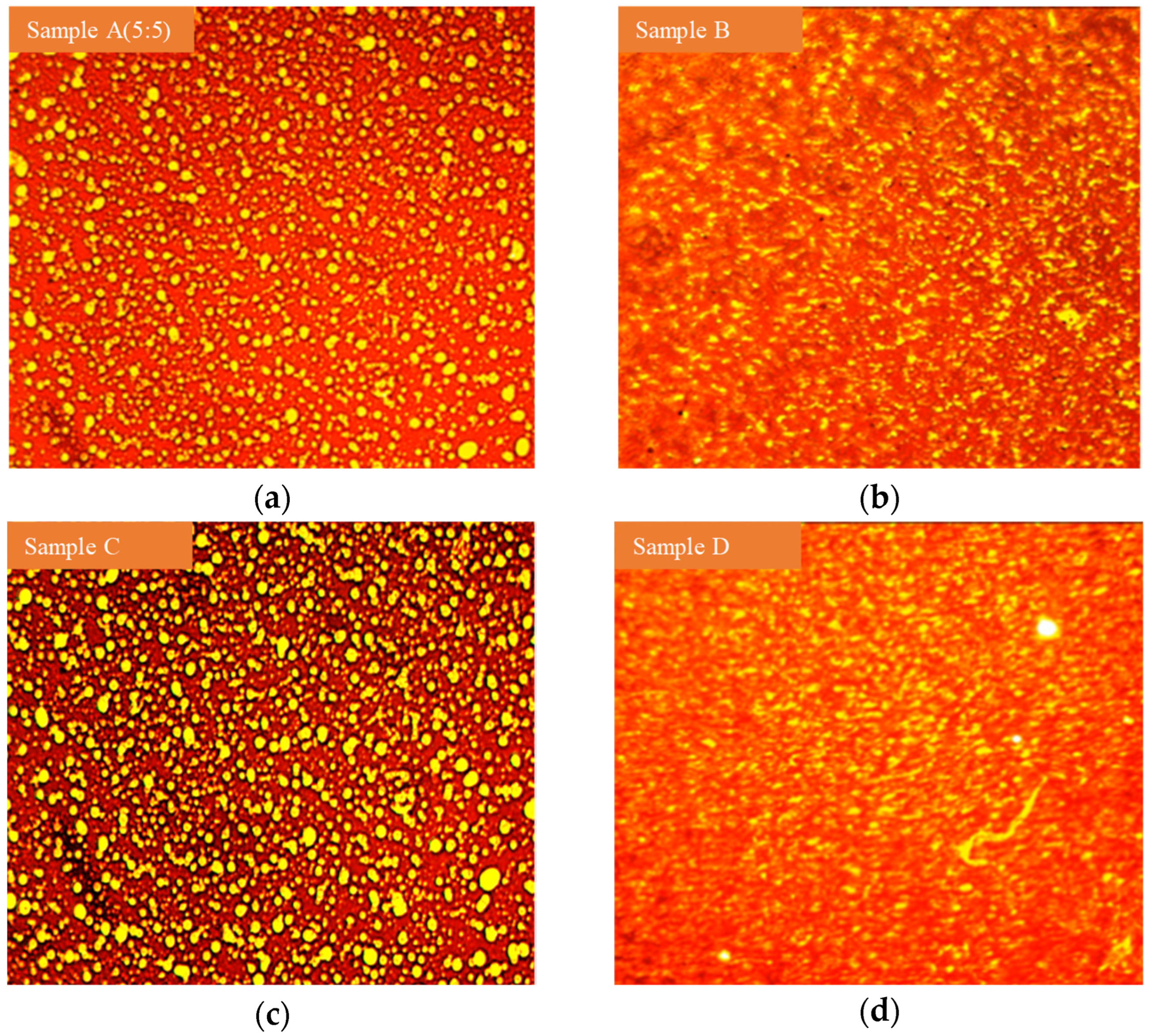

3.4.3. Microstructure Analysis of SBR/PP Composite-Modified Asphalt

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, K.; You, L.; Wang, D. High-Temperature Performance of Polymer-Modified Asphalt Mixes: Preliminary Evaluation of the Usefulness of Standard Technical Index in Polymer-Modified Asphalt. Polymers 2019, 11, 1404. [Google Scholar] [CrossRef]

- Habbouche, J.; Hajj, E.Y.; Sebaaly, P.E.; Piratheepan, M. A Critical Review of High Polymer-Modified Asphalt Binders and Mixtures. Int. J. Pavement Eng. 2020, 21, 686–702. [Google Scholar] [CrossRef]

- Xia, T.; Zhang, A.; Xu, J.; Chen, X.; Xia, X.; Zhu, H.; Li, Y. Rheological Behavior of Bitumen Modified by Reclaimed Polyethylene and Polypropylene from Different Recycling Sources. J. Appl. Polym. Sci. 2021, 138, 50435. [Google Scholar] [CrossRef]

- Zhang, H.; Gong, M.; Gao, D.; Yang, T.; Huang, Y. Comparative Analysis of Mechanical Behavior of Composite Modified Asphalt Mixture Based on PG Technology. Constr. Build. Mater. 2020, 259, 119771. [Google Scholar] [CrossRef]

- Ameli, A.; Norouzi, N.; Khabbaz, E.H.; Babagoli, R. Influence of Anti Stripping Agents on Performance of Binders and Asphalt Mixtures Containing Crumb Rubber and Styrene-Butadiene-Rubber. Constr. Build. Mater. 2020, 261, 119880. [Google Scholar] [CrossRef]

- Ming, L.Y.; Feng, C.P.; Siddig, E.A.A. Effect of Phenolic Resin on the Performance of the Styrene-Butadiene Rubber Modified Asphalt. Constr. Build. Mater. 2018, 181, 465–473. [Google Scholar] [CrossRef]

- Wu, S.; Montalvo, L. Repurposing Waste Plastics into Cleaner Asphalt Pavement Materials: A Critical Literature Review. J. Clean. Prod. 2021, 280, 124355. [Google Scholar] [CrossRef]

- Audy, R.; Enfrin, M.; Boom, Y.J.; Giustozzi, F. Selection of Recycled Waste Plastic for Incorporation in Sustainable Asphalt Pavements: A Novel Multi-Criteria Screening Tool Based on 31 Sources of Plastic. Sci. Total Environ. 2022, 829, 154604. [Google Scholar] [CrossRef] [PubMed]

- Duggal, P.; Shisodia, A.S.; Havelia, S.; Jolly, K. Use of Waste Plastic in Wearing Course of Flexible Pavement. In Proceedings of the Advances in Structural Engineering and Rehabilitation; Adhikari, S., Bhattacharjee, B., Bhattacharjee, J., Eds.; Springer: Singapore, 2020; pp. 177–187. [Google Scholar]

- Jerin, T.; Jahan, N.; Jaya, J.D.; Sami, N.A.; Hossain, M.I.; Islam, M.R. Polypropylene Modified Asphalt Mix to Improve Wearing Course of Flexible Pavement. In Proceedings of the International Conference on Transportation and Development 2020: Highway and Airfield Pavements, Seattle, WA, USA, 2020, 26–29 May 2020; pp. 61–71. [Google Scholar] [CrossRef]

- Cheng, P.; Li, Y.; Zhang, Z. Effect of Phenolic Resin on the Rheological and Morphological Characteristics of Styrene-Butadiene Rubber-Modified Asphalt. Materials 2020, 13, 5836. [Google Scholar] [CrossRef] [PubMed]

- Vamegh, M.; Ameri, M.; Chavoshian Naeni, S.F. Performance Evaluation of Fatigue Resistance of Asphalt Mixtures Modified by SBR/PP Polymer Blends and SBS. Constr. Build. Mater. 2019, 209, 202–214. [Google Scholar] [CrossRef]

- Wang, H.; Du, Z.; Liu, G.; Luo, X.; Yang, C. Effect of Long-Term Aging on Fatigue and Thermal Cracking Performance of Polyphosphoric Acid and Styrene–Butadiene–Styrene-Modified Bio-Blend Bitumen. Polymers 2023, 15, 2911. [Google Scholar] [CrossRef]

- Tam, H.L.S.; Tang, D.T.W.; Leung, W.Y.; Ho, K.M.; Greenfield, P.F. Performance Evaluation of Hybrid and Conventional Sequencing Batch Reactor and Continuous Processes. Water Sci. Technol. 2004, 50, 59–65. [Google Scholar] [CrossRef]

- Ren, Z.; Zhu, Y.; Wu, Q.; Zhu, M.; Guo, F.; Yu, H.; Yu, J. Enhanced Storage Stability of Different Polymer Modified Asphalt Binders through Nano-Montmorillonite Modification. Nanomaterials 2020, 10, 641. [Google Scholar] [CrossRef]

- Li, J.; Jia, S.; Yang, D.; Li, X.; Li, D.; Ye, X.; Guan, P.; Zhao, Y. Reutilization of Crystalline Waste Plastics for Modified Asphalt Using Twin-Screw Extrusion: Polyethylene and Polypropylene as Typical Subjects. J. Appl. Polym. Sci. 2022, 139, e52690. [Google Scholar] [CrossRef]

- Rohayzi, N.F.; Katman, H.Y.B.; Ibrahim, M.R.; Norhisham, S.; Rahman, N.A. Potential Additives in Natural Rubber-Modified Bitumen: A Review. Polymers 2023, 15, 1951. [Google Scholar] [CrossRef]

- Liu, G.; Fang, S.; Wang, Y.; Liu, J.; Liang, Y.; Cao, T.; Liu, Q. Emission of Volatile Organic Compounds in Crumb Rubber Modified Bitumen and Its Inhibition by Using Montmorillonite Nanoclay. Polymers 2023, 15, 1513. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zeng, D. Preparation of Devulcanized Ground Tire Rubber with Supercritical Carbon Dioxide Jet Pulverization. Mater. Lett. 2021, 282, 128878. [Google Scholar] [CrossRef]

- GB/T 2412-1980; Polypropylene—Method of Determination of Normal Indices. China Standard Publishing House: Beijing, China, 1981.

- Schaur, A.; Unterberger, S.H.; Lackner, R. Impact of Molecular Structure of PP on Thermo-Rheological Properties of Polymer-Modified Bitumen. Constr. Build. Mater. 2021, 287, 122981. [Google Scholar] [CrossRef]

- Singh, G.; Kaur, S.; Kothari, A.V.; Naik, D.G.; Vyas, P.B.; Gupta, V.K. Studies on the Influence of Molecular Weight and Isotacticity of Polypropylene on the Formation of Mesomorphic Phase. J. Appl. Polym. Sci. 2009, 113, 3181–3186. [Google Scholar] [CrossRef]

- Luo, J.; Yang, Y.; Huang, W.; Xie, C.; Chen, J.; Liu, H.; Ren, T.; Huang, X. Physical, Rheological, And Microsurface Characteristics of High-Viscosity Binder Modified with WMA Agents. Adv. Mater. Sci. Eng. 2022, 2022, e5098250. [Google Scholar] [CrossRef]

- Liu, S.; Cao, W.; Fang, J.; Shang, S. Variance Analysis and Performance Evaluation of Different Crumb Rubber Modified (CRM) Asphalt. Constr. Build. Mater. 2009, 23, 2701–2708. [Google Scholar] [CrossRef]

- Singh, D.; Girimath, S. Investigation of Rheological Properties and Superpave PG of PMB Mixed with Reclaimed Asphalt Pavement Binders. Constr. Build. Mater. 2016, 126, 834–842. [Google Scholar] [CrossRef]

- Jafari, M.; Babazadeh, A.; Aflaki, S. Effects of Stress Levels on Creep and Recovery Behavior of Modified Asphalt Binders with the Same Continuous Performance Grades. Transp. Res. Rec. 2015, 2505, 15–23. [Google Scholar] [CrossRef]

- JTG E20—2011; Test Specification for Asphalt and Asphalt Mixture in Highway Engineering. China Communications Publishing: Beijing, China, 2011.

- Lu, X.; Isacsson, U.; Ekblad, J. Phase Separation of SBS Polymer Modified Bitumens. J. Mater. Civ. Eng. 1999, 11, 51–57. [Google Scholar] [CrossRef]

- Gao, L.; Cai, N.; Fu, X.; He, R.; Zhang, H.; Zhou, J.; Kuang, D.; Liu, S. Influence of PPA on the Short-Term Antiaging Performance of Asphalt. Adv. Civ. Eng. 2021, 2021, e6628778. [Google Scholar] [CrossRef]

- Ghuzlan, K.A.; Al-Khateeb, G.G. Selection and Verification of Performance Grading for Asphalt Binders Produced in Jordan. Int. J. Pavement Eng. 2013, 14, 116–124. [Google Scholar] [CrossRef]

- Xing, C.; Li, M.; Liu, L.; Yang, R. Long-Term Aging Behavior of Plastic/Styrene Butadiene Rubber (SBR) Composite Modified Bitumen. Materials 2023, 16, 4567. [Google Scholar] [CrossRef]

- Jahromi, S.G.; Ahmadi, N.A.; Vossugh, S.; Mortazavi, M. Effects of Nanoclay on Rutting and Fatigue Resistance of Bitumen Binder. Int. J. Mater. Res. 2012, 103, 383–389. [Google Scholar] [CrossRef]

- Ma, X.; Ni, F.; Chen, R.; Wang, Y. Evaluation of Low-Temperature Performance of Porous Asphalt Mixture. J. Highw. Transp. Res. Dev. 2010, 4, 33–37. [Google Scholar] [CrossRef]

- Yan, K.; Li, Y.; Long, Z.; You, L.; Wang, M.; Zhang, M.; Diab, A. Mechanical Behaviors of Asphalt Mixtures Modified with European Rock Bitumen and Waste Cooking Oil. Constr. Build. Mater. 2022, 319, 125909. [Google Scholar] [CrossRef]

- Vamegh, M.; Ameri, M.; Chavoshian Naeni, S.F. Experimental Investigation of Effect of PP/SBR Polymer Blends on the Moisture Resistance and Rutting Performance of Asphalt Mixtures. Constr. Build. Mater. 2020, 253, 119197. [Google Scholar] [CrossRef]

- Pandey, A.; Islam, S.S.; Ransingchung R.N., G.D.; Ravindranath, S.S. Comparing the Performance of SBS and Thermoplastics Modified Asphalt Binders and Asphalt Mixes. Road Mater. Pavement Des. 2023, 24, 369–388. [Google Scholar] [CrossRef]

- Yue, S.; Wang, J.-S.; Wu, T.; Wang, H. A New Separation Measure for Improving the Effectiveness of Validity Indices. Inf. Sci. 2010, 180, 748–764. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Ren, S.; Shi, J.; Luo, H. Thermo-Stability and Aging Performance of Modified Asphalt with Crumb Rubber Activated by Microwave and TOR. Mater. Des. 2017, 127, 84–96. [Google Scholar] [CrossRef]

- Rolere, S.; Cartault, M.; Sainte-Beuve, J.; Bonfils, F. A Rheological Method Exploiting Cole-Cole Plot Allows Gel Quantification in Natural Rubber. Polym. Test. 2017, 61, 378–385. [Google Scholar] [CrossRef]

| Test Index | Test Result | Specification Requirement | Test Method |

|---|---|---|---|

| Penetration (25 °C)/0.1 mm | 69 | 60~80 | T0604 |

| Softening point/°C | 49 | ≥45 | T0606 |

| Ductility (15 °C)/cm | >100 | ≥100 | T0605 |

| Sample Number | M SBR:M PP * | Compatibilizer/% | Crosslinker/% |

|---|---|---|---|

| A (3:7) | 3:7 | 0 | 0 |

| A (5:5) | 5:5 | 0 | 0 |

| A (7:3) | 7:3 | 0 | 0 |

| B | 5:5 | 1.5 | 0 |

| C | 5:5 | 0 | 0.5 |

| D | 5:5 | 1.5 | 0.5 |

| Sample Number | Penetration (25 °C)/0.1 mm | Softening Point/°C | Ductility (5 °C)/cm | Softening Point Difference/°C |

|---|---|---|---|---|

| Virgin asphalt | 69 | 49 | 6 | / |

| A (3:7) | 41 | 68 | 11 | 1.9 |

| A (5:5) | 48 | 64 | 59 | 2.1 |

| A (7:3) | 57 | 58 | 83 | 2.2 |

| B | 54 | 62 | 101 | 1.8 |

| C | 47 | 66 | 88 | 2.0 |

| D | 51 | 65 | 90 | 1.8 |

| Sample Number | Dynamic Shear Rate 10 Rad/s (1.59 Hz) | Bending Creep (BBR, 60 s) | PG | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Unaged | RTFOT Ageing | PAV Ageing | |||||||

| Temperature/°C | G*/sin δ /kPa | G*/sin δ /kPa | Temperature/°C | G*·sin δ /Mpa | Temperature/°C | Stiffness Modulus/Mpa | m | ||

| Virgin asphalt | 64 | 1.6 | 2.3 | 25 | 4.4 | −12 | 57.21 | 0.38 | PG 64-22 |

| A (3:7) | 82 | 1.8 | 2.7 | 37 | 2.7 | −6 | 214.59 | 0.37 | PG 82-16 |

| A (5:5) | 82 | 1.4 | 2.5 | 34 | 2.0 | −12 | 200.28 | 0.33 | PG 82-22 |

| A (7:3) | 76 | 1.7 | 3.3 | 31 | 1.9 | −12 | 174.53 | 0.39 | PG 76-22 |

| B | 76 | 1.6 | 3.5 | 28 | 3.6 | −18 | 39.23 | 0.51 | PG 76-28 |

| C | 82 | 1.7 | 2.5 | 34 | 1.8 | −12 | 186.54 | 0.43 | PG 82-22 |

| D | 82 | 1.5 | 2.4 | 31 | 1.7 | −18 | 68.84 | 0.45 | PG 82-28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Hou, D.; Li, Z.; Wang, H.; Dong, S. Evaluation of the Thermal Stability and Micro-Modification Mechanism of SBR/PP-Modified Asphalt. Polymers 2024, 16, 456. https://doi.org/10.3390/polym16040456

Zhang Q, Hou D, Li Z, Wang H, Dong S. Evaluation of the Thermal Stability and Micro-Modification Mechanism of SBR/PP-Modified Asphalt. Polymers. 2024; 16(4):456. https://doi.org/10.3390/polym16040456

Chicago/Turabian StyleZhang, Qing, Dehua Hou, Zhongyu Li, Hainian Wang, and Shi Dong. 2024. "Evaluation of the Thermal Stability and Micro-Modification Mechanism of SBR/PP-Modified Asphalt" Polymers 16, no. 4: 456. https://doi.org/10.3390/polym16040456