Recent Developments in Inorganic Composites in Rotational Molding

Abstract

:1. Introduction

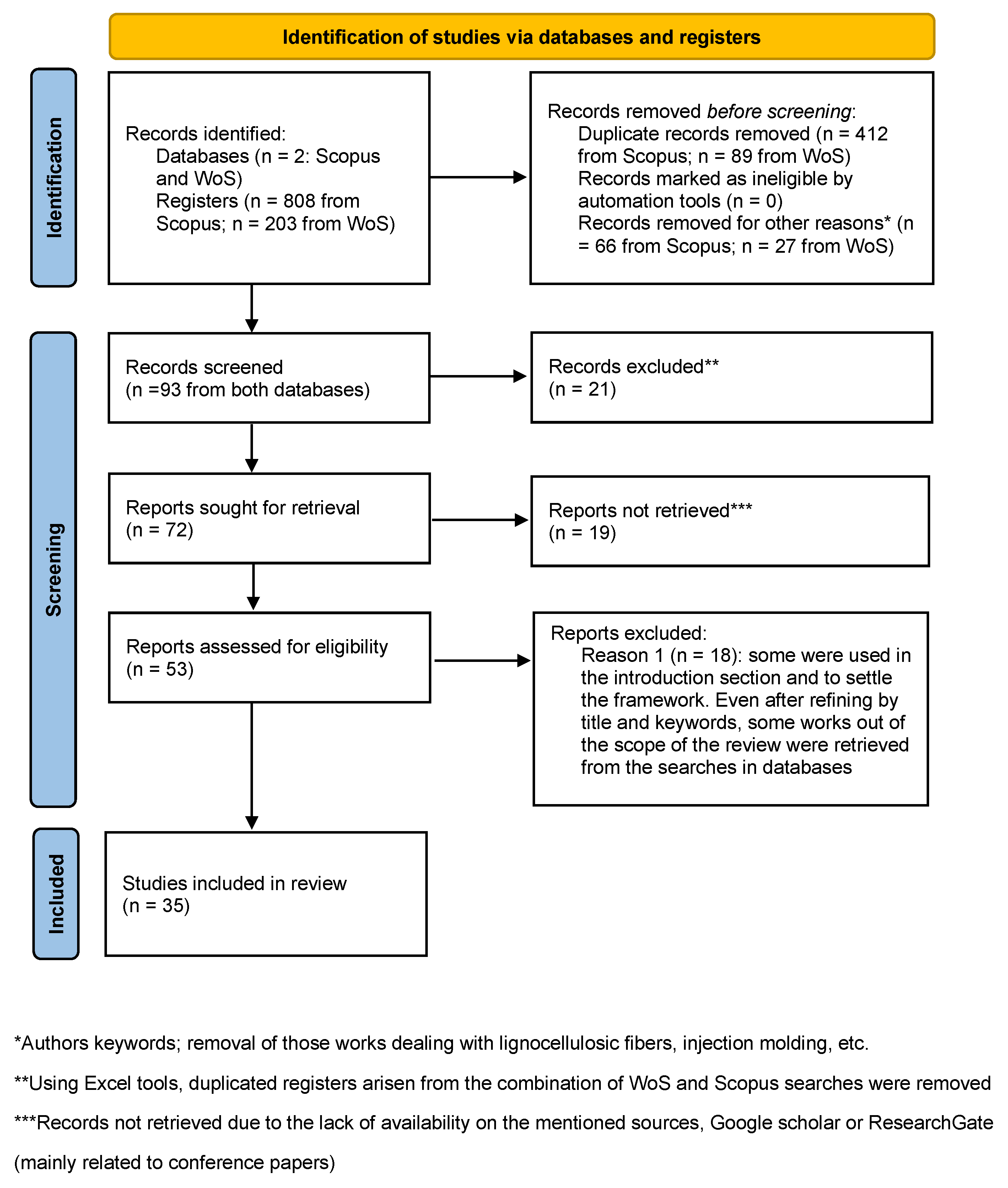

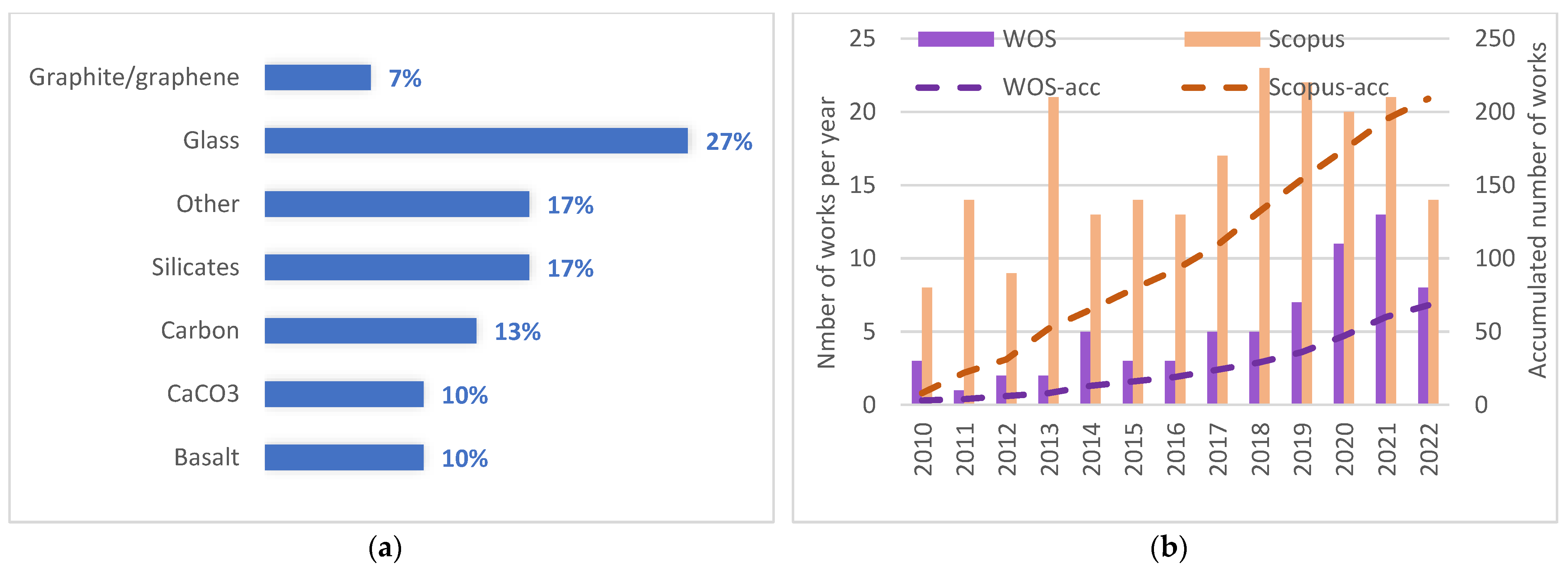

2. Materials and Methods

3. Analysis of the Retrieved Works

| Filler | Size | Density (g·cm−3) | Ratio (%) | Preprocessing | Treatment | Matrix | Tensile | Flexural | Impact | Ref. | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| σ | E | σ | E | |||||||||

| Vermiculite | <200 μm | -- | 10 | Dry blending | No | HDPE | −76 | −40 | −63 | 35 | −66 | [16] |

| Molten blending | −14 | 18 | 45 | −50 | −54 | |||||||

| Quartz flour | <100 μm | 2.65 | 5 | Dry blending | PE-MA | LLDPE | −23 | 0 | -- | -- | -- | [17] |

| Glass dust | 150 μm | 2.56 | 20 | Dry blending | No | LLDPE | 7 | 41 | -- | -- | 21 | [19] |

| Graphite | 100–500 μm | 2.26 | Dry blending | Antioxidant | LLDPE | −35 | 0 | -- | -- | −87 | [23] | |

| Molten blending | −43 | −12 | -- | -- | −87 | |||||||

| Glass fiber | 14 μm 1 | -- | 20 | Dry blending | Plasma | LLDPE | 20 | 20 | -- | 99 | −62 | [21] |

| Hollow glass microspheres | 20 μm | 0.46 | 20 | Melt blending | Hydroxylation + silanization | PE | 1 | 49 | -- | -- | -- | [30] |

| PCL | 8 | 110 | -- | -- | -- | [31] | ||||||

| Copper slag | 30–500 μm | 3.04 | 10 | Dry blending | No | PLA | −20 | 21 | -- | -- | 0 | [22] |

| Basalt powder | 10 μm | -- | 20 | Mixing | No | PU | 13 | 33 | -- | -- | -- | [32] |

| Halloysite nanotubes | <4 μm | 2.55 | 5 | Molten blending | No | HDPE | −23 | 35 | 0 | 0 | −64 | [33] |

| LMDPE | −8 | 0 | 0 | 9 | −54 | |||||||

| CaCO3 | 2 μm | -- | 10 | Molten blending | Slip agent (erucamide) | LMDPE | 0 | −39 | -- | -- | −35 | [34] |

| TiO2/ZnO | Nano | -- | 2 | Molten blending | No | HDPE | 10 | -- | -- | 15 | -- | [35] |

| Carbon black | Nano | 0.1 | 0.5 | Dry blending | No | PA-12 | 20 | 0 | -- | -- | -- | [29] |

| Carbon nanofiber | Nano | -- | 0.1 | Dry blending | Plasma | LMDPE | 10 | 17 | -- | -- | 20 | [28] |

| Graphite | Nano | 2.26 | 0.25 | Dry blending | Sonication + antioxidant | LLDPE | -- | -- | -- | -- | −80 | [24] |

| Molten blending | −10 | -- | -- | -- | −31 | |||||||

| Fumed silica | Nano | -- | 4 | Molten blending | No | LLDPE | 10 | 150 | -- | 18 | −7 | [36] |

3.1. Composites with Glass Fibers or Glass Particles

3.2. Composites with Nanoparticles

3.3. Composites with Other Fillers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gupta, N.; Ramkumar, P.L.; Sangani, V. An Approach toward Augmenting Materials, Additives, Processability and Parameterization in Rotational Molding: A Review. Mater. Manuf. Process. 2020, 35, 1539–1556. [Google Scholar] [CrossRef]

- Aniśko, J.; Barczewski, M.; Mietliński, P.; Piasecki, A.; Szulc, J. Valorization of Disposable Polylactide (PLA) Cups by Rotational Molding Technology: The Influence of Pre-Processing Grinding and Thermal Treatment. Polym. Test. 2022, 107, 107481. [Google Scholar] [CrossRef]

- Pick, L.; Hanna, P.R.; Gorman, L. Assessment of Processibility and Properties of Raw Post-Consumer Waste Polyethylene in the Rotational Moulding Process. J. Polym. Eng. 2022, 42, 374–383. [Google Scholar] [CrossRef]

- Arribasplata-Seguin, A.; Quispe-Dominguez, R.; Tupia-Anticona, W.; Acosta-Sullcahuamán, J. Rotational Molding Parameters of Wood-Plastic Composite Materials Made of Recycled High Density Polyethylene and Wood Particles. Compos. B Eng. 2021, 217, 108876. [Google Scholar] [CrossRef]

- Cestari, S.P.; Martin, P.J.; Hanna, P.R.; Kearns, M.P.; Mendes, L.C.; Millar, B. Use of Virgin/Recycled Polyethylene Blends in Rotational Moulding. J. Polym. Eng. 2021, 41, 509–516. [Google Scholar] [CrossRef]

- Dou, Y.; Rodrigue, D. Morphological, Thermal and Mechanical Properties of Recycled HDPE Foams via Rotational Molding. J. Cell. Plast. 2022, 58, 305–323. [Google Scholar] [CrossRef]

- Díaz, S.; Ortega, Z.; McCourt, M.; Kearns, M.P.; Benítez, A.N. Recycling of Polymeric Fraction of Cable Waste by Rotational Moulding. Waste Manag. 2018, 76, 199–206. [Google Scholar] [CrossRef]

- Dou, Y.; Rodrigue, D. Rotomolding of Foamed and Unfoamed GTR-LLDPE Blends: Mechanical, Morphological and Physical Properties. Cell. Polym. 2018, 37, 55–68. [Google Scholar] [CrossRef]

- Shaker, R.; Rodrigue, D. Rotomolding of Thermoplastic Elastomers Based on Low-Density Polyethylene and Recycled Natural Rubber. Appl. Sci. 2019, 9, 5430. [Google Scholar] [CrossRef] [Green Version]

- Ortega, Z.; Monzón, M.D.; Benítez, A.N.; Kearns, M.; McCourt, M.; Hornsby, P.R. Banana and Abaca Fiber-Reinforced Plastic Composites Obtained by Rotational Molding Process. Mater. Manuf. Process. 2013, 28, 879–883. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; Pérez-Fonseca, A.A.; González-García, Y.; Ramírez-Arreola, D.E.; González-Núñez, R.; Rodrigue, D.; Robledo-Ortíz, J.R. Polylactic Acid–Agave Fiber Biocomposites Produced by Rotational Molding: A Comparative Study with Compression Molding. Adv. Polym. Technol. 2018, 37, 2528–2540. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Krawczak, A.; Wesoły, K.; Szostak, M. Rotational Molding of Biocomposites with Addition of Buckwheat Husk Filler. Structure-Property Correlation Assessment for Materials Based on Polyethylene (PE) and Poly(Lactic Acid) PLA. Compos. B Eng. 2020, 202, 108410. [Google Scholar] [CrossRef]

- González-López, M.E.; Pérez-Fonseca, A.A.; Cisneros-López, E.O.; Manríquez-González, R.; Ramírez-Arreola, D.E.; Rodrigue, D.; Robledo-Ortíz, J.R. Effect of Maleated PLA on the Properties of Rotomolded PLA-Agave Fiber Biocomposites. J. Polym. Environ. 2019, 27, 61–73. [Google Scholar] [CrossRef]

- Robledo-Ortíz, J.R.; González-López, M.E.; Martín del Campo, A.S.; Peponi, L.; González-Nuñez, R.; Rodrigue, D.; Pérez-Fonseca, A.A. Fiber-Matrix Interface Improvement via Glycidyl Methacrylate Compatibilization for Rotomolded Poly(Lactic Acid)/Agave Fiber Biocomposites. J. Compos. Mater. 2020, 55, 201–212. [Google Scholar] [CrossRef]

- Daryadel, M.; Azdast, T.; Khatami, M.; Moradian, M. Investigation of Tensile Properties of Polymeric Nanocomposite Samples in the Rotational Molding Process. Polym. Bull. 2021, 78, 2465–2481. [Google Scholar] [CrossRef]

- Aniśko, J.; Barczewski, M.; Piasecki, A.; Skórczewska, K.; Szulc, J.; Szostak, M. The Relationship between a Rotational Molding Processing Procedure and the Structure and Properties of Biobased Polyethylene Composites Filled with Expanded Vermiculite. Materials 2022, 15, 5903. [Google Scholar] [CrossRef]

- Głogowska, K.; Pączkowski, P.; Samujło, B. Study on the Properties and Structure of Rotationally Moulded Linear Low-Density Polyethylene Filled with Quartz Flour. Materials 2022, 15, 2154. [Google Scholar] [CrossRef] [PubMed]

- Sangeetha, V.; Gopinath, D.; Prithivirajan, R.; Girish Chandran, V.; Manoj Kumar, R. Investigating the Mechanical, Thermal and Melt Flow Index Properties of HNTs—LLDPE Nano Composites for the Applications of Rotational Moulding. Polym. Test. 2020, 89, 106595. [Google Scholar] [CrossRef]

- Gupta, N.; Ramkumar, P. Effect of Industrially Processed Glass Fibre Dust on Mechanical, Thermal and Morphological Properties Mixed with LLDPE for Rotational Molding Process. Sadhana Acad. Proc. Eng. Sci. 2021, 46, 1–14. [Google Scholar] [CrossRef]

- Chang, W.C.; Harkin-Jones, E.; Kearns, M.; McCouri, M. Glass Fibre-Reinforced Polyethylene Composites in Rotational Moulding. In Proceedings of the Annual Technical Conference—ANTEC, Conference Proceedings, Boston, MA, USA, 1–5 May 2011; Volume 3, pp. 2474–2478. [Google Scholar]

- Ghanem, Z.; Šourkova, H.J.; Sezemský, J.; Špatenka, P. The Effect of Plasma Treatment of Polyethylene Powder and Glass Fibers on Selected Properties of Their Composites Prepared via Rotational Molding. Polymers 2022, 14, 2592. [Google Scholar] [CrossRef]

- Barczewski, M.; Hejna, A.; Aniśko, J.; Andrzejewski, J.; Piasecki, A.; Mysiukiewicz, O.; Bąk, M.; Gapiński, B.; Ortega, Z. Rotational Molding of Polylactide (PLA) Composites Filled with Copper Slag as a Waste Filler from Metallurgical Industry. Polym. Test. 2022, 106, 107449. [Google Scholar] [CrossRef]

- Mhike, W.; Focke, W.W. Surface Resistivity and Mechanical Properties of Rotationally Molded Polyethylene/Graphite Composites. J. Vinyl Addit. Technol. 2013, 19, 258–270. [Google Scholar] [CrossRef] [Green Version]

- Mhike, W.; Focke, W.W.; Asante, J.K.O. Rotomolded Antistatic and Flame-Retarded Graphite Nanocomposites. J. Thermoplast. Compos. Mater. 2018, 31, 535–552. [Google Scholar] [CrossRef] [Green Version]

- León, L.D.V.E.; Escocio, V.A.; Visconte, L.L.Y.; Junior, J.C.J.; Pacheco, E.B.A.V. Rotomolding and Polyethylene Composites with Rotomolded Lignocellulosic Materials: A Review. J. Reinf. Plast. Compos. 2020, 39, 459–472. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Andrzejewski, J.; Kosmela, P.; Piasecki, A.; Szostak, M.; Kuang, T. Rotational Molding of Linear Low-Density Polyethylene Composites Filled with Wheat Bran. Polymers 2020, 12, 1004. [Google Scholar] [CrossRef]

- Abhilash, S.S.; Lal, A.R.; Lenin Singaravelu, D. A Comparative Study of Mechanical, Morphological and Vibration Damping Characteristics of Wood Fiber Reinforced LLDPE Processed by Rotational Moulding. Mater. Today Proc. 2022, 59, 510–515. [Google Scholar] [CrossRef]

- Zepeda-Rodríguez, Z.; Arellano-Martínez, M.R.; Cruz-Barba, E.; Zamudio-Ojeda, A.; Rodrigue, D.; Vázquez-Lepe, M.; González-Núñez, R. Mechanical and Thermal Properties of Polyethylene/Carbon Nanofiber Composites Produced by Rotational Molding. Polym. Compos. 2020, 41, 1224–1233. [Google Scholar] [CrossRef]

- Shirinbayan, M.; Montazeri, A.; Nouri Sedeh, M.; Abbasnezhad, N.; Fitoussi, J.; Tcharkhrtchi, A. Rotational Molding of Polyamide-12 Nanocomposites: Modeling of the Viscoelastic Behavior. Int. J. Mater. Form. 2021, 14, 143–152. [Google Scholar] [CrossRef]

- Stagnaro, P.; Utzeri, R.; Vignali, A.; Falcone, G.; Iannace, S.; Bertini, F. Lightweight Polyethylene-hollow Glass Microspheres Composites for Rotational Molding Technology. J. Appl. Polym. Sci. 2021, 138, 49766. [Google Scholar] [CrossRef]

- Vignali, A.; Iannace, S.; Falcone, G.; Utzeri, R.; Stagnaro, P.; Bertini, F. Lightweight Poly(ε-Caprolactone) Composites with Surface Modified Hollow Glass Microspheres for Use in Rotational Molding: Thermal, Rheological and Mechanical Properties. Polymers 2019, 11, 624. [Google Scholar] [CrossRef]

- Barczewski, M.; Wojciechowska, P.; Szostak, M. Mechanical Properties and Structure of Reactive Rotationally Molded Polyurethane—Basalt Powder Composites. In Advances in Manufacturing II; Gapiński, B., Szostak, M., Ivanov, V., Eds.; MANUFACTURING 2019. Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2019; pp. 601–609. [Google Scholar]

- Höfler, G.; Lin, R.J.T.; Jayaraman, K. Rotational Moulding and Mechanical Characterisation of Halloysite Reinforced Polyethylenes. J. Polym. Res. 2018, 25, 132. [Google Scholar] [CrossRef]

- Baumer, M.I.; Leite, J.L.; Becker, D. Influence of Calcium Carbonate and Slip Agent Addition on Linear Medium Density Polyethylene Processed by Rotational Molding. Mater. Res. 2013, 17, 130–137. [Google Scholar] [CrossRef] [Green Version]

- Ghanbarpour, B.; Moslemi, A. Evaluation of Mechanical, Optical, and Antibacterial Properties of Metal-Oxide Dispersed HDPE Nanocomposites Processed by Rotational Molding. Polym. Compos. 2022, 43, 3983–3991. [Google Scholar] [CrossRef]

- Chandran, V.G.; Waigaonkar, S.D. Rotational Molding of Linear Low Density Polyethylene (LLDPE) Fumed Silica Nanocomposites. Int. Polym. Process. 2017, 32, 50–57. [Google Scholar] [CrossRef]

- Castellanos, D.; Martin, P.; McCourt, M.; Kearns, M.; Butterfield, J.; Cassidy, P. Densification of Fibre-Reinforced Composite Polymers under Rotational Moulding Conditions. Plast. Rubber Compos. 2022, 51, 423–435. [Google Scholar] [CrossRef]

- Hamidi, A.; Farzaneh, S.; Nony, F.; Ortega, Z.; Khelladi, S.; Monzon, M.; Bakir, F.; Tcharkhtchi, A. Modelling of Sintering during Rotational Moulding of the Thermoplastic Polymers. Int. J. Mater. Form. 2015, 9, 519–530. [Google Scholar] [CrossRef] [Green Version]

- Gupta, N.; Ramkumar, P.L. Analysis of Synthetic Fiber-Reinforced LLDPE Based on Melt Flow Index for Rotational Molding. Springer Proc. Mater. 2020, 8, 599–606. [Google Scholar] [CrossRef]

- Jamshidi, S.; Sundararaj, U. Improvement of Barrier Properties of Rotomolded PE Containers with Nanoclay. In Proceedings of the AIP Conference Proceedings, Cleveland, OH, USA, 22 May 2015; AIP Publishing LLCAIP Publishing: Melville, NY, USA, 2015; Volume 1664, p. 070014. [Google Scholar]

- Calò, E.; Massaro, C.; Terzi, R.; Cancellara, A.; Pesce, E.; Re, M.; Greco, A.; Maffezzoli, A.; Gonzalez-Chi, P.I.; Salomi, A. Rotational Molding of Polyamide-6 Nanocomposites with Improved Flame Retardancy. Int. Polym. Process. 2012, 27, 370–377. [Google Scholar] [CrossRef]

- Chandran, V.G.; Waigaonkar, S.D. Investigations on Cycle Time Reduction, Dynamic Mechanical Properties and Creep for Rotationally Moldable Nano Composites of Linear Low Density Polyethylene and Fumed Silica. Nanosyst. Phys. Chem. Math. 2016, 7, 609–612. [Google Scholar] [CrossRef] [Green Version]

- Girish Chandran, V.; Waigaonkar, S.D. Mechanical Properties and Creep Behavior of Rotationally Moldable Linear Low Density Polyethylene-Fumed Silica Nanocomposites. Polym. Compos. 2017, 38, 421–430. [Google Scholar] [CrossRef]

- Chandran, V.G.; Waigaonkar, S.D. Rheological and Dynamic Mechanical Characteristics of Rotationally Moldable Linear Low-Density Polyethylene Fumed Silica Nanocomposites. Polym. Compos. 2016, 37, 2995–3002. [Google Scholar] [CrossRef]

- Karimzadeh, S.; Azdast, T.; Hasanzadeh, R.; Moradian, M.; Akrami, H. Foam Rotational Molding of Hybrid Polyethylene Nanocomposites: Synergistic Effect of Microtalc and Nanoclay. Polyolefins J. 2022, 9, 129–138. [Google Scholar] [CrossRef]

- Rusu, E. Nylon 612/TiO2 Composites by Anionic Copolymerization-Molding Process: Comparative Evaluation of Thermal and Mechanical Performance. J. Compos. Mater. 2020, 54, 345–362. [Google Scholar] [CrossRef]

- Shen, M.; Zhou, L.; Chen, Z.; Shen, Y.; Huang, B.; Lv, J. Effects of Basalt Powder and Silica Fume on Ultra-High-Strength Cementitious Matrix: A Comparative Study. Case Stud. Constr. Mater. 2022, 17, e01397. [Google Scholar] [CrossRef]

- Lezzerini, M.; Luti, L.; Aquino, A.; Gallello, G.; Pagnotta, S. Effect of Marble Waste Powder as a Binder Replacement on the Mechanical Resistance of Cement Mortars. Appl. Sci. 2022, 12, 4481. [Google Scholar] [CrossRef]

| Keywords | Scopus | WoS |

|---|---|---|

| Composite | 447 | 393 |

| Inorganic | 33 | 6 |

| Inorganic + composite | 23 | 5 |

| Composite – cellulose 1 | 379 | 101 |

| Composite + fiber | 230 | 47 |

| Composite + filler | 86 | 22 |

| Composite + fiber − cellulose | 170 | 47 |

| Composite + filler − cellulose | 62 | 22 |

| Waste or residue | 106 | 18 |

| Composite + waste (or residue) | 78 | 6 |

| Waste or residue – cellulose | 86 | 17 |

| Composite + waste (or residue) − cellulose | 59 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortega, Z.; McCourt, M.; Romero, F.; Suárez, L.; Cunningham, E. Recent Developments in Inorganic Composites in Rotational Molding. Polymers 2022, 14, 5260. https://doi.org/10.3390/polym14235260

Ortega Z, McCourt M, Romero F, Suárez L, Cunningham E. Recent Developments in Inorganic Composites in Rotational Molding. Polymers. 2022; 14(23):5260. https://doi.org/10.3390/polym14235260

Chicago/Turabian StyleOrtega, Zaida, Mark McCourt, Francisco Romero, Luis Suárez, and Eoin Cunningham. 2022. "Recent Developments in Inorganic Composites in Rotational Molding" Polymers 14, no. 23: 5260. https://doi.org/10.3390/polym14235260