Study on Flexural Behavior of Glass Fiber Reinforced Plastic Sandwich Composites Using Liquid Thermoplastic Resin

Abstract

:1. Introduction

2. Materials and Testing

2.1. Skin Materials

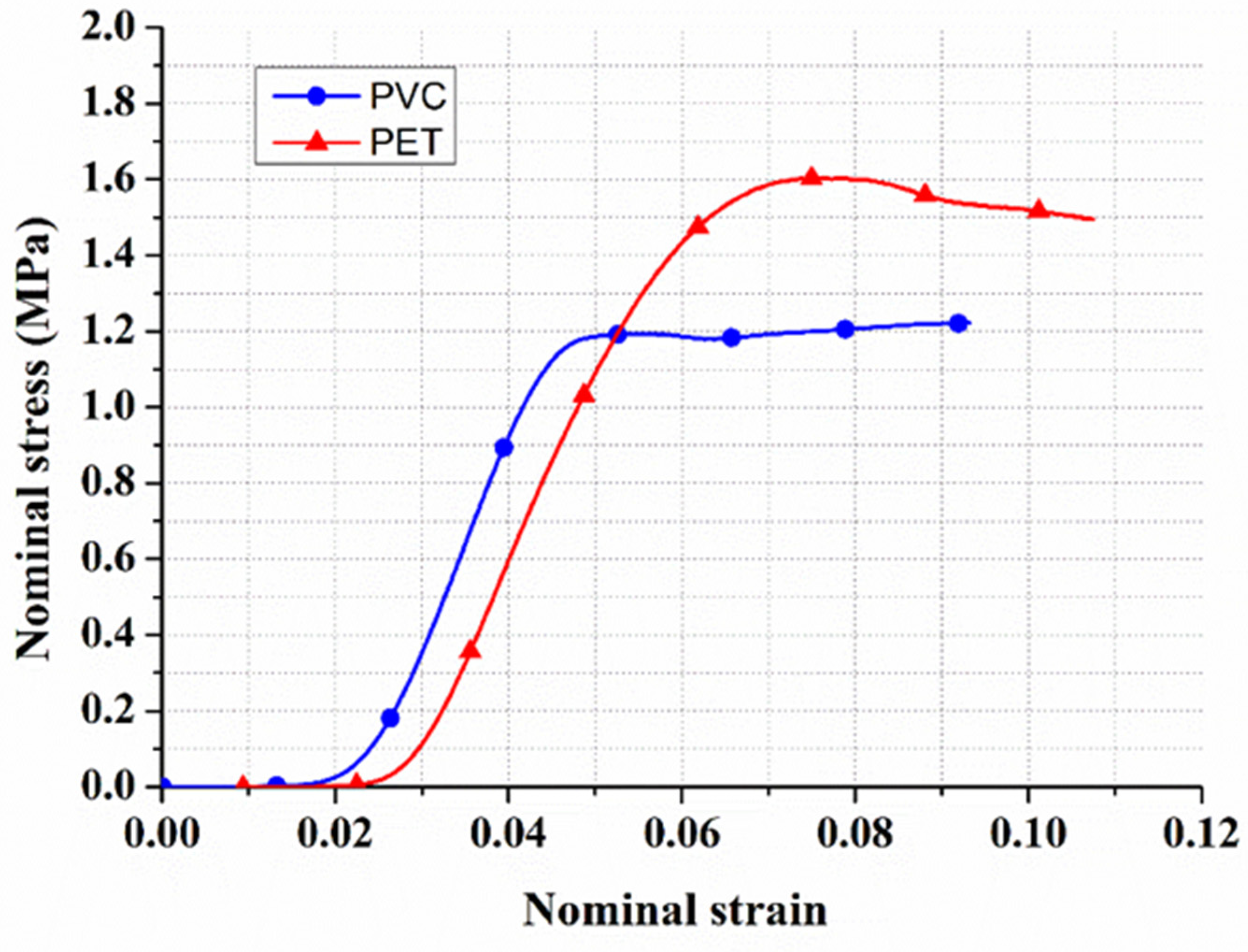

2.2. Core Materials

2.3. Liquid Thermoplastic Resin

2.4. Fabrication Process

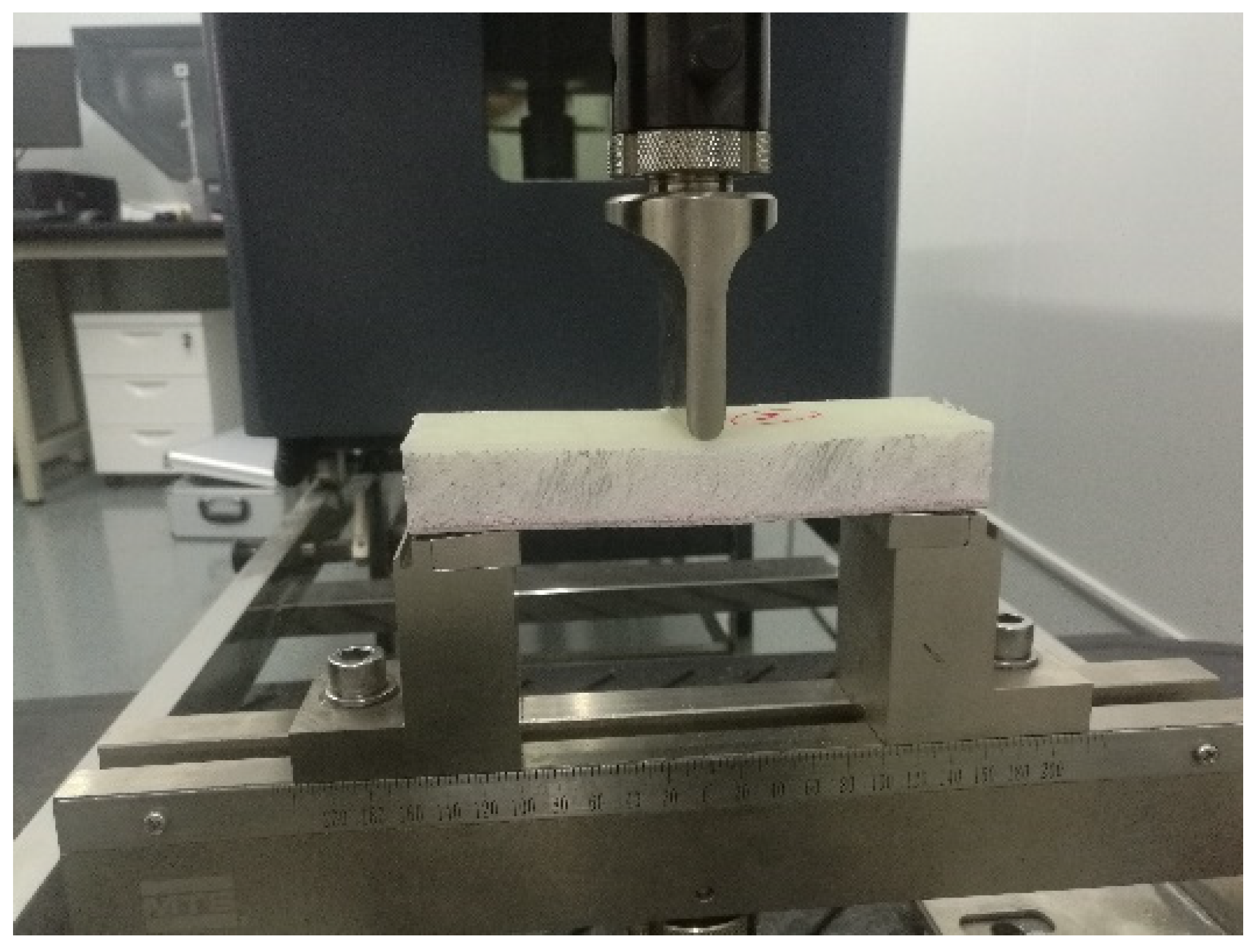

2.5. Flexural Test

3. Finite Element Modeling

3.1. Modeling of the Foam

3.2. Modeling of the Upper and Lower Skins

- Tensile fiber failure for σ11 ≥ 0:

- 2.

- Compressive fiber failure for σ11 < 0:

- 3.

- Tensile matrix failure for σ22 + σ33 > 0:

- 4.

- Compressive matrix failure for σ22 + σ33 < 0:

- 5.

- Interlaminar tensile failure for σ33 > 0:

- 6.

- Interlaminar compression failure for σ33 < 0:where σij denotes the stress components, and the tensile and compressive allowable strengths for the lamina are denoted by subscripts T and C, respectively. XT, YT, and ZT denote the allowable tensile strengths in the three respective material directions. Similarly, XC, YC, and ZC denote the allowable tensile strengths in the three respective material directions. Furthermore, S12, S13, and S23 denote the allowable shear strengths in the respective principal material directions.

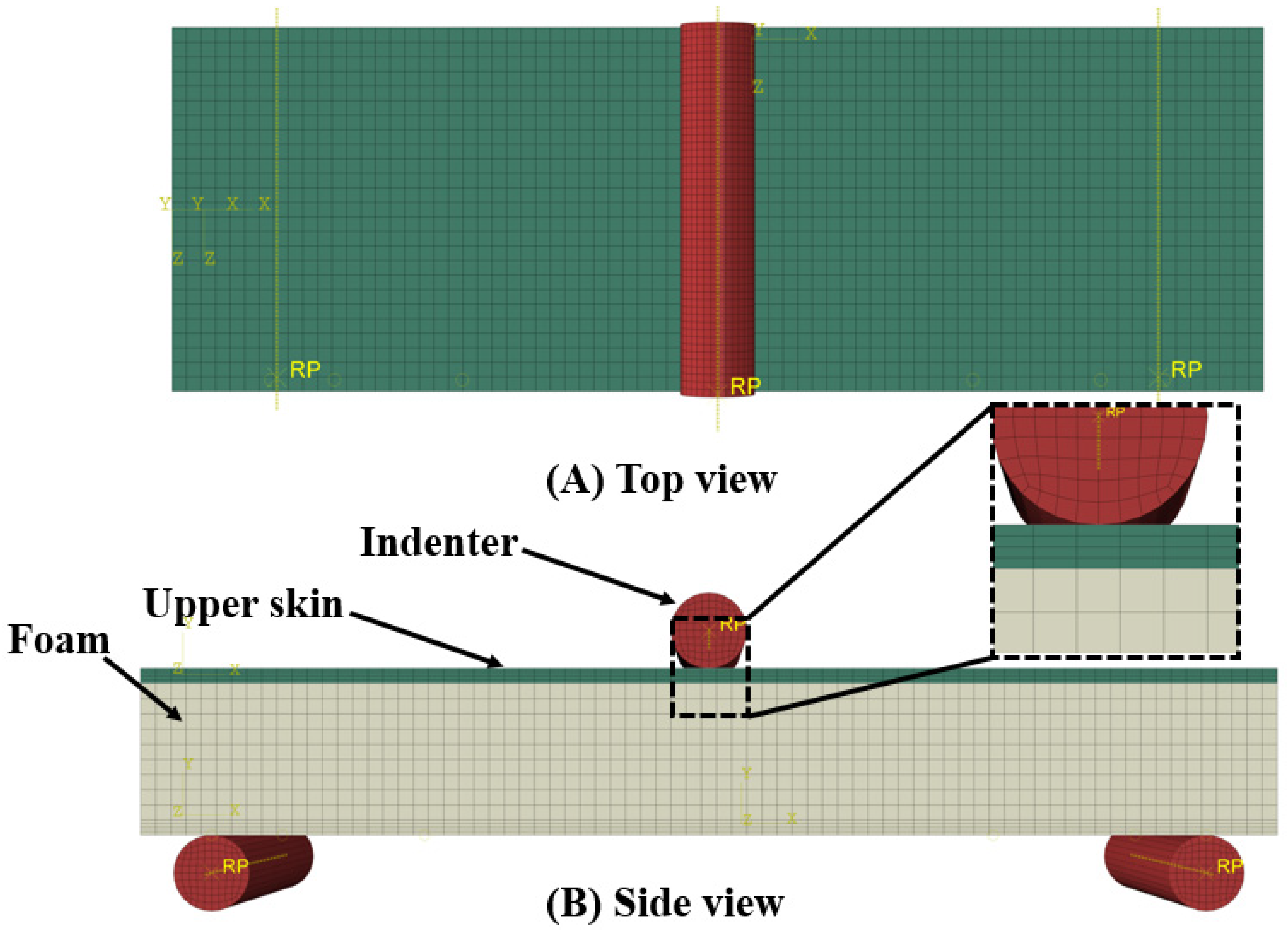

3.3. Flexural Test Model

4. Results and Discussion

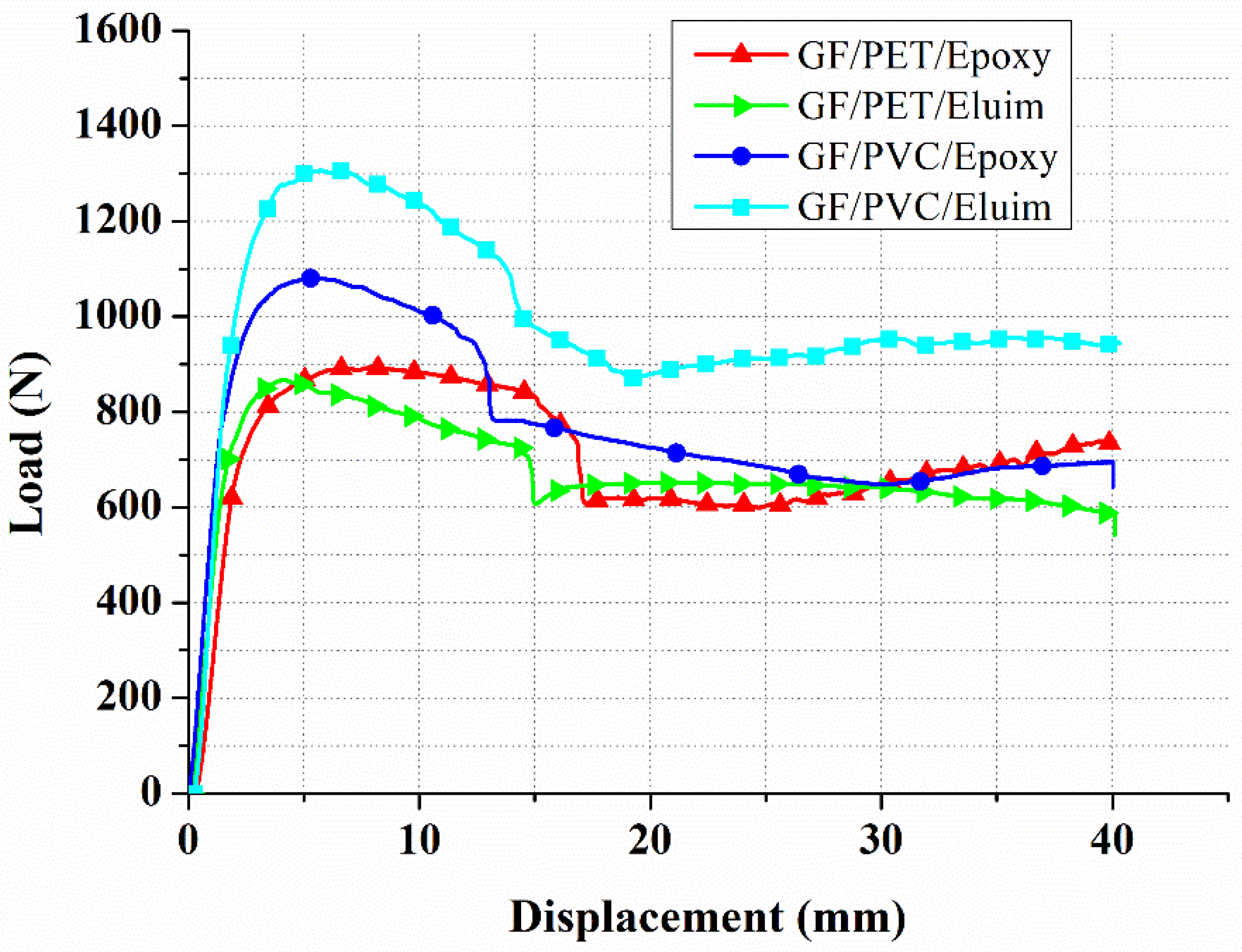

4.1. Experimental Results

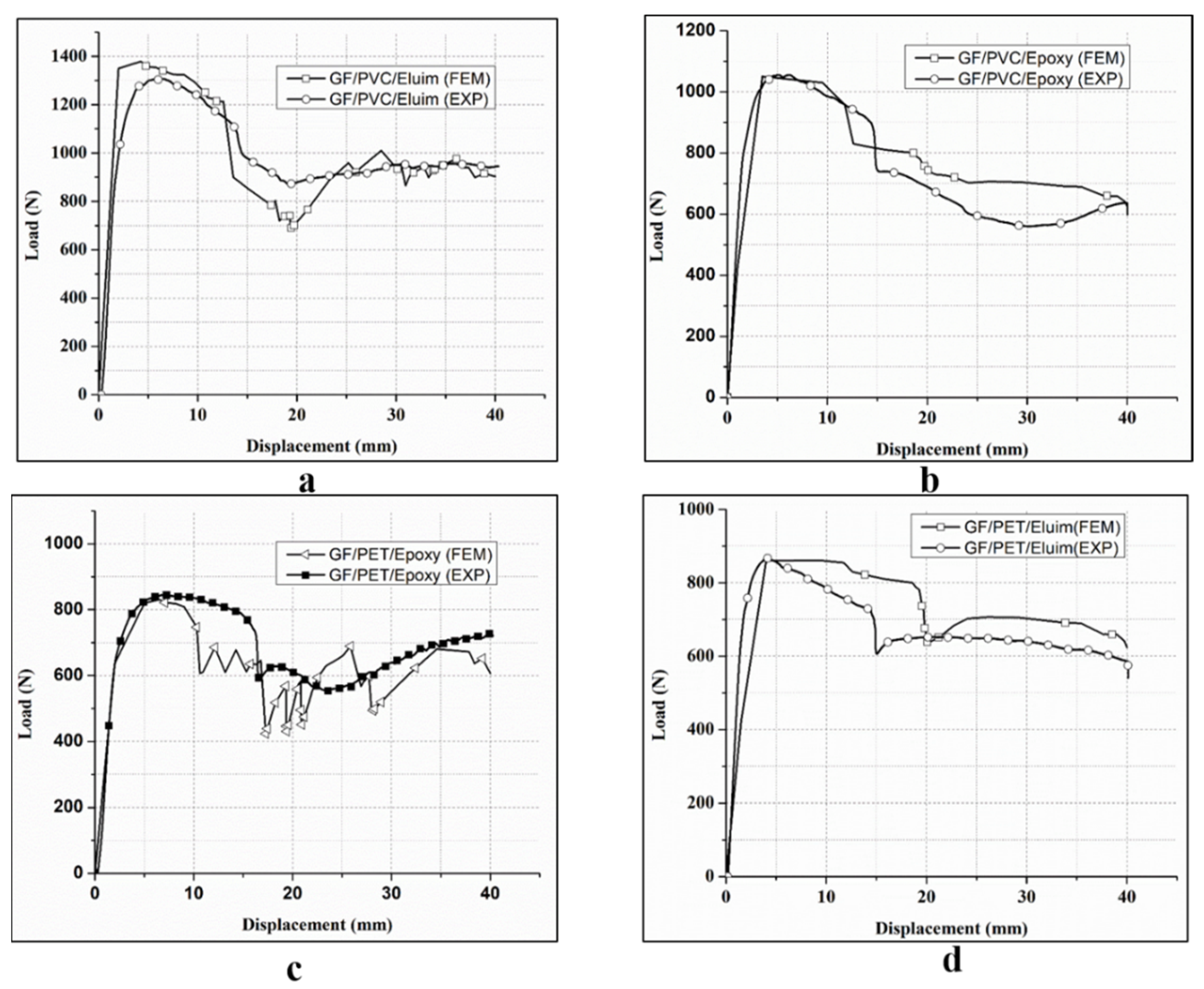

4.2. Validity of FEM Results

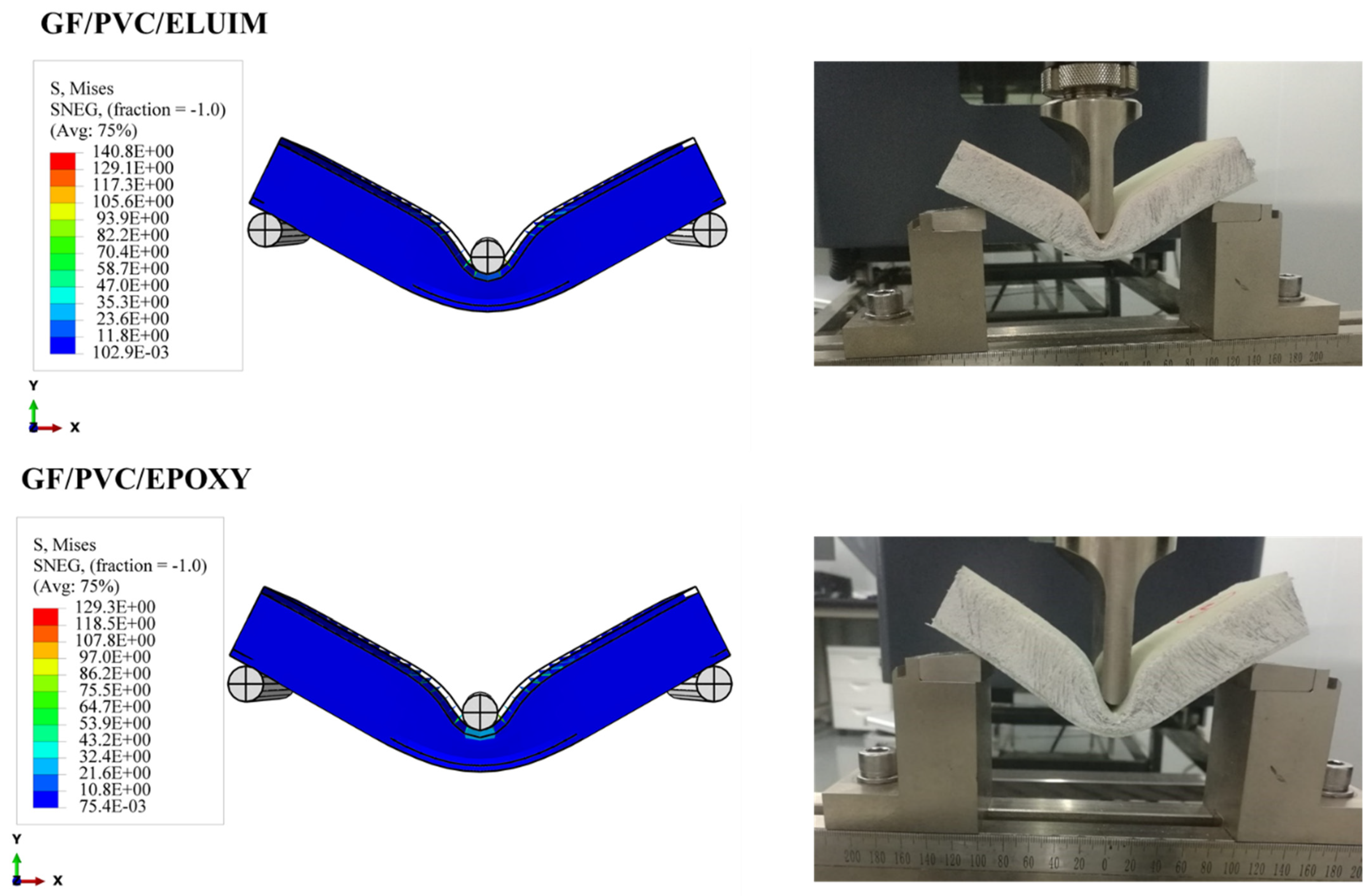

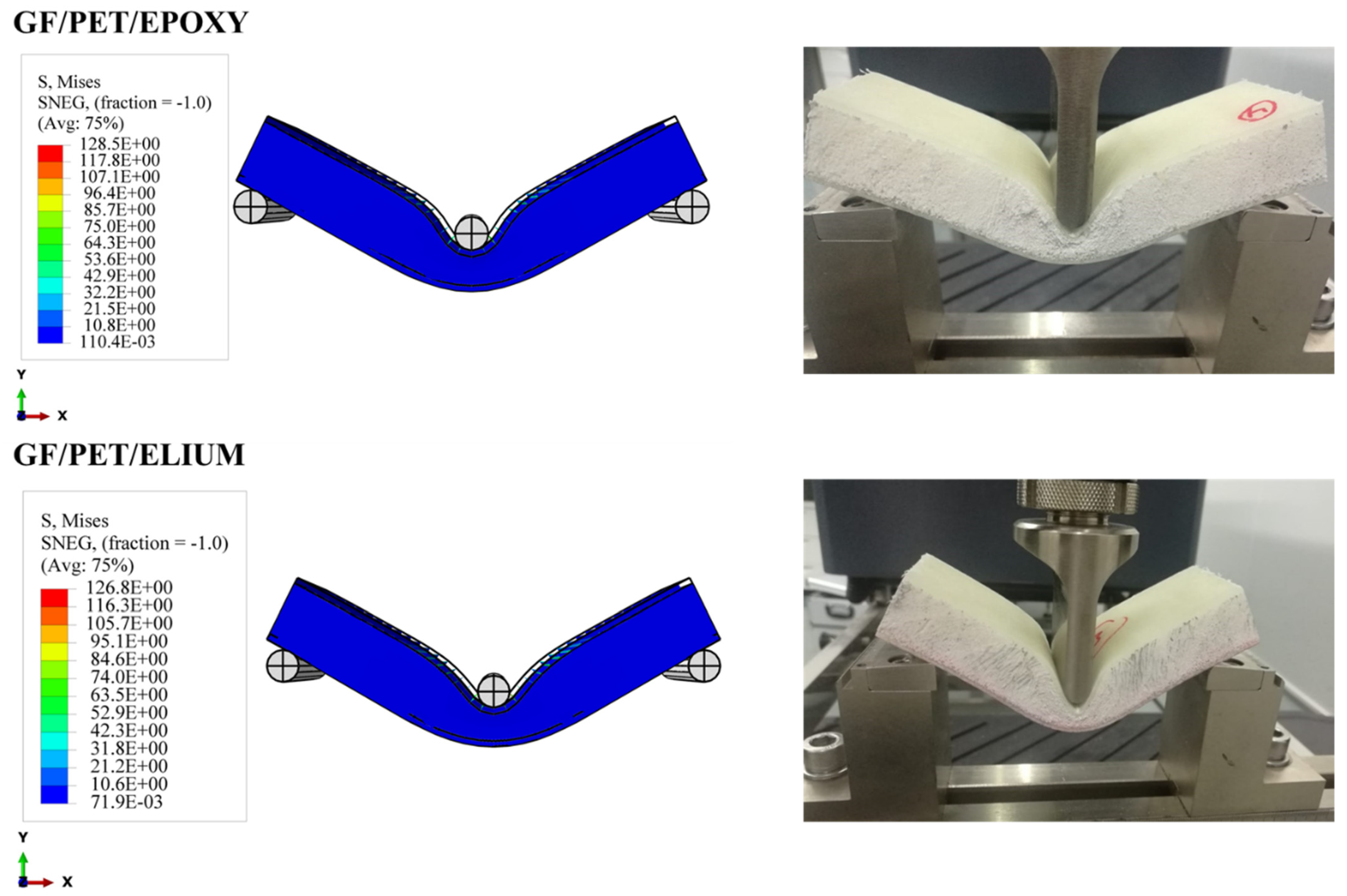

4.3. Failure Behaviors

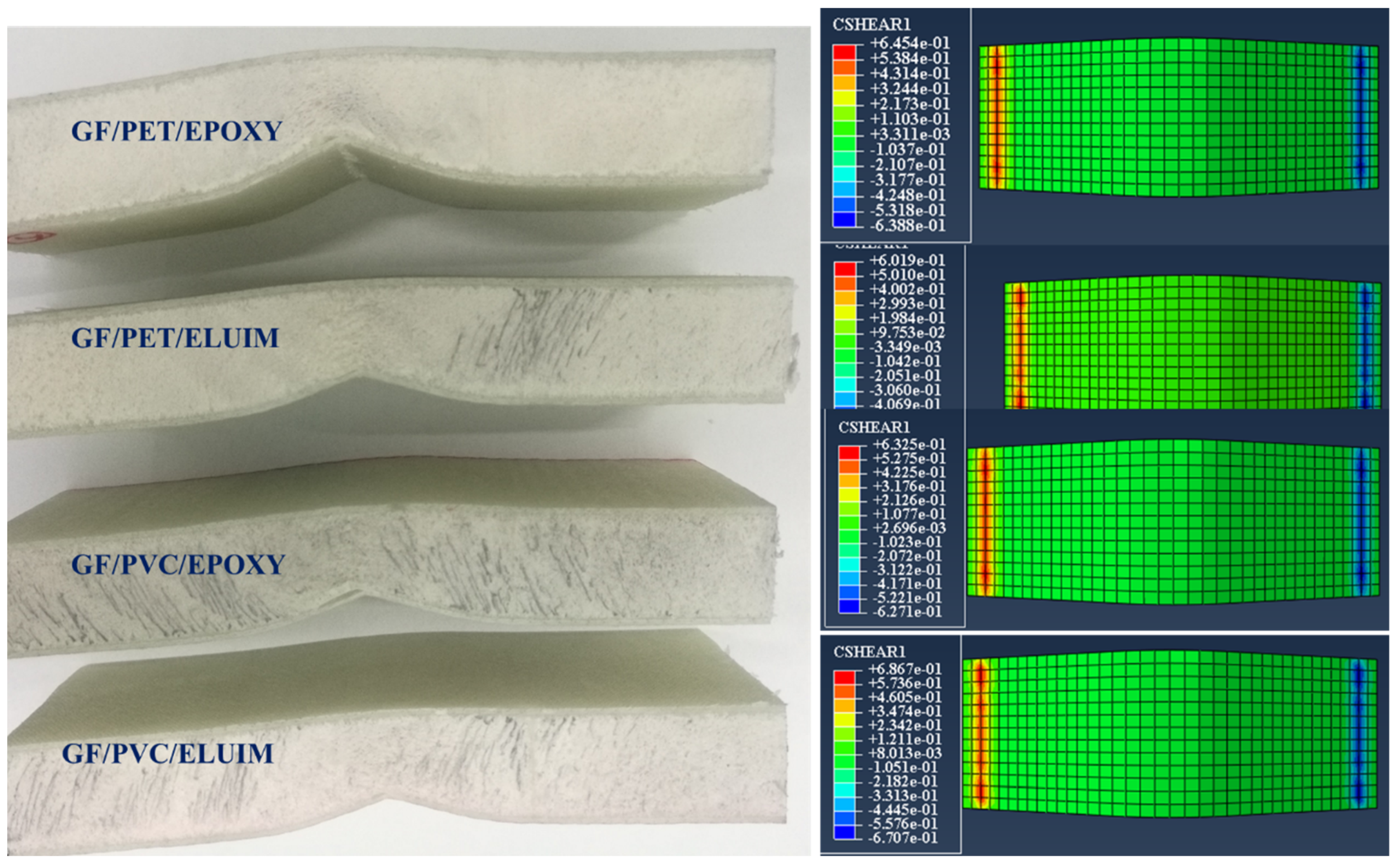

4.3.1. Foam Damage

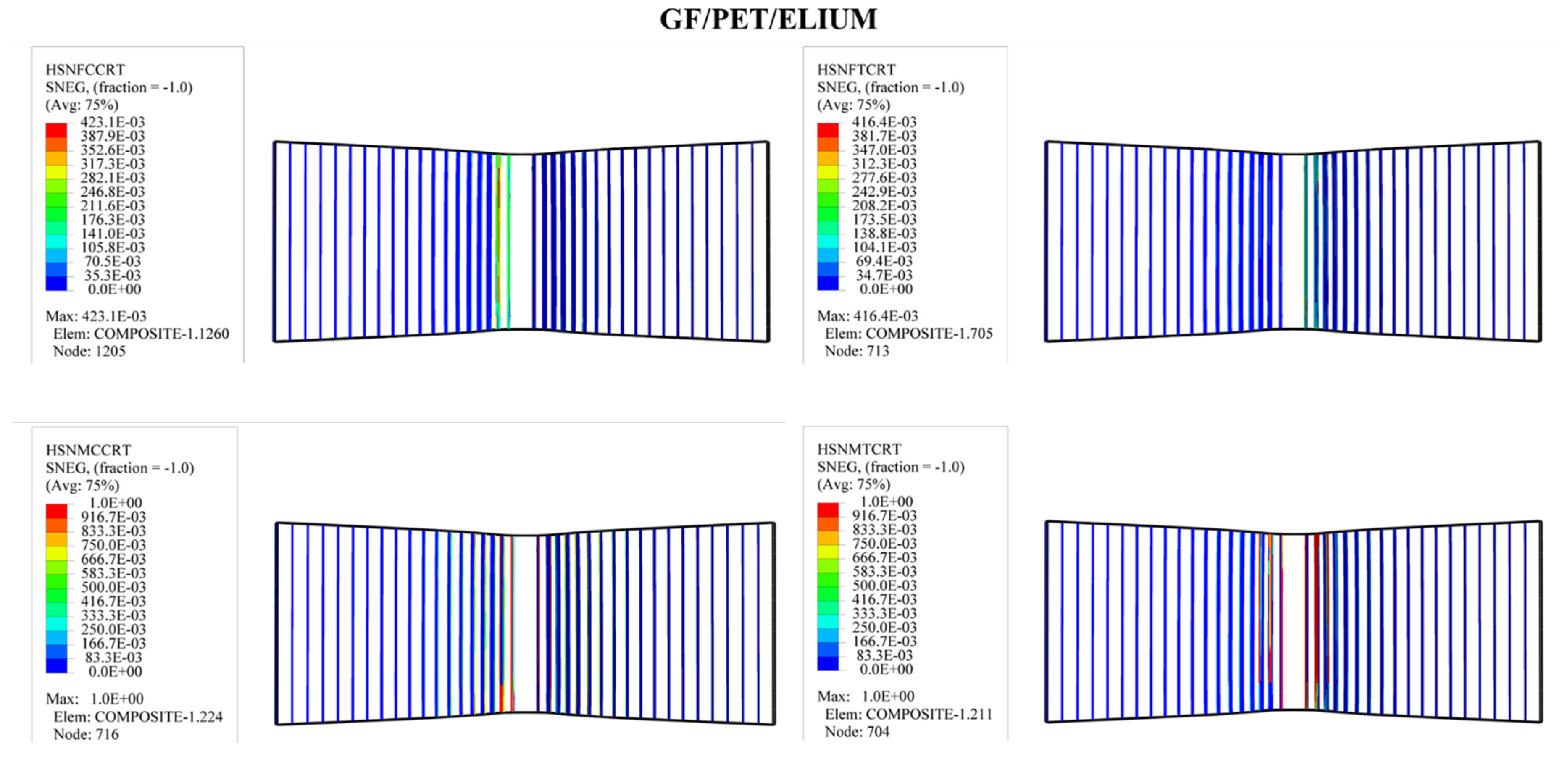

4.3.2. Upper and Lower Skin Damage

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grünewald, J.; Parlevliet, P.P.; Matschinski, A.; Altstädt, V. Mechanical performance of CF/PEEK–PEI foam core sandwich structures. J. Sandw. Struct. Mater. 2017, 21, 2680–2699. [Google Scholar] [CrossRef]

- Valenza, A.; Fiore, V.; Calabrese, L. Three-point flexural behaviour of GFRP sandwich composites: A failure map. Adv. Compos. Mater. 2010, 19, 79–90. [Google Scholar] [CrossRef]

- Borsellino, C.; Calabrese, L.; Valenza, A. Experimental and numerical evaluation of sandwich composite structures. Compos. Sci. Technol. 2004, 64, 1709–1715. [Google Scholar] [CrossRef]

- Zhang, F.; Mohmmed, R.; Sun, B.; Gu, B. Damage Behaviors of Foam Sandwiched Composite Materials Under Quasi-Static Three-point Bending. Appl. Compos. Mater. 2013, 20, 1231–1246. [Google Scholar] [CrossRef]

- Mostafa, A.; Shankar, K.; Morozov, E. Behaviour of PU-foam/glass-fibre composite sandwich panels under flexural static load. Mater. Struct. 2015, 48, 1545–1559. [Google Scholar] [CrossRef]

- Russell, B.; Liu, T.; Fleck, N.; Deshpande, V. Quasi-static three-point bending of carbon fiber sandwich beams with square honeycomb cores. J. Appl. Mech. 2011, 78, 031008. [Google Scholar] [CrossRef]

- Sun, Y.; Guo, L.-C.; Wang, T.-S.; Zhong, S.-Y.; Pan, H.-Z. Bending behavior of composite sandwich structures with graded corrugated truss cores. Compos. Struct. 2017, 185, 446–454. [Google Scholar] [CrossRef]

- Wang, B.; Shi, Y.; Zhou, C.; Li, T. Failure mechanism of PMI foam core sandwich beam in bending. Int. J. Simul. Multidiscip. Des. Optim. 2015, 6, A8. [Google Scholar] [CrossRef]

- Wang, N.-z.; Xiang, C.; Ao, L.; Li, Y.-x.; Zhang, H.-w.; Yuan, L. Three-point bending performance of a new aluminum foam composite structure. Trans. Nonferrous Met. Soc. China 2016, 26, 359–368. [Google Scholar] [CrossRef]

- Zhang, J.; Supernak, P.; Mueller-Alander, S.; Wang, C.H. Improving the bending strength and energy absorption of corrugated sandwich composite structure. Mater. Des. 2013, 52, 767–773. [Google Scholar] [CrossRef]

- Kaboglu, C. The effect of different types of core material on the flexural behavior of sandwich composites for wind turbine blades. J. Therm. Eng. 2017, 3, 1102–1109. [Google Scholar] [CrossRef]

- Krzyżak, A.; Mazur, M.; Gajewski, M.; Drozd, K.; Komorek, A.; Przybyłek, P. Sandwich structured composites for aeronautics: Methods of manufacturing affecting some mechanical properties. Int. J. Aerosp. Eng. 2016, 2016, 7816912. [Google Scholar] [CrossRef]

- Champliaud, H.; Feng, Z.; Bersee, H. Three-point bending testing of sandwich beams and finite element comparison. In Proceedings of the ASME 2009 International Mechanical Engineering Congress and Exposition, Lake Buena Vista, FL, USA, 13–19 November 2009; pp. 357–363. [Google Scholar]

- Berggreen, C.; Branner, K.; Jensen, J.F.; Schultz, J.P. Application and analysis of sandwich elements in the primary structure of large wind turbine blades. J. Sandw. Struct. Mater. 2007, 9, 525–552. [Google Scholar] [CrossRef]

- Mostafa, A.; Shankar, K.; Morozov, E. Experimental, theoretical and numerical investigation of the flexural behaviour of the composite sandwich panels with PVC foam core. Appl. Compos. Mater. 2014, 21, 661–675. [Google Scholar] [CrossRef]

- Carrera, E.; Pagani, A.; Valvano, S. Shell elements with through-the-thickness variable kinematics for the analysis of laminated composite and sandwich structures. Compos. Part B Eng. 2017, 111, 294–314. [Google Scholar] [CrossRef]

- Nunes, J.; Silva, J. Sandwiched composites in aerospace engineering. In Advanced Composite Materials for Aerospace Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 129–174. [Google Scholar]

- Riccio, A.; Raimondo, A.; Sellitto, A.; Acanfora, V.; Zarrelli, M. Multifunctional Polypropylene Core for Aerospace Sandwich Composite Panels. Procedia Eng. 2016, 167, 64–70. [Google Scholar] [CrossRef]

- Melnyk, L.H.; Derykolenko, O.M.; Mazin, Y.O.; Matsenko, O.I.; Piven, V.S. Modern Trends in the Development of Renewable Energy: The Experience of the EU and Leading Countries of the World. Механізм регулювання екoнoміки 2020, 3C, 117–133. [Google Scholar] [CrossRef]

- Bazilevs, Y.; Hsu, M.C.; Kiendl, J.; Benson, D. A computational procedure for prebending of wind turbine blades. Int. J. Numer. Methods Eng. 2012, 89, 323–336. [Google Scholar] [CrossRef]

- Atas, C.; Sevim, C. On the impact response of sandwich composites with cores of balsa wood and PVC foam. Compos. Struct. 2010, 93, 40–48. [Google Scholar] [CrossRef]

- Asad, M.; Zahra, T.; Thambiratnam, D.P.; Chan, T.H.T.; Zhuge, Y. Geometrically modified auxetic polyurethane foams and their potential application in impact mitigation of masonry structures. Constr. Build. Mater. 2021, 311, 125170. [Google Scholar] [CrossRef]

- Fan, G.Z.; Ren, X.; Wang, S.L.; Luo, C.; Xie, Y.M. A novel cement-based auxetic foam composite: Experimental study. Case Stud. Constr. Mater. 2022, 17, e01159. [Google Scholar] [CrossRef]

- Cheng, H.C.; Scarpa, F.; Panzera, T.H.; Farrow, I.; Peng, H.X. Shear stiffness and energy absorption of auxetic open cell foams as sandwich cores. Phys. Status Solidi (B) 2019, 256, 1800411. [Google Scholar] [CrossRef]

- Zhu, D.; Shi, H.; Fang, H.; Liu, W.; Qi, Y.; Bai, Y. Fiber reinforced composites sandwich panels with web reinforced wood core for building floor applications. Compos. Part B Eng. 2018, 150, 196–211. [Google Scholar] [CrossRef]

- Ma, Q.; Rejab, M.; Siregar, J.; Guan, Z. A review of the recent trends on core structures and impact response of sandwich panels. J. Compos. Mater. 2021, 55, 2513–2555. [Google Scholar] [CrossRef]

- Wei, X.; Xiong, J.; Wang, J.; Xu, W. New advances in fiber-reinforced composite honeycomb materials. Sci. China Technol. Sci. 2020, 63, 1348–1370. [Google Scholar] [CrossRef]

- Lan, X.; Feng, S.; Huang, Q.; Zhou, T. A comparative study of blast resistance of cylindrical sandwich panels with aluminum foam and auxetic honeycomb cores. Aerosp. Sci. Technol. 2019, 87, 37–47. [Google Scholar] [CrossRef]

- Manalo, A.; Aravinthan, T.; Fam, A.; Benmokrane, B. State-of-the-art review on FRP sandwich systems for lightweight civil infrastructure. J. Compos. Constr. 2017, 21, 04016068. [Google Scholar] [CrossRef]

- Saseendran, V.; Berggreen, C.; Krueger, R. Mode mixity analysis of face/core debonds in a single cantilever beam sandwich specimen. J. Sandw. Struct. Mater. 2020, 22, 1879–1909. [Google Scholar] [CrossRef]

- Viana, G.; Carlsson, L. Influences of foam density and core thickness on debond toughness of sandwich specimens with PVC foam core. J. Sandw. Struct. Mater. 2003, 5, 103–118. [Google Scholar] [CrossRef]

- Vijaya Ramnath, B.; Alagarraja, K.; Elanchezhian, C. Review on Sandwich Composite and their Applications. Mater. Today: Proc. 2019, 16, 859–864. [Google Scholar] [CrossRef]

- Fang, H.; Liu, W.; Lu, W.; Wan, L. Flexural properties of grooved perforation sandwich composites. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2010, 25, 583–587. [Google Scholar] [CrossRef]

- Bao, L.; Miura, Y.; Kemmochi, K. Improving bending characteristics of FRP sandwich structures with reinforcement webs. Adv. Compos. Mater. 2018, 27, 221–233. [Google Scholar] [CrossRef]

- Umer, R.; Waggy, E.; Haq, M.; Loos, A. Experimental and numerical characterizations of flexural behavior of VARTM-infused composite sandwich structures. J. Reinf. Plast. Compos. 2012, 31, 67–76. [Google Scholar] [CrossRef]

- Giglio, M.; Gilioli, A.; Manes, A. Numerical investigation of a three point bending test on sandwich panels with aluminum skins and Nomex™ honeycomb core. Comput. Mater. Sci. 2012, 56, 69–78. [Google Scholar] [CrossRef]

- Ivañez, I.; Santiuste, C.; Sanchez-Saez, S. FEM analysis of dynamic flexural behaviour of composite sandwich beams with foam core. Compos. Struct. 2010, 92, 2285–2291. [Google Scholar] [CrossRef]

- Potluri, R.; Raju, M.N.; Babu, K.R.P. Finite Element Analysis ofCellular Foam Core Sandwich Structures. Mater. Today: Proc. 2017, 4, 2501–2510. [Google Scholar] [CrossRef]

- Wang, P.; WANG, P.; LI, X. Experimental and numerical evaluation of fatigue behavior of foam core sandwich structure. Compos. Struct. 2013, 3, 50–51. [Google Scholar] [CrossRef]

- Ijaz, H.; Saleem, W.; Zain-ul-Abdein, M.; Mabrouki, T.; Rubaiee, S.; Salmeen Bin Mahfouz, A. Finite Element Analysis of Bend Test of Sandwich Structures Using Strain Energy Based Homogenization Method. Adv. Mater. Sci. Eng. 2017, 2017, 8670207. [Google Scholar] [CrossRef]

- Zhu, D.; Zhang, X.; Zhang, H. Effects of strain rate and temperature on mechanical properties of Kevlar 49 aramid fabric reinforced epoxy polymers under dynamic tensile loading. Acta Mater. Compos. Sin. 2016, 33, 459–468. [Google Scholar]

- Arezoo, S.; Tagarielli, V.; Petrinic, N.; Reed, J. The mechanical response of Rohacell foams at different length scales. J. Mater. Sci. 2011, 46, 6863–6870. [Google Scholar] [CrossRef]

- Hashin, Z.; Rotem, A. A fatigue failure criterion for fiber reinforced materials. J. Compos. Mater. 1973, 7, 448–464. [Google Scholar] [CrossRef] [Green Version]

- Echaabi, J.; Trochu, F.; Gauvin, R. Review of failure criteria of fibrous composite materials. Polym. Compos. 1996, 17, 786–798. [Google Scholar] [CrossRef]

- Hashin, Z. Fatigue failure criteria for unidirectional fiber composites. J. Appl. Mech. Dec. 1981, 48, 846–852. [Google Scholar] [CrossRef]

- Wang, N.; Raza, A.; Si, Y.; Yu, J.; Sun, G.; Ding, B. Tortuously structured polyvinyl chloride/polyurethane fibrous membranes for high-efficiency fine particulate filtration. J. Colloid Interface Sci. 2013, 398, 240–246. [Google Scholar] [CrossRef] [PubMed]

- Herranen, H.; Pabut, O.; Eerme, M.; Majak, J.; Pohlak, M.; Jaan, K.; Saarna, M.; Allikas, G.; Aruniit, A. Design and testing of sandwich structures with different core materials. Mater. Sci. 2012, 18, 45–50. [Google Scholar] [CrossRef]

- Manalo, A.; Surendar, S.; van Erp, G.; Benmokrane, B. Flexural behavior of an FRP sandwich system with glass-fiber skins and a phenolic core at elevated in-service temperature. Compos. Struct. 2016, 152, 96–105. [Google Scholar] [CrossRef]

- Liu, J.; Tao, J.; Li, F.; Zhao, Z. Flexural properties of a novel foam core sandwich structure reinforced by stiffeners. Constr. Build. Mater. 2020, 235, 117475. [Google Scholar] [CrossRef]

- Pandey, A.; Muchhala, D.; Kumar, R.; Sriram, S.; Venkat, A.N.C.; Mondal, D.P. Flexural deformation behavior of carbon fiber reinforced aluminium hybrid foam sandwich structure. Compos. Part B Eng. 2020, 183, 107729. [Google Scholar] [CrossRef]

- Dukhan, N.; Rayess, N.; Hadley, J. Characterization of aluminum foam–polypropylene interpenetrating phase composites: Flexural test results. Mech. Mater. 2010, 42, 134–141. [Google Scholar] [CrossRef]

- Zhang, P.; Cheng, Y.; Liu, J.; Li, Y.; Zhang, C.; Hou, H.; Wang, C. Experimental study on the dynamic response of foam-filled corrugated core sandwich panels subjected to air blast loading. Compos. Part B Eng. 2016, 105, 67–81. [Google Scholar] [CrossRef]

- Park, S.; Thanakkasaranee, S.; Shin, H.; Lee, Y.; Tak, G.; Seo, J. Pet/bio-based terpolyester blends with high dimensional thermal stability. Polymers 2021, 13, 728. [Google Scholar] [CrossRef] [PubMed]

- Albanese, M.; Boyenval, J.; Marchese, P.; Sullalti, S.; Celli, A. The aliphatic counterpart of PET, PPT and PBT aromatic polyesters: Effect of the molecular structure on thermo-mechanical properties. AIMS Mol. Sci 2016, 3, 32–51. [Google Scholar]

- Steeves, C.A.; Fleck, N.A. Material selection in sandwich beam construction. Scr. Mater. 2004, 50, 1335–1339. [Google Scholar] [CrossRef]

- Kalaprasad, G.; Pradeep, P.; Mathew, G.; Pavithran, C.; Thomas, S. Thermal conductivity and thermal diffusivity analyses of low-density polyethylene composites reinforced with sisal, glass and intimately mixed sisal/glass fibres. Compos. Sci. Technol. 2000, 60, 2967–2977. [Google Scholar] [CrossRef]

- Kootsookos, A.; Burchill, P.J. The effect of the degree of cure on the corrosion resistance of vinyl ester/glass fibre composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 501–508. [Google Scholar] [CrossRef]

- Torre, L.; Kenny, J.M. Impact testing and simulation of composite sandwich structures for civil transportation. Compos. Struct. 2000, 50, 257–267. [Google Scholar] [CrossRef]

| Property | GF/Epoxy | GF/Elium | Property | GF/Epoxy | GF/Elium |

|---|---|---|---|---|---|

| Longitudinal Young’s moduli, E11 (GPa) | 15.1 | 15.6 | Longitudinal tensile strength, Xt (MPa) | 280 | 292 |

| Transverse Young’s moduli, E22 (GPa) | 15.1 | 15.6 | Longitudinal compressive strength, Xc (MPa) | 144.5 | 176 |

| Out-of-plane Young’s moduli, E33 (GPa) | 3.7 | 3.9 | Transverse tensile strength, Yt (MPa) | 280 | 292 |

| Poisson’s ratio, ν11 | 0.21 | 0.21 | Transverse compressive strength, Yc (MPa) | 239 | 176 |

| Poisson’s ratio, ν13 | 0.1 | 0.1 | Longitudinal shear strength, S12 (MPa) | 48 | 62 |

| Poisson’s ratio, ν23 | 0.1 | 0.1 | Transverse shear strength, S23 (MPa) | 48 | 62 |

| Shear modulus, G12 (GPa) | 2.3 | 2.6 | Density, ρ (kg/m3) | 1624 | 1550 |

| Shear modulus, G13 (GPa) | 2.3 | 2.6 | Thickness, h (mm) | 2 | 2 |

| Shear modulus, G23 (GPa) | 1.96 | 2.53 | Fiber volume fraction (%) | 69 | 68 |

| Property | PVC | PET |

|---|---|---|

| Density (kg/m3) | 60 | 75 |

| Elastic modulus (MPa) | 100 | 89 |

| Shear modulus (MPa) | 21 | 13 |

| Tensile strength (MPa) | 1.82 | 1.49 |

| Compressive strength (MPa) | 0.98 | 0.96 |

| Shear strength (MPa) | 0.79 | 0.53 |

| Elongation at break (%) | 18 | 44 |

| Property | Epoxy 2040 | Elium® 188 |

|---|---|---|

| Density (kg/m3) | 1.16 | 1.18 |

| Tensile strength (MPa) | 45–85 | 55–76 |

| Tensile modulus (MPa) | 2800–3400 | 3100–3300 |

| Flexural modulus (MPa) | 2600–3600 | 3250 |

| Flexural strength (MPa) | 100–130 | 130 |

| Elongation at break (%) | 1.3–5.0 | 4–6 |

| Sandwich Structures | Load (N) | Flexural Strength (MPa) | Flexural Modulus (GPa) | Load Standard Deviation |

|---|---|---|---|---|

| GF/PVC/Elium | 1308 | 243.75 | 0.26 | 18.8 |

| GF/PVC/Epoxy | 1156 | 206.25 | 0.215 | 12.6 |

| GF/PET/Elium | 868 | 165 | 0.18 | 16.3 |

| GF/PET/Epoxy | 845 | 159.4 | 0.16 | 23.03 |

| Sandwich Structure | Core Shear Ultimate Strength (MPa) | Facing Stress (MPa) |

|---|---|---|

| GF/PVC/Elium | 0.6 | 14.8 |

| GF/PVC/Epoxy | 0.52 | 13.12 |

| GF/PET/Elium | 0.40 | 9.8 |

| GF/PET/Epoxy | 0.38 | 9.6 |

| Sandwich Composite Type | Peak Load (N) | ||

|---|---|---|---|

| EXP. | NUM. | Error | |

| GV/PVC/Elium | 1307.9 | 1378.7 | 5.4% |

| GF/PVC/Epoxy | 1055.9 | 1034.5 | 2% |

| GF/PET/Elium | 867.9 | 860.5 | 0.85% |

| GF/PET/Epoxy | 845.2 | 830.7 | 1.7% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alshahrani, H.; Ahmed, A. Study on Flexural Behavior of Glass Fiber Reinforced Plastic Sandwich Composites Using Liquid Thermoplastic Resin. Polymers 2022, 14, 4045. https://doi.org/10.3390/polym14194045

Alshahrani H, Ahmed A. Study on Flexural Behavior of Glass Fiber Reinforced Plastic Sandwich Composites Using Liquid Thermoplastic Resin. Polymers. 2022; 14(19):4045. https://doi.org/10.3390/polym14194045

Chicago/Turabian StyleAlshahrani, Hassan, and Azzam Ahmed. 2022. "Study on Flexural Behavior of Glass Fiber Reinforced Plastic Sandwich Composites Using Liquid Thermoplastic Resin" Polymers 14, no. 19: 4045. https://doi.org/10.3390/polym14194045