Effect of Sanding and Plasma Treatment of 3D-Printed Parts on Bonding to Wood with PVAc Adhesive

Abstract

:1. Introduction

2. Materials and Methods

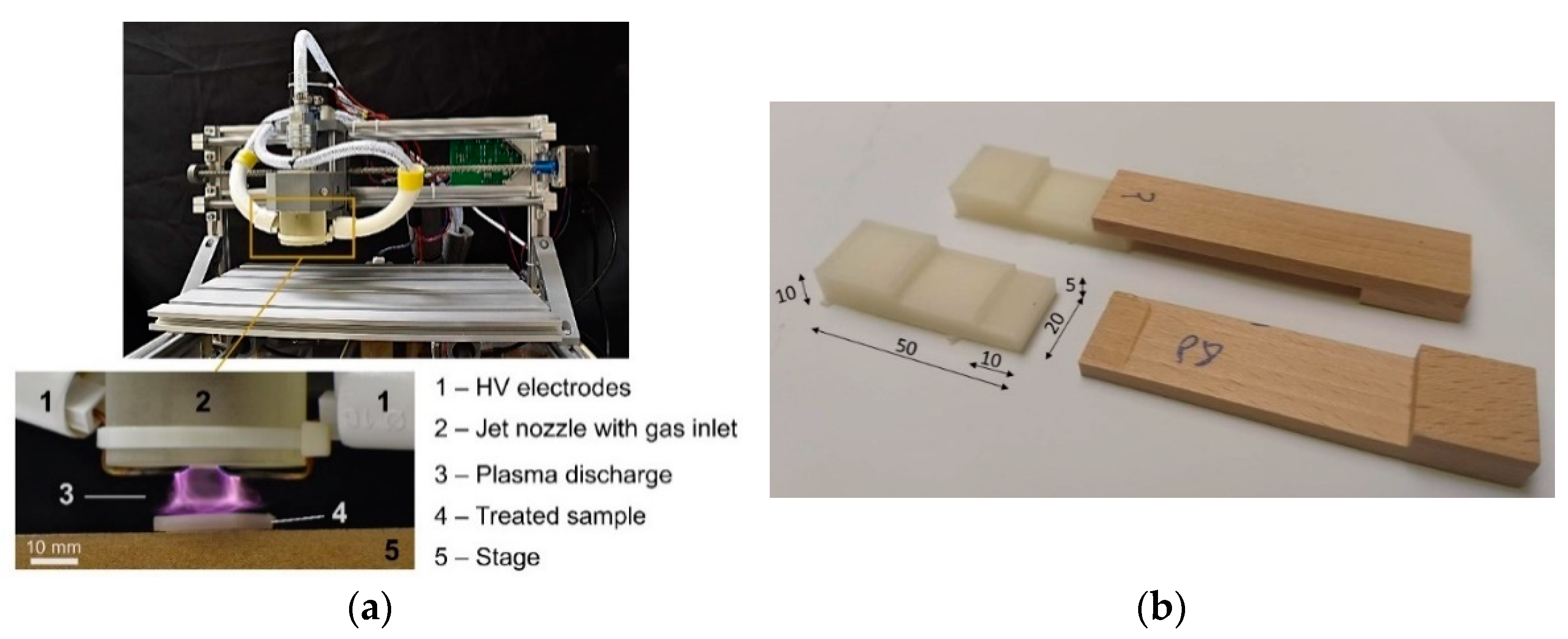

2.1. Plasma Treatment

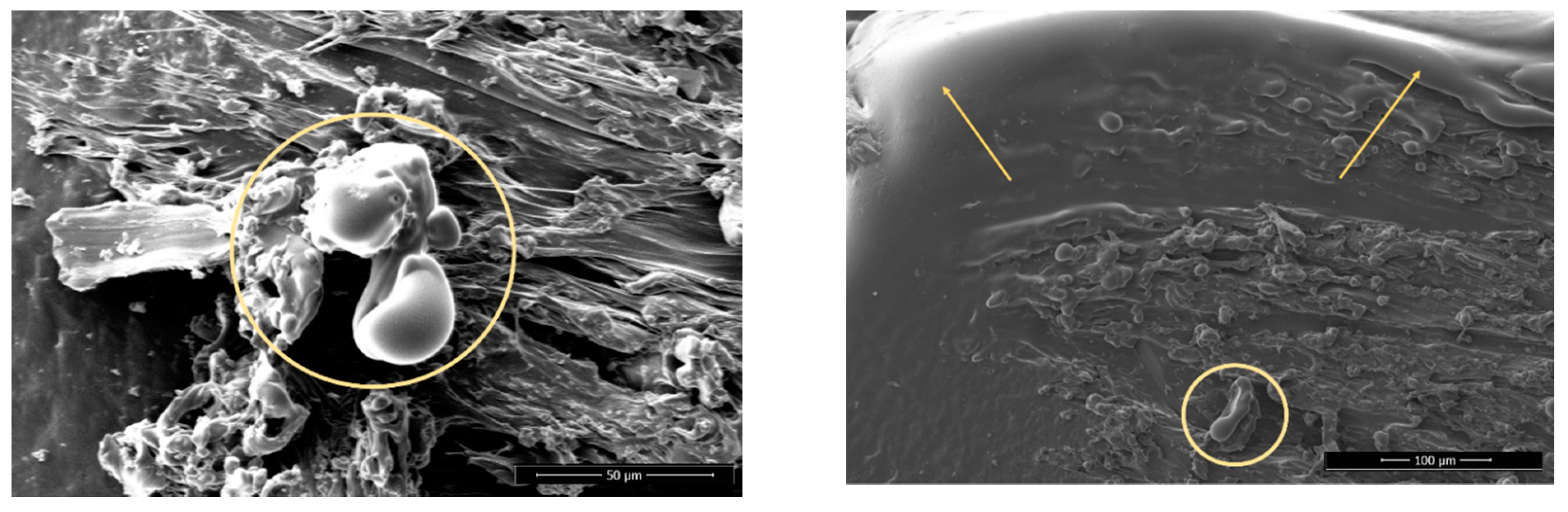

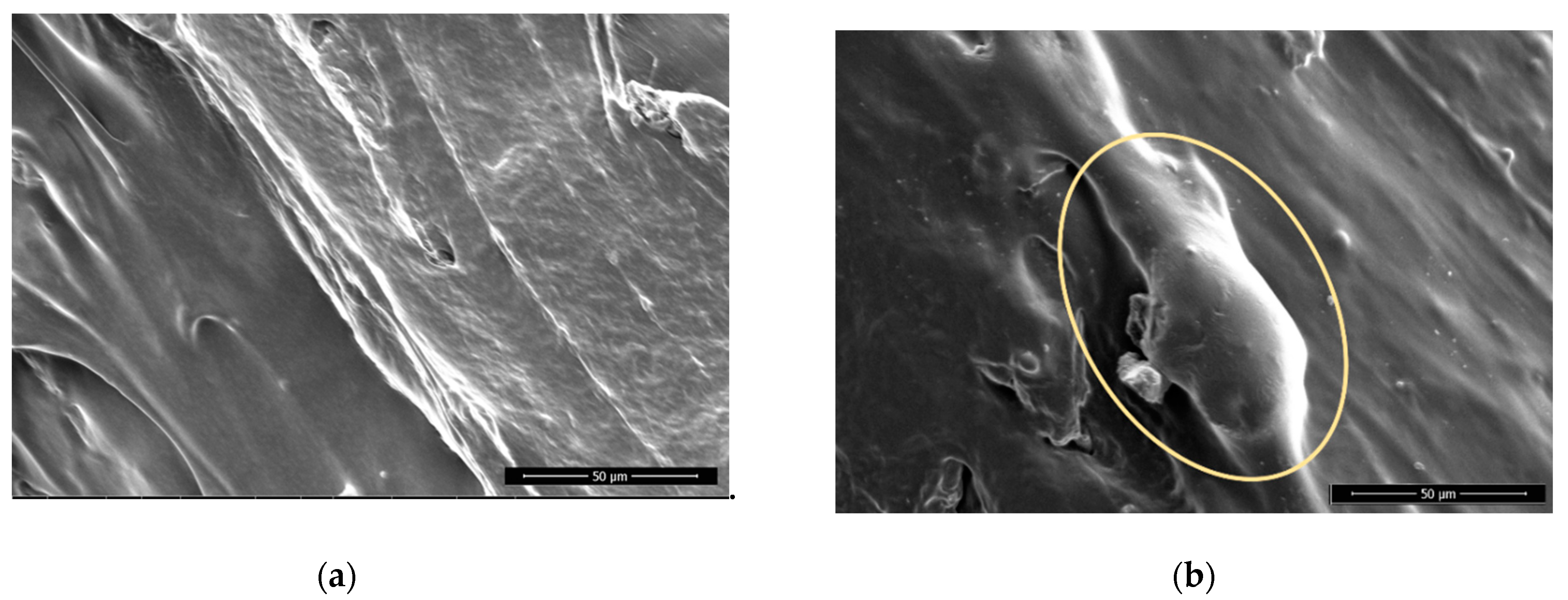

2.2. Scanning Electron Microscopy (SEM)

2.3. Surface Roughness

2.4. Water Contact Angle Measurements

2.5. Adhesive Bonding

3. Results and Discussion

3.1. Surface Microstructures

3.2. Surface Roughness

3.3. Water Contact Angles

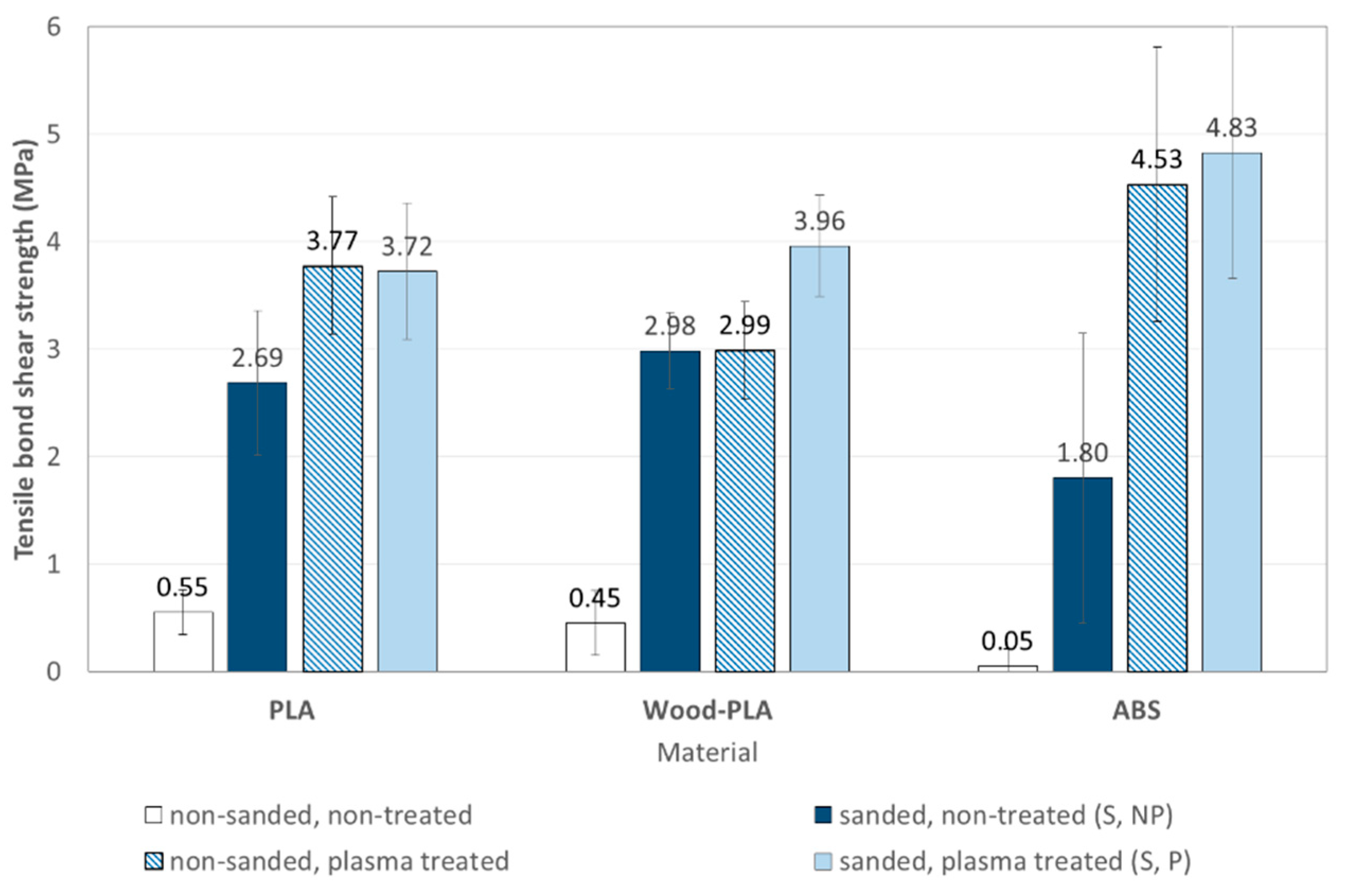

3.4. Bond Tensile-Shear Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Duty, C.E.; Kunc, V.; Compton, B.; Post, B.; Erdman, D.; Smith, R.; Love, L. Structure and mechanical behavior of Big Area Additive Manufacturing (BAAM) materials. Rapid Prototyp. J. 2017, 23, 181–189. [Google Scholar] [CrossRef]

- Lamm, M.E.; Wang, L.; Kishore, V.; Tekinalp, H.; Kunc, V.; Wang, J.; Ozcan, S. Material Extrusion Additive Manufacturing of Wood and Lignocellulosic Filled Composites. Polymers 2020, 12, 2115. [Google Scholar] [CrossRef] [PubMed]

- Ayrilmis, N.; Kariž, M.; Kitek Kuzman, M. Effect of wood flour content on surface properties of 3D printed materials produced from wood flour/PLA filament. Int. J. Polym. Anal. Charact. 2019, 24, 659–666. [Google Scholar] [CrossRef]

- Ahmed, W.; Alnajjar, F.; Zaneldin, E.; Al-Marzouqi, A.H.; Gochoo, M.; Khalid, S. Implementing FDM 3D Printing Strategies Using Natural Fibers to Produce Biomass Composite. Materials 2020, 13, 4065. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [Green Version]

- Kovan, V.; Altan, G.; Topal, E.S. Effect of layer thickness and print orientation on strength of 3D printed and adhesively bonded single lap joints. J. Mech. Sci. Technol. 2017, 31, 2197–2201. [Google Scholar] [CrossRef]

- Eckelman, C.A.; Suddarth, S.K. Analysis and design of furniture frames. Wood Sci. Technol. 1969, 3, 239–255. [Google Scholar] [CrossRef]

- Marra, A.A. Adhesives for wood composites. In Proceedings of the 1980 Symposium: Wood Adhesives Research, Application and Needs, Madison, WI, USA, 23–25 September 1980; pp. 202–206. [Google Scholar]

- Kariz, M.; Kuzman, M.K.; Sernek, M. Adhesive bonding of 3D-printed ABS parts and wood. J. Adhes. Sci. Technol. 2017, 31, 1683–1690. [Google Scholar] [CrossRef]

- Kain, S.; Ecker, J.V.; Haider, A.; Musso, M.; Petutschnigg, A. Effects of the infill pattern on mechanical properties of fused layer modeling (FLM) 3D printed wood/polylactic acid (PLA) composites. Eur. J. Wood Prod. 2020, 78, 65–74. [Google Scholar] [CrossRef]

- Sauerbier, P.; Köhler, R.; Renner, G.; Militz, H. Surface activation of Polylactic Acid-Based Wood-Plastic Composite by Atmospheric Pressure Plasma Treatment. Materials 2020, 13, 4673. [Google Scholar] [CrossRef]

- Dugbenoo, E.; Arif, M.F.; Wardle, B.L.; Kumar, S. Enhanced Bonding via Additive Manufacturing-Enabled Surface Tailoring of 3D Printed Continuous-Fiber Composites. Adv. Eng. Mater. 2018, 20, 1800691. [Google Scholar] [CrossRef]

- Baran, E.H.; Erbil, H.Y. Surface modification of 3D printed PLA objects by fused deposition modeling: A review. Colloids Interfaces 2019, 3, 43. [Google Scholar] [CrossRef] [Green Version]

- Leicht, H.; Orf, L.; Hesselbach, J.; Vudugula, H.; Kraus, E.; Baudrit, B.; Hochrein, T.; Bastian, M. Adhesive bonding of 3D-printed plastic components. J. Adhes. 2020, 96, 48–63. [Google Scholar] [CrossRef]

- Abourayana, H.; Dobbyn, P.; Dowling, D. Enhancing the mechanical performance of additive manufactured polymer components using atmospheric plasma pre-treatments. Plasma Process. Polym. 2018, 15, 1700141. [Google Scholar] [CrossRef]

- Abourayana, H.; Dobbyn, P.; Whyte, P.; Dowling, D.P. Investigation of the performance of a pilot-scale barrel atmospheric plasma system for plasma activation of polymer particles. Nanotechnol. Precis. Eng. 2019, 2, 1–7. [Google Scholar] [CrossRef]

- Žigon, J.; Kovač, J.; Zaplotnik, R.; Saražin, J.; Šernek, M.; Petrič, M.; Dahle, S. Enhancement of strength of adhesive bond between wood and metal using atmospheric plasma treatment. Cellulose 2020, 27, 6411–6424. [Google Scholar] [CrossRef]

- Yang, J.; Bei, J.; Wang, S. Improving cell affinity of poly(d,l-lactide) film modified by anhydrous ammonia plasma treatment. Polym. Adv. Technol. 2002, 13, 220–226. [Google Scholar] [CrossRef]

- Wan, Y.; Yang, J.; Yang, J.; Bei, J.; Wang, S. Cell adhesion on gaseous plasma modified poly-(l-lactide) surface under shear stress field. Biomaterials 2003, 24, 3757–3764. [Google Scholar] [CrossRef]

- Jiao, Y.; Xu, J.; Zhou, C. Effect of Ammonia Plasma Treatment on the Properties and Cytocompatibility of a Poly(l-Lactic Acid) Film Surface. J. Biomater. Sci. Polym. Ed. 2012, 23, 763–777. [Google Scholar] [CrossRef]

- Guowei, Z.; Junping, G.; Qiang, G.; Yashao, C. Surface Modification of Biodegradable Poly(d,l-lactic acid) by Nitrogen and Nitrogen/Hydrogen Plasma for Improving Surface Hydrophilicity. Plasma Sci. Technol. 2011, 13, 230. [Google Scholar] [CrossRef]

- Ferreira, B.M.P.; Pinheiro, L.M.P.; Nascente, P.A.P.; Ferreira, M.J.; Duek, E.A.R. Plasma surface treatments of poly(l-lactic acid) (PLLA) and poly(hydroxybutyrate-co-hydroxyvalerate) (PHBV). Mater. Sci. Eng. 2009, 29, 806–813. [Google Scholar] [CrossRef]

- Yang, J.; Bei, J.; Wang, S. Enhanced cell affinity of poly (d,l-lactide) by combining plasma treatment with collagen anchorage. Biomaterials 2002, 23, 2607–2614. [Google Scholar] [CrossRef]

- Ding, Z.; Chen, J.; Gao, S.; Chang, J.; Zhang, J.; Kang, E.T. Immobilization of chitosan onto poly-l-lactic acid film surface by plasma graft polymerization to control the morphology of fibroblast and liver cells. Biomaterials 2004, 25, 1059–1067. [Google Scholar] [CrossRef]

- Li, H.; Xia, Y.; Wu, J.; He, Q.; Zhou, X.; Lu, G.; Shang, L.; Boey, F.; Venkatraman, S.S.; Zhang, H. Surface Modification of Smooth Poly(l-lactic acid) Films for Gelatin Immobilization. ACS Appl. Mater. Interfaces 2012, 4, 687–693. [Google Scholar] [CrossRef]

- Tenn, N.; Follain, N.; Fatyeyeva, K.; Poncin-Epaillard, F.; Labrugère, C.; Marais, S. Impact of hydrophobic plasma treatments on the barrier properties of poly(lactic acid) films. RSC Adv. 2014, 4, 5626. [Google Scholar] [CrossRef]

- Izdebska-Podsiadły, J.; Dörsam, E. Effects of argon low temperature plasma on PLA film surface and aging behaviors. Vacuum 2017, 145, 278–284. [Google Scholar] [CrossRef]

- De Geyter, N.; Morent, R.; Desmet, T.; Trentesaux, M.; Gengembre, L.; Dubruel, P.; Leys, C.; Payen, E. Plasma modification of polylactic acid in a medium pressure DBD. Surf. Coat. Technol. 2010, 204, 3272–3279. [Google Scholar] [CrossRef]

- Jacobs, T.; Declercq, H.; De Geyter, N.; Cornelissen, R.; Dubruel, P.; Leys, C.; Beaurain, A.; Payen, E.; Morent, R. Plasma surface modification of polylactic acid to promote interaction with fibroblasts. J Mater. Sci. Mater. Med. 2013, 24, 469–478. [Google Scholar] [CrossRef] [PubMed]

- Moraczewski, K.; Rytlewski, P.; Malinowski, R.; Żenkiewicz, M. Comparison of some effects of modification of a polylactide surface layer by chemical, plasma, and laser methods. Appl. Surf. Sci. 2015, 346, 11–17. [Google Scholar] [CrossRef]

- López-García, J. Chapter 10—Wettability Analysis and Water Absorption Studies of Plasma Activated Polymeric Materials. In Non-Thermal Plasma Technology for Polymeric Materials: Applications in Composites, Nanostructured Materials, and Biomedical Fields; Mozetič, M., Cvelbar, U., Spatenka, P., Thomas, S., Praveen, K.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 261–285. [Google Scholar] [CrossRef]

- Dahle, S.; Žigon, J.; Uranjek, I.; Petrič, M. Performance of a water-borne stain on beech, spruce, MDF and OSB improved by plasma pre-treatment. In Proceedings of the IRGWP 51st Annual Conference, Bled, Slovenia, 7–11 June 2020. [Google Scholar] [CrossRef]

- Jordá-Vilaplana, A.; Fombuena, V.; García-García, D.; Samper, M.D.; Sánchez-Nácher, L. Surface modification of polylactic acid (PLA) by air atmospheric plasma treatment. Eur. Polym. J. 2014, 58, 23–33. [Google Scholar] [CrossRef]

- Mance, A.M.; Waldo, R.A.; Dow, A.A. Interactions of Electroless Catalysts with Plasma-Oxidized Surfaces of Polystyrene-Based Resins. J. Electrochem. Soc. 1989, 136, 1667. [Google Scholar] [CrossRef]

- Abuelazaim, M.M. The Effect of Gas Flow Rate on Plasma Etched Porosity of Acrylonitrile-Butadiene-Styrene Plastic. Master’s Thesis, San Jose State University, San Jose, CA, USA, 1994. [Google Scholar] [CrossRef]

- Holc, M.; Zaplotnik, R.; Mozetic, M.; Vesel, A. Surface Modification and Aging of Polyacrylonitrile Butadiene Styrene Polymer Induced by Treatment in RF Oxygen Plasma. IEEE Trans. Plasma Sci. 2018, 46, 3669–3676. [Google Scholar] [CrossRef]

- Hsiao, R.-C.; Sung, T.-L.; Liu, C.-M.; Teii, S.; Chan, T.-C.; Ono, S.; Teii, K.; Yang, C.-C.; Zeng, S.-C. Hydrophilic Stability of Plastic Surfaces Treated in Low- and Atmospheric-Pressure Radio-Frequency Plasmas. IEEE Trans. Plasma Sci. 2014, 42, 3837–3841. [Google Scholar] [CrossRef]

- White, J.; Tenore, C.; Pavich, A.; Scherzer, R.; Stagon, S. Environmentally benign metallization of material extrusion technology 3D printed acrylonitrile butadiene styrene parts using physical vapor deposition. Addit. Manuf. 2018, 22, 279–285. [Google Scholar] [CrossRef]

- Chlupova, S.; Kelar, J.; Slavicek, P. Changing the Surface Properties of ABS Plastic by Plasma. Plasma Phys. Technol. 2018, 4, 32–35. [Google Scholar] [CrossRef]

- Abenojar, J.; Torregrosa-Coque, R.; Martínez, M.A.; Martín-Martínez, J.M. Surface modifications of polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) copolymer by treatment with atmospheric plasma. Surf. Coat. Technol. 2009, 203, 2173–2180. [Google Scholar] [CrossRef]

- Martinez, M.A.; Abenojar, J.; Lopez de Armentia, S. Environmentally Friendly Plasma Activation of Acrylonitrile–Butadiene–Styrene and Polydimethylsiloxane Surfaces to Improve Paint Adhesion. Coatings 2018, 8, 428. [Google Scholar] [CrossRef] [Green Version]

- Brocherieux, A.; Dessaux, O.; Goudmand, P.; Gengembre, L.; Grimblot, J.; Brunel, M.; Lazzaroni, R. Characterization of nickel films deposited by cold remote nitrogen plasma on acrylonitrile-butadiene-styrene copolymer. Appl. Surf. Sci. 1995, 90, 47–58. [Google Scholar] [CrossRef]

- Kredl, J.; Drache, S.; Quade, A.; Polak, M.; Muller, S.; Peglow, S.; Hippler, R.; Kolb, J.F. DC Operated Air Plasma Jet for Antimicrobial Copper Coatings on Temperature Labile Surfaces. IEEE Trans. Plasma Sci. 2014, 42, 2756–2757. [Google Scholar] [CrossRef]

- Schutte, J.; Leveneur, J.; Yuan, X.; Potgieter, J. Evaluation of the effects of corona discharge plasma exposure proximity to Fused Deposition Modelling 3D Printed Acrylonitrile Butadiene Styrene. In Proceedings of the 25th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Stuttgart, Germany, 20–22 November 2018. [Google Scholar] [CrossRef]

- Alanis, A.; Hernández Valdésa, A.; María Guadalupea, N.-V.; Lopeza, R.; Mendozaa, R.; Mathew, A.P.; Díaz de León, R.; Valencia, L. Plasma surface-modification of cellulose nanocrystals: A green alternative towards mechanical reinforcement of ABS. RSC Adv. 2019, 9, 17417–17424. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Jarquín, S.; Moreno-Pedraza, A.; Guillén-Alonso, H.; Winkler, R. Template for 3D Printing a Low-Temperature Plasma Probe. Anal. Chem. 2016, 88, 6976–6980. [Google Scholar] [CrossRef]

- Dahle, S.; Žigon, J.; Gospodarič, B.; Zaplotnik, R.; Merhar, M.; Petrič, M. Open-source integrated plasma treatment and CNC machining system. Zenodo 2020. [Google Scholar] [CrossRef]

- Kariz, M.; Krapez, D.T.; Dahle, S.; Kuzman, M.K.; Šernek, M.; Žigon, J. Raw and analyted data for manuscript: Effect of sanding and plasma treatment of 3D printed parts on bonding to wood with PVAc adhesive. Zenodo 2021. [Google Scholar] [CrossRef]

- Baldan, A. Adhesion phenomena in bonded joints. Int. J. Adhes. Adhes. 2012, 38, 95–116. [Google Scholar] [CrossRef]

- Petrič, M.; Oven, P. Determination of wettability of wood and its significance in wood science and technology: A critical review. Rev. Adhes. Adhes. 2015, 3, 121–187. [Google Scholar] [CrossRef]

- Nussbaum, R.M. Natural surface inactivation of Scots pine and Norway spruce evaluated by contact anglemeasurements. Holz Als Roh-und Werkst. 1999, 57, 419–424. [Google Scholar] [CrossRef]

- De Meijer, M. A review of interfacial aspects in wood coatings: Wetting, surface energy, substrate penetration and adhesion. In Proceedings of the COST E18 Final Seminar, Paris, France, 26–27 April 2004. [Google Scholar]

- SIST EN 205:2016. Adhesives—Wood Adhesives for Non-Structural Applications—DETERMINATION of Tensile Shear Strength of Lap Joints; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- Le Duigou, A.; Castro, M.; Bevan, R.; Martin, N. 3D printing of wood fibre biocomposites: From mechanical to actuation functionality. Mater. Des. 2016, 96, 106–114. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Microstructure and mechanical performance of 3D printed wood-PLA/PHA using fused deposition modelling: Effect of printing temperature. Polymers 2019, 11, 1778. [Google Scholar] [CrossRef] [Green Version]

- Oztan, C.; Karkkainen, R.; Fittipaldi, M.; Nygren, G.; Roberson, L.; Lane, M.; Celik, E. Microstructure and mechanical properties of three dimensional-printed continuous fiber composites. J. Compos. Mater. 2019, 53, 271–280. [Google Scholar] [CrossRef]

- ISO. ISO 25178-2. Geometrical Product sPecifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- Khun, N.W.; Liu, E. Thermal, mechanical and tribological properties of polycarbonate/acrylonitrile-butadiene-styrene blends. J. Polym. Eng. 2013, 33, 535–543. [Google Scholar] [CrossRef]

- Shahid, M.; Hashim, S.A. Effect of surface roughness on the strength of cleavage joints. Int. J. Adhes. Adhes. 2002, 22, 235–244. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Marmur, A. Wetting on Hydrophobic Rough Surfaces: To Be Heterogeneous or Not To Be? Langmuir 2003, 19, 8343–8348. [Google Scholar] [CrossRef]

- Qiao, L.; Easteal, A.J.; Bolt, C.J.; Coveny, P.K.; Franich, R.A. Improvement of the water resistance of poly (vinyl acetate) emulsion wood adhesive. Pigment Resin Technol. 2002, 29, 152–158. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood—Chemistry, Ultrastructure, Reactions; Walter de Gruyter: Berlin, Germany, 1989; pp. 26–59. [Google Scholar]

- Follrich, J.; Müller, U.; Gindl, W. Effects of thermal modification on the adhesion between spruce wood (Picea abies Karst.) and a thermoplastic polymer. Holz als Roh-und Werkst. 2006, 64, 373–376. [Google Scholar] [CrossRef]

- Stehr, M.; Gardner, D.J.; Wålinder, M.E. Dynamic wettability of different machined wood surfaces. J. Adhes. 2001, 76, 185–200. [Google Scholar] [CrossRef]

- Galindo, S.; Urena-Nunez, F. Enhanced surface hydrophobicity of poly(lactic acid) by Co60 gamma ray irradiation. Rev. Mex. Fis. 2018, 64, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Sernek, M. Comparative Analysis of Inactivated Wood Surfaces. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 24 April 2002. [Google Scholar]

- Kuzman, M.K.; Ayrilmis, N.; Sernek, M.; Kariz, M. Effect of selected printing settings on viscoelastic behaviour of 3D printed polymers with and without wood. Mater. Res. Express 2019, 6, 105362. [Google Scholar] [CrossRef]

| NP | P | Sdr NP[%]-Sdr P[%] | ||||

|---|---|---|---|---|---|---|

| Sa [µm] | Sa [µm] | avg ∆ | STD | avg ∆ | STD | |

| PLA, NS | 14.85 | 13.87 | 0.99 | 0.48 | 45.83 | 29.95 |

| PLA, S | 14.66 | 14.48 | 0.18 | 1.24 | −1.37 | 34.72 |

| Wood-PLA, NS | 25.03 | 26.37 | −1.34 | 1.33 | −48.37 | 51.95 |

| Wood-PLA, S | 19.03 | 19.95 | −0.92 | 1.00 | −34.94 | 22.69 |

| ABS, NS | 26.23 | 28.15 | −1.92 | 3.32 | −42.28 | 32.43 |

| ABS, S | 17.10 | 16.89 | 0.21 | 2.35 | −37.32 | 23.88 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kariž, M.; Tomec, D.K.; Dahle, S.; Kuzman, M.K.; Šernek, M.; Žigon, J. Effect of Sanding and Plasma Treatment of 3D-Printed Parts on Bonding to Wood with PVAc Adhesive. Polymers 2021, 13, 1211. https://doi.org/10.3390/polym13081211

Kariž M, Tomec DK, Dahle S, Kuzman MK, Šernek M, Žigon J. Effect of Sanding and Plasma Treatment of 3D-Printed Parts on Bonding to Wood with PVAc Adhesive. Polymers. 2021; 13(8):1211. https://doi.org/10.3390/polym13081211

Chicago/Turabian StyleKariž, Mirko, Daša Krapež Tomec, Sebastian Dahle, Manja Kitek Kuzman, Milan Šernek, and Jure Žigon. 2021. "Effect of Sanding and Plasma Treatment of 3D-Printed Parts on Bonding to Wood with PVAc Adhesive" Polymers 13, no. 8: 1211. https://doi.org/10.3390/polym13081211