Oversized Planer Shavings for the Core Layer of Lightweight Particleboard

Abstract

:1. Introduction

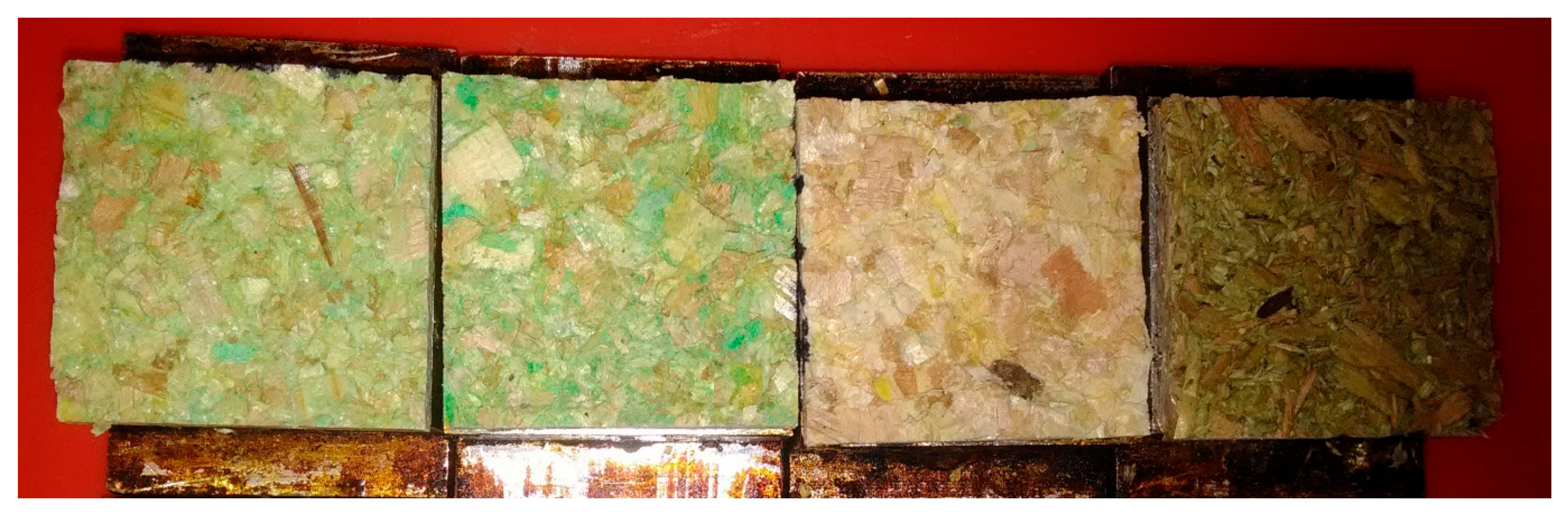

2. Materials and Methods

3. Results and Discussion

3.1. Raw Material Characterization

3.2. Thickness Swelling and Water Absorption

3.3. Mechanical Properties

3.3.1. Internal Bond

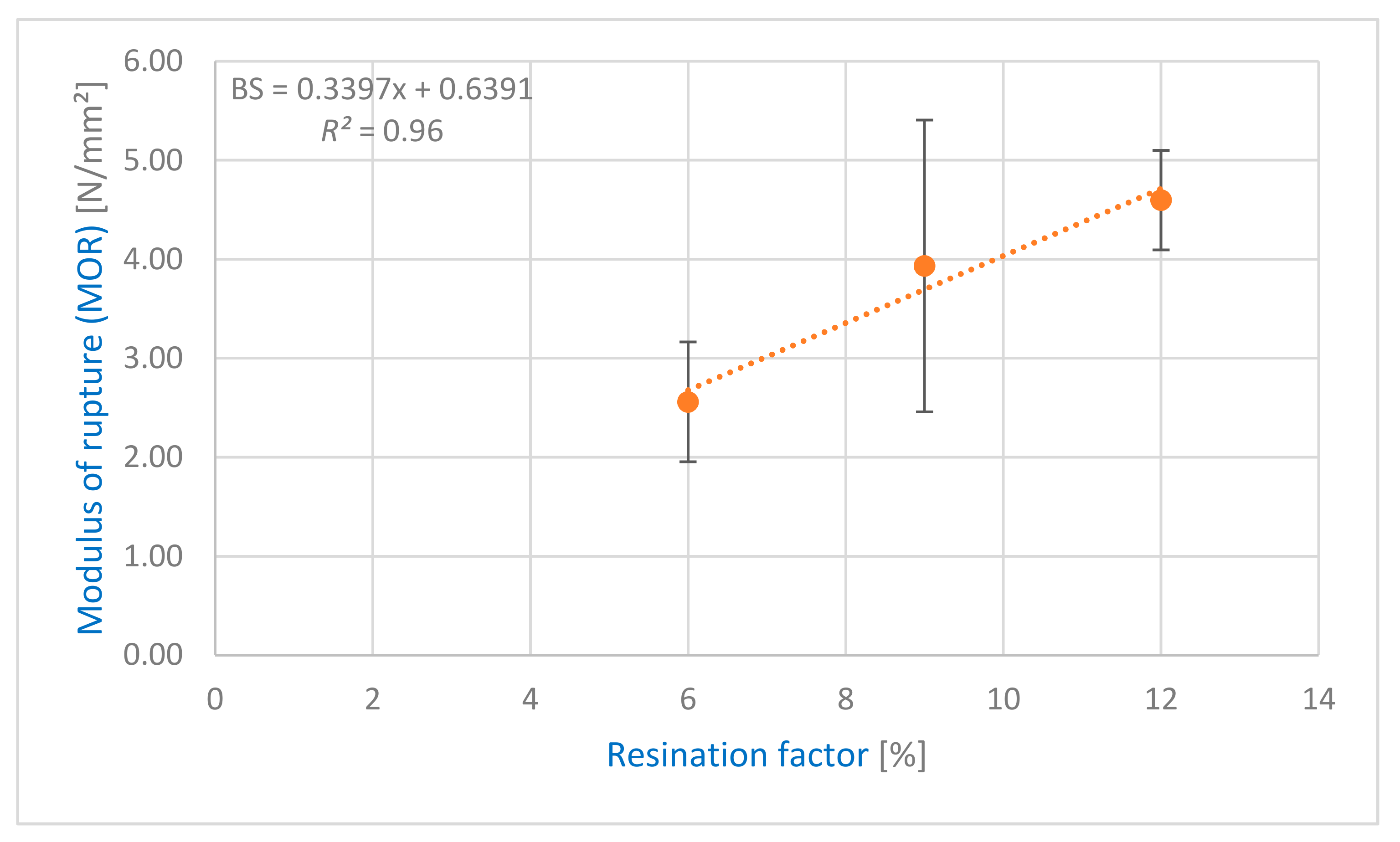

3.3.2. Modulus of Rupture and Modulus of Elasticity

3.4. Density Profile

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Paulitsch, M.; Barbu, M.C. Holzwerkstoffe der Moderne; DRW-Verlag Weinbrenner: Leinfelden-Echterdingen, Germany, 2015. [Google Scholar]

- Cetiner, I.; Shea, A.D. Wood waste as an alternative thermal insulation for buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Fagundes, H. Diagnosis of Lumber Production and Waste Generation from Wood Processing of Planted Forests in Rio Grande do Sul. Ph.D. Thesis, Federal University of Rio Grande do Sul, Porto Alegre, Brazil, 2003. [Google Scholar]

- Pásztory, Z.; Mohácsiné, I.R.; Börcsök, Z. Investigation of thermal insulation panels made of black locust tree bark. Constr. Build. Mater. 2017, 147, 733–735. [Google Scholar] [CrossRef]

- Mohammed, A.M.; Elnokaly, A.; Aly, A.M.M. Empirical investigation to explore potential gains from the amalgamation of Phase Changing Materials (PCMs) and wood shavings. Energy Built Environ. 2020. [Google Scholar] [CrossRef]

- Faria, D.L.; Lopes, T.A.; Mendes, L.M.; Guimarães, J.B., Jr. Valorization of wood shavings waste for the production of wood particulate composites. Matéria 2020, 25. [Google Scholar] [CrossRef]

- Harkin, M. Uses for Sawdust, Shavings and Waste Chips; Forest Products Laboratory: Madison, WI, USA, 1969. [Google Scholar]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Bederina, M.; Marmoret, L.; Mezreb, K.; Khenfer, M.M.; Bali, A.; Quéneudec, M. Effect of the addition of wood shavings on thermal conductivity of sand concretes: Experimental study and modelling. Constr. Build. Mater. 2007, 21, 662–668. [Google Scholar] [CrossRef]

- Taoukil, D.; el Bouardi, A.; Sick, F.; Mimet, A.; Ezbakhe, H.; Ajzoul, T. Moisture content influence on the thermal conductivity and diffusivity of wood–concrete composite. Constr. Build. Mater. 2013, 48, 104–115. [Google Scholar] [CrossRef]

- Lakrafli, H.; Tahiri, S.; Albizane, A.; Bouhria, M.; el Otmani, M.E. Experimental study of thermal conductivity of leather and carpentry wastes. Constr. Build. Mater. 2013, 48, 566–574. [Google Scholar] [CrossRef]

- Belhadj, B.; Bederina, M.; Montrelay, N.; Houessou, J.; Quéneudec, M. Effect of substitution of wood shavings by barley straws on the physico-mechanical properties of lightweight sand concrete. Constr. Build. Mater. 2014, 66, 247–258. [Google Scholar] [CrossRef]

- Muller, R.; Feiden, A.; Lucio, L.T.; Marques, F.S.; Mari, A.; Gerke, L.V. Influence of wood shavings bed material for dairy cattle on biogas methane content. J. Food Agric. Environ. 2015, 13, 210–212. [Google Scholar]

- Sotiropoulou, A.; Gavela, S.; Nikoloutsopoulos, N.; Passa, D.; Papadakos, G. Experimental study of wood shaving addition in mortar and statistical modeling on selected effects. J. Mech. Behav. Mater. 2017, 26, 55–63. [Google Scholar] [CrossRef]

- Ahn, G.C.; Jang, S.S.; Kwak, H.J.; Lee, S.R.; Oh, Y.K.; Park, K.K. Characteristics of Rice Hulls, Sawdust, Wood Shavings and Mixture of Sawdust and Wood Shavings, and Their Usefulness According to the Pen Location for Hanwoo Cattle. Asian Australas. J. Anim. Sci. 2016, 29, 599–605. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Daian, G.; Ozarska, B. Wood waste management practices and strategies to increase sustainability standards in the Australian wooden furniture manufacturing sector. J. Clean. Prod. 2009, 17, 1594–1602. [Google Scholar] [CrossRef]

- Renström, R.; Lindquist, L.; Wikström, F. Study of the environmental impact of wood fuel processing. In Proceedings of the 14th International Drying Symposium, Sao Paolo, Brasil, 22–25 August 2004. [Google Scholar]

- Peter, R. Skiing in sawdust. For. Prod. J. 1965, 15, 30. [Google Scholar]

- Viforr, S.; Salmén, L. From wood shavings to mechanical pulp—A new raw material? Nord. Pulp Pap. Res. J. 2005, 20, 418–422. [Google Scholar] [CrossRef]

- Kang, T.; Soong, G.; Olson, J.; Martinez, D.M. Low Consistency Refining of Wood Shavings; Pulp and Paper Canada: Montréal, QC, Canada, 2009; Volume 111, pp. 317–321. [Google Scholar]

- Fjellström, H.; Engstrand, P.; Granfeldt, T.; Logenius, L. Predicting CTMP bleachability using wood shavings. In ISWFPC, e2mp-Energy Efficient Mechanical Pulping Project 2011–2017; ISWFPC: Tianjin, China, 2011; pp. 613–616. [Google Scholar]

- Antov, P.; Savov, V.; Neykov, N. Influence of the composition on the exploitation properties of combined medium density fibreboards manufactured with coniferous wood residues. Eur. Mech. Sci. J. 2018, 2, 140–145. [Google Scholar]

- Ibrahim, A.; Olayimika, S.O.; Oyero, J.O.; Yisa, T.A.; Ibrahim, S.U.; Yakubu, U.P. A study of optimal utilization of wood resource through alternative use of wood waste in fish smoking. Int. J. Fish. Aquac. 2015, 7, 127–131. [Google Scholar] [CrossRef] [Green Version]

- Rowell, R.M. Advances in Biorefineries: Biomass and Waste Supply Chain Exploitation. The Use of Biomass to Produce Bio-Based Composites and Building Materials; Woodhead Pub: Cambridge, UK, 2014. [Google Scholar]

- Yel, H.; Dönmez-Cavdar, A.; Kalaycioĝlu, H.; Aras, U. Influence of Planer Shavings and Waste Particleboards Usage in Core layer on Physical and Mechanical Properties of Three-layer Particleboards. J. For. Fac. Kast. Univ. 2014, 14, 215–221. [Google Scholar]

- Lopes, T.A.; Vilela, A.P.; Silva, D.W.; Mendes, R.F.; Mendes, L.M. High density particleboards produced with wood shavings. Sci. For. For. Sci. 2016, 44, 623–628. [Google Scholar] [CrossRef]

- Nemli, G.; Hızıroğlu, S.; Usta, M.; Serin, Z.; Ozdemir, T.; Kalaycıoğlu, H. Effect of Residue Type and Tannin Content on Properties of Particleboard Manufactured from Black Locust. For. Prod. J. 2004, 54, 36–40. [Google Scholar]

- Nemli, G.; Aydın, A. Evaluation of the physical and mechanical properties of particleboard made from the needle litter of Pinus pinaster Ait. Ind. Crop. Prod. 2007, 26, 252–258. [Google Scholar] [CrossRef]

- Bektas, I.; Guler, C.; Kalaycioğlu, H.; Mengeloglu, F.; Nacar, M. The Manufacture of Particleboards using Sunflower Stalks (helianthus annuus L.) and Poplar Wood (populus alba L). J. Compos. Mater. 2005, 39, 467–473. [Google Scholar] [CrossRef]

- Cosereanu, C.; Brenci, L.; Zeleniuc, O.; Fotin, A. Effect of particle size and geometry on the performance of single-layer and three-layer particleboard made from sunflower seed husks. Bioresources 2015, 10, 1127–1136. [Google Scholar] [CrossRef] [Green Version]

- Gürü, M.; Tekeli, S.; Bilici, İ. Manufacturing of urea-formaldehyde-based composite particleboard from almond shell. Mater. Des. 2006, 27, 1148–1151. [Google Scholar] [CrossRef]

- Barbu, M.C.; Montecuccoli, Z.; Förg, J.; Barbeck, U.; Klímek, P.; Petutschnigg, A.; Tudor, E.M. Potential of Brewer’s Spent Grain as a Potential Replacement of Wood in pMDI, UF or MUF Bonded Particleboard. Polymers 2021, 13, 319. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Majidi, R.; Arsalan, M.G.; Moradiyan, A.; Militz, H.; Ntalos, G.; Papadopoulos, A.N. Penetration of Different Liquids in Wood-Based Composites: The Effect of Adsorption Energy. Forests 2021, 12, 63. [Google Scholar] [CrossRef]

- Barbu, M.C.; Sepperer, T.; Tudor, E.M.; Petutschnigg, A. Walnut and Hazelnut Shells: Untapped Industrial Resources and Their Suitability in Lignocellulosic Composites. Appl. Sci. 2020, 10, 6340. [Google Scholar] [CrossRef]

- Iždinský, J.; Vidholdová, Z.; Reinprecht, L. Particleboards from Recycled Wood. Forests 2020, 11, 1166. [Google Scholar] [CrossRef]

- Antov, P.; Mantanis, G.I.; Savov, V. Development of Wood Composites from Recycled Fibres Bonded with Magnesium Lignosulfonate. Forests 2020, 11, 613. [Google Scholar] [CrossRef]

- Rammou, E.; Mitani, A.; Ntalos, G.; Koutsianitis, D.; Taghiyari, H.R.; Papadopoulos, A.N. The Potential Use of Seaweed (Posidonia oceanica) as an Alternative Lignocellulosic Raw Material for Wood Composites Manufacture. Coatings 2021, 11, 69. [Google Scholar] [CrossRef]

- Papadopoulos, A.N. Advances in Wood Composites. Polymers 2020, 12, 48. [Google Scholar] [CrossRef] [Green Version]

- Papadopoulos, A.N.; Taghiyari, H.R. Innovative Wood Surface Treatments Based on Nanotechnology. Coatings 2019, 9, 866. [Google Scholar] [CrossRef] [Green Version]

- Pizzi, A.; Papadopoulos, A.N.; Policardi, F. Wood composites and their polymer binders. Polymers 2020, 12, 1115. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 319:2005—Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- European Committee for Standardization. EN 310:2005—Wood Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- European Committee for Standardization. EN317:2005—Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- European Committee for Standardization. EN 326-1:2005—Wood Based Panels-Sampling, Cutting and Inspection—Part 1: Sampling and Cutting of Test Pieces and Expression of Test Results; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- European Committee for Standardization. EN 322:2005—Wood-Based Panels; Determination of Moisture Content; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- Bufalino, L.; Albino, V.C.S.; de Sa, V.A.; Correa, A.A.R.; Mendes, L.M.; Almeida, N.A. Particleboards Made from Australian Red Cedar > Processing Variables and Evaluation of Mixed-Species. J. Trop. For. Sci. 2012, 24, 162–172. [Google Scholar]

- Maloney, T.M. Modern Particleboard and Dry-Process Fiberboard Manufacturing; Miller Freeman: San Francisco, CA, USA, 1992. [Google Scholar]

- Antov, P.; Savov, V.; Neykov, N. Sustainable bio-based adhesives for eco-friendly wood composites. A review. Wood Res. 2020, 65, 51–62. [Google Scholar] [CrossRef]

- Kulman, S.; Boiko, L.; Gurová, D.H.; Sedliačik, J. The effect of temperature and moisture changes on modulus of elasticity and modulus of rupture of particleboard. Acta Facultatis Xylologiae Zvolen 2019, 61, 43–52. [Google Scholar]

| Particleboard | Material Type | Density (kg/m3) | Thickness (mm) | Resination Factor (%) | Adhesive Application | Mixer Type |

|---|---|---|---|---|---|---|

| C12P_M | PS | 475 | 10 | 12 | pouring | Ploughshare |

| C12S_M | PS | 475 | 10 | 12 | spraying | Ploughshare |

| C12S_D | PS | 475 | 10 | 12 | spraying | Drum |

| 9S_M | PS | 475 | 10 | 9 | spraying | Ploughshare |

| 6S_M | PS | 475 | 10 | 6 | spraying | Ploughshare |

| Reference | WP * | 475 | 10 | 12 | spraying | Ploughshare |

| Particleboard Type | Thickness Swelling | Water Absorption | MC | Density |

|---|---|---|---|---|

| (%) | (%) | [%] | (kg/m3) | |

| C12P_M | 17 a,b,c,d (1.8) | 51 a,b (5) | 8.1 a (0.1) | 472 c (19) |

| C12S_M | 17 a,b,c,d (2.5) | 53 c (5) | 8.0 a (0.1) | 475 c (19) |

| C12S_D | 18 a,b,c,d (2) | 55 c (4) | 8.0 a (0.1) | 442 a (25) |

| 9S_M | 16 a,b,c,d (3) | 47 a (6) | 9.0 a (0.1) | 501 d (17) |

| 6S_M | 19 a,b,c,d (2) | 54 c (4) | 9.1 a (0.2) | 446 a (30) |

| Reference | 26 e (2.6) | 60 d (7) | 8.0 a (0.1) | 455 b (17) |

| Particleboard Type | IB | MOR | MOE |

|---|---|---|---|

| (N/mm2) | (N/mm2) | (N/mm2) | |

| C12P_M | 0.10 b (0.02) | 4.47 d (0.74) | 593 c,d (134) |

| C12S_M | 0.15 c (0.04) | 4.60 d (0.50) | 653 e (91) |

| C12S_D | 0.04 a (0.01) | 2.63 a,b (0.40) | 259 a (50) |

| 9S_M | 0.48 e (0.16) | 3.93 c (1.47) | 574 c (188) |

| 6S_M | 0.34 d (0.15) | 2.56 a,b (0.61) | 418 b (65) |

| Reference | 0.06 a (0.02) | 2.69 a,b (1.34) | 546 c (208) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gößwald, J.; Barbu, M.C.; Petutschnigg, A.; Krišťák, Ľ.; Tudor, E.M. Oversized Planer Shavings for the Core Layer of Lightweight Particleboard. Polymers 2021, 13, 1125. https://doi.org/10.3390/polym13071125

Gößwald J, Barbu MC, Petutschnigg A, Krišťák Ľ, Tudor EM. Oversized Planer Shavings for the Core Layer of Lightweight Particleboard. Polymers. 2021; 13(7):1125. https://doi.org/10.3390/polym13071125

Chicago/Turabian StyleGößwald, Jakob, Marius Cătălin Barbu, Alexander Petutschnigg, Ľuboš Krišťák, and Eugenia Mariana Tudor. 2021. "Oversized Planer Shavings for the Core Layer of Lightweight Particleboard" Polymers 13, no. 7: 1125. https://doi.org/10.3390/polym13071125