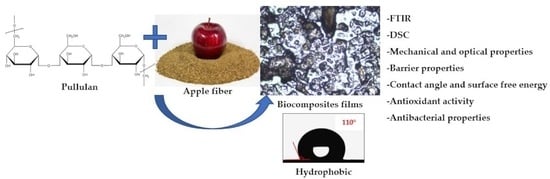

Pullulan–Apple Fiber Biocomposite Films: Optical, Mechanical, Barrier, Antioxidant and Antibacterial Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Biocomposite Films Preparation

2.3. Surface Morphology of the Films

2.4. Infrared Spectra

2.5. Thermal Analysis

2.6. Grammage, Thickness, Mechanical, and Optical Properties

2.7. Barrier Properties

2.7.1. Oil Permeability

2.7.2. Water Vapor Permeability

2.8. Contact Angle and Surface Free Energy

2.9. Antioxidant Activity

2.9.1. DPPH Free Radical Scavenging Assay

2.9.2. β-Carotene Bleaching Test

2.10. Antibacterial Properties

2.11. Biodegradability

2.12. Statistical Analysis

3. Results and Discussion

3.1. Appearance and Surface Morphology of the Films

3.2. FTIR and DSC Assays

3.3. Grammage, Thickness, Mechanical, and Optical Properties

3.4. Barrier Properties

3.5. Contact Angles and Surface Free Energy

3.6. Antioxidant Activity

3.7. Antibacterial Properties

3.8. Biodegradability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chiellini, E.; Cinelli, P.; Imam, S.H.; Mao, L. Composite films based on biorelated agro-industrial waste and poly(vinyl alcohol). Preparation and mechanical properties characterization. Biomacromolecules 2001, 2, 1029–1037. [Google Scholar] [CrossRef] [PubMed]

- Shin, S.H.; Kim, S.J.; Lee, S.H.; Park, K.M.; Han, J. Apple Peel and Carboxymethylcellulose-Based Nanocomposite Films Containing Different Nanoclays. J. Food Sci. 2014, 79, E342–E353. [Google Scholar] [CrossRef] [PubMed]

- Gustafsson, J.; Landberg, M.; Bátori, V.; Åkesson, D.; Taherzadeh, M.J.; Zamani, A. Development of bio-based films and 3D objects from apple pomace. Polymers 2019, 11, 289. [Google Scholar] [CrossRef] [Green Version]

- Choi, I.; Chang, Y.; Shin, S.H.; Joo, E.; Song, H.J.; Eom, H.; Han, J. Development of biopolymer composite films using a microfluidization technique for carboxymethylcellulose and apple skin particles. Int. J. Mol. Sci. 2017, 18, 1278. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ravishankar, S.; Zhu, L.; Olsen, C.W.; McHugh, T.H.; Friedman, M. Edible apple film wraps containing plant antimicrobials inactivate foodborne pathogens on meat and poultry products. J. Food Sci. 2009, 74, M440–M445. [Google Scholar] [CrossRef]

- Mild, R.M.; Joens, L.A.; Friedman, M.; Olsen, C.W.; McHugh, T.H.; Law, B.; Ravishankar, S. Antimicrobial edible apple films inactivate antibiotic resistant and susceptible Campylobacter jejuni strains on chicken breast. J. Food Sci. 2011, 76, M163–M168. [Google Scholar] [CrossRef] [PubMed]

- Du, W.X.; Avena-Bustillos, R.J.; Woods, R.; Breksa, A.P.; McHugh, T.H.; Friedman, M.; Levin, C.E.; Mandrell, R. Sensory evaluation of baked chicken wrapped with antimicrobial apple and tomato edible films formulated with cinnamaldehyde and carvacrol. J. Agric. Food Chem. 2012, 60, 7799–7804. [Google Scholar] [CrossRef] [PubMed]

- Moreira, M.R.; Cassani, L.; Martín-Belloso, O.; Soliva-Fortuny, R. Effects of polysaccharide-based edible coatings enriched with dietary fiber on quality attributes of fresh-cut apples. J. Food Sci. Technol. 2015, 52, 7795–7805. [Google Scholar] [CrossRef] [Green Version]

- Hassannia-Kolaee, M.; Khodaiyan, F.; Pourahmad, R.; Shahabi-Ghahfarrokhi, I. Development of ecofriendly bionanocomposite: Whey protein isolate/pullulan films with nano-SiO2. Int. J. Biol. Macromol. 2016, 86, 139–144. [Google Scholar] [CrossRef] [PubMed]

- Niu, B.; Shao, P.; Chen, H.; Sun, P. Structural and physiochemical characterization of novel hydrophobic packaging films based on pullulan derivatives for fruits preservation. Carbohydr. Polym. 2019, 208, 276–284. [Google Scholar] [CrossRef]

- Tong, Q.; Xiao, Q.; Lim, L.T. Effects of glycerol, sorbitol, xylitol and fructose plasticisers on mechanical and moisture barrier properties of pullulan-alginate-carboxymethylcellulose blend films. Int. J. Food Sci. Technol. 2013, 48, 870–878. [Google Scholar] [CrossRef]

- Luís, Â.; Ramos, A.; Domingues, F. Pullulan Films Containing Rockrose Essential Oil for Potential Food Packaging Applications. Antibiotics 2020, 9, 681. [Google Scholar] [CrossRef] [PubMed]

- Luís, Â.; Gallardo, E.; Ramos, A.; Domingues, F. Design and characterization of bioactive bilayer films: Release kinetics of isopropyl palmitate. Antibiotics 2020, 9, 443. [Google Scholar] [CrossRef] [PubMed]

- Yan, Q.; Hou, H.; Guo, P.; Dong, H. Effects of extrusion and glycerol content on properties of oxidized and acetylated corn starch-based films. Carbohydr. Polym. 2012, 87, 707–712. [Google Scholar] [CrossRef]

- Luís, Â.; Domingues, F.; Ramos, A. Production of Hydrophobic Zein-Based Films Bioinspired by The Lotus Leaf Surface: Characterization and Bioactive Properties. Microorganisms 2019, 7, 267. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luís, Â.; Silva, F.; Sousa, S.; Duarte, A.P.; Domingues, F. Antistaphylococcal and biofilm inhibitory activities of gallic, caffeic, and chlorogenic acids. Biofouling 2014, 30, 69–79. [Google Scholar] [CrossRef] [PubMed]

- Good, R.; Van Oss, C. The modern theory of contact angles and the hydrogen bond components of surface energies. In Modern Approaches to Wettability Applications; Schrader, M., Loeb, G., Eds.; Plenum Press: New York, NY, USA, 1991; pp. 1–27. [Google Scholar]

- Silva, Â.; Duarte, A.; Sousa, S.; Ramos, A.; Domingues, F.C. Characterization and antimicrobial activity of cellulose derivatives films incorporated with a resveratrol inclusion complex. LWT–Food Sci. Technol. 2016, 73, 481–489. [Google Scholar] [CrossRef]

- Luís, Â.; Pereira, L.; Domingues, F.; Ramos, A. Development of a carboxymethyl xylan film containing licorice essential oil with antioxidant properties to inhibit the growth of foodborne pathogens. LWT-Food Sci. Technol. 2019, 111, 218–225. [Google Scholar] [CrossRef]

- Kumar, D.; Kumar, P.; Pandey, J. Binary grafted chitosan film: Synthesis, characterization, antibacterial activity and prospects for food packaging. Int. J. Biol. Macromol. 2018, 115, 341–348. [Google Scholar] [CrossRef] [PubMed]

- Hezarkhani, M.; Yilmaz, E. Pullulan modification via poly(N-vinylimidazole) grafting. Int. J. Biol. Macromol. 2019, 123, 149–156. [Google Scholar] [CrossRef]

- Ramos, Ó.L.; Fernandes, J.C.; Silva, S.I.; Pintado, M.E.; Malcata, F.X. Edible Films and Coatings from Whey Proteins: A Review on Formulation, and on Mechanical and Bioactive Properties. Crit. Rev. Food Sci. Nutr. 2012, 52, 533–552. [Google Scholar] [CrossRef] [PubMed]

- Mahmud, S.; Hasan, K.M.F.; Jahid, M.A.; Mohiuddin, K.; Zhang, R.; Zhu, J. Comprehensive review on plant fiber-reinforced polymeric biocomposites. J. Mater. Sci. 2021, 56, 7231–7264. [Google Scholar] [CrossRef]

- Chu, Y.; Xu, T.; Gao, C.; Liu, X.; Zhang, N.; Feng, X.; Liu, X.; Shen, X.; Tang, X. Evaluations of physicochemical and biological properties of pullulan-based films incorporated with cinnamon essential oil and Tween 80. Int. J. Biol. Macromol. 2019, 122, 388–394. [Google Scholar] [CrossRef]

- Díaz, O.; Ferreiro, T.; Rodríguez-Otero, J.L.; Cobos, Á. Characterization of chickpea (Cicer arietinum L.) flour films: Effects of pH and plasticizer concentration. Int. J. Mol. Sci. 2019, 20, 1246. [Google Scholar] [CrossRef] [Green Version]

- Liang, J.; Yan, H.; Zhang, J.; Dai, W.; Gao, X.; Zhou, Y.; Wan, X.; Puligundla, P. Preparation and characterization of antioxidant edible chitosan films incorporated with epigallocatechin gallate nanocapsules. Carbohydr. Polym. 2017, 171, 300–306. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Shao, X.; Jiang, R.; Shen, Z.; Ma, Z. Mechanical and barrier properties of corn distarch phosphate-zein bilayer films by thermocompression. Int. J. Biol. Macromol. 2018, 118, 2076–2081. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Ali, F.; Dong, S.; Yin, Z.; Li, S.; Chen, Y. Preparation, characterization and functional evaluation of chitosan-based films with zein coatings produced by cold plasma. Carbohydr. Polym. 2018, 202, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Dong, F.; Padua, G.W.; Wang, Y. Controlled formation of hydrophobic surfaces by self-assembly of an amphiphilic natural protein from aqueous solutions. Soft Matter 2013, 9, 5933–5941. [Google Scholar] [CrossRef]

- Wang, G.; Guo, Z.; Liu, W. Interfacial effects of superhydrophobic plant surfaces: A Review. J. Bionic Eng. 2014, 11, 325–345. [Google Scholar] [CrossRef]

- Song, K.; Lee, J.; Choi, S.O.; Kim, J. Interaction of surface energy components between solid and liquid on wettability, and its application to textile anti-wetting finish. Polymers 2019, 11, 498. [Google Scholar] [CrossRef] [Green Version]

- Reis, S.F.; Rai, D.K.; Abu-Ghannam, N. Apple pomace as a potential ingredient for the development of new functional foods. Int. J. Food Sci. Technol. 2014, 49, 1743–1750. [Google Scholar] [CrossRef]

- Serra, A.T.; Matias, A.A.; Frade, R.F.M.; Duarte, R.O.; Feliciano, R.P.; Bronze, M.R.; Figueira, M.E.; Carvalho, A.; Duarte, C.M.M. Characterization of traditional and exotic apple varieties from Portugal. Part 2–Antioxidant and antiproliferative activities. J. Funct. Foods 2010, 2, 46–53. [Google Scholar] [CrossRef]

- Yadav, M.; Liu, Y.; Chiu, F. Fabrication of Cellulose Nanocrystal/Silver/Alginate Bionanocomposite Films with Enhanced Mechanical and Barrier Properties for Food Packaging Application. Nanomaterials 2019, 9, 1523. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nouraddini, M.; Esmaiili, M.; Mohtarami, F. Development and characterization of edible films based on eggplant flour and corn starch. Int. J. Biol. Macromol. 2018, 120, 1639–1645. [Google Scholar] [CrossRef] [PubMed]

| Properties 1 | Pullulan | Pullulan and Apple Fiber | p-Value | |

|---|---|---|---|---|

| Grammage (g/m2) | 96.18 ± 4.63 | 131.52 ± 2.78 | 0.001 * | |

| Thickness (µm) | 35.59 ± 6.54 | 155.87 ± 11.35 | <0.001 * | |

| Mechanical | Peak Elongation (%) | 221.51 ± 39.07 | 2.81 ± 0.13 | 0.010 * |

| Tensile Index (N m/g) | 0.47 ± 0.06 | 4.18 ± 0.45 | 0.004 * | |

| Tensile Strength (N/m) | 42.05 ± 4.81 | 550.33 ± 57.37 | 0.004 * | |

| Elastic Modulus (MPa) | 4.51 ± 0.70 | 286.39 ± 44.12 | 0.008 * | |

| Optical | L* (lightness) | 28.77 ± 2.08 | 39.30 ± 0.20 | 0.012 * |

| a* (redness) | −0.12 ± 0.01 | 0.39 ± 0.07 | 0.020 * | |

| b* (yellowness) | −1.55 ± 0.14 | 5.93 ± 0.45 | 0.002 * | |

| Transparency (%) | 94.13 ± 0.80 | 87.98 ± 0.24 | 0.003 * | |

| Permeability 1 | Pullulan | Pullulan and Apple Fiber | p-Value | |

|---|---|---|---|---|

| Water vapor | WVTR (g/m2 day) | 55.50 ± 1.76 | 41.16 ± 7.06 | 0.065 |

| WVP (g/Pa day m) | 1.49 × 10-6 ± 4.75 × 10−8 | 4.85 × 10-6 ± 8.32 × 10−7 | 0.020 * | |

| Oil | OP (g mm/m2 day) | 3.43 ± 0.08 | 124.21 ± 9.55 | 0.002 * |

| Properties 1 | Pullulan | Pullulan and Apple Fiber | p-Value | ||

|---|---|---|---|---|---|

| Lower Side a | Upper Side b | Lower Side (Smooth) c | Upper Side (Rough) d | ||

| Water contact angle (°) | 66.17 ± 1.79 | 64.99 ± 3.11 | 99.69 ± 2.11 | 109.75 ± 4.83 | <0.001 ac* <0.001 bd* |

| Diiodomethane contact angle (°) | 31.42 ± 1.32 | 37.05 ± 0.43 | 44.72 ± 1.87 | 41.82 ± 2.02 | 0.001 ac* 0.049 bd* |

| Ethylene glycol contact angle (°) | 59.06 ± 1.95 | 49.93 ± 0.78 | 44.72 ± 1.87 | 41.82 ± 2.02 | 0.001 ac* 0.011 bd* |

| Total surface free energy, ɤT (mN/m) | 40.92 ± 2.04 | 43.10 ± 2.15 | 42.43 ± 1.39 | 41.33 ± 0.52 | 0.361 ac 0.288 bd |

| Polar component, ɤP (mN/m) | 27.62 ± 1.37 | 31.25 ± 1.55 | 1.13 ± 0.33 | 2.95 ± 0.43 | 0.001 ac* <0.001bd* |

| Dispersive component, ɤD (mN/m) | 13.28 ± 0.65 | 11.84 ± 0.58 | 41.29 ± 1.37 | 38.38 ± 0.29 | <0.001ac* <0.001 bd* |

| Properties 1 | Pullulan | Pullulan and Apple Fiber | p-Value | |

|---|---|---|---|---|

| β-carotene bleaching test | Inhibition (%) | 0.00 ± 0.00 | 0.96 ± 0.06 | 0.001 * |

| Biodegradability | Weight loss (%) | 100.00 ± 0.00 | 100.00 ± 0.00 | >0.05 |

| Diameters of Inhibition Zones 1 | Pullulan | Pullulan and Apple Fiber | p-Value | |

|---|---|---|---|---|

| Lower Side (Smooth) | Upper Side (Rough) | |||

| Staphylococcus aureus ATCC 25923 | 0.00 ± 0.00 (−) | 6.00 ± 0.00 (+) | 6.00 ± 0.00 (+) | <0.001 * |

| Listeria monocytogenes LMG 16779 | 0.00 ± 0.00 (−) | 6.00 ± 0.00 (+) | 6.00 ± 0.00 (+) | <0.001 * |

| Enterococcus faecalis ATCC 29212 | 0.00 ± 0.00 (−) | 6.00 ± 0.00 (+) | 6.00 ± 0.00 (+) | <0.001 * |

| Bacillus cereus ATCC 11778 | 0.00 ± 0.00 (−) | 6.00 ± 0.00 (+) | 6.00 ± 0.00 (+) | <0.001 * |

| Salmonella typhimurium ATCC 13311 | 0.00 ± 0.00 (−) | 6.00 ± 0.00 (+) | 6.00 ± 0.00 (+) | <0.001 * |

| Escherichia coli ATCC 25922 | 0.00 ± 0.00 (−) | 6.00 ± 0.00 (+) | 6.00 ± 0.00 (+) | <0.001 * |

| Pseudomonas aeruginosa ATCC 27853 | 0.00 ± 0.00 (−) | 6.00 ± 0.00 (+) | 6.00 ± 0.00 (+) | <0.001 * |

| Pullulan | Pullulan and Apple Fiber | |

|---|---|---|

| Lower Side (Smooth) | Upper Side (Rough) | |

| Staphylococcus aureus ATCC 25923 | ||

|  |  |

| Listeria monocytogenes LMG 16779 | ||

|  |  |

| Enterococcus faecalis ATCC 29212 | ||

|  |  |

| Bacillus cereus ATCC 11778 | ||

|  |  |

| Salmonella Typhimurium ATCC 13311 | ||

|  |  |

| Escherichia coli ATCC 25922 | ||

|  |  |

| Pseudomonas aeruginosa ATCC 27853 | ||

|  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luís, Â.; Ramos, A.; Domingues, F. Pullulan–Apple Fiber Biocomposite Films: Optical, Mechanical, Barrier, Antioxidant and Antibacterial Properties. Polymers 2021, 13, 870. https://doi.org/10.3390/polym13060870

Luís Â, Ramos A, Domingues F. Pullulan–Apple Fiber Biocomposite Films: Optical, Mechanical, Barrier, Antioxidant and Antibacterial Properties. Polymers. 2021; 13(6):870. https://doi.org/10.3390/polym13060870

Chicago/Turabian StyleLuís, Ângelo, Ana Ramos, and Fernanda Domingues. 2021. "Pullulan–Apple Fiber Biocomposite Films: Optical, Mechanical, Barrier, Antioxidant and Antibacterial Properties" Polymers 13, no. 6: 870. https://doi.org/10.3390/polym13060870