Development and Characterization of Field Structured Magnetic Composites

Abstract

:1. Introduction

2. Materials

3. Experimental Methods

3.1. Dual-Cure Resin Formulation Preparation and Testing

3.2. Fabrication of Magnetic Field Structured Composites Using Polymer Casting and AM

3.3. Characterization of Magnetic Polymer Composites

4. Results and Discussion

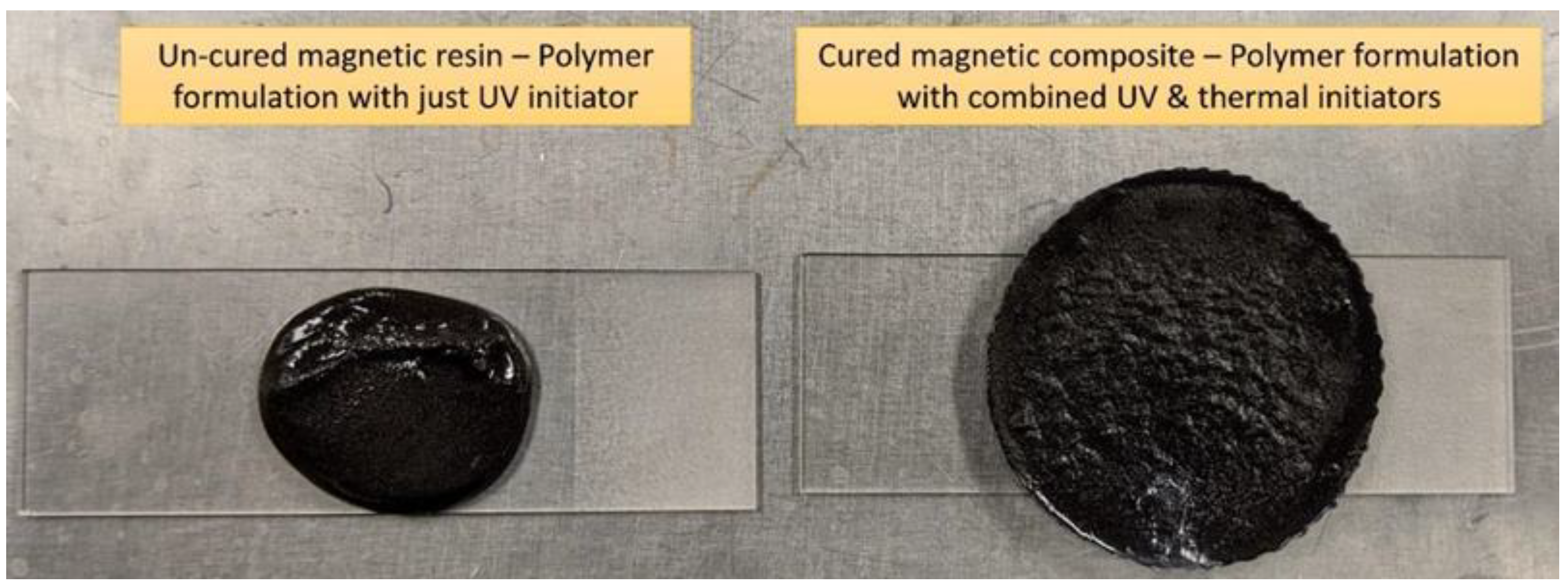

4.1. Evaluation of Dual-Cure Resin Formulation

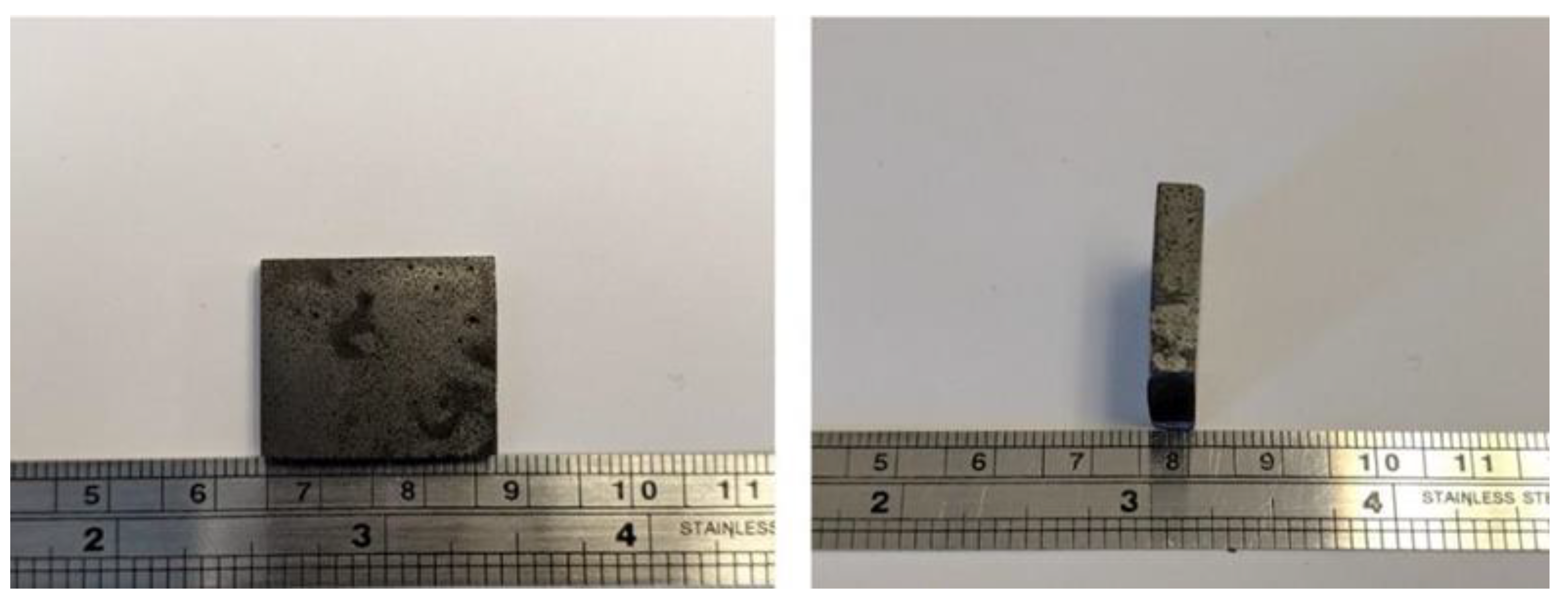

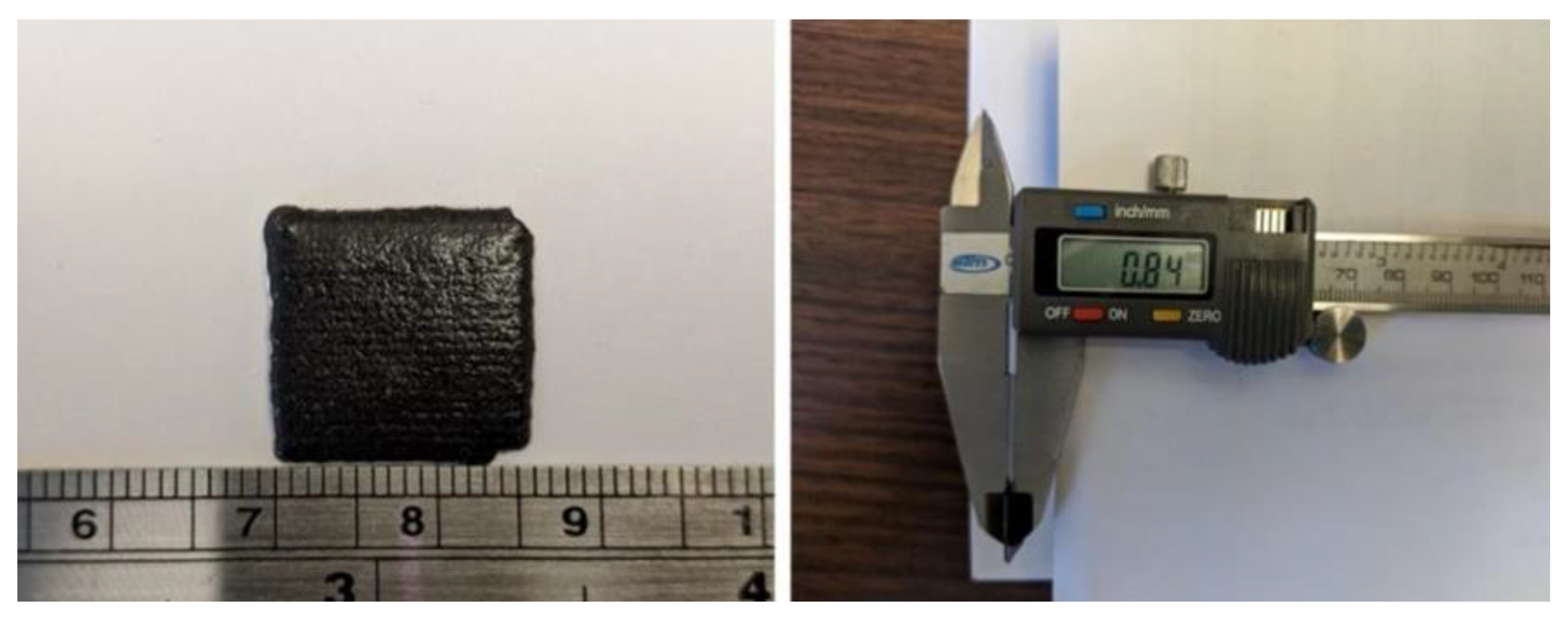

4.2. Manufacturing Field Structured Magnetic Composites Using Polymer Casting and Additive Manufacturing

4.3. Characterization of Magnetic Polymer Composites

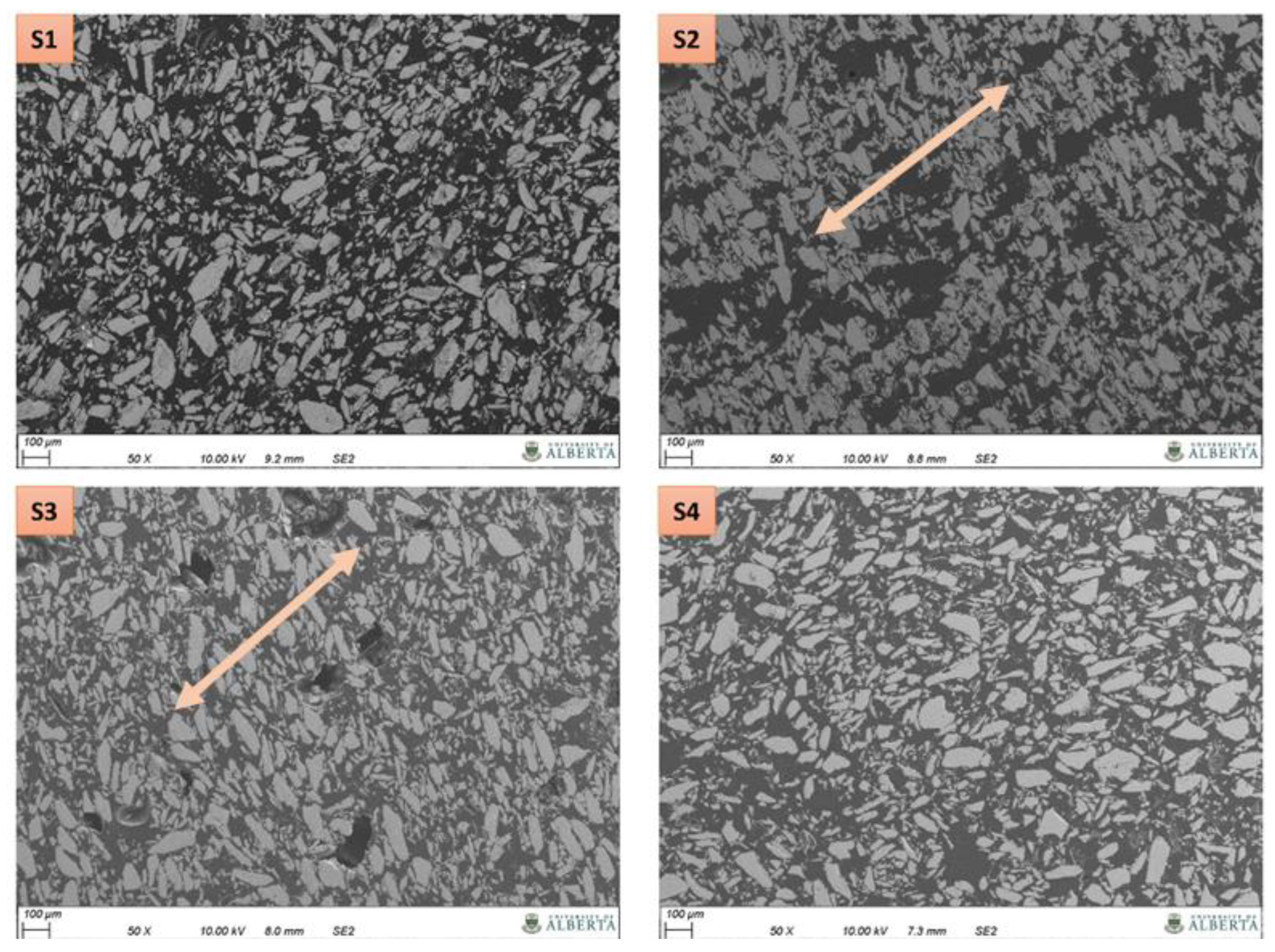

4.3.1. Scanning Electron Microscopy

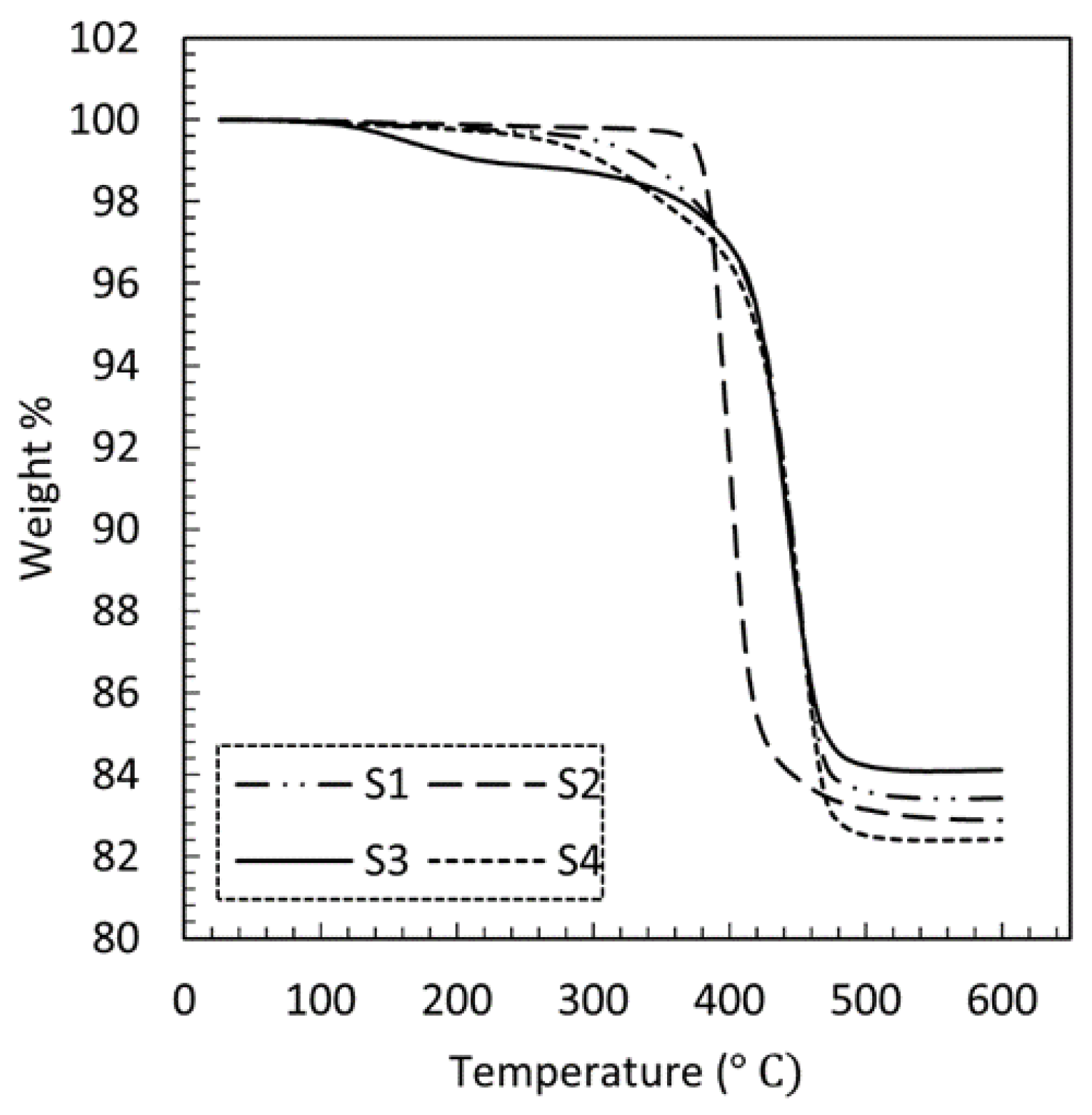

4.3.2. Thermogravimetric Analysis

4.3.3. X-ray Diffraction Analysis

4.3.4. FTIR Spectroscopy

4.3.5. Magnetic Characterization

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Najgebauer, M.; Szczygłowski, J.; Ślusarek, B.; Przybylski, M.; Kapłon, A.; Rolek, J. Magnetic Composites in Electric Motors. In Analysis and Simulation of Electrical and Computer Systems; Mazur, D., Gołębiowski, M., Korkosz, M., Eds.; Springer International Publishing: New York, NY, USA, 2018; pp. 15–28. [Google Scholar] [CrossRef]

- Coey, J.M.D. Permanent Magnets: Plugging the Gap. Scr. Mater. 2012, 67, 524–529. [Google Scholar] [CrossRef]

- Brown, D.; Ma, B.M.; Chen, Z. Developments in the Processing and Properties of NdFeb-Type Permanent Magnets. J. Magn. Magn. Mater. 2002, 248, 432–440. [Google Scholar] [CrossRef]

- Ormerod, J.; Constantinides, S. Bonded Permanent Magnets: Current Status and Future Opportunities (Invited). J. Appl. Phys. 1997, 81, 4816–4820. [Google Scholar] [CrossRef] [Green Version]

- Xiao, J.; Otaigbe, J.U. Polymer-Bonded Magnets: Part I. Analytic Thermogravimetry to Determine the Effect of Surface Modification on Dispersion of Nd–Fe–B Fillers. J. Mater. Res. 1999, 14, 2893–2896. [Google Scholar] [CrossRef]

- Martin, J.; Venturini, E.; Odinek, J.; Anderson, R. Anisotropic Magnetism in Field-Structured Composites. Phys. Rev. E 2000, 61, 2818–2830. [Google Scholar] [CrossRef] [Green Version]

- Volpe, V.; D’Auria, M.; Sorrentino, L.; Davino, D.; Pantani, R. Injection Molding of Magneto-Sensitive Polymer Composites. Mater. Today Commun. 2018, 15, 280–287. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Willard, M.A.; Brück, E.; Chen, C.H.; Sankar, S.G.; Liu, J.P. Magnetic Materials and Devices for the 21st Century: Stronger, Lighter, and More Energy Efficient. Adv. Mater. 2011, 23, 821–842. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Flynn, T.J.; Nation, J.C.; Kershaw, J.; Scott Stephens, L.; Trinkle, C.A. Photopatternable NdFeB Polymer Micromagnets for Microfluidics and Microrobotics Applications. J. Micromech. Microeng. 2013, 23, 065002. [Google Scholar] [CrossRef]

- Khosla, A.; Kassegne, S. Fabrication of NdFeB-Based Permanent Rare-Earth Micromagnets by Novel Hybrid Micromolding Process. Microsyst. Technol. 2015, 21, 2315–2320. [Google Scholar] [CrossRef]

- Yamahata, C.; Lotto, C.; Al-Assaf, E.; Gijs, M.A.M. A PMMA Valveless Micropump Using Electromagnetic Actuation. Microfluid. Nanofluidics 2005, 1, 197–207. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Masaoka, S.; Uehara, M.; Fujita, T.; Higuchi, K.; Maenaka, K. Micro-Structuring of Thick NdFeB Films Using High-Power Plasma Etching for Magnetic MEMS Application. J. Micromech. Microeng. 2011, 21, 045011. [Google Scholar] [CrossRef]

- Wang, W.; Yao, Z.; Chen, J.C.; Fang, J. Composite Elastic Magnet Films with Hard Magnetic Feature. J. Micromech. Microeng. 2004, 14, 1321–1327. [Google Scholar] [CrossRef]

- Damean, N.; Parviz, B.A.; Lee, J.N.; Odom, T.; Whitesides, G.M. Composite Ferromagnetic Photoresist for the Fabrication of Microelectromechanical Systems. J. Micromech. Microeng. 2005, 15, 29–34. [Google Scholar] [CrossRef]

- Yuan, Z.C.; Williams, A.J.; Shields, T.C.; Blackburn, S.; Ponton, C.B. The Production of Sr Hexaferrite Thick Films by Screen Printing. J. Magn. Magn. Mater. 2002, 247, 257–269. [Google Scholar] [CrossRef]

- Romero, J.J.; Cuadrado, R.; Pina, E.; de Hoyos, A.; Pigazo, F.; Palomares, F.J.; Hernando, A.; Sastre, R.; Gonzalez, J.M. Anisotropic Polymer Bonded Hard-Magnetic Films for Microelectromechanical System Applications. J. Appl. Phys. 2006, 99, 08N303. [Google Scholar] [CrossRef]

- Thévenot, J.; Oliveira, H.; Sandre, O.; Lecommandoux, S. Magnetic Responsive Polymer Composite Materials. Chem. Soc. Rev. 2013, 42, 7099. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Compton, B.G.; Kemp, J.W.; Novikov, T.V.; Pack, R.C.; Nlebedim, C.I.; Duty, C.E.; Rios, O.; Paranthaman, M.P. Direct-Write 3D Printing of NdFeB Bonded Magnets. Mater. Manuf. Process. 2018, 33, 109–113. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, X.; Guo, Z.; Ye, S.; Sui, Y.; Volinsky, A.A. 3D Printing of NdFeB Bonded Magnets with SrFe12O19 Addition. J. Alloys Compd. 2019, 779, 900–907. [Google Scholar] [CrossRef]

- Nagarajan, B.; Kamkar, M.; Schoen, M.A.W.; Sundararaj, U.; Trudel, S.; Qureshi, A.J.; Mertiny, P. Development and Characterization of Stable Polymer Formulations for Manufacturing Magnetic Composites. J. Manuf. Mater. Process. 2020, 4, 4. [Google Scholar] [CrossRef] [Green Version]

- Yan, Y.; Liu, L.; Ding, C.; Nguyen, L.; Moss, J.; Mei, Y.; Lu, G.Q. Additive Manufacturing of Magnetic Components for Heterogeneous Integration. In Proceedings of the IEEE 67th Electronic Components and Technology Conference, Orlando, FL, USA, 30 May–2 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 324–330. [Google Scholar] [CrossRef]

- Shen, A.; Peng, X.; Bailey, C.P.; Dardona, S.; Ma, A.W.K. 3D Printing of Polymer-Bonded Magnets from Highly Concentrated, Plate-like Particle Suspensions. Mater. Des. 2019, 183, 108133. [Google Scholar] [CrossRef]

- Shen, A.; Bailey, C.P.; Ma, A.W.K.; Dardona, S. UV-Assisted Direct Write of Polymer-Bonded Magnets. J. Magn. Magn. Mater. 2018, 462, 220–225. [Google Scholar] [CrossRef]

- Huber, C.; Abert, C.; Bruckner, F.; Groenefeld, M.; Muthsam, O.; Schuschnigg, S.; Sirak, K.; Thanhoffer, R.; Teliban, I.; Vogler, C.; et al. 3D Print of Polymer Bonded Rare-Earth Magnets, and 3D Magnetic Field Scanning with an End-User 3D Printer. Appl. Phys. Lett. 2016, 109, 162401. [Google Scholar] [CrossRef]

- Li, L.; Tirado, A.; Nlebedim, I.C.; Rios, O.; Post, B.; Kunc, V.; Lowden, R.R.; Lara-Curzio, E.; Fredette, R.; Ormerod, J.; et al. Big Area Additive Manufacturing of High Performance Bonded NdFeB Magnets. Sci. Rep. 2016, 6, 36212. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Post, B.; Kunc, V.; Elliott, A.M.; Paranthaman, M.P. Additive Manufacturing of Near-Net-Shape Bonded Magnets: Prospects and Challenges. Scr. Mater. 2017, 135, 100–104. [Google Scholar] [CrossRef]

- Parans Paranthaman, M.; Yildirim, V.; Lamichhane, T.N.; Begley, B.A.; Post, B.K.; Hassen, A.A.; Sales, B.C.; Gandha, K.; Nlebedim, I.C. Additive Manufacturing of Isotropic NdFeB PPS Bonded Permanent Magnets. Materials 2020, 13, 3319. [Google Scholar] [CrossRef]

- Nlebedim, I.C.; Ucar, H.; Hatter, C.B.; McCallum, R.W.; McCall, S.K.; Kramer, M.J.; Paranthaman, M.P. Studies on in Situ Magnetic Alignment of Bonded Anisotropic Nd-Fe-B Alloy Powders. J. Magn. Magn. Mater. 2017, 422, 168–173. [Google Scholar] [CrossRef] [Green Version]

- Gandha, K.; Li, L.; Nlebedim, I.C.; Post, B.K.; Kunc, V.; Sales, B.C.; Bell, J.; Paranthaman, M.P. Additive Manufacturing of Anisotropic Hybrid NdFeB-SmFeN Nylon Composite Bonded Magnets. J. Magn. Magn. Mater. 2018, 467, 8–13. [Google Scholar] [CrossRef]

- Khazdozian, H.A.; Li, L.; Paranthaman, M.P.; McCall, S.K.; Kramer, M.J.; Nlebedim, I.C. Low-Field Alignment of Anisotropic Bonded Magnets for Additive Manufacturing of Permanent Magnet Motors. JOM 2019, 71, 626–632. [Google Scholar] [CrossRef]

- Gandha, K.; Nlebedim, I.C.; Kunc, V.; Lara-Curzio, E.; Fredette, R.; Paranthaman, M.P. Additive Manufacturing of Highly Dense Anisotropic Nd–Fe–B Bonded Magnets. Scr. Mater. 2020, 183, 91–95. [Google Scholar] [CrossRef]

- Sarkar, A.; Somashekara, M.A.; Paranthaman, M.P.; Kramer, M.; Haase, C.; Nlebedim, I.C. Functionalizing Magnet Additive Manufacturing with In-Situ Magnetic Field Source. Addit. Manuf. 2020, 34, 101289. [Google Scholar] [CrossRef]

- Rudin, A.; Choi, P. The Elements of Polymer Science and Engineering, 3rd ed.; Elsevier: Boston, MA, USA, 2013; pp. 341–389. [Google Scholar]

- Nagarajan, B.; Aguilera, A.F.E.; Qureshi, A.; Mertiny, P. Additive Manufacturing of Magnetically Loaded Polymer Composites: An Experimental Study for Process Development. In Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017; American Society of Mechanical Engineers: New York, NY, USA, 2017. V002T02A032. [Google Scholar]

- Nagarajan, B.; Schoen, M.A.W.; Trudel, S.; Qureshi, A.J.; Mertiny, P. Rheology-Assisted Microstructure Control for Printing Magnetic Composites—Material and Process Development. Polymers 2020, 12, 2143. [Google Scholar] [CrossRef] [PubMed]

- Schläfer, D.; Walker, T.; Mattern, N.; Grünberger, W.; Hinz, D. Analysis of Texture Distribution in NdFeB Hard Magnets by Means of X-ray Diffraction in Bragg-Brentano Geometry. Texture Stress. Microstruct. 1996, 26, 71–81. [Google Scholar] [CrossRef]

- Uhl, F.M.; Webster, D.C.; Davuluri, S.P.; Wong, S.C. UV Curable Epoxy Acrylate–Clay Nanocomposites. Eur. Polym. J. 2006, 42, 2596–2605. [Google Scholar] [CrossRef]

- Wu, K.C.; Halloran, J.W. Photopolymerization Monitoring of Ceramic Stereolithography Resins by FTIR Methods. J. Mater. Sci. 2005, 40, 71–76. [Google Scholar] [CrossRef]

- Nagarajan, B.; Mertiny, P.; Qureshi, A.J. Magnetically Loaded Polymer Composites Using Stereolithography—Material Processing and Characterization. Mater. Today Commun. 2020, 25, 101520. [Google Scholar] [CrossRef]

| Sample | Material | Manufacturing Process | Magnetic Alignment |

|---|---|---|---|

| S1 | MQA-38-14 dispersed in dual-cure prepolymer | Material-jetting AM | Yes |

| S2 | MQA-38-14 dispersed in heat-curable epoxy resin | Polymer casting | Yes |

| S3 | MQA-38-14 dispersed in dual-cure prepolymer | Polymer casting | Yes |

| S4 | MQA-38-14 dispersed in dual-cure prepolymer | Polymer casting | No |

| Sample | Residue wt% at 200 °C | Residue wt% at 600 °C |

|---|---|---|

| S1 | 99.7 | 83.4 |

| S2 | 99.8 | 82.9 |

| S3 | 99.1 | 84.1 |

| S4 | 99.7 | 82.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagarajan, B.; Wang, Y.; Taheri, M.; Trudel, S.; Bryant, S.; Qureshi, A.J.; Mertiny, P. Development and Characterization of Field Structured Magnetic Composites. Polymers 2021, 13, 2843. https://doi.org/10.3390/polym13172843

Nagarajan B, Wang Y, Taheri M, Trudel S, Bryant S, Qureshi AJ, Mertiny P. Development and Characterization of Field Structured Magnetic Composites. Polymers. 2021; 13(17):2843. https://doi.org/10.3390/polym13172843

Chicago/Turabian StyleNagarajan, Balakrishnan, Yingnan Wang, Maryam Taheri, Simon Trudel, Steven Bryant, Ahmed Jawad Qureshi, and Pierre Mertiny. 2021. "Development and Characterization of Field Structured Magnetic Composites" Polymers 13, no. 17: 2843. https://doi.org/10.3390/polym13172843