An Assessment of the Thermal Behavior of Envelope Surface Coatings with Different Colors

Abstract

:1. Introduction

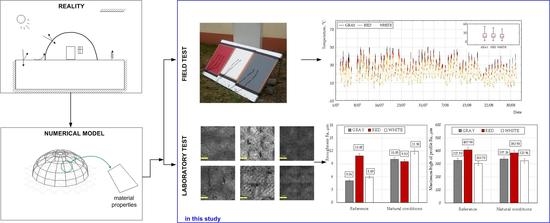

2. Methodology

2.1. Measurement of Surface Temperature

- -

- YSI 44005 thermistors with a measuring range from −40 to +105 °C and measuring accuracy of 0.5 °C, connected to a Geokon 8002 multi-channel recorder (Lebanon, NH, USA) for surface temperature measurement,

- -

- USB st-171 temperature and humidity recorders with a measuring range for temperatures from −40 to +70 °C and humidity from 0 to 100%, and a measurement accuracy of 0.5 °C and a 3% measurement of temperature and air humidity.

2.2. Measurement of Surface Roughness

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pultowicz, A. The premises of renewable energy sources market development in Poland in the light of sustainable development idea. Probl. Sustain. Dev. 2009, 4, 109–115. [Google Scholar]

- Małek, M.; Łasica, W.; Jackowski, M.; Kadela, M. Effect of waste glass addition as a replacement for fine aggregate on properties of mortar. Materials 2020, 13, 3189. [Google Scholar] [CrossRef] [PubMed]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M. Characteristics of recycled polypropylene fibers as an addition to concrete fabrication based on portland cement. Materials 2020, 13, 1827. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kadela, M.; Kukiełka, A.; Małek, M. Characteristics of lightweight concrete based on a synthetic polymer foaming agent. Materials 2020, 13, 4979. [Google Scholar] [CrossRef] [PubMed]

- Kain, G.; Tudor, E.M.; Barbu, M.-C. Bark thermal insulation panels: An explorative study on the effects of bark species. Polymers 2020, 12, 2140. [Google Scholar] [CrossRef]

- Ozel, M. Thermal performance and optimum insulation thickness of building walls with different structure materials. Appl. Therm. Eng. 2011, 31, 3854–3863. [Google Scholar] [CrossRef]

- Orlik-Kożdoń, B. Assessment of the application efficiency of recycling materials in thermal insulations. Constr. Build. Mater. 2017, 156, 476–485. [Google Scholar] [CrossRef]

- Pokorska-Silva, I.; Nowoświat, A.; Fedorowicz, L. Estimation of heat retention index basing on temperature measurements. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 062014. [Google Scholar] [CrossRef]

- Termentzidis, K. Thermal conductivity anisotropy in nanostructures and nanostructured materials. J. Phys. D Appl. Phys. 2018, 51, 094003. [Google Scholar] [CrossRef]

- Biswas, K.; Shrestha, S.; Hun, D.; Atchley, J. Thermally anisotropic composites for improving the energy efficiency of building envelopes. Energies 2019, 12, 3783. [Google Scholar] [CrossRef] [Green Version]

- Parida, B.; Iniyanb, S.; Goicc, R. A review of solar photovoltaic technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636. [Google Scholar] [CrossRef]

- Chwieduk, D. Solar Energy of the Building; Arkady: Warsaw, Poland, 2011. [Google Scholar]

- Tsagarakis, K.P.; Efthymiou, L.; Michopoulos, A.; Mavragani, A.; Anđelković, A.S.; Antolini, F.; Bacic, M.; Bajare, D.; Baralis, M.; Bogusz, W.; et al. A review of the legal framework in shallow geothermal energy in selected European countries: Need for guidelines. Renew. Energy 2020, 147, 2556–2571. [Google Scholar] [CrossRef]

- Szufa, S.; Adrian, Ł.; Piersa, P.; Romanowska-Duda, Z.; Grzesik, M.; Cebula, A.; Kowalczyk, S. Experimental studies on energy crops torrefaction process using batch reactor to estimate torrefaction temperature and residence time. In Renewable Energy Sources: Engineering, Technology, Innovation ICORES 2017; Mudryk, K., Werle, S., Eds.; Springer: Cham, Switzerland, 2018; pp. 365–373. [Google Scholar] [CrossRef]

- Pokorska-Silva, I.; Kadela, M.; Fedorowicz, L. Variations of ground temperature in shallow depths in the Silesian region. IOP Conf. Ser. Mater. Sci. Eng. 2019, 603, 052024. [Google Scholar] [CrossRef]

- Orzechowski, T.; Ziętala, K. The influence of absorption properties of colored paints on thermal comfort in the room. District Heat. Heat. Ventil. 2014, 45, 312–316. [Google Scholar]

- Grudzińska, M. Building compartment surface layer with specific properties of radiation absorption and transmission. Civ. Eng. Arch. 2007, 1, 17–44. [Google Scholar] [CrossRef]

- Cheng, V.; Ng, E.; Givoni, B. Effect of envelope colour and thermal mass on indoor temperatures in hot humid climate. Sol. Energy 2005, 78, 528–534. [Google Scholar] [CrossRef]

- Kontoleon, K.J.; Bikas, D.K. The effect of south wall’s outdoor absorption coefficient on time lag, decrement factor and temperature variations. Energy Build. 2007, 39, 1011–1018. [Google Scholar] [CrossRef]

- Kalnæs, S.E.; Jelle, B.P. Vacuum insulation panel products: A state-of-the-art review and future research pathways. Appl. Energy 2014, 116, 355–375. [Google Scholar] [CrossRef] [Green Version]

- Synnefa, A.; Santamouris, M.; Apostolakis, K. On the development, optical properties and thermal performance of cool colored coatings for the urban environment. Sol. Energy 2007, 81, 488–497. [Google Scholar] [CrossRef]

- Pokorska-Silva, I. Analysis of Thermal Efficiency of Buildings Based on Experimental Research and Numerical Simulations. Ph.D. Thesis, Silesian University of Technology, Gliwice, Poland, 2018. [Google Scholar]

- Kobielak, S.; Zamiar, Z. Oval concrete domes. Arch. Civ. Mech. Eng. 2017, 17, 486–501. [Google Scholar] [CrossRef]

- Kolarevic, B. Digital Age: Manufacturing; Taylor and Francis Group: New York, NY, USA, 2003. [Google Scholar]

- Cauberg, N.; Tysmans, T.; Adriaenssens, S.; Wastiels, J.; Mollaert, M.; Belkassem, B. Shell elements of textile reinforced concrete using fabric formwork. A case study. Adv. Structur. Eng. 2012, 15, 677–689. [Google Scholar] [CrossRef]

- Çiki, D.T. The Evolution and Change of Building Facades: A Research for Developing Alternative Composite Surface Materials. Master’s Thesis, The Graduate School of Engineering and Sciences of İzmir Institute of Technology, Izmir, Turkey, June 2007. Available online: https://core.ac.uk/download/pdf/324141224.pdf (accessed on 11 November 2020).

- Allen, W. Envelope Design for Buildings; Architectural Press: Oxford, UK, 1997. [Google Scholar]

- Ulrike, P.; Ron, N. Constructing energy efficiency: Rethinking and redesigning the architectural detail. J. Arch. Eng. 2013, 19. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Thue, J.V.; Tenpierik, M.J.; Grynning, S.; Uvslokk, S.; Gustavsen, A. Vacuum insulation panels for building applications: A review and beyond. Energy Build. 2010, 42, 147–172. [Google Scholar] [CrossRef] [Green Version]

- Nowoświat, A.; Olechowska, M.; Marchacz, M. The effect of acoustical remedies changing the reverberation time for different frequencies in a dome used for worship: A case study. Appl. Acoust. 2020, 160, 107143. [Google Scholar] [CrossRef]

- Parker, F. The Story of David B. South and the Monolithic Dome; Monolithic Dome Institute: Italy, TX, USA, 2004. [Google Scholar]

- Wilson, A. Practical Design of Concrete Shells; Monolithic Dome Institute: Italy, TX, USA, 2005. [Google Scholar]

- Pokorska-Silva, I.; Kadela, M.; Fedorowicz, L. A reliable numerical model for assessing the thermal behavior of a dome building. J. Build. Eng. 2020, 32, 101706. [Google Scholar] [CrossRef]

- Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture; ISO 4288:2011; European Committee for Standardization: Brussels, Belgium, 2011.

- Geometrical Product Specifications (GPS)—Surface texture: Profile Method—Nominal Characteristics of Contact (Stylus) Instruments; ISO 3274:2011; European Committee for Standardization: Brussels, Belgium, 2011.

- Małek, M.; Sudoł, E. Influence of different kinds of paints on self-cleaning process of the facade coating. IOP Conf. Ser. Mater. Sci. Eng. 2019, 603, 052062. [Google Scholar] [CrossRef] [Green Version]

- Klemm, P. General Construction. Physics of Buildings; Arkady: Warsaw, Poland, 2007; Volume 2. [Google Scholar]

- Kim, I.-J. A study on wear development of floor surfaces: Impact on pedestrian walkway slip-resistance performance. Tribol. Int. 2016, 95, 316–323. [Google Scholar] [CrossRef]

- Kim, I.-J. Investigation of floor surface finishes for optimal slip resistance performance. J. Shaw. 2018, 9, 17–24. [Google Scholar] [CrossRef]

- Chen, C.C.; Chen, Z.X.; Chang, C.L.; Lin, F.L. The slip-resistance effect evaluation of floor roughness under different liquid viscosity. Proc. Manuf. 2015, 3. [Google Scholar] [CrossRef] [Green Version]

| July–August * | September–October | November–December | January–February | March–April * | May–June * | July–August | September–October | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tav | Tmax | Tav | Tmax | Tav | Tmax | Tav | Tmax | Tav | Tmax | Tav | Tmax | Tav | Tmax | Tav | Tmax | ||

| °C | |||||||||||||||||

| Partition | Gray | 21.1 | 50.8 | 10.6 | 35.4 | 1.2 | 14.2 | −2.4 | 12.2 | - | - | - | - | 21.7 | 52.7 | 10.8 | 36.6 |

| Red | 20.6 | 46.9 | 10.5 | 33.8 | 1.2 | 14.1 | −2.3 | 12.0 | - | - | - | - | 21.3 | 49.6 | 10.8 | 32.6 | |

| White | 19.7 | 43.7 | 10.3 | 31.3 | 1.2 | 13.3 | −2.2 | 11.4 | - | - | - | - | 20.8 | 46.7 | 10.4 | 31.8 | |

| Air | 21.1 | 38.8 | 12.1 | 31.1 | 3.4 | 19.2 | −0.3 | 10.6 | 8.8 | 30.5 | 18.6 | 32.6 | 21.5 | 34.9 | 13.5 | 30.8 | |

| July–August 2017 * | July–August 2018 | July–August 2016 | 5 July | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Coating | Coating | Building | |||||||

| Tav | Tmax | Tav | Tmax | Tav | Tmax | Tav | Tmax | ||

| °C | |||||||||

| Coating | Grey | 21.1 | 50.8 | 21.7 | 52.7 | - | - | - | - |

| Red | 20.6 | 46.9 | 21.3 | 49.6 | 22.3 | 54.1 | 24.5 | 40.2 | |

| White | 19.7 | 43.7 | 20.8 | 49.1 | - | - | - | - | |

| Air | 21.1 | 38.8 | 21.5 | 34.9 | - | 19.7 | 19.3 | 26.9 | |

| Material Name and Surface Type | Absorption Coefficient α |

|---|---|

| High-Temperature Radiation | |

| Red ceramic brick | 0.70–0.74 |

| Concrete with smooth surface | 0.60 |

| Light concrete | 0.42 |

| Dark concrete | 0.73 |

| Black roofing felt | 0.91 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pokorska-Silva, I.; Kadela, M.; Małek, M.; Fedorowicz, L. An Assessment of the Thermal Behavior of Envelope Surface Coatings with Different Colors. Polymers 2021, 13, 82. https://doi.org/10.3390/polym13010082

Pokorska-Silva I, Kadela M, Małek M, Fedorowicz L. An Assessment of the Thermal Behavior of Envelope Surface Coatings with Different Colors. Polymers. 2021; 13(1):82. https://doi.org/10.3390/polym13010082

Chicago/Turabian StylePokorska-Silva, Iwona, Marta Kadela, Marcin Małek, and Lidia Fedorowicz. 2021. "An Assessment of the Thermal Behavior of Envelope Surface Coatings with Different Colors" Polymers 13, no. 1: 82. https://doi.org/10.3390/polym13010082