Basalt Fiber Modified Ethylene Vinyl Acetate/Magnesium Hydroxide Composites with Balanced Flame Retardancy and Improved Mechanical Properties

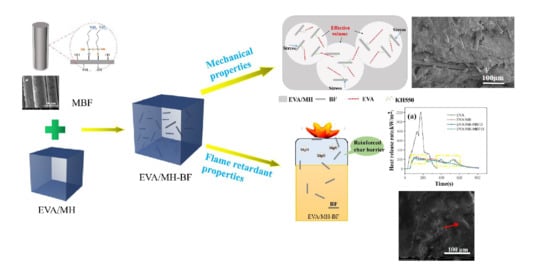

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

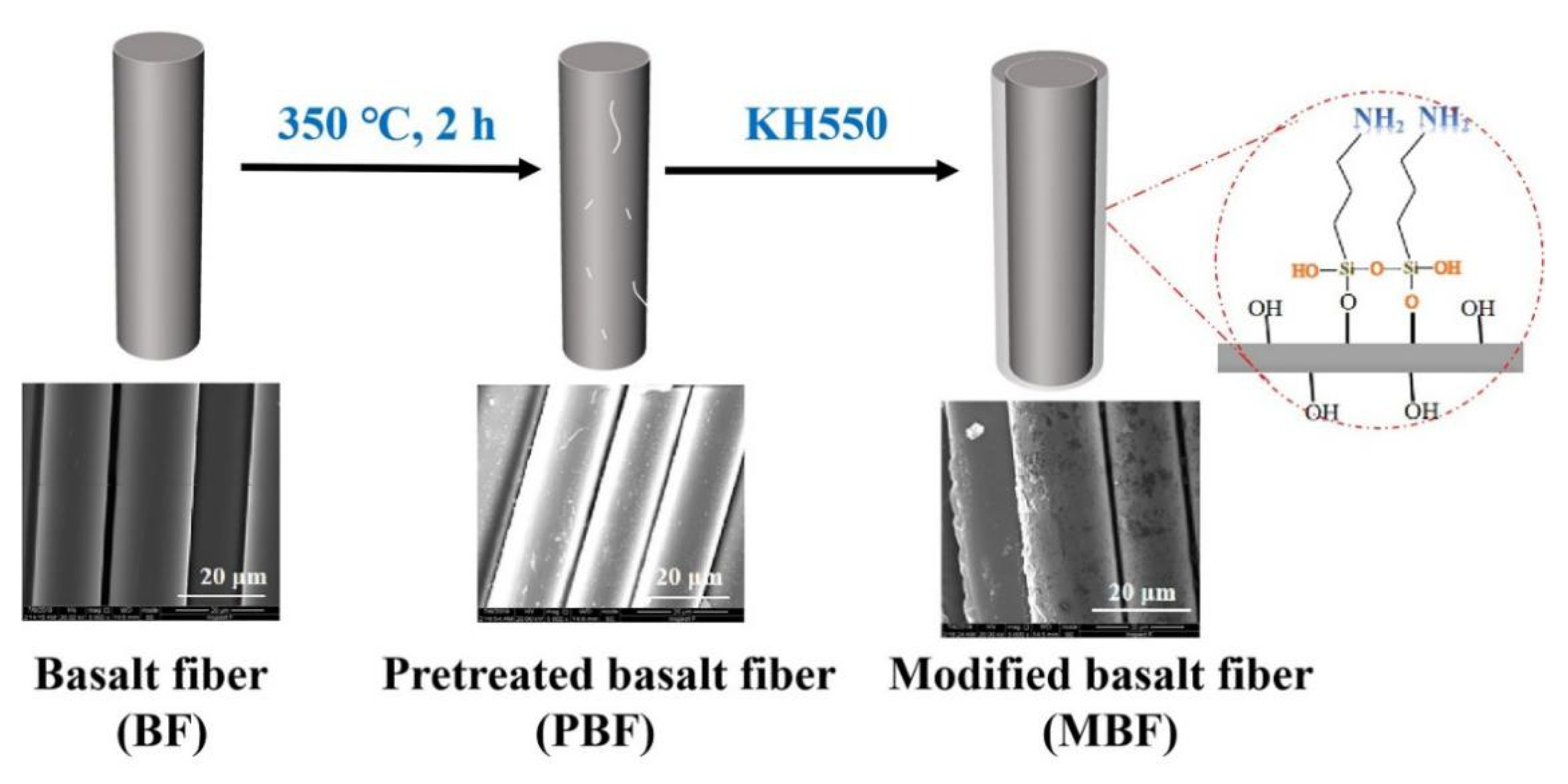

2.2. Pretreatment of Basalt Fiber

2.3. Surface Modification of Basalt Fiber

2.4. Fabrication of EVA/MH-BF Composites

2.5. Characterization

3. Results and Discussion

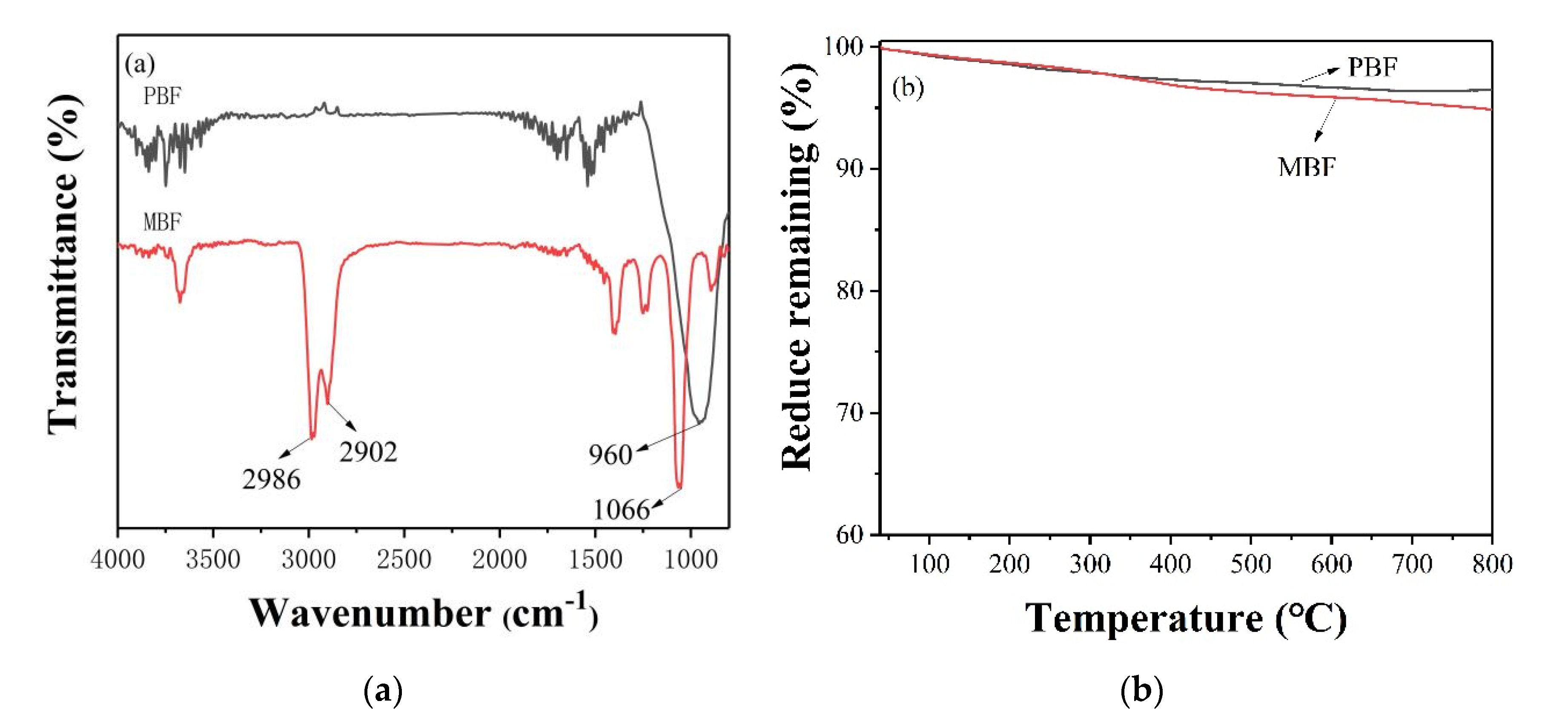

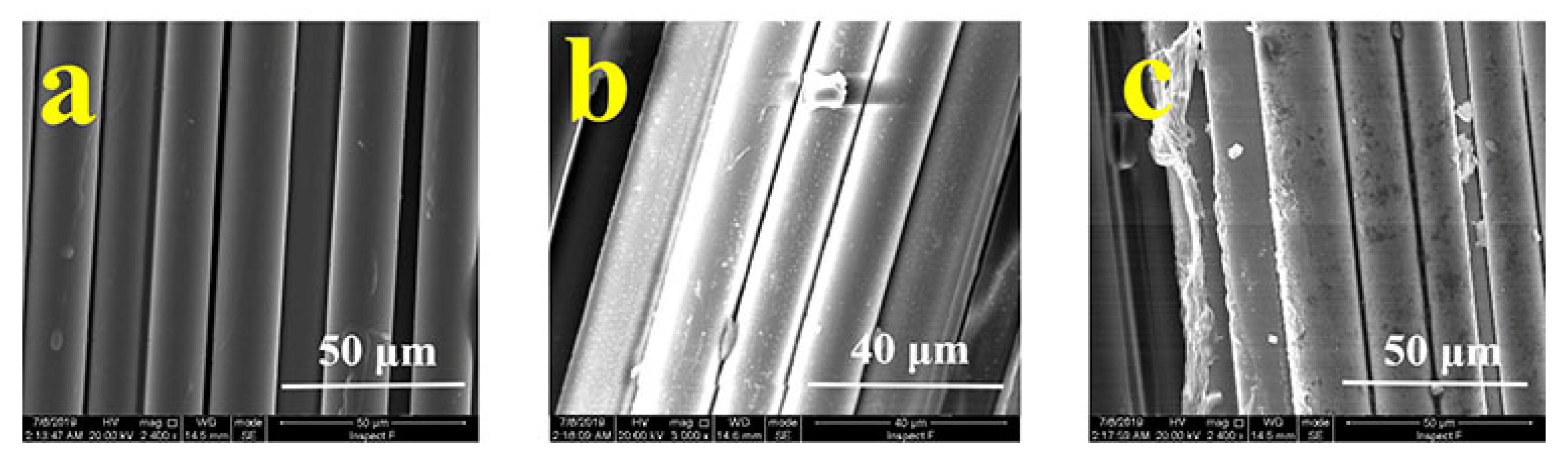

3.1. Structural Characterization of Modified Basalt fiber

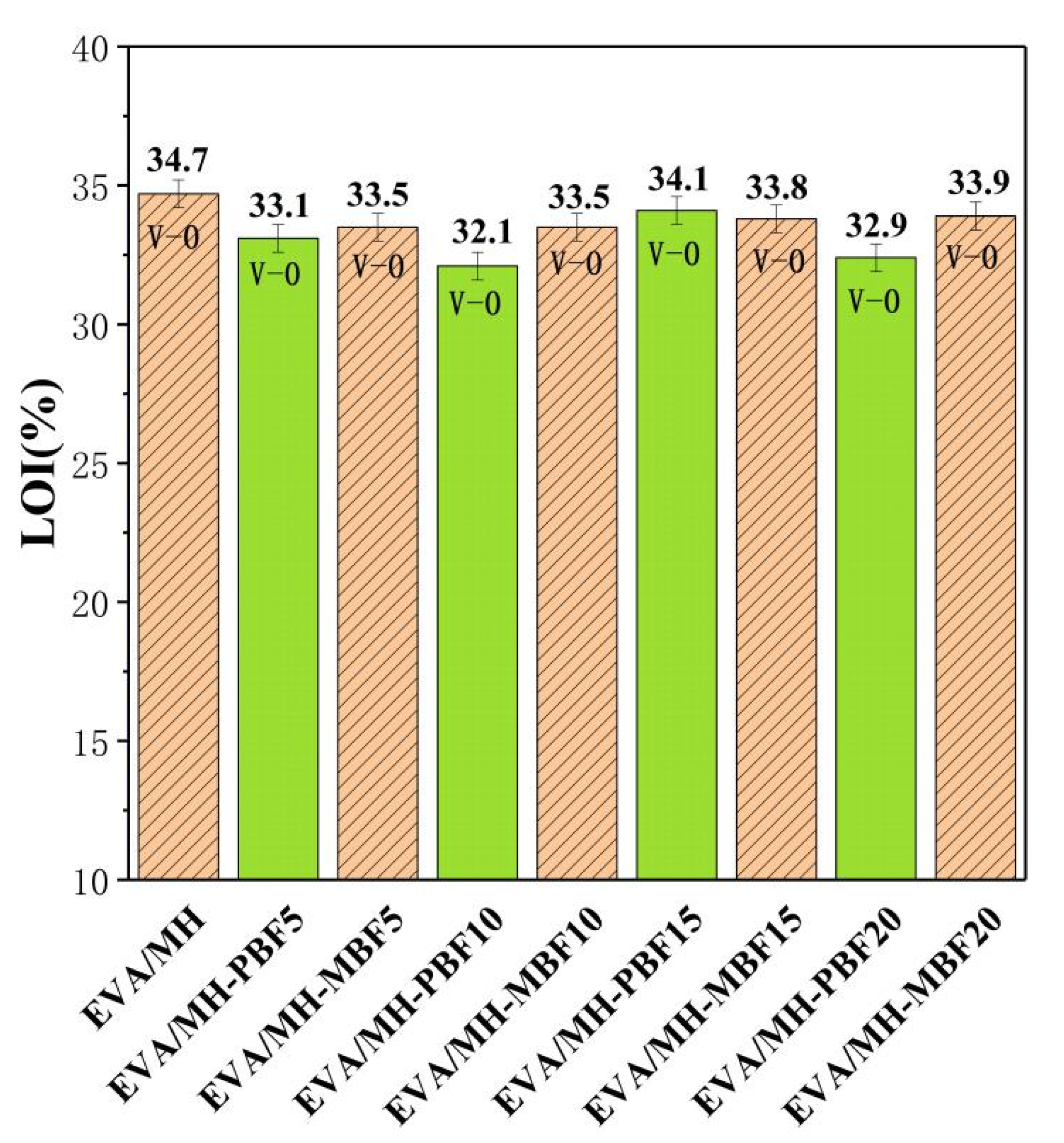

3.2. Flame Retardant Properties

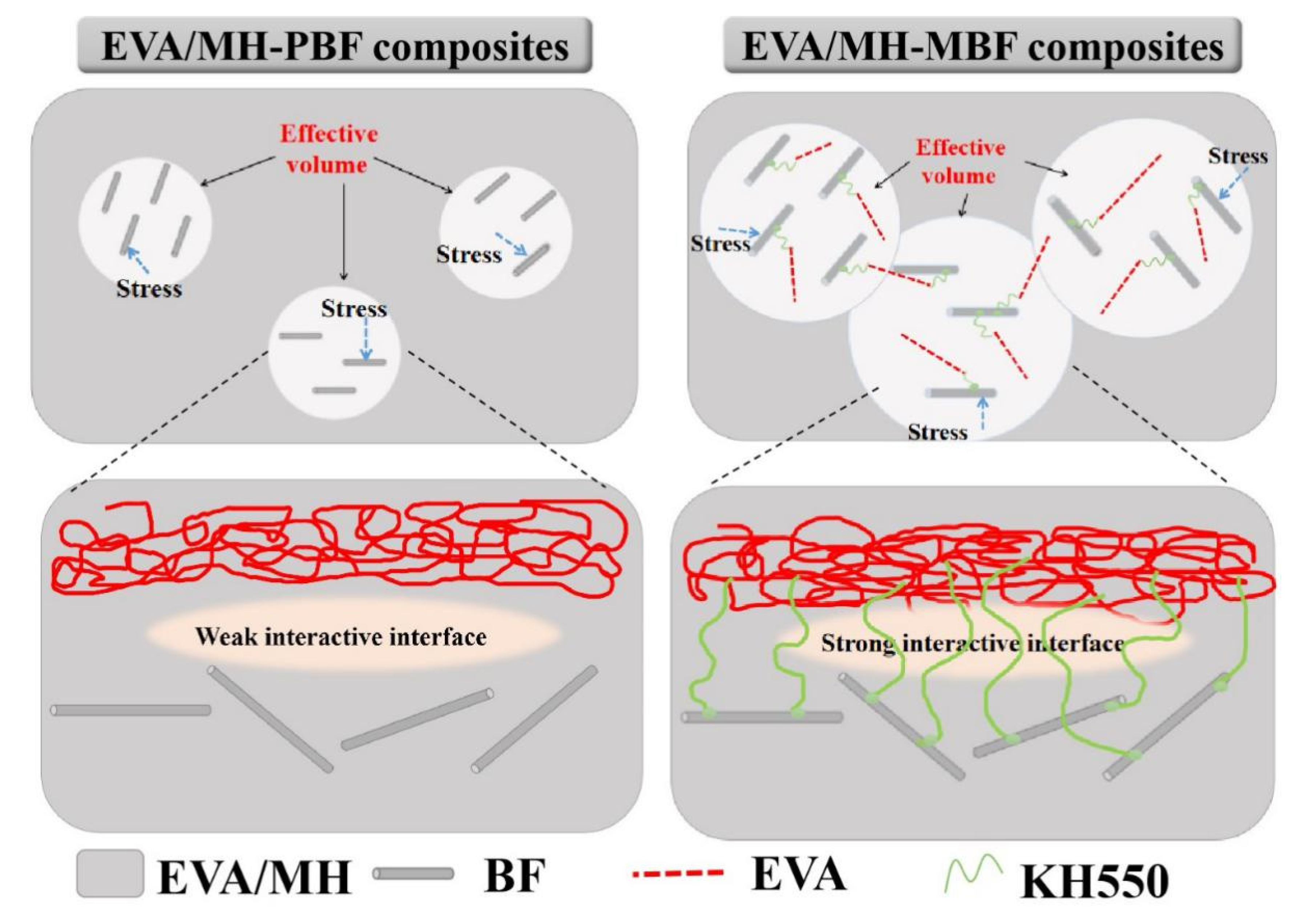

3.3. Mechanical Property

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dutta, S.K.; Bhowmick, A.K.; Mukunda, P.G.; Chaki, T.K. Thermal degradation studies of electron beam cured ethylene-vinyl acetate copolymer. Polym. Degrad. Stab. 1995, 50, 75–82. [Google Scholar] [CrossRef]

- Kalali, E.N.; De Juan, S.; Wang, X.; Nie, S.; Wang, R.; Wang, D.-Y. Comparative study on synergistic effect of LDH and zirconium phosphate with aluminum trihydroxide on flame retardancy of EVA composites. J. Therm. Anal. Calerim. 2015, 121, 619–626. [Google Scholar] [CrossRef] [Green Version]

- Lou, F.; Wu, K.; Wang, Q.; Qian, Z.; Li, S.; Guo, W. Improved flame-retardant and ceramifiable properties of eva composites by combination of ammonium polyphosphate and aluminum hydroxide. Polymers 2019, 11, 125. [Google Scholar] [CrossRef] [Green Version]

- Du, J.-Z.; Jin, L.; Zeng, H.-Y.; Feng, B.; Xu, S.; Zhou, E.-G.; Shi, X.K.; Liu, L.; Hu, X. Facile preparation of an efficient flame retardant and its application in ethylene vinyl acetate. Appl. Clay Sci. 2019, 168, 96–105. [Google Scholar] [CrossRef]

- Oualha, M.A.; Omri, N.; Oualha, R.; Nouioui, M.A.; Abderrabba, M.; Amdouni, N.; Laoutid, F. Development of metal hydroxide nanoparticles from eggshell waste and seawater and their application as flame retardants for ethylene-vinyl acetate copolymer (EVA). Int. J. Biol. Macromol. 2019, 128, 994–1001. [Google Scholar] [CrossRef]

- Zhang, W.; Li, X.; Shan, Z.; Wang, S.; Xiao, Y. Surface modification of magnesium hydroxide by wet process and effect on the thermal stability of silicone rubber. Appl. Surf. Sci. 2019, 465, 740–746. [Google Scholar] [CrossRef]

- Liauw, C.; Lees, G.; Hurst, S.; Rothon, R.; Ali, S. Effect of silane-based filler surface treatment formulation on the interfacial properties of impact modified polypropylene/magnesium hydroxide composites. Compos. Part A Appl. Sci. 1998, 29, 1313–1318. [Google Scholar] [CrossRef]

- Yang, G.; Park, M.; Park, S.-J. Recent progresses of fabrication and characterization of fibers-reinforced composites: A review. Compos. Commun. 2019, 14, 34–42. [Google Scholar] [CrossRef]

- Mudhukrishnan, M.; Hariharan, P.; Palanikumar, K. Measurement and analysis of thrust force and delamination in drilling glass fiber reinforced polypropylene composites using different drills. Measurement 2020, 149, 106973. [Google Scholar] [CrossRef]

- Deng, H.; Xu, J.; Li, X.; Ye, Y.; Chen, H.; Chen, S.; Chen, S.Y.; Miao, L.; Lin, H. The synergistic action between anhydride grafted carbon fiber and intumescent flame retardant enhances flame retardancy and mechanical properties of polypropylene composites. Sci. Technol. Adv. Mater. 2018, 19, 718–731. [Google Scholar] [CrossRef] [Green Version]

- Yang, W.; Jia, Z.; Chen, Y.; Zhang, Y.; Si, J.; Lu, H.; Yang, B. Carbon nanotube reinforced polylactide/basalt fiber composites containing aluminium hypophosphite: Thermal degradation, flame retardancy and mechanical properties. RSC Adv. 2015, 5, 105869–105879. [Google Scholar] [CrossRef]

- Khosravi, H.; Eslami-Farsani, R. Enhanced mechanical properties of unidirectional basalt fiber/epoxy composites using silane-modified Na+-montmorillonite nanoclay. Polym. Test. 2016, 55, 135–142. [Google Scholar] [CrossRef]

- Bhat, T.; Chevali, V.; Liu, X.; Feih, S.; Mouritz, A.P. Fire structural resistance of basalt fibre composite. Compos. Part A Appl. Sci. 2015, 71, 107–115. [Google Scholar] [CrossRef]

- Wei, B.; Song, S.; Cao, H. Strengthening of basalt fibers with nano-SiO2–epoxy composite coating. Mater. Des. 2011, 32, 4180–4186. [Google Scholar] [CrossRef]

- Sang, L.; Zhao, M.; Liang, Q.; Wei, Z. Silane-treated basalt fiber–reinforced poly(butylene succinate) biocomposites: Interfacial crystallization and tensile properties. Polymers 2017, 9, 351. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiao, B.; Li, H.; Xian, G. Hygrothermal Ageing of Basalt Fiber Reinforced Epoxy Composites. In Advances in FRP Composites in Civil Engineering; Ye, L., Feng, P., Yue, Q., Eds.; Springer: Beijing, China, 2010; pp. 356–359. [Google Scholar]

- Sang, L.; Han, S.; Li, Z.; Yang, X.; Hou, W. Development of short basalt fiber reinforced polylactide composites and their feasible evaluation for 3D printing applications. Compos. Part B Eng. 2019, 164, 629–639. [Google Scholar] [CrossRef]

- Attia, N.F.; Hegazi, E.M.; Abdelmageed, A.A. Smart modification of inorganic fibers and flammability mechanical and radiation shielding properties of their rubber composites. J. Therm. Anal. Calerim. 2018, 132, 1567–1578. [Google Scholar] [CrossRef]

- Guo, J.; Mu, S.; Yu, C.; Hu, C.; Guan, F.; Zhang, H.; Gong, Y. Mechanical and thermal properties of polypropylene/modified basalt fabric composites. J. Appl. Polym. Sci. 2015, 132, 42504. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, X.; Ni, H.; Rong, X.; Zhang, Q.; Xiao, X.; Huan, H.; Liu, J.F.; Wu, Z. Surface modification of basalt fiber with organic/inorganic composites for biofilm carrier used in wastewater treatment. ACS Sustain. Chem. Eng. 2018, 6, 2596–2602. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, S.; Huang, J.; Zhao, G.; Liu, Y. Interfacial modification of basalt fiber filling composites with graphene oxide and polydopamine for enhanced mechanical and tribological properties. RSC Adv. 2018, 8, 12222–12231. [Google Scholar] [CrossRef] [Green Version]

- Hu, X. Study on Surface Modification of Basalt Microfibers to Reinforce Phenolic Resin Composites and its Friction Properties. Master’s Thesis, Southeast University, Nanjing, China, 2019. [Google Scholar]

- Li, W.; Chen, M.; Yang, Y.; Yuan, D.; Ren, Y.; Cai, X. Dielectric property of modified barium titanate/polyamide 11 nanocomposites with different surfactants. J. Appl. Polym. Sci. 2019, 136, 47447. [Google Scholar] [CrossRef]

- Chen, B.; Zhao, T.; Luan, D.; Liao, L.; Huang, L.; Tang, Q. Effect of interfacial interaction on rheological, electrically conductive, and electromagnetic shielding properties of polyethylene/GO composites. Polym. Eng. Sci. 2018, 58, 1174–1181. [Google Scholar] [CrossRef]

- Peng, C.; Zhang, H.; You, Z.; Xu, F.; Jiang, G.; Lv, S.; Zhang, R.; Yang, H. Preparation and anti-icing properties of a superhydrophobic silicone coating on asphalt mixture. Constr. Build. Mater. 2018, 189, 227–235. [Google Scholar] [CrossRef]

- Qi, C. Preparation of Basalt Continuous Fiber Wetting Agent and its Influence on Fiber Properties. Master’s Thesis, Harbin University of Technology, Heilongjiang, China, 2010. [Google Scholar]

- Du, S.; Lin, X.; Jian, R.; Deng, C.; Wang, Y. Flame-retardant wrapped ramie fibers towards suppressing “candlewick effect” of polypropylene/ramie fiber composites. Chin. J. Polym. Sci. 2014, 33, 84–94. [Google Scholar] [CrossRef]

- Qiu, J.; Lai, X.; Li, H.; Gao, J.; Zeng, X.; Liao, X. Facile fabrication of a novel polyborosiloxane-decorated layered double hydroxide for remarkably reducing fire hazard of silicone rubber. Compos. Part B Eng. 2019, 175, 107068. [Google Scholar] [CrossRef]

- Islam, M.N.; Islam, M.S. mechanical properties of chemically treated sawdust-reinforced recycled polyethylene composites. Ind. Eng. Chem. Res. 2011, 50, 11124–11129. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, J.; Zhang, W.; Pan, Y.-T.; Wang, D.-Y.; Yang, R. Synthesis of a novel dual layered double hydroxide hybrid nanomaterial and its application in epoxy nanocomposites. Chem. Eng. J. 2020, 381, 122777. [Google Scholar] [CrossRef]

- Wen, X.; Liu, Z.; Li, Z.; Zhang, J.; Wang, D.-Y.; Szymańska, K.; Chen, X.; Mijowska, E.; Tang, T. Constructing multifunctional nanofiller with reactive interface in PLA/CB-g-DOPO composites for simultaneously improving flame retardancy, electrical conductivity and mechanical properties. Compos. Sci. Technol. 2019, 188, 107988. [Google Scholar] [CrossRef]

- Wang, X.; Kalali, E.N.; Wang, D.-Y. An in situ polymerization approach for functionalized MoS2/nylon-6 nanocomposites with enhanced mechanical properties and thermal stability. J. Mater. Chem. A 2015, 3, 24112–24120. [Google Scholar] [CrossRef]

| Sample | EVA/phr | MH/phr | PBF/phr | MBF/phr |

|---|---|---|---|---|

| EVA/MH | 100 | 150 | / | / |

| EVA/MH-PBF5 | 100 | 150 | 5 | / |

| EVA/MH-PBF10 | 100 | 150 | 10 | / |

| EVA/MH-PBF15 | 100 | 150 | 15 | / |

| EVA/MH-PBF20 | 100 | 150 | 20 | / |

| EVA/MH-MBF5 | 100 | 150 | / | 5 |

| EVA/MH-MBF10 | 100 | 150 | / | 10 |

| EVA/MH-MBF15 | 100 | 150 | / | 15 |

| EVA/MH-MBF20 | 100 | 150 | / | 20 |

| TTI (s) | pHRR (kW/m2) | TpHRR (s) | THR (MJ/m2) | pSPR (m2/s) | TSP (m2) | FIGRA (kW/(m2·s)) | |

|---|---|---|---|---|---|---|---|

| EVA | 29 ± 4 | 1196 ± 271 | 175 ± 5 | 139 ± 15 | 0.100 ± 0.001 | 14.7 ± 0.7 | 6.83 |

| EVA/MH | 59 ± 6 | 260 ± 3 | 130 ± 25 | 109 ± 10 | 0.037 ± 0.002 | 10.1 ± 2.0 | 2.00 |

| EVA/MH-PBF15 | 57 ± 1 | 242 ± 2 | 105 ± 5 | 96 ± 5 | 0.027 ± 0.002 | 8.4 ± 0.5 | 2.30 |

| EVA/MH-MBF15 | 56 ± 1 | 219 ± 14 | 100 ± 15 | 93 ± 13 | 0.038 ± 0.009 | 8.6 ± 0.2 | 2.19 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, D.; Yin, G.; Bi, Q.; Yin, X.; Wang, N.; Wang, D.-Y. Basalt Fiber Modified Ethylene Vinyl Acetate/Magnesium Hydroxide Composites with Balanced Flame Retardancy and Improved Mechanical Properties. Polymers 2020, 12, 2107. https://doi.org/10.3390/polym12092107

Yao D, Yin G, Bi Q, Yin X, Wang N, Wang D-Y. Basalt Fiber Modified Ethylene Vinyl Acetate/Magnesium Hydroxide Composites with Balanced Flame Retardancy and Improved Mechanical Properties. Polymers. 2020; 12(9):2107. https://doi.org/10.3390/polym12092107

Chicago/Turabian StyleYao, Dongwei, Guangzhong Yin, Qingqing Bi, Xu Yin, Na Wang, and De-Yi Wang. 2020. "Basalt Fiber Modified Ethylene Vinyl Acetate/Magnesium Hydroxide Composites with Balanced Flame Retardancy and Improved Mechanical Properties" Polymers 12, no. 9: 2107. https://doi.org/10.3390/polym12092107