The Effect of Acidic and Alkaline pH on the Physico-Mechanical Properties of Surimi-Based Edible Films Incorporated with Green Tea Extract

Abstract

:1. Introduction

2. Material and Methods

2.1. Materials

2.2. Preparation of Film-Forming Solution

2.3. Determination of Film Properties

2.3.1. Measurement of Film Thickness

2.3.2. Film Solubility

2.3.3. Light Transparency of Films

2.3.4. Water Vapor Permeability (WVP)

2.3.5. Mechanical Properties

2.3.6. Determination of Color Difference

2.3.7. Thermal Analysis of Films

2.3.8. Protein Pattern Analysis of Films

2.3.9. Statistical Study of Films

3. Results and Discussions

3.1. Film Thickness

3.2. Film Solubility

3.3. Transparency

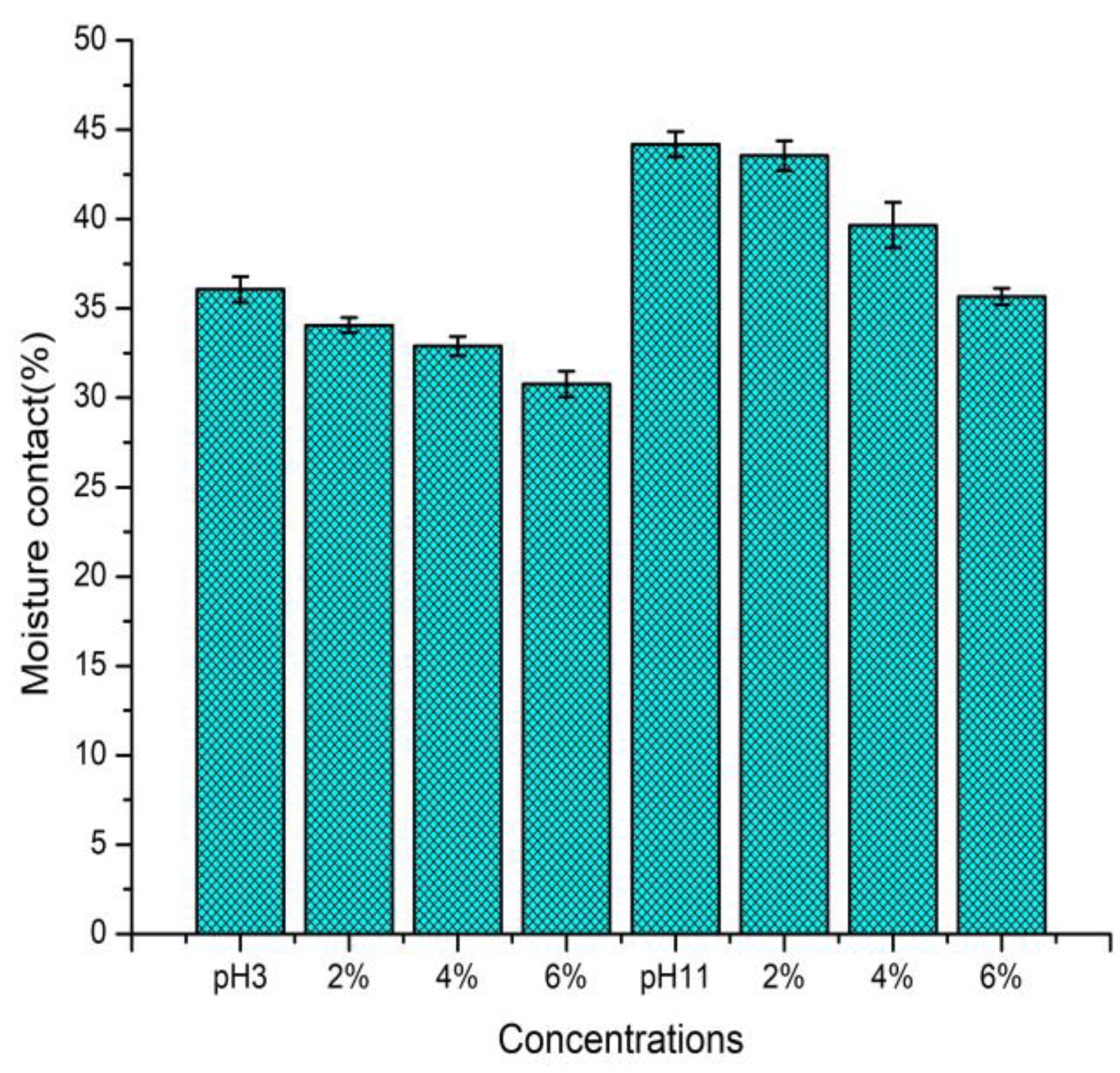

3.4. Water Vapor Permeability (WVP)

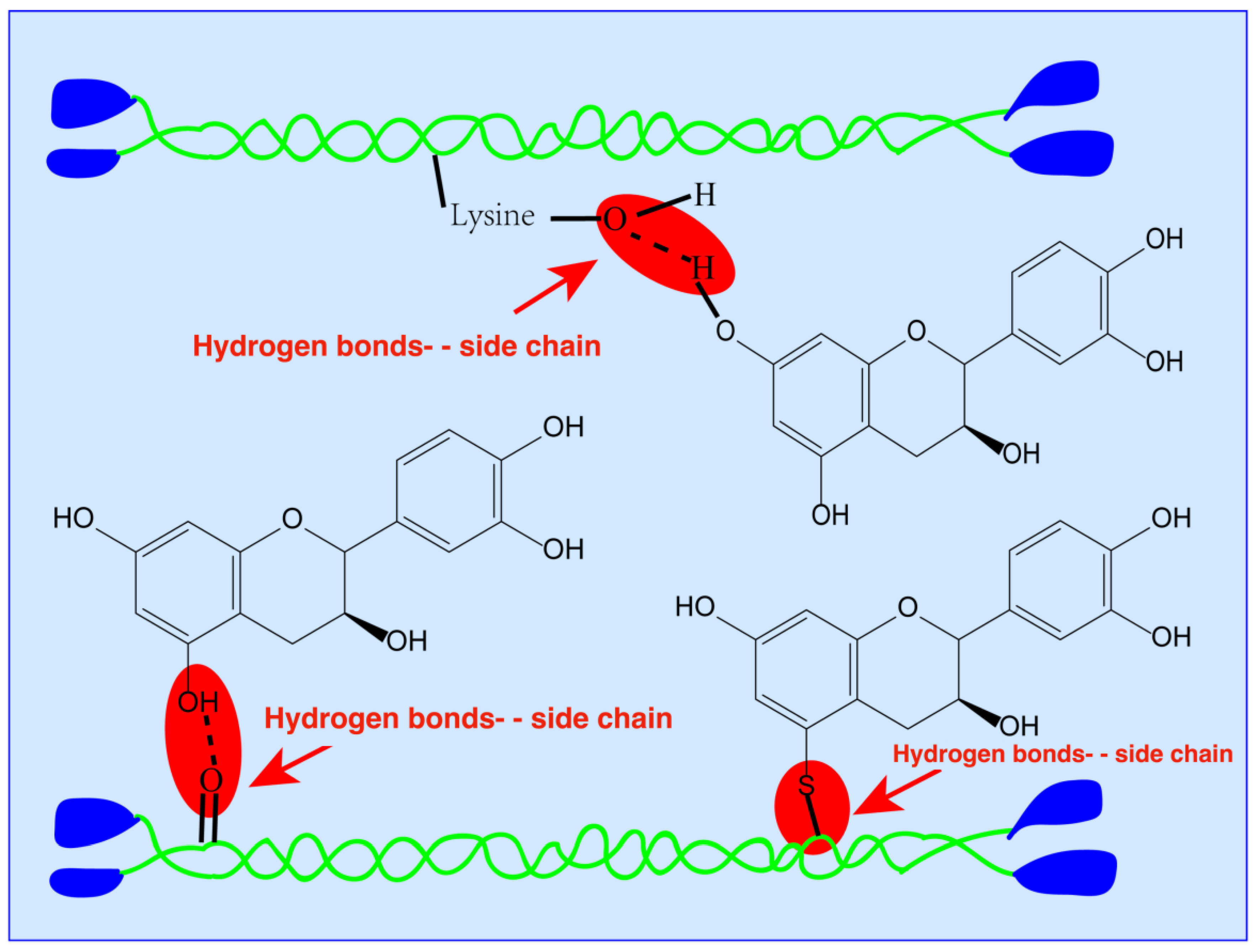

3.5. Mechanical Properties

3.6. Color

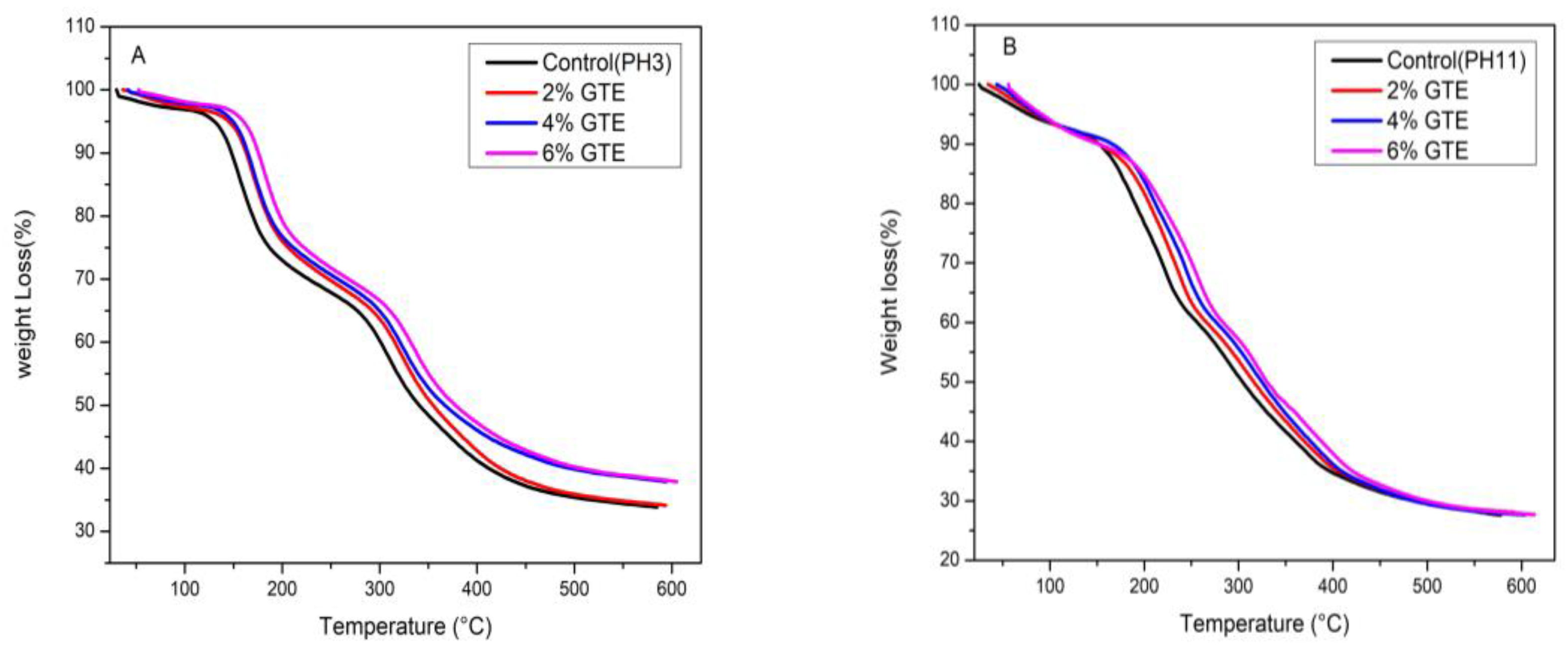

3.7. Thermo-Gravimetric Analysis

3.8. Protein Pattern

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Galus, S.; Kadzińska, J. Food applications of emulsion-based edible films and coatings. Trends Food Sci. Technol. 2015, 45, 273–283. [Google Scholar] [CrossRef]

- Nie, X.; Gong, Y.; Wang, N.; Meng, X. Preparation and characterization of edible myofibrillar protein-based film incorporated with grape seed procyanidins and green tea polyphenol. LWT Food Sci. Technol. 2015, 64, 1042–1046. [Google Scholar] [CrossRef]

- Kaewprachu, P.; Osako, K.; Rungraeng, N.; Rawdkuen, S. Characterization of fish myofibrillar protein film incorporated with catechin-Kradon extract. Int. J. Biol. Macromol. 2018, 107, 1463–1473. [Google Scholar] [CrossRef] [PubMed]

- Chinabhark, K.; Benjakul, S.; Prodpran, T. Effect of pH on the properties of protein-based film from bigeye snapper (Priacanthus tayenus) surimi. Bioresour. Technol. 2007, 98, 221–225. [Google Scholar] [CrossRef] [PubMed]

- Kaewprachu, P.; Osako, K.; Benjakul, S.; Suthiluk, P.; Rawdkuen, S. Shelf life extension for Bluefin tuna slices (Thunnus thynnus) wrapped with myofibrillar protein film incorporated with catechin-Kradon extract. Food Control 2017, 79, 333–343. [Google Scholar] [CrossRef]

- Munir, S.; Hu, Y.; Liu, Y.; Xiong, S. Enhanced properties of silver carp surimi-based edible films incorporated with pomegranate peel and grape seed extracts under acidic condition. Food Packag. Shelf Life 2019, 19, 114–120. [Google Scholar] [CrossRef]

- Fisheries Administration Bureau of Departmen of Agriculture. China Fishery Statistics Yearbooks 2019; China Agriculture Press: Beijing, China, 2019; ISBN 978-7-109-25510-4.

- Kaewprachu, P.; Rungraeng, N.; Osako, K.; Rawdkuen, S. Properties of fish myofibrillar protein film incorporated with catechin-Kradon extract. Food Packag. Shelf Life 2017, 13, 56–65. [Google Scholar] [CrossRef]

- Hanani, Z.A.N.; Yee, F.C.; Nor-Khaizura, M.A.R. Effect of pomegranate (Punica granatum L.) peel powder on the antioxidant and antimicrobial properties of fish gelatin films as active packaging. Food Hydrocoll. 2019, 89, 253–259. [Google Scholar] [CrossRef]

- Nie, X.; Zhao, L.; Wang, N.; Meng, X. Phenolics-protein interaction involved in silver carp myofibrilliar protein films with hydrolysable and condensed tannins. LWT Food Sci. Technol. 2017, 81, 258–264. [Google Scholar] [CrossRef]

- Quan, T.H.; Benjakul, S.; Sae-leaw, T.; Balange, A.K.; Maqsood, S. Protein–polyphenol conjugates: Antioxidant property, functionalities and their applications. Trends Food Sci. Technol. 2019, 91, 507–517. [Google Scholar] [CrossRef]

- Gulua, L.; Nikolaishvili, L.; Jgenti, M.; Turmanidze, T.; Dzneladze, G. Polyphenol content, anti-lipase and antioxidant activity of teas made in Georgia. Ann. Agrar. Sci. 2018, 16, 357–361. [Google Scholar] [CrossRef]

- Siripatrawan, U.; Noipha, S. Active film from chitosan incorporating green tea extract for shelf life extension of pork sausages. Food Hydrocoll. 2012, 27, 102–108. [Google Scholar] [CrossRef]

- Sang, S.; Lambert, J.D.; Ho, C.-T.; Yang, C.S. The chemistry and biotransformation of tea constituents. Pharmacol. Res. 2011, 64, 87–99. [Google Scholar] [CrossRef] [PubMed]

- Matthews, C.M. Steep your genes in health: Drink tea. Proceedings 2010, 23, 142–144. [Google Scholar] [CrossRef]

- Lei, Y.; Wu, H.; Jiao, C.; Jiang, Y.; Liu, R.; Xiao, D.; Lu, J.; Zhang, Z.; Shen, G.; Li, S. Investigation of the structural and physical properties, antioxidant and antimicrobial activity of pectin-konjac glucomannan composite edible films incorporated with tea polyphenol. Food Hydrocoll. 2019, 94, 128–135. [Google Scholar] [CrossRef]

- He, L.; Mu, C.; Shi, J.; Zhang, Q.; Shi, B.; Lin, W. Modification of collagen with a natural cross-linker, procyanidin. Int. J. Biol. Macromol. 2011, 48, 354–359. [Google Scholar] [CrossRef]

- Niu, H.; Xia, X.; Wang, C.; Kong, B.; Liu, Q. Thermal stability and gel quality of myofibrillar protein as affected by soy protein isolates subjected to an acidic pH and mild heating. Food Chem. 2018, 242, 188–195. [Google Scholar] [CrossRef]

- Gennadios, A.; Handa, A.; Froning, G.W.; Weller, C.L.; Hanna, M.A. Physical Properties of Egg White−Dialdehyde Starch Films. J. Agric. Food Chem. 1998, 46, 1297–1302. [Google Scholar] [CrossRef]

- Shiku, Y.; Hamaguchi, P.Y.; Benjakul, S.; Visessanguan, W.; Tanaka, M. Effect of surimi quality on properties of edible films based on Alaska pollack. Food Chem. 2004, 86, 493–499. [Google Scholar] [CrossRef]

- Iwata, K.I.; Ishizaki, S.H.; Handa, A.K.; Tanaka, M.U. Preparation and characterization of edible films from fish water-soluble proteins. Fish. Sci. 2000, 66, 372–378. [Google Scholar] [CrossRef]

- Gennadios, A.; Weller, C.L.; Hanna, M.A.; Froning, G.W. Mechanical and Barrier Properties of Egg Albumen Films. J. Food Sci. 1996, 61, 585–589. [Google Scholar] [CrossRef]

- Hoque, M.S.; Benjakul, S.; Prodpran, T. Effects of partial hydrolysis and plasticizer content on the properties of film from cuttlefish (Sepia pharaonis) skin gelatin. Food Hydrocoll. 2011, 25, 82–90. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, L.; Yu, Y.; Zhou, H.; Guo, T.; Dai, H.; Zhang, Y. Physico-mechanical and antioxidant properties of gelatin film from rabbit skin incorporated with rosemary acid. Food Packag. Shelf Life 2019, 19, 121–130. [Google Scholar] [CrossRef]

- Arfat, Y.A.; Benjakul, S.; Prodpran, T.; Osako, K. Development and characterisation of blend films based on fish protein isolate and fish skin gelatin. Food Hydrocoll. 2014, 39, 58–67. [Google Scholar] [CrossRef]

- Hamaguchi, P.Y.; WuYin, W.; Tanaka, M. Effect of pH on the formation of edible films made from the muscle proteins of Blue marlin (Makaira mazara). Food Chem. 2007, 100, 914–920. [Google Scholar] [CrossRef]

- Ozdal, T.; Capanoglu, E.; Altay, F. A review on protein–phenolic interactions and associated changes. Food Res. Int. 2013, 51, 954–970. [Google Scholar] [CrossRef]

- Oujifard, A.; Benjakul, S.; Prodpran, T.; Seyfabadi, J. Properties of red tilapia (Oreochromis niloticus) protein based film as affected by cryoprotectants. Food Hydrocoll. 2013, 32, 245–251. [Google Scholar] [CrossRef]

- Friesen, K.; Chang, C.; Nickerson, M. Incorporation of phenolic compounds, rutin and epicatechin, into soy protein isolate films: Mechanical, barrier and cross-linking properties. Food Chem. 2015, 172, 18–23. [Google Scholar] [CrossRef]

- He, Y.; Park, J.W.; Yin, T. Biochemical and Gelling Properties of Silver Carp Surimi as Affected by Harvesting Season and Chopping Time. J. Food Process. Preserv. 2019, 43, e14247. [Google Scholar] [CrossRef]

- Sun, X.D.; Holley, R.A. Factors Influencing Gel Formation by Myofibrillar Proteins in Muscle Foods. Compr. Rev. Sci. Food Saf. 2011, 10, 33–51. [Google Scholar] [CrossRef]

- Nilsuwan, K.; Benjakul, S.; Prodpran, T. Influence of Palm Oil and Glycerol on Properties of Fish Skin Gelatin-Based Films. J. Food Sci. Technol. 2016, 53, 2715–2724. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, Y.; Sun, Z. Effects of Gelatin-Polyphenol and Gelatin–Genipin Cross-Linking on the Structure of Gelatin Hydrogels. Int. J. Food Prop. 2018, 20, 1–11. [Google Scholar] [CrossRef]

- Cao, Y.; Xiong, Y.L. Chlorogenic Acid-Mediated Gel Formation of Oxidatively Stressed Myofibrillar Protein. Food Chem. 2015, 180, 235–243. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; True, A.D.; Chen, J.; Xiong, Y.L. Dual Role (Anti- and Pro-Oxidant) of Gallic Acid in Mediating Myofibrillar Protein Gelation and Gel In vitro Digestion. J. Agric. Food Chem. 2016, 64, 3054–3061. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.B.; Zhang, W.G.; Zou, Y.F.; Xing, L.J.; Zheng, H.B.; Xu, X.L.; Zhou, G.H. Influence of RosA-protein adducts formation on myofibrillar protein gelation prop- erties under oxidative stress. Food Hydrocoll. 2017, 67, 197–205. [Google Scholar] [CrossRef]

- Tongnuanchan, P.; Benjakul, S.; Prodpran, T.; Nilsuwan, K. Emulsion Film Based on Fish Skin Gelatin and Palm Oil: Physical, Structural and Thermal Properties. Food Hydrocoll. 2015, 48, 248–259. [Google Scholar] [CrossRef]

- Rattaya, S.; Benjakul, S.; Prodpran, T. Properties of fish skin gelatin film incorporated with seaweed extract. J. Food Eng. 2009, 95, 151–157. [Google Scholar] [CrossRef]

- Zhang, X.; Do, M.D.; Casey, P.; Sulistio, A.; Qiao, G.G.; Lundin, L.; Lillford, P.; Kosaraju, S. Chemical Cross-Linking Gelatin with Natural Phenolic Compounds as Studied by High-Resolution NMR Spectroscopy. Biomacromolecules 2010, 11, 1125–1132. [Google Scholar] [CrossRef]

- Strauss, G.; Gibson, S.M. Plant Phenolics as Cross-Linkers of Gelatin Gels and Gelatin-Based Coacervates for Use as Food Ingredients. Food Hydrocoll. 2004, 18, 81–89. [Google Scholar] [CrossRef]

- Prodpran, T.; Benjakul, S.; Phatcharat, S. Effect of Phenolic Compounds on Protein Cross-Linking and Properties of Film from Fish Myofibrillar Protein. Int. J. Biol. Macromol. 2012, 51, 774–782. [Google Scholar] [CrossRef]

- Guerrero, P.; Nur Hanani, Z.A.; Kerry, J.P.; de la Caba, K. Characterization of soy protein-based films prepared with acids and oils by compression. J. Food Eng. 2011, 107, 41–49. [Google Scholar] [CrossRef]

- Weng, W.; Hamaguchi, P.Y.; Osako, K.; Tanaka, M. Effect of endogenous acid proteinases on the properties of edible films from Alaska pollack surimi. Food Chem. 2007, 105, 996–1002. [Google Scholar] [CrossRef]

- Weng, W.; Hamaguchi, P.Y.; Osako, K.; Tanaka, M. Properties of edible surimi film as affected by heat treatment of film-forming solution. Food Sci. Technol. Res. 2007, 13, 391–398. [Google Scholar] [CrossRef]

| PH Level | Source | (w/w Protein) | Thickness (mm) | FS (%) | Transparency (% mm−1) |

|---|---|---|---|---|---|

| pH 3 | Control | Control | 0.087 ± 0.002F | 54.76 ± 0.17B | 3.11 ± 0.17C |

| GTE | 2% | 0.088 ± 0.002F | 36.90 ± 0.13E | 3.28 ± 0.06CB | |

| 4% | 0.093 ± 0.001E | 32.95 ± 0.17G | 3.38 ± 0.20B | ||

| 6% | 0.098 ± 0.002D | 30.48 ± 0.2H | 3.59 ± 0.18A | ||

| pH 11 | Control | Control | 0.92 ± 0.002E | 64.22 ± 0.08A | 0.96 ± 0.08F |

| GTE | 2% | 0.100 ± 0.002C | 42.65 ± 0.09C | 3.11 ± 0.15C | |

| 4% | 0.103 ± 0.002B | 39.66 ± 0.14D | 2.38 ± 0.16D | ||

| 6% | 0.107 ± 0.002A | 36.27 ± 0.17F | 1.96 ± 0.18E |

| PH Level | Source | (w/w Protein) | WVP (×10−12 gm−1 S−1 pa−1) | TS(MPa) | EAB (%) |

|---|---|---|---|---|---|

| pH 3 | Control | Control | 3.15 ± 0.04B | 2.57 ± 0.14G | 164.77 ± 3.06B |

| GTE | 2% | 2.40 ± 0.03ED | 3.97 ± 0.20E | 88.95 ± 6.62F | |

| 4% | 2.22 ± 0.04F | 4.17 ± 0.10D | 97.06 ± 5.80F | ||

| 6% | 2.06 ± 0.05G | 5.66 ± 0.17A | 131.38 ± 5.32E | ||

| pH 11 | Control | Control | 3.63 ± 0.05A | 2.74 ± 0.09F | 187.35 ± 5.94A |

| GTE | 2% | 2.68 ± 0.09C | 5.18 ± 0.11C | 154.21 ± 8.68C | |

| 4% | 2.46 ± 0.04D | 5.45 ± 0.06B | 144.20 ± 10.55D | ||

| 6% | 2.32 ± 0.08EF | 5.68 ± 0.08A | 122.26 ± 13.27E |

| pH | Sample | Thermal Transition Temperature (Tg) |

|---|---|---|

| pH3 | Control | 59.5 |

| 2% | 91.1 | |

| 4% | 115.4 | |

| 6% | 128.9 | |

| pH11 | Control | 65.2 |

| 2% | 97.7 | |

| 4% | 108.1 | |

| 6% | 133.8 |

| PH level | Source | (w/w Protein) | L* | a* | b* | ΔE* |

|---|---|---|---|---|---|---|

| pH 3 | Control | Control | 91.49 ± 0.07A | –0.36 ± 0.03C | 1.42 ± 0.06G | 7.27 ± 0.11G |

| GTE | 2% | 90.69 ± 0.05B | –0.35 ± 0.03C | 2.30 ± 0.05F | 9.29 ± 0.08F | |

| 4% | 89.40 ± 0.04C | –0.67 ± 0.04D | 4.40 ± 0.03E | 13.37 ± 0.08E | ||

| 6% | 88.79 ± 0.07D | –0.95 ± 0.03E | 7.48 ± 0.05C | 18.11 ± 0.09C | ||

| pH 11 | Control | Control | 91.53 ± 0.04A | 0.22 ± 0.03B | 1.25 ± 0.06H | 7.15 ± 0.08H |

| GTE | 2% | 86.66 ± 0.14E | 0.21 ± 0.03B | 4.76 ± 0.16D | 17.69 ± 0.12D | |

| 4% | 83.50 ± 0.12F | 0.21 ± 0.02B | 12.60 ± 0.12B | 31.08 ± 0.18B | ||

| 6% | 81.75 ± 0.10G | 0.13 ± 0.03A | 20.72 ± 0.10A | 44.51 ± 0.16A |

| Samples | (w/w of Protein) | Δ1 | Δ2 | Δ3 | Δ4 | Residue (%) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Td1 | Δw1 | Td2 | Δw2 | Td3 | Δw3 | Td4 | Δw4 | |||

| pH 3 | Control | 127.7 | 4.9 | 187.6 | 20.7 | 312.7 | 18.5 | 455.2 | 18.3 | 35.6 |

| 2% | 144.7 | 4.5 | 209.7 | 25.2 | 319.1 | 16.6 | 445.1 | 17.1 | 36.6 | |

| 4% | 147.2 | 4.9 | 205.2 | 18.3 | 304.7 | 13.9 | 427.2 | 19.4 | 43.5 | |

| 6% | 148.5 | 3.8 | 221.1 | 21.5 | 309.5 | 10.1 | 423.6 | 20.1 | 44.5 | |

| pH 11 | Control | 160.4 | 11.3 | 235.3 | 24.5 | 397.6 | 30.2 | 487.6 | 4.1 | 29.9 |

| 2% | 177.6 | 11.9 | 251.9 | 25.3 | 392.6 | 27.4 | 495.1 | 5.6 | 29.8 | |

| 4% | 167.1 | 10.0 | 263.6 | 25.5 | 391.1 | 23.8 | 467.6 | 6.8 | 33.9 | |

| 6% | 176.3 | 11.7 | 275.4 | 26.5 | 337.5 | 13.4 | 440.6 | 14.3 | 34.1 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Munir, S.; Javed, M.; Hu, Y.; Liu, Y.; Xiong, S. The Effect of Acidic and Alkaline pH on the Physico-Mechanical Properties of Surimi-Based Edible Films Incorporated with Green Tea Extract. Polymers 2020, 12, 2281. https://doi.org/10.3390/polym12102281

Munir S, Javed M, Hu Y, Liu Y, Xiong S. The Effect of Acidic and Alkaline pH on the Physico-Mechanical Properties of Surimi-Based Edible Films Incorporated with Green Tea Extract. Polymers. 2020; 12(10):2281. https://doi.org/10.3390/polym12102281

Chicago/Turabian StyleMunir, Sadia, Miral Javed, Yang Hu, Youming Liu, and Shanbai Xiong. 2020. "The Effect of Acidic and Alkaline pH on the Physico-Mechanical Properties of Surimi-Based Edible Films Incorporated with Green Tea Extract" Polymers 12, no. 10: 2281. https://doi.org/10.3390/polym12102281