On the Role of Polymer Viscoelasticity in Enhanced Oil Recovery: Extensive Laboratory Data and Review

Abstract

:1. Introduction

1.1. Overview of Polymer-Enhanced Oil Recovery

1.2. Scope of the Study

- Effect of polymer viscoelasticity, different polymer chemistries, polymer molecular weight distributions and concentrations on the oil recovery;

- Effect of reservoir properties on polymer viscoelasticity and its related recovery efficiency;

- Effect of thermal, chemical, mechanical and chemical degradation on the polymer’s viscoelastic flow behavior;

- Contribution and importance of the viscoelastic flow characteristics on EOR.

1.3. Paper Organization

2. Polymers for Enhanced Oil Recovery (EOR): Types and Chemistry

2.1. Synthetic Polymers

2.2. Biopolymers

3. Viscoelasticity in Enhanced Oil Recovery

3.1. Viscoelasticity as Per Definition

3.1.1. Linear Viscoelasticity

3.1.2. Non-Linear Viscoelasticity

3.1.3. Normal Stress Difference, N1

3.1.4. Weissenberg Number

3.1.5. Deborah Number

3.1.6. M Parameter

3.2. Viscoelastic Flow Phenomena in Porous Media

- (a)

- Shear thinning;

- (b)

- Shear thickening; and

- (c)

- Elastic turbulence.

3.2.1. Shear-Thinning Behavior

3.2.2. Shear-Thickening Behavior

3.2.3. Elastic Turbulence

3.3. Experimental Approaches for the Assessment of Polymer Viscoelasticity

3.3.1. Quantitative Fluid Property Evaluations

Measurement of Relaxation Time

Measurement of Shear Viscosity

- (a)

- Permeability measurement;

- (b)

- Quantitative polymer characterization including viscosity evaluation; and

- (c)

- A qualitative polymer characterization including streamline visualization.

Other Viscoelastic Properties

3.3.2. Qualitative Flow Evaluation

3.4. Impacts on Polymer Viscoelasticity in Oil Reservoirs

3.4.1. Solvent Salinity

3.4.2. Polymer Concentration

3.4.3. Molecular Weight

3.4.4. Mechanical Degradation

3.4.5. Thermal Degradation

3.4.6. Chemical Degradation

3.4.7. Biological Degradation

3.4.8. Impact of Reservoir Rock on the Viscoelastic Flow Behavior

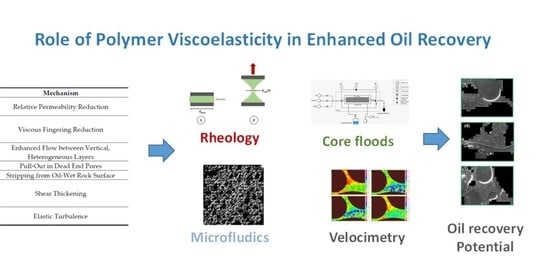

4. Viscoelasticity-Related Recovery Mechanisms and Their Importance in EOR Applications

5. Polymer Viscoelasticity and Enhanced Oil Recovery: A Two-Folded Partnership

6. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations and Symbols

| AMPS | 2-acrylamide-2-methyl |

| CaBER | Capillary break-up extensional rheometer |

| CT | Computer tomography |

| DLS | Dynamic light scattering |

| EOR | Enhanced oil recovery |

| eVROC | Extensional viscometer-rheometer-on-a-chip |

| FiSER | Filament stretching extensional rheometer |

| GSG | Glass-Silicon-Glass |

| HPAM | Hydrolyzed polyacrylamide |

| ODES-DOS | Optically-detected elastocapillary self-thinning dripping-onto-substract |

| PAM | Polyacrylamide |

| PEO | Polyethylene oxide |

| PTFE | Polytetrafluorethane |

| PV | Pore volume |

| RF | Recovery factor |

| ROJER | Rayleigh-Ohnesorge Jet Elongational Rheometer |

| SRB | Sulphate-reducing bacteria |

| B | Deformation tensor [-] |

| γ | Shear rate [s−1] |

| γoverlap | Overlap shear rate G’ vs. G’’ [s−1] |

| De | Deborah number [-] |

| Dp | Mean grain diameter [m] |

| Dparticle | Particle diameter [m] |

| δfluid | Fluid density [kg/m³] |

| δparticle | Particle density [kg/m³] |

| Δp | Differential pressure [Pa] |

| ε | Porosity [-] |

| f1 | Particle fraction [-] |

| φ1,2 | Time derivates [-] |

| g | Gravitational acceleration [m/s²] |

| G | Relaxation modulus [Pa.s] |

| G’ | Storage modulus [Pa.s] |

| G’’ | Loss modulus [Pa.s] |

| Hmicro | Microchannel height [m] |

| kwater | Relative water permeability [m²] |

| L | Flow length [m] |

| Lmicro | Microchannel length [m] |

| λ | Relaxation time [s] |

| Mw | Molecular weight [MDa] |

| Mw, max | Maximum molecular weight [MDa] |

| µ | Viscosity [Pa.s] |

| µapp | Apparent viscosity [Pa.s] |

| µdynamic | Dynamic viscosity [Pa.s] |

| N1,2 | Normal stress difference [Pa] |

| η | Shear viscosity [Pa.s] |

| Q | Flow rate [m³/s] |

| Rem | Modified Reynolds number [-] |

| Soi | Initial oil saturation [-] |

| Sor | Residual oil saturation [-] |

| σxx | Normal stress in x-direction [Pa] |

| σyy | Normal stress in y-direction [Pa] |

| t | Time [s] |

| τ | Shear stress [Pa] |

| vs | Superficial velocity [m/s] |

| vsettlement | Particle settlement velocity [m/s] |

| ν | Elastic stress [Pa] |

| Wi | Weissenberg number [-] |

References

- Wylde, J.J.; Slayer, J.L.; Barbu, V. Polymeric and Alkali-Surfactant Polymer Enhanced Oil Recovery Chemical Treatment: Chemistry and Strategies Required After Breakthrough into the Process. In Proceedings of the SPE International Symposium on Oilfield Chemistry, The Woodlands, TX, USA, 8–10 April 2013. [Google Scholar] [CrossRef]

- Clarke, A.; Howe, A.M.; Mitchell, J.; Staniland, J.; Hawkes, L.A. How Viscoelastic Polymer Flooding Enhances Displacement Efficiency. In Proceedings of the SPE Asia Pacific Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 11–13 August 2015. [Google Scholar] [CrossRef]

- Hon, V.Y.; Kechut, N.I.; Razak, W.N.A.W. Enhanced Oil Recovery Potential of Heavy-Oil Fields in Africa. In Proceedings of the International Oil Conference and Exhibition in Mexico, Veracruz, Mexico, 27–30 June 2007. [Google Scholar] [CrossRef]

- Iwere, F.O.; Heim, R.N.; Cherian, B.V. Numerical Simulation of Enhanced Oil Recovery in the Middle Bakken and Upper Three Forks Tight Oil Reservoirs of the Williston Basin. In Proceedings of the SPE Americas Unconventional Resources Conference, Pittsburgh, PA, USA, 5–7 June 2012. [Google Scholar]

- Wu, Y.; Ma, D.; Liu, S.; Wang, H.; Zhao, X. EOR of Superheated Steam Injection in Shallow Heavy Oil Reservoir: A Case Study. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 8–10 June 2010. [Google Scholar]

- Sahin, S.; Kalfa, U.; Celebioglu, D. Unique CO2-Injection Experience in the Bati Raman Field May Lead to a Proposal of EOR/Sequestration CO2 Network in the Middle East. In Proceedings of the SPE International Conference on CO2 Capture, Storage, and Utilization, New Orleans, LA, USA, 10–12 November 2010. [Google Scholar]

- Zhang, Y.P.; Huang, S.; Dong, M. Determining the Most Profitable ASP Flood Strategy for Enhanced Oil Recovery. J. Can. Pet. Technol. 2005, 44, 42–49. [Google Scholar] [CrossRef]

- Hincapie, R.E. Pore-Scale Investigation of the Viscoelastic Phenomenon during Enhanced Oil Recovery (EOR) Polymer Flooding through Porous Media; Papierflieger: Clausthal-Zellerfeld, Germany, 2016. [Google Scholar]

- Huh, C.; Pope, G.A. Residual Oil Saturation from Polymer Floods: Laboratory Measurements and Theoretical Interpretation. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Levitt, D.; Pope, G.A. Selection and Screening of Polymers for Enhanced-Oil Recovery. In Proceedings of the he SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Rock, A.; Hincapie, R.E.; Wegner, J.; Födisch, H.; Ganzer, L. Pore-scale Visualization of Oil Recovery by Viscoelastic Flow Instabilities during Polymer EOR. In Proceedings of the IOR 2017—19th European Symposium on Improved Oil Recovery, Stavanger, Norway, 24–27 April 2017; Volume 2017, pp. 1–17. [Google Scholar]

- Seright, R.S.; Wang, D.; Lerner, N.; Nguyen, A.; Sabid, J.; Tochor, R. Beneficial Relative Permeabilities for Polymer Flooding. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2018. [Google Scholar]

- Seright, R.S.; Seheult, J.M.; Talashek, T. Injectivity Characteristics of EOR Polymers. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar]

- Sheng, J.J. (Ed.) Modern Chemical Enhanced Oil Recovery; Gulf Professional Publishing: Boston, MA, USA, 2011; ISBN 978-1-85617-745-0. [Google Scholar]

- Wegner, J.; Hincapie, R.E.; Födisch, H.; Ganzer, L. Novel Visualisation of Chemical EOR Flooding Using a Lab-on-a-Chip Setup Supported by an Extensive Rheological Characterisation. In Proceedings of the SPE Asia Pacific Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 11–13 August 2015. [Google Scholar]

- Dong, H.; Fang, S.; Wang, D.; Wang, J.; Liu, Z.L.; Hou, W. Review of Practical Experience & Management by Polymer Flooding at Daqing. In Proceedings of the SPE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Sheng, J.J.; Leonhardt, B.; Azri, N. Status of Polymer-Flooding Technology. J. Can. Pet. Technol. 2015, 54, 116–126. [Google Scholar] [CrossRef]

- Abidin, A.Z.; Puspasari, T.; Nugroho, W.A. Polymers for Enhanced Oil Recovery Technology. Procedia Chem. 2012, 4, 11–16. [Google Scholar] [CrossRef] [Green Version]

- Hamid, S.A.A.; Muggeridge, A. Viscous Fingering in Reservoirs with Long Aspect Ratios. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2018. [Google Scholar]

- Tahir, M.; Hincapie, R.E.; Ganzer, L. An Elongational and Shear Evaluation of Polymer Viscoelasticity during Flow in Porous Media. Appl. Sci. 2020, 10, 4152. [Google Scholar] [CrossRef]

- Sorbie, K.S. Polymer-Improved Oil Recovery; Springer: Blackie, AB, Canada, 1991; ISBN 978-0-8493-7137-0. [Google Scholar]

- Luo, H.; Al-Shalabi, E.W.; Delshad, M.; Panthi, K.; Sepehrnoori, K. A Robust Geochemical Simulator to Model Improved-Oil-Recovery Methods. SPE J. 2016, 21, 55–73. [Google Scholar] [CrossRef]

- Yin, H.; Wang, D.; Zhong, H. Study on Flow Behavoirs of Viscoelastic Polymer Solution in Micropore with Dead End. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 24–27 September 2006. [Google Scholar]

- Wang, D.; Cheng, J.; Yang, Q.; Wenchao, G.; Qun, L.; Chen, F. Viscous-Elastic Polymer Can Increase Microscale Displacement Efficiency in Cores. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 1–4 October 2000. [Google Scholar]

- Howe, A.M.; Clarke, A.; Giernalczyk, D. Flow of concentrated viscoelastic polymer solutions in porous media: Effect of MW and concentration on elastic turbulence onset in various geometries. Soft Matter 2015, 11, 6419–6431. [Google Scholar] [CrossRef]

- Azad, M.S.; Trivedi, J.J. Quantification of the Viscoelastic Effects during Polymer Flooding: A Critical Review. SPE J. 2019, 24, 2731–2757. [Google Scholar] [CrossRef]

- Azad, M.S.; Trivedi, J.J. Extensional Effects during Viscoelastic Polymer Flooding: Understanding Unresolved Challenges. SPE J. 2020, 25, 1827–1841. [Google Scholar] [CrossRef]

- Azad, M.S.; Trivedi, J.J. Does Polymer’s Viscoelasticity Influence Heavy Oil Sweep Efficiency and Injectivity at 1ft/Day? In Proceedings of the SPE International Heavy Oil Conference and Exhibition, Kuwait City, Kuwait, 10–12 December 2018.

- Hincapie, R.E.; Rock, A.; Wegner, J.; Ganzer, L. Oil Mobilization by Viscoelastic Flow Instabilities Effects during Polymer EOR: A Pore-Scale Visualization Approach. In Proceedings of the SPE Latin America and Caribbean Petroleum Engineering Conference, Buenos Aires, Argentina, 17–19 May 2017. [Google Scholar]

- Rock, A.; Hincapie, R.E.; Wegner, J.; Ganzer, L. Advanced Flow Behavior Characterization of Enhanced Oil Recovery Polymers using Glass-Silicon-Glass Micromodels that Resemble Porous Media. In Proceedings of the SPE Europec featured at 79th EAGE Conference and Exhibition, Paris, France, 12–15 June 2017. [Google Scholar]

- Groisman, A.; Steinberg, V. Elastic Turbulence in a Polymer Solution Flow | Nature. Available online: https://www.nature.com/articles/35011019 (accessed on 14 August 2020).

- Chen, P.; Balasubramanian, S.; Bose, S.; Alzahabi, A.; Thakur, G. An Integrated Workflow of IOR/EOR Assessment in Oil Reservoirs. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018. [Google Scholar]

- Moreno, J.E.; Flew, S.; Gurpinar, O.; Liu, Y.; Gossuin, J. Effective Use of Laboratory Measurements on Eor Planning. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2018. [Google Scholar]

- Su, S.; Giddins, M.A.; Naccache, P.; Clarke, A.; Howe, A.M. Accurate Modeling of Polymer Enhanced Oil Recovery Corefloods by Reservoir Simulation. In Proceedings of the SPE Reservoir Characterisation and Simulation Conference and Exhibition, Abu Dhabi, UAE, 14–16 September 2015. [Google Scholar]

- Delamaide, E. Exploring the Upper Limit of Oil Viscosity for Polymer Flood in Heavy Oil. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2018. [Google Scholar]

- Pu, W.; Jiang, F.; He, Y.; Wei, B.; Tang, Y. Synthesis of a novel comb micro-block hydrophobically associating copolymer for Ca2+/Mg2+ resistance. RSC Adv. 2016, 6, 43634–43637. [Google Scholar] [CrossRef]

- Cai, S.; He, X.; Liu, K.; Rodrigues, A.M.; Zhang, R. Macromolecular interactions and synergy in xanthan/HPAM aqueous solutions. RSC Adv. 2017, 7, 41630–41639. [Google Scholar] [CrossRef] [Green Version]

- Menter, P. Acrylamide Polymerization—A Practical Approach. Bio-Rad Tech Note 2000, 1156, 24. [Google Scholar]

- Lentz, R.D.; Andrawes, F.F.; Barvenik, F.W.; Koehn, A.C. Acrylamide Monomer Leaching from Polyacrylamide-Treated Irrigation Furrows. J. Environ. Qual. 2008, 37, 2293–2298. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hotta, M.; Kennedy, J.; Higginbotham, C.; Morris, N. Durum Wheat Seed Germination Response to Hydrogel Coatings and Moisture under Drought Stress. Am. J. Agric. Biol. Sci. 2016, 11, 67–75. [Google Scholar] [CrossRef] [Green Version]

- Zweigle, M.L.; Lamphere, J.C. Cross-Linked, Water-Swellable Polymer Microgels. U.S. Patent 4,172,066, 23 October 1979. [Google Scholar]

- Karsani, K.S.M.E.; Al-Muntasheri, G.A.; Sultan, A.S.; Hussein, I.A. Impact of salts on polyacrylamide hydrolysis and gelation: New insights. J. Appl. Polym. Sci. 2014, 131, 41185. [Google Scholar] [CrossRef]

- Divers, T.; Gaillard, N.; Bataille, S.; Thomas, A.; Favéro, C. Successful Polymer Selection for CEOR: Brine Hardness and Mechanical Degradation Considerations. In Proceedings of the SPE Oil and Gas India Conference and Exhibition, Mumbai, India, 4–6 April 2017. [Google Scholar]

- Gaillard, N.; Giovannetti, B.; Leblanc, T.; Thomas, A.; Braun, O.; Favero, C. Selection of Customized Polymers to Enhance Oil Recovery from High Temperature Reservoirs. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Quito, Ecuador, 18–20 November 2015. [Google Scholar]

- The Polyacrylamide Matrix | National Diagnostics. Available online: https://www.nationaldiagnostics.com/electrophoresis/article/polyacrylamide-matrix (accessed on 14 August 2020).

- Zhu, D.; Zhang, J.; Han, Y.; Wang, H.; Feng, Y. Laboratory Study on the Potential EOR Use of HPAM/VES Hybrid in High-Temperature and High-Salinity Oil Reservoirs. Available online: https://www.hindawi.com/journals/jchem/2013/927519/ (accessed on 14 August 2020).

- Kulicke, W.; Hörl, H. Preparation and characterization of a series of poly(acrylamide-co-acrylates), with a copolymer composition between 0–96.3 mol-% acrylate units with the same degree and distribution of polymerization. Colloid Polym. Sci. 1985, 263, 530–540. [Google Scholar] [CrossRef]

- Spildo, K.; Sæ, E.I.Ø. Effect of Charge Distribution on the Viscosity and Viscoelastic Properties of Partially Hydrolyzed Polyacrylamide. Energy Fuels 2015, 29, 5609–5617. [Google Scholar] [CrossRef]

- Meng, L.; Kang, W.; Zhou, Y.; Wang, Z.; Liu, S.; Bai, B. Viscoelastic rheological property of different types of polymer solutions for enhanced oil recovery. J. Cent. South Univ. Technol. 2008, 15, 126–129. [Google Scholar] [CrossRef]

- Leonhardt, B.; Ernst, B.; Reimann, S.; Steigerwald, A.; Lehr, F. Field Testing The Polysaccharide Schizophyllan: Results of The First Year. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 12–16 April 2014. [Google Scholar]

- Needham, R.B.; Doe, P.H. Polymer Flooding Review. J. Pet. Technol. 1987, 39, 1.503–1.507. [Google Scholar] [CrossRef]

- Hincapie, R.E.; Ganzer, L. Assessment of Polymer Injectivity with Regards to Viscoelasticity: Lab Evaluations towards Better Field Operations. In Proceedings of the EUROPEC, Madrid, Spain, 1–4 June 2015. [Google Scholar]

- Mezger, T.G. Das Rheologie Handbuch: Für Anwender von Rotations- und Oszillations-Rheometern, 4th ed.; Vincentz Network: Hannover, Germany, 2012; ISBN 978-3-86630-863-3. [Google Scholar]

- Macosko, C.W. Rheology: Principles, Measurements, and Applications | Wiley. Available online: https://www.wiley.com/en-us/Rheology%3A+Principles%2C+Measurements%2C+and+Applications-p-9780471185758 (accessed on 14 August 2020).

- Clarke, A.; Howe, A.M.; Mitchell, J.; Staniland, J.; Hawkes, L.; Leeper, K. Mechanism of anomalously increased oil displacement with aqueous viscoelastic polymer solutions. Soft Matter 2015, 11, 3536–3541. [Google Scholar] [CrossRef]

- Tahir, M. Experimental Investigation of Sulfate-Modified Water and Polymer Flooding for Enhanced Oil Recovery. Ph.D. Thesis, Clausthal University of Technology, Clausthal-Zellerfeld, Germany, 2020. [Google Scholar] [CrossRef]

- Tahir, M.; Hincapie, R.E.; Ganzer, L. Influence of Sulfate Ions on the Combined Application of Modified Water and Polymer Flooding—Rheology and Oil Recovery. Energies 2020, 13, 2356. [Google Scholar] [CrossRef]

- Hincapie, R.E.; Duffy, J.; O’Grady, C.; Ganzer, L. An Approach to Determine Polymer Viscoelasticity Under Flow Through Porous Media by Combining Complementary Rheological Techniques. In Proceedings of the SPE Asia Pacific Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia, 11–13 August 2015. [Google Scholar]

- Scholz, C.; Wirner, F.; Gomez-Solano, J.R.; Bechinger, C. Enhanced dispersion by elastic turbulence in porous media. EPL Europhys. Lett. 2014, 107, 54003. [Google Scholar] [CrossRef] [Green Version]

- Be, M.; Hincapie, R.E.; Rock, A.; Gaol, C.L.; Tahir, M.; Ganzer, L. Comprehensive Evaluation of the EOR Polymer Viscoelastic Phenomenon at Low Reynolds Number. In Proceedings of the SPE Europec featured at 79th EAGE Conference and Exhibition, Paris, France, 12–15 June 2017. [Google Scholar]

- Galindo-Rosales, F.J.; Campo-Deaño, L.; Pinho, F.T.; van Bokhorst, E.; Hamersma, P.J.; Oliveira, M.S.N.; Alves, M.A. Microfluidic systems for the analysis of viscoelastic fluid flow phenomena in porous media. Microfluid. Nanofluidics 2012, 12, 485–498. [Google Scholar] [CrossRef] [Green Version]

- Sochi, T. Non-Newtonian flow in porous media. Polymer 2010, 51, 5007–5023. [Google Scholar] [CrossRef] [Green Version]

- Tahir, M.; Hincapie, R.E.; Be, M.; Ganzer, L. A Comprehensive Combination of Apparent and Shear Viscoelastic Data during Polymer Flooding for EOR Evaluations. World J. Eng. Technol. 2017, 5, 585–600. [Google Scholar] [CrossRef] [Green Version]

- Spaull, A.J.B. An Introduction to Rheology; Barnes, H.A., Hutton, J.F., Walters, K., Eds.; Elsevier Science Publishers: Amsterdam, The Netherlands, 1989. [Google Scholar]

- Elhajjaji, R.R.; Hincapie, R.E.; Tahir, M.; Rock, A.; Wegner, J.; Ganzer, L. Systematic Study of Viscoelastic Properties During Polymer-Surfactant Flooding in Porous Media. In Proceedings of the SPE Russian Petroleum Technology Conference and Exhibition, Moscow, Russia, 24–26 October 2016. [Google Scholar]

- Tahir, M.; Hincapie, R.E.; Be, M.; Ganzer, L. Experimental Evaluation of Polymer Viscoelasticity During Flow in Porous Media: Elongational and Shear Analysis. In Proceedings of the SPE Europec featured at 79th EAGE Conference and Exhibition, Paris, France, 12–15 June 2017. [Google Scholar]

- Tahir, M.; Hincapie, R.E.; Gaol, C.; Saefken, S.; Ganzer, L. Describing The Flow Behavior Of Smart Water In Micromodels With Wettability Modified Pore Structures. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering, Virtual Conference, 27–31 July 2020. [Google Scholar] [CrossRef]

- Tahir, M.; Hincapie, R.E.; Ganzer, L. Unlocking the Effects of Fluid Optimization on Remaining Oil Saturation for the Combined Sulfate-Modified Water and Polymer Flooding. Energies 2020, 13, 3049. [Google Scholar] [CrossRef]

- Rock, A. Pore Scale Visualization of Polymer Viscoelasticity Using Particle Tracing in Glass-Silicon-Glass Micormodels That Are Resembling Porous Media. Bachelor’s Thesis, Clausthal University of Technology, Clausthal-Zellerfeld, Germany, 2016. [Google Scholar]

- Al-Shakry, B.; Skauge, T.; Shaker Shiran, B.; Skauge, A. Polymer Injectivity: Investigation of Mechanical Degradation of Enhanced Oil Recovery Polymers Using In-Situ Rheology. Energies 2019, 12, 49. [Google Scholar] [CrossRef] [Green Version]

- Al-Shakry, B.; Skauge, T.; Shaker Shiran, B.; Skauge, A. Impact of Mechanical Degradation on Polymer Injectivity in Porous Media. Polymers 2018, 10, 742. [Google Scholar] [CrossRef] [Green Version]

- Skauge, A.; Zamani, N.; Gausdal Jacobsen, J.; Shaker Shiran, B.; Al-Shakry, B.; Skauge, T. Polymer Flow in Porous Media: Relevance to Enhanced Oil Recovery. Colloids Interfaces 2018, 2, 27. [Google Scholar] [CrossRef] [Green Version]

- Sousa, P.C.; Vega, E.J.; Sousa, R.G.; Montanero, J.M.; Alves, M.A. Measurement of relaxation times in extensional flow of weakly viscoelastic polymer solutions. Rheol. Acta 2017, 56, 11–20. [Google Scholar] [CrossRef] [Green Version]

- Collett, C.; Ardron, A.; Bauer, U.; Chapman, G.; Chaudan, E.; Hallmark, B.; Pratt, L.; Torres-Perez, M.D.; Wilson, D.I. A portable extensional rheometer for measuring the viscoelasticity of pitcher plant and other sticky liquids in the field. Plant Methods 2015, 11, 16. [Google Scholar] [CrossRef] [Green Version]

- Sachsenheimer, D.; Hochstein, B.; Willenbacher, N. Experimental study on the capillary thinning of entangled polymer solutions. Rheol. Acta 2014, 53, 725–739. [Google Scholar] [CrossRef]

- McKinley, G.H.; Anna, S.L.; Tripathi, A.; Yao, M. Extensional rheometry of polymeric fluids and the uniaxial elongation of viscoelastic filaments. In Proceedings of the 15th International Polymer Processing Society, Hertogenbosch, The Netherlands, 31 May–4 June 1999; p. 14. [Google Scholar]

- Bhardwaj, A.; Miller, E.; Rothstein, J.P. Filament stretching and capillary breakup extensional rheometry measurements of viscoelastic wormlike micelle solutions. J. Rheol. 2007, 51, 693–719. [Google Scholar] [CrossRef] [Green Version]

- Azad, M.S.; Dalsania, Y.K.; Trivedi, J.J. Capillary breakup extensional rheometry of associative and hydrolyzed polyacrylamide polymers for oil recovery applications. J. Appl. Polym. Sci. 2018, 135, 46253. [Google Scholar] [CrossRef]

- Clasen, C. Capillary breakup extensional rheometry of semi-dilute polymer solutions. Korea-Aust. Rheol. J. 2010, 22, 331–338. [Google Scholar]

- Dinic, J.; Zhang, Y.; Jimenez, L.N.; Sharma, V. Extensional Relaxation Times of Dilute, Aqueous Polymer Solutions. ACS Macro Lett. 2015, 4, 804–808. [Google Scholar] [CrossRef]

- Del Giudice, F.; Haward, S.J.; Shen, A.Q. Relaxation time of dilute polymer solutions: A microfluidic approach. J. Rheol. 2017, 61, 327–337. [Google Scholar] [CrossRef] [Green Version]

- Romeo, G.; D’Avino, G.; Greco, F.; Netti, P.A.; Maffettone, P.L. Viscoelastic flow-focusing in microchannels: Scaling properties of the particle radial distributions. Lab. Chip 2013, 13, 2802–2807. [Google Scholar] [CrossRef]

- Tahir, M.; Hincapie, R.E.; Foedisch, H.; Abdullah, H.; Ganzer, L. Impact of Sulphates Presence During Application of Smart Water Flooding Combined with Polymer Flooding. In Proceedings of the SPE Europec featured at 80th EAGE Conference and Exhibition, Copenhagen, Denmark, 11–14 June 2018. [Google Scholar]

- Tahir, M.; Hincapie, R.E.; Langanke, N.; Ganzer, L.; Jaeger, P. Coupling Microfluidics Data with Core Flooding Experiments to Understand Sulfonated/Polymer Water Injection. Polymers 2020, 12, 1227. [Google Scholar] [CrossRef]

- Campo-Deaño, L.; Galindo-Rosales, F.J.; Pinho, F.T.; Alves, M.A.; Oliveira, M.S.N. Flow of low viscosity Boger fluids through a microfluidic hyperbolic contraction. J. Non-Newton. Fluid Mech. 2011, 166, 1286–1296. [Google Scholar] [CrossRef] [Green Version]

- Herbas, J.G.; Wegner, J.; Hincapie, R.E.; Födisch, H.; Ganzer, L.; Castillo, J.A.D.; Mugizi, H.M. Comprehensive Micromodel Study to Evaluate Polymer EOR in Unconsolidated Sand Reservoirs. In Proceedings of the SPE Middle East Oil & Gas Show and Conference, Manama, Bahrain, 8–11 March 2015. [Google Scholar]

- Sousa, P.C.; Pinho, F.T.; Oliveira, M.S.N.; Alves, M.A. Efficient microfluidic rectifiers for viscoelastic fluid flow. J. Non-Newton. Fluid Mech. 2010, 165, 652–671. [Google Scholar] [CrossRef] [Green Version]

- Schumi, B.; Clemens, T.; Wegner, J.; Ganzer, L.; Kaiser, A.; Hincapie, R.E.; Leitenmueller, V. Alkali/Cosolvent/Polymer Flooding of High-TAN Oil: Using Phase Experiments, Micromodels, and Corefloods for Injection-Agent Selection. SPE Reserv. Eval. Eng. 2019, 23, 463–478. [Google Scholar] [CrossRef]

- Gaol, C.; Wegner, J.; Ganzer, L.; Dopffel, N.; Koegler, F.; Borovina, A.; Alkan, H. Investigation of Pore-Scale Mechanisms of Microbial Enhanced Oil Recovery MEOR Using Microfluidics Application. In Proceedings of the SPE Europec featured at 81st EAGE Conference and Exhibition, London, UK, 3–6 June 2019. [Google Scholar]

- Gaol, C.L.; Wegner, J.; Ganzer, L. Real structure micromodels based on reservoir rocks for enhanced oil recovery (EOR) applications. Lab. Chip 2020, 20, 2197–2208. [Google Scholar] [CrossRef] [PubMed]

- Seguin, D.; Montillet, A.; Comiti, J.; Huet, F. Experimental characterization of flow regimes in various porous media—II: Transition to turbulent regime. Chem. Eng. Sci. 1998, 53, 3897–3909. [Google Scholar] [CrossRef]

- Ergun, S.; Orning, A.A. Fluid Flow through Randomly Packed Columns and Fluidized Beds. Ind. Eng. Chem. 1949, 41, 1179–1184. [Google Scholar] [CrossRef]

- Tahir, M.; Hincapie, R.E.; Langanke, N.; Ganzer, L. Coupling Microfluidics Data with Core Flooding Experiments to Understand Sulphonated/Polymer Water Injection. In Proceedings of the Virtual SPE Europec featured at 82nd EAGE Conference and Exhibition, Amsterdam, The Netherlands, 8–11 December 2020. [Google Scholar] [CrossRef]

- Al-Saedi, H.N.; Al-Jaberi, S.K.; Al-Bazzaz, W.; Flori, R.E. Experimental Study of Flooding both Low Salinity Water and Foam in Sandstone Reservoirs Bearing Heavy Crude Oil. In Proceedings of the SPE Gas & Oil Technology Showcase and Conference, Dubai, UAE, 21–23 October 2019. [Google Scholar]

- Foedisch, H.; Abdullah, H.; Hincapie, R.E.; Ganzer, L. Optimizing Laboratory cEOR Flooding Evaluations to Assess Initial Oil Saturation and Mobility Ratio. In Proceedings of the SPE Europec featured at 80th EAGE Conference and Exhibition, Copenhagen, Denmark, 11–14 June 2018. [Google Scholar]

- Wu, Y.; Dong, M.; Shirif, E. Study of Alkaline/Polymer Flooding for Heavy-Oil Recovery Using Channeled Sandpacks. SPE Reserv. Eval. Eng. 2011, 14, 310–319. [Google Scholar] [CrossRef]

- Ringen, I.; Stiegler, H.; Nødland, O.; Hiorth, A.; Stavland, A. Polymer flooding in sandpacks with a dualporosity. In Proceedings of the The International Symposium of the Society of Core Analysts, Snowmass, CO, USA, 21–26 August 2016. [Google Scholar]

- Aitkulov, A.; Mohanty, K.K. Investigation of alkaline-surfactant-polymer flooding in a quarter five-spot sandpack for viscous oil recovery. J. Pet. Sci. Eng. 2019, 175, 706–718. [Google Scholar] [CrossRef]

- Mall-Gleissle, S.E.; Gleissle, W.; Buggisch, H.; McKinley, G.H. The normal stress behaviour of suspensions with viscoelastic matrix fluids. Rheol. Acta 2002, 41, 61–76. [Google Scholar] [CrossRef]

- Jensen, E.A.; Christiansen, J. deC. Measurements of first and second normal stress differences in a polymer melt. J. Non-Newton. Fluid Mech. 2008, 148, 41–46. [Google Scholar] [CrossRef]

- Nam, J.G.; Ahn, K.H.; Lee, S.J.; Hyun, K. First normal stress difference of entangled polymer solutions in large amplitude oscillatory shear flow. J. Rheol. 2010, 54, 1243–1266. [Google Scholar] [CrossRef]

- Duffy, J.; Rega, C.; Kroger, M.; Jack, A.; Amin, S. An algebraic approach for determining viscoelastic moduli from creep compliance through application of the Generalised Stokes-Einstein relation and Burgers model. Appl. Rheol. 2016, 26, 15130. [Google Scholar] [CrossRef]

- Pipe, C.J.; Kim, N.J.; McKinley, G.H. Microfluidic rheometry on a chip. In Proceedings of the 4th Annual European Rheology Conference (AERC 2007), Napoli, Italy, 12–14 April 2007. [Google Scholar]

- Galindo-Rosales, F.J.; Campo-Deaño, L.; Sousa, P.C.; Ribeiro, V.M.; Oliveira, M.S.N.; Alves, M.A.; Pinho, F.T. Viscoelastic instabilities in micro-scale flows. Exp. Therm. Fluid Sci. 2014, 59, 128–139. [Google Scholar] [CrossRef] [Green Version]

- Calvert, J.G. Glossary of atmospheric chemistry terms (Recommendations 1990). Pure Appl. Chem. 1990, 62, 2167–2219. [Google Scholar] [CrossRef] [Green Version]

- micromod Partikeltechnologie GmbH Downloads. 2018. Available online: https://www.micromod.de/de/downloads-45.html (accessed on 14 August 2020).

- Vik, B.; Kedir, A.; Kippe, V.; Sandengen, K.; Skauge, T.; Solbakken, J.; Zhu, D. Viscous Oil Recovery by Polymer Injection; Impact of In-Situ Polymer Rheology on Water Front Stabilization. In Proceedings of the SPE Europec featured at 80th EAGE Conference and Exhibition, Copenhagen, Denmark, 11–14 June 2018. [Google Scholar]

- Khamees, T.K.; Flori, R.E. Modeling the Combined Effects of Water Salinity and Polymer Rheology on the Performance of Polymer Flooding and In-Depth Gel Treatment. In Proceedings of the SPE Western Regional Meeting, Garden Grove, CA, USA, 22–26 April 2018. [Google Scholar]

- Turkoz, E.; Perazzo, A.; Arnold, C.B.; Stone, H.A. Salt type and concentration affect the viscoelasticity of polyelectrolyte solutions. Appl. Phys. Lett. 2018, 112, 203701. [Google Scholar] [CrossRef]

- Khorsandi, S.; Qiao, C.; Johns, R.T. Displacement Efficiency for Low Salinity Polymer Flooding Including Wettability Alteration. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016. [Google Scholar]

- Santo, A.; Muggeridge, A. An Investigation into the Benefits of Combined Polymer-Low Salinity Waterflooding. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Brisbane, Australia, 23–25 October 2018. [Google Scholar]

- Sasaki, K. Charge screening effect in metallic carbon nanotubes. Phys. Rev. B 2002, 65, 195412. [Google Scholar] [CrossRef] [Green Version]

- Hofmeister, F. Zur Lehre von der Wirkung der Salze: Zweite Mittheilung. 1888. Available online: http://publikationen.ub.uni-frankfurt.de/frontdoor/index/index/year/2007/docId/15978 (accessed on 14 August 2020).

- Heemskerk, J.; Rosmalen, R.; Janssen-van, R.; Holtslag, R.J.; Teeuw, D. Quantification of Viscoelastic Effects of Polyacrylamide Solutions. In Proceedings of the SPE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 15–18 April 1984. [Google Scholar]

- Seright, R.S.; Fan, T.; Wavrik, K.E.; Balaban, R.D.C. New Insights into Polymer Rheology in Porous Media. SPE J. 2010, 16, 35–42. [Google Scholar] [CrossRef]

- Klein, J.; Kulicke, W.M. Polymer-Polymer and Polymer-Solid Interaction and Their Relevance for Polymer Application in Enhanced Oil Recovery. In Proceedings of the SPE Oilfield and Geothermal Chemistry Symposium, Stanford, CA, USA, 28–30 May 1980. [Google Scholar]

- Müller, A.J.; Patruyo, L.G.; Montano, W.; Roversi-M., D.; Moreno, R.; Rami’rez, N.E.; Sa’ez, A.E. Mechanical Degradation of Polymers in Flows Through Porous Media: Effect of Flow Path Length and Particle Size. Appl. Mech. Rev. 1997, 50, S149–S155. [Google Scholar] [CrossRef]

- Bueche, F. Mechanical degradation of high polymers. J. Appl. Polym. Sci. 1960, 4, 101–106. [Google Scholar] [CrossRef]

- Larsen, H.A.; Drickamer, H.G. Mechanical Degradation and Cross Linking of Polymers by Plastic Deformation at High Pressure. J. Phys. Chem. 1957, 61, 1643–1646. [Google Scholar] [CrossRef]

- Frenkel Статьи Левича—кафедра Электрoхимии. Available online: http://www.elch.chem.msu.ru/wp3/index.php/ru/articles/levicharticles/ (accessed on 14 August 2020).

- Maurer, J.J.; Harvey, G.D. Thermal degradation characteristics of poly(acrylamide-co-acrylic acid) and poly(acrylamide-co-sodium acrylate) copolymers. Thermochim. Acta 1987, 121, 295–306. [Google Scholar] [CrossRef]

- Ray, S.; Cooney, R. Thermal Degradation of Polymer and Polymer Composites. Handb. Environ. Degrad. Mater. Second Ed. 2012, 213–242. [Google Scholar] [CrossRef]

- Thermal Degradation of Polymer—An Overview | ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/engineering/thermal-degradation-of-polymer (accessed on 3 April 2020).

- Rodriguez, L.; Antignard, S.; Giovannetti, B.; Dupuis, G.; Gaillard, N.; Jouenne, S.; Bourdarot, G.; Morel, D.; Zaitoun, A.; Grassl, B. A New Thermally Stable Synthetic Polymer for Harsh Conditions of Middle East Reservoirs. In Proceedings of the SEG/AAPG/EAGE/SPE Research and Development Petroleum Conference and Exhibition, Abu Dhabi, UAE, 9–10 May 2018; pp. 16–19. [Google Scholar]

- Saleh, L.D.; Wei, M.; Bai, B. Data Analysis and Updated Screening Criteria for Polymer Flooding Based on Oilfield Data. SPE Reserv. Eval. Eng. 2014, 17, 15–25. [Google Scholar] [CrossRef]

- Saboorian-Jooybari, H.; Dejam, M.; Chen, Z. Half-Century of Heavy Oil Polymer Flooding from Laboratory Core Floods to Pilot Tests and Field Applications. In Proceedings of the SPE Canada Heavy Oil Technical Conference, Calgary, AB, Canada, 9–11 June 2015. [Google Scholar]

- Mitova, V.; Grancharov, G.; Molero, C.; Borreguero, A.; Troev, K.; Rodríguez, J. Chemical Degradation of Polymers (Polyurethanes, Polycarbonate and Polyamide) by Esters of H-phosphonic and Phosphoric Acids. J. Macromol. Sci. 2013, 50, 774–795. [Google Scholar] [CrossRef]

- Chemical Degradation—An Overview | ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/materials-science/chemical-degradation (accessed on 3 April 2020).

- Lake, L.W. Enhanced Oil Recovery; Prentice Hall: Englewood Cliffs, NJ, USA, 1989; ISBN 978-0-13-281601-4. [Google Scholar]

- Jia, R.; Yang, D.; Abd, H.B. 51318-10567-Investigation of the Impact of an Enhanced Oil Recovery Polymer on Microbial Growth and MIC. 2018. Available online: https://store.nace.org/investigation-of-the-impact-of-an-enhanced-oil-recovery-polymer-on-microbial-growth-and-mic-2 (accessed on 14 August 2020).

- Al-Moqbali, W.; Joshi, S.J.; Al-Bahry, S.N.; Al-Wahaibi, Y.M.; Elshafie, A.E.; Al-Bemani, A.S.; Al-Hashmi, A.; Soundra Pandian, S.B. Biodegradation of Partially Hydrolyzed Polyacrylamide HPAM Using Bacteria Isolated from Omani Oil Fields. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 26–28 March 2018. [Google Scholar]

- Kolnes, J.; Nilsson, S. Effect of the Core Material on Gelation of a HPAM / Chromium System at High Temperature. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, Oklahoma, 21–24 April 1996. [Google Scholar]

- PetroWIKI. Polymer Waterflooding. Available online: https://petrowiki.org/Polymer_waterflooding (accessed on 14 August 2020).

- Austad, T.; Rezaeidoust, A.; Puntervold, T. Chemical Mechanism of Low Salinity Water Flooding in Sandstone Reservoirs. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010. [Google Scholar]

| Mechanism | Reference | |

|---|---|---|

| 1 | Relative Permeability Reduction | Sheng et al. [17], Sheng [14], Huh and Pope [9], Abidin et al. [18] |

| 2 | Viscous Fingering Reduction | Sheng et al. [17], Sheng [14], Clarke et al. [2], Dong et al. [16], Abdul Hamid and Muggeridge [19], Tahir et al. [20] |

| 3 | Enhanced Flow between Vertical, Heterogeneous Layers | Sheng et al. [17], Sorbie [21] |

| 4 | Pull-Out in Dead End Pores | Luo et al. [22], Yin et al. [23] |

| 5 | Stripping from Oil-Wet Rock Surface | Wang [24] |

| 6 | Shear Thickening | Rock et al. [11], Hincapie [8], Howe et al. [25], Clarke et al. [2], Azad and Trivedi [26,27,28] |

| 7 | Elastic Turbulence | Hincapie et al. [29], Rock et al. [30], Groisman and Steinberg [31] |

| Polymer Concentration, c [ppm] | Solution Salinity [g/l TDS] | Molecular Weight, MW [MDa] | Relaxation Time, λ [s] |

|---|---|---|---|

| 500 | 4.0 | 29 | n.a. |

| 1000 | 4.0 | 29 | 2.31 |

| 1500 | 4.0 | 29 | 3.33 |

| 500 | 0.4 | 29 | 17.22 |

| 1000 | 0.4 | 29 | 25.62 |

| 1500 | 0.4 | 29 | 40.93 |

| Reference | Recommended Maximum Reservoir Temperature [°C] |

|---|---|

| Taber et al. (1997) | <93 |

| Saleh et al. (2014) | <99 |

| Dickson et al. (2010) | <77 |

| Delamaide et al. (2016) | <80 |

| Saboorian-Joybari (2015) | <65 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rock, A.; Hincapie, R.E.; Tahir, M.; Langanke, N.; Ganzer, L. On the Role of Polymer Viscoelasticity in Enhanced Oil Recovery: Extensive Laboratory Data and Review. Polymers 2020, 12, 2276. https://doi.org/10.3390/polym12102276

Rock A, Hincapie RE, Tahir M, Langanke N, Ganzer L. On the Role of Polymer Viscoelasticity in Enhanced Oil Recovery: Extensive Laboratory Data and Review. Polymers. 2020; 12(10):2276. https://doi.org/10.3390/polym12102276

Chicago/Turabian StyleRock, Alexander, Rafael E. Hincapie, Muhammad Tahir, Nils Langanke, and Leonhard Ganzer. 2020. "On the Role of Polymer Viscoelasticity in Enhanced Oil Recovery: Extensive Laboratory Data and Review" Polymers 12, no. 10: 2276. https://doi.org/10.3390/polym12102276