Spatially Engraving Morphological Structure on a Polymeric Surface by Ion Beam Milling

Abstract

:1. Introduction

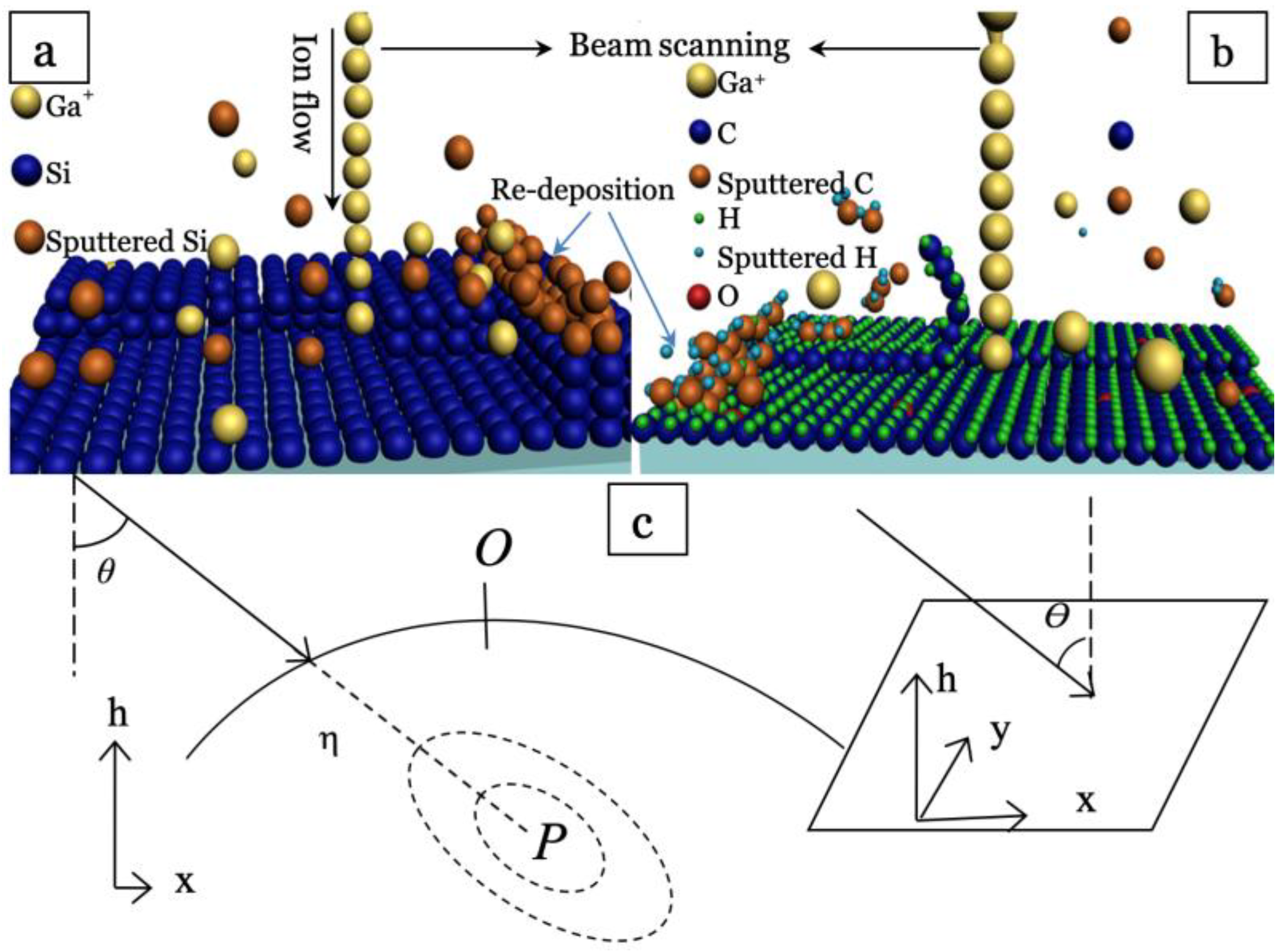

2. Theoretical Background

3. Experimental Methods

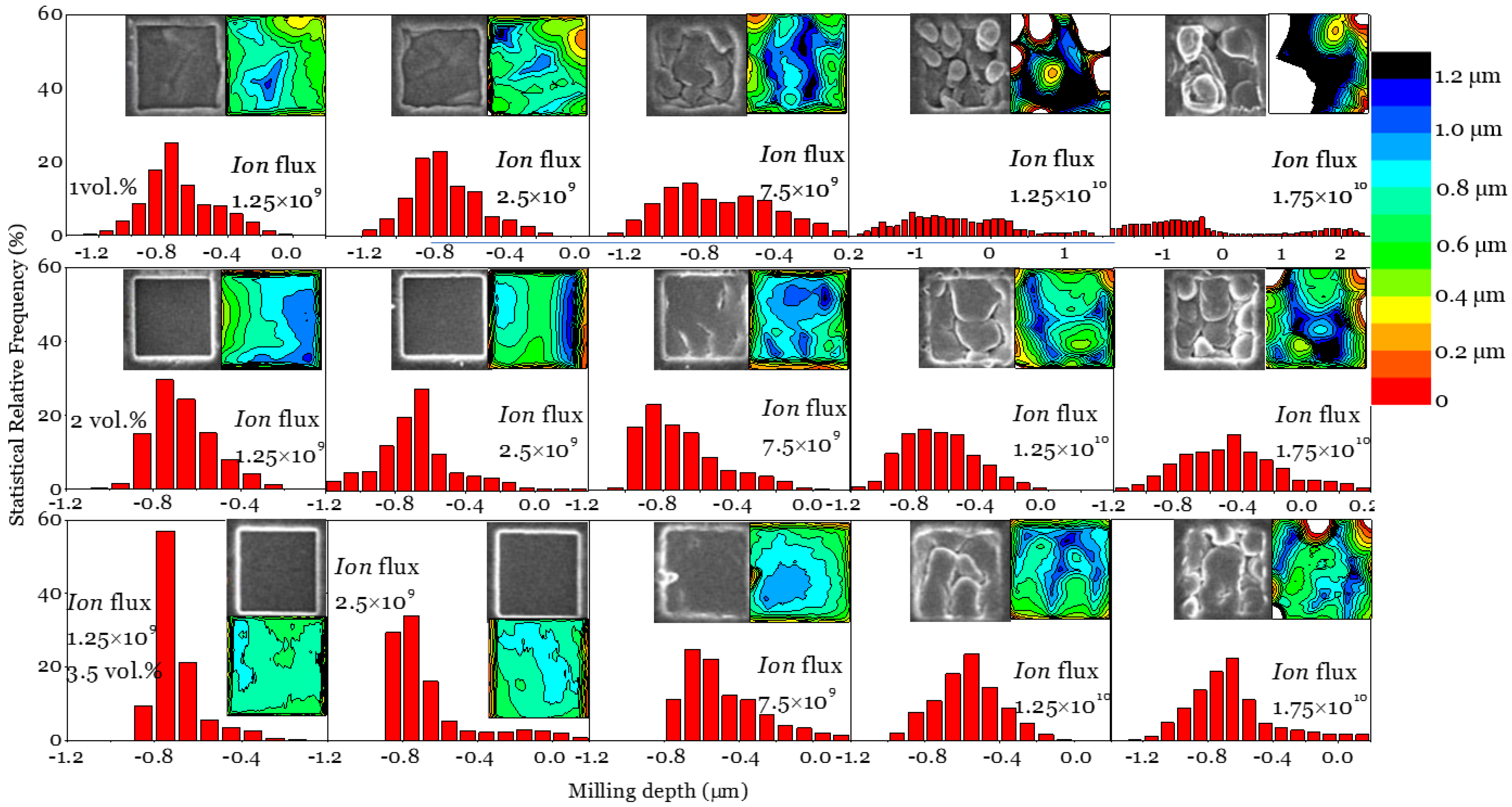

4. Results and Discussion

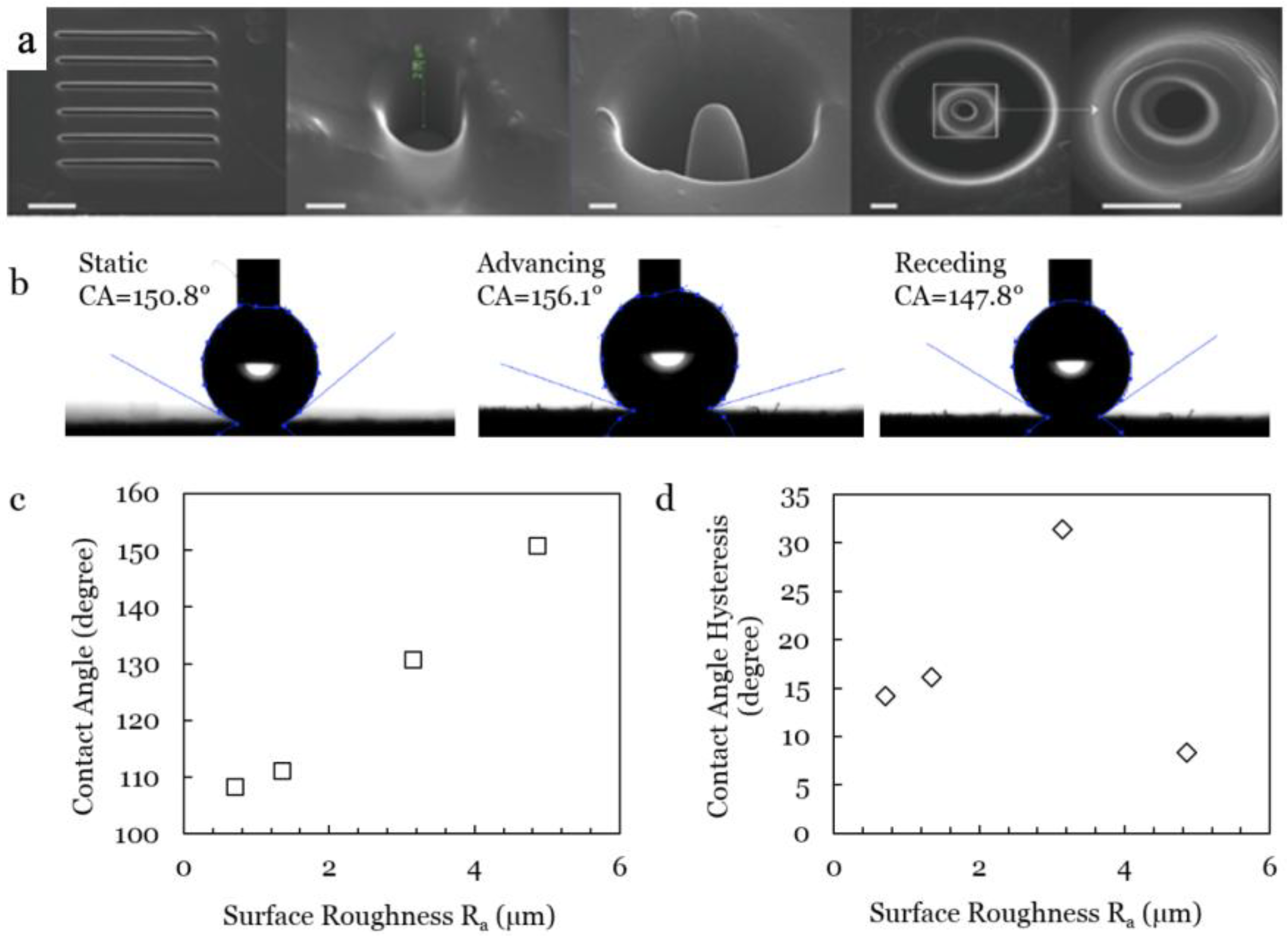

5. Application Demonstration

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Simpson, J.T.; Hunter, S.R.; Aytug, T. Superhydrophobic materials and coatings: A review. Rep. Prog. Phys. 2015, 78, 086501. [Google Scholar] [CrossRef] [PubMed]

- Yilgör, E.; Söz, C.K.; Yilgör, I. Wetting behavior of superhydrophobic poly(methyl methacrylate). Prog. Org. Coat. 2018, 125, 530–536. [Google Scholar] [CrossRef]

- Bhushan, B.; Jung, Y.C. Natural and biomimetic artificial surfaces for superhydrophobicity, self-cleaning, low adhesion, and drag reduction. Prog. Mater. Sci. 2011, 56, 1–108. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Liu, K.; Yao, X.; Jiang, L. Bioinspired Surfaces with Superwettability: New Insight on Theory, Design, and Applications. Chem. Rev. 2015, 115, 8230–8293. [Google Scholar] [CrossRef]

- Kochkodan, V.; Hilal, N. A comprehensive review on surface modified polymer membranes for biofouling mitigation. Desalination 2015, 356, 187–207. [Google Scholar] [CrossRef]

- Kreder, M.J.; Alvarenga, J.; Kim, P.; Aizenberg, J. Design of anti-icing surfaces: Smooth, textured or slippery? Nat. Rev. Mater. 2016, 1, 15003. [Google Scholar] [CrossRef]

- Zhang, C.; McAdams, D.A.; Grunlan, J.C. Nano/Micro-Manufacturing of Bioinspired Materials: A Review of Methods to Mimic Natural Structures. Adv. Mater. 2016, 28, 6292–6321. [Google Scholar] [CrossRef]

- Zhang, P.; Lin, L.; Zang, D.; Guo, X.; Liu, M. Designing Bioinspired Anti-Biofouling Surfaces based on a Superwettability Strategy. Small 2017, 13, 1503334. [Google Scholar] [CrossRef]

- Wang, D.; Cheewaruangroj, N.; Li, Y.; McHale, G.; Jiang, Y.; Wood, D.; Biggins, J.S.; Xu, B.B. Spatially configuring wrinkle pattern and multiscale surface evolution with structural confinement. Adv. Funct. Mater. 2018, 28, 1704228. [Google Scholar] [CrossRef]

- Huang, X.; Sun, Y.; Soh, S. Stimuli-Responsive Surfaces for Tunable and Reversible Control of Wettability. Adv. Mater. 2015, 27, 4062–4068. [Google Scholar] [CrossRef]

- Rhee, D.; Lee, W.K.; Odom, T.W. Crack-Free, Soft Wrinkles Enable Switchable Anisotropic Wetting. Angew. Chem. Int. Ed. 2017, 56, 6523–6527. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Liu, Y.; Xu, B.; Hui, D.; Fu, Y.Q. Spontaneous biaxial pattern generation and autonomous wetting switching on the surface of gold/shape memory polystyrene bilayer. Compos. Part B Eng. 2017, 122, 9–15. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Genzer, J.; Dickey, M.D. “2D or not 2D”: Shape-programming polymer sheets. Prog. Polym. Sci. 2016, 52, 79–106. [Google Scholar] [CrossRef]

- Xu, B.; Huang, W.; Pei, Y.; Chen, Z.; Kraft, A.; Reuben, R.; De Hosson, J.; Fu, Y. Mechanical properties of attapulgite clay reinforced polyurethane shape-memory nanocomposites. Eur. Polym. J. 2009, 45, 1904–1911. [Google Scholar] [CrossRef]

- Moon, M.W.; Lee, S.H.; Sun, J.Y.; Oh, K.H.; Vaziri, A.; Hutchinson, J.W. Wrinkled hard skins on polymers created by focused ion beam. Proc. Natl. Acad. Sci. USA 2007, 104, 1130–1133. [Google Scholar] [CrossRef] [Green Version]

- Xu, B.; Fu, Y.Q.; Huang, W.M.; Pei, Y.T.; Chen, Z.G.; De Hosson, J.T.; Kraft, A.; Reuben, R.L. Thermal-Mechanical Properties of Polyurethane-Clay Shape Memory Polymer Nanocomposites. Polymers 2010, 2, 31–39. [Google Scholar] [CrossRef] [Green Version]

- Giannuzzi, L.A.; Utlaut, M. A review of Ga+ FIB/SIMS. Surf. Interface Anal. 2011, 43, 475. [Google Scholar] [CrossRef]

- Roediger, P.; Wanzenboeck, H.D.; Waid, S.; Hochleitner, G.; Bertagnolli, E. Focused-ion-beam-inflicted surface amorphization and gallium implantation—New insights and removal by focused-electron-beam-induced etching. Nanotechnology 2011, 22, 235302. [Google Scholar] [CrossRef]

- Völlner, J.; Ziberi, B.; Frost, F.; Rauschenbach, B. Topography evolution mechanism on fused silica during low-energy ion beam sputtering. J. Appl. Phys. 2011, 109, 43501. [Google Scholar]

- Oehrlein, G.S.; Phaneuf, R.J.; Graves, D.B. Plasma-polymer interactions: A review of progress in understanding polymer resist mask durability during plasma etching for nanoscale fabrication. J. Vac. Sci. Technol. B 2011, 29, 10801. [Google Scholar] [CrossRef]

- Cahill, D.G. Morphological instabilities in thin-film growth and etching. J. Vac. Sci. Technol. A 2003, 21, S110–S116. [Google Scholar] [CrossRef]

- Brostow, W.; Gorman, B.P.; Olea-Mejia, O. Focused ion beam milling and scanning electron microscopy characterization of polymer+ metal hybrids. Mater. Lett. 2007, 61, 1333. [Google Scholar] [CrossRef]

- Brunner, S.; Gasser, P.; Simmler, H.; Wakili, K.G. Investigation of multilayered aluminium-coated polymer laminates by focused ion beam (FIB) etching. Surf. Coat. Technol. 2006, 200, 5908. [Google Scholar] [CrossRef]

- Pialat, E.; Trigaud, T.; Bernical, V.; Moliton, J.P. Milling of polymeric photonic crystals by focused ion beam. Mater. Sci. Eng. C 2005, 25, 618. [Google Scholar] [CrossRef]

- Mulders, J.; De Winter, D.; Duinkerken, W.; De Winter, M. Measurements and calculations of FIB milling yield of bulk metals. Microelectron. Eng. 2007, 84, 1540–1543. [Google Scholar] [CrossRef]

- Muñoz-Garcia, J.; Gago, R.; Vazquez, L.; Sánchez-García, J.A.; Cuerno, R. Observation and Modeling of Interrupted Pattern Coarsening: Surface Nanostructuring by Ion Erosion. Phys. Rev. Lett. 2010, 104, 026101. [Google Scholar] [CrossRef] [Green Version]

- Muñoz-Garcia, J.; Castro, M.; Cuerno, R. Nonlinear Ripple Dynamics on Amorphous Surfaces Patterned by Ion Beam Sputtering. Phys. Rev. Lett. 2006, 96, 086101. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bradley, R.M. Theory of ripple topography induced by ion bombardment. J. Vac. Sci. Technol. A 1988, 6, 2390–2395. [Google Scholar] [CrossRef]

- Eklund, E.A.; Bruinsma, R.; Rudnick, J.; Williams, R.S. Submicron-Scale Surface Roughening Induced by Ion Bombardment. Phys. Rev. Lett. 1991, 67, 1759. [Google Scholar] [CrossRef]

- Mitsui, T.; Stein, D.; Kim, Y.R.; Hoogerheide, D.; Golovchenko, J.A. Nanoscale Volcanoes: Accretion of Matter at Ion-Sculpted Nanopores. Phys. Rev. Lett. 2006, 96, 036102. [Google Scholar] [CrossRef]

- Rodríguez-Laguna, J.; Santalla, S.N.; Cuerno, R. Intrinsic geometry approach to surface kinetic roughening. J. Stat. Mech. Theory Exp. 2011, 2011, 05032. [Google Scholar] [CrossRef]

- Kardar, M.; Parisi, G.; Zhang, Y.C. Dynamic Scaling of Growing Interfaces. Phys. Rev. Lett. 1986, 56, 889–892. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Makeev, M.A.; Barabási, A.L. Effect of surface roughness on the secondary ion yield in ion sputtering. Appl. Phys. Lett. 1998, 73, 2209–2211. [Google Scholar] [CrossRef]

- Cuerno, R.; Barabasi, A.L. Dynamic Scaling of Ion-Sputtered Surfaces. Phys. Rev. Lett. 1995, 74, 4746–4749. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sigmund, P. Theory of Sputtering. I. Sputtering Yield of Amorphous and Polycrystalline Targets. Phys. Rev. 1969, 184, 383–416. [Google Scholar] [CrossRef]

- Castro, M.; Cuerno, R.; Vazquez, L.; Gago, R. Self-Organized Ordering of Nanostructures Produced by Ion-Beam Sputtering. Phys. Rev. Lett. 2005, 94, 016102. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Muñoz-Garcia, J.; Cuerno, R.; Castro, M. Coupling of morphology to surface transport in ion-beam-irradiated surfaces: Normal incidence and rotating targets. J. Phys. Condens. Matter 2009, 21, 224020. [Google Scholar] [CrossRef]

- Walmann, T.; Malthe-Sørenssen, A.; Feder, J.; Jøssang, T.; Hardy, H.H.; Meakin, P. Scaling Relations for the Lengths and Widths of Fractures. Phys. Rev. Lett. 1996, 77, 5393–5396. [Google Scholar] [CrossRef]

- Mullins, W.W. Theory of thermal grooving. J. Appl. Phys. 1957, 28, 333. [Google Scholar] [CrossRef]

- Herring, C. Effect of Change of Scale on Sintering Phenomena. J. Appl. Phys. 1950, 21, 301–303. [Google Scholar] [CrossRef]

- Mullins, J.F.; Lettieri, M.F. Chemosurgery of facial wrinkles. Tex. State J. Med. 1963, 59, 488. [Google Scholar] [PubMed]

- Jain, H.; Mundy, J. Analysis of ac conductivity of glasses by a power law relationship. J. Non-Cryst. Solids 1987, 91, 315–323. [Google Scholar] [CrossRef]

- Voss, S.; Imre, Á.W.; Mehrer, H. Mixed-alkali effect in Na–Rb borate glasses: A tracer diffusion and electrical conductivity study. Phys. Chem. Chem. Phys. 2004, 6, 3669–3675. [Google Scholar] [CrossRef]

- Makeev, M.A.; Cuerno, R.; Barabási, A.L. Morphology of ion-sputtered surfaces. Nuclear Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2002, 197, 185. [Google Scholar] [CrossRef]

- Makeev, M.A.; Barabási, A.L. Secondary ion yield changes on rippled interfaces. Appl. Phys. Lett. 1998, 72, 906–908. [Google Scholar] [CrossRef] [Green Version]

- Muñoz-García, J.; Cuerno, R.; Castro, M. Short-range stationary patterns and long-range disorder in an evolution equation for one-dimensional interfaces. Phys. Rev. E 2006, 74, 050103. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.H.; Ha, N.B.; Kim, J.S.; Joe, M.; Lee, K.R.; Cuerno, R. One-dimensional pattern of Au nanodots by ion-beam sputtering: Formation and mechanism. Nanotechnology 2011, 22, 285301. [Google Scholar] [CrossRef]

- Lu, H.; Wang, X.; Yao, Y.; Gou, J.; Hui, D.; Xu, B.; Fu, Y. Synergistic effect of siloxane modified aluminum nanopowders and carbon fiber on electrothermal efficiency of polymeric shape memory nanocomposite. Compos. Part B Eng. 2015, 80, 1–6. [Google Scholar] [CrossRef]

- Dai, X.; Du, Y.; Yang, J.; Wang, D.; Gu, J.; Li, Y.; Wang, S.; Xu, B.B.; Kong, J. Recoverable and self-healing electromagnetic wave absorbing nanocomposites. Compos. Sci. Technol. 2019, 174, 27–32. [Google Scholar] [CrossRef]

- Hood, P.J.; Havens, D.E. Structural and optical applications for shape memory polymers (SMP. Polymer Patches). U.S. Patent US6986855B1, 24 1 2002. [Google Scholar]

- Hood, P.J.; Garrigan, S.; Auffinger, F. Method of Making and Using Shape Memory. U.S. Patent US8808479B2, 15 12 2006. [Google Scholar]

- Xu, B.; Zhang, L.; Pei, Y.T.; Luom, J.K.; Tao, S.W.; de Hosson, J.T.M.; Fu, Y.Q. Electro-responsive polystyrene shape memory polymer nanocomposites. Nanosci. Nanotechnol. Lett. 2012, 4, 814–820. [Google Scholar] [CrossRef]

- Lei, M.; Xu, B.; Pei, Y.; Lu, H.; Fu, Y.Q. Micro-mechanics of nanostructured carbon/shape memory polymer hybrid thin film. Soft Matter 2016, 12, 106–114. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Fu, Y.Q.; Ahmad, M.; Luo, J.K.; Huang, W.M.; Kraft, A.; Reuben, R.; Pei, Y.T.; Chen, Z.G.; De Hosson, J.T.M. Thermo-mechanical properties of polystyrene-based shape memory nanocomposites. J. Mater. Chem. 2010, 20, 3442–3448. [Google Scholar] [CrossRef]

- Barna, A.; Kotis, L.; Labar, J.L.; Osvath, Z.; Toth, A.L.; Menyhard, M.; Zalar, A.; Panjan, P. Producing metastable nanophase with sharp interface by means of focused ion beam irradiation. J. Appl. Phys. 2007, 102, 044305. [Google Scholar] [CrossRef]

- Roush, M.; Andreadis, T.; Davarya, F.; Goktepe, O. Dynamic simulation of changes in near-surface composition during ion bombardment. Appl. Surf. Sci. 1982, 11, 235–242. [Google Scholar] [CrossRef]

- Möller, W.; Eckstein, W.; Biersack, J. Tridyn-binary collision simulation of atomic collisions and dynamic composition changes in solids. Comput. Phys. Commun. 1988, 51, 355–368. [Google Scholar] [CrossRef]

- Sun, J.; Luo, X.; Ritchie, J.M.; Chang, W.; Wang, W. An investigation of redeposition effect for deterministic fabrication of nanodots by focused ion beam. Precis. Eng. 2012, 36, 31. [Google Scholar] [CrossRef]

- Dang, Z.M.; Lin, Y.H.; Nan, C.W. Novel ferroelectric polymer composites with high dielectric constants. Adv. Mater. 2003, 15, 1625. [Google Scholar] [CrossRef]

- Pecharroman, C.; Esteban-Betegon, F.; Bartolome, J.F.; Lopez-Esteban, S.; Moya, J.S. New Percolative BaTiO3–Ni Composites with a High and Frequency-Independent Dielectric Constant. Adv. Mater. 2001, 13, 1541. [Google Scholar] [CrossRef]

- Pötschke, P.; Dudkin, S.M.; Alig, I. Dielectric spectroscopy on melt processed polycarbonate—Multiwalled carbon nanotube composites. Polymer 2003, 44, 5023–5030. [Google Scholar] [CrossRef]

- Regev, O.; ElKati, P.N.B.; Loos, J.; Koning, C.E. Preparation of Conductive Nanotube–Polymer Composites Using Latex Technology. Adv. Mater. 2004, 16, 284. [Google Scholar] [CrossRef]

- Dang, Z.M.; Wang, L.; Yin, Y.; Zhang, Q.; Lei, Q.Q. Giant dielectric permittivities in functionalized carbon-nanotube/electroactive-polymer nanocomposites. Adv. Mater. 2007, 19, 852. [Google Scholar] [CrossRef]

- Kolb, M.; Botet, R.; Jullien, R. Scaling of Kinetically Growing Clusters. Phys. Rev. Lett. 1983, 51, 1123–1126. [Google Scholar] [CrossRef]

- Karásek, L.; Meissner, B.; Asai, S.; Sumita, M. Percolation Concept: Polymer-Filler Gel Formation, Electrical Conductivity and Dynamic Electrical Properties of Carbon-Black-Filled Rubbers. Polym. J. 1996, 28, 121–126. [Google Scholar] [CrossRef] [Green Version]

- Jonscher, A.K. New interpretation of dielectric loss peaks. Nature 1975, 256, 566–568. [Google Scholar] [CrossRef]

- Mehrer, H. (Ed.) Series in Solid-State Sciences; Springer: Berlin, Germany, 2007; p. 221. [Google Scholar]

- Nicoli, M.; Cuerno, R.; Castro, M. Unstable Nonlocal Interface Dynamics. Phys. Rev. Lett. 2009, 102, 256102. [Google Scholar] [CrossRef] [PubMed]

- Ishitani, T.; Ohnishi, T.; Madokoro, Y.; Kawanami, Y. Focused-ion-beam “cutter” and “attacher” for micromachining and device transplantation. J. Vac. Sci. Technol. B 1991, 9, 2633. [Google Scholar] [CrossRef]

- Roy, X.; Sarazin, P.; Favis, B.D. Ultraporous nanosheath materials by layer-by-layer deposition onto co-continuous polymer-blend templates. Adv. Mater. 2006, 18, 1015. [Google Scholar] [CrossRef]

- Cuerno, R.; Vazquez, L.; Gago, R.; Castro, M. Surface nanopatterns induced by ion-beam sputtering. J. Phys. Condens. Matter 2009, 21, 220301. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, A.; Wang, D.; Zhou, H.; Li, Y.; Connor, C.; Kong, J.; Sun, J.; Xu, B.B. Spatially Engraving Morphological Structure on a Polymeric Surface by Ion Beam Milling. Polymers 2019, 11, 1229. https://doi.org/10.3390/polym11071229

Sun A, Wang D, Zhou H, Li Y, Connor C, Kong J, Sun J, Xu BB. Spatially Engraving Morphological Structure on a Polymeric Surface by Ion Beam Milling. Polymers. 2019; 11(7):1229. https://doi.org/10.3390/polym11071229

Chicago/Turabian StyleSun, Ansu, Ding Wang, Honghao Zhou, Yifan Li, Chris Connor, Jie Kong, Jining Sun, and Ben Bin Xu. 2019. "Spatially Engraving Morphological Structure on a Polymeric Surface by Ion Beam Milling" Polymers 11, no. 7: 1229. https://doi.org/10.3390/polym11071229