Lignin Transformation of One-Year-Old Plants During Anaerobic Digestion (AD)

Abstract

:1. Introduction

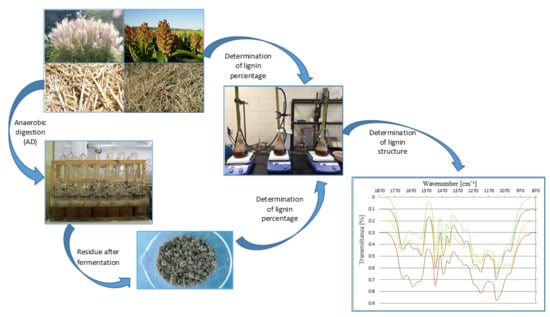

2. Materials and Methods

2.1. Plant Material and Sampling

2.2. Chemical Analysis

2.2.1. Determination of Lignin Percentage

2.2.2. Determination of Functional Groups

2.2.3. Fourier Transform-Infrared Spectroscopy of Lignin

2.3. Statistical Analysis

Anaerobic Digestion

3. Results and Discussion

3.1. Percentage of Lignin

3.2. Structure of Lignin

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Derkacheva, O.; Sukhov, D. Investigation of lignins by FTIR spectroscopy. Macromol. Symp. 2008, 265, 61–68. [Google Scholar] [CrossRef]

- Banoub, J.; Delmas, G.H.; Mackenzie, G.; Cachet, N.; Benjelloun Mlayah, B.; Delmas, M. A critique on the structural analysis of lignins and application of novel tandem mass spectrometric strategies to determine lignin sequencing. J. Mass Spectr. 2014, 50, 5–48. [Google Scholar] [CrossRef] [PubMed]

- Martone, P.T.; Estevez, J.M.; Lu, F.; Ruel, K.; Denny, M.W.; Somerville, C.; Ralph, J. Discovery of lignin in seaweed reveals convergent evolution of cell-wall architecture. Curr. Biol. 2009, 19, 169–175. [Google Scholar] [CrossRef]

- Doherty, W.; Mousavioun, P.; Fellows, C. Value-adding to cellulosic ethanol: Lignin polymers. Ind. Crop. Prod. 2011, 33, 259–276. [Google Scholar] [CrossRef] [Green Version]

- Lupoi, J.S.; Singh, S.; Parthasarathi, R.; Simmons, B.A.; Henry, R.J. Recent innovations in analytical methods for the qualitative and quantitative assessment of lignin. Renew. Sustain. Energy Rev. 2015, 49, 871–906. [Google Scholar] [CrossRef] [Green Version]

- Freudenberg, K. Biosynthesis and constitution of lignin. Nature 1959, 183, 1152. [Google Scholar] [CrossRef]

- Davison, B.H.; Drescher, S.R.; Tuskan, G.A.; Davis, M.F.; Nghiem, N.P. Variation of S/G ratio and lignin content in a Populus family influences the release of xylose by dilute acid hydrolysis. Appl. Biochem. Biotechnol. 2006, 129–132, 427–435. [Google Scholar] [CrossRef]

- Vanholme, R.; Demedts, B.; Morreel, K.; Ralph, J.; Boerjan, W. Lignin biosynthesis and structure. Plant Physiol. 2010, 153, 895–905. [Google Scholar] [CrossRef]

- Plomion, C.; Leprovost, G.; Stokes, A. Wood formation in trees. Plant Physiol. 2001, 127, 1513–1523. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Tsukahara, K.; Yagishita, T.; Sawayama, S. Performance of a fixed-bed reactor packed with carbon felt during anaerobic digestion of cellulose. Bioresour. Technol. 2004, 94, 197–201. [Google Scholar] [CrossRef] [PubMed]

- Brosse, N.; Dufour, F.A.; Meng, X.; Sun, Q.; Ragauskas, A. Miscanthus: A fast-growing crop for biofuels and chemicals production. Biofuels Bioprod. Bioref. 2012, 6, 580–598. [Google Scholar] [CrossRef]

- Dukiewicz, H.; Waliszewska, B.; Zborowska, M. Higher and lower heating values of selected lignocellulose materials. Ann. Wars. Univ. Life Sci-SGGW For. Wood Technol. 2014, 87, 60–63. [Google Scholar]

- Kozłowski, S.; Zielewicz, W.; Lutyński, A. Określanie wartości energetycznej Sorghum saccharatum (L.) Moench, Zea mays L. i Malva verticillata L. Łąkarstwo W Polsce 2007, 10, 131–140. [Google Scholar]

- She, D.; Xu, F.; Geng, Z.C.; Sun, R.C.; Jones, G.L.; Baird, M.S. Physicochemical characterization of extracted lignin from sweet sorghum stem. Ind. Crop. Prod. 2010, 32, 21–28. [Google Scholar] [CrossRef]

- Stefaniak, T.R.; Dahlberg, J.A.; Bean, B.W.; Dighe, N.; Wolfrum, E.J.; Rooney, W.L. Variation in biomass composition components among forage, biomass, sorghum-sudangrass, and sweet sorghum types. Crop Sci. 2012, 52, 1949–1954. [Google Scholar] [CrossRef]

- Tolbert, A.; Akinosho, H.; Khunsupat, R.; Naskar, A.K.; Ragauskas, A.J. Characterization and analysis of the molecular weight of lignin for biorefining studies. Biofuels. Bioprod. Biorefining 2014, 8, 836–856. [Google Scholar] [CrossRef]

- Lee, W.-C.; Kuan, W.-C. Miscanthus as cellulosic biomass for bioethanol production. Biotechnol. J. 2015, 10, 840–854. [Google Scholar] [CrossRef] [PubMed]

- Anami, S.E.; Zhang, L.-M.; Xia, Y.; Zhang, Y.-M.; Liu, Z.-Q.; Jing, H.-C. Sweet sorghum ideotypes: Genetic improvement of the biofuel syndrome. Food Energy Secur. 2015, 4, 159–177. [Google Scholar] [CrossRef]

- Mayer, F.; Gerin, P.A.; Noo, A.; Lemaigre, S.; Stilmant, D.; Schmit, T.; Leclech, N.; Ruelle, L.; Gennen, J.; von Francken-Welz, H.; et al. Assessment of energy crops alternative to maize for biogas production in the Greater Region. Bioresour. Technol. 2014, 166, 358–367. [Google Scholar] [CrossRef]

- Michalska, K.; Ledakowicz, S. Degradacja struktur lignocelulozowych oraz produktów ich hydrolizy. Inżynieria I Aparatura Chemiczna [Degradation of lignocellulosic structures and products of their hydrolysis. Eng. Chem. Appar. 2012, 51, 157. [Google Scholar]

- Castro, F.B.; Hotten, P.M.; Ørskov, E.R.; Rebeller, M. Inhibition of Rumen microbes by compounds formed in the steam treatment of wheat straw. Bioresour. Technol. 1994, 50, 25–30. [Google Scholar] [CrossRef]

- Pu, Y.; Hu, F.; Huang, F.; Davison, B.H.; Ragauskas, A.J. Assessing the molecular structure basis for biomass recalcitrance during dilute acid and hydrothermal pretreatments. Biotechnol. Biofuels 2013, 6, 1–13. [Google Scholar] [CrossRef]

- Ragauskas, A.J.; Beckham, G.T.; Biddy, M.J.; Chandra, R.; Chen, F.; Davis, M.F.; Davison, B.H.; Dixon, R.A.; Gilna, P.; Keller, M.; et al. Lignin valorization: Improving lignin processing in the biorefinery. Science 2014, 344, 1246843. [Google Scholar] [CrossRef]

- Theuretzbacher, F.; Lizasoain, J.; Lefever, C.; Saylor, M.K.; Enguidanos, R.; Weran, N.; Gronauer, A.; Bauer, A. Steam explosion pretreatment of wheat straw to improve methane yields: Investigation of the degradation kinetics of structural compounds during anaerobic digestion. Bioresour. Technol. 2015, 179, 299–305. [Google Scholar] [CrossRef]

- Mulat, D.G.; Dibdiakova, J.; Horn, S.J. Microbial biogas production from hydrolysis lignin: Insight into lignin structural changes. Biotechnol. Biofuels 2018, 11, 61–77. [Google Scholar] [CrossRef]

- Whittaker, C.; Hunt, J.; Misselbrook, T.; Shiel, I. How well does Miscanthus ensile for use in an anaerobic digestion plant? Biomass Bioenergy 2016, 88, 24–34. [Google Scholar] [CrossRef]

- Godin, B.; Agneessens, R.; Schmit, T.; Lamaudiere, S.; Goffart, J.P.; Gerin, P.A. Evolution of Sorghum and Corn Composition with the Harvest Period, with Focus on the Hemicelluloses Monosaccharidic Composition; Journée Annuelle de l’EDT Geproc and Envitam: Gembloux, Belgium, 2013. [Google Scholar]

- Galbe, M.; Zacchi, G. Pretreatment: The key to efficient utilization of lignocellulosic materials. Biomass Bioenergy 2012, 46, 70–78. [Google Scholar] [CrossRef]

- Mao, J.D.; Holtman, K.M.; Franqui-Villanueva, D. Chemical structures of corn stover and its residue after dilute acid prehydrolysis and enzymatic hydrolysis: Insight into factors limiting enzymatic hydrolysis. J. Agric. Food Chem. 2010, 58, 11680–11687. [Google Scholar] [CrossRef]

- Jung, S.; Foston, M.; Sullards, M.C.; Ragauskas, A.J. Surface characterization of dilute acid pretreated Populus deltoides by ToF-SIMS. Energy Fuels 2010, 24, 1347–1357. [Google Scholar] [CrossRef]

- Waliszewska, H.; Zborowska, M.; Waliszewska, B.; Borysiak, S.; Antczak, A.; Czekała, W. Transformation of miscanthus and sorghum cellulose during methane fermentation. Cellulose 2018, 25, 1207–1216. [Google Scholar] [CrossRef]

- Stachowiak-Wencek, A.; Zborowska, M.; Waliszewska, H. Waliszewska B., Zmiany struktury ligniny osadków kukurydzy pod wpływem fermentacji metanowej. Przemysł Chem. 2018, 97, 2162–2165. [Google Scholar]

- TAPPI method T 222 om-83. Acid-insoluble lignin in wood and pulp. In Test Methods, 1998–1999; TAPPI Press: Atlanta, GA, USA, 1999.

- Kačík, F.; Kačíková, D.; Bubenikova, T.; Veľková, V. Determination of methoxy groups in lignocellulosic materials. Drewno 2004, 47, 113–119. [Google Scholar]

- Lin, S.Y.; Dence, C.W. Methods in Lignin Chemistry, 3rd ed.; Springer: Berlin/Heidelberg, Germany, 1992. [Google Scholar] [CrossRef]

- Fan, M.; Dai, D.; Huang, B. Fourier Transform Infrared Spectroscopy for Natural Fibres, Fourier Transform Salih Mohammed Salih, IntechOpen. Available online: https://www.intechopen.com/books/fourier-transform-materials-analysis/fourier-transform-infrared-spectroscopy-for-natural-fibres (accessed on 23 May 2012). [CrossRef]

- Ungureanu, E.; Ungureanu, O.; Căpraru, A.-M.; Popa, V.I. Chemical modification and characterization of straw lignin. Cellul. Chem. Technol. 2009, 43, 263–269. [Google Scholar]

- DIN 38 414-S8. Bestimmung des Faulverhaltens “Schlamm und Sedimente”; BeuthVerlag GmbH: Berlin, Germany, 1985.

- Lewicki, A.; Pilarski, K.; Janczak, D.; Czekała, W.; Rodríguez Carmona, P.C.; Cieślik, M.; Witaszek, K. The biogas production from herbs and waste from herbal industry. J. Res. Appl. Agric. Eng. 2013, 58, 114–117. [Google Scholar]

- Shugang, Z.; Jing, W.; Hongxia, W.; Zhihua, Z.; Xibo, L. Changes in lignin content and activity of related enzymes in the endocarp during the walnut shell development period. Hortic. Plant J. 2016, 2, 141–146. [Google Scholar]

- Sannigrahi, P.; Ragauskas, A.J. Characterization of fermentation residues from the production of bio-ethanol from lignocellulosic feedstocks. J. Biobased Mater. Bioenergy 2011, 5, 514–519. [Google Scholar] [CrossRef]

- Fengel, D.; Wegener, G. Wood—Chemistry, Ultrastructure, Reactions, 2nd ed.; Walter de Gruyter: Berlin, Germany, 1989. [Google Scholar]

- Popescu, C.M.; Popescu, M.C.; Singurel, G.; Vasile, C.; Argyropoulos, D.S.; Willfor, S. Spectral characterization of eucalyptus wood. Appl. Spectrosc. 2007, 61, 1168–1177. [Google Scholar] [CrossRef]

- Hatfield, R.; Ralph, J.; Grabber, J.H. A potential role for sinapyl p-coumarate as a radical transfer mechanism in grass lignin formation. Planta 2008, 228, 919–928. [Google Scholar] [CrossRef] [PubMed]

- Faix, O.; Mozuch, M.D.; Kent Kirk, T. Degradation of gymnosperm (guaiacyl) vs. angiosperm (syringyl/guaiacyl) lignins by phanerochaete chrysosporium. Holzforschung 1985, 39, 203–208. [Google Scholar] [CrossRef]

- Lewis, N.; Yamamoto, E. Lignin: Occurrence, biogenesis and biodegradation. Annu. Rev. Plant Biol. 1990, 41, 455–496. [Google Scholar] [CrossRef] [PubMed]

- Skyba, O.; Douglas, C.J.; Mansfield, S.D. Syringyl-rich lignin renders poplars more resistant to degradation by wood decay fungi. Appl. Environ. Microbiol. 2013, 79, 2560–2571. [Google Scholar] [CrossRef]

- Obst, J.R.; Highley, T.L.; Miller, R.B. Influence of Lignin Type on the Decay of Woody Angiosperms by Trametes Versicolor. In Mycotoxins, Wood Decay, Plant Stress: Biocorrosion, and General Biodeterioration; Llewellyn, G.C., Dashek, W.V., O’Rear, C.E., Eds.; Biodeterioration Research; Springer: Boston, MA, USA, 1994; Volume 4. [Google Scholar]

- Chua, M.; Chen, C.; Chang, H. 13C NMR Spectroscopic study of spruce lignin degraded Phanerochaete Chrysosporium. Holzforsch.—Int. J. Biol. Chem. Phys. Technol. Wood 2009, 36, 165–172. [Google Scholar]

- Ruiz-Dueñas, F.J.; Martínez, A.T. Microbial degradation of lignin: How a bulky recalcitrant polymer is efficiently recycled in nature and how we can take advantage of this. Microb. Biotechnol. 2009, 2, 164–177. [Google Scholar] [CrossRef]

- Brauns, F.E.; Brauns, D.A. The Chemistry of Lignin: Covering the Literature for the Years 1949–1958; Academic Press: New York, NY, USA; London, UK, 1960. [Google Scholar]

- Zhao, Q. Lignification: Flexibility, Biosynthesis and Regulation. Trends Plant Sci. 2016, 21, 713–721. [Google Scholar] [CrossRef]

- Marques, G.; Rencoret, J.; Gutiérrez, A.; del Río, J.C. Evaluation of the chemical composition of different non-woody plant fibers used for pulp and paper manufacturing. Open Agric. J. 2010, 3, 93–101. [Google Scholar] [CrossRef]

- Lupoi, J.S.; Smith, E.A. Characterization of woody and herbaceous biomasses lignin composition with 1064 nm dispersive multichannel Raman spectroscopy. Appl. Spectrosc. 2012, 66, 903–910. [Google Scholar] [CrossRef] [PubMed]

- Sattler, S.E.; Palmer, N.A.; Saballos, A.; Greene, A.M.; Xin, Z.; Sarath, G.; Vermerris, W.; Pedersen, J.F. “Identification and Characterization of Four Missense Mutations in Brown midrib12 (Bmr12), the Caffeic O-Methyltranferase (COMT) of Sorghum”. Bioenerg. Res. 2012, 5, 855–865. [Google Scholar] [CrossRef]

- Mazumder, B. Fortunate Sons: New Estimates of Intergenerational Mobility in the United States Using Social Security Earnings Data. Rev. Econ. Stat. 2005, 87, 235–255. [Google Scholar] [CrossRef]

- Todorciuc, T.; Căpraru, A.-M.; Kratochvílová, I.; Popa, V.I. Characterization of non-wood lignin and its hydoxymethylated derivatives by spectroscopy and self-assembling investigations. Cellul. Chem. Technol. 2009, 43, 399–408. [Google Scholar]

- Xiao, Z.; Li, Y.; Wu, X.; Qi, G.; Li, N.; Zhang, K.; Wang, D.; Sun, X.S. Utilization of sorghum lignin to improve adhesion strength of soy protein adhesives on wood veneer. Ind. Crop. Prod. 2013, 50, 501–509. [Google Scholar] [CrossRef]

| Varieties | Harvest Growing Phase | Lignin (% d.m.) | Increase of Lignin Content During AD (%) | |

|---|---|---|---|---|

| NL | RL | |||

| Miscanthus ×giganteus | DV | 18.4a ± 0.9 | 27.6b ± 0.1 | 55.0 |

| AV | 24.4a ± 0.1 | 31.9b ± 0.8 | 30.9 | |

| M. sacchariflorus | DV | 18.4a ± 0.1 | 29.3b ± 3.1 | 59.4 |

| AV | 20.0a ± 0.1 | 26.6b ± 1.2 | 33.2 | |

| M. sinensis | DV | 17.9a ± 0.2 | 28.1b ± 0.2 | 57.3 |

| AV | 19.1a ± 0.2 | 25.4b ± 0.7 | 33.2 | |

| Mean of Miscanthus | DV | 18.2 ± 0.2 | 28.3 ± 0.7 | 57.2 |

| AV | 21.1 ± 2.3 | 28.0 ± 2.8 | 32.3 | |

| S. bicolor | DV | 15.4a ± 0.2 | 34.2b ± 0.2 | 122.3 |

| AV | 16.9a ± 0.1 | 32.6b ± 0.2 | 93.3 | |

| S. saccharatum | DV | 14.5a ± 0.1 | 41.1b ± 0.1 | 183.4 |

| AV | 16.4a ± 0.4 | 34.3b ± 0.2 | 109.4 | |

| Mean of Sorghum | DV | 15.0 ± 0.4 | 37.7 ± 3.4 | 152.0 |

| AV | 16.6 ± 0.2 | 33.4 ± 0.8 | 101.2 | |

| Position [cm−1] | Band Origin |

|---|---|

| 2936–2850 | C–H stretching in methyl and methylene groups |

| 1715–1705 | C=O stretching nonconjugated to the aromatic ring |

| 1660–1650 | C=O stretching in conjugation to the aromatic ring |

| 1620–1600 | Aromatic ring vibration |

| 1515–1510 | Aromatic ring vibration |

| 1460–1455 | C–H deformations |

| 1420 | Aromatic ring vibration |

| 1360–1350 | C–H deformations |

| 1330–1325 | Aromatic (syringyl) ring breaching |

| 1260–1220 | Aromatic (guaiacyl) ring breaching |

| 1160–1120 | C–O–C stretching |

| 1035 | C–H, C–O deformations |

| Varieties | Harvest Season | OCH3 (%) | Changes of OCH3 Content during AD (%) | OH (%) | Change of OH Content during AD (%) | ||

|---|---|---|---|---|---|---|---|

| NL | RL | NL | RL | ||||

| Miscanthus ×giganteus | DV | 12.8 | 12.6 | −1.56 | 3.6 | 1.5 | 58.33 |

| AV | 13.9 | 10.7 | −23.02 | 0.4 | 0.2 | 50.00 | |

| M. sacchariflorus | DV | 10.6 | 4.5 | −57.55 | 1.7 | 0.4 | 76.47 |

| AV | 12.6 | 12.3 | −2.38 | 1.6 | 0.8 | 50.00 | |

| M. sinensis | DV | 11.1 | 4.7 | −57.66 | 4.9 | 2.4 | 51.02 |

| AV | 10.5 | 9.7 | −7.62 | 1.7 | 0.8 | 52.94 | |

| Mean of miscanthus | DV | 11.5 | 7.2 | −37.39 | 3.4 | 1.4 | 58.82 |

| AV | 10.5 | 10.9 | −11.00 | 1.2 | 0.6 | 50.00 | |

| S. bicolor | DV | 10.8 | 8.4 | −22.22 | 5.0 | 3.4 | 32.00 |

| AV | 12.2 | 8.8 | −27.87 | 0.8 | 0.4 | 50.00 | |

| S. saccharatum | DV | 10.3 | 7.6 | −26.21 | 1.7 | 1.4 | 17.65 |

| AV | 9.3 | 2.5 | −73.12 | 1.0 | 0.8 | 20.00 | |

| Mean of sorghum | DV | 10.5 | 8.0 | −23.81 | 3.3 | 1.4 | 57.58 |

| AV | 10.7 | 5.6 | −47.66 | 0.9 | 0.6 | 33.33 | |

| Varieties | Harvest Season | S/G A1325/A1267 | Changes of S/G during AD (%) | Al/Ar A2930/A1510 | Changes of Al/Ar during AD (%) | ||

|---|---|---|---|---|---|---|---|

| NL | RL | NL | RL | ||||

| Miscanthus ×giganteus | DV | 0.59 | 0.61 | 3.39 | 0.54 | 0.39 | −27.78 |

| AV | 0.66 | 0.62 | −6.06 | 0.47 | 0.77 | 63.83 | |

| M. sacchariflorus | DV | 0.53 | 0.56 | 5.66 | 0.99 | 0.92 | −7.07 |

| AV | 0.65 | 0.53 | −18.46 | 0.85 | 1.11 | 30.59 | |

| M. sinensis | DV | 0.38 | 0.34 | −10.53 | 0.83 | 0.71 | −14.46 |

| AV | 0.49 | 0.28 | −42.86 | 0.61 | 1.02 | 67.21 | |

| Mean of miscanthus | DV | 0.5 | 0.55 | 10.00 | 0.79 | 0.67 | −15.19 |

| AV | 0.6 | 0.47 | −21.67 | 0.64 | 0.96 | 50.00 | |

| S. bicolor | DV | 0.59 | 0.55 | −6.78 | 0.74 | 0.89 | 20.27 |

| AV | 0.64 | 0.62 | −3.13 | 0.73 | 0.71 | 1.37 | |

| S. saccharatum | DV | 0.57 | 0.54 | −5.26 | 0.61 | 0.87 | 42.62 |

| AV | 0.61 | 0.44 | −27.87 | 0.54 | 0.81 | 50.00 | |

| Mean of sorghum | DV | 0.58 | 0.55 | −5.17 | 0.88 | 0.88 | 37.50 |

| AV | 0.63 | 0.53 | −15.87 | 0.76 | 0.76 | 18.75 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waliszewska, H.; Zborowska, M.; Stachowiak-Wencek, A.; Waliszewska, B.; Czekała, W. Lignin Transformation of One-Year-Old Plants During Anaerobic Digestion (AD). Polymers 2019, 11, 835. https://doi.org/10.3390/polym11050835

Waliszewska H, Zborowska M, Stachowiak-Wencek A, Waliszewska B, Czekała W. Lignin Transformation of One-Year-Old Plants During Anaerobic Digestion (AD). Polymers. 2019; 11(5):835. https://doi.org/10.3390/polym11050835

Chicago/Turabian StyleWaliszewska, Hanna, Magdalena Zborowska, Agata Stachowiak-Wencek, Bogusława Waliszewska, and Wojciech Czekała. 2019. "Lignin Transformation of One-Year-Old Plants During Anaerobic Digestion (AD)" Polymers 11, no. 5: 835. https://doi.org/10.3390/polym11050835