A Phenomenological Approach to Study Mechanical Properties of Polymeric Porous Structures Processed Using Supercritical CO2

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of the Materials and Characterizations

2.2. Mechanical Tests

2.3. Models Development

2.3.1. Generalized Polynomial Model

2.3.2. Ogden Model

2.3.3. Yeoh Model

2.3.4. Transformation Engineering Stress-True Stress

2.4. FEM Modeling

2.4.1. FEM Modeling for Tensile Test

2.4.2. FEM Modeling for Compression Test

3. Results and Discussion

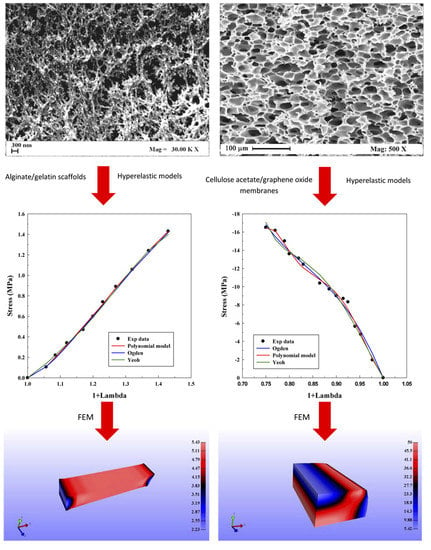

3.1. Morphological Results

3.2. Modeling Experimental Data Using Hyperelastic Equations

3.2.1. Tensile Tests

3.2.2. Compression Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Baldino, L.; Cardea, S.; Reverchon, E. Production of antimicrobial membranes loaded with potassium sorbate using a supercritical phase separation process. Innov. Food Sci. Emerg. Technol. 2016, 34, 77–85. [Google Scholar] [CrossRef]

- Martins, M.; Barros, A.A.; Quraishi, S.; Gurikov, P.; Raman, S.P.; Smirnova, I.; Duarte, A.R.C.; Reis, R.L. Preparation of macroporous alginate-based aerogels for biomedical applications. J. Supercrit. Fluids 2015, 106, 152–159. [Google Scholar] [CrossRef] [Green Version]

- Reverchon, E.; Cardea, S.; Rapuano, C. A new supercritical fluid-based process to produce scaffolds for tissue replacement. J. Supercrit. Fluids 2008, 45, 365–373. [Google Scholar] [CrossRef]

- Cardea, S.; Scognamiglio, M.; Reverchon, E. Supercritical assisted process for the generation of cellulose acetate loaded structures, potentially useful for tissue engineering applications. Mat. Sci. Eng. C 2016, 59, 480–487. [Google Scholar] [CrossRef]

- Silva, S.; Duarte, A.R.; Carvalho, A.F.; Mano, J.F.; Reis, R.L. Green processing of porous chitin structures for biomedical applications combining ionic liquids and supercritical fluid technology. Acta Biomater. 2011, 3, 1166–1172. [Google Scholar] [CrossRef] [PubMed]

- García-Gonzalez, C.A.; Alnief, M.; Smirnova, I. Polysaccharide-based aerogels-Promising biodegradable carriers for drug delivery systems. Carbohyd. Polym. 2011, 86, 1425–1438. [Google Scholar] [CrossRef]

- García-González, C.A.; Jin, M.; Gerth, J.; Álvarez-Lorenzo, C.; Smirnova, I. Polysaccharide-based aerogel microspheres for oral drug delivery. Carbohyd. Polym. 2015, 117, 796–806. [Google Scholar] [CrossRef] [PubMed]

- Baldino, L.; Concilio, S.; Cardea, S.; De Marco, I.; Reverchon, E. Complete glutaraldehyde elimination during chitosan hydrogel drying SC-CO2 processing. J. Supercrit. Fluids 2015, 103, 70–76. [Google Scholar] [CrossRef]

- Baldino, L.; Sarno, M.; Cardea, S.; Irusta, S.; Ciambelli, P.; Santamaría, J.; Reverchon, E. Formation of cellulose acetate-graphene oxide nanocomposites by supercritical CO2 assisted phase inversion. Ind. Eng. Chem. Res. 2015, 54, 8147–8156. [Google Scholar] [CrossRef]

- Baldino, L.; Concilio, S.; Cardea, S.; Reverchon, E. Interpenetration of natural polymer aerogels by supercritical drying. Polymers 2016, 8, 106. [Google Scholar] [CrossRef]

- Salgado, M.; Santos, F.; Rodríguez-Rojo, S.; Reis, R.L.; Duarte, A.R.; Cocero, M.J. Development of barley and yeast β-glucan aerogels for drug delivery by supercritical fluids. J. CO2 Util. 2017, 22, 262–269. [Google Scholar] [CrossRef]

- Naddeo, F.; Baldino, L.; Cardea, S.; Naddeo, A.; Reverchon, E. Finite element multiscale modelling of elastic behavior of cellulose acetate-Graphene oxide nanocomposites, produced using a SCCO2 assisted technique. J. Supercrit. Fluids 2018, 140, 248–257. [Google Scholar] [CrossRef]

- Sasson, A.; Patchornik, S.; Eliasy, R.; Robinson, D.; Haj-Ali, R. Hyperelastic mechanical behavior of chitosan hydrogels for nucleus pulposus replacement-Experimental testing and constitutive modeling. J. Mech. Behav. Biomed. Mater. 2012, 8, 143–153. [Google Scholar] [CrossRef] [PubMed]

- Shearer, T. A new strain energy function for the hyperelastic modelling of ligaments and tendons based on fascicle microstructure. J. Biomech. 2015, 48, 290–297. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mansouri, M.R.; Darijani, H. Constitutive modeling of isotropic hyperelastic materials in an exponential framework using a self-contained approach. Int. J. Solids Struct. 2014, 51, 4316–4326. [Google Scholar] [CrossRef] [Green Version]

- Karimi, A.; Shojaei, A.; Tehrami, P. Mechanical properties of the human spinal cord under the compressive loading. J. Chem. Neuroanat. 2017, 86, 15–18. [Google Scholar] [CrossRef]

- Previati, G.; Gobbi, M.; Mastinu, G. Silicone gels—Comparison by derivation of material model parameters. Polym. Test. 2017, 58, 270–279. [Google Scholar] [CrossRef]

- Rivlin, R.S.; Saunders, D.W. Large Elastic Deformations of Isotropic Materials VII. Experiments on the Deformation of Rubber. Philos. Trans. R. Soc. A 1951, 243, 251–288. [Google Scholar] [CrossRef]

- Chang, T.Y.P.; Saleeb, A.F.; Li, G. Large strain analysis of rubber-like materials based on a perturbed Lagrangian variational principle. Comput. Mech. 1991, 8, 221–233. [Google Scholar] [CrossRef]

- Ogden, R.W. Large Deformation Isotropic Elasticity—On the Correlation of Theory and Experiment for Incompressible Rubber like Solids. Proc. R. Soc. A 1972, 326, 565–584. [Google Scholar] [CrossRef]

- Yeoh, O.H. Some Forms of the Strain Energy Function for Rubber. Rubber Chem. Technol. 1993, 66, 754–771. [Google Scholar]

- Pawlikowski, M.; Skalski, K.; Sowinski, T. Hyper-elastic modelling of intervertebral disc polyurethane implant. Acta Bioeng. Biomech. 2013, 15, 43–50. [Google Scholar] [PubMed]

- Skacel, P.; Bursa, J. Comparison of constitutive models of arterial layers with distributed collagen fibers orientations. Acta Bioeng. Biomech. 2014, 16, 47–58. [Google Scholar]

- Slesarenko, V.; Rudykh, S. Towards mechanical characterization of soft digital materials for multimaterial 3-D printing. Int. J. Eng. Sci. 2018, 123, 62–72. [Google Scholar]

- Han, Q.F.; Wang, Z.W.; Tang, C.Y.; Chen, L.; Tsui, C.P.; Law, W.C. Hyper-elastic modeling and mechanical behavior investigation of porous poly-D-L-lactide/nano-hydroxyapatite scaffold material. J. Mech. Behav. Biomed. Mat. 2017, 71, 262–270. [Google Scholar]

- Baldino, L.; Naddeo, F.; Cardea, S.; Naddeo, A.; Reverchon, E. FEM modeling of the reinforcement mechanism of hydroxyapatite in PLLA scaffolds produced by supercritical drying, for tissue engineering applications. J. Mech. Behav. Biomed. Mat. 2015, 51, 225–256. [Google Scholar]

- Marra, F.; De Marco, I.; Reverchon, E. Numerical analysis of the characteristic times controlling supercritical antisolvent micronization. Chem. Eng. Sci. 2012, 71, 39–45. [Google Scholar] [CrossRef]

- Rackl, M. Material testing and hyperelastic material model curve fitting for Ogden, polynomial and Yeoh models. In Proceedings of the ScilabTEC 7th International Scilab Users Conference, Paris, France, 21–22 May 2015. [Google Scholar]

- Treloar, L.R.G. The elasticity and related properties of rubbers. Rep. Prog. Phys. 1973, 36, 755–826. [Google Scholar] [CrossRef]

- Ling, Y. Uniaxial true stress-strain after necking. AMP J. Technol. 1996, 5, 37–48. [Google Scholar]

- Dong, Y.; Lin, R.J.T.; Bhattacharyya, D. Determination of critical parameters for numerical simulation of acrylic sheet forming. J. Mater. Sci. 2005, 40, 399–410. [Google Scholar] [CrossRef]

- Mass, S.A.; Ellis, B.J.; Ateshian, G.A.; Weiss, J.A. FEBio: Finite elements for biomechanics. J. Biomech. Eng. 2012, 134, 011005. [Google Scholar] [CrossRef] [PubMed]

- Robinson, D.L.; Kersh, M.E.; Walsh, N.C.; Ackland, D.C.; de Steiger, R.N.; Pandy, M.G. Mechanical properties of normal and osteoarthritic human articular cartilage. J. Mech. Behav. Biomed. Mater. 2016, 61, 96–109. [Google Scholar] [CrossRef] [PubMed]

| Material | C1 (MPa) | C2 (MPa) | C3 (MPa) | AARD (%) |

|---|---|---|---|---|

| A/G (20/80% v/v) 2% w/w | 2.09 | −6.62 | 17.23 | 8.21 |

| A/G (50/50% v/v) 2% w/w | 0.81 | −1.51 | 2.49 | 7.51 |

| A/G (50/50% v/v) 5% w/w | 0.44 | 0.79 | -0.67 | 5.71 |

| A/G (80/20% v/v) 2% w/w | 1.19 | −1.14 | 3.42 | 9.22 |

| A/G (80/20% v/v) 5% w/w | 1.32 | −0.13 | 0.092 | 9.15 |

| Material | μ1 (MPa) | μ2 (MPa) | α1 | α2 | AARD (%) |

|---|---|---|---|---|---|

| A/G (20/80% v/v) 2% w/w | −3.57 | −72,658.00 | −8.81 | 0.00027 | 3.07 |

| A/G (50/50% v/v) 2% w/w | 184.74 | 6.58 | 0.016 | 0.018 | 8.93 |

| A/G (50/50% v/v) 5% w/w | 5571.26 | 2101.80 | 0.050 | −0.14 | 4.04 |

| A/G (80/20% v/v) 2% w/w | 1.95 | −0.000021 | 2.50 | −78.51 | 9.45 |

| A/G (80/20% v/v) 5% w/w | 451,719 | 0.190 | 0.000011 | 0.190 | 8.43 |

| Material | C10 (MPa) | C01 (MPa) | C20 (MPa) | C02 (MPa) | C11 (MPa) | AARD (%) |

|---|---|---|---|---|---|---|

| A/G (20/80% v/v) 2% w/w | −2.02 | 4.60 | −706.81 | 4426.25 | −3740.65 | 2.40 |

| A/G (50/50% v/v) 2% w/w | 1.89 | −0.98 | −152.39 | 1012.33 | −868.48 | 6.56 |

| A/G (50/50% v/v) 5% w/w | 4.05 | −3.86 | −11.98 | 87.91 | −77.87 | 3.95 |

| A/G (80/20% v/v) 2% w/w | 44.88 | −44.94 | −1470.64 | 9611.43 | −8226.17 | 2.10 |

| A/G (80/20% v/v) 5% w/w | 6.31 | −4.93 | −19.50 | 187.97 | −175.38 | 6.67 |

| Material | C1 (MPa) | C2 (MPa) | C3 (MPa) | AARD (%) |

|---|---|---|---|---|

| CA | 15.68 | −35.62 | 56.89 | 4.96 |

| CA (3% w/w GO) | 28.65 | −89.51 | 156.09 | 14.75 |

| CA (9% w/w GO) | 70.21 | −327.78 | 795.86 | 10.84 |

| Material | μ1 (MPa) | μ2 (MPa) | α1 | α2 | AARD (%) |

|---|---|---|---|---|---|

| CA | 18.92 | 21.66 | 9.18 | −4.17 | 6.06 |

| CA (3% w/w GO) | 21.42 | 20.35 | 25.86 | −13.06 | 3.60 |

| CA (9% w/w GO) | 44.60 | 23.91 | 41.78 | −12.10 | 2.53 |

| Material | C10 (MPa) | C01 (MPa) | C20 (MPa) | C02 (MPa) | C11 (MPa) | AARD (%) |

|---|---|---|---|---|---|---|

| CA | −192.30 | 203.68 | −12,033.70 | 46,593.40 | 35,041.82 | 3.53 |

| CA (3% w/w GO) | 1086.30 | −1011.29 | 16,952.70 | −61,260.80 | 45,493.80 | 3.01 |

| CA (9% w/w GO) | 1873.10 | −1732.28 | 35,351.70 | −132,802.01 | 99,498.93 | 2.52 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tabernero, A.; Baldino, L.; Cardea, S.; Martín del Valle, E.; Reverchon, E. A Phenomenological Approach to Study Mechanical Properties of Polymeric Porous Structures Processed Using Supercritical CO2. Polymers 2019, 11, 485. https://doi.org/10.3390/polym11030485

Tabernero A, Baldino L, Cardea S, Martín del Valle E, Reverchon E. A Phenomenological Approach to Study Mechanical Properties of Polymeric Porous Structures Processed Using Supercritical CO2. Polymers. 2019; 11(3):485. https://doi.org/10.3390/polym11030485

Chicago/Turabian StyleTabernero, Antonio, Lucia Baldino, Stefano Cardea, Eva Martín del Valle, and Ernesto Reverchon. 2019. "A Phenomenological Approach to Study Mechanical Properties of Polymeric Porous Structures Processed Using Supercritical CO2" Polymers 11, no. 3: 485. https://doi.org/10.3390/polym11030485