Use of CeO2 Nanoparticles to Enhance UV-Shielding of Transparent Regenerated Cellulose Films

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of RC/CeO2 Nanocomposite Films

2.3. Characterization

3. Results and Discussion

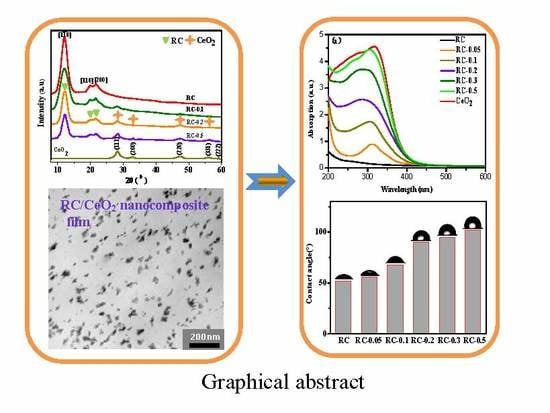

3.1. XRD and FTIR Results

3.2. Morphology and Structure of Nanocomposite Films

3.3. Optical Properties of Nanocomposite Films

3.4. Thermal Stability Properties of the RC and Nanocomposite Films

3.5. Surface Hydrophilic and Hydrophobic Properties of RC Nanocomposite Films

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Al-Asbahi, B.A. Influence of SiO2/TiO2 Nanocomposite on the Optoelectronic Properties of PFO/MEH-PPV-Based OLED Devices. Polymers 2018, 10, 800. [Google Scholar] [CrossRef]

- Wu, S.; Peng, S.; Wang, C.H. Multifunctional Polymer Nanocomposites Reinforced by Aligned Carbon Nanomaterials. Polymers 2018, 10, 542. [Google Scholar] [CrossRef]

- Garnier, B.; Boudenne, A. Use of hollow metallic particles for the thermal conductivity enhancement and lightening of filled polymer. Polym. Degrad. Stabil. 2016, 127, 113–118. [Google Scholar] [CrossRef]

- Kumar, S.; Sarita; Nehra, M.; Tankeshwar, K.; Kim, K.H. Recent advances and remaining challenges for polymeric nanocomposites in healthcare applications. Prog. Polym. Sci. 2018, 80, 1–38. [Google Scholar] [CrossRef]

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689. [Google Scholar] [CrossRef]

- Cai, J.; Kimura, S.; Wada, M.; Kuga, S. Nanoporous Cellulose as Metal Nanoparticles Support. Biomacromolecules 2009, 10, 87–94. [Google Scholar] [CrossRef] [PubMed]

- Opdenbosch, D.V.; Maisch, P.; Fritz-Popovski, G.; Paris, O.; Zollfrank, C. Transparent cellulose sheets as synthesis matrices for inorganic functional particles. Carbohyd. Polym. 2012, 87, 257–264. [Google Scholar] [CrossRef]

- Wang, S.; Lu, A.; Zhang, L. Recent advances in regenerated cellulose materials. Prog. Polym. Sci. 2016, 53, 169–206. [Google Scholar] [CrossRef]

- Feng, X.; Zhao, Y.; Jiang, Y.; Miao, M.; Cao, S.; Fang, J. Use of carbon dots to enhance UV-blocking of transparent nanocellulose films. Carbohydr. Polym. 2017, 161, 253–260. [Google Scholar] [CrossRef] [PubMed]

- Maniruzzaman, M.; Jang, S.D.; Kim, J. Titanium dioxide–cellulose hybrid nanocomposite and its glucose biosensor application. Mat. Sci. Eng. B 2012, 177, 844–848. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, J.; Zhang, L. In situ synthesis of plate-like Fe2O3, nanoparticles in porous cellulose films with obvious magnetic anisotropy. Cellulose 2011, 18, 663–673. [Google Scholar] [CrossRef]

- Muthulakshmi, L.; Rajini, N.; Varada, R.A.; Siengchin, S.; Kathiresan, T.; Jawaid, M.; Rajulu, A.V. Synthesis and characterization of cellulose/silver nanocomposites from bioflocculant reducing agent. Int. J. Biol. Macromol. 2017, 103, 1113–1120. [Google Scholar] [CrossRef] [PubMed]

- Yadav, M.; Mun, S.; Hyun, J.; Kim, J. Synthesis and characterization of iron oxide/cellulose nanocomposite film. Int. J. Biol. Macromol. 2015, 74, 142–149. [Google Scholar] [CrossRef] [PubMed]

- Tang, A.; Liu, Y.; Wang, Q.; Chen, R.; Liu, W.; Fang, Z.; Wang, L. A new photoelectric ink based on nanocellulose/CdS quantum dots for screen-printing. Carbohydr. Polym. 2016, 148, 29–35. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Zhou, Y.; He, M.; Yang, X. Novel multifunctional microspheres of polysiloxane@CeO2–PMMA: Optical properties and their application in optical diffusers. Opt. Mater. 2013, 36, 271–277. [Google Scholar] [CrossRef]

- Tu, K.; Wang, Q.; Lu, A.; Zhang, L. Portable Visible-Light Photocatalysts Constructed from Cu2O Nanoparticles and Graphene Oxide in Cellulose Matrix. J. Phys. Chem. C 2014, 118, 7202–7210. [Google Scholar] [CrossRef]

- Chang, C.; Peng, J.; Zhang, L.; Pang, D.W. Strongly fluorescent hydrogels with quantum dots embedded in cellulose matrices. J. Mater. Chem. 2009, 19, 7771–7776. [Google Scholar] [CrossRef]

- Duan, W.; Xie, A.; Shen, Y.; Wang, X.; Wang, F.; Zhang, Y.; Li, J. Fabrication of Superhydrophobic Cotton Fabrics with UV Protection Based on CeO2 Particles. Ind. Eng. Chem. Res. 2011, 50, 4441–4445. [Google Scholar] [CrossRef]

- Aklalouch, M.; Calleja, A.; Granados, X.; Ricart, S.; Boffa, V.; Ricci, F.; Puig, T.; Obradors, X. Hybrid sol–gel layers containing CeO2 nanoparticles as uv-protection of plastic lenses for concentrated photovoltaics. Sol. Energ. Mat. Sol. C 2014, 120, 175–182. [Google Scholar] [CrossRef]

- Ye, H.; Zhu, L.; Li, W.; Jiang, G.; Liu, H.; Chen, H. Anchoring CeO2, nanoparticles on monodispersed SiO2, spheres to construct hydrophobic polymer coating with enhanced uv absorption ability. Chem. Eng. J. 2017, 321, 268–276. [Google Scholar] [CrossRef]

- Lu, Z.; Mao, C.; Meng, M.; Liu, S.; Tian, Y.; Yu, L.; Sun, B.; Li, C.M. Fabrication of CeO2 nanoparticle-modified silk for UV protection and antibacterial applications. J. Colloid Interface Sci. 2014, 435, 8–14. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.K.; Chang, H.; Jang, H.D. Synthesis of micron-sized porous CeO2-SiO2 composite particles for ultraviolet absorption. Adv. Powder Technol. 2017, 28, 406–410. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Z.; Yuan, K.; Wen, F.; Tan, J.; Hu, C.; Wang, H. Fabrication of a modified straw cellulose and cerium oxide nanocomposite and its visible-light photocatalytic reduction activity. J. Environ. Eng. 2017, 5, 3734–3740. [Google Scholar] [CrossRef]

- Pan, C.; Zhang, D.; Shi, L.; Fang, J. Template-Free Synthesis, Controlled Conversion, and CO Oxidation Properties of CeO2, Nanorods, Nanotubes, Nanowires, and Nanocubes. Eur. J. Inorg. Chem. 2008, 15, 2429–2436. [Google Scholar] [CrossRef]

- Cai, J.; Zhang, L. Rapid dissolution of cellulose in LiOH/urea and NaOH/urea aqueous solutions. Macromol. Biosci. 2005, 5, 539–548. [Google Scholar] [CrossRef] [PubMed]

- Sèbe, G.; Hampichavant, F.; Ibarboure, E.; Koffi, A.L.; Tingaut, P. Supramolecular structure characterization of cellulose II nanowhiskers produced by acid hydrolysis of cellulose I substrates. Biomacromolecules 2012, 13, 570–578. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Wang, Y.; Chen, L.; Cai, J.; Zhang, L. Facile construction of cellulose nanocomposite aerogel containing TiO2 nanoparticles with high content and small size and their applications. Cellulose 2017, 24, 2229–2240. [Google Scholar] [CrossRef]

- Wang, W.; Bai, Q.; Liang, T. Two-sided surface oxidized cellulose membranes modified with PEI: Preparation, characterization and application for dyes removal. Polymers 2017, 9, 455. [Google Scholar] [CrossRef]

- Zhong, X.; Zhou, Y.; He, M.; Tong, Y.; Fan, L.; Cai, Z. Synthesis of organosiloxane-coated SiO2/CeO2 with multilayered hierarchical structure and its application in optical diffusers. J. Mater. Sci. 2017, 52, 12806–12817. [Google Scholar] [CrossRef]

- Gong, C.H.; Wang, X.X.; Liu, H.J.; Zhao, C.; Zhang, Y.D.; Jia, Y.S.; Meng, H.J.; Zhang, J.W.; Zhang, Z.J. Facile in situ synthesis of nickel/cellulose nanocomposites: Mechanisms, properties and perspectives. Cellulose 2014, 21, 4359–4368. [Google Scholar] [CrossRef]

- Duchemin, B.; Corre, D.L.; Leray, N.; Dufresne, A.; Staiger, M.P. All-cellulose composites based on microfibrillated cellulose and filter paper via a NaOH-urea solvent system. Cellulose 2016, 23, 593–609. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Si, R.; Liao, A.C.; Yan, C.H.; Xiao, C.X.; Kou, Y. Facile Alcohothermal Synthesis, Size-Dependent Ultraviolet Absorption, and Enhanced CO Conversion Activity of Ceria Nanocrystals. J. Phys. Chem. B 2003, 107, 10159–10167. [Google Scholar] [CrossRef]

- Mousavi-Kamazani, M.; Rahmatolahzadeh, R.; Beshkar, F. Facile Solvothermal Synthesis of CeO2–CuO Nanocomposite Photocatalyst Using Novel Precursors with Enhanced Photocatalytic Performance in Dye Degradation. J. Inorg. Organomet. Polym. 2017, 27, 1342–1350. [Google Scholar] [CrossRef]

- Aladpoosh, R.; Montazer, M. The role of cellulosic chains of cotton in biosynthesis of ZnO nanorods producing multifunctional properties: Mechanism, characterizations and features. Carbohydr. Polym. 2015, 126, 122–129. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.Q.; Kuang, C.X.; Zhong, M.Q.; Shi, Y.Q.; Chen, F. Synthesis, characterization and UV-shielding property of polystyrene-embedded CeO2 nanoparticles. Opt. Mater. 2013, 35, 2710–2715. [Google Scholar] [CrossRef]

- Ho, C.; Yu, J.C.; Kwong, T.; Mak, A.C.; Lai, S. Morphology-controllable synthesis of mesoporous CeO2 nano- and microstructures. Chem. Mater. 2005, 17, 4514–4522. [Google Scholar] [CrossRef]

- Hezam, A.; Namratha, K.; Drmosh, Q.A.; Yamani, Z.H.; Byrappa, K. Synthesis of heterostructured Bi2O3 –CeO2 –ZnO photocatalyst with enhanced sunlight photocatalytic activity. Ceram. Int. 2017, 43, 5292–5301. [Google Scholar] [CrossRef]

- Phoka, S.; Laokul, P.; Swatsitang, E.; Promarak, V.; Seraphin, S.; Maensiri, S. Synthesis, structural and optical properties of CeO2 nanoparticles synthesized by a simple polyvinyl pyrrolidone (PVP) solution route. Mater. Chem. Phys. 2009, 115, 423. [Google Scholar] [CrossRef]

- Liu, H.; Wang, M.; Wang, Y.; Liang, Y.; Cao, W.; Su, Y. Ionic liquid-templated synthesis of mesoporous CeO2–TiO2 nanoparticles and their enhanced photocatalytic activities under UV or visible light. J. Photochem. Photobiol. A 2011, 223, 157–164. [Google Scholar] [CrossRef]

- Ramasamy, V.; Vijayalakshmi, G. Effect of Zn doping on structural, optical and thermal properties of CeO2 nanoparticles. Superlattices Microstruct. 2015, 85, 510–521. [Google Scholar] [CrossRef]

- Yan, B.; Zhao, W. Wet chemical synthesis of nanometer CeO2 with strong ultraviolet absorption property by in situ assembly of hybrid precursors. Mater. Sci. Eng. B 2004, 110, 23–26. [Google Scholar] [CrossRef]

- Ning, R.; Wu, C.N.; Takeuchi, M.; Saito, T.; Isogai, A. Preparation and characterization of zinc oxide/tempo-oxidized cellulose nanofibril composite films. Cellulose 2017, 24, 4861–4870. [Google Scholar] [CrossRef]

- Azimi, G.; Dhiman, R.; Kwon, H.M.; Paxson, A.T.; Varanasi, K.K. Hydrophobicity of Rare-Earth Oxice Ceramics. Nat. Mater. 2013, 12, 315–320. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Zhang, B.; Jiang, S.; Bai, H.; Zhang, S. Use of CeO2 Nanoparticles to Enhance UV-Shielding of Transparent Regenerated Cellulose Films. Polymers 2019, 11, 458. https://doi.org/10.3390/polym11030458

Wang W, Zhang B, Jiang S, Bai H, Zhang S. Use of CeO2 Nanoparticles to Enhance UV-Shielding of Transparent Regenerated Cellulose Films. Polymers. 2019; 11(3):458. https://doi.org/10.3390/polym11030458

Chicago/Turabian StyleWang, Wei, Baikai Zhang, Shuai Jiang, Huiyu Bai, and Shengwen Zhang. 2019. "Use of CeO2 Nanoparticles to Enhance UV-Shielding of Transparent Regenerated Cellulose Films" Polymers 11, no. 3: 458. https://doi.org/10.3390/polym11030458

APA StyleWang, W., Zhang, B., Jiang, S., Bai, H., & Zhang, S. (2019). Use of CeO2 Nanoparticles to Enhance UV-Shielding of Transparent Regenerated Cellulose Films. Polymers, 11(3), 458. https://doi.org/10.3390/polym11030458