Synthesis of an Aqueous Self-Matting Acrylic Resin with Low Gloss and High Transparency via Controlling Surface Morphology

Abstract

:1. Introduction

2. Experimental

2.1. Materials

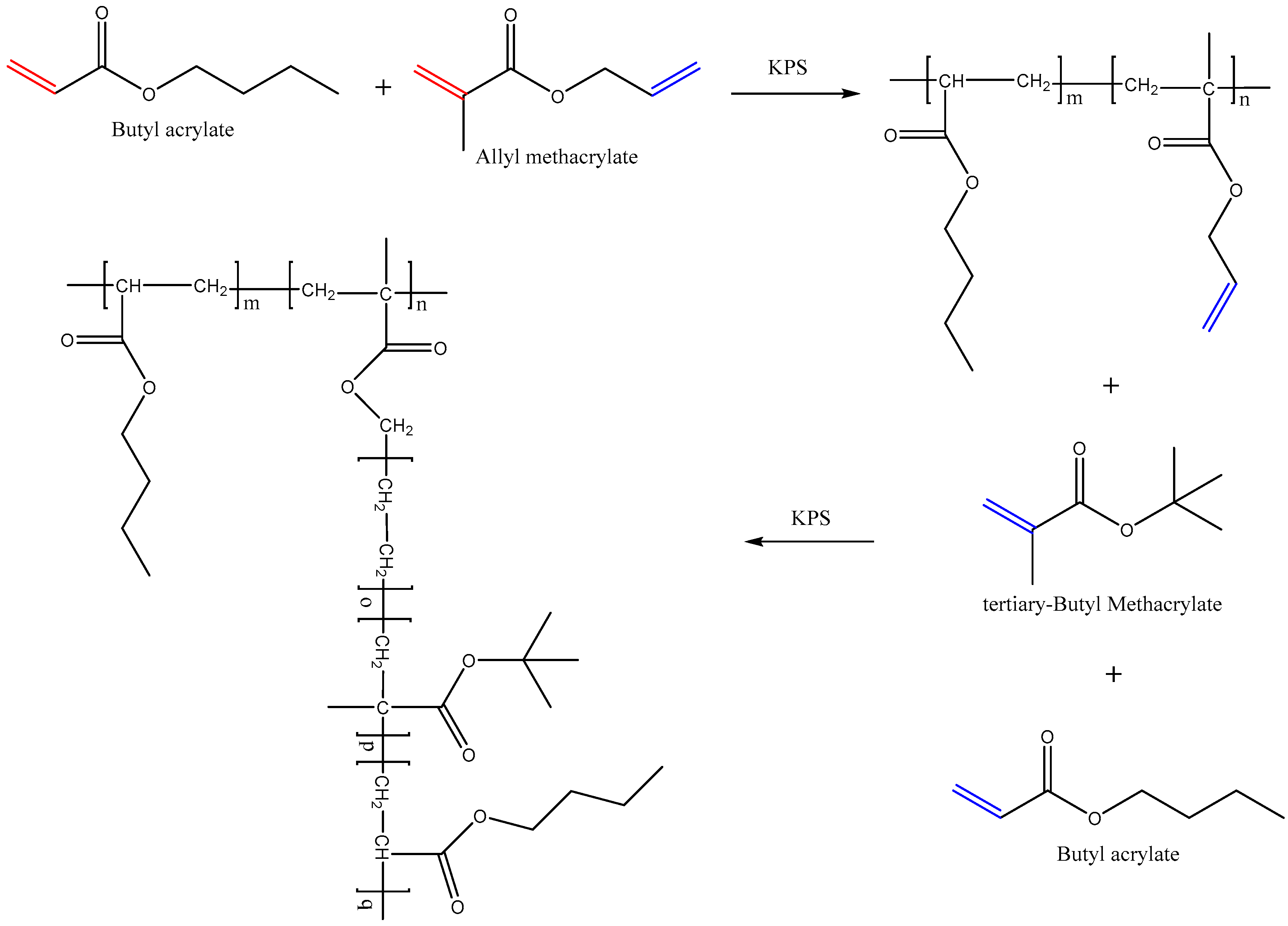

2.2. Preparation of Low Gloss Aqueous Acrylic Resins

2.3. Preparation of Low Gloss Aqueous Acrylic Films

2.4. Characterization

2.4.1. Attenuated Total Reflection-Fourier Transform Infrared Spectroscopy (ATR-FTIR)

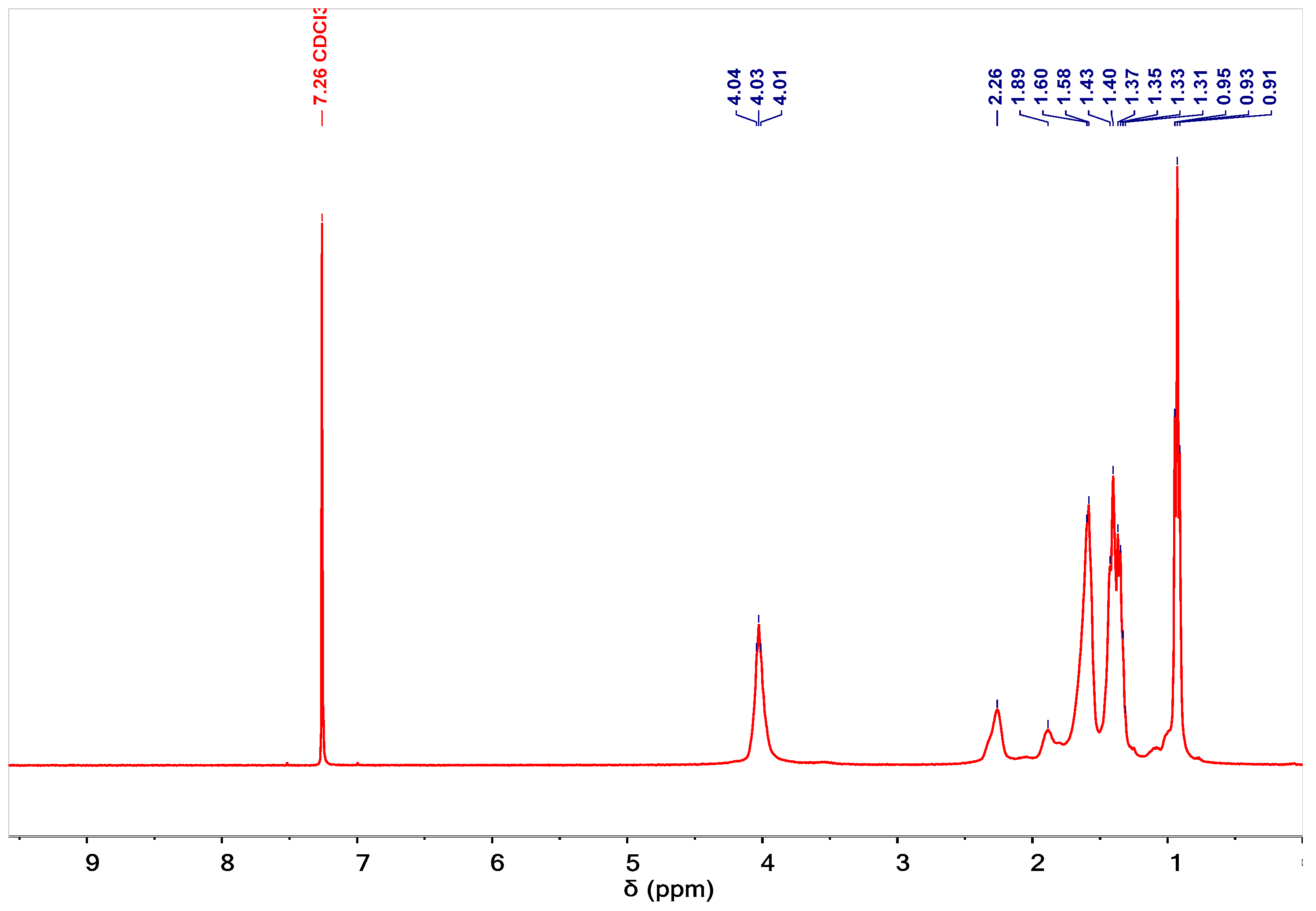

2.4.2. Nuclear Magnetic Resonance (NMR)

2.4.3. Scanning Electron Microscopy (SEM)

2.4.4. Atomic Force Microscopy (AFM)

2.4.5. Differential Scanning Calorimetry (DSC)

2.4.6. Transmission Electron Microscopy (TEM)

2.4.7. Ultraviolet-Visible Spectroscopy (UV-Vis)

2.4.8. Thermal Gravimetric Analysis (TGA)

2.4.9. Gloss Performance

2.4.10. Physical and Mechanical Properties

3. Results and Discussion

3.1. Structural Characterization

3.2. Particle Morphology Observation

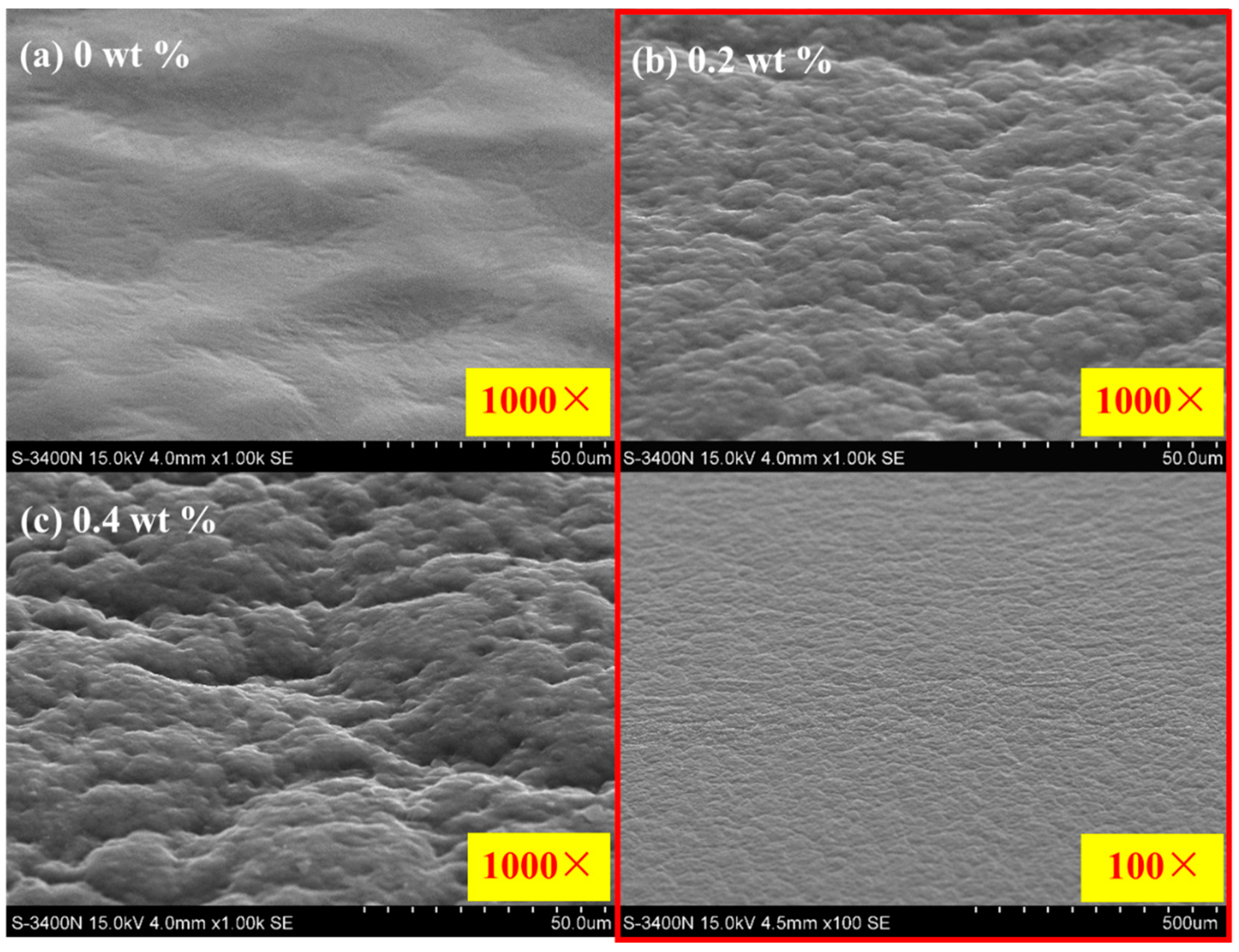

3.3. Film Surface Analysis

3.4. Surface Roughness

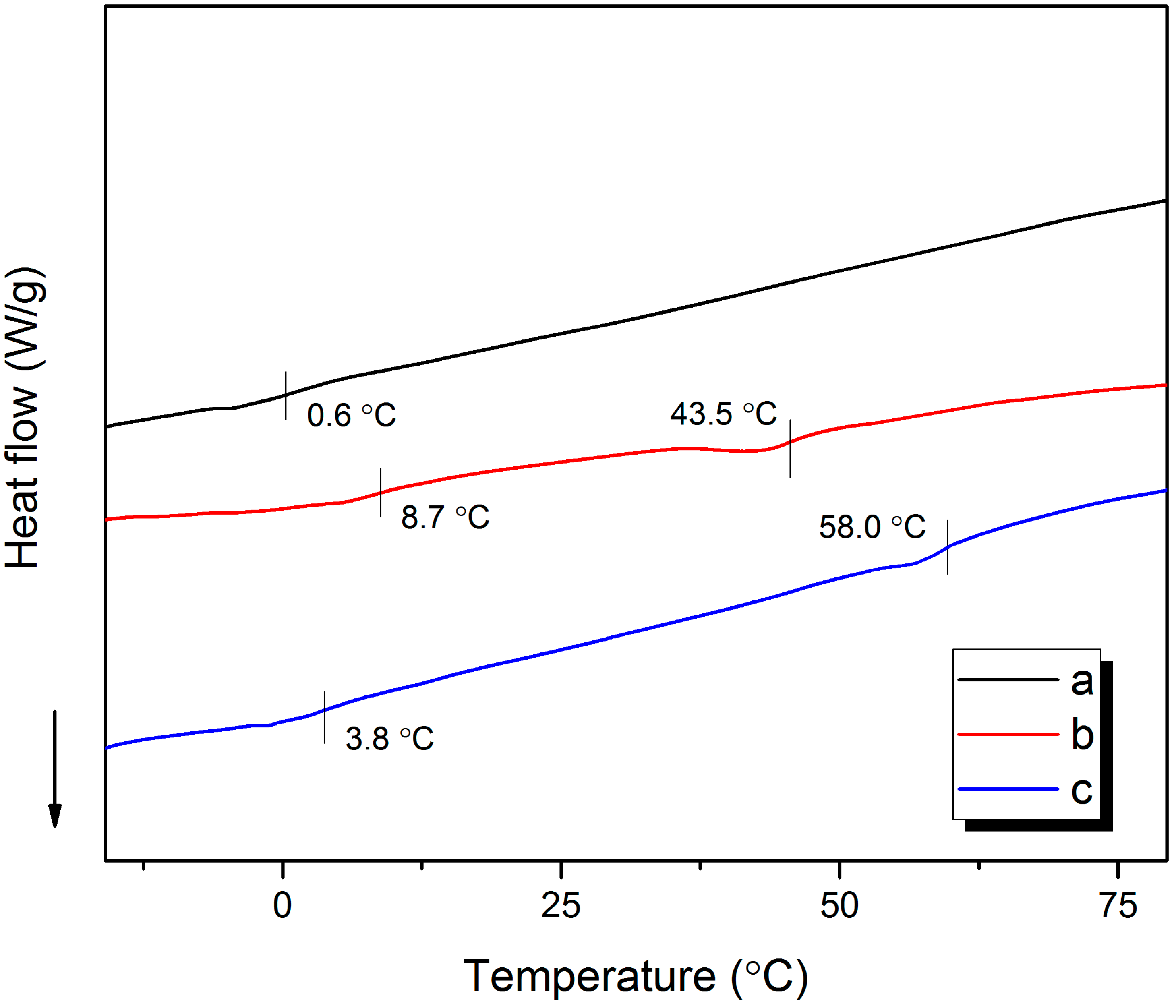

3.5. DSC Analysis

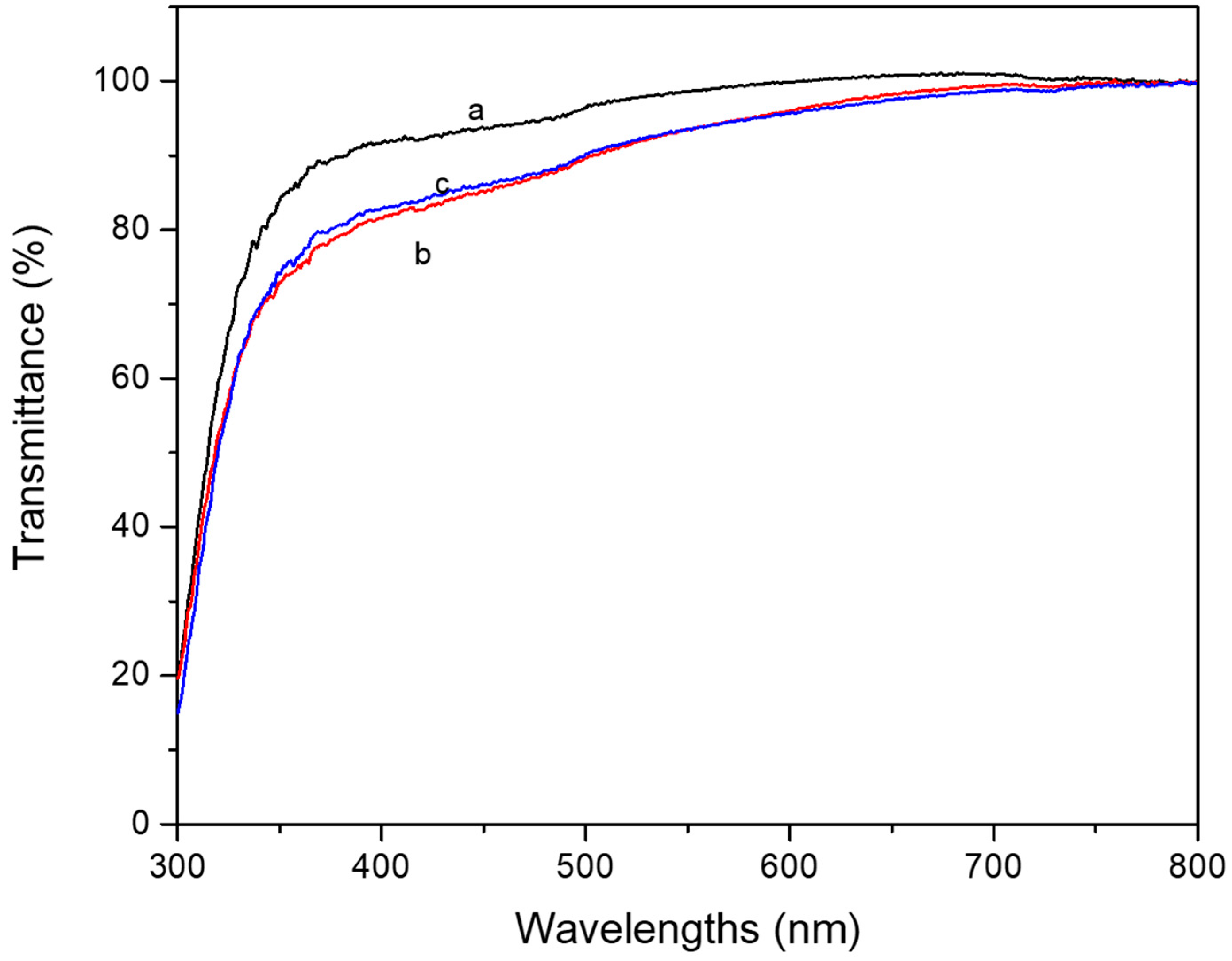

3.6. Film Transparency

3.7. Thermal Stability Analysis

3.8. Comprehensive Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bauer, F.; Decker, U.; Czihal, K.; Mehnert, R.; Riedel, C.; Riemschneider, M.; Schubert, R.; Buchmeiser, M.R. UV curing and matting of acrylate nanocomposite coatings by 172 nm excimer irradiation. Prog. Org. Coat. 2009, 64, 474–481. [Google Scholar] [CrossRef]

- Bauer, F.; Decker, U.; Naumov, S.; Riedel, C. Photoinitiator-free UV curing and matting of acrylate-based nanocomposite coatings: Part 3. Prog. Org. Coat. 2014, 77, 1085–1094. [Google Scholar] [CrossRef]

- Yong, Q.; Nian, F.; Liao, B.; Guo, Y.; Huang, L.; Wang, L.; Pang, H. Synthesis and surface analysis of self-matt coating based on waterborne polyurethane resin and study on the matt mechanism. Polym. Bull. 2017, 74, 1061–1076. [Google Scholar] [CrossRef]

- Zhu, J.; Huang, H.; Peng, X. Preparation and characterization of antiglare waterborne polyurethane. RSC Adv. 2016, 6, 102368–102372. [Google Scholar] [CrossRef]

- Al-Dahoudi, N.; Aegerter, M.A. Conducting, antistatic and antistatic-antiglare coatings made with hybrid sols. Mol. Cryst. Liq. Cryst. 2002, 374, 91–100. [Google Scholar]

- Yong, Q.; Pang, H.; Liao, B.; Mo, W.; Huang, F.; Huang, H.; Zhao, Y. Preparation and characterization of low gloss aqueous coating via forming self-roughed surface based on waterborne polyurethane acrylate hybrid emulsion. Prog. Org. Coat. 2018, 115, 18–26. [Google Scholar] [CrossRef]

- Li, P.; Nian, F.; Zhang, M.; Shen, M.; Dai, Y.; Pang, H.; Liao, B. Siloxane-modified polyacrylate low-residual pressure-sensitive adhesive with high peeling strength. J. Appl. Polym. Sci. 2016, 133, 1–9. [Google Scholar] [CrossRef]

- Ou, J.; Yang, Y.; Gan, J.; Ha, C.; Zhang, M. Preparation, properties, and applications of acrylic-polyurethane hybrid emulsions in extinction electrophoresis. J. Appl. Polym. Sci. 2014, 131, 40078. [Google Scholar] [CrossRef]

- Ou, J.; Zhang, M.; Liu, H.; Zhang, L.; Pang, H. Matting films prepared from waterborne acrylic/micro-SiO2 blends. J. Appl. Polym. Sci. 2015, 132, 1–8. [Google Scholar] [CrossRef]

- Aznar, A.C.; Pardini, O.R.; Amalvy, J.I. Glossy topcoat exterior paint formulations using water-based polyurethane/acrylic hybrid binders. Prog. Org. Coat. 2006, 55, 43–49. [Google Scholar] [CrossRef]

- Ettwein, F.; Rohrer-Vanzo, V.; Langthaler, G.; Werner, A.; Stern, T.; Moser, O.; Leitner, R.; Regenfelder, K. Consumer’s perception of high gloss furniture: Instrumental gloss measurement versus visual gloss evaluation. Eur. J. Wood Wood Prod. 2017, 75, 1009–1016. [Google Scholar] [CrossRef]

- Braun, J.H. Gloss of paint films and the mechanism of pigment involvement. J. Coat. Technol. 1991, 63, 43–51. [Google Scholar]

- Braun, J.H.; Fields, D.P. Gloss of paint films: II. Effect of pigment size. J. Coat. Technol. 1994, 66, 93–98. [Google Scholar]

- Fletcher, T.E. A simple model to describe relationships between gloss behaviour, matting agent concentration and the rheology of matted paints and coatings. Prog. Org. Coat. 2002, 44, 25–36. [Google Scholar] [CrossRef]

- Cawthorne, J.E.; Joyce, M.; Fleming, D. Use of a chemically modified clay as a replacement for silica in matte coated ink-jet papers. J. Coat. Technol. 2003, 75, 75–81. [Google Scholar] [CrossRef]

- Lamy, R.; Zunic, E.; Steding, R.; Aamodt, A. Preparation of stable slurries of spherically shaped silica for coatings. Prog. Org. Coat. 2011, 72, 96–101. [Google Scholar] [CrossRef]

- Xu, Q.; Ji, T.; Tian, Q.; Su, Y.; Niu, L.; Li, X.; Zhang, Z. Structural Adjustment of In-Situ Surface-Modified Silica Matting Agent and Its Effect on Coating Performance. Nano 2018, 13, 1850137. [Google Scholar] [CrossRef]

- Diakoumakos, C.D.; Jones, F.N. A new class of high-solids low-gloss mar resistant pigmented coatings prepared from an isophthalate-based oligoester, a melamine resin and various talcs. Surf. Coat. Technol. 2002, 150, 37–49. [Google Scholar] [CrossRef]

- Reichard, R. Specialty low gloss PVC resin vs. traditional low gloss modifiers. J. Vinyl Technol. 1991, 13, 179–183. [Google Scholar] [CrossRef]

- Rissa, K.; Lepistö, T.; Yrjölä, K. Effect of kaolin content on structure and functional properties of water-based coatings. Prog. Org. Coat. 2006, 55, 137–141. [Google Scholar] [CrossRef]

- Álvarez-García, S.; Martín-Martínez, J.M. Effect of the carbon black content on the thermal, rheological and mechanical properties of thermoplastic polyurethanes. J. Adhes. Sci. Technol. 2015, 29, 1136–1154. [Google Scholar] [CrossRef]

- Järnström, J.; Ihalainen, P.; Backfolk, K.; Peltonen, J. Roughness of pigment coatings and its influence on gloss. Appl. Surf. Sci. 2008, 254, 5741–5749. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, M.J. Study on siloxane-acrylic aqueous dispersions for use in exterior decorative coatings. Surf. Coat. Int. Part B Coat. Trans. 2005, 88, 107–111. [Google Scholar] [CrossRef]

- Xiao, J.; Qiu, Z.; Yang, W.; Qiu, J.; Yang, T.; Xu, Y.; Zeng, Y.; Wang, F.C.; Li, S.K. Organosilicone modification of allyl methacrylate with speier’s catalyst for waterborne self-matting styrene-acrylic emulsion. Prog. Org. Coat. 2018, 116, 1–6. [Google Scholar] [CrossRef]

- Sun, Z.; Fan, H.; Chen, Y.; Huang, J. Synthesis of self-matting waterborne polyurethane coatings with excellent transmittance. Polym. Int. 2018, 67, 78–84. [Google Scholar] [CrossRef]

- Landy, M.S. Visual perception: A gloss on surface properties. Nature 2007, 447, 158–159. [Google Scholar] [CrossRef] [PubMed]

- De la Rie, E.R.; Delaney, J.K.; Morales, K.M.; Maines, C.A.; Sung, L.-P. Modification of Surface Roughness by Various Varnishes and Effect on Light Reflection. Stud. Conserv. 2010, 55, 134–143. [Google Scholar] [CrossRef]

- Leloup, F.B.; Obein, G.; Pointer, M.R.; Hanselaer, P. Toward the soft metrology of surface gloss: A review. Color Res. Appl. 2014, 39, 559–570. [Google Scholar] [CrossRef]

- Simpson, L.A. Factors controlling gloss of paint films. Prog. Org. Coat. 1978, 6, 1–30. [Google Scholar] [CrossRef]

- Trezza, T.A.; Krochta, J.M. Heterogeneity of Biopolymer Coatings. J. Appl. Polym. Sci. 2001, 79, 2221–2229. [Google Scholar] [CrossRef]

- Gunde, M.K.; Kunaver, M.; Čekada, M. Surface analysis of matt powder coatings. Dye. Pigment. 2006, 74, 202–207. [Google Scholar] [CrossRef]

- Elton, N.J.; Legrix, A. Reflectometry of drying latex paint. J. Coat. Technol. Res. 2014, 11, 185–197. [Google Scholar] [CrossRef]

- Larena, A.; Pinto, G. The effect of surface roughness and crystallinity on the light scattering of polyethylene tubular blown films. Polym. Eng. Sci. 1993, 33, 742–747. [Google Scholar] [CrossRef]

- Uribe-Padilla, J.; Graells-Sobré, M.; Salgado-Valle, J. A novel contribution to the modeling of the matting efficiency of aqueous polyurethane dispersions. Prog. Org. Coat. 2017, 109, 179–185. [Google Scholar] [CrossRef]

- Cao, X.; Ge, X.; Chen, H.; Li, W. Effects of trimethylol propane and AAS salt on properties of waterborne polyurethane with low gloss. Prog. Org. Coat. 2017, 107, 5–13. [Google Scholar] [CrossRef]

- Basu, S.K.; Scriven, L.E.; Francis, L.F.; McCormick, A.V. Mechanism of wrinkle formation in curing coatings. Prog. Org. Coat. 2005, 53, 1–16. [Google Scholar] [CrossRef]

- Lee, S.S.; Koo, J.H.; Lee, S.S.; Chai, S.G.; Lim, J.C. Gloss reduction in low temperature curable hybrid powder coatings. Prog. Org. Coat. 2003, 46, 266–272. [Google Scholar] [CrossRef]

- Giles, S.L.; Heller, N.W.M.; Clayton, C.R.; Walker, M.E.; Wytiaz, M.J.; Wynne, J.H. Novel Methods of Producing Low-Reflectance Coatings Utilizing Synergistic Effects of Polymer Phase Separation. ACS Appl. Mater. Interfaces 2016, 8, 26251–26257. [Google Scholar] [CrossRef] [PubMed]

| Component | Abbr. | Composition (wt %) |

|---|---|---|

| Monomer | BA | 19.6–20 |

| AMA | 0–0.4 | |

| t-BMA | 4.8 | |

| BA | 0.2 | |

| Emulsifier | SD | 0.075 |

| Initiator | KPS | 0.15 |

| Medium | DI | 75 |

| Type of Test | 0 wt % | 0.2 wt % | 0.4 wt % |

|---|---|---|---|

| Solid content (%) | 25 | 25 | 25 |

| 60° specular gloss (°) | 78.0 | 4.0 | 3.2 |

| Flexibility (mm) | 2 | 2 | 2 |

| Abrasion resistance (/circle) | 200 | 250 | 280 |

| Adhesion | 5B | 5B | 4B |

| Pencil hardness | H | 2H | 4H |

| Touch feeling | Soft-touch | Soft-touch | Hard-touch |

| Water resistance | Poor | Good | Good |

| Impact resistance (500 g) | Good | Good | Good |

| Storage stability (180 days) | Good | Good | Good |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yong, Q.; Liang, C. Synthesis of an Aqueous Self-Matting Acrylic Resin with Low Gloss and High Transparency via Controlling Surface Morphology. Polymers 2019, 11, 322. https://doi.org/10.3390/polym11020322

Yong Q, Liang C. Synthesis of an Aqueous Self-Matting Acrylic Resin with Low Gloss and High Transparency via Controlling Surface Morphology. Polymers. 2019; 11(2):322. https://doi.org/10.3390/polym11020322

Chicago/Turabian StyleYong, Qiwen, and Caizhen Liang. 2019. "Synthesis of an Aqueous Self-Matting Acrylic Resin with Low Gloss and High Transparency via Controlling Surface Morphology" Polymers 11, no. 2: 322. https://doi.org/10.3390/polym11020322