Synergistic Effect of Fullerenes on the Laser-Induced Periodic Surface Structuring of Poly(3-Hexyl Thiophene)

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Laser-Induced Periodic Surface Structuring on P3HT at 266 nm

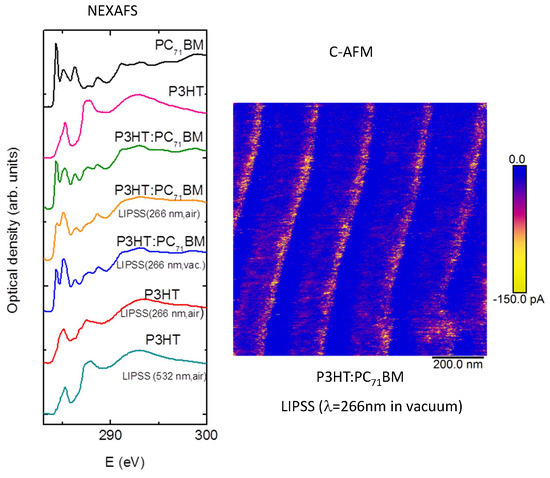

3.2. Laser-Induced Periodic Surface Structuring on P3HT:PC71BM at 266 nm

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

).

).

).

).

References

- Nougaret, L.; Kassa, H.G.; Cai, R.; Patois, T.; Nysten, B.; van Breemen, A.J.J.M.; Gelinck, G.H.; de Leeuw, D.M.; Marrani, A.; Hu, Z.; et al. Nanoscale Design of Multifunctional Organic Layers for Low-Power High-Density Memory Devices. ACS Nano 2014, 8, 3498–3505. [Google Scholar] [CrossRef] [PubMed]

- Ganesh, V.A.; Raut, H.K.; Nair, A.S.; Ramakrishna, S. A review on self-cleaning coatings. J. Mater. Chem. 2011, 21, 16304–16322. [Google Scholar] [CrossRef]

- Whiter, R.A.; Boughey, C.; Smith, M.; Kar-Narayan, S. Mechanical Energy Harvesting Performance of Ferroelectric Polymer Nanowires Grown via Template-Wetting. Energy Technol. 2018, 6, 928–934. [Google Scholar] [CrossRef] [PubMed]

- Rebollar, E.; Castillejo, M.; Ezquerra, T.A. Laser induced periodic surface structures on polymer films: From fundamentals to applications. Eur. Polym. J. 2015, 73, 162–174. [Google Scholar] [CrossRef] [Green Version]

- Rebollar, E.; de Aldana, J.R.V.; Perez-Hernandez, J.A.; Ezquerra, T.A.; Moreno, P.; Castillejo, M. Ultraviolet and infrared femtosecond laser induced periodic surface structures on thin polymer films. Appl. Phys. Lett. 2012, 100. [Google Scholar] [CrossRef]

- Bolle, M.; Lazare, S.; Leblanc, M.; Wilmes, A. Submicron periodic structures produced on polymer surfaces with polarized excimer laser ultraviolet-radiation. Appl. Phys. Lett. 1992, 60, 674–676. [Google Scholar] [CrossRef]

- Csete, M.; Bor, Z. Laser-induced periodic surface structure formation on polyethylene-terephthalate. Appl. Surf. Sci. 1998, 133, 5–16. [Google Scholar] [CrossRef]

- Rueda, D.R.; Martin-Fabiani, I.; Soccio, M.; Alayo, N.; Perez-Murano, F.; Rebollar, E.; Garcia-Gutierrez, M.C.; Castillejo, M.; Ezquerra, T.A. Grazing-incidence small-angle X-ray scattering of soft and hard nanofabricated gratings. J. Appl. Crystallogr. 2012, 45, 1038–1045. [Google Scholar] [CrossRef]

- Rebollar, E.; Perez, S.; Hernandez, M.; Domingo, C.; Martin, M.; Ezquerra, T.A.; Garcia-Ruiz, J.P.; Castillejo, M. Physicochemical modifications accompanying UV laser induced surface structures on poly(ethylene terephthalate) and their effect on adhesion of mesenchymal cells. Phys. Chem. Chem. Phys. 2014, 16, 17551–17559. [Google Scholar] [CrossRef]

- Guosheng, Z.; Fauchet, P.M.; Siegman, A.E. Growth of spontaneous periodic surface-structures on solids during laser illumination. Phys. Rev. B 1982, 26, 5366–5381. [Google Scholar] [CrossRef]

- Ludwigs, S. (Ed.) P3HT Revisited—From Molecular Scale to Solar Cell Devices; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Winokur, M.J.; Spiegel, D.; Kim, Y.; Hotta, S.; Heeger, A.J. Structural and Absorption Studies of The Thermochromic Transition in Poly(3-Hexylthiophene). Synth. Met. 1989, 28, C419–C426. [Google Scholar] [CrossRef]

- Bolognesi, A.; Porzio, W.; Zhuo, G.; Ezquerra, T. The thermal behaviour of poly(3-octylthienylene) synthesized by an Ni-based catalyst: DSC, optical microscopy and XRD analyses. Eur. Polym. J. 1996, 32, 1097–1103. [Google Scholar] [CrossRef]

- Chae, S.; Yi, A.; Lee, H.H.; Choi, J.; Kim, H.J. Laser-induced orientation transformation of a conjugated polymer thin film with enhanced vertical charge transport. J. Mater. Chem. C 2018, 6. [Google Scholar] [CrossRef]

- Rodriguez-Rodriguez, A.; Rebollar, E.; Soccio, M.; Ezquerra, T.A.; Rueda, D.R.; Garcia-Ramos, J.V.; Castillejo, M.; Garcia-Gutierrez, M.C. Laser-Induced Periodic Surface Structures on Conjugated Polymers: Poly(3-hexylthiophene). Macromolecules 2015, 48, 4024–4031. [Google Scholar] [CrossRef] [Green Version]

- Rodriguez-Rodriguez, A.; Rebollar, E.; Ezquerra, T.A.; Castillejo, M.; Garcia-Ramos, J.V.; Garcia-Gutierrez, M.-C. Patterning Conjugated Polymers by Laser: Synergy of Nanostructure Formation in the All-Polymer Heterojunction P3HT/PCDTBT. Langmuir 2018, 34, 115–125. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Rodriguez, A.; Garcia-Gutierrez, M.-C.; Ezquerra, T.A.; Brady, M.A.; Wang, C.; Rebollar, E. Resonant soft X-ray scattering unravels the hierarchical morphology of nanostructured bulk heterojunction photovoltaic thin films. Phys. Rev. Mater. 2018, 2. [Google Scholar] [CrossRef]

- Moore, G.E. Cramming More Components onto Integrated Circuits. Electronics 1965, 38, 114–117. [Google Scholar] [CrossRef]

- Li, G.; Zhu, R.; Yang, Y. Polymer solar cells. Nat. Photonics 2012, 6, 153–161. [Google Scholar] [CrossRef]

- Cui, J.; Rodriguez-Rodriguez, A.; Hernandez, M.; Garcia-Gutierrez, M.-C.; Nogales, A.; Castillejo, M.; Mosegui Gonzalez, D.; Mueller-Buschbaum, P.; Ezquerra, T.A.; Rebollar, E. Laser-Induced Periodic Surface Structures on P3HT and on Its Photovoltaic Blend with PC71BM. ACS Appl. Mater. Interfaces 2016, 8, 31894–31901. [Google Scholar] [CrossRef] [PubMed]

- Gann, E.; Young, A.T.; Collins, B.A.; Yan, H.; Nasiatka, J.; Padmore, H.A.; Ade, H.; Hexemer, A.; Wang, C. Soft X-ray scattering facility at the Advanced Light Source with real-time data processing and analysis. Rev. Sci. Instrum. 2012, 83. [Google Scholar] [CrossRef]

- Izumi, T.; Kobashi, S.; Takimiya, K.; Aso, Y.; Otsubo, T. Synthesis and spectroscopic properties of a series of beta-blocked long oligothiophenes up to the 96-mer: Revaluation of effective conjugation length. J. Am. Chem. Soc. 2003, 125, 5286–5287. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Nogales, A.; Ezquerra, T.A.; Rebollar, E. Influence of substrate and film thickness on polymer LIPSS formation. Appl. Surf. Sci. 2017, 394, 125–131. [Google Scholar] [CrossRef]

- Rebollar, E.; de Aldana, J.R.V.; Martin-Fabiani, I.; Hernandez, M.; Rueda, D.R.; Ezquerra, T.A.; Domingo, C.; Moreno, P.; Castillejo, M. Assessment of femtosecond laser induced periodic surface structures on polymer films. Phys. Chem. Chem. Phys. 2013, 15, 11287–11298. [Google Scholar] [CrossRef] [PubMed]

- Dillon, R.O.; Woollam, J.A.; Katkanant, V. Use of raman-scattering to investigate disorder and crystallite formation in as-deposited and annealed carbon-films. Phys. Rev. B 1984, 29, 3482–3489. [Google Scholar] [CrossRef]

- Kanai, K.; Miyazaki, T.; Suzuki, H.; Inaba, M.; Ouchi, Y.; Seki, K. Effect of annealing on the electronic structure of poly(3-hexylthiophene) thin film. Phys. Chem. Chem. Phys. 2010, 12, 273–282. [Google Scholar] [CrossRef]

- Watts, B.; Swaraj, S.; Nordlund, D.; Luening, J.; Ade, H. Calibrated NEXAFS spectra of common conjugated polymers. J. Chem. Phys. 2011, 134. [Google Scholar] [CrossRef]

- Germack, D.S.; Chan, C.K.; Hamadani, B.H.; Richter, L.J.; Fischer, D.A.; Gundlach, D.J.; DeLongchamp, D.M. Substrate-dependent interface composition and charge transport in films for organic photovoltaics. Appl. Phys. Lett. 2009, 94. [Google Scholar] [CrossRef]

- Bazylewski, P.F.; Kim, K.H.; Forrest, J.L.; Tada, H.; Choi, D.H.; Chang, G.S. Side-chain effects on electronic structure and molecular stacking arrangement of PCBM spin-coated films. Chem. Phys. Lett. 2011, 508, 90–94. [Google Scholar] [CrossRef]

- Gu, Y.; Wang, C.; Liu, F.; Chen, J.; Dyck, O.E.; Duscher, G.; Russell, T.P. Guided crystallization of P3HT in ternary blend solar cell based on P3HT:PCPDTBT:PCBM. Energy Environ. Sci. 2014, 7, 3782–3790. [Google Scholar] [CrossRef]

- Kiel, J.W.; Eberle, A.P.R.; Mackay, M.E. Nanoparticle Agglomeration in Polymer-Based Solar Cells. Phys. Rev. Lett. 2010, 105. [Google Scholar] [CrossRef]

- Jiao, X.; Ye, L.; Ade, H. Quantitative Morphology–Performance Correlations in Organic Solar Cells: Insights from Soft X-ray Scattering. Adv. Energy Mater. 2017, 7. [Google Scholar] [CrossRef]

- Rebollar, E.; Gaspard, S.; Oujja, M.; Villavieja, M.M.; Corrales, T.; Bosch, P.; Georgiou, S.; Castillejo, M. Pulsed laser deposition of polymers doped with fluorescent molecular sensors. Appl. Phys. A-Mater. Sci. Process. 2006, 84, 171–180. [Google Scholar] [CrossRef]

- Dzwilewski, A.; Wagberg, T.; Edman, L. Photo-Induced and Resist-Free Imprint Patterning of Fullerene Materials for Use in Functional Electronics. J. Am. Chem. Soc. 2009, 131, 4006–4011. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez-Fernández, E.; Rodríguez-Rodríguez, A.; García-Gutiérrez, M.C.; Nogales, A.; Ezquerra, T.A.; Rebollar, E. Functional nanostructured surfaces induced by laser on fullerene thin films. Appl. Surf. Sci. 2019, in press. [Google Scholar] [CrossRef]

) indicates the polarization vector of the laser beam.

) indicates the polarization vector of the laser beam.

) indicates the polarization vector of the laser beam.

) indicates the polarization vector of the laser beam.

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Rodríguez, Á.; Gutiérrez-Fernández, E.; García-Gutiérrez, M.-C.; Nogales, A.; Ezquerra, T.A.; Rebollar, E. Synergistic Effect of Fullerenes on the Laser-Induced Periodic Surface Structuring of Poly(3-Hexyl Thiophene). Polymers 2019, 11, 190. https://doi.org/10.3390/polym11020190

Rodríguez-Rodríguez Á, Gutiérrez-Fernández E, García-Gutiérrez M-C, Nogales A, Ezquerra TA, Rebollar E. Synergistic Effect of Fullerenes on the Laser-Induced Periodic Surface Structuring of Poly(3-Hexyl Thiophene). Polymers. 2019; 11(2):190. https://doi.org/10.3390/polym11020190

Chicago/Turabian StyleRodríguez-Rodríguez, Álvaro, Edgar Gutiérrez-Fernández, Mari-Cruz García-Gutiérrez, Aurora Nogales, Tiberio A. Ezquerra, and Esther Rebollar. 2019. "Synergistic Effect of Fullerenes on the Laser-Induced Periodic Surface Structuring of Poly(3-Hexyl Thiophene)" Polymers 11, no. 2: 190. https://doi.org/10.3390/polym11020190