Hybrid Nanocomposites of Cellulose/Carbon-Nanotubes/Polyurethane with Rapidly Water Sensitive Shape Memory Effect and Strain Sensing Performance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

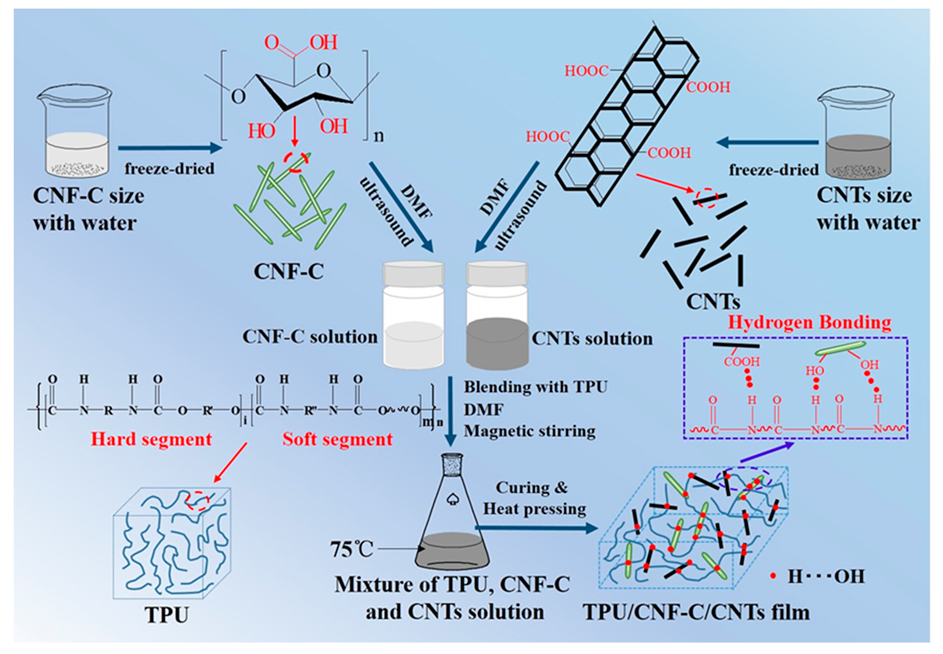

2.2. Preparation of TPU/CNF-C/CNTs Hybrid Films

2.3. Characterization by Attenuated Total Reflectance Fourier Transform Infrared Spectroscopy (ATR FT-IR)

2.4. Characterization by Wide Angle X-Ray Diffraction (WAXRD)

2.5. Characterization by Differential Scanning Calorimetry (DSC)

2.6. Characterization by Tensile Tests

2.7. Shape Memory Behavior Measurements

2.8. Tests of Sensing Performance

3. Results and Discussions

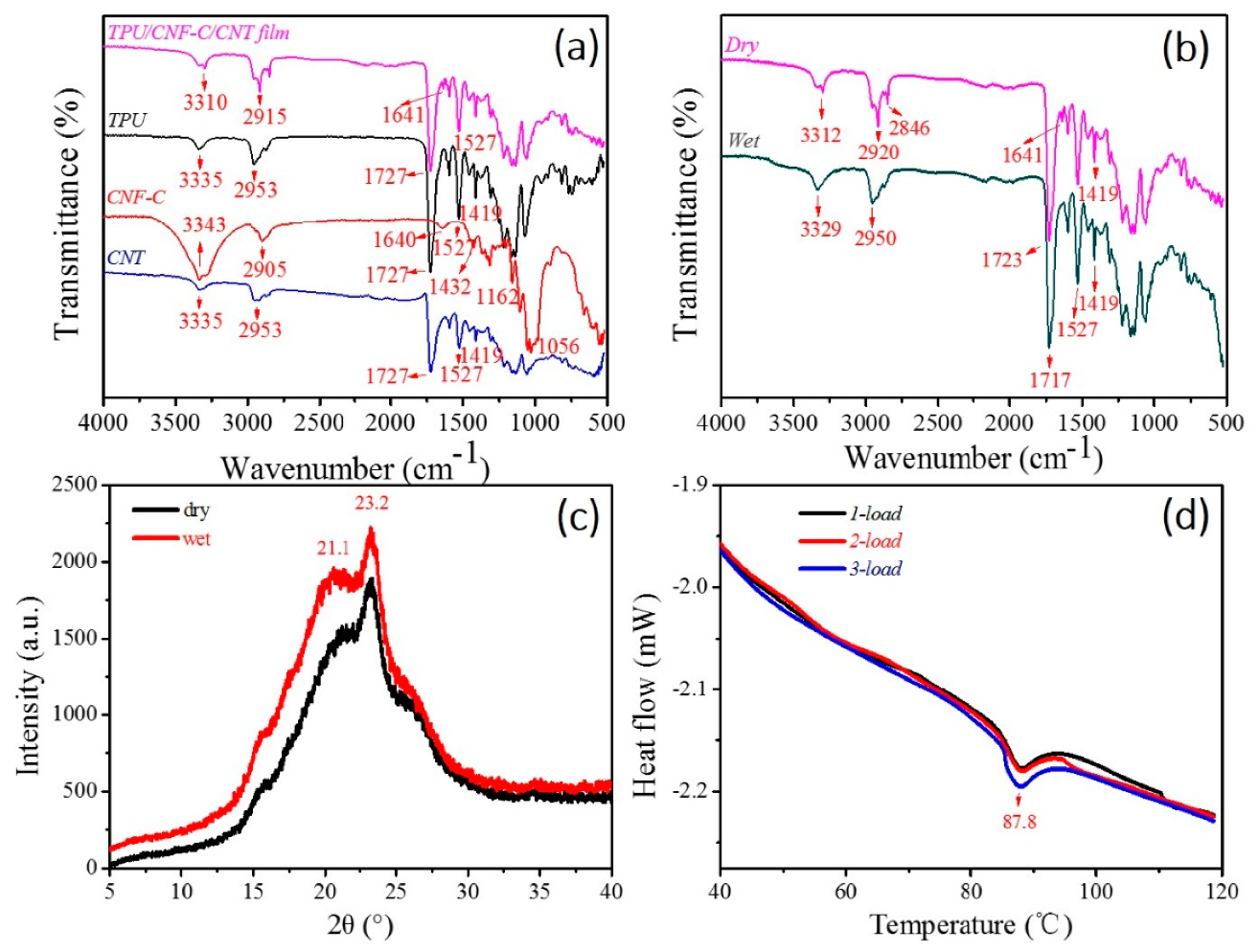

3.1. Physical Properties of TPU/CNF-C/CNTs Films

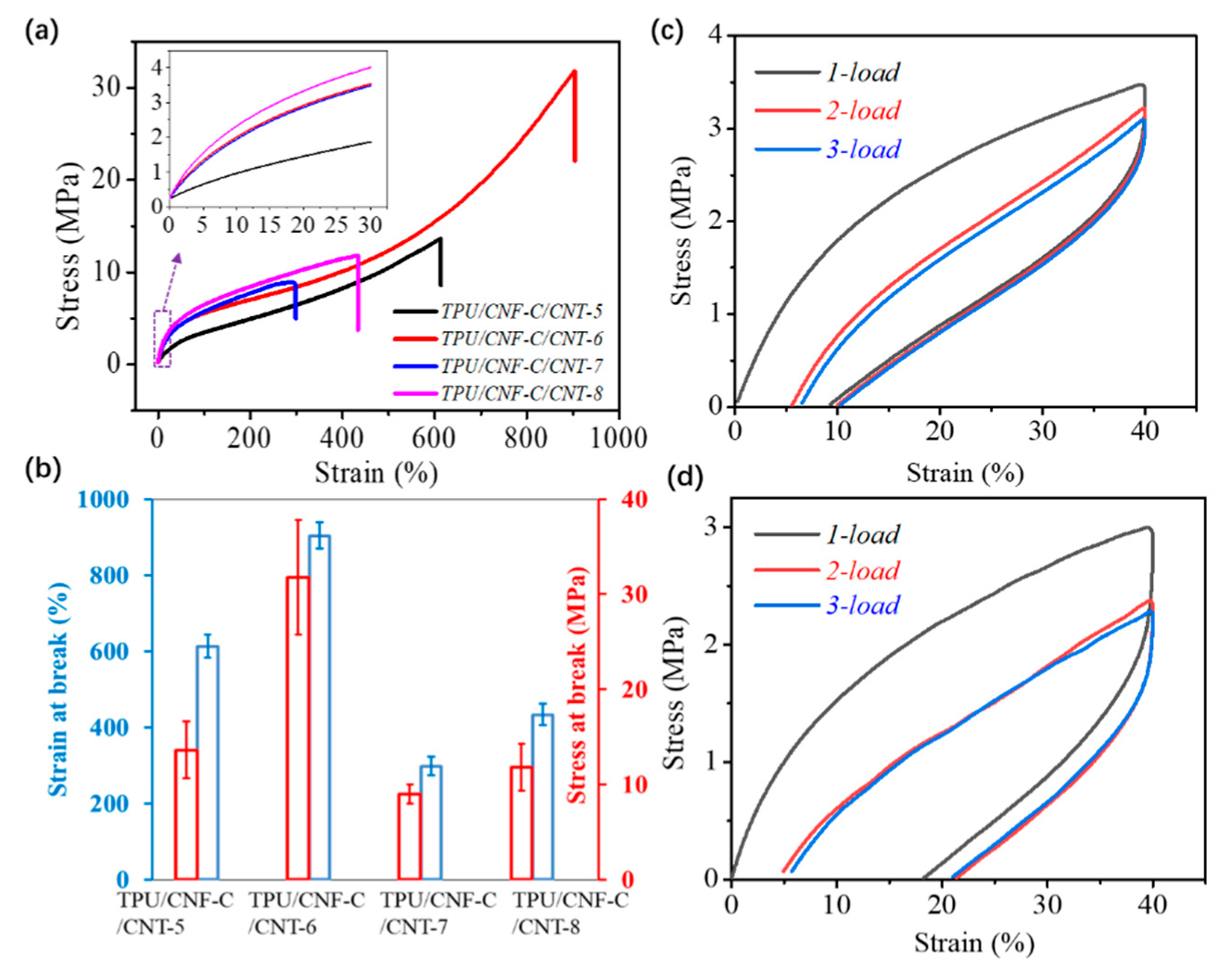

3.2. Mechanical Properties of TPU/CNF-C/CNTs Films

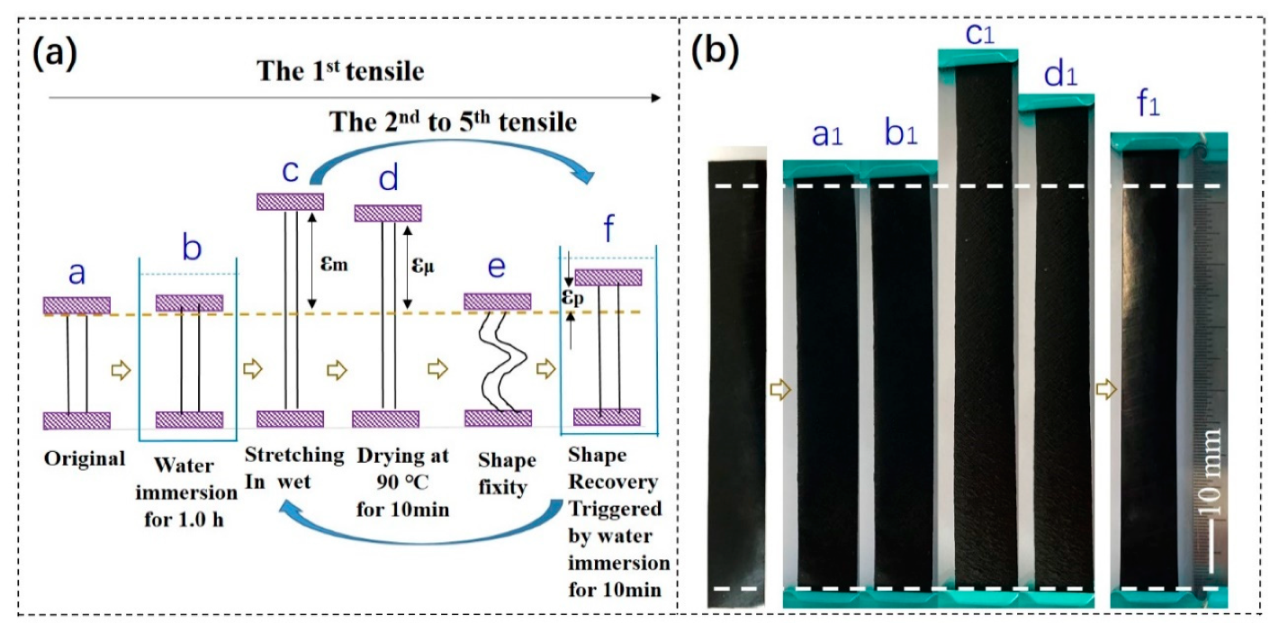

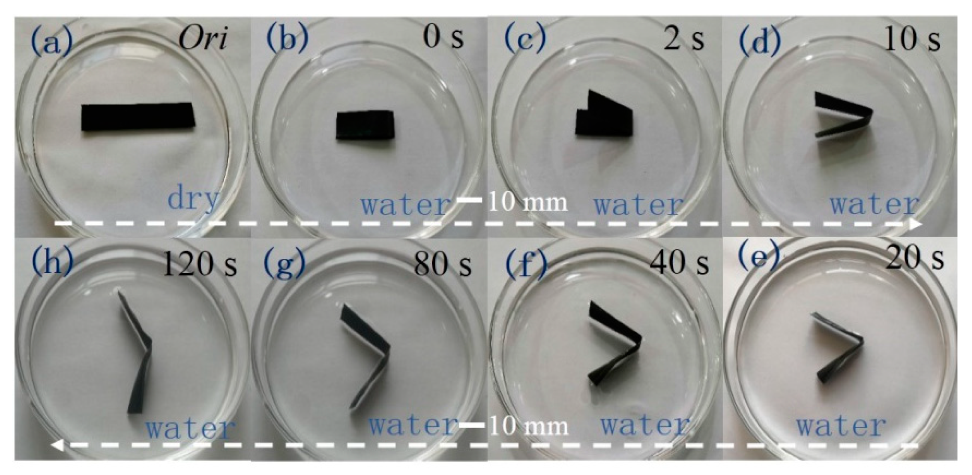

3.3. Rapid Response to Water Stimulation

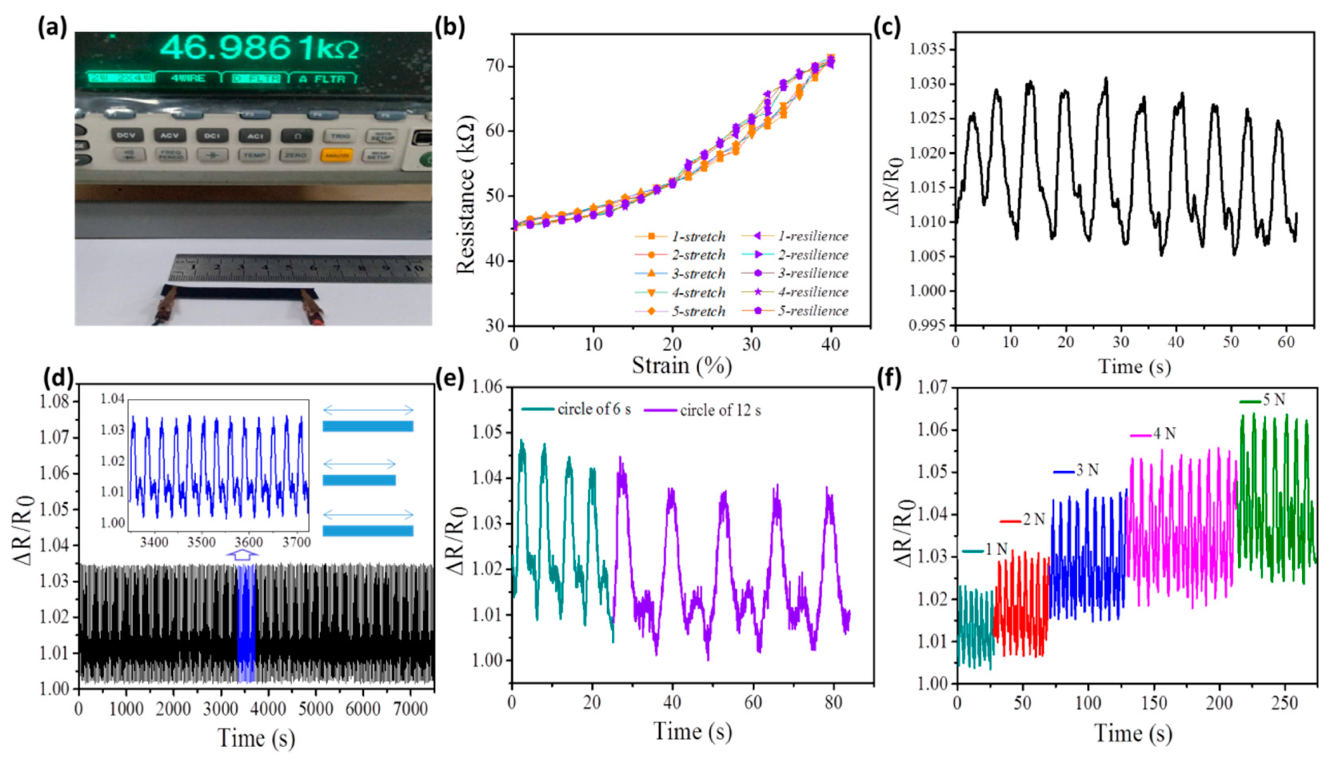

3.4. Characterization of Sensing Performance

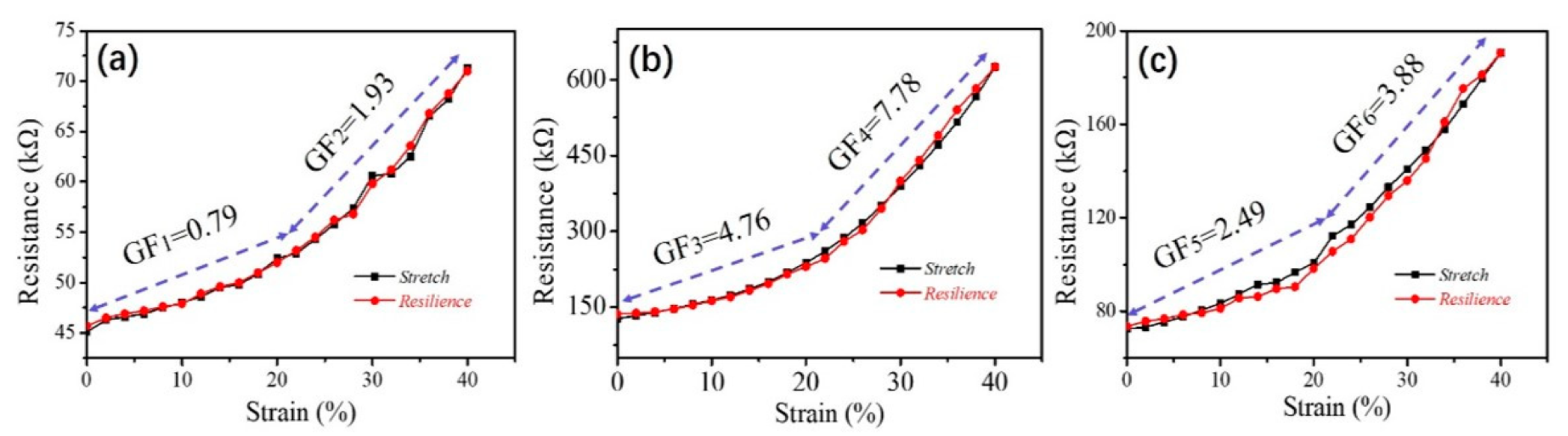

3.5. Comparison of Sensing Performance Before, During, and After SME

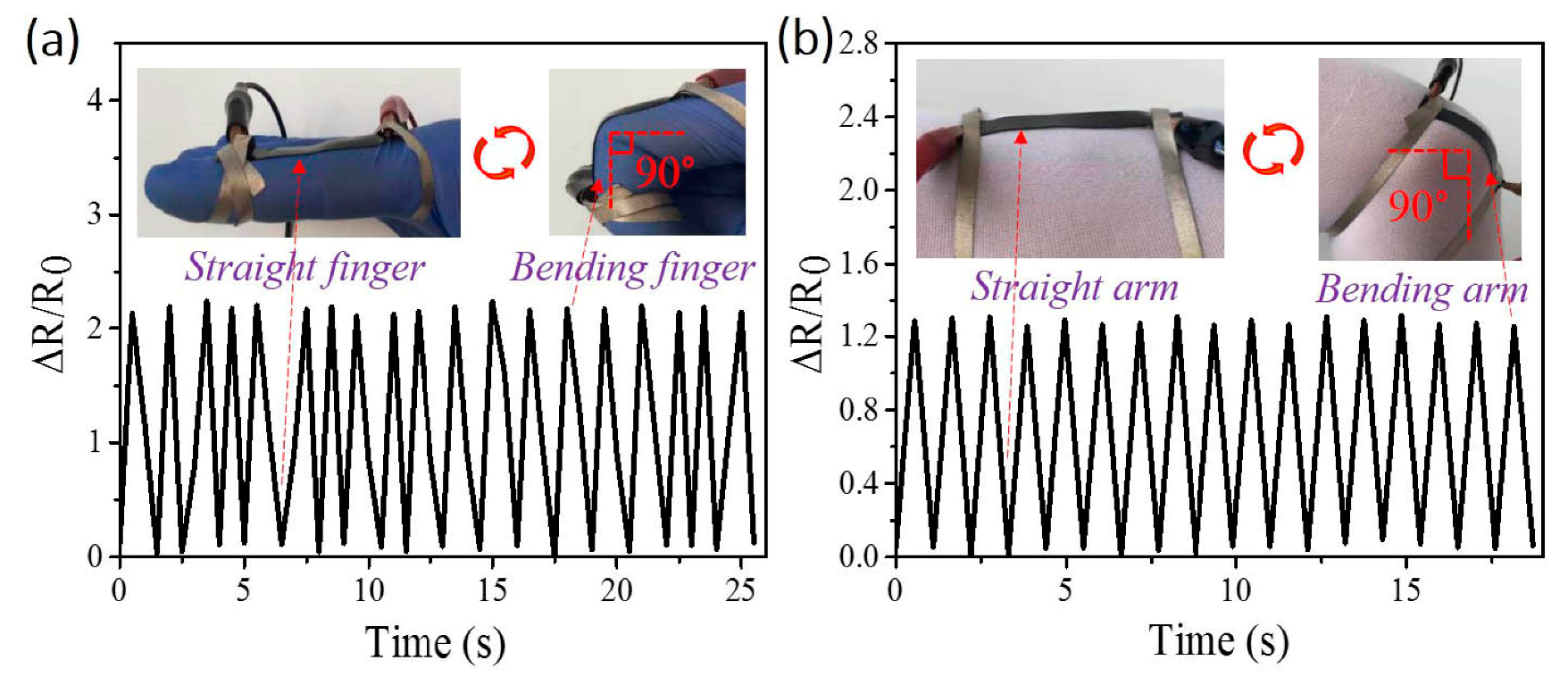

3.6. Application Demonstration of Limb Motion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Luo, H.; Li, Z.; Yi, G. Multi-stimuli responsive carbon nanotube-shape memory polymeric composites. Mater. Lett. 2014, 137, 385–388. [Google Scholar] [CrossRef]

- Liu, T.; Zhou, T.; Yao, Y. Stimulus methods of multi-functional shape memory polymer nanocomposites: A review. Composites Part A. Appl. Sci. Manuf. 2017, 100, 20–30. [Google Scholar] [CrossRef]

- Bai, Y.; Chen, X. A fast water-induced shape memory polymer based on hydroxyethyl cellulose/graphene oxide composites. Composites Part A. Appl. Sci. Manuf. 2017, 103, 9–16. [Google Scholar] [CrossRef]

- Xiao, X.; Gu, Y.; Wu, G. Controllable crimpness of animal hairs via water-stimulated shape fixation for regulation of thermal insulation. Polymers 2019, 11, 172. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Zhou, H.; Qian, K. Mechanism study of biopolymer hair as a coupled thermo-water responsive smart material. Smart Mater. Struct. 2017, 26, 035023. [Google Scholar] [CrossRef]

- Wu, T.; O’Kelly, K.; Chen, B. Poly (vinyl alcohol) particle-reinforced elastomer composites with water-active shape-memory effects. Eur. Polym. J. 2014, 53, 230–237. [Google Scholar] [CrossRef]

- Nath, T.; Chou, H.P.; Disawal, R. Comparative study of electrically and hot water actuated shape memory alloy using developed thermo-mechanical cycletest bench. Def. Sci. J. 2017, 67, 101–107. [Google Scholar]

- Wu, T.; Frydrych, M.; O’Kelly, K. Poly (glycerol sebacate urethane)-cellulose nano- composites with water-active shape-memory effects. Biomacromolecules 2014, 15, 2663–2671. [Google Scholar] [CrossRef]

- Qi, X.; Yao, X.; Deng, S. Water-induced shape memory effect of graphene oxide reinforced polyvinyl alcohol nanocomposites. J. Mater. Chem. A 2014, 2, 2240–2249. [Google Scholar] [CrossRef]

- Bai, Q.; Zhang, G.; Xu, B. Thermal and water dual-responsive shape memory poly (vinyl alcohol)/Al2O3 nanocomposite. RSC Adv. 2015, 5, 91213–91217. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, Z.; Liu, Z. Cellulose nanofibers/polyurethane shape memory composites with fast water-responsivity. J. Mater. Chem. B. 2018, 6, 1668–1677. [Google Scholar] [CrossRef]

- Chalissery, D.; Pretsch, T.; Staub, S. Additive manufacturing of information carriers based on shape memory polyester urethane. Polymers 2019, 11, 1005. [Google Scholar] [CrossRef] [PubMed]

- Elseddawy, A.M.; Zein, W.A.; Phillips, A.H. Carbon nanotube-based nanoelectromechanical resonator as strain sensor. J. Comput. Theor. Nanosci. 2014, 11, 1174–1177. [Google Scholar] [CrossRef]

- Nie, B.; Li, X.; Shao, J. Flexible and transparent strain sensors with embedded multiwalled-carbon-nanotubes meshes. ACS Appl. Mater. Interfaces 2017, 9, 40681–40689. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.; Dong, X.; Gao, Y. Probing the structure evolution/orientation induced by interaction between polyurethane segments and SiO2 surface in shape memory process. Polymer 2014, 55, 4289. [Google Scholar] [CrossRef]

- Montero de Espinosa, L.; Meesorn, W.; Moatsou, D. Bioinspired polymer systems with stimuli-responsive mechanical properties. Chem. Rev. 2017, 117, 12851–12892. [Google Scholar] [CrossRef] [PubMed]

- Tan, L.; Hu, J.; Ying, R.K. Quick water-responsive shape memory hybrids with cellulose nanofibers. J. Polym. Sci. Part A Polym. Chem. 2017, 55, 767–775. [Google Scholar] [CrossRef]

- Bumbudsanpharoke, N.; Lee, W.; Chung, U. Study of humidity-responsive behavior in chiral nematic cellulose nanocrystal films for colorimetric response. Cellulose 2018, 25, 305–317. [Google Scholar] [CrossRef]

- Zhu, Y.; Hu, J.; Luo, H. Rapidly switchable water-sensitive shape-memory cellulose/elastomer nano-composites. Soft Matter 2012, 8, 2509–2517. [Google Scholar] [CrossRef]

- Li, Y.; Chen, H.; Liu, D. pH-responsive shape memory poly (ethylene glycol)-poly (ε-caprolactone)-based polyurethane/cellulose nanocrystals nanocomposite. ACS Appl. Mater. Interfaces 2015, 7, 12988–12999. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Yang, G. Multi-stimulus-responsive shape-memory polymer nanocomposite network cross-linked by cellulose nanocrystals. ACS Appl. Mater. Interfaces 2015, 7, 4118–4126. [Google Scholar] [CrossRef]

- Ryu, S.; Lee, P.; Chou, J.B. Extremely elastic wearable carbon nanotube fiber strain sensor for monitoring of human motion. ACS Nano 2015, 9, 5929–5936. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.R.; Her, S.C.; Yang, X.X. Synthesis and characterization of multi-walled carbon nanotube/graphene nanoplatelet hybrid film for flexible strain sensors. Nanomaterials 2018, 8, 786. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.; Liu, Y.; Liu, Y.; Peng, H.X.; Leng, J. Mechanical and shape recovery properties of shape memory polymer composite embedded with cup-stacked carbon nanotubes. J. Intell. Mater. Syst. Struct. 2013, 25, 1264–1275. [Google Scholar] [CrossRef]

- Du, F.P.; Ye, E.Z.; Yang, W.; Shen, T.H.; Tang, C.Y.; Xie, X.L.; Law, W.C. Electroactive shape memory polymer based on optimized multi-walled carbon nanotubes/polyvinylalcohol nanocomposites. Compos. Part B Eng. 2015, 68, 170–175. [Google Scholar] [CrossRef]

- Chen, L.; Li, W.; Liu, X. Carbon nanotubes array reinforced shape-memory epoxy with fast responses to low-power microwaves. J. Appl. Polym. Sci. 2019, 136, 47563. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.; Zou, F. Development of polyhydroxyalkanoate-based polyurethane with water-thermal response shape-memory behavior as new 3D elastomers scaffolds. Polymers 2019, 11, 1030. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Gu, Y.; Wu, G. A flexible piezoresistive sensor with highly elastic weave pattern for motion detection. Smart Mater. Struct. 2019, 28, 035020. [Google Scholar] [CrossRef]

- Frewin, C.L.; Ecker, M.; Joshi-Imre, A. Electrical properties of thiol-ene-based shape memory polymers intended for flexible electronics. Polymers 2019, 11, 902. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.L.; Wu, G.Z.; Zhou, H.T. Preparation and property evaluation of conductive hydrogel using poly (vinyl alcohol)/polyethylene glycol/graphene oxide for human electrocardiogram acquisition. Polymers 2017, 9, 259. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Xu, X.; Xin, Y. Coaxial thermoplastic elastomer-wrapped carbon nanotube fibers for deformable and wearable strain sensors. Adv. Funct. Mater. 2018, 28, 1705591. [Google Scholar] [CrossRef]

- Karimov, K.S.; Khalid, F.A.; Chani, M.T.S. Carbon nanotubes based strain sensors. Measurement 2012, 45, 918–921. [Google Scholar] [CrossRef]

- Wang, H.; Luo, H.; Zhou, X. Conductive multi-shape polymer composites towards stimuli sensing. Mater. Lett. 2017, 198, 132–135. [Google Scholar] [CrossRef]

- Jiang, G.; Zhang, M.; Feng, J. High oxygen barrier property of poly (propylene carbonate)/polyethylene glycol nanocomposites with low loading of cellulose nanocrytals. ACS Sustain. Chem. Eng. 2017, 5, 11246–11254. [Google Scholar] [CrossRef]

- Gong, J.; Hosaka, E.; Sakai, K. Processing and thermal response of temperature-sensitive-gel (TSG)/polymer composites. Polymers 2018, 10, 486. [Google Scholar] [CrossRef] [PubMed]

- Mao, Y.; Miyazaki, T.; Sakai, K. A 3D printable thermal energy storage crystalline gel using mask-projection stereolithography. Polymers 2018, 10, 1117. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Chen, Q.; Song, Q. Strong and stretchable polypyrrole hydrogels with biphase microstructure as electrodes for substrate-free stretchable supercapacitors. Adv. Mater. Interfaces 2019, 6, 1900133. [Google Scholar] [CrossRef]

- Wu, G.Z.; Li, S.M.; He, W.T. Effect of percentage of graphene oxide on phase transition of water induced shape memory behavior of PVA-go-PEG hydrogel. Mater. Res. Express 2018, 5, 115703. [Google Scholar] [CrossRef]

- Zhang, Z.; Qi, X.; Li, S. Water-actuated shape-memory and mechanically-adaptive poly (ethylene vinyl acetate) achieved by adding hydrophilic poly (vinyl alcohol). Eur. Polym. J. 2018, 98, 237–245. [Google Scholar] [CrossRef]

- Yan, J.; Rodrigues, M.T.F.; Song, Z. Reversible formation of g-C3N4 3D hydrogels through ionic liquid activation: Gelation behavior and room-temperature gas-sensing properties. Adv. Funct. Mater. 2017, 27, 1700653. [Google Scholar] [CrossRef]

- Bai, Y.; Jiang, C.; Wang, Q. Multi-shape-memory property study of novel poly (ε-caprolactone)/ethyl cellulose polymer networks. Macromol. Chem. Phys. 2013, 214, 2465–2472. [Google Scholar] [CrossRef]

- Wang, W.; Liu, D.; Lu, L. The improvement of the shape memory function of poly (ε-caprolactone)/nano-crystalline cellulose nanocomposites via recrystallization under a high-pressure environment. J. Mater. Chem. A 2016, 4, 5984–5992. [Google Scholar] [CrossRef]

- Nicharat, A.; Shirole, A.; Foster, E.J. Thermally activated shape memory behavior of melt-mixed polyurethane/cellulose nanocrystal composites. J. Appl. Polym. Sci. 2017, 134, 45033. [Google Scholar] [CrossRef]

- Du, Y.; Li, D.; Liu, L. Recent achievements of self-healing graphene/polymer composites. Polymers 2018, 10, 114. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Hu, J.; Gui, X. Is biopolymer hair a multi-responsive smart material? Polym. Chem. 2017, 8, 283–294. [Google Scholar] [CrossRef]

- Yang, G.; Wan, X.; Liu, Y. Luminescent poly (vinyl alcohol)/carbon quantum dots composites with tunable water-induced shape memory behavior in different pH and temperature environments. ACS Appl. Mater. Interfaces 2016, 8, 34744–34754. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.Y.; Li, D.W.; Zhao, M. Highly stretchable and bio-based sensors for sensitive strain detection of angular displacements. Cellulose 2019, 26, 3401–3413. [Google Scholar] [CrossRef]

- Trung, T.Q.; Lee, N.E. Flexible and stretchable physical sensor integrated platforms for wearable human-activity monitoringand personal healthcare. Adv. Mater. 2016, 28, 4338–4372. [Google Scholar] [CrossRef]

- Liang, B.; Lin, Z.; Chen, W. Ultra-stretchable and highly sensitive strain sensor based on gradient structure carbon nanotubes. Nanoscale 2018, 10, 13599–13606. [Google Scholar] [CrossRef]

- Park, J.J.; Hyun, W.J.; Mun, S.C.; Park, Y.T.; Park, O.O. Highly stretchable and wearable graphene strain sensors with controllable sensitivity for human motion monitoring. ACS Appl. Mater. Interfaces 2015, 7, 6317–6324. [Google Scholar] [CrossRef]

- Wang, X.; Sparkman, J.; Gou, J. Strain sensing of printed carbon nanotube sensors on polyurethane substrate with spray deposition modeling. Compos. Commun. 2017, 3, 1–6. [Google Scholar] [CrossRef]

- Ma, L.; Wei, Y.; Wang, Y. Multi-dimensional strain sensor based on carbon nanotube film with aligned conductive networks. Compos. Sci. Technol. 2018, 165, 190–197. [Google Scholar] [CrossRef]

| Sample Code | TPU/g | CNF-C/g | CNTs/g | CNTs/wt% |

|---|---|---|---|---|

| TPU/CNF-C/CNT-5 | 4.5 | 0.225 | 0.225 | 5.0 |

| TPU/CNF-C/CNT-6 | 4.5 | 0.225 | 0.27 | 6.0 |

| TPU/CNF-C/CNT-7 | 4.5 | 0.225 | 0.315 | 7.0 |

| TPU/CNF-C/CNT-8 | 4.5 | 0.225 | 0.36 | 8.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, G.; Gu, Y.; Hou, X.; Li, R.; Ke, H.; Xiao, X. Hybrid Nanocomposites of Cellulose/Carbon-Nanotubes/Polyurethane with Rapidly Water Sensitive Shape Memory Effect and Strain Sensing Performance. Polymers 2019, 11, 1586. https://doi.org/10.3390/polym11101586

Wu G, Gu Y, Hou X, Li R, Ke H, Xiao X. Hybrid Nanocomposites of Cellulose/Carbon-Nanotubes/Polyurethane with Rapidly Water Sensitive Shape Memory Effect and Strain Sensing Performance. Polymers. 2019; 11(10):1586. https://doi.org/10.3390/polym11101586

Chicago/Turabian StyleWu, Guanzheng, Yanjia Gu, Xiuliang Hou, Ruiqing Li, Huizhen Ke, and Xueliang Xiao. 2019. "Hybrid Nanocomposites of Cellulose/Carbon-Nanotubes/Polyurethane with Rapidly Water Sensitive Shape Memory Effect and Strain Sensing Performance" Polymers 11, no. 10: 1586. https://doi.org/10.3390/polym11101586