Experimental Investigation of the Compactability and Cracking Behavior of Polyacrylamide-Treated Saline Soil in Gansu Province, China

Abstract

1. Introduction

2. Experimental Methods

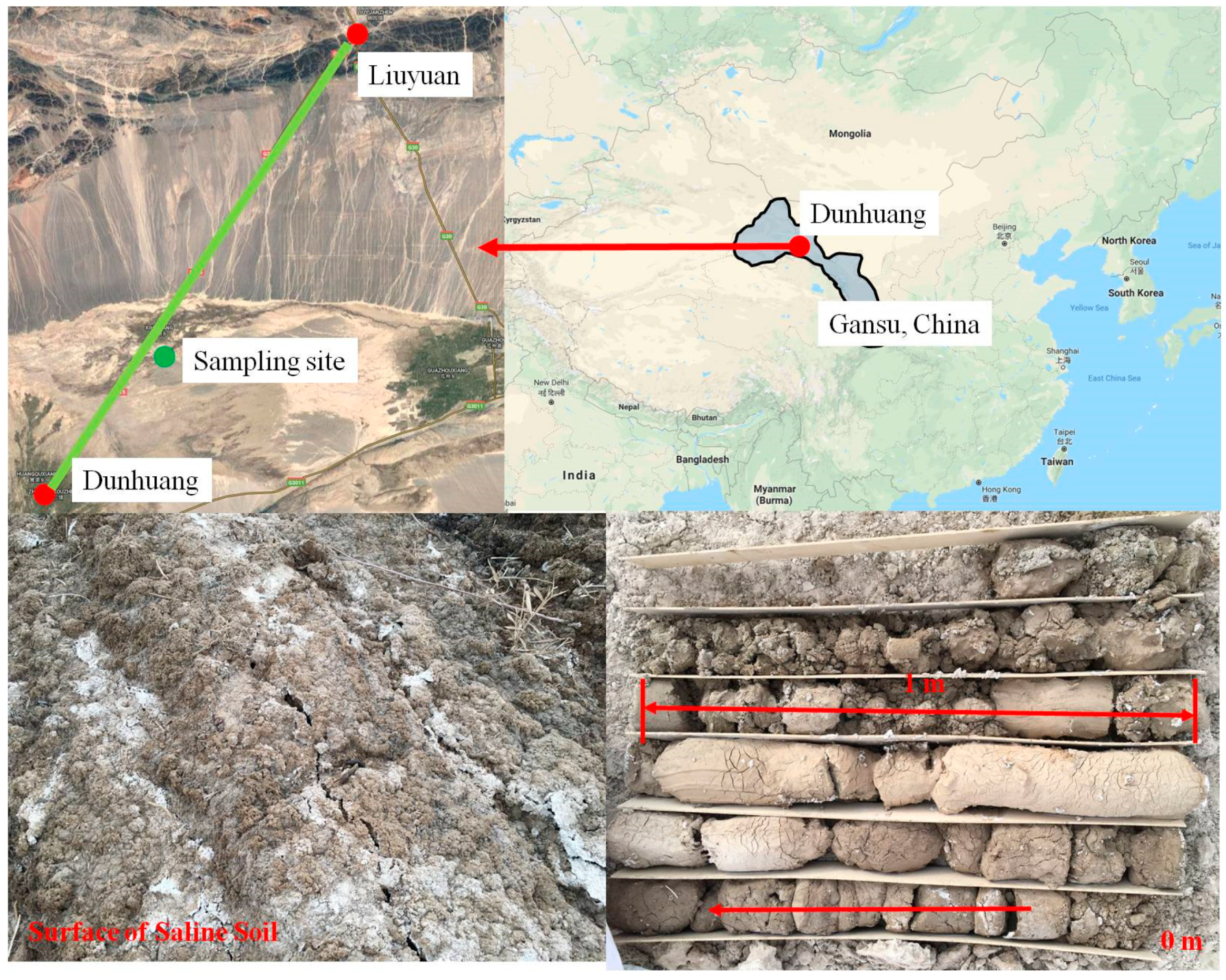

2.1. Materials

2.2. Test Method

3. Results

3.1. Consistency Limits of the PAM-Treated Saline Soil Samples

3.2. Compaction Curves for the PAM-Treated Saline Soil Samples

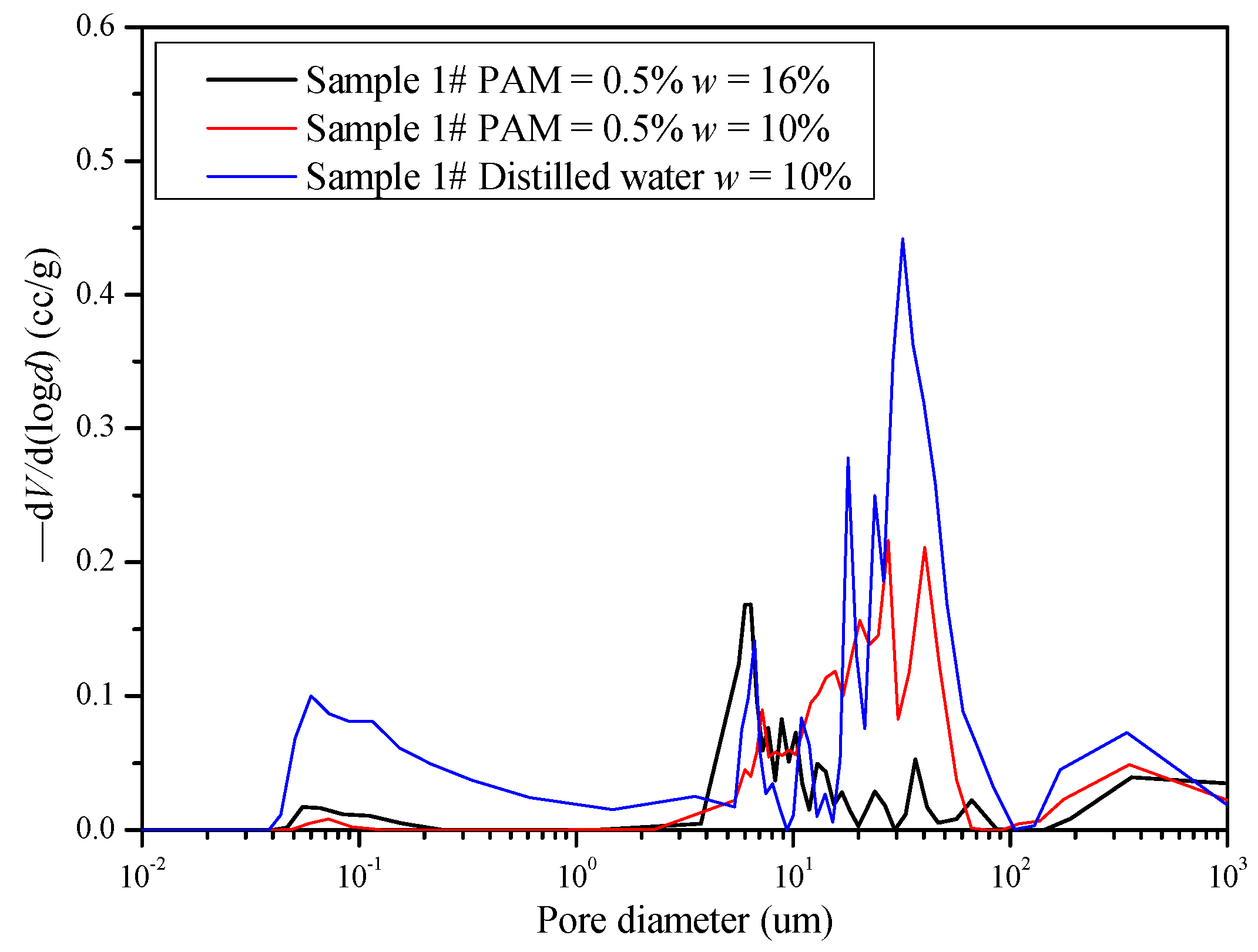

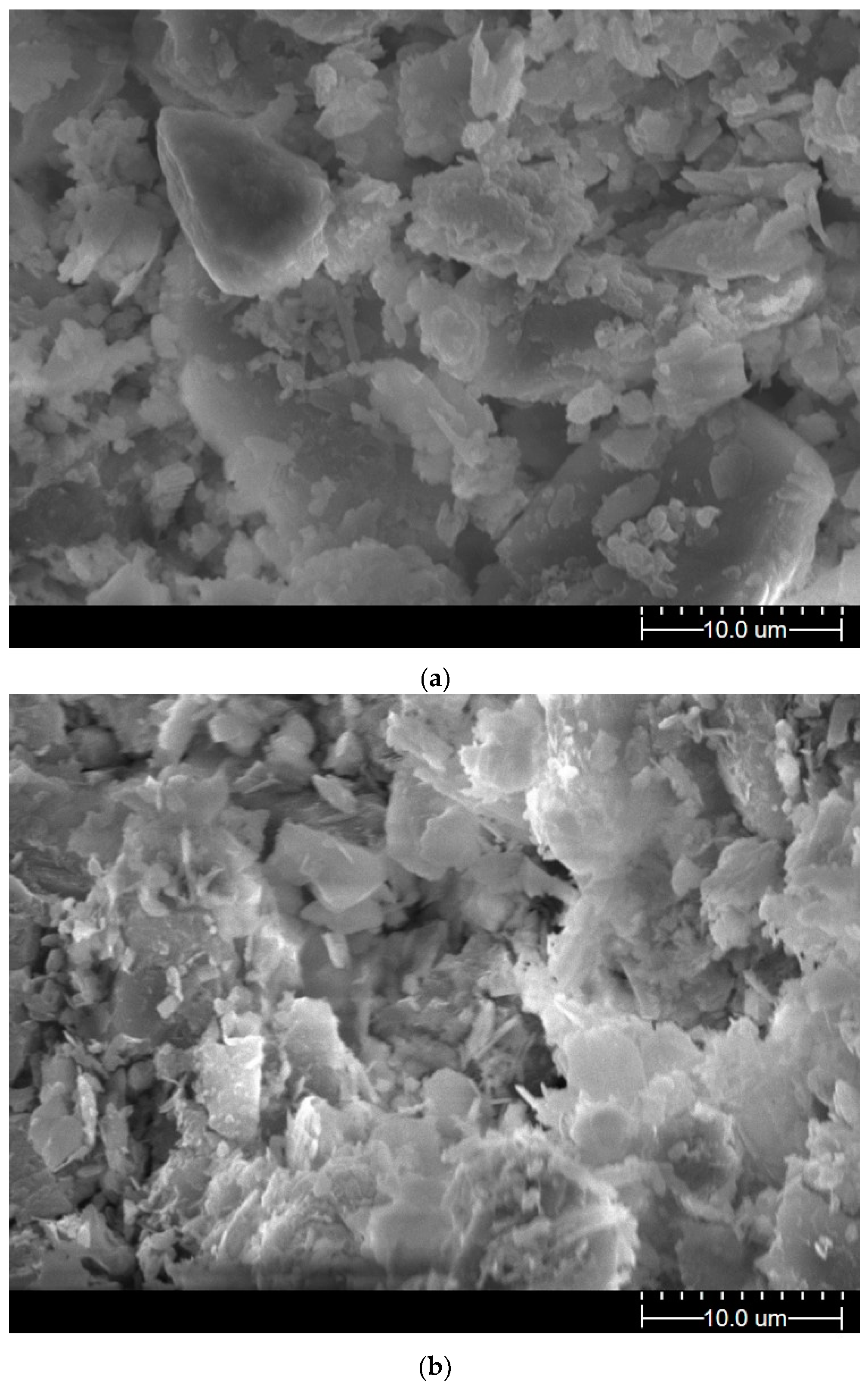

3.3. Microstructure of the PAM-Treated Saline Soil Samples

3.4. Cracking Behavior of the PAM-Treated Saline Soil Samples

4. Discussion

4.1. Compactibility and Physical Properties

4.2. Cracking Behavior and Physical Properties

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Sardinha, M.; Muller, T.; Schmeisky, H.; Joergensen, R.G. Microbial Performance in Soils Along a Salinity Gradient Under Acidic Conditions. Appl. Soil. Ecol. 2003, 23, 237–244. [Google Scholar] [CrossRef]

- Ruehrwein, R.A.; Ward, D.W. Mechanism of Clay Aggregation by Polyelectrolytes. Soil. Sci. 1952, 6, 485–492. [Google Scholar] [CrossRef]

- Deng, Y.F.; Liu, S.Y.; Huang, J.A.; Li, K.; Du, Y.J.; Jing, F. Strength and Permeability of Cemented Soil with PAM. In Proceedings of the Fourth International Conference on Grouting and Deep Mixing; ASCE: Reston, VA, USA, 2012. [Google Scholar]

- Ajayi, M.A.; Grissom, W.A.; Smith, L.S.; Jones, E.E. Epoxy–Resin–Based Chemical Stabilization of a Fine, Poorly Graded Soil System. Transp. Res. Rec. 1991, 1295, 95–108. [Google Scholar]

- Santoni, R.; Tingle, J.; Webster, S. Stabilization of Silty Sand with Nontraditional Additives. Transp. Res. Rec. 2002, 1787, 61–70. [Google Scholar] [CrossRef]

- Andrews, R.C.; Duffy, P. Polymer Stabilisation and Best Value Management of Unsealed Road Networks. Road Transp. Res. J. Aust. New Zealand Res. Pract. 2008, 3, 59. [Google Scholar]

- Lentz, R.D.; Shainberg, I.; Sojka, R.E.; Carter, D.L. Preventing Irrigation Furrow Erosion with Small Applications of Polymers. Soil Sci. Soc. Am. J. 1992, 56, 1926–1932. [Google Scholar] [CrossRef]

- Ross, C.W.; Sojka, R.E.; Foerster, J.A. Scanning Electron Micrographs of Polyacrylamide–Treated Soil in Irrigation Furrows. J. Soil Water Conserv. 2003, 58, 327–331. [Google Scholar]

- Sojka, R.E.; Bjorneberg, D.L.; Entry, J.A.; Lentz, R.D.; Orts, W.J. Polyacrylamide in Agriculture and Environmental Land Management; Sparks, D.L., Ed.; Elsevier Academic Press Inc.: San Diego, CA, USA, 2007; p. 75. [Google Scholar]

- Orts, W.J.; Roa–Espinosa, A.; Sojka, R.E.; Glenn, G.M.; Imam, S.H.; Erlacher, K.; Pedersen, J.S. Use of Synthetic Polymers and Biopolymers for Soil Stabilization in Agricultural, Construction, and Military Applications. J. Mater. Civil. Eng. 2007, 19, 58–66. [Google Scholar] [CrossRef]

- Lentz, R.D.; Sojka, R.E. Field Results Using Polyacrylamide to Manage Furrow Erosion and Infiltration. Soil Sci. 1994, 158, 274–282. [Google Scholar] [CrossRef]

- Georgees, R.N.; Hassan, R.A.; Evans, R.P.; Jegatheesan, P. Resilient Response Characterization of Pavement Foundation Materials Using a Polyacrylamide–Based Stabilizer. J. Mater. Civil. Eng. 2018, 30, 04017252. [Google Scholar] [CrossRef]

- Washburn, E.W. Note On a Method of Determining the Distribution of Pore Sizes in a Porous Material. Proc. Natl. Acad. Sci. USA 1921, 4, 115–116. [Google Scholar] [CrossRef]

- Diamond, S. Pore size distributions in clays. Clay. Clay Miner. 1970, 18, 7–23. [Google Scholar] [CrossRef]

- Penumadu, D.; Dean, J. Compressibility effect in evaluating the pore–size distribution of kaolin clay using mercury intrusion porosimetry. Can. Geotech. J. 2000, 37, 393–405. [Google Scholar] [CrossRef]

- Romero, E.; Simms, P.H. Microstructure investigation in unsaturated soils: A review with special attention to contribution of mercury intrusion porosimetry and environmental scanning electron microscopy. Geotech. Geol. Eng. 2008, 26, 705–727. [Google Scholar] [CrossRef]

- Zhang, T.W.; Yue, X.B.; Deng, Y.F.; Zhang, D.W.; Liu, S.Y. Mechanical Behaviour and Micro–Structure of Cement–Stabilised Marine Clay with a Metakaolin Agent. Constr. Build Mater. 2014, 73, 51–57. [Google Scholar] [CrossRef]

- Tang, C.S.; Cui, Y.J.; Tang, A.M.; Shi, B. Experiment Evidence On the Temperature Dependence of Desiccation Cracking Behavior of Clayey Soils. Eng. Geol. 2010, 114, 261–266. [Google Scholar] [CrossRef]

- Sridharan, A.; Rao, G.V. Mechanisms Controlling the Liquid Limit of Clays. In Proceedings of the Istanbul Conference on Soil Mechanics and Foundation Engineering; TBTAK: Istanbul, Turkey, 1975; pp. 75–84. [Google Scholar]

- Sridharan, A.; El–Shafei, A.; Miura, N. Mechanisms Controlling the Undrained Strength Behavior of Remolded Ariake Marine Clays. Mar. Georesour. Geotechnol. 2002, 20, 21–50. [Google Scholar] [CrossRef]

- Blotz, L.R.; Benson, C.H.; Boutwell, G.P. Estimating Optimum Water Content and Maximum Dry Unit Weight for Compacted Clays. J. Geotech. Geoenviron. Eng. 1998, 124, 907–912. [Google Scholar] [CrossRef]

- Zhang, X.D.; Chen, Y.G.; Ye, W.M.; Cui, Y.J.; Deng, Y.F.; Chen, B. Effect of Salt Concentration On Desiccation Cracking Behavior of GMZ Bentonite. Environ. Earth Sci. 2017, 76, 531. [Google Scholar] [CrossRef]

- Tang, C.S.; Cui, Y.J.; Shi, B.; Tang, A.M.; Liu, C. Desiccation and Cracking Behaviour of Clay Layer From Slurry State Under Wetting–Drying Cycles. Geoderma 2011, 166, 111–118. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Liu, C.; Zhao, L.Z.; Wang, B.J. Influencing Factors of Geometrical Structure of Surface Shrinkage Cracks in Clayey Soils. Eng. Geol. 2008, 101, 204–217. [Google Scholar] [CrossRef]

- Koumoto, T.; Houlsby, G.T. Theory and Practice of the Fall Cone Test. Géotechnique 2001, 8, 701–712. [Google Scholar] [CrossRef]

- Sharma, B.; Bora, P.K. Plastic Limit, Liquid Limit and Undrained Shear Strength of Soil—Reappraisal. J. Geotech. Geoenviron. Eng. 2003, 8, 774–777. [Google Scholar] [CrossRef]

- Miller, C.J.; Mi, H.; Yesiller, N. Experimental Analysis of Desiccation Crack Propagation in Clay Liners. J. Am. Water Resour Assoc. 1998, 34, 677–686. [Google Scholar] [CrossRef]

- Velde, B. Structure of Surface Cracks in Soil and Muds. Geoderma 1999, 93, 101–124. [Google Scholar] [CrossRef]

- Yesiller, N.; Miller, C.J.; Inci, G.; Yaldo, K. Desiccation and Cracking Behavior of Three Compacted Landfill Liner Soils. Eng. Geol. 2000, 57, 105–121. [Google Scholar] [CrossRef]

- Albrecht, B.A.; Benson, C.H. Effect of Desiccation On Compacted Natural Clays. J. Geotech. Geoenviron. Eng. 2001, 127, 67–75. [Google Scholar] [CrossRef]

- Boivin, P.; Garnier, P.; Tessier, D. Relationship Between Clay Content, Clay Type, and Shrinkage Properties of Soil Samples. Soil Sci. Soc. Am. J. 2004, 68, 1145–1153. [Google Scholar] [CrossRef]

- Nahlawi, H.; Kodikara, J.K. Laboratory Experiments On Desiccation Cracking of Thin Soil Layers. Geotech. Geol. Eng. 2006, 24, 1641–1664. [Google Scholar] [CrossRef]

- Rodríguez, R.; Sánchez, M.; Ledesma, A.; Lloret, A. Experimental and Numerical Analysis of Desiccation of a Mining Waste. Can. Geotech. J. 2007, 44, 644–658. [Google Scholar] [CrossRef]

- Peron, H.; Hueckel, T.; Laloui, L.; Hu, L.B. Fundamentals of Desiccation Cracking of Fine–Grained Soils: Experimental Characterisation and Mechanisms Identification. Can. Geotech. J. 2009, 46, 1177–1201. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Liu, C.; Gao, L.; Inyang, H.I. Experimental Investigation of the Desiccation Cracking Behavior of Soil Layers during Drying. J. Mater. Civil. Eng. 2011, 23, 873–878. [Google Scholar] [CrossRef]

- Wu, L.Z.; Li, B.; Huang, R.Q.; Sun, P. Experimental study and modeling of shear rheology in sandstone with non–persistent joints. Eng. Geol. 2017, 222, 201–211. [Google Scholar] [CrossRef]

- Wu, L.Z.; Zhou, Y.; Sun, P.; Shi, J.S.; Liu, G.G.; Bai, L.Y. Laboratory Characterization of Rainfall–induced Loess Slope Failure. Caten. 2017, 150, 1–8. [Google Scholar] [CrossRef]

- Wang, L.L.; Tang, C.S.; Shi, B.; Cui, Y.J.; Zhang, G.Q.; Hilary, I. Nucleation and propagation mechanisms of soil desiccation cracks. Eng. Geol. 2018, 238, 27–35. [Google Scholar] [CrossRef]

- Tang, C.S.; Wang, D.Y.; Zhu, C.; Zhou, Q.Y.; Xu, S.K.; Shi, B. Characterizing drying–induced clayey soil desiccation cracking process using electrical resistivity method. Appl. Clay Sci. 2018, 152, 101–112. [Google Scholar] [CrossRef]

- Morris, P.H.; Graham, J.; Williams, D.J. Cracking in Drying Soils. Can. Geotech. J. 1992, 29, 263–277. [Google Scholar] [CrossRef]

- Costa, S.; Kodikara, J.; Shannon, B. Salient factors controlling desiccation cracking of clay in laboratory experiments. Géotechniqu. 2013, 63, 18–29. [Google Scholar] [CrossRef]

| Soil Depth | Natural Water Content w0 (%) | Wet Density (Mg/m3) | Dry Density (Mg/m3) | Saturation Degree Sr (%) | Void Ratio e | Compression Coefficient a |

|---|---|---|---|---|---|---|

| 0–0.05 m | 12.2 | 1.86 | 1.66 | 60.4 | 0.5 | 0.1 |

| 2.0–3.0 m | 27.1 | 2.05 | 1.61 | 100.0 | 0.8 | 0.4 |

| Soil Depth | PH | CO32− (mg/kg) | HCO3− (mg/kg) | Cl− (mg/kg) | Ca2+ (mg/kg) | Mg2+ (mg/kg) | Na+ + K+ (mg/kg) | Total Soluble Salt (mg/kg) | Salinity (%) |

|---|---|---|---|---|---|---|---|---|---|

| 0–0.05 m | 7.84 | 0 | 404.93 | 7407.77 | 4987.56 | 148.84 | 75.02 | 15,326.68 | 1.53 |

| 2.0–3.0 m | 8.22 | 0 | 438.67 | 3037.36 | 337.27 | 55.81 | 3716.87 | 9913.03 | 0.99 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Deng, Y.; Lan, H.; Zhang, F.; Zhang, H.; Wang, C.; Tan, Y.; Yu, R. Experimental Investigation of the Compactability and Cracking Behavior of Polyacrylamide-Treated Saline Soil in Gansu Province, China. Polymers 2019, 11, 90. https://doi.org/10.3390/polym11010090

Zhang T, Deng Y, Lan H, Zhang F, Zhang H, Wang C, Tan Y, Yu R. Experimental Investigation of the Compactability and Cracking Behavior of Polyacrylamide-Treated Saline Soil in Gansu Province, China. Polymers. 2019; 11(1):90. https://doi.org/10.3390/polym11010090

Chicago/Turabian StyleZhang, Tongwei, Yongfeng Deng, Hengxing Lan, Fanyu Zhang, Huyuan Zhang, Chong Wang, Yu Tan, and Rongguang Yu. 2019. "Experimental Investigation of the Compactability and Cracking Behavior of Polyacrylamide-Treated Saline Soil in Gansu Province, China" Polymers 11, no. 1: 90. https://doi.org/10.3390/polym11010090

APA StyleZhang, T., Deng, Y., Lan, H., Zhang, F., Zhang, H., Wang, C., Tan, Y., & Yu, R. (2019). Experimental Investigation of the Compactability and Cracking Behavior of Polyacrylamide-Treated Saline Soil in Gansu Province, China. Polymers, 11(1), 90. https://doi.org/10.3390/polym11010090