Polyethylene Nanocomposites for Power Cable Insulations

Abstract

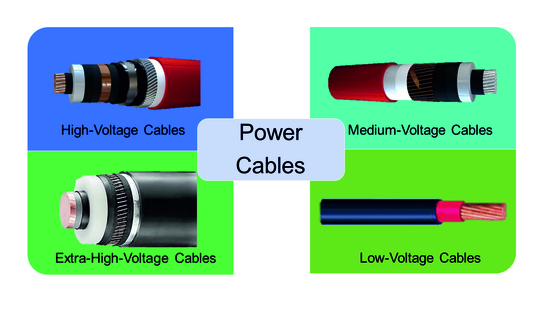

:1. Introduction

2. Critical Challenges of Polymer-Based Nanocomposites in Industrial Applications

3. Polymers for Power Cable Insulations

3.1. Power Cable Insulations Based on Polyethylene (PE)

3.2. Power Cable Insulations Based on Crosslinked Polyethylene (XLPE)

3.3. Power Cable Insulations Based on Other Classes of Polymers

4. Nanocomposites for Power Cable Insulations

4.1. Fillers Used in Nanocomposites

4.2. Methods for the Preparation of Nanocomposites

4.3. Surface Modification of Fillers to be Used in Nanocomposites

5. Electrical Conductivity of Nanocomposites

5.1. General Aspects of Electrical Conduction

5.2. Conductivity of Nanocomposites Based on Polyethylene (PE)

6. Permittivity and Loss Factor of Nanocomposites

6.1. General Aspects of the Complex Dielectric Permittivity

6.2. Permittivity and Loss Factor of Nanocomposites Based on Polyethylene (PE)

7. Partial Discharges in Nanocomposites

7.1. Partial Discharges and Measurement Thereof

7.2. Partial Discharges in Nanocomposites Based on Polyethylene (PE)

- Reduction of the polymer free space (preventing the erosion progress starting from PDs);

- Segmentation of the polymer matrix (hindering the development of PDs);

- Coupling agents that enhance the bonds between matrices and fillers (hindering the development of PDs);

- Different values of the electrical permittivity of the matrix and the filler (decreasing the electric field local values and hindering the initiation and the development of PDs);

- Nanofiller residues piled-up on the surfaces of specimens (hindering the development of PDs).

8. Space Charge in Nanocomposites

8.1. Space Charge Accumulation

8.2. Space Charge Reduction

8.3. Space Charges in Nanocomposites Based on Polyethylene (PE)

9. Electrical Treeing in Nanocomposites

9.1. General Characteristics of Electrical Treeing

9.2. Electrical Treeing in Nanocomposites Based on Polyethylene (PE)

10. Water Treeing in Nanocomposites

10.1. General Characteristics

10.2. Water Treeing in Nanocomposites Based on Polyethylene (PE)

11. Electrical Breakdown of Nanocomposites

11.1. General Aspects of the Breakdown in Solid Dielectrics

11.2. Electrical Breakdown in Nanocomposites Based on Polyethylene (PE)

12. Conclusions and Outlook

- While the introduction of microsized inorganic particles rarely results in an improvement of the electrical properties of composites, the reduction of the particle sizes to the order of nanometres results in improvements of the thermal, mechanical and electrical properties. This is very often due to the interface chemistry and interfacial strength, which increase exponentially in comparison to composites containing microsized particles.

- For the manufacturing of power cables, commonly insulating fillers such as layered silicates, montmorillonite clays, Al2O3, TiO2 and SiO2 are used; in the case of conducting fillers, graphite platelets and carbon nanotubes are among the most commonly used congeners. Such conducting fillers can improve the mechanical properties of nanocomposites (required in mechanical applications) and electrical conductivity (required for electromagnetic shielding and semiconductor layers of cables). With respect to insulating fillers, layered silicates or clays are in the range of a few nm in thickness and in the range of 100 nm in the other two dimensions, while the sizes of nanoparticles such as SiO2, TiO2 and Al2O3 are in the range of 30-40 nm.

- The introduction of low contents of nanofillers can increase the resistance to partial discharges (superficial and in the volume of the material), the resistance to electrical trees and water trees, the volume resistivity and the dielectric strength. The comparison of unfilled with nanofilled materials revealed that space charge accumulation phenomena were considerably affected by the presence of nanofillers.

- In the case of nanocomposites, the permittivity is often reduced, and, at low frequencies, it is found to be a ‘quasi-DC’ feature (large negative slopes in both the real permittivity and tan delta). By using compatibilizers, an increase of the permittivity can be obtained for certain values of the frequency. Depending on the type of compatibilizer, the nanocomposites lifetime can be increased over two orders of magnitude compared to the unfilled polymer.

- the homogeneous dispersion of the nanoparticles and the characterization of the dispersion phase,

- the online control of the technological processes during commercial manufacturing of nanodielectrics,

- the detailed understanding of the interactions at the interfaces, the charge dynamics and the electrical breakdown behavior of such systems,

- studies of ageing and degradation mechanisms of nanodielectrics (required for their use as cable insulations in submarine applications, superconducting cables, etc.), and

- the detailed understanding of interactions at molecular/atomic level (e.g., the DC current decreases if certain types of nanofillers are added to PI and increases, on the other hand, if layered silicates are dispersed in EVA and PP).

- the mechanisms of doping nanoparticles for improving the characteristics and properties of insulation materials,

- the variations of the electrical conductivity and space charge under the combined action of heat and electrical field,

- the behavior of nanodielectrics to long-term applications in operation (i.e., lifetime estimation to multiple demands),

- the manufacture of recyclable materials for insulation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | alternating current |

| CB | carbon black |

| DC | direct current |

| ε* | relative complex dielectric permittivity |

| ε′/ε″ | real/imaginary part of the complex relative permittivity |

| EHVC | extra high voltage cables |

| EPDM | ethylene-propylene-diene-monomer rubber |

| EPR/EPM | ethylene-propylene rubber |

| EVA | ethylene-vinyl-acetate |

| HDPE | high-density polyethylene |

| HV | high-voltage |

| HVAC | high-voltage alternating current |

| HVDC | high-voltage direct current |

| IEC | International Electrotechnical Commission |

| i-PP | isotactic polypropylene |

| LDPE | low-density polyethylene |

| LIPP | laser-induced pressure propagation method |

| LLDPE | linear low-density polyethylene |

| LV | low-voltage |

| MA | maleic anhydride |

| MMT | montmorillonite |

| MV | medium-voltage |

| PD | partial discharge |

| PE | polyethylene |

| PEA | pulsed electro-acoustic method |

| PI | polyimide |

| POSS | polyhedral oligomeric silsesquioxane |

| PP | polypropylene |

| tanδ | dissipation factor |

| TSM | thermal step method |

| XLPE | crosslinked polyethylene |

References

- Gubanski, S.M. Insulating materials for next generations of HVAC and HVDC cables. In Proceedings of the IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016; pp. 1–6. [Google Scholar]

- Zaccone, E. Chapter 2—Innovative Cables. In Advanced Technologies for Future Transmission Grids; Migliavacca, G., Ed.; Springer: London, UK, 2013; pp. 39–84. ISBN 978-1-4471-4548-6. [Google Scholar]

- Tanaka, T.; Imai, T. Advances in nanodielectric materials over the past 50 years. IEEE Electr. Insul. Mag. 2013, 29, 10–23. [Google Scholar] [CrossRef]

- Barber, K.; Alexander, G. Insulation of electrical cables over the past 50 years. IEEE Electr. Insul. Mag. 2013, 29, 27–32. [Google Scholar] [CrossRef]

- Taiwan Turnkey-Project Association. Available online: http://www.tpcc.org.tw/wholeplant2/mainchoose/ 1-4.htm (accessed on 19 March 2018).

- Jow, J.; Gross, L.; Mendelsohn, A.; Aarts, M.; Kjellqvist, J. Overview of insulating materials system for power cable applications. In Proceedings of the IEEE International Conference on Solid Dielectrics (ICSD), Toulouse, France, 5–9 July 2004; pp. 398–402. [Google Scholar]

- Zhou, Y.; Peng, S.; Hu, J.; He, J. Polymeric insulation materials for HVDC cables: DEVELOPMENT, challenges and future perspective. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1308–1318. [Google Scholar] [CrossRef]

- Green, C.D.; Vaughan, A.S.; Stevens, G.C.; Pye, A.; Sutton, S.J.; Geussens, T.; Fairhurst, M.J. Thermoplastic cable insulation comprising a blend of isotactic polypropylene and a propylene-ethylene copolymer. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 639–648. [Google Scholar] [CrossRef] [Green Version]

- Martin, C.P.; Vaughan, A.S.; Sutton, S.J. The thermomechanical behaviour of crosslinked polyethylene cable insulation material. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Albuquerque, NM, USA, 19–22 October 2003; pp. 88–91. [Google Scholar] [Green Version]

- Andritsch, T.; Vaughan, A.S.; Stevens, G.C. Novel insulation materials for high voltage cable systems. IEEE Electr. Insul. Mag. 2017, 33, 27–33. [Google Scholar] [CrossRef] [Green Version]

- Jarvid, M.; Johansson, A.; Kroon, R.; Bjuggren, J.M.; Wutzel, H.; Englund, V.; Gubanski, S.; Andersson, M.R.; Müller, C. A new application area for fullerenes: Voltage stabilizers for power cable insulation. Adv. Mater. 2014, 27, 897–902. [Google Scholar] [CrossRef] [PubMed]

- Belli, S.; Perego, G.; Bareggi, A.; Caimi, L.; Donazzi, F.; Zaccone, E. P-Laser: Breakthrough in power cable systems. In Proceedings of the IEEE International Symposium on Electrical Insulation (ISEI), San Diego, CA, USA, 6–9 June 2010; pp. 1–5. [Google Scholar]

- Roy, M.; Nelson, J.K.; MacCrone, R.K.; Schadler, L.S. Candidate mechanisms controlling the electrical characteristics of silica/XLPE nanodielectrics. J. Mater. Sci. 2007, 42, 3789–3799. [Google Scholar] [CrossRef]

- Pleşa, I.; Noţingher, P.V.; Schlögl, S.; Sumereder, C.; Muhr, M. Properties of Polymer Composites Used in High-Voltage Applications. Polymers 2016, 8, 173. [Google Scholar] [CrossRef]

- Seiler, J.; Kindersberger, J. Insight into the Interphase in Polymer Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 537–547. [Google Scholar] [CrossRef]

- Danikas, M.G. On Two Nanocomposite Models: Differences, Similarities and Interpretational Possibilities Regarding Tsagaropoulos’ Model and Tanaka’s Model. J. Electr. Eng. 2010, 61, 241–246. [Google Scholar] [CrossRef]

- Reed, C.W. Functionalization of nanocomposite dielectrics. In Proceedings of the IEEE International Symposium on Electrical Insulation (ISEI), San Diego, CA, USA, 6–9 June 2010; pp. 1–4. [Google Scholar]

- Li, Z.; Du, B. Polymeric Insulation for High-Voltage DC Extruded Cables: Challenges and Development Directions. IEEE Electr. Insul. Mag. 2018, 34, 30–43. [Google Scholar] [CrossRef]

- Peng, S.; He, J.; Hu, J.; Huang, X.; Jiang, P. Influence of Functionalized MgO Nanoparticles on Electrical Properties of Polyethylene Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1512–1519. [Google Scholar] [CrossRef]

- Liu, D.; Hoang, A.T.; Pourrahimi, A.M.; Pallon, L.K.; Nilsson, F.; Gubanski, S.M.; Olsson, R.T.; Hedenqvist, M.S.; Gedde, U.W. Influence of nanoparticle surface coating on electrical conductivity of LDPE/Al2O3 nanocomposites for HVDC cable insulations. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1396–1404. [Google Scholar] [CrossRef]

- Luo, S.; Wang, S.; Tu, Y.; Wang, C.; Qin, S. Direct Current Electrical Characteristics of Nano-CB/LDPE Composite. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1390–1395. [Google Scholar] [CrossRef]

- Montanari, G.C.; Seri, P.; Lei, X.; Ye, H.; Zhuang, Q.; Morshuis, P.; Stevens, G.; Vaughan, A. Next Generation Polymeric High Voltage Direct Current Cables—A Quantum Leap Needed? IEEE Electr. Insul. Mag. 2018, 34, 24–31. [Google Scholar] [CrossRef]

- Hampton, R.N. Some of the considerations for materials operating under high-voltage, direct current stresses. IEEE Electr. Insul. Mag. 2008, 24, 5–13. [Google Scholar] [CrossRef]

- Reed, C.W. An assessment of material selection for high voltage DC extruded polymer cables. IEEE Electr. Insul. Mag. 2017, 33, 22–26. [Google Scholar] [CrossRef]

- Seifert, J.M.; Karner, H.C. Dielectric diagnostic of moisture induced degradation processes in mineral reinforced high-voltage composite insulation. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Millbrae, CA, USA, 20–23 October 1996; pp. 825–828. [Google Scholar]

- Sumangala, M.G.; Poovamma, P.K.; Dwarakanath, K.; Arunachala Sastry, K.S.; Ratra, M.C. Degradation of electrical properties of organic industrial laminates due to moisture absorption. In Proceedings of the 3rd International Conference on Conduction and Breakdown in Solid Dielectrics (ICSD), Trondheim, Norway, 3–6 July1989; pp. 484–488. [Google Scholar]

- Hashizume, T.; Shinoda, C.; Nakamura, K.; Hotta, M.; Tani, T.; Taniguchi, T. A consideration on changes of AC breakdown voltages during an accelerated test of immersed dry-cured XLPE cables. In Proceedings of the 3rd International Conference on Properties and Applications of Dielectric Materials (ICPADM), Tokyo, Japan, 8–12 July 1991; pp. 490–493. [Google Scholar]

- Pourrahimi, A.M.; Pallon, L.K.H.; Liu, D.; Hoang, T.A.; Gubanski, S.; Hedenqvist, M.S.; Olsson, R.T.; Gedde, U.W. Polyethylene Nanocomposites for the Next Generation of Ultralow-Transmission-Loss HVDC Cables: Insulation Containing Moisture-Resistant MgO Nanoparticles. ACS Appl. Mater. Interfaces 2016, 8, 14824–14835. [Google Scholar] [CrossRef]

- Cherney, E.A. Nanodielectrics applications-today and tomorrow. IEEE Electr. Insul. Mag. 2013, 29, 59–65. [Google Scholar] [CrossRef]

- Ohki, Y. Development of XLPE-insulated cable for high-voltage dc submarine transmission line (1) [News from Japn]. IEEE Electr. Insul. Mag. 2013, 29, 65–67. [Google Scholar] [CrossRef]

- Ohki, Y. Development of XLPE-insulated cable for high-voltage dc submarine transmission line (2) [News from Japn]. IEEE Electr. Insul. Mag. 2013, 29, 85–87. [Google Scholar] [CrossRef]

- Ohki, Y. Development of an XLPE-insulated cable for LCC-HVDC power lines [News from Japn]. IEEE Electr. Insul. Mag. 2018, 34, 62–65. [Google Scholar] [CrossRef]

- Chen, G.; Hao, M.; Xu, Z.; Vaughan, A.; Cao, J.; Wang, H. Review of high voltage direct current cables. CSEE J. Power Energy Syst. 2015, 1, 9–21. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Du, B.X.; Kong, X.X.; Li, Z.L. Nonlinear Conductivity and Interface Charge Behaviors between LDPE and EPDM/SiC Composite for HVDC Cable Accessory. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1566–1573. [Google Scholar] [CrossRef]

- Guo, M.; Fréchette, M.; Éric, D.; Demarquette, N.R.; Daigle, J.C. Polyethylene/polyhedral oligomeric silsesquioxanes composites: Electrical insulation for high voltage power cables. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 798–807. [Google Scholar] [CrossRef] [Green Version]

- Du, B.X.; Kong, X.X.; Cui, B.; Li, J. Improved ampacity of buried HVDC cable with high thermal conductivity LDPE/BN insulation. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 2667–2676. [Google Scholar] [CrossRef]

- Hanley, T.L.; Burford, R.P.; Fleming, R.J.; Barber, K.W. A general review of polymeric insulation for use in HVDC cables. IEEE Electr. Insul. Mag. 2003, 19, 13–24. [Google Scholar] [CrossRef]

- Kim, D.W.; Yoshino, K.; Inoue, T.; Abe, M.; Uchikawa, N. Influence of morphology on electrical properties of syndiotactic polypropylene compared with those of isotactic polypropylene. Jpn. J. Appl. Phys. Part 1 1999, 38, 3580–3584. [Google Scholar] [CrossRef]

- Vahedy, V. Polymer insulated high voltage cables. IEEE Electr. Insul. Mag. 2006, 22, 13–18. [Google Scholar] [CrossRef]

- Kryszewski, M. The effect of modification of supermolecular structure on the properties of polymers. Pure Appl. Chem. 1979, 51, 2395–2408. [Google Scholar] [CrossRef] [Green Version]

- Ueki, M.M.; Zanin, M. Influence of additives on the dielectric strength of high-density polyethylene. IEEE Trans. Dielectr. Electr. Insul. 1999, 6, 876–881. [Google Scholar] [CrossRef]

- Dissado, L.A.; Fothergill, J.C. Electrical Degradation and Breakdown in Polymers; Peter Peregrinus Ltd.: London, UK, 1992; pp. 1–620. ISBN 9780863411960. [Google Scholar]

- Khalil, M.S. Effect of thermal cycling on dc conductivity and morphology of polyethylene. Int. J. Polym. Mater. 1995, 28, 179–185. [Google Scholar] [CrossRef]

- Tanaka, T.; Greenwood, A. Advanced Power Cable Technology, Vol. 1—Basic Concepts and Testing; CRC Press: Boca Raton, FL, USA, 1983; p. 15, ISBN 10 0849351650/ISBN 13 9780849351655. [Google Scholar]

- Khonakdar, H.A.; Morshedian, J.; Wagenknecht, U.; Jafari, S.H. An investigation of chemical crosslinking effect on properties of high-density polyethylene. Polymer 2003, 44, 4301–4309. [Google Scholar] [CrossRef]

- Fabris, F.W.; Stedile, F.C.; Mauler, R.S.; Nachtigall, S.M.B. Free radical modification of LDPE with vinyltriethoxysilane. Eur. Polym. J. 2004, 40, 1119–1126. [Google Scholar] [CrossRef]

- Spencer, M.; Parent, J.S.; Whitney, R.A. Composition distribution in poly(ethylene-graft-vinyltrimethoxysilane). Polymers 2003, 44, 2015–2023. [Google Scholar] [CrossRef]

- Melo, R.P.; Aguiar, V.O.; Marques, M.F.V. Silane Crosslinked Polyethylene from Different Commercial PE’s: Influence of Comonomer, Catalyst Type and Evaluation of HLPB as Crosslinking Coagent. Mater. Res. 2015, 18, 313–319. [Google Scholar] [CrossRef] [Green Version]

- Ueno, K.; Uda, I.; Tada, S. Radiation-crosslinked polyethylene for wire and cable applications. Int. J. Radiat. Appl. Instrum. C Radiat. Phys. Chem. 1991, 37, 89–91. [Google Scholar] [CrossRef]

- Sasaki, T.; Hosoi, F.; Hagiwara, M.; Araki, K.; Saito, E.; Ishitani, H.; Uesugi, K. Development of radiation crosslinking process for high voltage power cable. Radiat. Phys. Chem. 1979, 14, 821–830. [Google Scholar] [CrossRef]

- Gheysari, D.; Behjat, A. Radiation crosslinking of LDPE and HDPE with 5 and 10 MeV electron beams. Eur. Polym. J. 2001, 37, 2011–2016. [Google Scholar] [CrossRef]

- Svoboda, P. Influence of Branching Density in Ethylene-Octene Copolymers on Electron Beam Crosslinkability. Polymers 2015, 7, 2522–2534. [Google Scholar] [CrossRef] [Green Version]

- Taralli, C.; Tencer, C. High Voltage EPR Insulation Cable System—Manufacturing and Insulation Relevant Characteristics; E-CIGRE Paper; CIGRE: Paris, France, 1988. [Google Scholar]

- Mazzanti, G.; Montanari, G.C. A comparision between XLPE and EPR as insulation materials for high voltage cables. IEEE Power Eng. Rev. 1997, 12, 15–28. [Google Scholar] [CrossRef]

- David, E.; Fréchette, M. Polymer nanocomposites-major conclusions and achievements reached so far. IEEE Electr. Insul. Mag. 2013, 29, 29–36. [Google Scholar] [CrossRef]

- Calebrese, C.; Hui, L.; Schadler, L.S.; Nelson, J.K. A review on the importance of nanocomposite processing to enhance electrical insulation. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 938–945. [Google Scholar] [CrossRef]

- Thostenson, E.; Li, C.; Chou, T. Review Nanocomposites in Context. Compos. Sci. Technol. 2005, 65, 491–516. [Google Scholar] [CrossRef]

- Marquis, M.D.; Guillaume, E.; Chivas-Joly, C. Chapter 11, Properties of nanofillers in polymer. In Nanocomposites and Polymers with Analytical Methods; InTech: Rijeka, Croatia, 2011; pp. 261–284. ISBN 978-953-307-352-1. [Google Scholar]

- Peng, S.; He, J.; Hu, J. Influence of surface modification on electrical properties of polyethylene SiO2 nanocomposites. In Proceedings of the IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; pp. 372–375. [Google Scholar]

- Hussain, F.; Hojjati, M.; Okamoto, M.; Gorga, R.E. Review article: Polymer-matrix Nanocomposites, Processing, Manufacturing, and Application: An Overview. J. Compos. Mater. 2006, 40, 1511–1575. [Google Scholar] [CrossRef]

- Xanthos, M. Chapter 1, Polymers and polymer composites. In Functional Fillers for Plastics, 2nd ed.; Xanthos, M., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2010; pp. 1–18. ISBN 9783527310548. [Google Scholar]

- Pavlidou, S.; Papaspyrides, C.D. A review on polymer-layered silicate nanocomposites. Prog. Polym. Sci. 2008, 33, 1119–1198. [Google Scholar] [CrossRef]

- Jordan, J.; Jacob, K.I.; Tannenbaum, R.; Sharaf, M.A.; Jasiuk, I. Experimental trends in polymer nanocomposites—A review. Mater. Sci. Eng. A 2005, 393, 1–11. [Google Scholar] [CrossRef]

- Roy, M.; Nelson, J.K.; Schadler, L.S.; Zou, C.; Fothergill, J.C. The influence of physical and chemical linkage on the properties of nanocomposites. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Nashville, TN, USA, 16–19 October 2005; pp. 183–186. [Google Scholar]

- Reed, C.W. Self-assembly of polymer nanocomposites for dielectrics and HV insulation. In Proceedings of the IEEE International Conference on Solid Dielectrics (ICSD), Winchester, UK, 8–13 July 2007; pp. 397–400. [Google Scholar]

- Manias, E.; Touny, A.; Wu, L.; Strawhecker, K.; Lu, B.; Chung, T.C. Polypropylene/montmorillonite nanocomposites. Review of the synthetic routes and materials properties. Chem. Mater. 2001, 13, 3516–3523. [Google Scholar] [CrossRef]

- Tronto, J.; Bordonal, A.C.; Naal, Z.; Valim, J.B. Chapter 1—Conducting Polymers/Layered Double Hydroxides Intercalated Nanocomposites. In Materials Science—Advanced Topics; Mastai, Y., Ed.; InTechOpen: London, UK, 2013; pp. 3–31. ISBN 978-953-51-1140-5. [Google Scholar]

- Lutz, B.; Kindersberger, J. Influence of absorbed water on volume resistivity of epoxy resin insulators. In Proceedings of the 10th IEEE International Conference on Solid Dielectrics (ICSD), Potsdam, Germany, 4–9 July 2010; pp. 1–4. [Google Scholar]

- Smith, R.C.; Liang, C.; Landry, M.; Nelson, J.K.; Schadler, L.S. Studies to unravel some underlying mechanisms in nanodielectrics. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Vancouver, BC, Canada, 14–17 October 2007; pp. 286–289. [Google Scholar]

- Patel, R.R.; Gupta, N. Volume Resistivity of Epoxy containing Nano-sized Al2O3 fillers. In Proceedings of the Fifteenth National Power Systems Conference (NPSC), Bombay, India, 16–18 December 2008; pp. 361–365. [Google Scholar]

- Mera, G.; Gallei, M.; Bernard, S.; Ionescu, E. Ceramic Nanocomposites from Tailor-Made Preceramic Polymers. Nanomaterials 2015, 5, 468–540. [Google Scholar] [CrossRef] [Green Version]

- Sangermano, M.; Yagci, Y.; Rizza, G. In Situ Synthesis of Silver− Epoxy Nanocomposites by Photoinduced Electron Transfer and Cationic Polymerization Processes. Macromolecules 2007, 40, 8827–8829. [Google Scholar] [CrossRef]

- Zhang, H.; Tang, L.C.; Zhang, Z.; Friedrich, K.; Sprenger, S. Fracture behaviours of in situ silica nanoparticle-filled epoxy at different temperatures. Polymer 2008, 49, 3816–3825. [Google Scholar] [CrossRef]

- Yang, F.; Ou, Y.; Yu, Z. Polyamide 6/silica nanocomposites prepared by in situ polymerization. J. Appl. Polym. Sci. 1998, 69, 355–361. [Google Scholar] [CrossRef]

- Papirer, E.; Schultz, J.; Turchi, C. Surface properties of a calcium carbonate filler treated with stearic acid. Eur. Polym. J. 1984, 20, 1155–1158. [Google Scholar] [CrossRef]

- Sahin, M.; Schögl, S.; Kaiser, S.; Kern, W.; Wang, J.; Grützmacher, H. Efficient initiation of radical-mediated thiol-ene chemistry with photoactive silica particles. J. Polym. Sci. A Polym. Chem. 2017, 55, 894–902. [Google Scholar] [CrossRef]

- Roszkowski, P.; Sahin, M.; Ayalur-Karunakaran, S.; Gammer, C.; Schlögl, S.; Kern, W.; Krawczyk, K.K. Synthesis and evaluation of new radical photoinitiators bearing trialkoxysilyl groups for surface immobilization. Polymer 2017, 129, 207–220. [Google Scholar] [CrossRef]

- Sahin, M.; Krawczyk, K.K.; Roszkowski, P.; Wang, J.; Kaynak, B.; Kern, W.; Schlögl, S.; Grützmache, H. Photoactive silica nanoparticles: Influence of surface functionalization on migration and kinetics of radical-induced photopolymerization reactions. Eur. Polym. J. 2018, 98, 430–438. [Google Scholar] [CrossRef]

- Sahin, M.; Schlögl, S.; Kalinka, G.; Wang, J.; Kaynak, B.; Mühlbacher, I.; Ziegler, W.; Kern, W.; Grützmacher, H. Tailoring the interfaces in glass fiber-reinforced photopolymer composites. Polymer 2018, 141, 221–231. [Google Scholar] [CrossRef]

- Pallon, L.K.H.; Hoang, A.T.; Pourrahimi, A.M.; Hedenqvist, M.S.; Nilsson, F.; Gubanski, S.; Gedde, U.W.; Olsson, R.T. The impact of MgO nanoparticle interface in ultra-insulating polyethylene nanocomposites for high voltage DC cables. J. Mater. Chem. A 2016, 4, 8590–8601. [Google Scholar] [CrossRef]

- Kango, S.; Kalia, S.; Celli, A.; Njuguna, J.; Habibi, Y.; Kumar, R. Surface modification of inorganic nanoparticles for development of organic–inorganic nanocomposites—A review. Prog. Polym. Sci. 2013, 38, 1232–1261. [Google Scholar] [CrossRef]

- Shokoohi, S.; Arefazar, A.; Khosrokhavar, R. Silane coupling agents in polymer-based reinforced composites: A review. J. Reinf. Plast. Compos. 2008, 27, 473–485. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Ruan, W.H. Surface modification of nanoscale fillers for improving properties of polymer nanocomposites: A review. Mater. Sci. Technol. 2006, 22, 787–796. [Google Scholar] [CrossRef]

- Tasdelen, M.A. Diels–Alder “click” reactions: RECENT applications in polymer and material science. Polym. Chem. 2011, 2, 2133–2145. [Google Scholar] [CrossRef]

- Neouze, M.A.; Schubert, U. Surface modification and functionalization of metal and metal oxide nanoparticles by organic ligands. Chem. Monthly 2008, 139, 183–195. [Google Scholar] [CrossRef]

- Jonkheijm, P.; Weinrich, D.; Schröder, H.; Niemeyer, C.M.; Waldmann, H. Chemical Strategies for Generating Protein Biochips. Angew. Chem. 2008, 47, 9618–9647. [Google Scholar] [CrossRef] [PubMed]

- Sato, K.; Kondo, S.; Tsukada, M.; Ishigaki, T.; Kamiya, H. Influence of solid fraction on the optimum molecular weight of polymer dispersants in aqueous TiO2 nanoparticle suspensions. J. Am. Ceram. Soc. 2007, 90, 3401–3406. [Google Scholar] [CrossRef]

- Nsib, F.; Ayed, N.; Chevalier, Y. Dispersion of hematite suspensions with sodium polymethacrylate dispersants in alkaline medium. Colloids Surf. A 2006, 286, 17–26. [Google Scholar] [CrossRef]

- Kumar, N. Comprehensive Physics XII. In Unit II: Current Electricity; Kumar, N., Ed.; Unit II Current Electricity: New Delhi, India, 2003; p. 283. ISBN 978-81-7008-592-8. [Google Scholar]

- Kao, K.C. Electrical Conduction and Photoconduction. In Dielectric Phenomena in Solids with Emphasis on Physical Concepts of Electronic Processes; Kao, K.C., Ed.; Elsevier Academic Press: San Diego, CA, USA, 2004; pp. 381–514. ISBN 978-0-12-396561-5. [Google Scholar]

- Lewis, T.J. Charge transport in polyethylene nano dielectrics. IEEE Electr. Insul. Mag. 2014, 21, 497–502. [Google Scholar] [CrossRef]

- Enriquez, D.J.; Reyes, S.; Cabrera, B.; Cruz, N.; Mendoza, A. Polymer Structures. Available online: https://www.slideshare.net/deschui/polymer-structures-27240126 (accessed on 9 August 2017).

- Fothergill, J.C. Electrical properties. In Dielectric Polymer Nanocomposites; Nelson, J.K., Ed.; Springer: New York, NY, USA, 2010; pp. 197–228. ISBN 978-1-4419-1590-0. [Google Scholar]

- Hoang, A.T.; Pallon, L.; Liu, D.; Serdyuk, Y.V.; Gubanski, S.M.; Gedde, U.W. Charge Transport in LDPE Nanocomposites Part I—Experimental Approach. Polymers 2016, 8, 87. [Google Scholar] [CrossRef]

- Fleming, R.J.; Ammala, A.; Lang, S.B.; Casey, P.S. Conductivity and space charge in LDPE containing nano-and micro-sized ZnO particles. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 118–126. [Google Scholar] [CrossRef]

- Ishimoto, K.; Kanegae, E.; Ohki, Y.; Tanaka, T.; Sekiguchi, Y.; Murata, Y.; Reddy, C.C. Superiority of dielectric properties of LDPE/MgO nanocomposites over microcomposites. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1735–1742. [Google Scholar] [CrossRef]

- Masuda, S.; Okuzumi, S.; Kurniant, R.; Murakami, Y.; Nagao, M.; Murata, Y.; Sekiguchi, Y. DC conduction and electrical breakdown of MgO/LDPE nanocomposite. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Vancouver, BC, Canada, 14–17 October 2007; pp. 290–293. [Google Scholar]

- Murakami, Y.; Nemoto, M.; Okuzumi, S.; Masuda, S.; Nagao, M.; Hozumi, N.; Sekiguchi, Y. DC conduction and electrical breakdown of MgO/LDPE nanocomposite. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 33–39. [Google Scholar] [CrossRef]

- Pleşa, I. Influence of Inorganic Fillers on the Dielectric Properties of Polymer Nanocomposites Based on Polyethylene. Ph.D. Thesis, Politehnica University of Bucharest, Bucharest, Romania, 2012. [Google Scholar]

- Tanaka, T.; Kozako, M.; Fuse, N.; Ohki, Y. Proposal of a multi-core model for polymer nanocomposite dielectrics. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 669–681. [Google Scholar] [CrossRef]

- Pleşa, I.; Ciuprina, F.; Notingher, P.V.; Panaitescu, D. Inorganic nanofiller effects on resistivity and absorption currents in LDPE nanocomposites. Rev. Roum. Sci. Tech. 2011, 56, 277–284. [Google Scholar]

- Pleşa, I.; Zaharescu, T. Effects of gamma irradiation on resistivity and absorption currents in nanocomposites based on thermoplastic polymers. In Proceedings of the 8th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 23–25 May 2013; pp. 1–6. [Google Scholar]

- Lewis, T.J. Interfaces: NANOMETRIC dielectrics. J. Phys. D Appl. Phys. 2005, 38, 202–212. [Google Scholar] [CrossRef]

- Yan, Z.; Han, B.; Zhao, H.; Yang, J.; Li, C. Space charge and conductivity characteristics of CB/XLPE nanocomposites. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Niigata, Japan, 1–5 June 2014; pp. 30–33. [Google Scholar]

- Tanaka, T.; Bulinski, A.; Castellon, J.; Frechette, M.; Gubanski, S.; Kindersberger, J.; Montanari, G.C.; Nagao, M.; Morshuis, P.; Tanaka, Y.; et al. Dielectric properties of XLPE/SiO2 nanocomposites based on CIGRE WG D1.24 cooperative test results. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1482–1517. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, K.; Wang, C.; Yang, L.; Wang, F. Study on dielectric properties of TiO2/XLPE nanocomposites. In Proceedings of the International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016; pp. 1–4. [Google Scholar]

- Murata, Y.; Goshowaki, M.; Reddy, C.C.; Sekiguchi, Y.; Hishinuma, N.; Hayase, Y.; Tanaka, Y.; Takada, T. Investigation of space charge distribution and volume resistivity of XLPE/MgO nanocomposite material under DC voltage application. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Yokkaichi, Japan, 7–11 September 2008; pp. 502–505. [Google Scholar]

- Schönhals, A. Dielectric Spectroscopy on Dynamics of Amorphous Polymeric Systems. Novocontrol Appl. Note Dielectr. 1998, 1, 1–17. [Google Scholar]

- Debye, P. Polar molecules. Chem. Cat. 1929, 48, 1036–1037. [Google Scholar]

- Smith, R.C.; Hui, L.; Nelson, J.K.; Schadler, L.S. Interfacial charge behavior in nanodielectrics. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Virginia Beach, VA, USA, 18–21 October 2009; pp. 650–653. [Google Scholar]

- Tanaka, T. Dielectrics Nanocomposites with Insulating Properties. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 914–928. [Google Scholar] [CrossRef]

- Ciuprina, F.; Pleşa, I.; Notingher, P.V.; Tudorache, T.; Panaitescu, D. Dielectric Properties of Nanodielectrics with Inorganic Fillers. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Chicoutimi, QC, Canada, 26–29 October 2008; pp. 682–685. [Google Scholar]

- Ciuprina, F.; Pleşa, I.; Notingher, P.V.; Zaharescu, T.; Rain, P.; Panaitescu, D. Dielectric properties of LDPE-SiO2 nanocomposites. In Proceedings of the 10th IEEE International Conference on Solid Dielectrics (ICSD), Potsdam, Germany, 4–9 July 2010; pp. 1–4. [Google Scholar]

- Ciuprina, F.; Zaharescu, T.; Jipa, S.; Pleşa, I.; Noţingher, P.V.; Panaitescu, D. Effects of ionizing radiation on the dielectric properties of LDPE-Al2O3 nanocomposites. UPB Sci. Bull. Ser. C 2010, 72, 259–268. [Google Scholar]

- Panaitescu, D.; Ciuprina, F.; Iorga, M.; Frone, A.; Radovici, C.; Ghiurea, M.; Sever, S.; Pleşa, I. Effects of SiO2 and Al2O3 nanofillers on polyethylene properties. J. Appl. Polym. Sci. 2011, 122, 1921–1935. [Google Scholar] [CrossRef]

- Ciuprina, F.; Zaharescu, T.; Pleşa, I. Effects of γ-radiation on dielectric properties of LDPE-Al2O3 nanocomposites. Radiat. Phys. Chem. 2013, 84, 145–150. [Google Scholar] [CrossRef]

- Shengtao, L.; Guilai, Y.; Fengyan, N.; Suna, B.; Jianying, L.; Tuo, Z. Investigation on the dielectric properties of nano-titanium dioxide—Low density polyethylene composites. In Proceedings of the International Conference on Solid Dielectrics (ICSD), Potsdam, Germany, 4–9 July 2010; pp. 1–4. [Google Scholar]

- Zhang, C.; Stevens, G.C. The dielectric response of polar and non-polar nanodielectrics. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 606–617. [Google Scholar] [CrossRef]

- Jonscher, A.K. Dielectric Relaxation in Solids; Chelsea Dielectrics: London, UK, 1983; pp. 1–380, ISBN 0950871109 9780950871103. [Google Scholar]

- Comer, A.C.; Kalika, D.S.; Rowe, B.W.; Freeman, B.D.; Paul, D.R. Dynamic relaxation characteristics of Matrimid polyimide. Polymer 2009, 50, 891–897. [Google Scholar] [CrossRef]

- Nguyen, T.; Bentz, D.; Byrd, E. Method for measuring water diffusion in a coating applied to a substrate. J. Coat. Technol. 1995, 67, 37–46. [Google Scholar]

- Roy, M.; Nelson, J.K.; MacCrone, R.K.; Schadler, L.S.; Reed, C.W.; Keefe, R.; Zenger, W. Polymer Nanocomposite Dielectrics—The Role of the Interface. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 629–643. [Google Scholar] [CrossRef]

- Smith, R.C.; Liang, C.; Landry, M.; Nelson, J.K.; Schadler, L.S. The mechanisms leading to the useful electrical properties of polymer nanodielectrics. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 187–196. [Google Scholar] [CrossRef]

- Hui, L.; Schadler, L.S.; Nelson, J.K. The Influence of Moisture on the Electrical Properties of Crosslinked Polyethylene/Silica Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 641–653. [Google Scholar] [CrossRef]

- Hui, L.; Nelson, J.K.; Schadler, L.S. The influence of moisture on the electrical performance of XLPE/silica nanocomposites. In Proceedings of the 10th IEEE International Conference on Solid Dielectrics (ICSD), Potsdam, Germany, 4–9 July 2010; pp. 1–4. [Google Scholar]

- Scarpa, P.C.N.; Bulinski, A.T.; Bamji, S.; Das-Gupta, D.K. Dielectric spectroscopy of AC aged polyethylene in the frequency range of 10−5 Hz to 106 Hz. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Virginia Beach, VA, USA, 22–25 October 1995; pp. 81–84. [Google Scholar]

- Kyritsis, A.; Pissis, P.; Grammatikakis, J. Dielectric relaxation spectroscopy in poly(hydroxyethyl acrylates)/water hydrogels. J. Polym. Sci. Part B Polym. Phys. 1995, 33, 1737–1750. [Google Scholar] [CrossRef]

- Medjdoub, A.; Boubakeur, A.; Lebey, T. Dielectric spectroscopy analysis behavior of low density polyethylene. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Chicoutimi, QC, Canada, 26–29 October 2008; pp. 517–520. [Google Scholar]

- Scarpa, P.C.N.; Leguenza, E.L.; Das-Gupta, D.K. A study of electrical ageing of cross-linked polyethylene by dielectric spectroscopy. In Proceedings of the 10th International Symposium on Electrets (ISE), Athens, Greece, 22–24 September 1999; pp. 395–398. [Google Scholar]

- Fothergil, J.C.; See, K.B.A.; Jour, M.N.A.; Dissado, L.A. Sub-Hertz dielectric spectroscopy. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Kitakyushu, Japan, 5–9 June 2005; pp. 821–824. [Google Scholar]

- David, E.; Castellon, J.; Fréchette, M.; Guo, M.; Helal, E. Dielectric properties of various metallic Oxide/LDPE nanocomposites compounded by different techniques. In Proceedings of the IEEE Electrical Insulation Conference (EIC), Baltimore, MD, USA, 11–14 June 2017; pp. 151–154. [Google Scholar]

- Kuffel, E.; Zaengl, W.S.; Kuffel, J. High Voltage Engineering—Fundamentals; Newnes: Oxford, UK, 2000; p. 421. ISBN 0-7506-3634-3. [Google Scholar]

- Notingher, P.V. Structure. Properties (Vol. 1). Materials for Electrotechnics; Politehnica Press: Bucharest, Romania, 2004; pp. 350–403. ISBN 973-8449-81-2/973-8449-81-0. [Google Scholar]

- Tanaka, T.; Iizuka, T. Generic PD resistance characteristics of polymer nanocomposites. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), West Lafayette, IN, USA, 17–20 October 2010; pp. 1–4. [Google Scholar]

- High-Voltage Test Techniques—Partial Discharge Measurements, 3rd ed.; IEC 60270; IEC: Geneva, Switzerland, 2002.

- James, J.; Kulkarni, S.V.; Parekh, B.R. Partial discharge in high voltage equipment-HV cable. In Proceedings of the IEEE 9th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Harbin, China, 19–23 July 2009; pp. 445–448. [Google Scholar]

- Kozako, M.; Fuse, N.; Shibata, K.; Hirai, N.; Ohki, Y.; Okamoto, T.; Tanaka, T. Surface Change of Polyamide Nanocomposite Caused by Partial Discharges. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Albuquerque, NM, USA, 19–22 October 2003; pp. 75–78. [Google Scholar]

- Maity, P.; Basu, S.; Parameswaran, V.; Gupta, N. Degradation of Polymer Dielectrics with Nanometeric Metal-oxide Fillers due to Surface Discharges. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 52–62. [Google Scholar] [CrossRef]

- Tanaka, T.; Ohki, Y.; Ochi, M.; Harada, M.; Imai, T. Enhanced Partial Discharge Resistance of Epoxy/Clay Nanocomposite Prepared by Newly Developed Organic Modification and Solubilization Methods. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 81–89. [Google Scholar] [CrossRef]

- Wensheng, G.A.O.; Ning, S.U.; Quingduo, Y.I.N. Size effect of partial discharge in solid void defects. In Proceedings of the IEEE 9th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Harbin, China, 19–23 July 2009; pp. 501–504. [Google Scholar]

- Illias, H.A.; Tunio, M.A.; Bakar, A.H.A.; Mokhlis, H.; Chen, G. Partial Discharge Phenomena within an Artificial Void in Cable Insulation Geometry: Experimental Validation and Simulation. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 451–459. [Google Scholar] [CrossRef]

- Arief, Y.Z.; Ahmad, H.; Hikita, M. Partial discharge characteristics of XLPE cable joint and interfacial phenomena with artificial defects. In Proceedings of the IEEE 2nd International Power and Energy Conference (PECON), Johor Bahru, Malaysia, 1–3 December 2008; pp. 977–982. [Google Scholar]

- Aulia, S.; Abdul-Malek, Z.; Arief, Y.Z.; Piah, M.A.M.; Jaafar, M. Partial Discharge Characteristic of Linear Low Density Polyethylene and Silica Nanocomposite. Appl. Mech. Mater. 2014, 554, 133–136. [Google Scholar] [CrossRef]

- Sami, A.; David, E.; Frechette, M.; Savoie, S. Breakdown and Surface Discharge Involving PE/SiO2 Nanocomposites. In Proceedings of the IEEE International Symposium on Electrical Insulation (ISEI), San Diego, CA, USA, 6–9 June 2010; pp. 1–4. [Google Scholar]

- Gao, J.; Zhang, J.; Ji, Q.; Liu, J.; Zhang, M.; Zhang, X. Study on Breakdown and Partial Discharge of Polyethylene/Montmorillonite Nanocomposites. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Yokkaichi, Japan, 7–11 September 2008; pp. 597–600. [Google Scholar]

- Uddin, F. Clays, Nanoclays, and Montmorillonite Minerals. Metall. Mater. Trans. A 2008, 39, 2804–2814. [Google Scholar] [CrossRef]

- Tanaka, T.; Nose, A.; Ohki, Y.; Murata, Y. PD Resistance Evaluation of LDPE/MgO Nanocomposite by a Rod-to-Plane Electrode System. In Proceedings of the 8th International Conference on Properties and Applications of Dielectric Materials (ICPADM), Bali, Indonesia, 26–30 June 2006; pp. 319–322. [Google Scholar]

- Guastavino, F.; Dardano, A.; Ratto, A.; Torello, E.; Hoyos, M.; Gomez-Elvira, J.M.; Tiemblo, P. Resistance to surface partial discharges of LDPE nanocomposites. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Vancouver, BC, Canada, 14–17 October 2007; pp. 244–247. [Google Scholar]

- Chen, S.; Huang, R.; Peng, Z.; Wang, X.; Cheng, X. The Effect of Nano- ZnO on Withstanding Corona Aging in Low-Density Polyethylene. In Proceedings of the 10th IEEE International Conference on Solid Dielectrics (ICSD), Potsdam, Germany, 4–9 July 2010; pp. 255–258. [Google Scholar]

- Zheng, M.B.; Chen, S.Q.; Cheng, X.; Wang, X.; Peng, Z.R. Study on the Similarity of Photo and Corona Aging in Nano-ZnO/LDPE Composite. In Proceedings of the IEEE 9th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Harbin, China, 19–23 July 2009; pp. 816–819. [Google Scholar]

- Yamano, Y.; Okada, M. Reduction of PD in a Void by Additives of Azobenzoic Compound in HDPE Insulating material. IEEE Trans. Dielectr. Electr. Insul. 2001, 8, 889–896. [Google Scholar] [CrossRef]

- Aulia, S.; Ahmad, M.H.; Abdul-Malek, Z.; Arie, Y.Z.; Lau, K.Y.; Novizon, N. Partial Discharge Characteristics in LLDPE-Natural Rubber Blends: Correlating Electrical Quantities with Surface Degradation. J. Electr. Eng Technol. 2016, 11, 709–718. [Google Scholar] [CrossRef]

- Lau, K.Y.; Vaughan, A.S.; Chen, G.; Hosier, I.L.; Holt, A.F.; Ching, K.Y. On the space charge and DC breakdown behavior of polyethylene/silica nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 340–351. [Google Scholar] [CrossRef]

- Fleming, R.J. Space Charge in Polymers, Particularly Polyethylene. Braz. J. Phys. 1999, 29, 280–294. [Google Scholar] [CrossRef]

- Notingher, P.V. On the Breakdown Mechanism of Inhomogenous Solid Dielectrics. Rev. Roum. Sci. Tech. 1979, 24, 651–663. [Google Scholar]

- Notingher, P.V. Méthodes de calcul de la dureé de rupture dans le systeme pointe-plan. Rev. Roum. Sci. Tech. 1986, 31, 59–68. [Google Scholar]

- Moreau, E.; Mayoux, C.; Laurent, C.; Boudet, A. The Structural Characteristics of Water Trees in Power Cables and Laboratory Specimens. Trans. Dielectr. Electr. Insul. 1993, 28, 54–64. [Google Scholar] [CrossRef]

- Ohki, Y.; Ebinuma, Y.; Katakai, S. Space Charge Formation in Water-treed Insulation. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 707–712. [Google Scholar] [CrossRef]

- Stancu, C.; Notingher, P.V.; Ciuprina, F.; Notingher, P., Jr.; Agnel, S.; Castellon, J.; Toureille, A. Computation of the Electric Field in Cable Insulation in the Presence of Water Trees and Space Charge. IEEE Trans. Ind. Appl. 2009, 45, 30–49. [Google Scholar] [CrossRef]

- Stancu, C.; Notingher, P.V.; Notingher, P., Jr. Influence of Space Charge Related to Water Trees on the Breakdown Voltage of Power Cable Insulation. J. Electrostat. 2013, 71, 145–154. [Google Scholar] [CrossRef]

- Stancu, C.; Notingher, P.N.; Notingher, P., Jr. Computation of the Electric Field in Aged Underground Medium Voltage Cable Insulation. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1530–1539. [Google Scholar] [CrossRef]

- Fothergill, J.C. Ageing, Space Charge and Nanodielectrics: Ten Things We Don’t Know About Dielectrics. In Proceedings of the IEEE International Conference on Solid Dielectrics (ICSD), Winchester, UK, 8–13 July 2007; pp. 1–10. [Google Scholar]

- Stancu, C. Characterization of Polymeric Insulation Ageing State by Water Tree and Space Charge Measurements. Ph.D. Thesis, Politehnica University of Bucharest (UPB), Bucharest, Romania, Montpellier 2 University 2 (UM2), Montpellier, France, 2008. [Google Scholar]

- Ieda, M. Electrical conduction and carrier traps in polymeric materials. IEEE Trans. Electr. Insul. 1984, EI-19, 162–178. [Google Scholar] [CrossRef]

- Nelson, J.K.; Hu, Y. The Impact of Nanocomposite Formulations on Electrical Voltage Endurance. In Proceedings of the IEEE International Conference on Solid Dielectrics (ICSD), Toulouse, France, 5–9 July 2004; pp. 832–835. [Google Scholar]

- Lv, Z.; Wu, K.; Wang, X.; Zhao, X.; Dissado, L.A.; Niu, Y. Thickness dependence of space charge in XLPE and its nanocomposites under temperature gradient. In Proceedings of the IEEE International Conference on Solid Dielectrics (ICSD), Bologna, Italy, 30 June–4 July 2013; pp. 250–253. [Google Scholar]

- Chen, X.; Wang, X.; Wu, K.; Peng, Z.R.; Cheng, Y.H.; Tu, D.M. Space charge measurement in LDPE films under temperature gradient and dc stress. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1796–1805. [Google Scholar] [CrossRef]

- Nelson, J.K.; Fothergill, J.C.; Dissado, L.A.; Peasgood, W. Towards an understanding of nanometric dielectrics. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Cancun, Mexico, 20–24 October 2002; pp. 295–298. [Google Scholar] [Green Version]

- Yin, Y.; Chen, J.; Xiao, D.; Tu, D.; Yin, R.; Qian, H. Effect of Space Charge in Nanocomposite of LDPE/TiO2. In Proceedings of the IEEE 7th International Conference on Properties and Applications of Dielectric Materials (ICPADM), Nagoya, Japan, 1–5 June 2003; pp. 913–916. [Google Scholar]

- Yin, Y.; Wu, J.; Lan, L.; Li, X.; Wang, Q. Effect of nanosilica grain size on the trap density distribution in LDPE/silica nanocomposite. In Proceedings of the IEEE International Conference on Solid Dielectrics (ICSD), Bologna, Italy, 30 June–4 July 2013; pp. 726–729. [Google Scholar]

- Nelson, J.K.; Fothergill, J.C. Internal charge behaviour in nanocomposites. Nanotechnology 2004, 15, 586–595. [Google Scholar] [CrossRef]

- Tanaka, T.; Montanari, G.C.; Mülthaupt, R. Polymer Nanocomposites as Dielectrics and Electrical Insulation—Perspectives for Processing Technologies, Material Characterization and Future Applications. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 763–784. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, G.; Vaughan, A. Space charge dynamics in silica-based polyethylene nanocomposites. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Des Moines, IA, USA, 19–22 October 2014; pp. 727–730. [Google Scholar]

- Xu, Z.; Guo, M.; Frechette, M.; David, E.; Chen, G. Space charge properties of LDPE-based composites with three types of POSS. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 679–682. [Google Scholar]

- Fleming, R.J.; Ammala, A.; Casey, P.S.; Lang, S.B. Conductivity and Space Charge in LDPE/BaSrTiO3 Nanocomposites. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), West Lafayette, IN, USA, 17–20 October 2010; pp. 1–4. [Google Scholar]

- Fleming, R.J.; Ammala, A.; Casey, P.S.; Lang, S.B. Conductivity and Space Charge in LDPE/BaSrTiO3 Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 15–23. [Google Scholar] [CrossRef]

- Tian, F.; Lei, Q.; Wang, X.; Wang, Y. Investigation of electrical properties of LDPE/ZnO nanocomposite dielectrics. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 763–769. [Google Scholar] [CrossRef]

- Murata, Y.; Murakami, Y.; Nemoto, M.; Sekiguchi, Y.; Inoue, Y.; Kanaoka, M.; Hozumi, N.; Nagao, M. Effects of Nano-sized MgO-filler on Electrical Phenomena under DC Voltage Application in LDPE. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Nashville, TN, USA, 16–19 October 2005; pp. 158–161. [Google Scholar]

- Taima, J.; Inaoka, K.; Maezawa, T.; Tanaka, Y.; Takada, T.; Murata, Y. Observation of Space Charge Formation in LDPE/MgO Nano-composite under DC Stress at High Temperature. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Kansas City, MO, USA, 15–18 October 2006; pp. 302–305. [Google Scholar]

- Sato, S.; Yanagisawa, S.; Tanaka, Y.; Takada, T.; Watanabe, R.; Tomita, N. Investigation of Space Charge Behavior in Polyimide film during Elevating Temperature. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Boulder, CO, USA, 17–20 October 2004; pp. 57–60. [Google Scholar]

- Zheng, Y.; Wang, Q.; Yin, Y.; Li, X. Temperature Effect on Space Charge Dynamics in LDPE/MgO Nanocomposite under DC Stress. In Proceedings of the 10th IEEE International Conference on Solid Dielectrics (ICSD), Potsdam, Germany, 4–9 July 2010; pp. 1–4. [Google Scholar]

- Wu, K.; Chen, X.; Liu, X.; Wang, X.; Cheng, Y.; Dissado, L.A. Study of the space charge behavior in polyethylene nanocomposites under temperature gradient. In Proceedings of the International Conference on Electrical Insulating Materials (ISEIM), Kyoto, Japan, 6–10 September 2011; pp. 84–87. [Google Scholar]

- Wu, J.; Liu, W.; Zheng, Y.; Wang, Q.; Yin, Y. Effect of Nano-additive Size on the Space Charge Behaviour in LDPE/SiO2 Nanocomposite. In Proceedings of the 10th IEEE International Conference on Solid Dielectrics (ICSD), Potsdam, Germany, 4–9 July 2010; pp. 1–4. [Google Scholar]

- Yang, L.; Bai, G.; Liu, Y.; Gu, J.; Li, J.; Zhang, H. Electric Field Inducement of Montmorillonite in LDPE and Properties of Electrical Tree Growing in this Composite. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1684–1693. [Google Scholar] [CrossRef]

- Pitsa, D.; Vardakis, G.E.; Danikas, M.G.; Chen, Y. Electrical Tree Simulation and Breakdown in Nanocomposite Polymers: The Role of Nanoparticles. In Proceedings of the IEEE International Conference on Solid Dielectrics (ICSD), Potsdam, Germany, 4–9 July 2010; pp. 1–3. [Google Scholar]

- Notingher, P.V. Contributii la Studiul Solicitarilor Materialelor Izolante din Masinile Electrice. Ph.D. Thesis, Politehnica University of Bucharest, Bucharest, Romania, 1983. [Google Scholar]

- Holto, J.; Ildstad, E. Electrical Treeing in Extruded Polypropylene High Voltage Cable Insulation. In Proceedings of the International Conference on High Voltage Engineering and Application (ICHVE), New Orleans, LA, USA, 11–14 October 2010; pp. 373–376. [Google Scholar]

- Du, B.X.; Ma, Z.L.; Gao, Y. Phenomena and Mechanism of Electrical Tree in Silicone Rubber. In Proceedings of the IEEE 9th International Conference on Properties and Applications of Dielectric Materials (ICPADM), Harbin, China, 19–23 July 2009; pp. 37–40. [Google Scholar]

- Guastavino, F.; Dardano, A.; Montanari, G.C.; Testa, L.; Bellucci, F. Electrical Treeing in EVA-Boehmite and EVA-Montmorillonite Nanocomposites. In Proceedings of the IEEE Electrical Insulation Conference (EIC), Montreal, QC, Canada, 31 May–3 June 2009; pp. 382–386. [Google Scholar]

- Rouha, N.; Beroual, A. Physico-Chemical Diagnosis of EPDM Electrical Aging by Tree Phenomenon. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1577–1583. [Google Scholar] [CrossRef]

- Cui, Y.; Wu, G.; Wu, C.; Luo, Y. Possible Mechanism of Electrical Treeing and Breakdown for Polyimide Nanocomposite Film Used in Inverter-Fed Motor. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), West Lafayette, IN, USA, 17–20 October 2010; pp. 1–4. [Google Scholar]

- Bahadoorsingh, S.; Rowland, S.M. Investigating the Influence of the Lubricant Coating on Hypodermic Needles on Electrical Tree Characteristics in Epoxy Resin. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 701–708. [Google Scholar] [CrossRef]

- Dissado, L.A. Understanding Electrical Trees in Solid: From Experiment to Theory. IEEE Trans. Dielectr. Electr. Insul. 2002, 9, 483–497. [Google Scholar] [CrossRef]

- Champion, J.V.; Dodd, S.J.; Vaughan, A.S.; Zhao, Y.; Sutton, S.J. The Effect of Voltage, Temperature and Morphology on Electrical Treeing in Polyethylene Blends. In Proceedings of the 8th International Conference on Dielectric Materials, Measurements and Applications, Edinburgh, UK, 17–21 September 2000; pp. 35–40. [Google Scholar]

- Chen, G.; Tham, C.H. Electrical Treeing Characteristics in XLPE Power Cable Insulation in Frequency Range between 20 and 500 Hz. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 179–188. [Google Scholar] [CrossRef]

- Wang, H.; He, J.; Zhang, X.; Li, Z.; Li, L.; Guan, G. Electrical Tree Inception Characteristics of XLPE Insulation Under Power-Frequency Voltage and Superimposed Impulse Voltage. In Proceedings of the 11th International Symposium on High Voltage Engineering (ISH), London, UK, 27–23 August 1999; pp. 320–323. [Google Scholar]

- Champion, J.V.; Dodd, S.J. The effect of material composition and temperature on electrical tree growth in epoxy resins. In Proceedings of the 8th International Conference on Dielectric Materials, Measurements and Applications, Edinburgh, UK, 17–21 September 2000; pp. 30–34. [Google Scholar]

- Alapati, S.; Thomas, M.J.; Ajay, K. Effect of morphology on electrical treeing in low density polyethylene nanocomposites. IET Sci. Meas. Technol. 2014, 8, 60–68. [Google Scholar] [CrossRef]

- Cooper, J.M.; Stevens, G.C. The influence of physical properties on electrical treeing in a cross-linked synthetic resin. J. Phys. D Appl. Phys. 1990, 23, 1528–1535. [Google Scholar] [CrossRef]

- Dodd, S.J.; Champion, J.V.; Zhao, Y.; Vaughan, A.S.; Sutton, S.J.; Swingler, S.G. Influence of Morphology on Electrical Treeing in Polyethylene Blends. IEE Proc. 2003, 150, 58–64. [Google Scholar] [CrossRef]

- Harlin, A.; Shuvalov, M.; Ovsienko, V.; Juhanoja, J. Insulation Morphology Effects on the Electrical Treeing Resistance. IEEE Trans. Dielectr. Electr. Insul. 2002, 9, 401–405. [Google Scholar] [CrossRef]

- Hozumi, N.; Ishida, M.; Okamoto, T.; Fukagawa, H. The influence of morphology on electrical tree initiation in polyethylene under ac and impulse voltages. IEEE Trans. Dielectr. Electr. Insul. 1990, 25, 707–714. [Google Scholar] [CrossRef]

- Jarvid, M. Voltage Stabilizers: From Design to Synthesis, Processing and Electrical Characterization. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2014. [Google Scholar]

- Kurnianto, R.; Murakami, Y.; Hozumi, N.; Nagao, M. Characterization of Tree Growth in Filled Resin: The effect of filler and moisture content. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 427–435. [Google Scholar] [CrossRef]

- Auckland, D.W.; Taha, A.; Varlow, B.R. Correlation of Mechanical Properties with Electrical Treeing Behaviour at Elevated Temperatures. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Pocono Manor, PA, USA, 17–20 October 1993; pp. 636–641. [Google Scholar]

- Berg, G.; Sæternes, H.H.; Aakervik, J.; Hvidsten, S. The Effect of Hydrostatic Pressure on Electrical Treeing in Silicone Cable Joints. In Proceedings of the IEEE International Symposium on Electrical Insulation (ISEI), San Juan, PR, USA, 10–13 June 2012; pp. 609–612. [Google Scholar]

- Varlow, B.R.; Auckland, D.W. The Influence of Mechanical Factors on Electrical Treeing. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 761–765. [Google Scholar] [CrossRef]

- Jarvid, E.M.; Johansson, A.B.; Blennow, J.H.M.; Andersson, M.R.; Gubanski, S.M. Evaluation of the Performance of Several Object Types for Electrical Treeing Experiments. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1712–1719. [Google Scholar] [CrossRef]

- Vijh, A.K.; Crine, J.-P. Influence of Metallic Electrodes on Electrical Tree Initiation in Polyethylene. J. Appl. Phys. 1989, 65, 398–399. [Google Scholar] [CrossRef]

- Jarvid, M.; Johansson, A.; Englund, V.; Gubanski, S.; Andersson, M.R. Electrical tree inhibition by voltage stabilizers. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Montreal, QC, Canada, 14–17 October 2012; pp. 605–608. [Google Scholar]

- Johansson, A.B. Characterising Resistance to Electrical Treeing in New XLPE-Based Materials for High-Voltage Cables. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2015. [Google Scholar]

- Vogelsang, R.; Farr, T.; Fröhlich, K. The effect of barriers on electrical tree propagation in composite insulation materials. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 373–382. [Google Scholar] [CrossRef]

- Ding, H.Z.; Varlow, B.R. Effect of nanofillers on electrical treeing in epoxy resin subjected to AC voltage. In Proceedings of the Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Boulder, CO, USA, 17–20 October 2004; pp. 332–335. [Google Scholar]

- Kurnianto, R.; Murakami, Y.; Nagao, M.; Hozumi, N.; Murata, Y. Treeing breakdown in inorganic filler/LDPE nanocomposite material. IEE J. Trans. Fundam. Mater. 2007, 127, 29–34. [Google Scholar] [CrossRef]

- Yamano, Y.; Iizuka, M. Improvement of electrical tree resistance of LDPE by mixed addition of nanoparticles and phthalocyanine. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 329–337. [Google Scholar] [CrossRef]

- Yamano, Y.; Iizuka, M. Suppression of Electrical Tree Initiation in LDPE by Additives of Polycyclic Compounds. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 189–198. [Google Scholar] [CrossRef]

- Bahder, G.; Katz, C.; Lawson, J.; Vahlstrom, W. Electrical and electro-chemical treeing effect in polyethylene and crosslinked polyethylene cables. IEEE Trans. Power APP Syst. 1974, PAS-93, 977–990. [Google Scholar] [CrossRef]

- Khalil, M.S.; Gastli, A. Investigation of the dependence of DC insulation resistivity of ultra-clean polyethylene on temperature and electric field. IEEE Trans. Power Deliv. 1999, 14, 699–704. [Google Scholar] [CrossRef]

- Englund, V.; Huuva, R.; Gubanski, S.M.; Hjertberg, T. Synthesis and Efficiency of Voltage Stabilizers for XLPE Cable Insulation. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1455–1461. [Google Scholar] [CrossRef]

- Alapati, S.; Thomas, M.J. Electrical treeing and the associated PD characteristics in LDPE nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 697–704. [Google Scholar] [CrossRef]

- Yamano, Y. Control of Electrical Tree at Initiation Stage in LDPE by Mixed Addition of Al2O3 Nano-particle and Azobenzoic Compound. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 209–216. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, J.; Liu, J.; Ji, Q.; Zhang, M.; Zhang, X. Studies on Electrical Tree and Partial Discharge Properties of PE/MMT Nanocomposites. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Yokkaichi, Japan, 7–11 September 2008; pp. 311–314. [Google Scholar]

- Chi, X.; Gao, J.; Zhang, X. Electrical Tree Propagating Characteristics of Polyethylene/Nano-Montmorillonite Composites. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 1530–1536. [Google Scholar] [CrossRef]

- Guastavino, F.; Dardano, A.; Squarcia, S.; Tiemblo, P.; Guzman, J.; Benito, E.; Garcia, N. Electrical treeing in LDPE nanocomposite materials. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Virginia Beach, VA, USA, 18–21 October 2009; pp. 697–700. [Google Scholar]

- Guastavino, F.; Dardano, A.; Squarcia, S.; Tiemblo, P.; Guzman, J.; Garcia, N. An experimental study about electrical treeing inside LDPE nanocomposites. In Proceedings of the 10th IEEE International Conference on Solid Dielectrics (ICSD), Potsdam, Germany, 4–9 July 2010; pp. 1–4. [Google Scholar]

- Tiemblo, P.; Hoyos, M.; Gomez-Elvira, J.M.; Guzman, J.; Garcia, N.; Dardano, A.; Guastavino, F. The Development of Electrical Treeing in LDPE and its Nanocomposites with Spherical Silica and Fibrous and Laminar Silicates. J. Phys. D Appl. Phys. 2008, 41, 1–8. [Google Scholar] [CrossRef]

- Kurnianto, R.; Murakami, Y.; Hozumi, N.; Nagao, M.; Murata, Y. Some Fundamentals on Treeing Breakdown in Inorganic-filler/LDPE Nano-composite Material. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Kansas City, MO, USA, 15–18 October 2006; pp. 373–376. [Google Scholar]

- Tanaka, T. Buds for Treeing in Epoxy Nanocomposites and their Possible Interaction with Nano Fillers. In Proceedings of the 10th IEEE International Conference on Solid Dielectrics (ICSD), Potsdam, Germany, 4–9 July 2010; pp. 1–4. [Google Scholar]

- Kawano, M.; Murakami, Y.; Nagao, M.; Sekiguchi, Y.; Reddy, C.C.; Murata, Y. Treeing Breakdown Phenomena in MgO/LDPE Nanocomposite Material. In Proceedings of the IEEE International Conference on Applications and Dielectric Materials (ICPADM), Harbin, China, 19–23 July 2009; pp. 837–840. [Google Scholar]

- Tanaka, T.; Iizuka, T.; Sekiguchi, Y.; Murata, Y.; Ohki, Y. Tree Initiation and Growth in LDPE/MgO Nanocomposites and Roles of Nano Fillers. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Virginia Beach, VA, USA, 18–21 October 2009; pp. 646–649. [Google Scholar]

- Tanaka, T.; Yokoyama, K.; Ohki, Y.; Murata, Y.; Sekiguchi, Y.; Goshowaki, M. High Field Light Emission in LDPE/MgO Nanocomposite. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Yokkaichi, Japan, 7–11 September 2008; pp. 506–509. [Google Scholar]

- Xiao, C.; Zhang, Y.; Zheng, F.; Xia, J.; Wu, C. Treeing-Like Breakdown in Electron beam Irradiated LDPE with/without Nano- Powder Doping. In Proceedings of the 8th International Conference on Applications and Dielectric Materials (ICPADM), Bali, Indonesia, 26–30 June 2006; pp. 167–170. [Google Scholar]

- Chen, J.L.; Filippini, J.C. The Morphology and Behavior of the Water Tree. IEEE Trans. Electr. Insul. 1993, 28, 271–286. [Google Scholar] [CrossRef]

- Stucki, F.; Mueller, K.-B. Properties of Individual Water Trees in VPE Cables. Elektrizitätswirtschaft 1993, 92, 1732–1736. [Google Scholar]

- Meyer, C.T. Water absorption during Water Treeing in Polyethylene. IEEE Trans. Electr. Insul. 1983, IE-18, 28–31. [Google Scholar] [CrossRef]

- Steennis, E.F.; Kreuger, F.H. Water Treeing in Polyethylene Cables. IEEE Trans. Electr. Insul. 1990, 25, 989–1028. [Google Scholar] [CrossRef]

- Visata, O.I.; Teissedre, G.; Filipinni, J.C.; Notingher, P.V. An Investigation on the Distribution of Ions and Water in Water Trees by FTIR Microspectroscopy. In Proceedings of the IEEE 7th International Conference on Solid Dielectrics (ICSD), Eindhoven, The Netherlands, 25–29 June 2001; pp. 373–376. [Google Scholar]

- Chiru, O.; Notingher, P.V.; Jipa, S.; Setnescu, T.; Setnescu, R. Influence of antioxidant content on water trees development. In Proceedings of the ‘Electrotechnics ‘96’ Symposium, Bucharest, Romania, 6–7 December 1996; pp. 157–164. [Google Scholar]

- Crine, J.-P. Electrical, Chemical and Mechanical Processes in Water Treeing. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 681–694. [Google Scholar] [CrossRef]

- Nagao, M.; Watanabe, S.; Murakami, Y.; Murata, Y.; Sekiguchi, Y.; Goshowaki, M. Water tree retardation of MgO/LDPE and MgO/XLPE nanocomposites. In Proceedings of the International Symposium on Electrical Insulating Materials, (ISEIM), Yokkaichi, Japan, 7–11 September 2008; pp. 483–486. [Google Scholar]

- Notingher, P.V.; Ciuprina, F.; Radu, I.; Filippini, J.C.; Gosse, B.; Jipa, S.; Setnescu, T.; Setnescu, R.; Mihalcea, T. Studies on Water Treeing and Chemiluminescence on Irradiated Polyethylene. In Proceedings of the IEEE International Symposium on Electrical Insulation, Montreal, QC, Canada, 16–19 June 1996; pp. 163–167. [Google Scholar]

- Ross, R. Inception and Propagation Mechanisms of Water Treeing. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 660–680. [Google Scholar] [CrossRef]

- Notingher, P.V.; Ciuprina, F.; Radu, I. The influence of ageing process on the shape and the propagation kinetics of the water trees in needle-plane polyethylene samples. In Proceedings of the IEEE International Conference on Conduction and Breakdown in Solid Dielectrics (ICSD), Västeras, Sweden, 22–25 June 1998; pp. 341–344. [Google Scholar]

- Nunes, S.L.; Shaw, M.T. Water Treeing in Polyethylene—A Review of Mechanisms. IEEE Trans. Electr. Insul. 1980, 15, 437–450. [Google Scholar] [CrossRef]

- Shaw, M.T.; Shaw, S.H. Water Treeing in Solid Dielectrics. IEEE Trans. Electr. Insul. 1984, 19, 419–452. [Google Scholar] [CrossRef]

- Visata, O.I. Influence des Arborescences d’eau sur les Propriétés Diélectriques des Polymères. Ph.D. Thesis, Universite Joseph Fourier-Grenoble 1, France et University Politehnica of Bucarest, Bucharest, Romania, 2001. [Google Scholar]

- Notingher, P.V.; Radu, I.; Filippini, J.C. Electric Field Calculations in Polymers in the Presence of Water-Trees. In Proceedings of the IEEE 5th International Conference on Conduction and Breakdown in Solid Dielectrics (ICSD), Leicester, UK, 10–13 July 1995; pp. 666–670. [Google Scholar]

- Bahder, G.; Eager, G.S.; Lukac, R.G. Influence of Electrochemical Trees on the Electrical Properties of Extruded Polymeric Insulation. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Downingtown, PA, USA, 21–23 October 1974; pp. 289–301. [Google Scholar]

- Tabata, T.; Nagai, H.; Fukuda, T.; Iwata, Z. Sulfide Attack and Treeing of Polyethylene Insulated Cables-Cause and Prevention. IEEE Trans. Power Appar. Syst. 1972, 91, 1354–1360. [Google Scholar] [CrossRef]

- Tanaka, T.; Fukuda, T.; Suzuki, S.; Nitta, Y.; Goto, H.; Kubota, K. Water Trees in crosslinked Polyethylene Power Cables. IEEE Trans. Power Appar. Syst. 1974, PAS-93, 693–702. [Google Scholar] [CrossRef]

- Wojtas, S. Investigations of Polyethylene Insulation Resistivity of Power Cables. In Proceedings of the International Conference on Polymer Insulated Power Cables (Jicable), Paris, France, 21–25 September 1987; pp. 436–440. [Google Scholar]

- Radu, I.; Acedo, M.; Notingher, P.; Frutos, F.; Filippini, J.C. A Study on the Dependence of Water Tree Permittivity with Time. In Proceedings of the Annual Report of the Conference on Electrical Insulation and Dielectric Phenomena (ICSD), San Francisco, CA, USA, 20–23 October 1996; pp. 762–765. [Google Scholar]

- Stucki, F.; Schönenberger, A. Dielectric Properties on Single Water Trees. In Proceedings of the 4th International Conference on Conduction and Breakdown in Solid Dielectrics (ICSD), Sestri Levante, Italy, 22–25 June 1992; pp. 373–377. [Google Scholar]

- Bouzerara, R. Effet de la Température sur la Dégradation du Polyéthylène par le Phénomène d’arborescences d’eau. Ph.D. Thesis, Université Joseph Fourier (UJF), Grenoble, France, 1989. [Google Scholar]

- Densley, J. Ageing and diagnostics in extruded insulations for power cables. In Proceedings of the 5th International Conference on Conduction and Breakdown in Solid Dielectrics (ICSD), Leicester, UK, 10–13 July 1995; pp. 1–15. [Google Scholar]

- Castellani, L.; Peruzzotti, F.; Zaopo, A.; Cinquemani, P.L.; Foulger, S.; Filippini, J.C.; Lachevre, V. Water Treeing Retardant Materials for Cable Insulators. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Minneapolis, MN, USA, 19–22 October 1997; pp. 1–4. [Google Scholar]

- Castellani, L.; Perozzotti, F.; Zaopo, A.; Cinquemani, P.L.; Foulger, S.; Filippini, J.C.; Lachêvre, V. Evaluation of Materials for WTR-insulated Power Cables. IEEE Trans. Dielectr. Electr. Insul. 2000, 7, 818–824. [Google Scholar] [CrossRef]

- Wen, Y.; Foulger, S.H.; Cinquemani, P.L.; Peruzzotti, F.; Zaopo, A. Development and testing of medium voltage power cables with water treeing retardant materials. In Proceedings of the IEEE International Symposium on Electrical Insulation, Arlington, VA, USA, 7–10 June 1998; pp. 534–537. [Google Scholar]

- Faremo, H.; Ildstad, E. The EFI test method for accelerated growth of water trees. In Proceedings of the IEEE International Symposium on Electrical Insulation, Toronto, ON, Canada, 3–6 June 1990; pp. 191–194. [Google Scholar]

- Hui, L.; Smith, R.; Nelson, J.K.; Schadler, L.S. Electrochemical Treeing in XLPE/silica Nanocomposites. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Virginia Beach, VA, USA, 18–21 October 2009; pp. 511–514. [Google Scholar]

- Ashcraft, A.C. Treeing Update-Part III: Water Treeing in Polymeric Dielectrics. In Proceedings of the World Electrotechnical Congress, Moscow, Russia, 22 June 1977. [Google Scholar]

- Huang, X.; Ma, Z.; Jiang, P.; Kim, C.; Liu, F.; Wang, G.; Zhang, J. Influence of Silica Nanoparticle Surface Treatments on the Water Treeing Characteristics of Low Density Polyethylene. In Proceedings of the IEEE 9th International Conference on Properties and Applications of Dielectric Materials (ICPADM), Harbin, China, 19–23 July 2009; pp. 757–760. [Google Scholar]

- Huang, X.; Liu, F.; Jiang, P. Effect of Nanoparticle Surface Treatment on Morphology, Electrical and Water Treeing Behavior of LLDPE Composites. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1697–1704. [Google Scholar] [CrossRef]

- Li, X.; Xu, M.; Liu, X.; Xie, D.; Darong, X. Study of Montmorillonite on Morphology and Water Treeing Behavior in Crosslinking Polyethylene. In Proceedings of the International Conference on Electrical Insulating Materials (ISEIM), Kyoto, Japan, 6–10 September 2011; pp. 205–208. [Google Scholar]

- Huang, X.Y.; Kim, C.; Jiang, P.K.; Yin, Y.; Li, Z. Influence of aluminum nanoparticle surface treatment on the electrical properties of polyethylene composites. J. Appl. Phys. 2009, 105, 014105:1–014105:10. [Google Scholar] [CrossRef]

- Fan, Z.H.; Yoshimura, N. The influence of crystalline morphology on the growth of water trees in PE. IEEE Trans. Dielectr. Electr. Insul. 1996, 3, 849–858. [Google Scholar] [CrossRef]

- Green, C.; Vaughan, A. Nanodielectrics—How Much Do We Really Understand? IEEE Electr. Insul. Mag. 2008, 24, 6–16. [Google Scholar] [CrossRef]

- Guo, M.; Fréchette, M.; David, E.; Demarquette, N.R. Influence of fabrication techniques on the dielectric properties of PE/POSS polymeric composites. In Proceedings of the IEEE Electrical Insulation Conference (EIC), Montreal, QC, Canada, 19–22 June 2016; pp. 297–300. [Google Scholar]

- Huang, X.; Jiang, P.; Tanaka, T. A review of dielectric polymer composites with high thermal conductivity. IEEE Electr. Insul. Mag. 2011, 27, 8–16. [Google Scholar] [CrossRef]

- Roy, M.; Reed, C.W.; MacCrone, R.K.; Schadler, L.S.; Nelson, J.K.; Keefe, R.; Zenger, W. Evidence for the role of the interface in polyolefin nanocomposites. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Kitakyushu, Japan, 5–9 June 2005; pp. 223–226. [Google Scholar]

- Reading, M.; Vaughan, A.S. Comparison of rheological, thermal and electrical properties of poly(ethylene oxide) composites with micro and nano sized silicon dioxide filler. In Proceedings of the 10th IEEE International Conference on Solid Dielectrics (ICSD), Potsdam, Germany, 4–9 July 2010; pp. 1–4. [Google Scholar]

- Artbauer, J. Electric strength of polymers. J. Phys. D Appl. Phys. 1996, 29, 446–456. [Google Scholar] [CrossRef]

- Lewis, T.J. Interfaces are the Dominant Feature of Dielectrics at the Nanometric Level. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 739–753. [Google Scholar] [CrossRef]

- Nelson, J.K.; Huan, Y.; Krentz, T.M.; Schadler, L.S.; Dryzek, J.; Benicewicz, B.C.; Bell, M. Free volume in nanodielectrics. In Proceedings of the IEEE 11th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), Sydney, Australia, 19–22 July 2015; pp. 40–43. [Google Scholar]

- Lau, K.Y.; Vaughan, A.S.; Chen, G.; Hosier, I.L. Polyethylene nanodielectrics: The effect of nanosilica and its surface treatment on electrical breakdown strength. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Montreal, QC, Canada, 14–17 October 2012; pp. 21–24. [Google Scholar]

- IEEE Std. 930-2004. IEEE Guide for the Statistical Analysis of Electrical Insulation Breakdown Data; IEEE: Piscataway, NJ, USA, 2005; pp. 1–41. [Google Scholar]

- Virtanen, S.; Vaughan, A.S.; Yang, L.; Saiz, F.; Quirke, N. Dielectric breakdown strength and electrical conductivity of low density polyethylene octylnanosilica composite. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 58–61. [Google Scholar]

- Wang, W.; Li, S.; Tang, F.; Li, J. Characteristics on Breakdown Performance of Polyethylene/Silica Dioxide Nanocomposites. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Montreal, QC, Canada, 14–17 October 2012; pp. 521–524. [Google Scholar]

- Guastavino, F.; Ratto, A.; Torello, E.; Hoyos, M.; Garcia, N.; Reinecke, H.; Benito, E.; Tiemblo, P. AC electrical strength measurements on LDPE nanocomposites. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Kansas City, MO, USA, 15–18 October 2006; pp. 329–332. [Google Scholar]

- Green, C.D.; Vaughan, A.S.; Mitchell, G.R.; Liu, T. Structure Property Relationships in Polyethylene/Montmorillonite Nanodielectrics. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 134–143. [Google Scholar] [CrossRef]

- Vaughan, A.S.; Green, C.D.; Zhang, Y.; Chen, G. Nanocomposites for high voltage applications: EFFECT of sample preparation on AC breakdown statistics. In Proceedings of the Annual Report Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Nashville, TN, USA, 16–19 October 2005; pp. 732–735. [Google Scholar]

- Vaughan, A.S.; Swingler, S.G.; Zhang, Y. Polyethylene nanodielectrics: The influence of nanoclays on structure formation and dielectric breakdown. IEEJ Trans. Fundam. Mater. 2006, 126, 1057–1063. [Google Scholar] [CrossRef]

- Shah, K.S.; Jain, R.C.; Shrinet, V.; Singh, A.K.; Bharambe, D.P. High Density Polyethylene (HDPE) Clay Nanocomposite for Dielectric Applications. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 853–861. [Google Scholar] [CrossRef]

- Guo, M.; David, É.; Fréchette, M.; Demarquette, N.R. Low-density polyethylene/polyhedral oligomeric silsesquioxanes composites obtained by extrusion. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Toronto, ON, Canada, 16–19 October 2016; pp. 647–650. [Google Scholar]

- Reddy, C.C.; Gosyowaki, M.; Murata, Y.; Sekiguchi, Y. Superior thermal breakdown performance of MgO-LDPE nanocomposite materials for HVDC insulation. In Proceedings of the International Symposium on Electrical Insulating Materials (ISEIM), Yokkaichi, Japan, 7–11 September 2008; pp. 661–664. [Google Scholar]

- Reddy, C.C.; Ramu, T.S. Polymer Nanocomposites as Insulation for HV DC Cables—Investigations on the Thermal Breakdown. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 221–227. [Google Scholar] [CrossRef]

- Ma, D.; Siegel, R.W.; Hong, J.-I.; Schadler, L.S.; Mårtensson, E.; Önneby, C. Influence of nanoparticle surfaces on the electrical breakdown strength of nanoparticle-filled low-density polyethylene. J. Mater. Res. 2004, 19, 857–863. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, C.; Zhang, Z.; Xiao, K. Anti-thermal Aging Properties of Low-Density Polyethylene-Based Nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1003–1013. [Google Scholar] [CrossRef]

- Esthappan, K.S.; Kuttappan, K.S.; Josepha, R. Effect of titanium dioxide on the thermal ageing of polypropylene. Polym. Degrad. Stab. 2012, 97, 615–620. [Google Scholar] [CrossRef]

| Origin | Selected Examples of Nanofillers | |

|---|---|---|

| natural | animal | silk, wool, hair |

| mineral | asbestos | |

| cellulose | wood, seed, leaf, fruit, stalk, bast | |

| synthetic | inorganic | oxides: TiO2, SiO2, Al2O3, ZnO, MgO, Sb2O3 |

| hydroxides: Al(OH)3, Mg(OH)2 | ||

| metals: Al, Au, Ag, B, Sn, Cu, steel | ||

| silicates: talc, mica, nanoclay, kaolin | ||

| salts: CaCO3, BaSO4, CaSO4 | ||

| carbides: SiC nitrides: AlN, BN | ||

| organic | carbon based materials: graphite fibers, nanotubes, carbon black, graphene | |

| natural polymers: cellulose and wood fibers, cotton, flax, starch | ||

| synthetic polymers: aramid, polyester, polyamide, poly(vinyl alcohol) fibers | ||

| Nanocomposite (Type of Filler) | Filler Content (wt %) | DC Relative Resistivity |

|---|---|---|

| Pure LDPE | 0 | 1 |

| LDPE/nano-SiO2 | 2 | 0.54 |

| LDPE/nano-Al2O3 | 2 | 0.16 |

| LDPE/nano-TiO2 | 2 | 1.07 |

| LDPE/nano-TiO2 | 5 | 0.33 |

| MgO content (wt %) | 0 | 1 | 2 | 5 | 8 | 102 |

| Tree length (μm) | 118 | 76 | 66 | 77 | 62 | 55 |

| MgO content (wt %) | 0 | 0.2 | 0.4 | 0.5 | 0.8 | 1 |

| Tree Inception Voltage (kVrms) | 2.65 | 2.73 | 2.93 | 3.09 | 3.13 | 3.16 |

| Nanocomposites | Sample Thickness (mm) | Ubd (kV) | Ebd (kV·mm−1) | A (%) |

|---|---|---|---|---|

| Unfilled LDPE | 0.51 | 23.304 | 45.694 | 4.42 |

| LDPE/nano-SiO2–2 wt % | 0.59 | 23.565 | 39.941 | 2.36 |

| LDPE/nano-Al2O3–2 wt % | 0.55 | 22.439 | 42.616 | 4.16 |

| LDPE/nano-SiO2–5 wt % | 0.55 | 21.820 | 39.673 | 12.46 |

| LDPE/nano-Al2O3–5 wt % | 0.53 | 21.273 | 40.138 | 8.37 |

| LDPE/nano-TiO2–5 wt % | 0.54 | 20.995 | 38.879 | 2.37 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite