Layer-Structured Design and Fabrication of Cyanate Ester Nanocomposites for Excellent Electromagnetic Shielding with Absorption-Dominated Characteristic

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

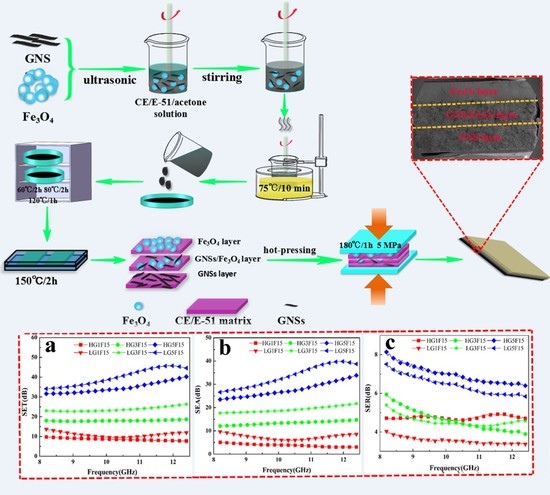

2.2. Preparation of Layer-Structured GNSs/Fe3O4/CE Nanocomposite

2.3. Characterization

3. Results

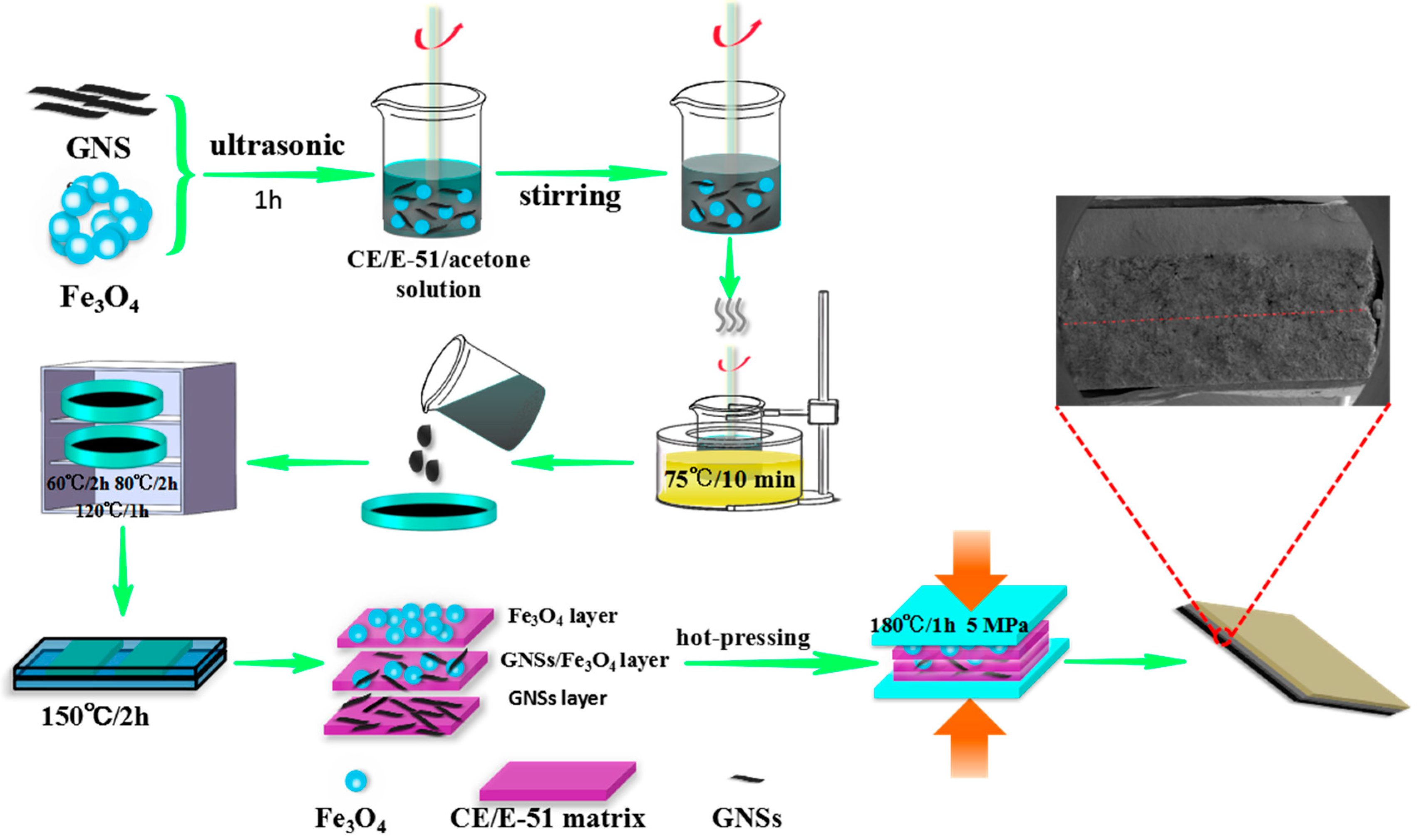

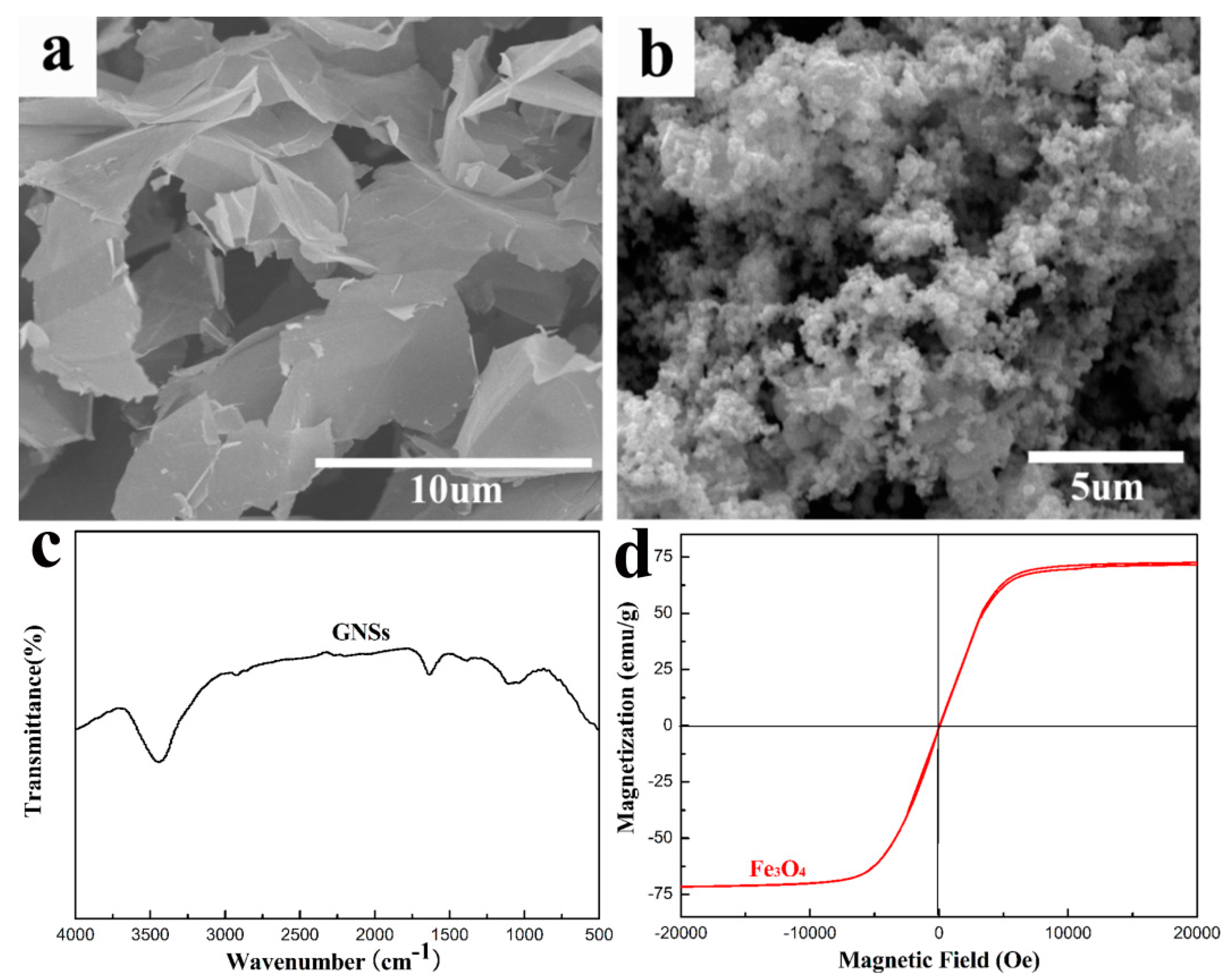

3.1. Structural Characterization

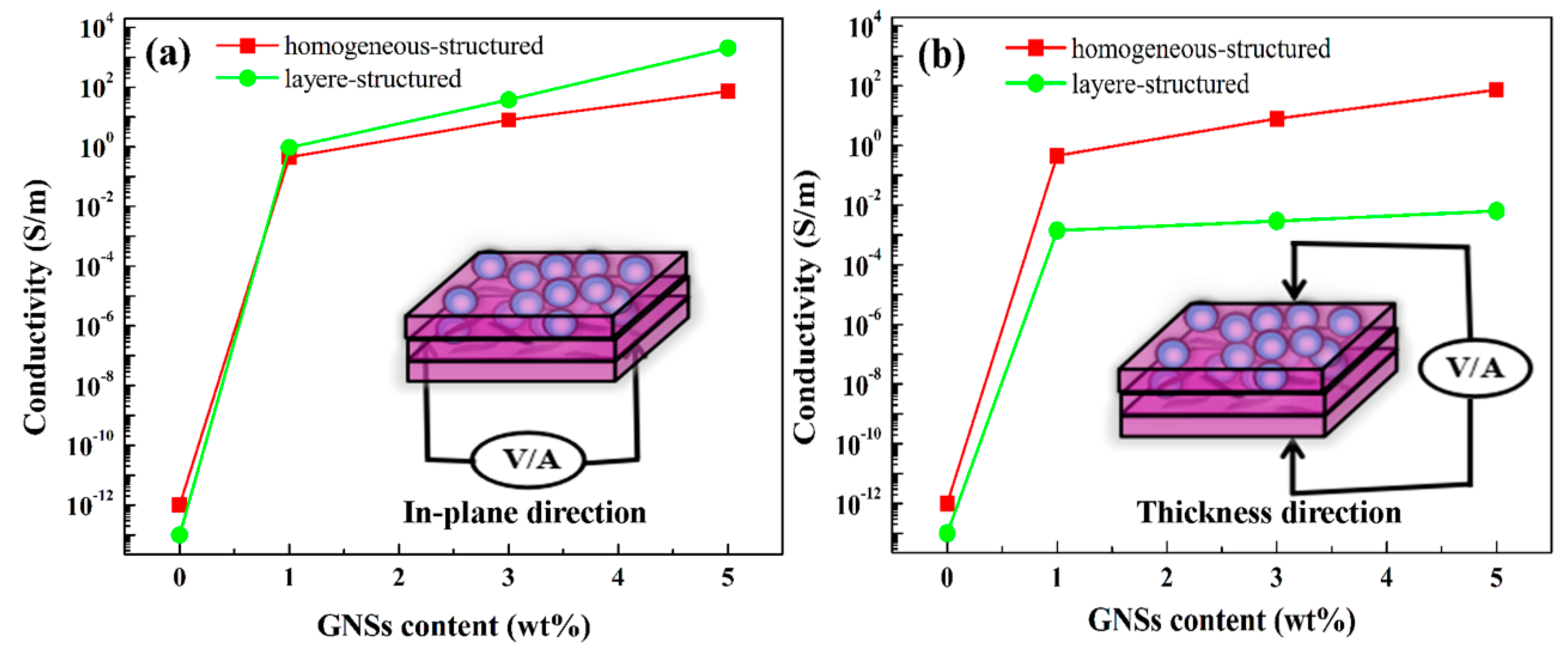

3.2. Electrical Property of Nanocomposites

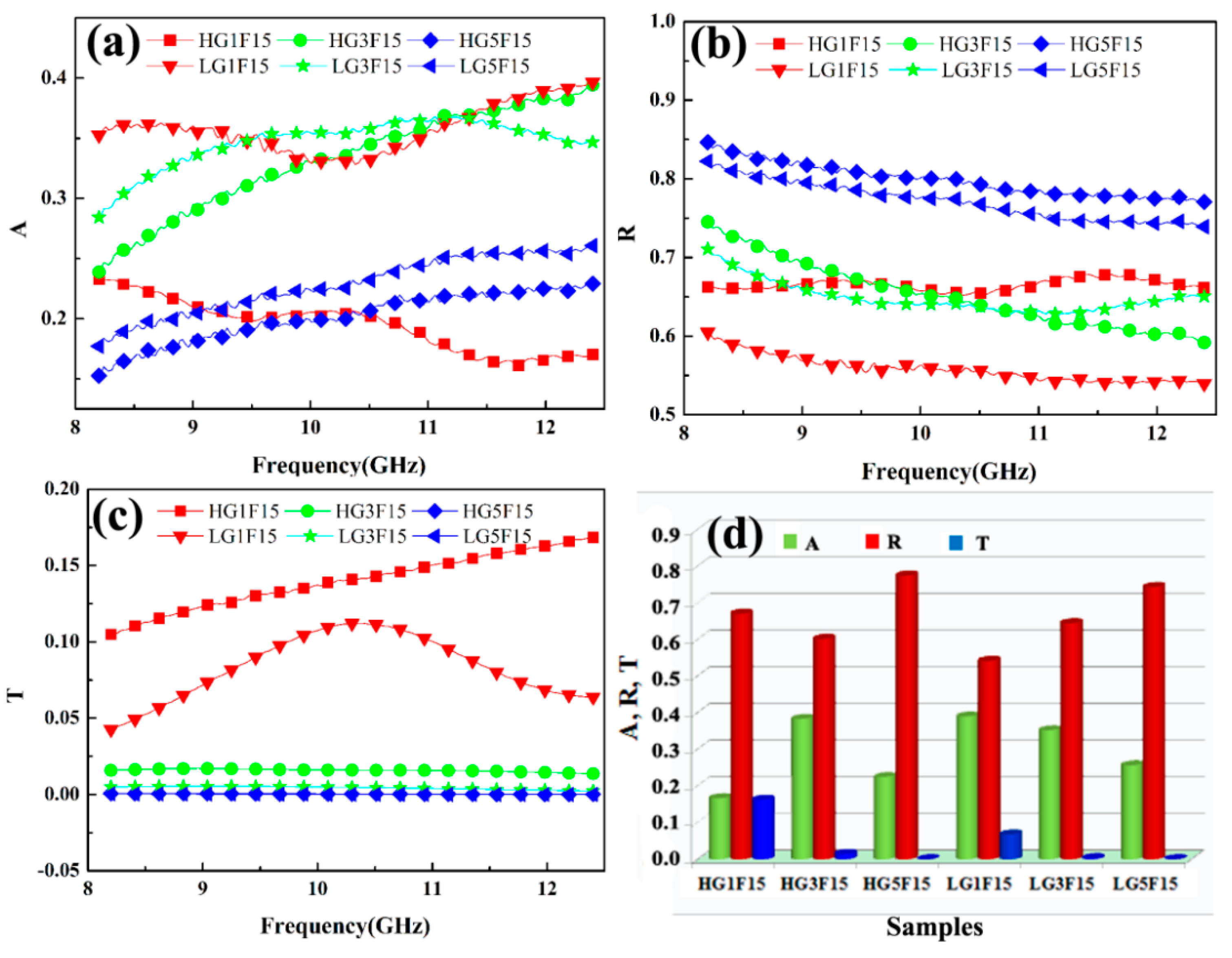

3.3. EMI Shielding Performance of Nanocomposite

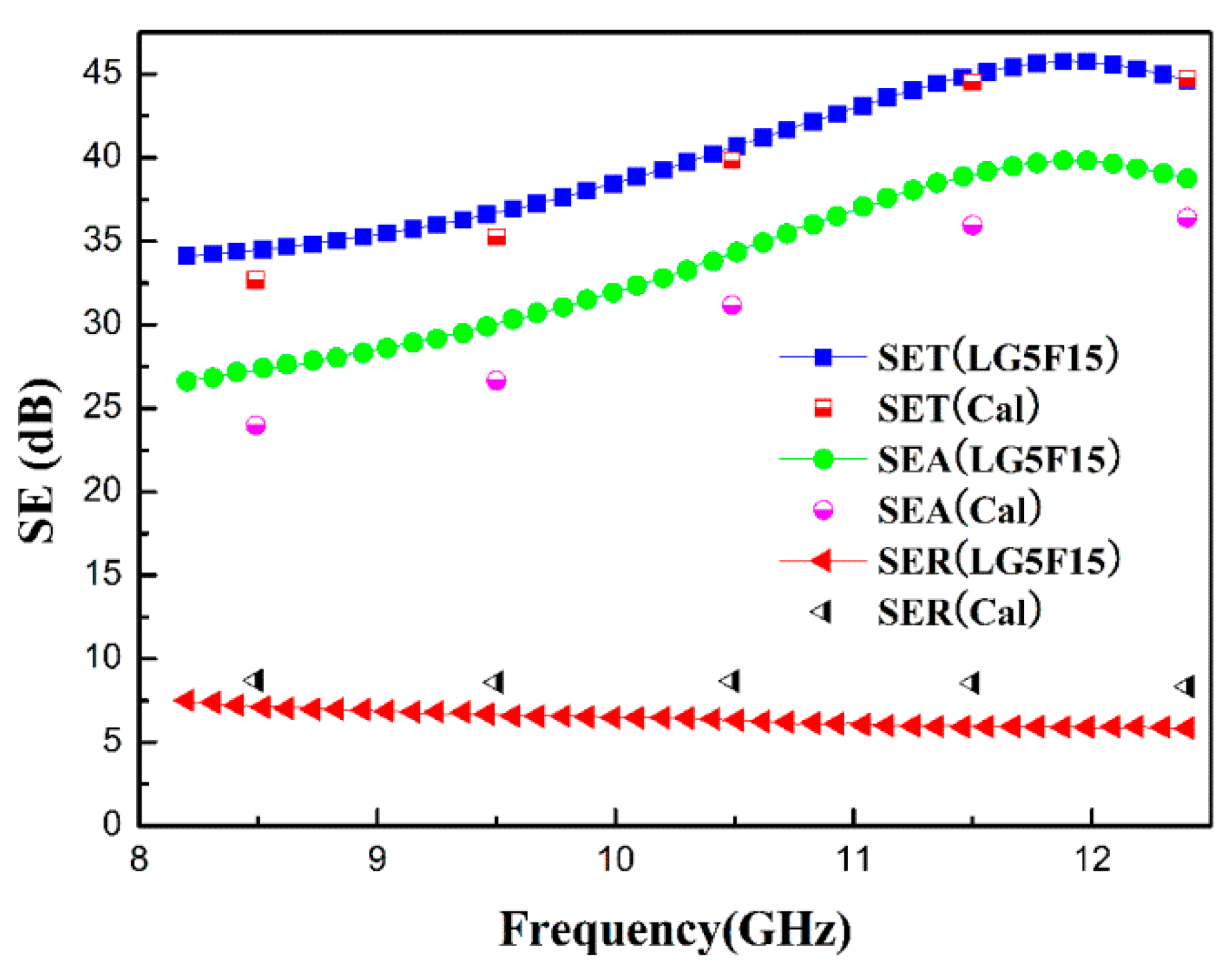

3.4. Theoretical Simulation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Kumar, P.; Shahzad, F.; Yu, S.; Hong, S.M.; Kim, Y.; Koo, C.M. Large-area reduced graphene oxide thin film with excellent thermal conductivity and electromagnetic interference shielding effectiveness. Carbon 2015, 94, 494–500. [Google Scholar] [CrossRef]

- Sabira, K.; Jayakrishnan, M.P.; Saheeda, P.; Jayalekshmi, S. On the absorption dominated EMI shielding effects in free standing and flexible films of poly (vinylidene fluoride)/graphene nanocomposite. Eur. Polym. J. 2017, 99, 437–444. [Google Scholar] [CrossRef]

- Yang, H.; Yu, Z.; Wu, P.; Zou, H.; Liu, P. Electromagnetic interference shielding effectiveness of microcellular polyimide/in situ thermally reduced graphene oxide/carbon nanotubes nanocomposites. Appl. Surf. Sci. 2018, 434, 318–325. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, X.; Yang, M.; Yang, S.; Wu, H.; Guo, S.; Wang, Y. Ordered multilayer film of (graphene oxide/polymer and boron nitride/polymer) nanocomposites: An ideal EMI shielding material with excellent electrical insulation and high thermal conductivity. Compos. Sci. Technol. 2016, 136, 104–110. [Google Scholar] [CrossRef]

- Ebrahimi, I.; Gashti, M.P. Corrigendum to “Polypyrrole-MWCNT-Ag composites for electromagnetic shielding: Comparison between chemical deposition and UV-reduction approaches”. Phys. Chem. Solids 2018, 118, 80–87. [Google Scholar] [CrossRef]

- Jia, L.C.; Yan, D.X.; Liu, X.; Ma, R.; Wu, H.Y.; Li, Z.M. Highly efficient and reliable transparent electromagnetic interference shielding film. ACS Appl. Mater. Interface 2018, 10, 11941–11949. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.P.; Mishra, M.; Hashim, D.P.; Narayanan, T.N.; Hahm, M.G.; Kumar, P.; Dwivedi, J.; Kedawat, G.; Gupta, A.; Singh, B.P.; Chandra, A.; et al. Probing the engineered sandwich network of vertically aligned carbon nanotube–reduced graphene oxide composites for high performance electromagnetic interference shielding applications. Carbon 2015, 85, 79–88. [Google Scholar] [CrossRef]

- Jia, L.C.; Yan, D.X.; Cui, C.H.; Jiang, X.; Ji, X.; Li, Z.M. Electrically conductive and electromagnetic interference shielding of polyethylene composites with devisable carbon nanotube networks. J. Mater. Chem. C 2015, 3, 9369–9378. [Google Scholar] [CrossRef]

- Qing, Y.; Min, D.; Zhou, Y.; Luo, F.; Zhou, W. Graphene nanosheet and flake carbonyl iron particle-filled epoxy–silicone composites as thin–thickness and wide-bandwidth microwave absorber. Carbon 2015, 86, 98–107. [Google Scholar] [CrossRef]

- Zeng, Z.; Jin, H.; Chen, M.; Li, W.; Zhang, Z. Lightweight and anisotropic porous MWCNT/WPU composites for ultrahigh performance electromagnetic interference shielding. Adv. Funct. Mater. 2016, 26, 303–310. [Google Scholar] [CrossRef]

- Jia, L.C.; Yan, D.X.; Yang, Y.; Zhou, D.; Cui, C.H.; Bianco, E.; Lou, J.; Vajtai, R.; Li, B.; Ajayan, P.M.; et al. High strain tolerant EMI shielding using carbon nanotube network stabilized rubber composite. Adv. Mater. Technol. 2017, 2, 1700078. [Google Scholar] [CrossRef]

- Jing, Q.; Jia, Y.L.; Tan, L.P.; Silberschmidt, V.V.; Li, L.; Dong, Z.L. Preparation, characterization and properties of polycaprolactone diol-functionalized multi-walled carbon nanotube/thermoplastic polyurethane composite. Compos. Part A Appl. Sci. Manuf. 2015, 70, 8–15. [Google Scholar] [CrossRef] [Green Version]

- Jia, L.C.; Jiao, Z.H.; Yan, D.X.; Li, Z.M. Octadecylamine-grafted graphene oxide helps the dispersion of carbon nanotubes in ethylene vinyl acetate. Polymers 2017, 9, 397. [Google Scholar] [CrossRef]

- Wu, H.Y.; Jia, L.C.; Yan, D.X.; Gao, J.F.; Zhang, X.P.; Ren, P.G.; Li, Z.M. Simultaneously improved electromagnetic interference shielding and mechanical performance of segregated carbon nanotube/polypropylene composite via solid phase molding. Compos. Sci. Technol. 2018, 156, 87–94. [Google Scholar] [CrossRef]

- Thomassin, J.M.; Jérôme, C.; Pardoen, T.; Pardoen, T.; Bailly, C.; Huynen, I.; Detrembleur, C. Polymer/carbon based composites as electromagnetic interference (EMI) shielding materials. Mater. Sci. Eng. R Rep. 2013, 74, 211–232. [Google Scholar] [CrossRef]

- Sun, X.; Hao, S.; Li, H.; Peng, H. developing polymer composite materials: Carbon nanotubes or graphene? Adv. Mater. 2013, 25, 5153–5176. [Google Scholar] [CrossRef] [PubMed]

- Che, R.C.; Peng, L.; Duan, X.F.; Chen, Q.; Liang, X.L. Microwave absorption enhancement and complex permittivity and permeability of fe encapsulated within carbon nanotubes. Adv. Mater. 2004, 16, 401–405. [Google Scholar] [CrossRef]

- Kim, S.S.; Kim, S.T.; Ahn, J.M.; Kim, K.H. Magnetic and microwave absorbing properties of Co-Fe thin films plated on hollow ceramic microspheres of low density. J. Magn. Magn. Mater. 2004, 271, 39–45. [Google Scholar] [CrossRef]

- Lin, S.C.; Ma, C.C.M.; Hsiao, S.T.; Wang, Y.S.; Yang, C.Y.; Liao, W.H.; Li, S.M.; Wang, J.A.; Cheng, T.Y.; Lin, C.W.; et al. Electromagnetic interference shielding performance of waterborne polyurethane composites filled with silver nanoparticles deposited on functionalized graphene. Appl. Surf. Sci. 2016, 385, 436–444. [Google Scholar] [CrossRef]

- Liu, Y.; Zeng, J.; Han, D.; Wu, K.; Chai, S.; Chen, F.; Fu, Q. Graphene enhanced flexible expanded graphite film with high electric, thermal conductivities and EMI shielding at low content. Carbon 2018, 133, 435–445. [Google Scholar] [CrossRef]

- Ren, F.; Song, D.P.; Li, Z.; Jia, L.C.; Zhao, Y.; Yan, D.Y.; Ren, P.G. Synergistic effect of graphene nanosheets and carbonyl iron nickel alloy hybrid fillers on electromagnetic interference shielding and thermal conductivity of cyanate ester composites. J. Mater. Chem. C 2018, 6, 1476–1486. [Google Scholar] [CrossRef]

- Chen, Z.; Ren, W.; Gao, L.; Liu, B.; Pei, S.; Cheng, H.M. Three-dimensional flexible and conductive interconnected graphene networks grown by chemical vapour deposition. Nat. Mater. 2011, 10, 424–428. [Google Scholar] [CrossRef] [PubMed]

- Gui, X.; Li, H.; Zhang, L.; Jia, Y.; Liu, L.; Li, Z. A facile route to isotropic conductive nanocomposites by direct polymer infiltration of carbon nanotube sponges. ACS Nano 2011, 5, 4276–4283. [Google Scholar] [CrossRef] [PubMed]

- Song, W.L.; Cao, M.S.; Lu, M.M.; Bi, S.; Wang, C.Y.; Liu, J. Flexible graphene/polymer composite films in sandwich structures for effective electromagnetic interference shielding. Carbon 2014, 66, 67–76. [Google Scholar] [CrossRef]

- Micheli, D.; Vricella, A.; Pastore, R.; Delfini, A.; Morles, R.B.; Marchetti, M.; Santoni, F.; Bastianelli, L.; Moglie, F.; Primiani, V.M.; et al. Electromagnetic properties of carbon nanotube reinforced concrete composites for frequency selective shielding structures. Constr. Build. Mater. 2017, 131, 267–277. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, F.Q.; Ni, L.J.; Liang, K.; Marcus, K.; Liu, S.L. Easily fabricated and lightweight PPy/PDA/AgNW composites for excellent electromagnetic interference shielding. Nanoscale 2017, 9, 18318–18325. [Google Scholar] [CrossRef] [PubMed]

- Jia, L.C.; Yan, D.X.; Cui, C.; Ji, X.; Li, Z.M. A unique double percolated polymer composite for highly efficient electromagnetic interference shielding. Macromol. Mater. Eng. 2016, 301, 1232–1241. [Google Scholar] [CrossRef]

- Kim, S.; Oh, J.S.; Kim, M.G.; Jang, W.; Wang, M.; Kim, Y. Electromagnetic interference (EMI) transparent shielding of reduced graphene oxide (RGO) interleaved structure fabricated by electrophoretic deposition. ACS Appl. Mater. Interface 2014, 6, 17647–17653. [Google Scholar] [CrossRef] [PubMed]

- Jia, L.C.; Li, Y.K.; Yan, D.X. Flexible and efficient electromagnetic interference shielding materials from ground tire rubber. Carbon 2017, 121, 267–273. [Google Scholar] [CrossRef]

- Yuen, S.M.; Ma, C.C.M.; Chuang, C.Y.; Yu, K.C.; Wu, S.Y.L.; Yang, C.C.; Wei, M.H. Effect of processing method on the shielding effectiveness of electromagnetic interference of MWCNT/PMMA composites. Compos. Sci. Technol. 2008, 68, 963–968. [Google Scholar] [CrossRef]

- Hu, M.; Gao, J.; Dong, Y.; Li, K.; Shan, G.; Yang, S. Flexible transparent PES/silver nanowires/PET sandwich-structured film for high-efficiency electromagnetic interference shielding. Langmuir 2012, 28, 7101–7106. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Hou, L.; Bi, S.; Lu, Y. Enhanced X-band electromagnetic-interference shielding performance of layer-structured fabric-supported Polyaniline/Cobalt-Nickel coatings. ACS Appl. Mater. Interface 2017, 9, 33059–33070. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.Q.; Yang, B.; Teng, J.; Lei, J.; Yan, D.X.; Zhong, G.J. Tunable electromagnetic interference shielding effectiveness via multilayer assembly of regenerated cellulose as a supporting substrate and carbon nanotubes/polymer as a functional layer. J. Mater. Chem. C 2017, 5, 3130–3138. [Google Scholar] [CrossRef]

- Joo, J.; Lee, C.Y. High frequency electromagnetic interference shielding response of mixtures and multilayer films based on conducting polymers. J. Appl. Phys. 2000, 88, 513–518. [Google Scholar] [CrossRef]

- Shailaja, P.; Singh, B.P.; Mathur, R.B.; Dhami, T.L.; Saini, P.; Dhawan, S.K. Improved electromagnetic interference shielding properties of MWCNT-PMMA composites using layered structures. Nanoscale Res. Lett. 2009, 4, 327–334. [Google Scholar]

- Xu, Y.; Yang, Y.; Yan, D.X.; Duan, H.; Zhao, Z.; Liu, Y. Gradient structure design of flexible waterborne polyurethane conductive films for ultraefficient electromagnetic shielding with low reflection characteristic. ACS Appl. Mater. Interface 2018, 10, 19143–19152. [Google Scholar] [CrossRef] [PubMed]

- Guan, D.G.; Huang, W.X.; Mao, J.; Jiang, Y.; Chen, J.Z.; Ming-Jing, T.U. Study on shielding functionally gradient materials with low reflection loss and high absorption loss for electromagnetic wave. J. Funct. Mater. 2003, 2, 1259–1262. [Google Scholar]

- Shui, X.; Chung, D.D.L. Nickel filament polymer-matrix composites with low surface impedance and high electromagnetic interference shielding effectiveness. J. Electron. Mater. 1997, 26, 928–934. [Google Scholar] [CrossRef]

- Yun, J.; Ji, S.I.; Lee, Y.S.; Kim, H.I. Effect of oxyfluorination on electromagnetic interference shielding behavior of MWCNT/PVA/PAAc composite microcapsules. Eur. Polym. J. 2010, 46, 900–909. [Google Scholar] [CrossRef]

- Bose, S.; Sharma, M.; Bharati, A.; Moldenaers, P.; Cardinaels, R. A strategy to achieve enhanced electromagnetic interference shielding at ultra-low concentration of multiwall carbon nanotubes in PαMSAN/PMMA blends in the presence of a random copolymer PS-r-PMMA. RSC Adv. 2016, 6, 26959–26966. [Google Scholar] [CrossRef]

- Song, J.; Yuan, Q.; Zhang, H. Elevated conductivity and electromagnetic interference shielding effectiveness of PVDF/PETG/carbon fiber composites through incorporating carbon black. J. Polym. Res. 2015, 22, 158. [Google Scholar] [CrossRef]

- Lee, C.Y.; Song, H.G.; Jang, K.S.; Oh, E.J.; Epstein, E.J.; Joo, J. Electromagnetic interference shielding efficiency of polyaniline mixtures and multilayer films. Synth. Met. 1999, 102, 1346–1349. [Google Scholar] [CrossRef]

- Li, Y.; Shen, B.; Yi, D.; Zhang, L.; Zhai, W.; Wei, X.; Zheng, W. The influence of gradient and sandwich configurations on the electromagnetic interference shielding performance of multilayered thermoplastic polyurethane/graphene composite foams. Compos. Sci. Technol. 2017, 138, 209–216. [Google Scholar] [CrossRef]

- Ren, F.; Zhu, G.; Ren, P.G. Cyanate ester resin filled with graphene nanosheets and CoFe2O4-reduced graphene oxide nanohybrids as a microwave absorber. Appl. Surf. Sci. 2015, 351, 40–47. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, Y.; Jin, J.; Song, M. A comparative study on the effect of carbon fillers on electrical and thermal conductivity of a cyanate ester resin. Polym. Test. 2017, 60, 293–298. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Liang, G.; Jiao, Y.; Gu, A.; Liu, L.; Yuan, L.; Zhang, W. Two-layer materials of polyethylene and a carbon nanotube/cyanate ester composite with high dielectric constant and extremely low dielectric loss. Carbon 2013, 54, 224–233. [Google Scholar] [CrossRef]

- Chao, F.; Bowler, N.; Tan, X.L.; Liang, G.Z.; Kessler, M.R. Influence of adsorbed moisture on the properties of BaTiO3/cyanate ester composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1266–1271. [Google Scholar] [CrossRef]

- Wooster, T.J.; Abrol, S.; Hey, J.M.; MacFarlane, D.R. Thermal, mechanical, and conductivity properties of cyanate ester composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 75–82. [Google Scholar] [CrossRef]

- Gupta, T.K.; Singh, B.P.; Dhakate, S.R.; Singh, V.N.; Mathur, R.B. Improved nanoindentation and microwave shielding properties of modified MWCNT reinforced polyurethane composites. J. Mater. Chem. A 2013, 1, 9138–9149. [Google Scholar] [CrossRef]

- Zhou, E.; Xi, J.; Guo, Y.; Liu, Y.; Xu, Z.; Li, P.; Gao, W.; Ying, J.; Chen, Z.; Gao, C. Synergistic effect of graphene and carbon nanotube for high-performance electromagnetic interference shielding films. Carbon 2018, 133, 316–322. [Google Scholar] [CrossRef]

- Zhu, Z.; Sun, X.; Xue, H.; Guo, H.; Fan, X.; Pan, X. Graphene-carbonyl iron cross-linked composites with excellent electromagnetic wave absorption properties. J. Mater. Chem. C 2014, 2, 6582–6591. [Google Scholar] [CrossRef]

- Zhang, H.; Han, H.; Xu, X. Dynamic and regional constructive electromagnetic protecting materials made by MWNT/Fe3O4/poly pyrrole doped vitrimers. Compos. Sci. Technol. 2018, 158, 61–66. [Google Scholar] [CrossRef]

- Kong, J.A. Electromagnetic Wave Theory; John Wiley & Sons: New York, NY, USA, 1986. [Google Scholar]

- Micheli, D.; Pastore, R.; Vricella, A.; Marchetti, M. Matter’s electromagnetic signature reproduction by graded-dielectric multilayer assembly. IEEE Trans. Microw. Theory Tech. 2017, 65, 2801–2809. [Google Scholar] [CrossRef]

| Sample Name | Structures | Total Fillers | Fillers Distribution in Each Layer | Thickness |

|---|---|---|---|---|

| HG1F15 | Homogeneous-structured | 1 wt % GNSs + 15 wt % Fe3O4 | ~ | 2 mm |

| HG3F15 | 3 wt % GNSs + 15 wt % Fe3O4 | ~ | ||

| HG5F15 | 5 wt % GNSs + 15 wt % Fe3O4 | ~ | ||

| LG1F15 | Layer-structured | 1 wt % GNSs + 15 wt % Fe3O4 | Initial: 30 wt % Fe3O4 | |

| Interlayer: 1 wt % GNSs + 15 wt % Fe3O4 | ||||

| Bottom: 2 wt % GNSs | ||||

| LG3F15 | 3 wt % GNSs + 15 wt % Fe3O4 | Initial: 30 wt % Fe3O4 | ||

| Interlayer: 3 wt % GNSs + 15 wt % Fe3O4 | ||||

| Bottom: 6 wt % GNSs | ||||

| LG5F15 | 5 wt % GNSs + 15 wt % Fe3O4 | Initial: 30 wt % Fe3O4 | ||

| Interlayer: 5 wt % GNSs + 15 wt % Fe3O4 | ||||

| Bottom: 10 wt % GNSs |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, F.; Guo, Z.-Z.; Guo, H.; Jia, L.-C.; Zhao, Y.-C.; Ren, P.-G.; Yan, D.-X. Layer-Structured Design and Fabrication of Cyanate Ester Nanocomposites for Excellent Electromagnetic Shielding with Absorption-Dominated Characteristic. Polymers 2018, 10, 933. https://doi.org/10.3390/polym10090933

Ren F, Guo Z-Z, Guo H, Jia L-C, Zhao Y-C, Ren P-G, Yan D-X. Layer-Structured Design and Fabrication of Cyanate Ester Nanocomposites for Excellent Electromagnetic Shielding with Absorption-Dominated Characteristic. Polymers. 2018; 10(9):933. https://doi.org/10.3390/polym10090933

Chicago/Turabian StyleRen, Fang, Zheng-Zheng Guo, Han Guo, Li-Chuan Jia, Yu-Chen Zhao, Peng-Gang Ren, and Ding-Xiang Yan. 2018. "Layer-Structured Design and Fabrication of Cyanate Ester Nanocomposites for Excellent Electromagnetic Shielding with Absorption-Dominated Characteristic" Polymers 10, no. 9: 933. https://doi.org/10.3390/polym10090933