Effect of Thermal Processing and Heat Treatment Condition on 3D Printing PPS Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

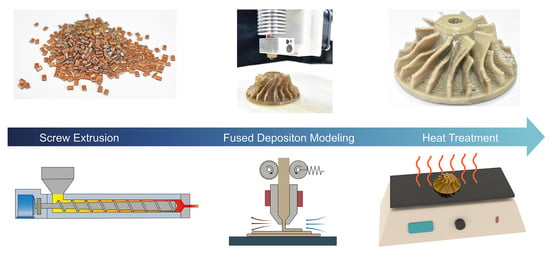

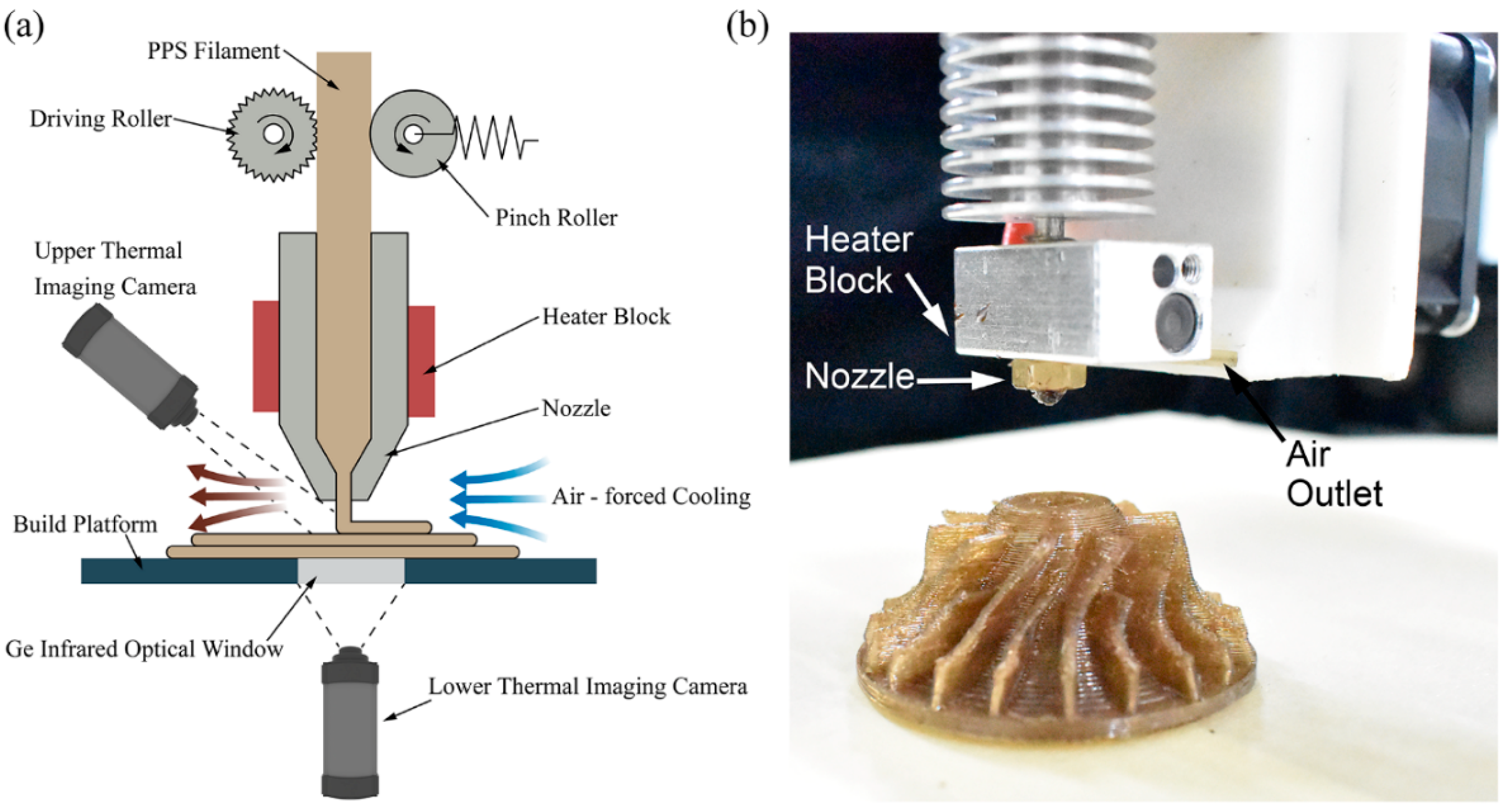

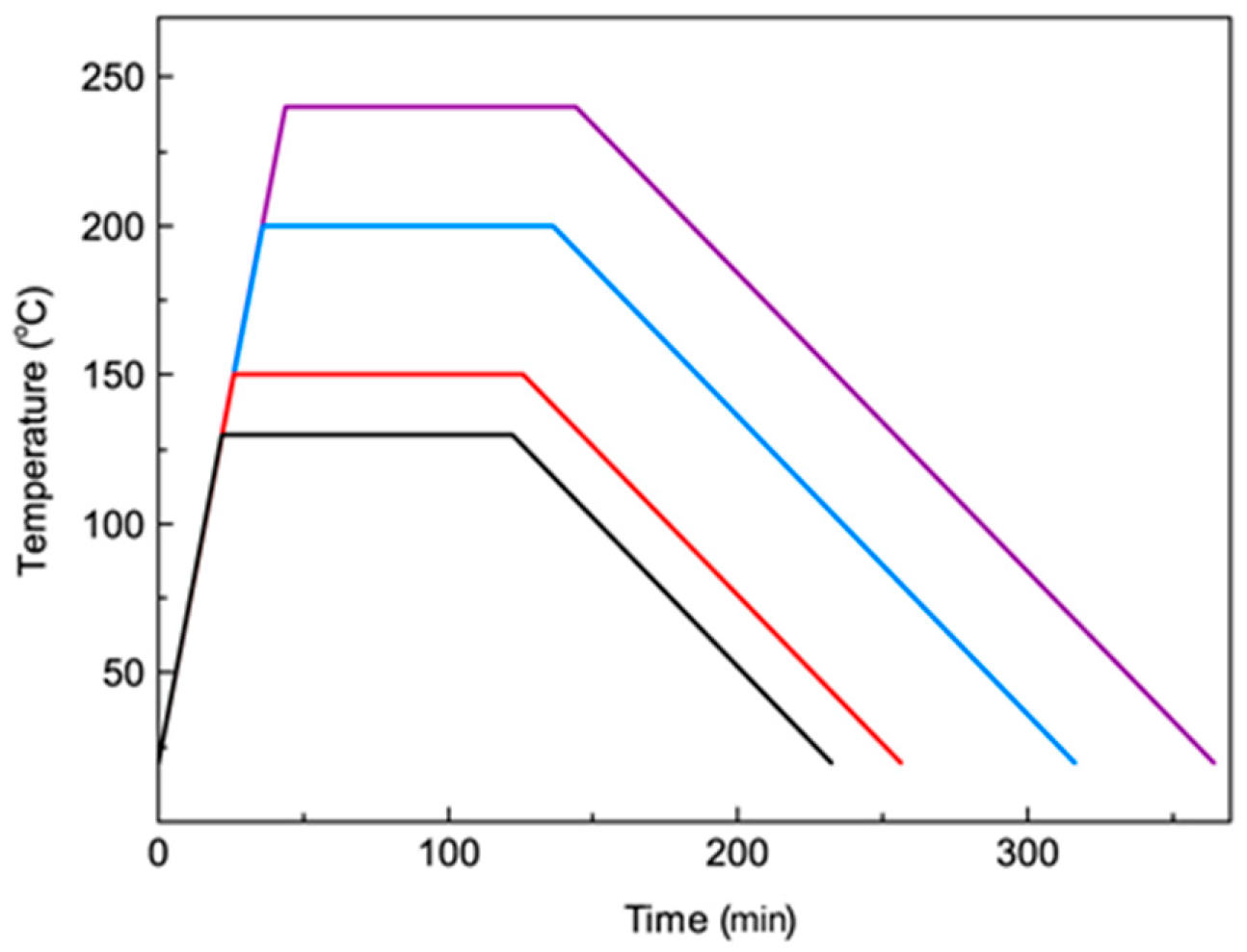

2.2. Experimental Procedure

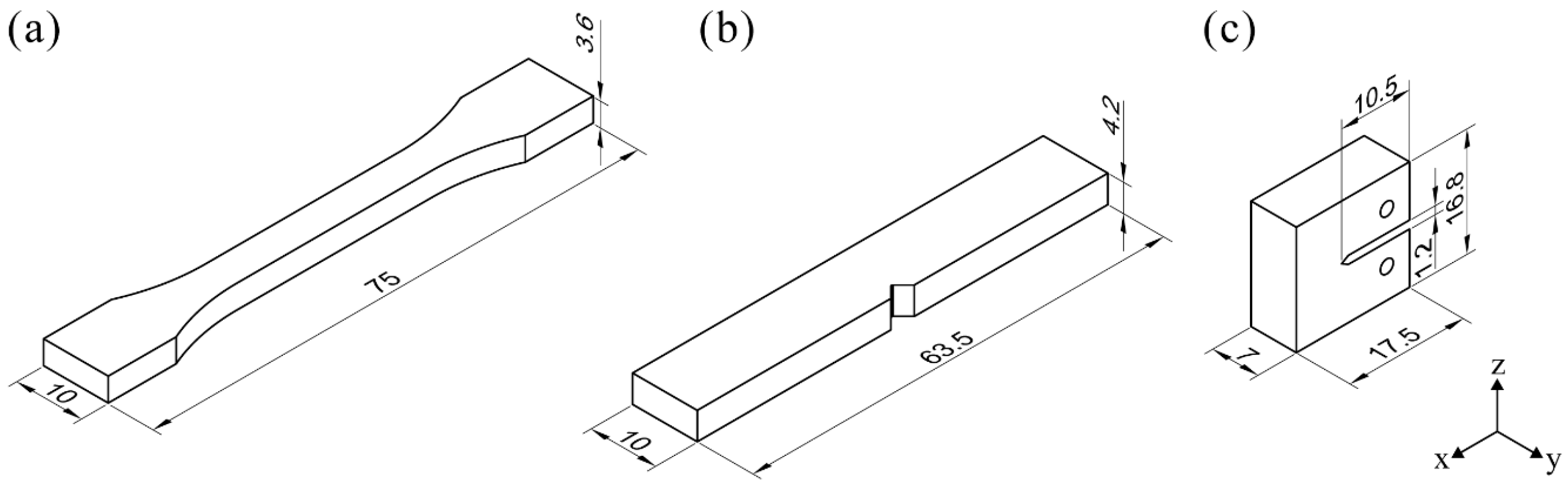

2.3. Testing of Mechanical Properties

2.4. Differential Scanning Calorimetry Analysis

2.5. Fourier Transform Infrared Spectroscopy

3. Results and Discussion

3.1. FTIR Analysis

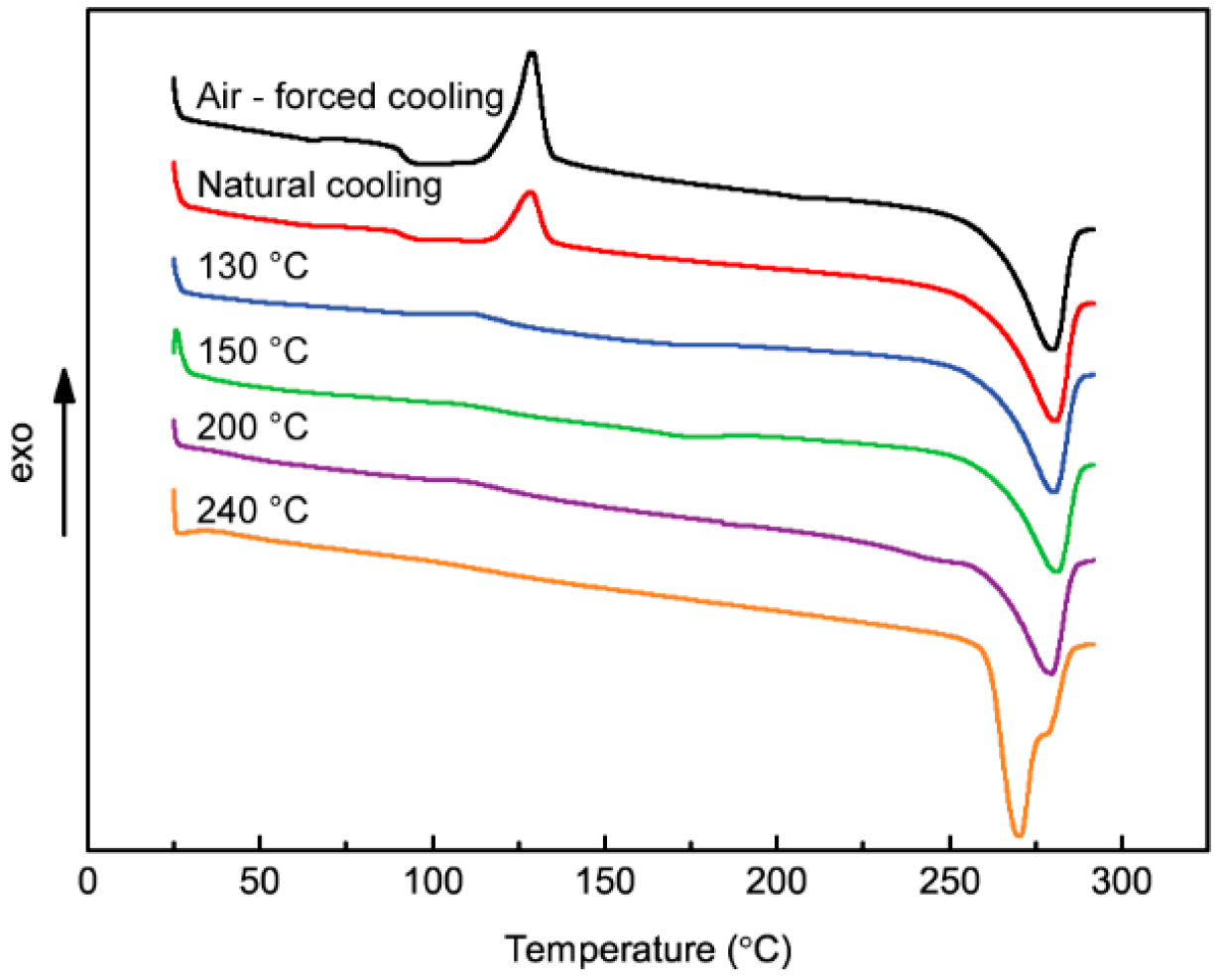

3.2. DSC Analysis

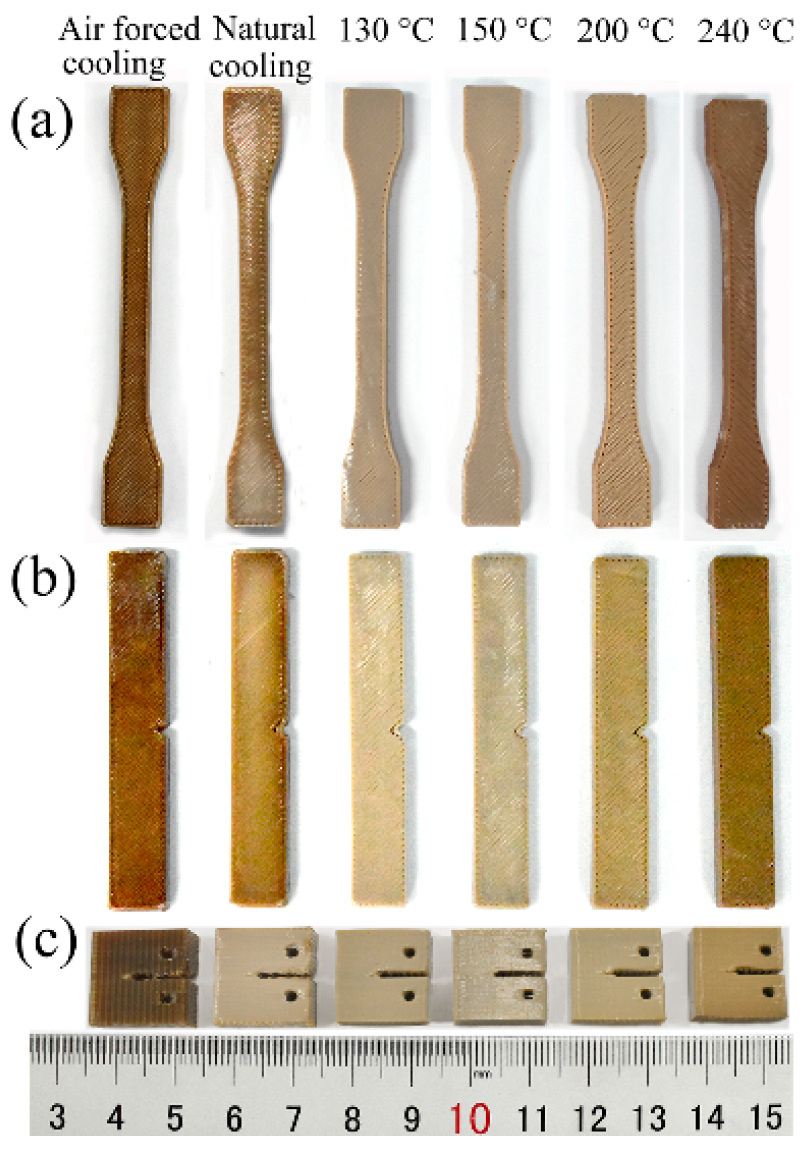

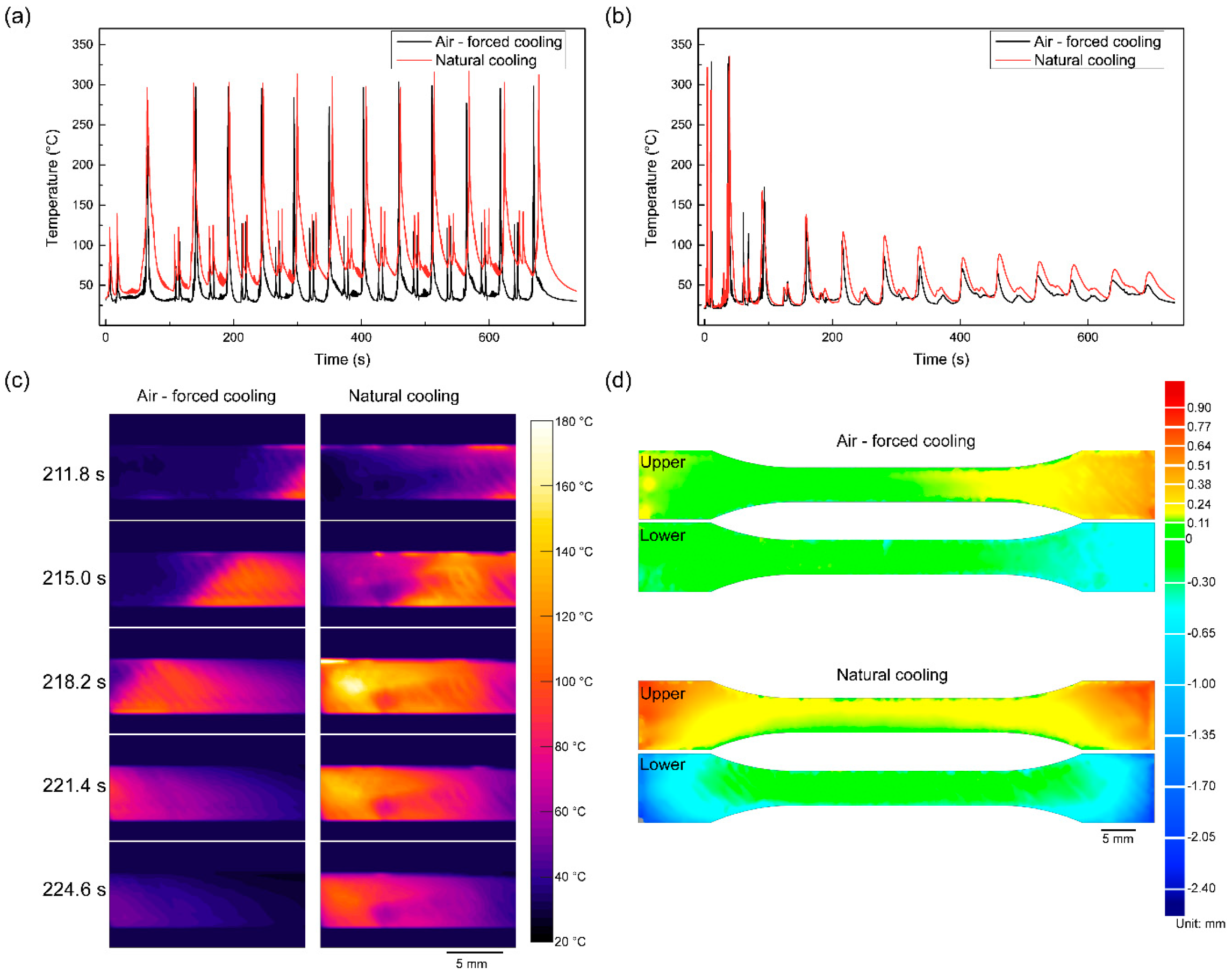

3.3. Effect of the Thermal Processing Condition on Temperature Profiles and the Accuracy of 3D-Printed PPS Samples

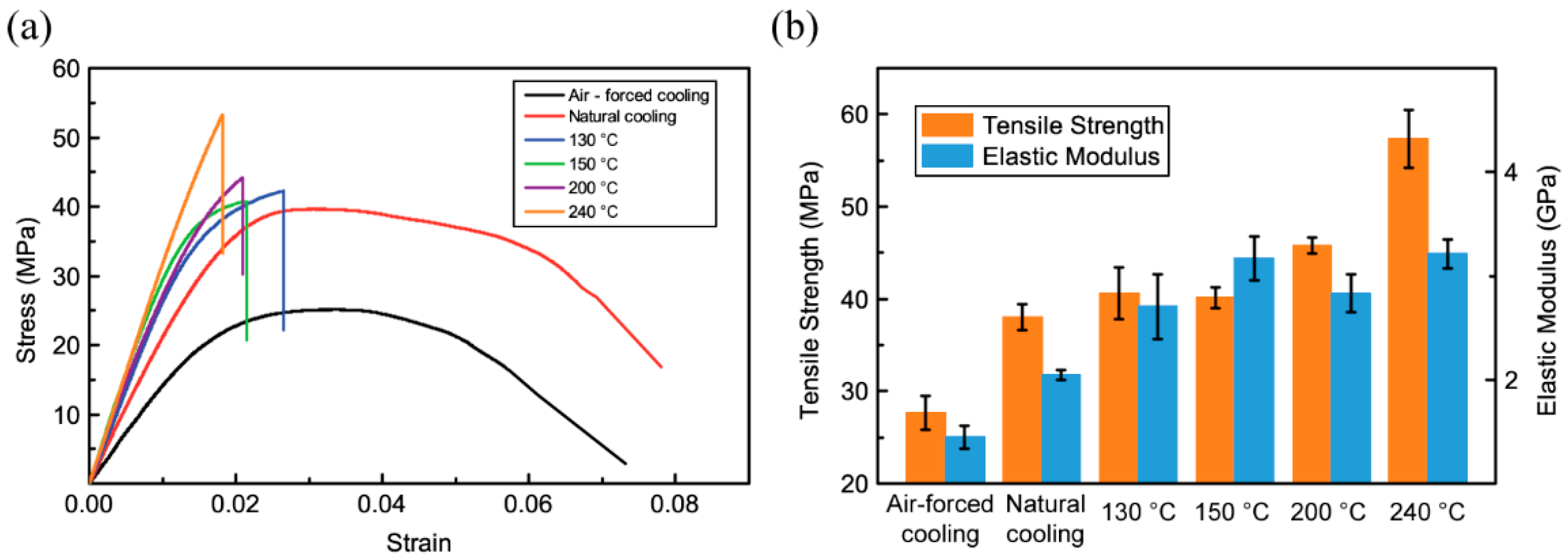

3.4. Tensile Properties of 3D-Printed PPS Samples

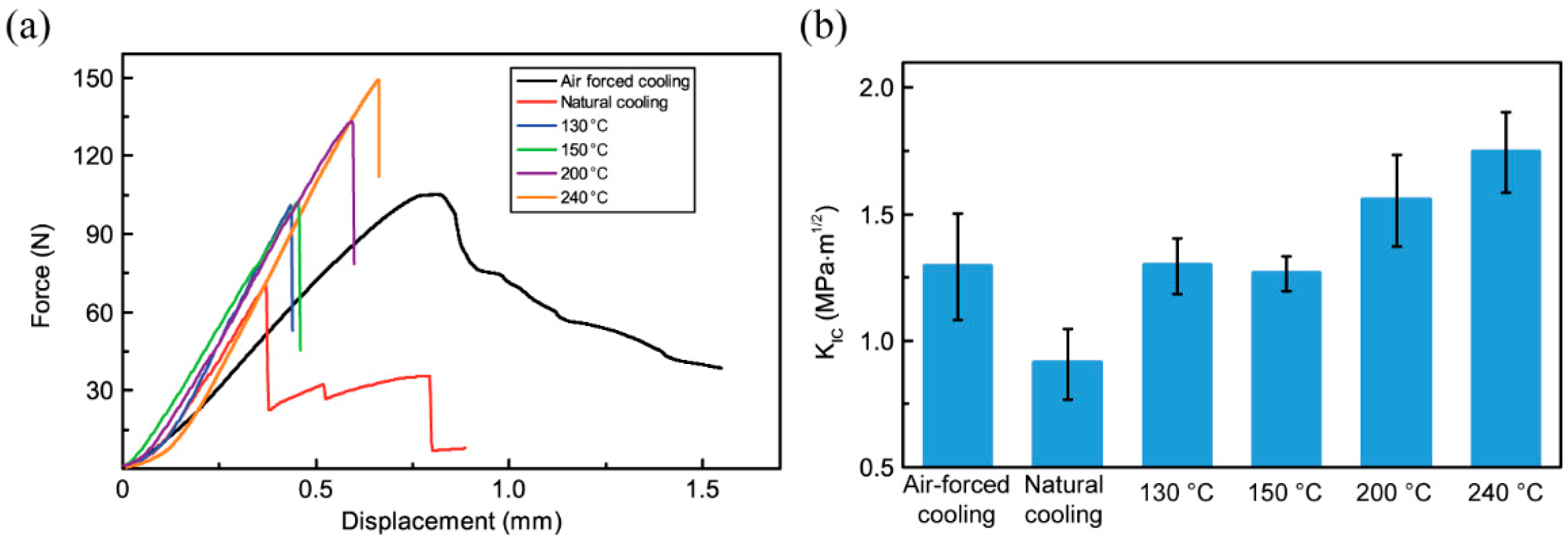

3.5. Fracture Toughness of 3D-Printed PPS Samples

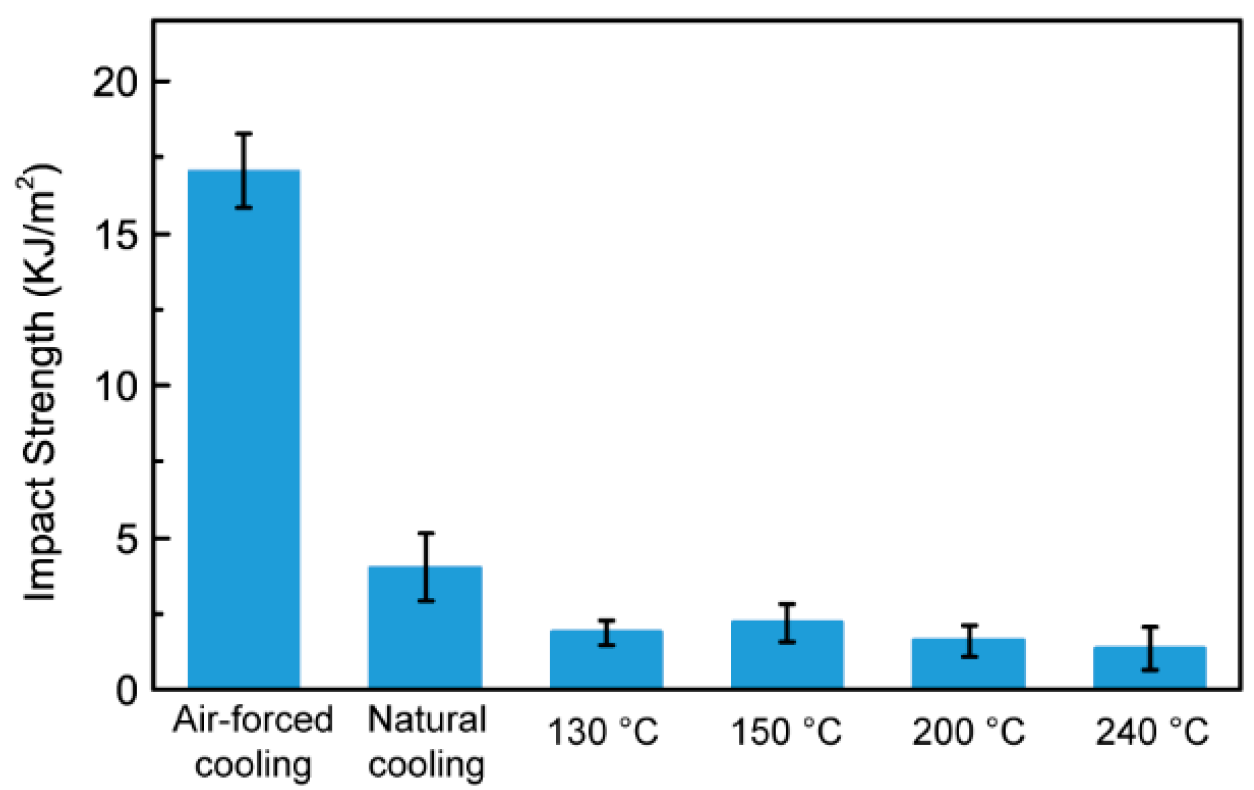

3.6. Izod Notched Impact Properties of 3D-Printed PPS Samples

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nishihata, N.; Koizumi, T.; Ichikawa, Y.; Katto, T. Plane strain fracture toughness of polyphenylene sulfide. Polym. Eng. Sci. 2004, 38, 403–408. [Google Scholar] [CrossRef]

- Fan, T.; Li, Z.; Cheng, B.; Li, J. Preparation, characterization of PPS micro-porous membranes and their excellent performance in vacuum membrane distillation. J. Membr. Sci. 2018, 556, 107–117. [Google Scholar] [CrossRef]

- Kim, K.; Kim, J. BN-MWCNT/PPS core-shell structured composite for high thermal conductivity with electrical insulating via particle coating. Polymer 2016, 101, 168–175. [Google Scholar] [CrossRef]

- Gu, J.; Guo, Y.; Yang, X.; Liang, C.; Geng, W.; Tang, L.; Li, N.; Zhang, Q. Synergistic improvement of thermal conductivities of polyphenylene sulfide composites filled with boron nitride hybrid fillers. Compos. Part A 2017, 95, 267–273. [Google Scholar] [CrossRef]

- Cai, W.; Hu, G. Oxidation degradation of polyphenylene sulfide needle felt at different sulfuric acid dew point temperatures. High Perform. Polym. 2015, 27, 94–99. [Google Scholar] [CrossRef]

- Huo, P.; Cebe, P. Effects of thermal history on the rigid amorphous phase in poly(phenylene sulfide). Colloid Polym. Sci. 1992, 270, 840–852. [Google Scholar] [CrossRef]

- Lu, D.; Mai, Y.; Li, R.; Ye, L. Impact strength and crystallization behavior of Nano-SiOx/Poly(phenylene sulfide) (PPS) composites with heat-treated PPS. Macromol. Mater. Eng. 2003, 288, 693–698. [Google Scholar] [CrossRef]

- Park, M.; Lee, K.; Choe, C.; Jo, W. A thermoanalytical study on solid-state cure of poly(p-phenylene sulfide). Polym. Eng. Sci. 1994, 34, 81–85. [Google Scholar] [CrossRef]

- Upcraft, S.; Fletcher, R. The rapid prototyping technologies. Assembly Autom. 2003, 23, 318–330. [Google Scholar] [CrossRef]

- Leon, A.; Chen, Q.; Palaganas, N.B.; Palaganas, J.O.; Manapat, J.; Advincula, R.C. High performance polymer nanocomposites for additive manufacturing applications. React. Funct. Polym. 2016, 103, 141–155. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- Senatov, F.S.; Niaza, K.V.; Stepashkin, A.A.; Kaloshkin, S.D. Low-cycle fatigue behavior of 3d-printed PLA-based porous scaffolds. Compos. Part B. 2016, 97, 193–200. [Google Scholar] [CrossRef]

- Bose, S.; Vahabzadeh, S.; Bandyopadhyay, A. Bone tissue engineering using 3D printing. Mater. Today 2016, 16, 496–504. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Kotlinski, J. Mechanical properties of commercial rapid prototyping materials. Rapid Prototyp. J. 2014, 20, 499–510. [Google Scholar] [CrossRef]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Adv. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Kishore, V.; Chen, X.; Ajinjeru, C.; Hassen, A.A.; Lindahl, J.; Failla, J.; Kunc, V.; Duty, C. Additive manufacturing of high performance semicrystalline thermoplastics and their composites. In Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 8–10 August 2016. [Google Scholar]

- Fitzharris, E.R.; Watanabe, N.; Rosen, D.W.; Shofner, M.L. Effects of material properties on warpage in fused deposition modeling parts. Int. J. Adv. Manuf. Technol. 2018, 95, 2059–2070. [Google Scholar] [CrossRef]

- Denardo, N.M. Additive Manufacturing of Carbon Fiber-Reinforced Thermoplastic Composites. Master’s Thesis, Purdue University, West Lafayette, OH, USA, August 2016. [Google Scholar]

- Yang, C.; Tian, X.; Li, D.; Cao, Y.; Zhao, F.; Shi, C. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material. J. Mater. Process. Technol. 2017, 248, 1–7. [Google Scholar] [CrossRef]

- Wang, L.; Gramlich, W.M.; Gardner, D.J. Improving the impact strength of Poly(lactic acid) (PLA) in fused layer modeling (FLM). Polymer 2017, 114, 242–248. [Google Scholar] [CrossRef]

- Kishore, V.; Ajinjeru, C.; Nycz, A.; Post, B.; Lindahl, J.; Kunc, V.; Duty, C. Infrared preheating to improve interlayer strength of big area additive manufacturing (BAAM) components. Adv. Manuf. 2017, 14, 7–12. [Google Scholar] [CrossRef]

- Brady, D.G. The crystallinity of poly(phenylene sulfide) and its effect on polymer properties. J. Appl. Polym. Sci. 1976, 20, 2541–2551. [Google Scholar] [CrossRef]

- Cheung, M.F.; Plummer, H.K. Tensile fracture morphology of polysulfone-poly(phenylene sulfide) blends. Polym. Bull. 1991, 26, 349–356. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Nozzle diameter | 0.4 mm |

| Nozzle temperature | 285 °C |

| Printing speed 1 | 680 mm/min |

| Layer thickness | 0.3 mm |

| Number of contours | 1 |

| Infill pattern | Rectilinear |

| Raster angle | 45°/−45° |

| Raster width | 0.4 mm |

| Raster gap | 0 mm |

| Extrusion multiplier | 0.9 |

| Outline overlap | 0.06 mm |

| Sample | Enthalpy (J/g) | Crystallinity (%) | |

|---|---|---|---|

| ΔHc | ΔHm | Xc | |

| Air-forced cooling | 20.03 | 35.41 | 19.13 |

| Natural cooling | 9.31 | 36.77 | 35.43 |

| 130 °C | 2.96 | 36.15 | 42.28 |

| 150 °C | -- | 33.31 | 42.75 |

| 200 °C | -- | 39.16 | 50.04 |

| 240 °C | -- | 49.67 | 64.08 |

| Thermal Condition | H (μm) | a (μm) | b (μm) | c (μm) |

|---|---|---|---|---|

| 130 °C | 87.6 ± 8.2 | 290.7 ± 10.7 | 306.7 ± 15.6 | 134.1 ± 9.2 |

| 150 °C | 108.8 ± 6.1 | 297.6 ± 12.1 | 380.8 ± 10.2 | 187.9 ± 10.5 |

| 200 °C | 144.9 ± 10.5 | 299.4 ± 13.1 | 364.7 ± 8.9 | 240.8 ± 16.9 |

| 240 °C | 204.9 ± 13.1 | 303.2 ± 11.2 | 370.8 ± 13.5 | 248.5 ± 19.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, P.; Zhao, J.; Wu, W.; Wang, Y.; Wang, B.; Wang, S.; Li, G. Effect of Thermal Processing and Heat Treatment Condition on 3D Printing PPS Properties. Polymers 2018, 10, 875. https://doi.org/10.3390/polym10080875

Geng P, Zhao J, Wu W, Wang Y, Wang B, Wang S, Li G. Effect of Thermal Processing and Heat Treatment Condition on 3D Printing PPS Properties. Polymers. 2018; 10(8):875. https://doi.org/10.3390/polym10080875

Chicago/Turabian StyleGeng, Peng, Ji Zhao, Wenzheng Wu, Yulei Wang, Bofan Wang, Shuobang Wang, and Guiwei Li. 2018. "Effect of Thermal Processing and Heat Treatment Condition on 3D Printing PPS Properties" Polymers 10, no. 8: 875. https://doi.org/10.3390/polym10080875