A Novel Technique for Fiber Formation: Mechanotropic Spinning—Principle and Realization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

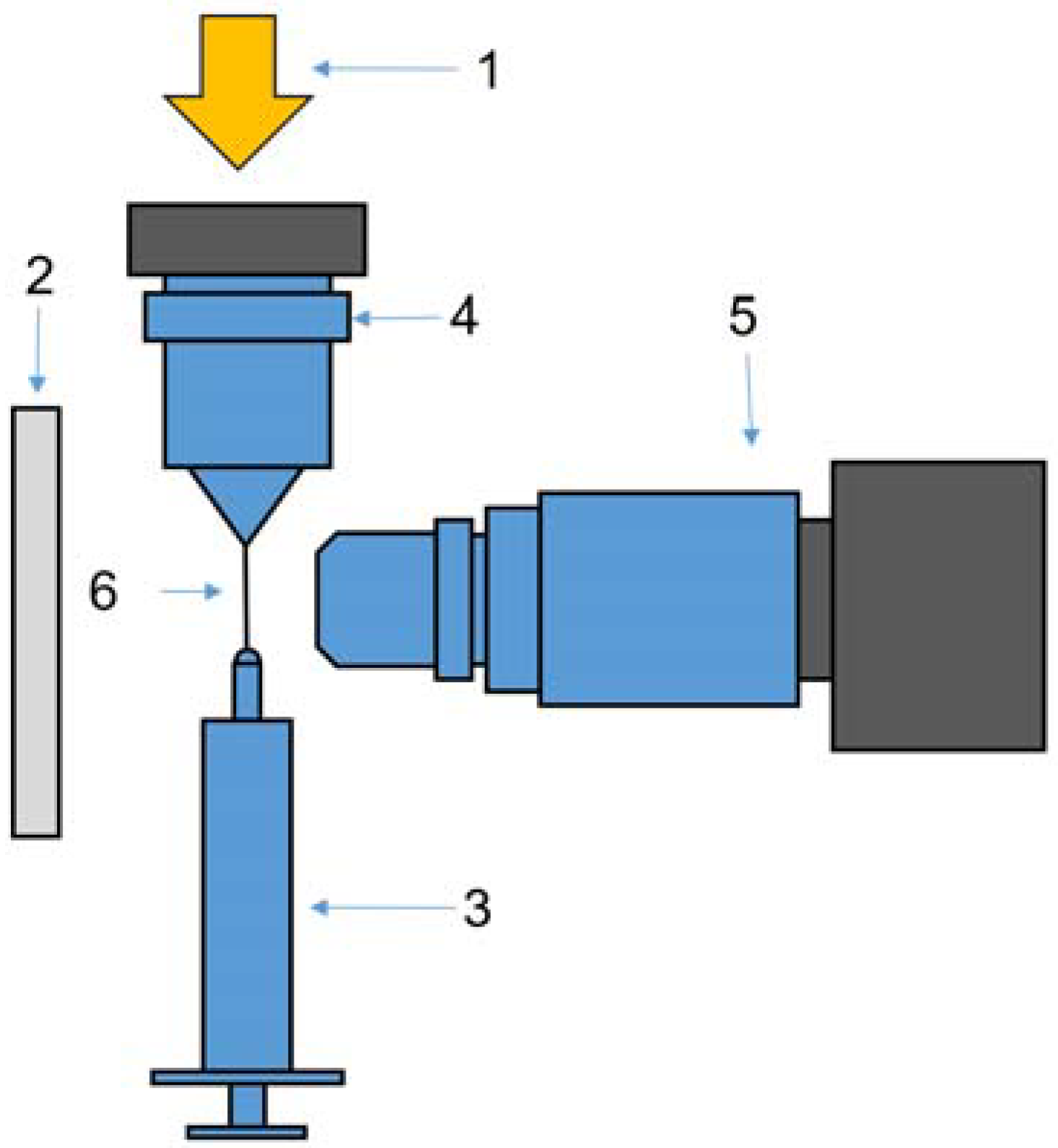

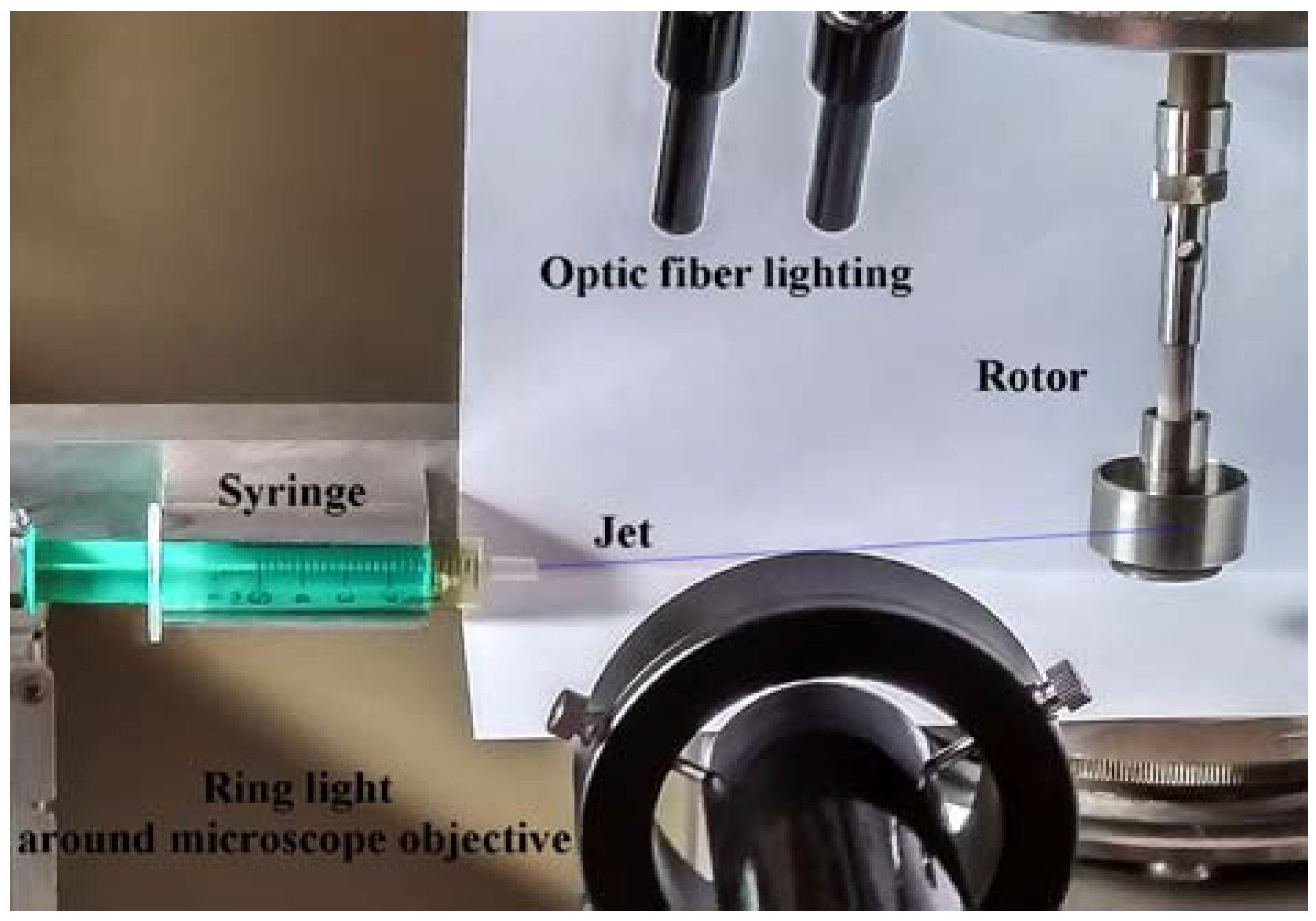

2.2. Experimental Setup

3. Results and Discussion

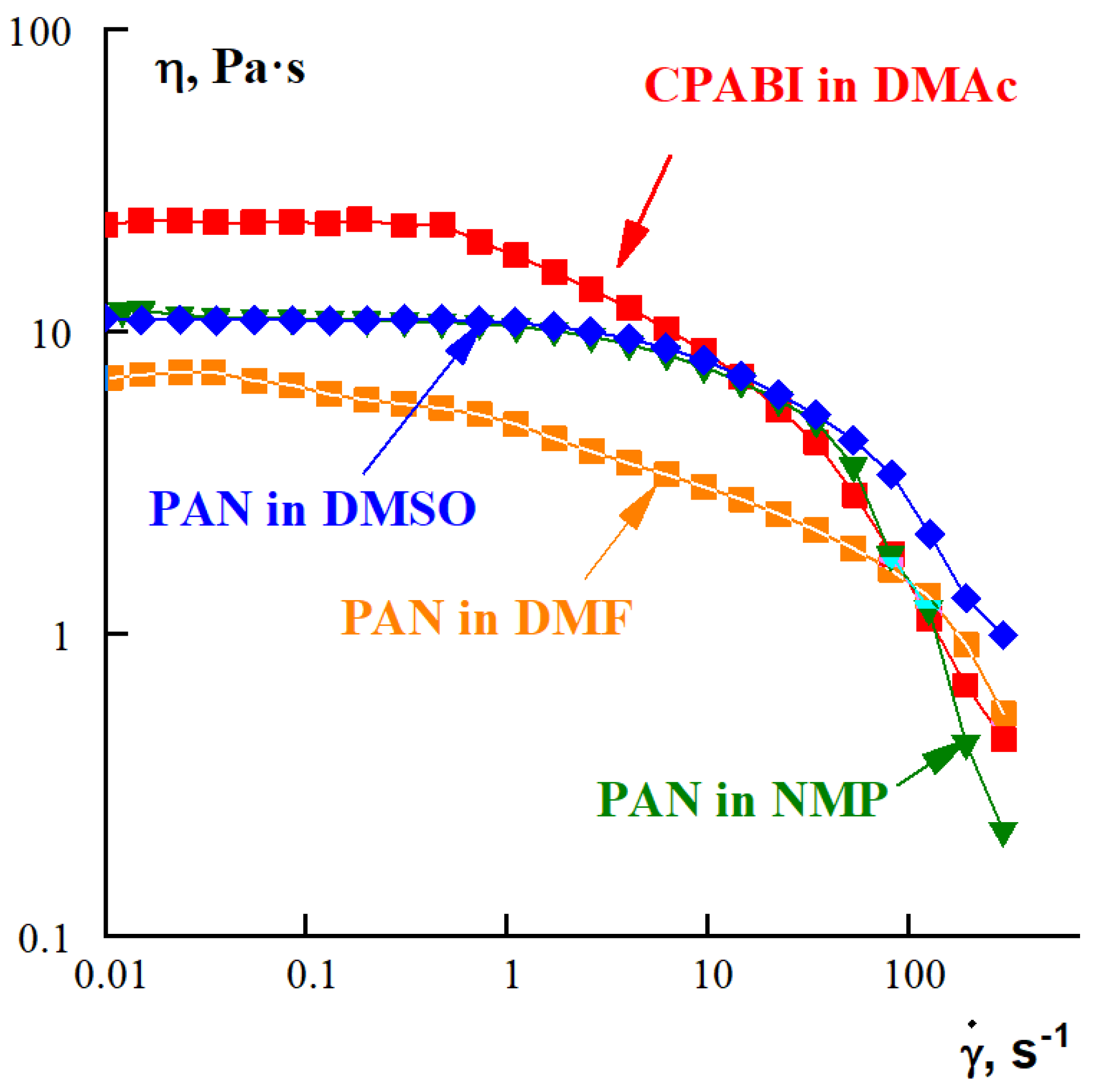

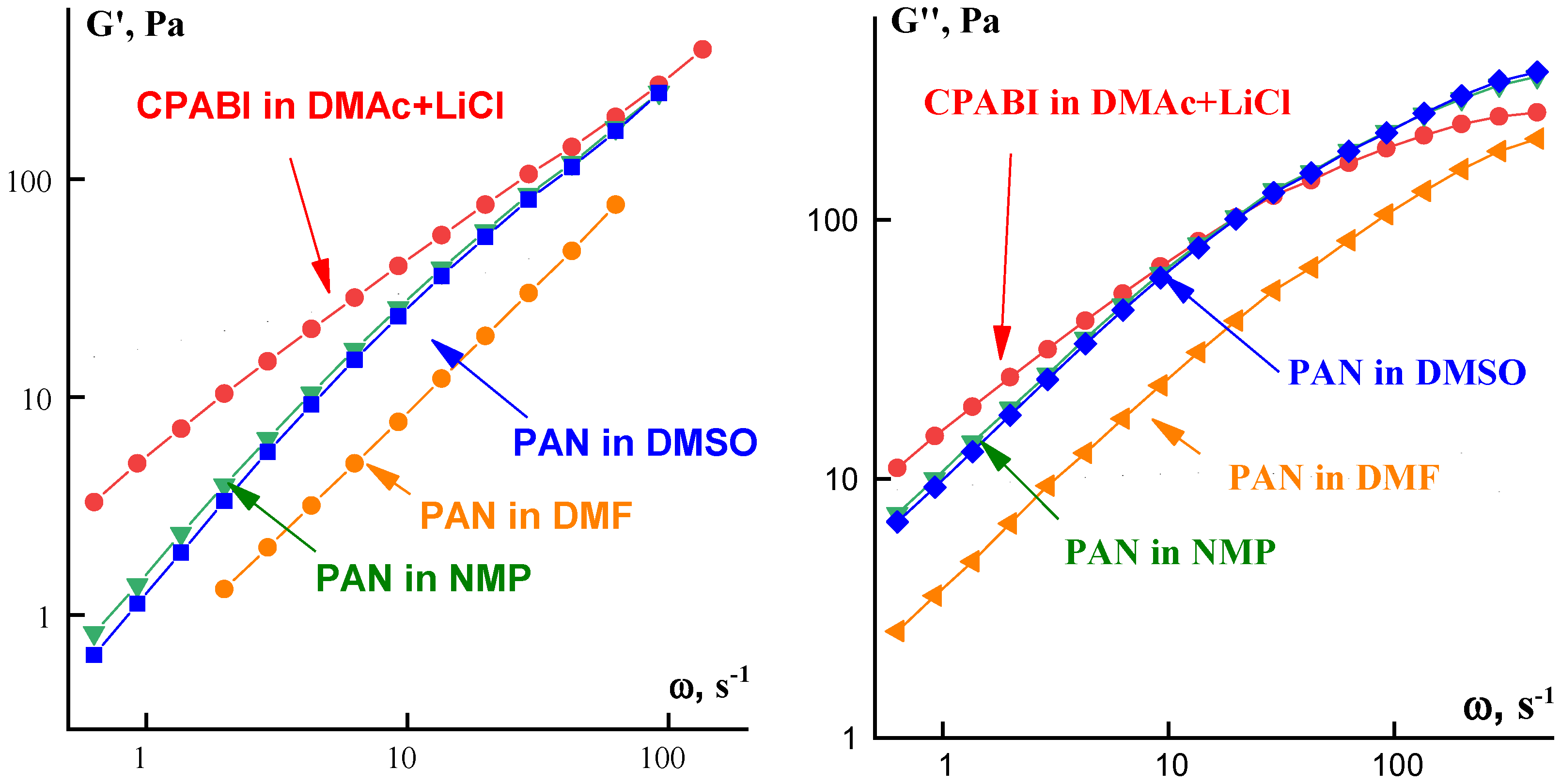

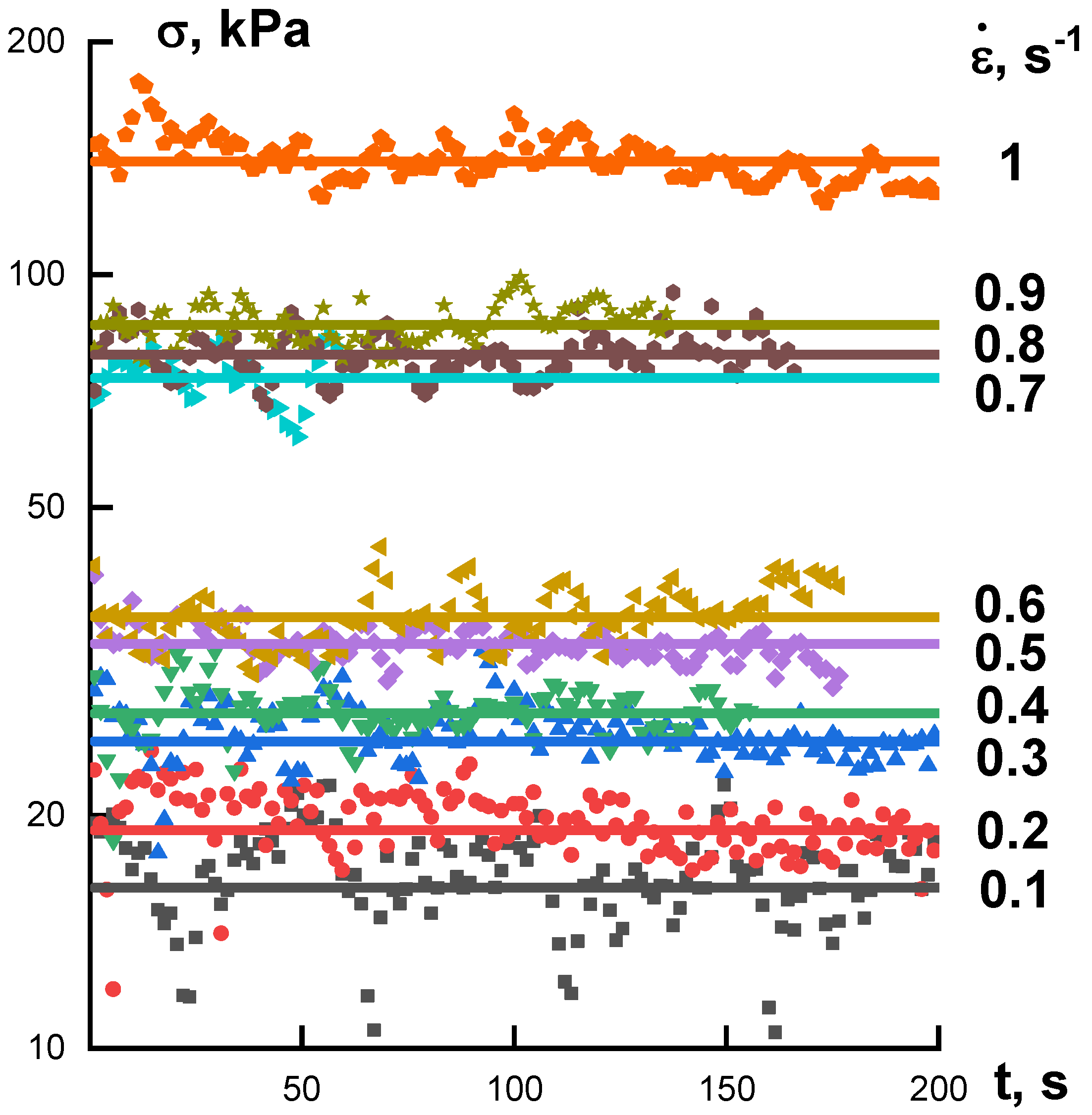

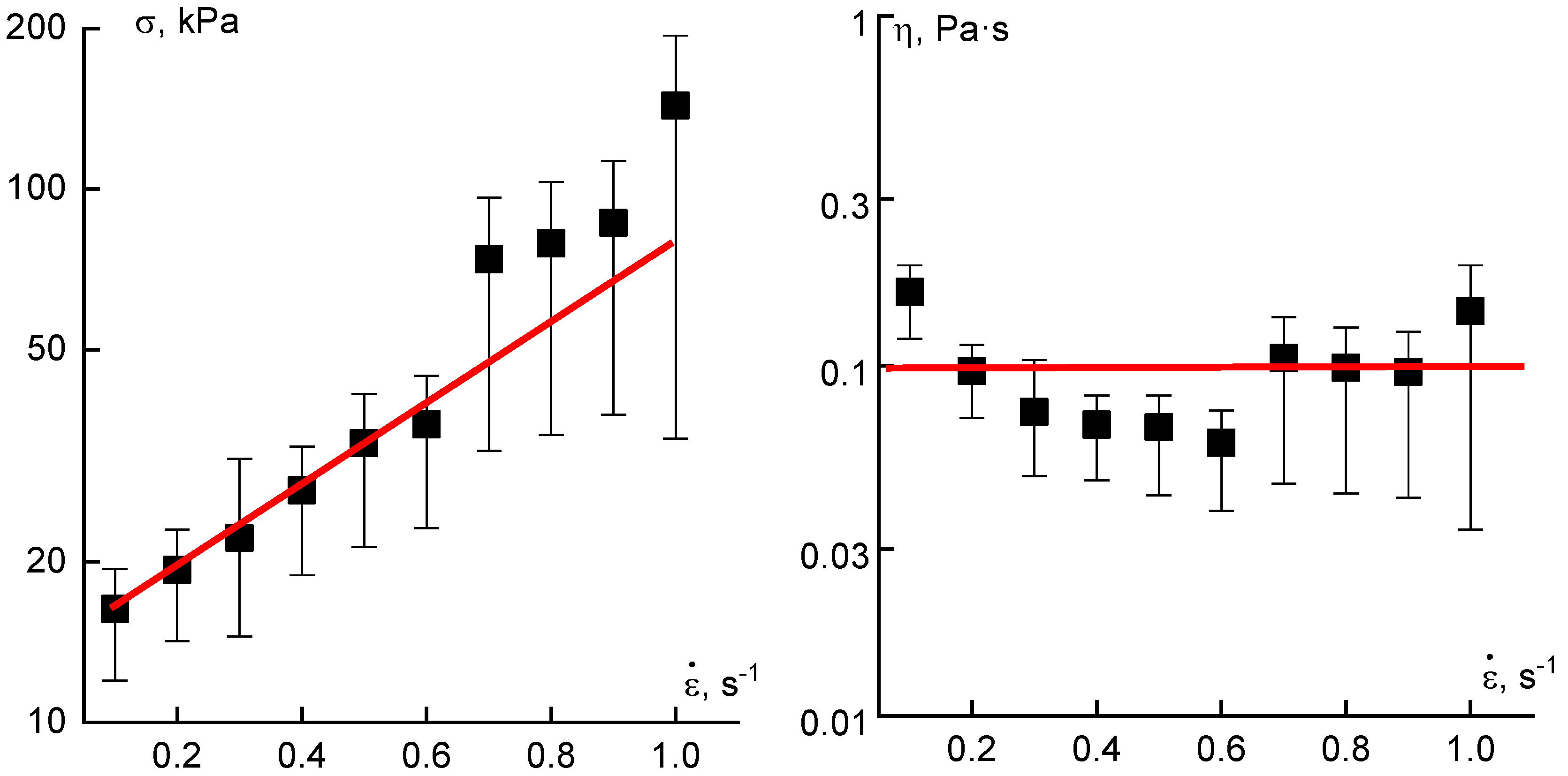

3.1. Rheological Properties of Samples

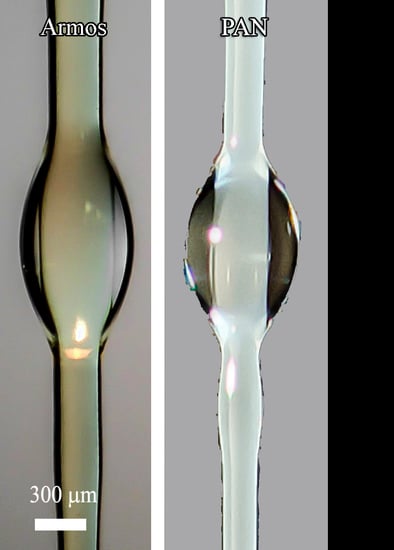

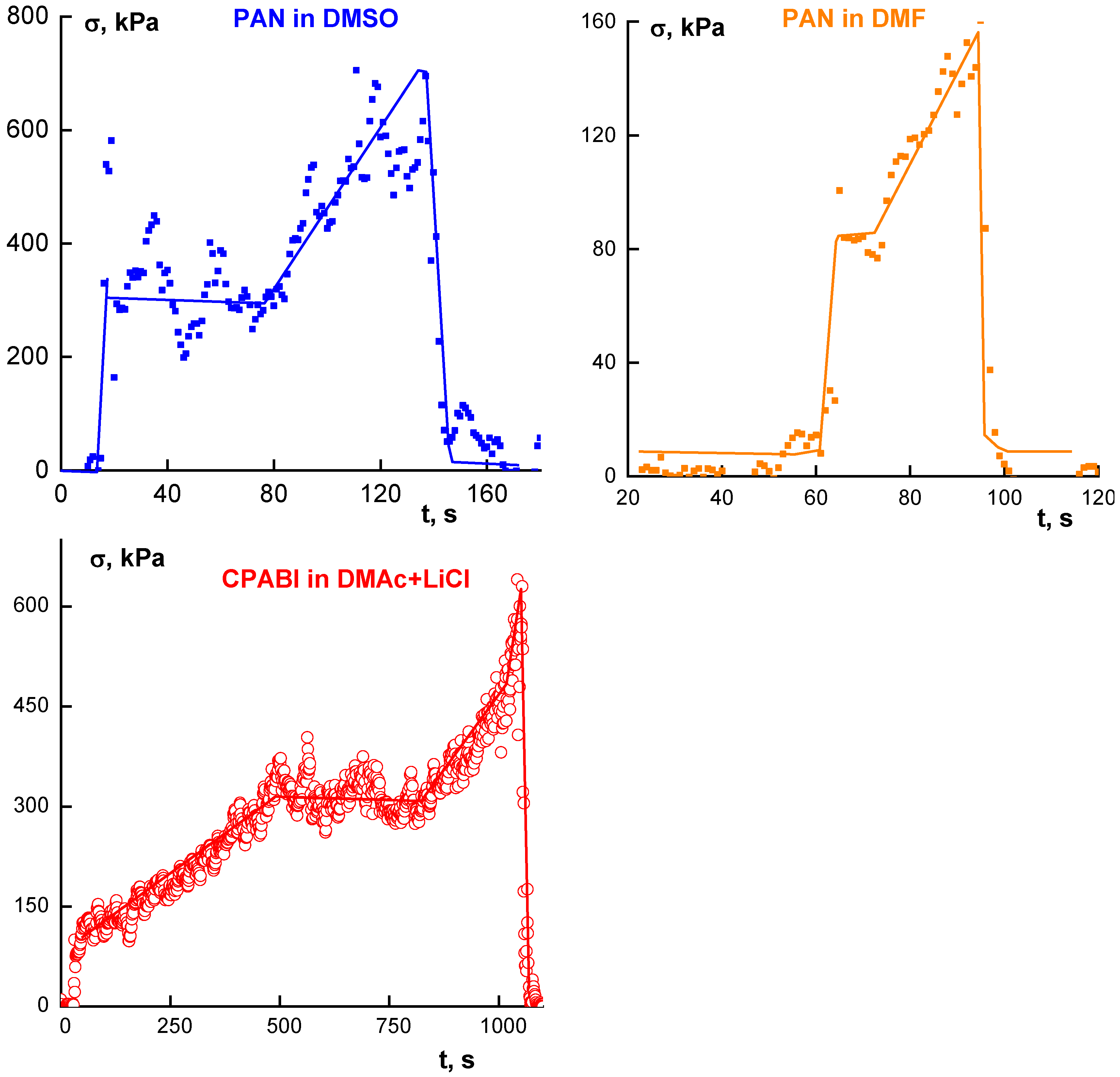

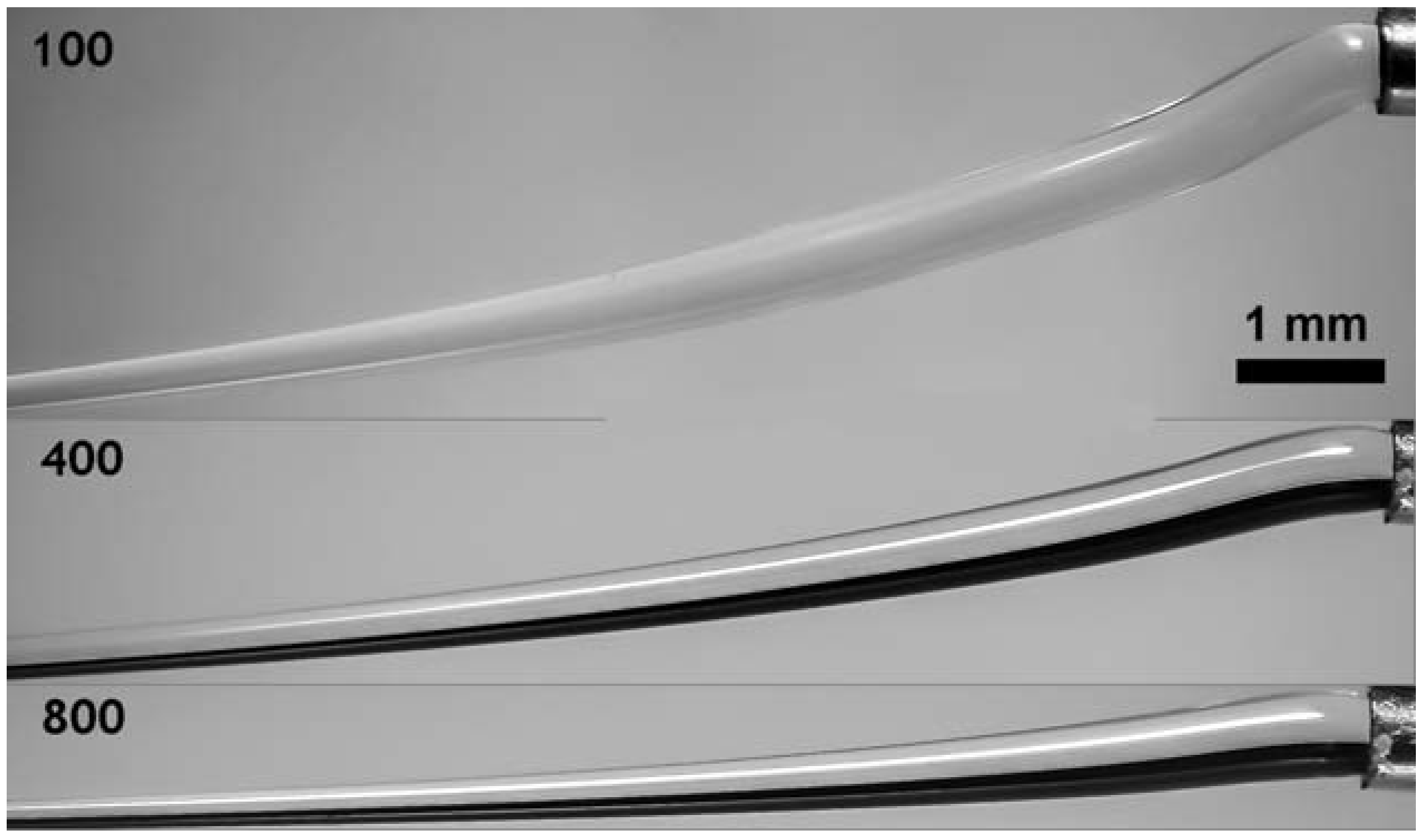

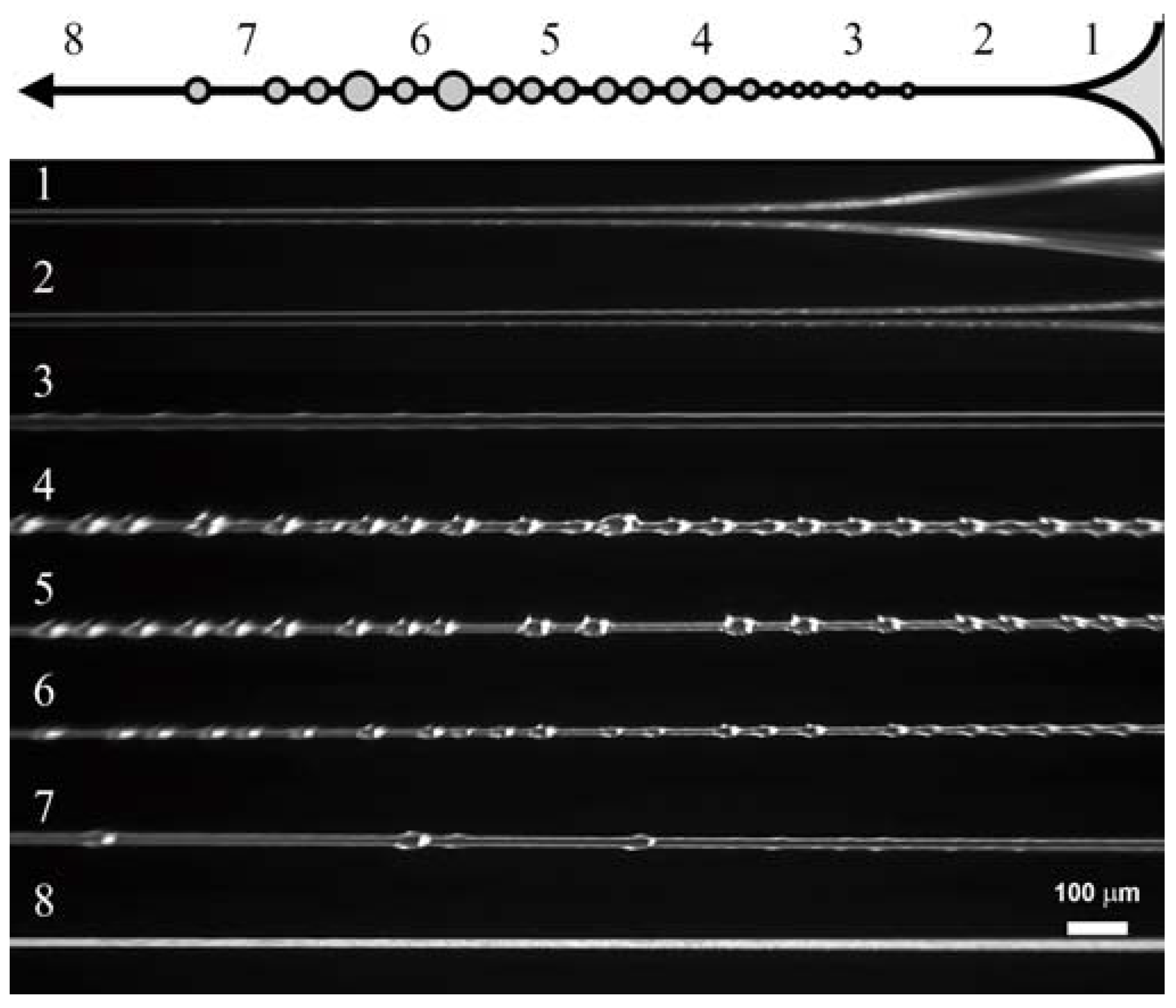

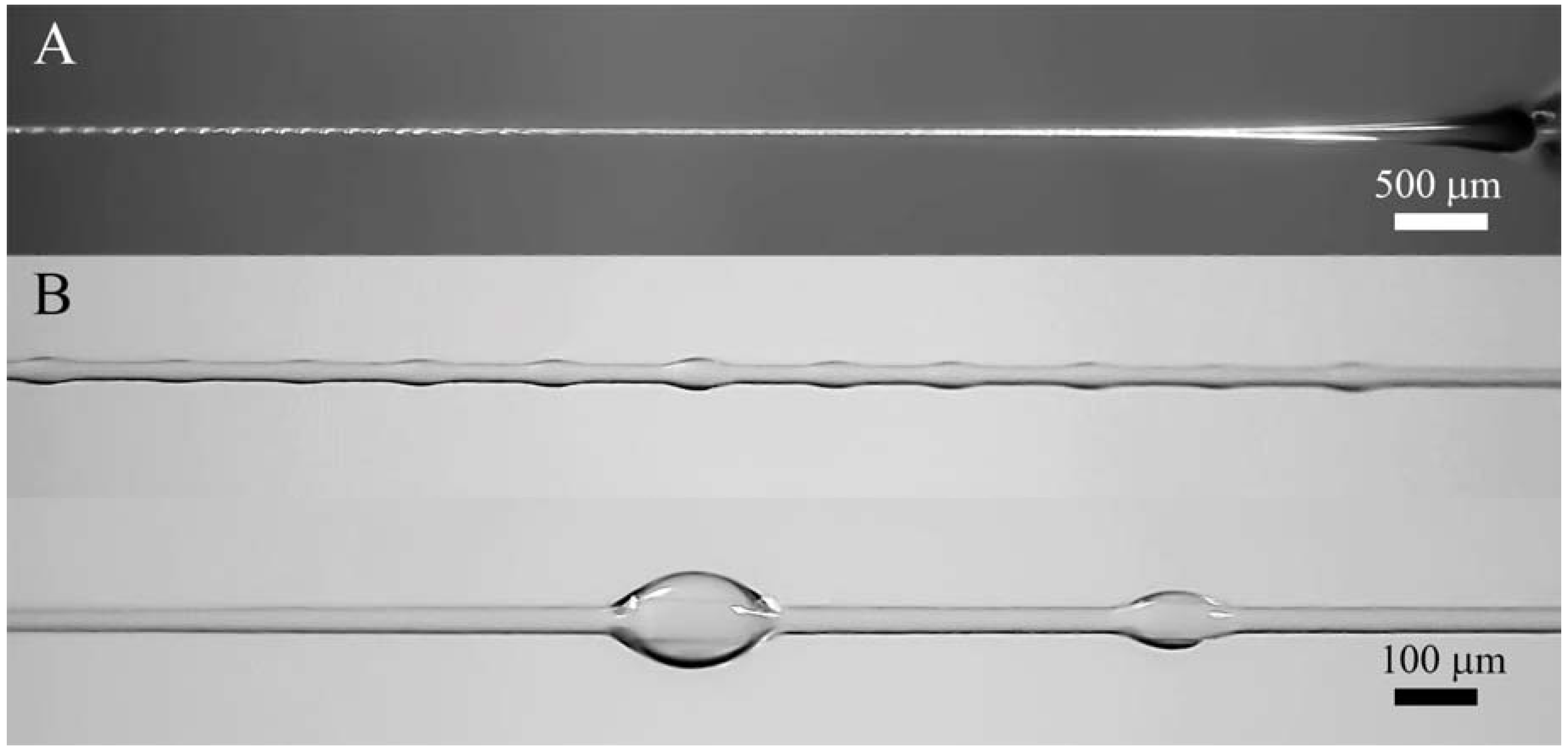

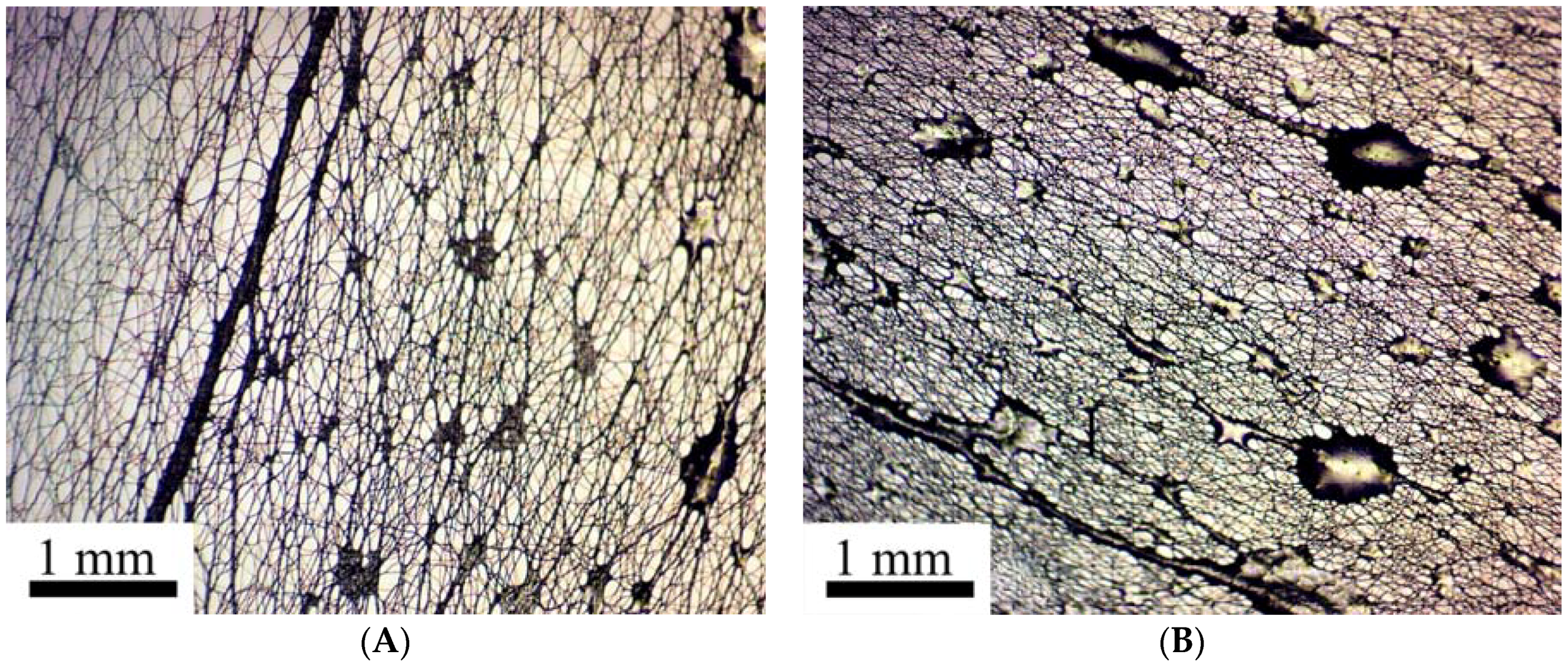

3.2. Fiber Spinning

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

Theoretical Considerations

References

- Vinogradov, G.V.; Malkin, A.Y.; Volosevich, V.V.; Shatalov, V.P.; Yudin, V.P. Flow, high-elastic (recoverable) deformations and rupture of uncured high MW linear polymers in unaxial extension. J. Polym. Sci. Polym. Phys. Ed. 1975, 13, 1721–1735. [Google Scholar] [CrossRef]

- Vinogradov, G.V.; Malkin, A.Y.; Volosevich, V.V. Some fundamental problems in viscoelastic behavior of polymers in shear and extension. Appl. Polym. Symp. 1975, 27, 47–59. [Google Scholar]

- Meissner, J. Experimental aspects in polymer melt elongational rheology. Chem. Engngy Commun. 1985, 33, 159–180. [Google Scholar] [CrossRef]

- Spiegelberg, S.H.; McKinley, G.H. Stress relaxation and elastic decohesion of viscoelastic polymer solutions un extensional flow. J. Non-Newton. Fluid Mech. 1996, 67, 49–76. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Petrie, C.J.S. Some conditions for rupture of polymer liquids in extension. J. Rheol. 1997, 41, 1–25. [Google Scholar] [CrossRef]

- Joshi, Y.M.; Denn, M.M. Rupture of entangled polymeric liquids in elongation flow. J. Rheol. 2003, 47, 291–298. [Google Scholar] [CrossRef]

- Wang, Y.; Boukany, P.E.; Wang, S.-Q.; Wang, X.R. Elastic breakup in uniaxial extension of entangled polymer melts. Phys. Rev. Lett. 2007, 99, 237801. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wang, S.-Q. From elastic deformations to terminal flow of a monodispersed entangled polymer melt in uniaxial extension. J. Rheol. 2008, 52, 1275–1290. [Google Scholar] [CrossRef]

- Barroso, V.C.; Andrade, R.J.; Maia, J.M. An experimental study on the citeria for failure of polymer melts in uniaxial extension: The test case of a polyisobutylene melt in different deformation regimes. J. Rheol. 2010, 54, 605–618. [Google Scholar] [CrossRef]

- Rasmussen, H.K. Catastrophic failure of polymer melts during extension. J. Non-Newton. Fluid Mech. 2013, 198, 136–140. [Google Scholar] [CrossRef] [Green Version]

- Wagner, M.H.; Demarmels, A. A constitutive analysis of extensional flows of polyisobutyleme. J. Rheol. 1990, 34, 943–958. [Google Scholar] [CrossRef]

- Wagner, M.H. Scaling relations for elongational flow of polystyrene melts and concentrated solutions of polystyrene in oligomer styrene. Rheol. Acta 2014, 53, 765–777. [Google Scholar] [CrossRef]

- Hawke, L.G.D.; Huang, Q.; Hassager, O.; Read, D.J. Modifying the pom-pom model for extensional viscosity overshoots. J. Rheol. 2015, 59, 995–1017. [Google Scholar] [CrossRef] [Green Version]

- Narimissa, E.; Wagner, M.H. From linear viscoelasticity to elongational flow of polydisperse linear and branched polymer melts: The hierarchical multi-mode molecular stress function model. Polymer 2016, 104, 204–214. [Google Scholar] [CrossRef]

- Watanabe, H.; Matsumiya, Y. Revisit the Elongational viscosity of FENE Dumbbell model. J. Soc. Rheol. Jpn. 2017, 45, 185–190. [Google Scholar] [CrossRef]

- Rasmussen, H.K.; Fasano, A. Flow and breakup of low-density polyethylene. Rheol. Acta 2018. [Google Scholar] [CrossRef]

- Münstedt, H.; Laun, H. Elongational properties and molecular structure of polyethylene melts. Rheol. Acta 1981, 29, 211–221. [Google Scholar] [CrossRef]

- Münstedt, H.; Kurzbeck, S.; Egerstdőrger, L. Influence of molecular structure on rheological properties of polyethylenes. Rheol. Acta 1998, 37, 21–29. [Google Scholar] [CrossRef]

- Burghelea, T.; Starý, Z.; Münstedt, H. On the “viscosity overshoot” during the uniaxial extension of a low density polyethylene. J. Non-Newton. Fluid Mech. 2011, 166, 1198–1209. [Google Scholar] [CrossRef]

- Stadler, F.J.; Kaschta, J.; Münstedt, H.; Becker, F.; Buback, M. Influence of molecular mass distribution and long-chain branching on strain hardening of low density polyethylene. Rheol. Acta 2009, 48, 478–490. [Google Scholar] [CrossRef]

- Ruymbeke van, E.; Muliawan, E.B.; Hatzikiriakos, S.G.; Watanabe, T.; Hirao, A.; Vlassopoulos, D. Viscoelasticity and extensional rheology of model Cayley-tree polymers of different generation. J. Rheol. 2010, 54, 653–662. [Google Scholar] [CrossRef]

- Hoyle, D.M.; Huang, Q.; Auh, D.; Hassell, D.; Rasmussen, H.K.; Skov, A.L.; Harlen, O.G.; Hassager, O.; McLeigh, T.C.B. Transient overshoot extensional rheology of long-chain branched polyethylenes: Experimental and numerical comparison between filament stretching and cross-slot flow. J. Rheol. 2013, 57, 293–313. [Google Scholar] [CrossRef] [Green Version]

- Huang, Q.; Mednova, O.; Rasmussen, H.K.; Alvarez, N.J.; Slov, A.L.; Almdal, K.; Hassager, O. Concentrated polymer solutions are different from melts: Role of entanglements. Macromolecules 2013, 46, 5026–5035. [Google Scholar] [CrossRef]

- Huang, Q.; Hengeller, L.; Alvarez, N.J.; Hassager, O. Bridging the gap between polymer melts and solutions in extensional behavior. Macromolecules 2015, 48, 4158–4163. [Google Scholar] [CrossRef] [Green Version]

- Huang, Q.; Agostin, S.; Hengeller, L.; Shivokhin, M.; Alvarez, N.J.; Hutchings, L.R.; Hassager, O. Dynamics of star polymers in fast extensional flow and stress relaxation. Macromolecules 2016, 49, 6694–6699. [Google Scholar] [CrossRef]

- Costanzo, S.; Huang, Q.; Ianniruberto, G.; Marrucci, G.; Hassager, O.; Vlassopoulos, D. Shear and extensional rheology of polystyrene melts and solutions with the same number of entanglements. Macromolecules 2016, 49, 3925–3935. [Google Scholar] [CrossRef] [Green Version]

- López-Barrón, C.R.; Zeng, Y.; Richards, J.J. Chain stretching and recoiling during startup and cessation of extensional flow of bidisperse polystyrene blends. J. Rheol. 2017, 61, 697–710. [Google Scholar] [CrossRef]

- Lentzakis, H.; Vlassopoulos, D.; Read, D.J.; Lee, H.; Chang, T.; Driva, P.; Hadjichristidis, N. Uniaxial extensional rheology of well-characterized comby polymers. J. Rheol. 2013, 57, 605–625. [Google Scholar] [CrossRef]

- Zhu, A.; Wang, S.-Q. Mechanisms for different failure modes in startup uniaxial extension: Tensile (rupture-like) failure and necking. J. Rheol. 2013, 57, 223–248. [Google Scholar] [CrossRef]

- Münstedt, H.; Starý, Z. Steady states in extensional flow of strain hardening polymer melts and the uncertainties of their deformations. J. Rheol. 2013, 57, 1065–1077. [Google Scholar] [CrossRef]

- Ingereneau, F.; Kellay, H. Stretching Polymers in Droplet-Pinch-off Experiments. Phys Rev. X 2013, 3, 041002. [Google Scholar]

- Hoyle, D.M.; Fielding, S.M. Ceiteria for extensional necking instability in complex fluids and soft solids. Part I: Imposed Hencky strain rate protocol. J. Rheol. 2016, 60, 1347–1375. [Google Scholar] [CrossRef]

- Huang, Q.; Alvarez, N.J.; Shabbier, A.; Hassager, O. Multiple cracks propagate simultaneously in polymeric fluids in tension. Phys. Rev. Lett. 2016, 117, 087801. [Google Scholar] [CrossRef] [PubMed]

- Burghelea, T.; Starý, Z.; Münstedt, H. Local versus integral measurements of the extensional viscosity of polymer melts. J. Rheol. 2009, 53, 1363–1377. [Google Scholar] [CrossRef]

- Bazilevsly, A.V.; Entov, V.M.; Rozhkov, A.N. Third European Rheology Conference and Golden Jubilee Meeting of the British Society Rheology; Oliver, D.R., Ed.; Springer: Dordrecht, The Netherlands, 1990; pp. 41–43. [Google Scholar]

- Entov, V.M.; Hinch, E.J. Effect of a spectrum of relaxation times on the capillary thinning of a filament of elastic liquid. J. Non-Newton. Fluid Mech. 1997, 72, 31–53. [Google Scholar] [CrossRef]

- Schridar, T.; Tirtaatmadja, V.; Nguyen, D.A.; Gupta, R.K. Measurement of extensional viscosity of polymer solutions. J. Non-Newton. Fluid Mech. 1991, 40, 271–280. [Google Scholar] [CrossRef]

- Tirtaatmadia, V.; Sridhar, T. A filament stretching device for measument of extensional viscosity. J. Rheol. 1993, 37, 1081–1102. [Google Scholar] [CrossRef]

- Yao, M.; McKinley, G.H. Numerical simulation of extensional deformations of viscoelastic liquid bridges in filament stretching device. J. Non-Newton. Fluid Mech. 1998, 74, 47–88. [Google Scholar] [CrossRef]

- Anna, S.L.; McKinley, G.H. Elasto-capillary thinning and breakup of model elastic liquids. J. Rheol. 2001, 45, 115–138. [Google Scholar] [CrossRef] [Green Version]

- Szabo, P.; McKinley, G.H.; Clasen, C. Constant force extensional rheometry of polymer solutions. J. Non-Newton. Fluid Mech. 2002, 169, 26–41. [Google Scholar] [CrossRef]

- Bach, A.; Rasmussen, H.K.; Hassager, O. Extensional viscosity for polymer melts measures in the filament stretching rheometer. J. Rheol. 2003, 47, 429–442. [Google Scholar] [CrossRef] [Green Version]

- Rodd, L.; Scott, T.; Cooper-White, J.; McKinley, G.H. Capillary break-up rheometry of low-viscosity elastic fluids. Appl. Rheol. 2005, 15, 12037. [Google Scholar]

- Tirtaatmadia, V.; McKinley, G.H.; Copper-White, J.J. Drop formation and breakup of low-viscosity fluids: Effects of molecular weight and concentration. Phys. Fluids 2006, 18, 043101. [Google Scholar] [CrossRef]

- Clasen, C.; Plog, J.P.; Kulicke, W.M.; Owens, M.; Macosko, C.; Scriven, L.E.; Verani, M.; McKinley, G.H. How dilute are dilute solutions in extensional flows. J. Rheol. 2006, 50, 849–881. [Google Scholar] [CrossRef]

- Bhat, P.P.; Appathurai, S.; Harris, M.T.; Pasquali, M.; McKinley, G.H.; Basaran, O.A. Formation of beads-on-a-string structures during break-up of viscoelastic filaments. Nat. Phys. 2010, 6, 625–631. [Google Scholar] [CrossRef] [Green Version]

- McKinley, G.H.; Sridhar, T. Filament-stretching rheometry of complex fluids. Annu. Rev. Fluid Mech. 2002, 34, 375–415. [Google Scholar] [CrossRef]

- Mackley, M.R.; Butler, S.A.; Huxley, S.; Reis, N.M.; Barbosa, A.I.; Tembely, M. The observation and evaluation of extensional filament deformation and breakup profiles for non-Newtonian fluids using a high strain rate double piston apparatus. J. Non-Newton. Fluid Mech. 2017, 237, 13–27. [Google Scholar] [CrossRef]

- Swartjes, F.H.M.; Peters, G.W.M.; Rastogi, S.; Meijer, H.E.H. Stress induced crystallization in elongational flow. Int. Polym. Process. 2003, 18, 53–66. [Google Scholar] [CrossRef]

- Hadinata, C.; Boos, D.; Gabriel, C.; Wassner, E.; Rullmann, M.; Kao, N.; Laun, M. Elongation-induced crystallization of a high molecular weight isotactic polybuthene-1 melt. Compared to shear-induced crystallization. J. Rheol. 2007, 51, 195–215. [Google Scholar] [CrossRef]

- Sentmanat, M.; Delgadillo-Velázquez, O.; Hadzikiriakos, S.G. Crystallization of an ethylene-based butane elastomer. The effect of uniaxial extension. Rheol. Acta 2010, 49, 931–939. [Google Scholar] [CrossRef]

- Chellamuthu, M.; Arira, D.; Winter, H.H.; Rothstein, J.P. Extensional flow-induced crystallization of isotactic poly-1-betene using a filament stretching rheometer. J. Rheol. 2011, 44, 901–920. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, W.; Cui, K.; Tian, N.; Wang, X.; Liu, L.; Li, L.; Zhao, Y. Extensional rheometer for in situ X-ray scattering study on flow-induced crystallization of polymers. Rev. Sci. Instrum. 2011, 62, 045104. [Google Scholar] [CrossRef] [PubMed]

- Wingstrand, S.L.; Drongelen von, M.; Mortenson, K.; Graham, R.S.; Huang, Q.; Hassager, O. Influence of extensional stress overshoot om crystallization of LDPE. Macromolecules 2017, 50, 1134–1140. [Google Scholar] [CrossRef]

- Janeschitz-Kriegl, H.; Katajski, E.; Stadlbauer, M. Flow as am effective promotor of nucleation in polymer melts. A quantitative evaluation. Rheol. Acta 2003, 42, 355–364. [Google Scholar] [CrossRef]

- Huang, Q.; Alvarez, H.J.; Matsumiya, Y.; Rasmussen, H.K.; Watanabe, H.; Hassager, O. Extensional Rheology of Entangled Polystyrene Solutions Suggests Importance of Nematic Interactions. ACS Macro Lett. 2013, 2, 741–744. [Google Scholar] [CrossRef]

- Goldin, M.; Yerushalmi, H.; Pfeffer, R.; Shinnar, R. Breakup if a laminar capillary jet of a viscoelastic fluid. J. Fluid Mech. 1969, 38, 689–711. [Google Scholar] [CrossRef]

- Olivera, M.S.N.; Yeh, R.; McKinley, G.H. Iterated stretching, extensional rheology and formation of beads-on-a-string structures in polymer solutions. J. Non-Newton. Fluid Mech. 2006, 137, 137–148. [Google Scholar] [CrossRef] [Green Version]

- Chang, H.C.; Demekhin, E.A.; Kalaidin, E. Iterated stretching of viscoelastic jets. Phys. Fluids 1999, 11, 1717–1737. [Google Scholar] [CrossRef]

- Li, J.; Fontelos, M.A. Drop dynamics on the bead-on-string structure for viscoelastic jets: A numerical study. Phys. Fluids 2003, 15, 922–937. [Google Scholar] [CrossRef]

- Classen, C.; Eggers, J.; Fontelos, M.A.; Li, J.; McKinley, G.H. The bead-on-string structure of viscoelastic threads. J. Fluid Mech. 2006, 556, 283–308. [Google Scholar] [CrossRef]

- Sattler, R.; Wagner, C.; Eggers, J. Blistering pattern and formation of nanofibers in capillary thinning of polymer solutions. Phys. Rev. Lett. 2008, 100, 164502. [Google Scholar] [CrossRef] [PubMed]

- Sattler, R.; Gier, S.; Eggers, J.; Wagner, C. The final stages of capillary break-up on polymer solutions. Phys. Fluids 2012, 24, 023101. [Google Scholar] [CrossRef]

- Frenkel, S.Y.; Baranov, V.G.; Bel’nikevich, N.G.; Panov, Y.N. Orientation mechanism of formation of a solid phase in polymer solutions under extensional hydrodynamic field. Vysokomol. Soedin. Lett. Ed. 1964, 6, 1917. [Google Scholar]

- Ver Strate, G.; Philippoff, W. Phase separation in flowing polymer solutions. J. Polym. Sci. Polym. Lett. Ed. 1974, 12, 267–275. [Google Scholar] [CrossRef]

- Onuki, A. Shear-Induced Phase Separation in Polymer Solutions. Phys. Soc. Jpn. 1990, 59, 3427–3430. [Google Scholar] [CrossRef]

- Stieger, M.; Richtering, W. Shear-induced phase separation in aqueous polymer solutions: Temperature-sensitive microgels and linear polymer chains. Macromolecules 2003, 36, 8811–8818. [Google Scholar] [CrossRef]

- Hashimoto, T.; Murase, H.; Ohta, Y. Shear-Induced Phase Separation of entangled polymer solutions: Formation of optically anisotropic strings as precursor structures of shish-kebab. Macromol. Symp. 2009, 279, 88–95. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Arinstein, A.; Kulichikhin, V.G. Polymer extension flows and instabilities. Prog. Polym. Sci. 2014, 39, 959–978. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Semakov, A.V.; Skvortsov, I.Y.; Zatonskikh, P.; Kulichikhin, V.G.; Subbotin, A.V.; Semenov, A.N. Spinnability of dilute polymer solutions. Macromolecules 2017, 50, 8231–8244. [Google Scholar] [CrossRef]

- Kulichikhin, V.G.; Malkin, A.Y.; Semakov, A.V.; Skvortsov, I.Y.; Arinstein, A. Liquid filament instability due to stretch-induced phase separation in polymer solutions. Eur. Phys. J. E 2014, 37, 10. [Google Scholar] [CrossRef] [PubMed]

- Kulichikhin, V.G.; Semakov, A.V.; Subbotin, A.V.; Malkin, A.Y. Extension Rheology of Polymer Solutions over the Whole Concentration Range: From Fundamental Science to Fiber Spinning. In Proceedings of the XVIIth International Congress on Rheology (ICR2016), Kyoto, Japan, 7–11 August 2016. [Google Scholar]

- Semakov, A.V.; Kulichikhin, V.G.; Tereshin, A.K.; Antonov, S.V.; Malkin, A.Y. On the nature of phase separation of polymer solutions at high extension rates. J. Polym. Sci. Part B Polym. Phys. 2015, 53, 559–565. [Google Scholar] [CrossRef]

- Li, W.; Hao, J.; Zhou, P.; Liu, Y.; Lu, C.; Zhang, Z. Solvent solubility parameter dependent homogeneity and sol–gel transitions of concentrated polyacrylonitrile solutions. J. Appl. Polym. Sci. 2017, 134, 45405. [Google Scholar] [CrossRef]

- Kapitsa, P.L. Wave flow of thin layers of viscous liquid. J. Exp. Theor. Phys. 1948, 18, 3–28. [Google Scholar]

- Malkin, A.; Kurbanaliev, M.K.; Beghishev, V.P. Strength and long-term fracture of polymers formed from different solvents. Polym. Process Eng. 1983, 1, 93–108. [Google Scholar]

- Hou, C.; Qu, R.; Liang, Y.; Wang, C. Kinetics of diffusion in polyacrylonitrile fiber formation. J. Appl. Polym. Sci. 2005, 96, 1529–1533. [Google Scholar] [CrossRef]

- Zeng, X.; Zhang, G.; Zhang, Y.; Zhao, J.; Pan, D. Diffusion Mechanism of As-spun Polyacrylonitrile Fiber in a Dimethyl Sulfoxide-Water Coagulation Bath. J. Macromol. Sci. Part A 2006, 43, 1711–1720. [Google Scholar] [CrossRef]

- Schoolaert, E.; Ryckx, P.; Geltmeyer, J.; Maji, S.; Van Steenberge, P.H.; D’hooge, D.R.; Hoogenboom, R.; De Clerck, K. Waterborne Electrospinning of Poly(N-isopropylacrylamide) by Control of Environmental Parameters. ACS Appl. Mater. Interfaces 2017, 9, 24100. [Google Scholar] [CrossRef] [PubMed]

- Kotomin, S.V.; Kulichikhin, V.G.; Skvortsov, I.Y. “Mechanotropic” mechanism of electrospinning. In Proceedings of the 9th International Conference on Times of Polymers and Composites to be published in Journal of Materials Science and Engineering, Ischia, Italy, 17–21 June 2018; Volume 1981, p. 020183. [Google Scholar]

- Subbotin, A.V.; Semenov, A.N. Phase Separation in Dilute Polymer Solutions at High-Rate Extension. J. Polym. Sci. Part B Phys. Ed. 2016, 54, 1066–1073. [Google Scholar] [CrossRef]

- Semenov, A.N.; Subbotin, A.V. Phase Separation Kinetics in Unentangled Polymer Solutions under High-Rate Extension. J. Polym. Sci. Part B Phys. Ed. 2017, 55, 623–637. [Google Scholar] [CrossRef]

- Subbotin, A.; Stepanyan, R.; Chiche, A.; Slot, J.J.M.; ten Brinke, G. Dynamics of an electrically charged polymer jet. Phys. Fluids 2013, 25, 103101. [Google Scholar] [CrossRef] [Green Version]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kulichikhin, V.G.; Skvortsov, I.Y.; Subbotin, A.V.; Kotomin, S.V.; Malkin, A.Y. A Novel Technique for Fiber Formation: Mechanotropic Spinning—Principle and Realization. Polymers 2018, 10, 856. https://doi.org/10.3390/polym10080856

Kulichikhin VG, Skvortsov IY, Subbotin AV, Kotomin SV, Malkin AY. A Novel Technique for Fiber Formation: Mechanotropic Spinning—Principle and Realization. Polymers. 2018; 10(8):856. https://doi.org/10.3390/polym10080856

Chicago/Turabian StyleKulichikhin, Valery G., Ivan Yu. Skvortsov, Andrey V. Subbotin, Sergey V. Kotomin, and Alexander Ya. Malkin. 2018. "A Novel Technique for Fiber Formation: Mechanotropic Spinning—Principle and Realization" Polymers 10, no. 8: 856. https://doi.org/10.3390/polym10080856