Thermal Conductivity of Aluminosilicate- and Aluminum Oxide-Filled Thermosets for Injection Molding: Effect of Filler Content, Filler Size and Filler Geometry

Abstract

:1. Introduction

2. Models for Predicting Thermal Conductivity of Two-Phase Polymer Composite

3. Materials, Sample Fabrication and Testing Methods

3.1. Materials

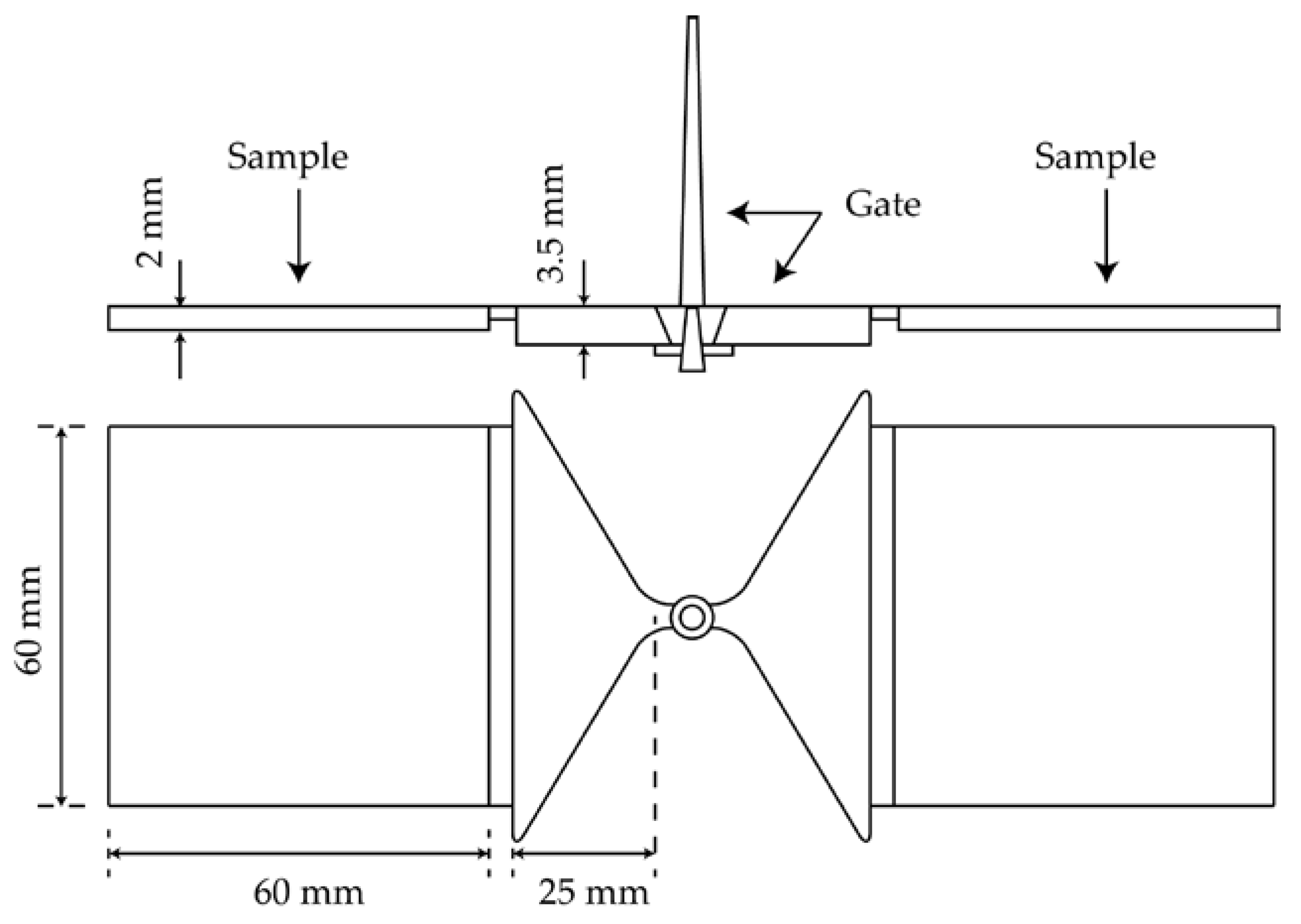

3.2. Sample Fabrication

3.3. Testing Methods

4. Results and Discussion

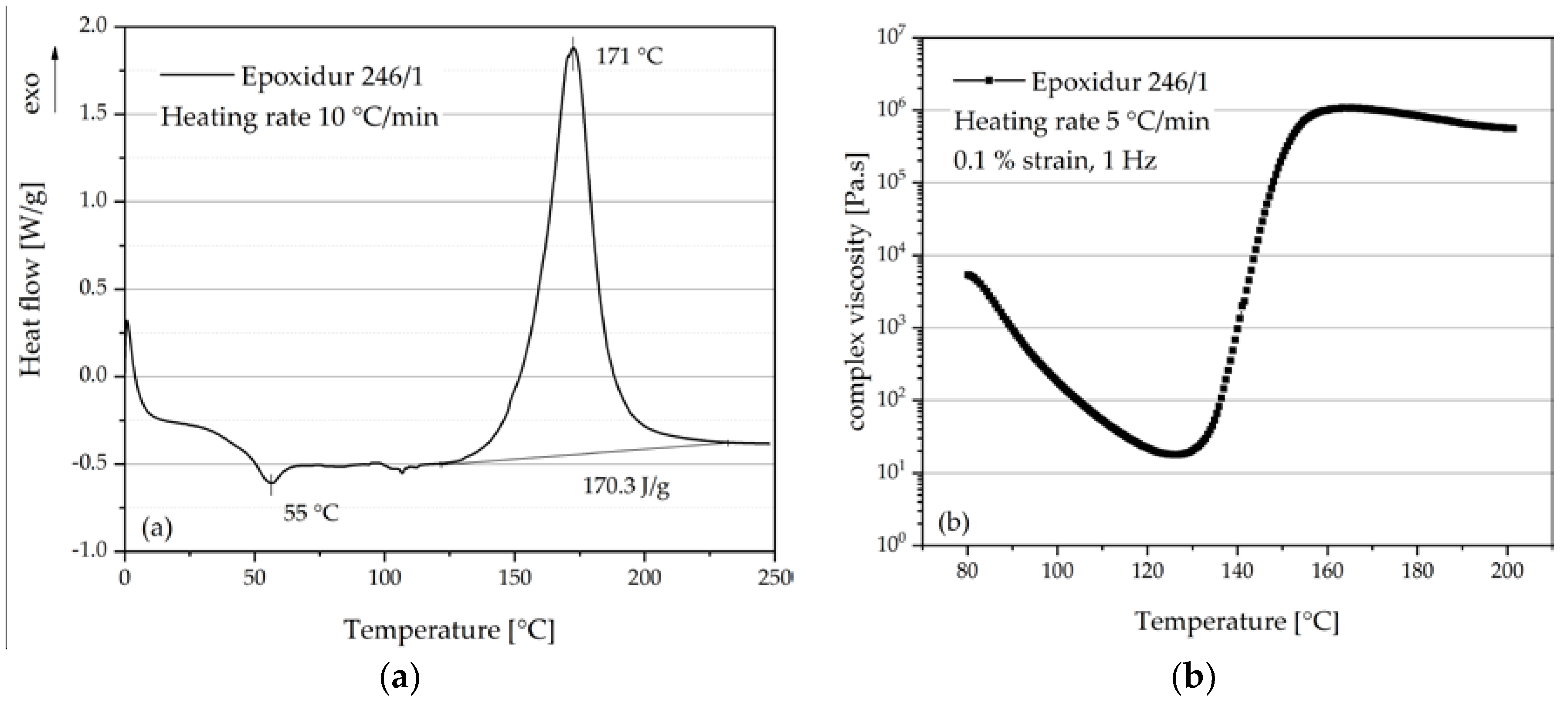

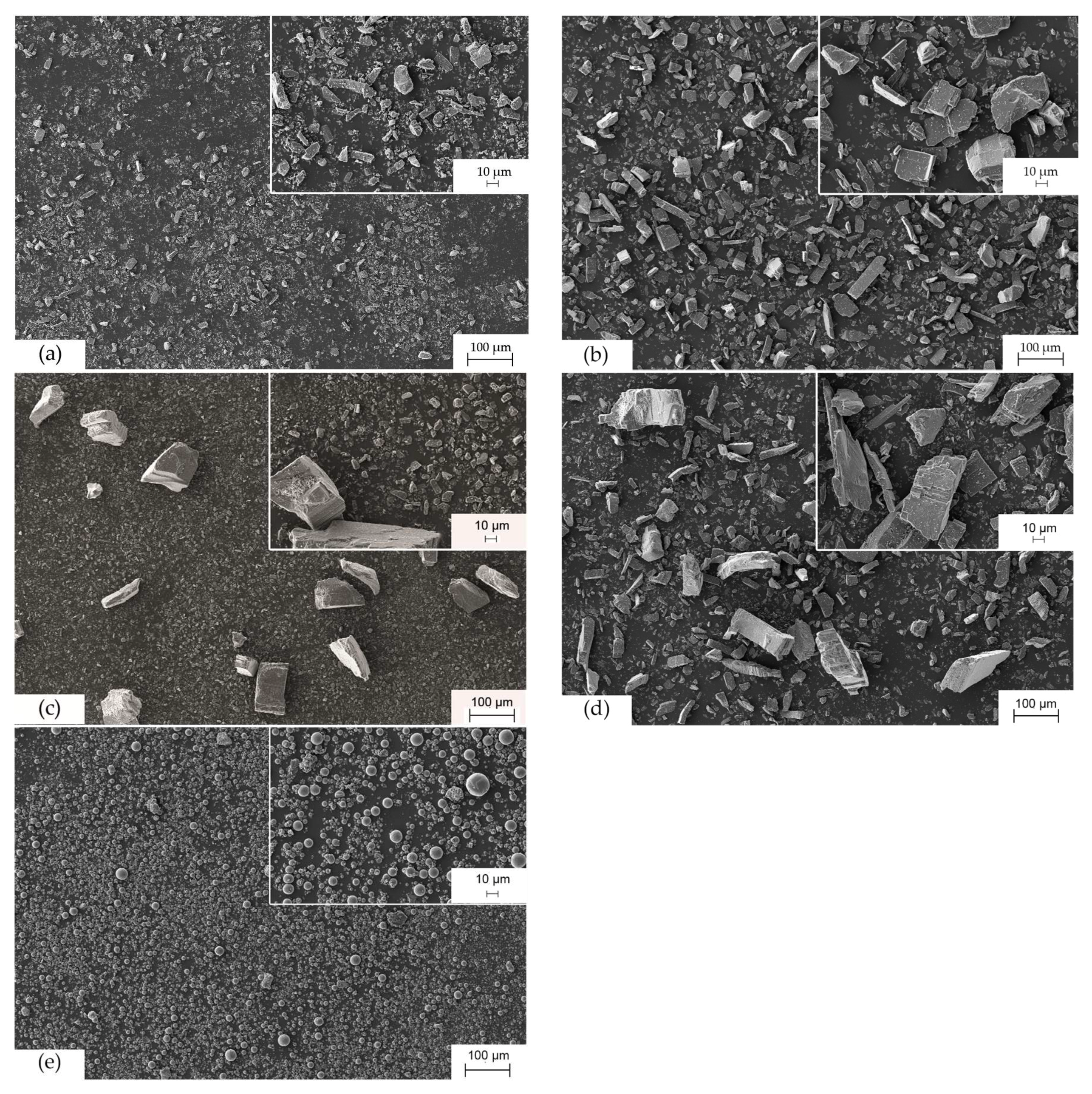

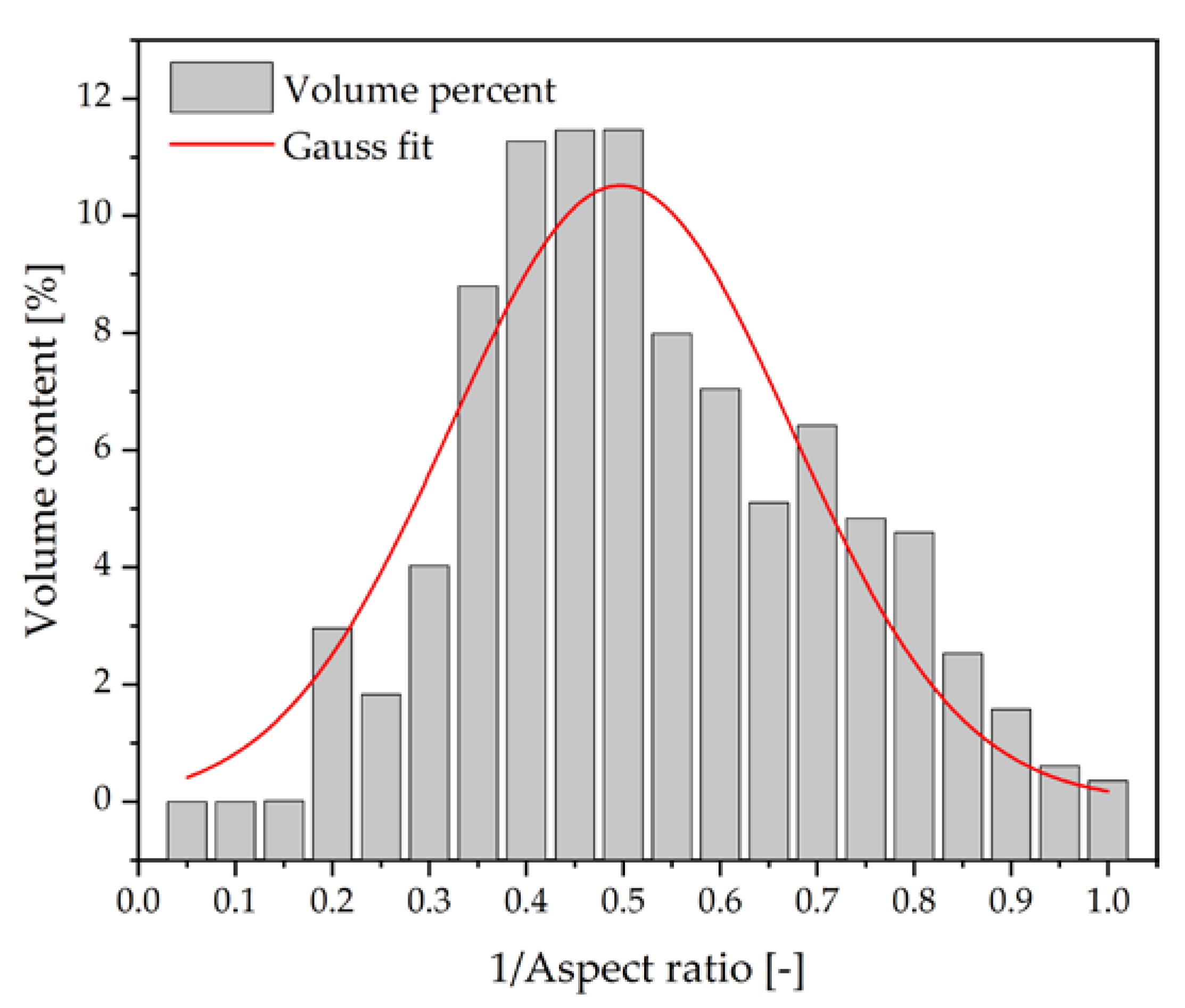

4.1. Characterization of the Polymer Matrix and Fillers

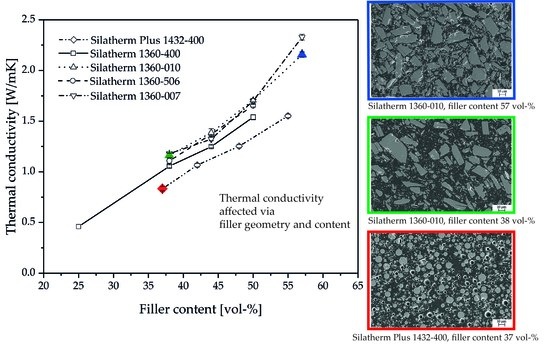

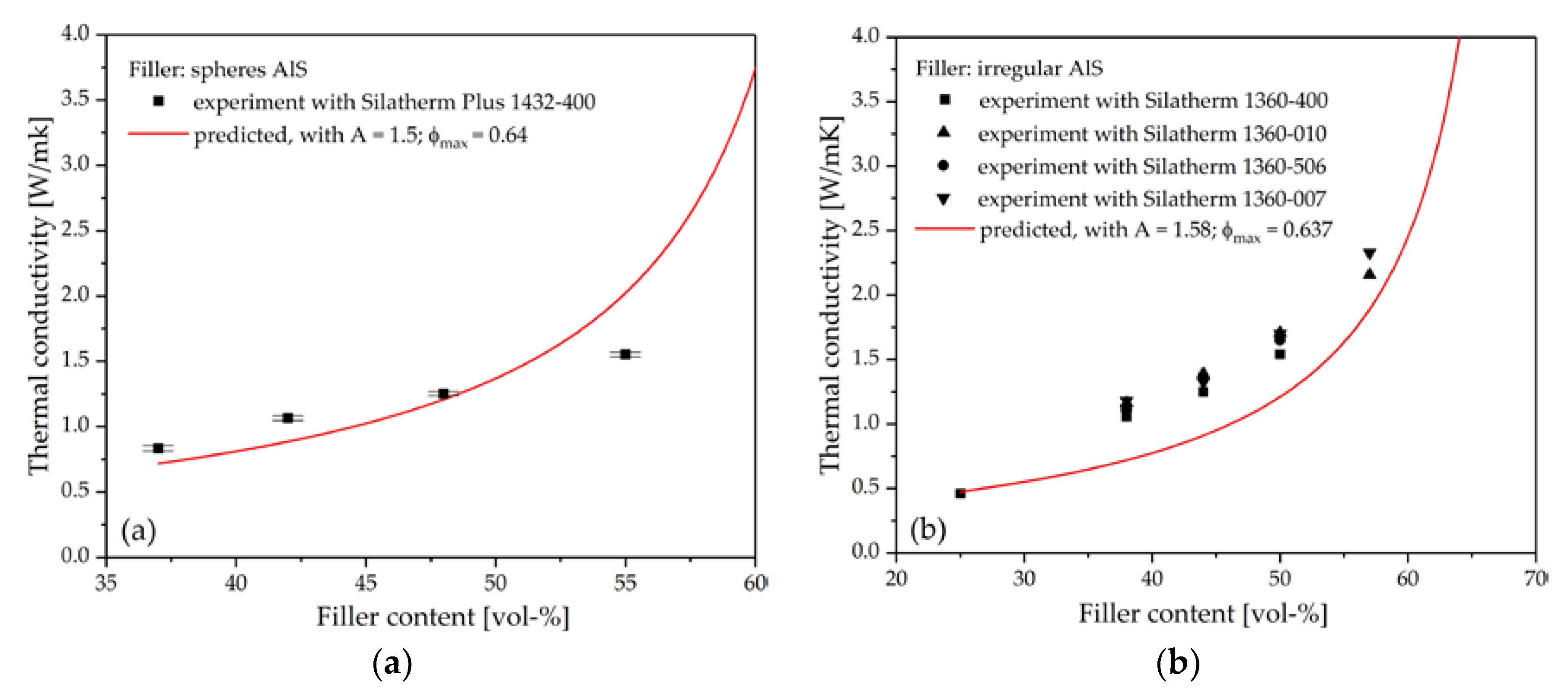

4.2. Thermal Coductivity of Composites

4.3. Distribution of Fillers in Injection Moled Samples

5. Conclusions

- For AlS and AlO filler, the thermal conductivity increases with an increasing filler content. It confirms that the increase of the content of thermal conductive filler is an important approach to improve the thermal conductivity of composites. When the filler content of composites is over 50 vol %, the increasing of fillers is more effective than low filled composites;

- Smaller fillers cannot improve the thermal conductivity as well as larger fillers can. Thus, fillers with bigger particle size should be considered preferable as raw material for composites with a high thermal conductivity;

- Fillers with sphere geometry are not as effective as those with cuboid geometry to improve the thermal conductivity. This is attributed to the smaller surface area of sphere fillers and more thermal-resistant interfaces;

- The Lewis-Nielsen equation is suitable to predict the thermal conductivity of a two-phase system with spheres filler content within 50 vol %. For irregular fillers, the predicted results obtained are smaller than the experimental values.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dudek, R.; Vogel, D.; Michel, B. Mechanical failure in cob-technology using glob-top encapsulation. IEEE Trans. Compon. Packag. Manuf. Technol. Part C 1996, 19, 232–240. [Google Scholar] [CrossRef]

- Henry, L.; Neville, K. Handbook of Epoxy Resins; Mc Crow-Hill Book: New York, NY, USA; San Francisko, CA, USA; Toronto, ON, Canada; London, UK; Sydney, Australia, 1967. [Google Scholar]

- Zhu, B.; Ma, J.; Wu, J.; Yung, K.; Xie, C. Study on the properties of the epoxy-matrix composites filled with thermally conductive aln and bn ceramic particles. J. Appl. Polym. Sci. 2010, 118, 2754–2764. [Google Scholar] [CrossRef]

- Agrawal, A.; Satapathy, A. Effects of aluminium nitride inclusions on thermal and electrical properties of epoxy and polypropylene: An experimental investigation. Compos. Part A 2014, 63, 51–58. [Google Scholar] [CrossRef]

- Gu, J.; Zhang, Q.; Dang, J.; Xie, C. Thermal conductivity epoxy resin composites filled with boron nitride. Polym. Adv. Technol. 2012, 23, 1025–1028. [Google Scholar] [CrossRef]

- Lee, E.S.; Lee, S.M.; Shanefield, D.J.; Cannon, W.R. Enhanced thermal conductivity of polymer matrix composite via high solids loading of aluminum nitride in epoxy resin. J. Am. Ceram. Soc. 2008, 91, 1169–1174. [Google Scholar] [CrossRef]

- Ganguli, S.; Roy, A.K.; Anderson, D.P. Improved thermal conductivity for chemically functionalized exfoliated graphite/epoxy composites. Carbon 2008, 46, 806–817. [Google Scholar] [CrossRef]

- Hsieh, C.Y.; Chung, S.L. High thermal conductivity epoxy molding compound filled with a combustion synthesized aln powder. J. Appl. Polym. Sci. 2006, 102, 4734–4740. [Google Scholar] [CrossRef]

- Gumede, T.; Luyt, A.; Hassan, M.; Pérez-Camargo, R.; Tercjak, A.; Müller, A. Morphology, nucleation, and isothermal crystallization kinetics of poly(ε-caprolactone) mixed with a polycarbonate/mwcnts masterbatch. Polymers 2017, 9, 709. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, J.; Guo, J.; Sun, X.; Xu, L. The study of thermal, mechanical and shape memory properties of chopped carbon fiber-reinforced tpi shape memory polymer composites. Polymers 2017, 9, 594. [Google Scholar] [CrossRef]

- Kim, M.; Lee, J.; Roh, H.-G.; Kim, D.; Byeon, J.; Park, J. Effects of covalent functionalization of mwcnts on the thermal properties and non-isothermal crystallization behaviors of PPS composites. Polymers 2017, 9, 460. [Google Scholar] [CrossRef]

- Kim, M.; Park, S.; Park, J. Effect of the grafting reaction of aluminum nitride on the multi-walled carbon nanotubes on the thermal properties of the poly(phenylene sulfide) composites. Polymers 2017, 9, 452. [Google Scholar] [CrossRef]

- Hong, H.; Kim, J.; Kim, T.-I. Effective assembly of nano-ceramic materials for high and anisotropic thermal conductivity in a polymer composite. Polymers 2017, 9, 413. [Google Scholar] [CrossRef]

- Amesöder, S. Wärmeleitende Kunststoffe für das Spritzgießen; Lehrstuhl für Kunststofftechnik, Friedrich-Alexander-University: Erlangen, Germany, 2009. [Google Scholar]

- Sol-Gel, Z. Chemistry of silicates and aluminosilicates. Ceram.-Silikáty 2005, 49, 287–298. [Google Scholar]

- Nielsen, L.E. The thermal and electrical conductivity of two-phase systems. Ind. Eng. Chem. Fundam. 1974, 13, 17–20. [Google Scholar] [CrossRef]

- Pal, R. On the lewis-nielsen model for thermal/electrical conductivity of composites. Compos. Part A 2008, 39, 718–726. [Google Scholar] [CrossRef]

- Hopmann, C.; Adamy, M. Wirtschaftliche wärmeleiter: Compoundierung von wärmeleitfähigen kunststoffen mit hybriden füllstoffsystemen. Kunststoffe 2016, 8, 89–93. [Google Scholar]

- Affdl, J.; Kardos, J. The halpin-tsai equations: A review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar] [CrossRef]

- Hiroshi, H.; Minoru, T. Equivalent inclusion method for steady state heat conduction in composites. Int. J. Eng. Sci. 1986, 24, 1159–1172. [Google Scholar] [CrossRef]

- Progelhof, R.; Throne, J.; Ruetsch, R. Methods for predicting the thermal conductivity of composite systems: A review. Polym. Eng. Sci. 1976, 16, 615–625. [Google Scholar] [CrossRef]

- Lewis, T.; Nielsen, L. Dynamic mechanical properties of particulate-filled composites. J. Appl. Polym. Sci. 1970, 14, 1449–1471. [Google Scholar] [CrossRef]

- Ultramid Hauptbroschüre; BASF: Ludwigshafen, Germany, 2017.

- Burger, N.; Laachachi, A.; Ferriol, M.; Lutz, M.; Toniazzo, V.; Ruch, D. Review of thermal conductivity in composites: Mechanisms, parameters and theory. Prog. Polym. Sci. 2016, 61, 1–28. [Google Scholar] [CrossRef]

- Bigg, D. Thermally conductive polymer compositions. Polym. Compos. 1986, 7, 125–140. [Google Scholar] [CrossRef]

- Heinle, C. Simulationsgestützte Entwicklung von Bauteilen aus Wärmeleitenden Kunststoffen. Ph.D. Thesis, Friedrich-Alexander-University, Erlangen, Germany, 2012. [Google Scholar]

| Product | Typical chemical analysis (Weight %) | Density (g/cm3) | Thermal conductivity (W/mK) | Mohs hardness (-) | ||||

|---|---|---|---|---|---|---|---|---|

| Al2O3 | SiO2 | TiO2 | Fe2O3 | Rests | ||||

| Silatherm 1360 | 55 | 43 | 1 | 0.5 | 0.5 | 3.65 | 14 | 5 |

| Silatherm Plus 1432 | 99 | - | - | - | 1 | 4 | 30 | 9 |

| Product | Silatherm 1360 EST * | Silatherm plus 1432 EST * | ||||

|---|---|---|---|---|---|---|

| Classify | 007 | 506 | 010 | 400 | −400 | |

| Upper gain size | D90% in µm | 94 | 129 | 22 | 12 | 16 |

| Average gain size | D50% in µm | 28 | 10 | 9 | 5 | 5 |

| Lower gain size | D10% in µm | 2 | 1 | 1 | 1 | 1 |

| Particle geometry | Cuboid | Spherical | ||||

| Filler | Classify of particle size | Filler content | |

|---|---|---|---|

| (Weight %) | (Volume %) | ||

| AlS (Silatherm 1360) | 007 | 65, 70, 75, 80 | 38, 44, 50, 57 |

| AlS (Silatherm 1360) | 506 | 65, 70, 75 | 38, 44, 50 |

| AlS (Silatherm 1360) | 010 | 65, 70, 75, 80 | 38, 44, 50, 57 |

| AlS (Silatherm 1360) | 400 | 50, 65, 70, 75 | 25, 38, 44, 50 |

| AlO (Silahterm Plus 1432) | 400 | 65, 70, 75, 80 | 37, 42, 48, 55 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Zhai, Z.; Drummer, D. Thermal Conductivity of Aluminosilicate- and Aluminum Oxide-Filled Thermosets for Injection Molding: Effect of Filler Content, Filler Size and Filler Geometry. Polymers 2018, 10, 457. https://doi.org/10.3390/polym10040457

Zhao Y, Zhai Z, Drummer D. Thermal Conductivity of Aluminosilicate- and Aluminum Oxide-Filled Thermosets for Injection Molding: Effect of Filler Content, Filler Size and Filler Geometry. Polymers. 2018; 10(4):457. https://doi.org/10.3390/polym10040457

Chicago/Turabian StyleZhao, Yang, Zhanyu Zhai, and Dietmar Drummer. 2018. "Thermal Conductivity of Aluminosilicate- and Aluminum Oxide-Filled Thermosets for Injection Molding: Effect of Filler Content, Filler Size and Filler Geometry" Polymers 10, no. 4: 457. https://doi.org/10.3390/polym10040457