Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites

Abstract

:1. Introduction

2. Experiment

2.1. Materials

2.2. Preparation of Composites

2.3. Measurements and Characterization

2.3.1. Microscopy and Structure

2.3.2. Non-Isothermal Crystallization Behavior

2.3.3. Mechanical Properties

3. Results and Discussion

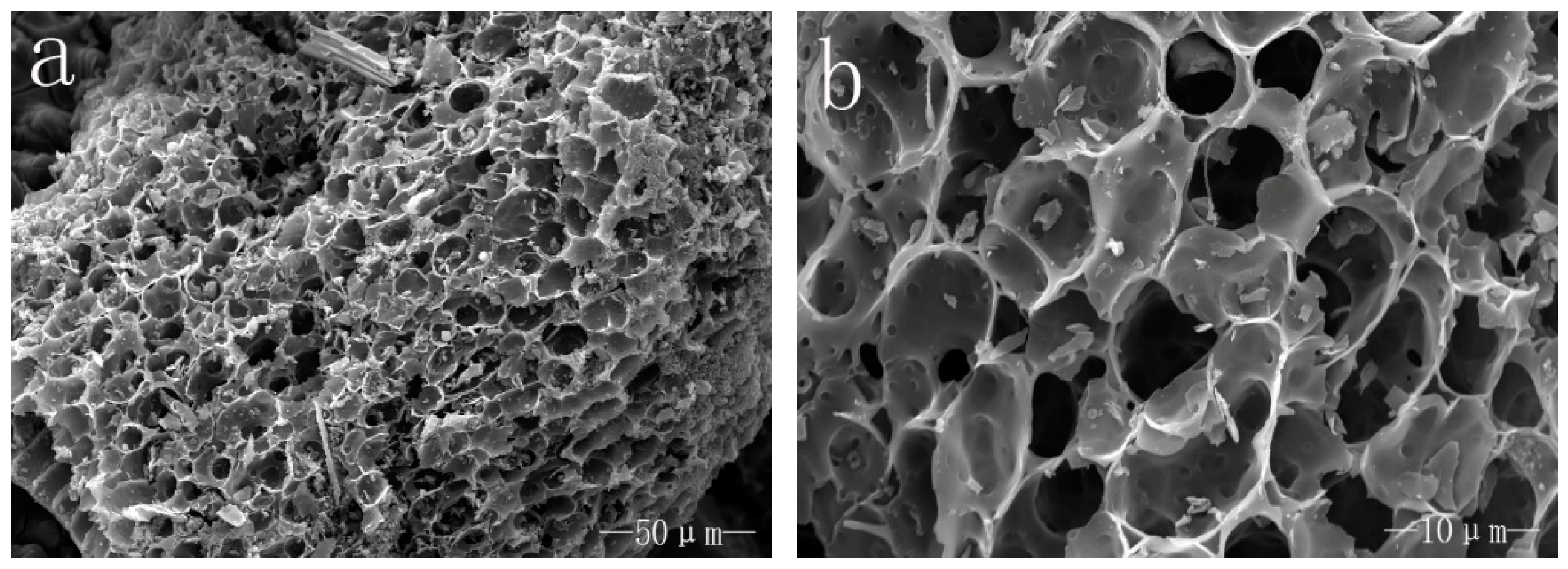

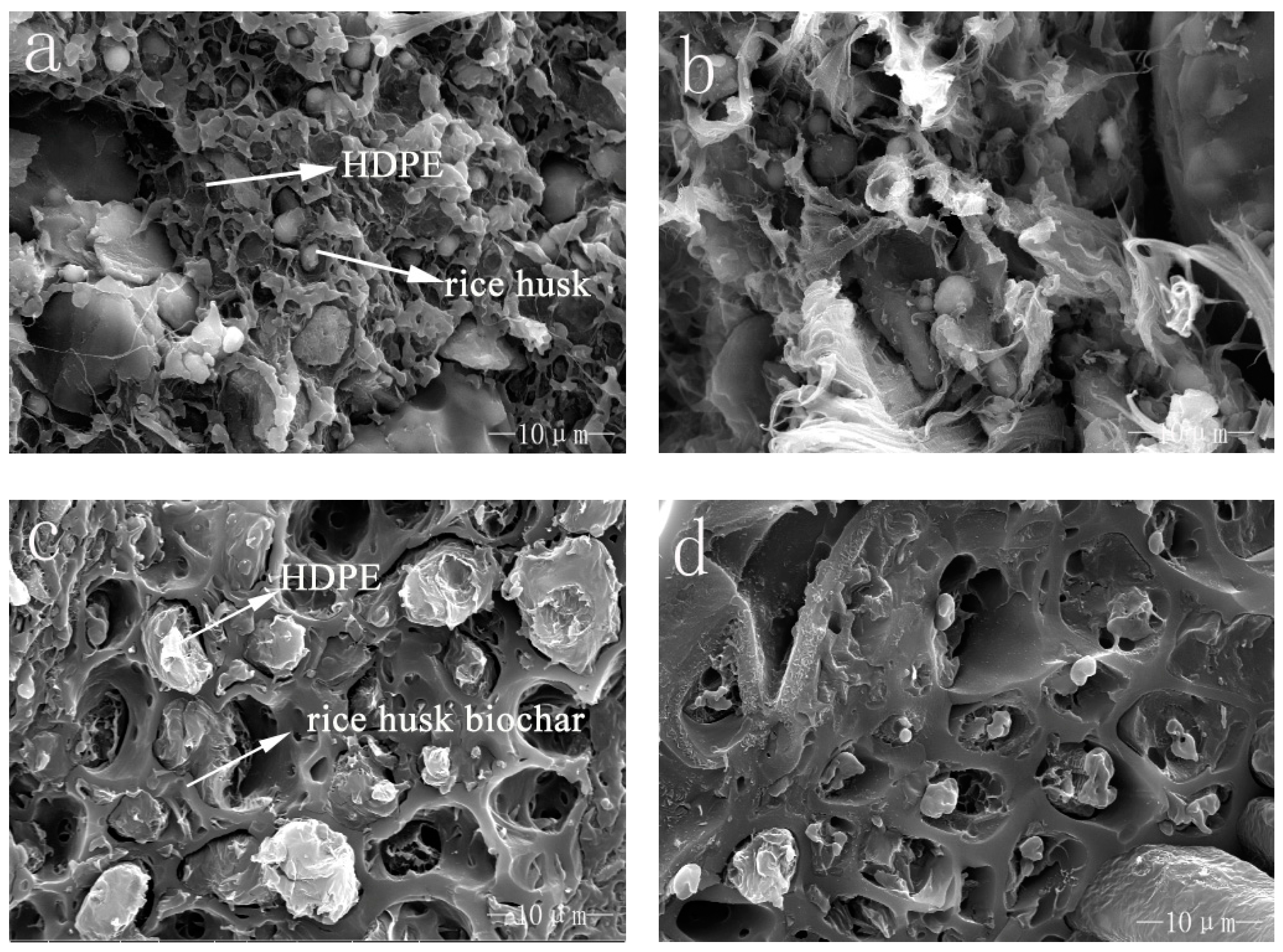

3.1. SEM Observations

3.2. Non-Isothermal Crystallization Behavior

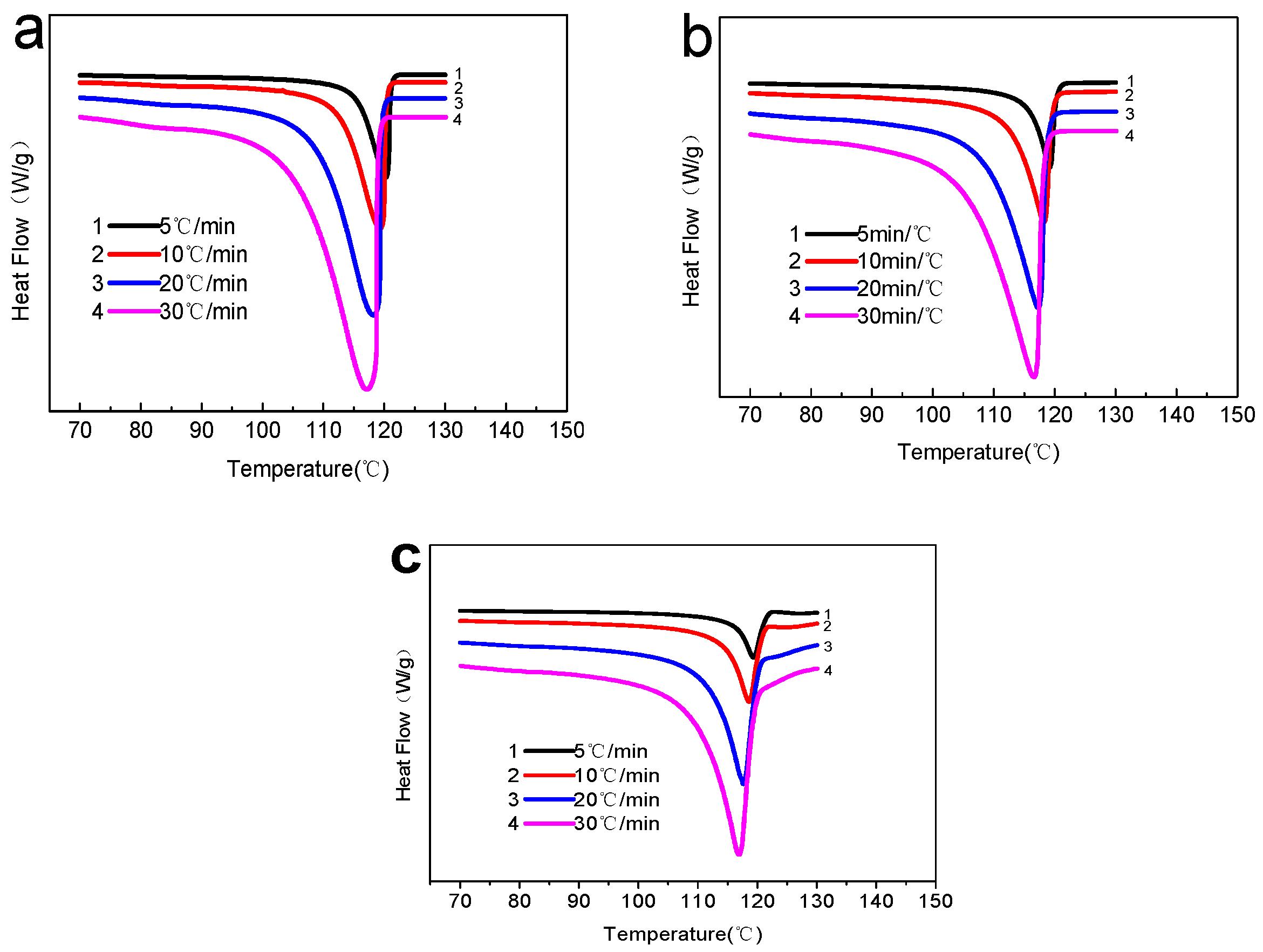

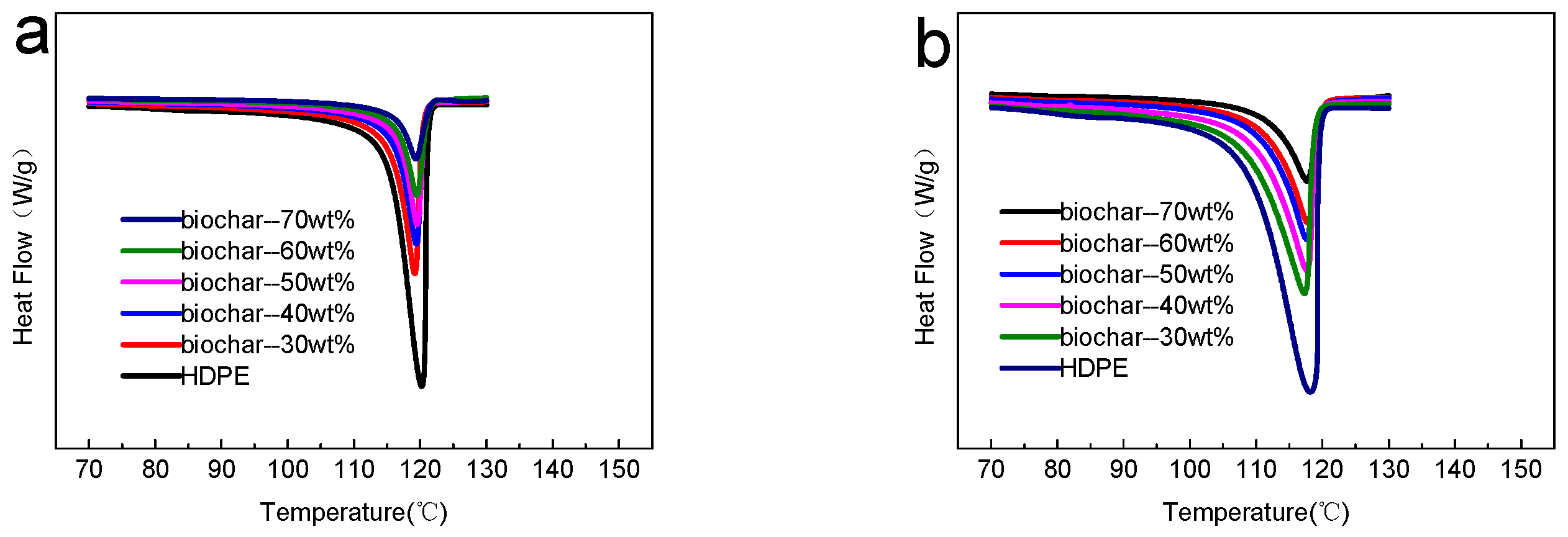

3.2.1. Crystallization Behavior

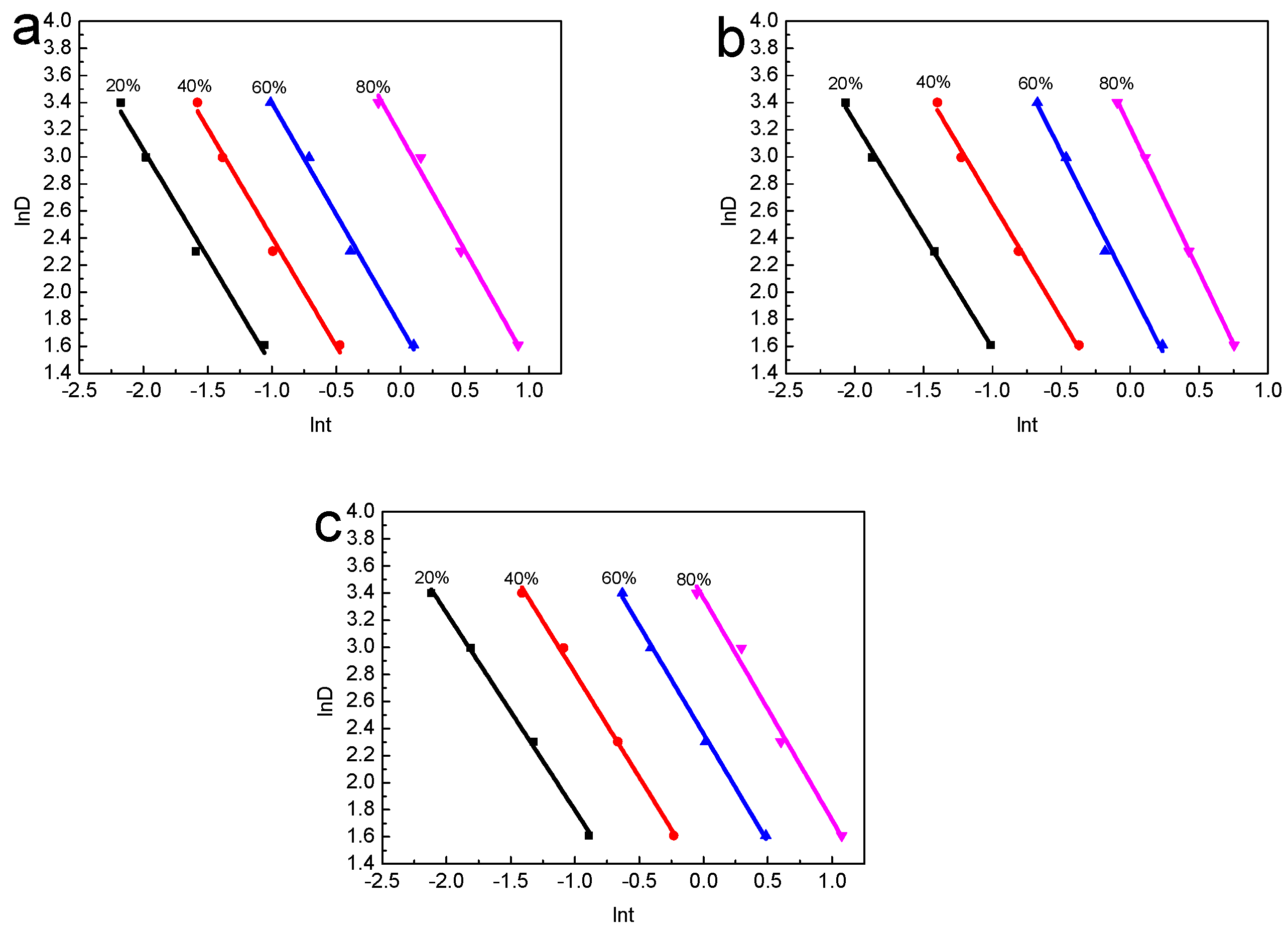

3.2.2. Non-Isothermal Crystallization Kinetics

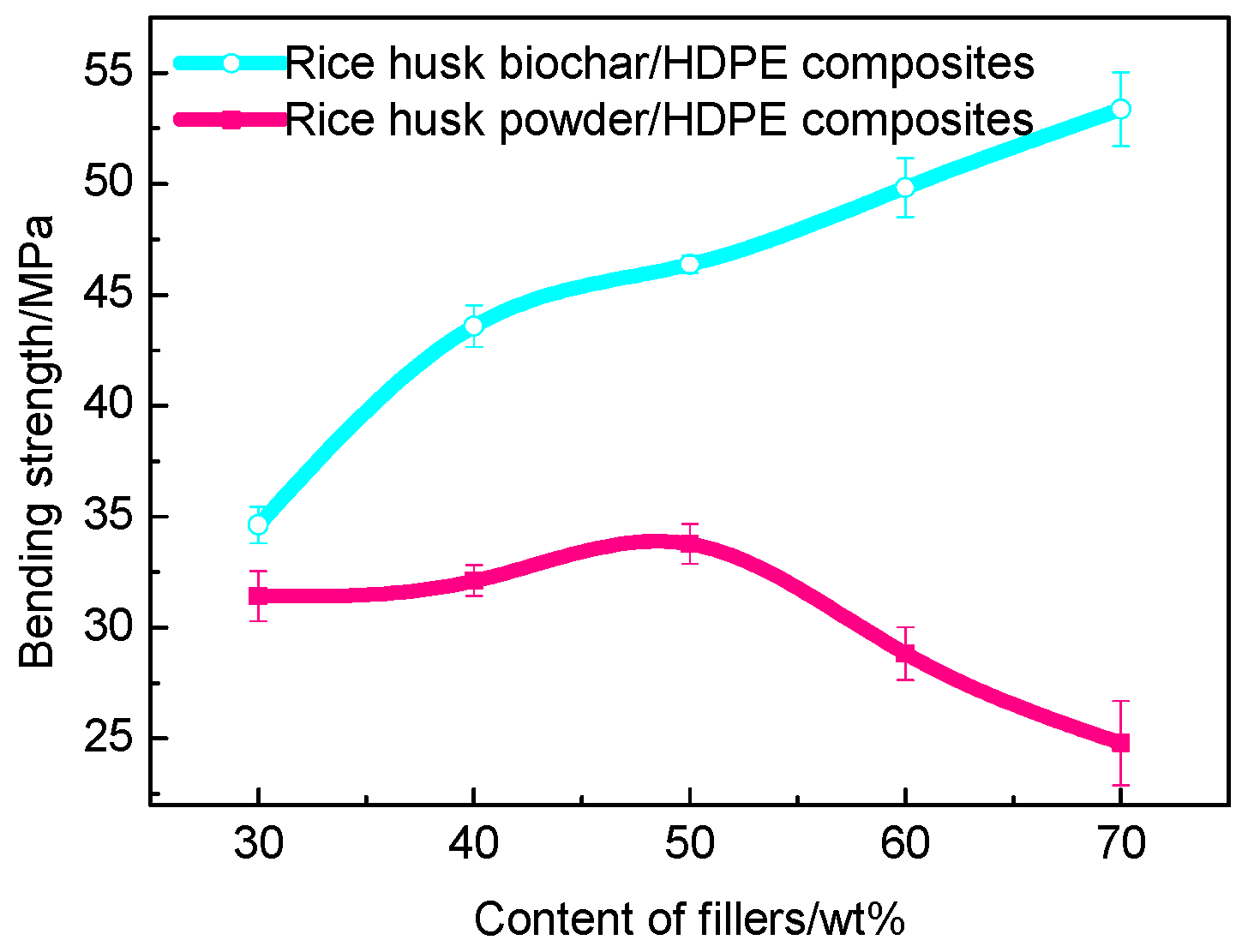

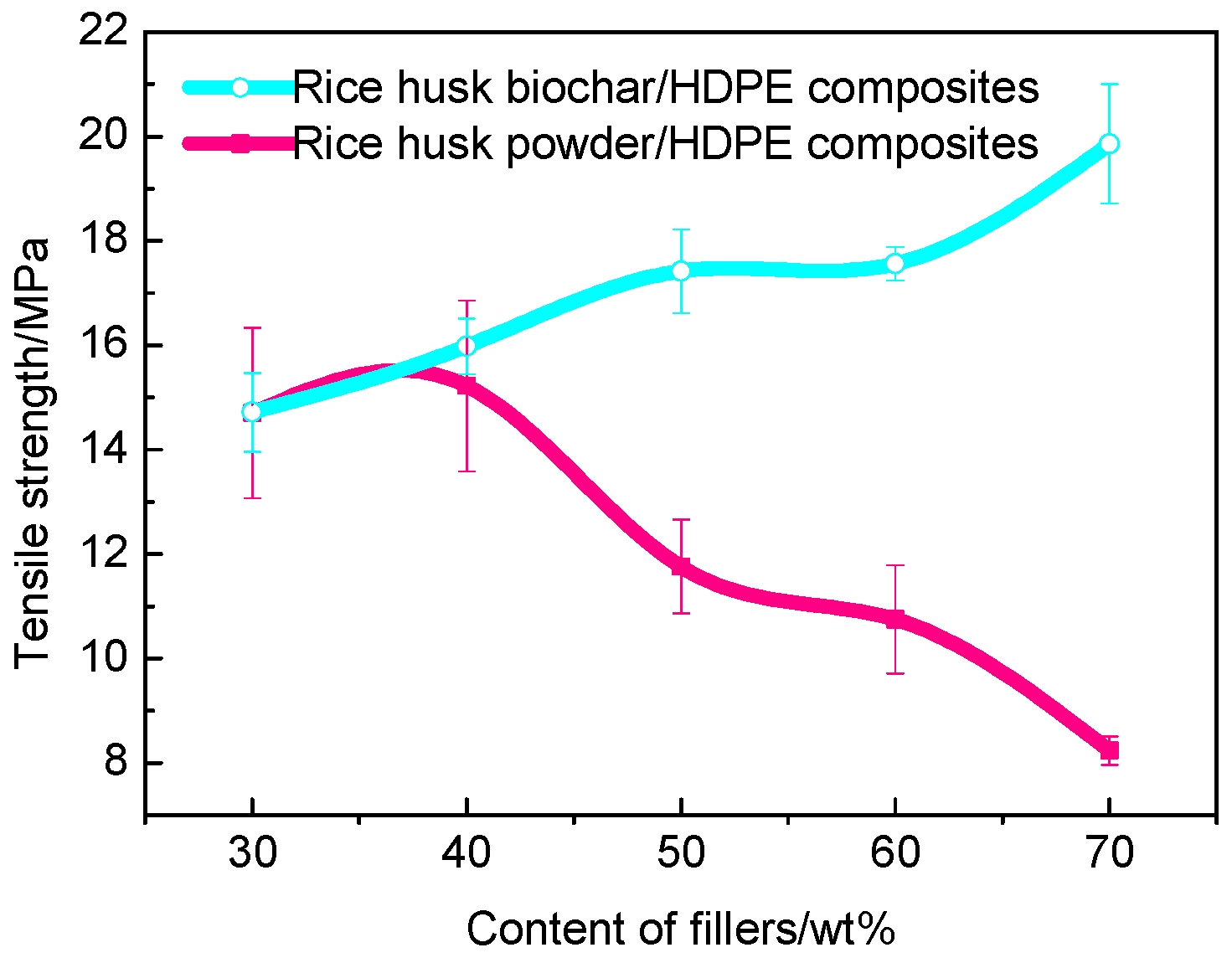

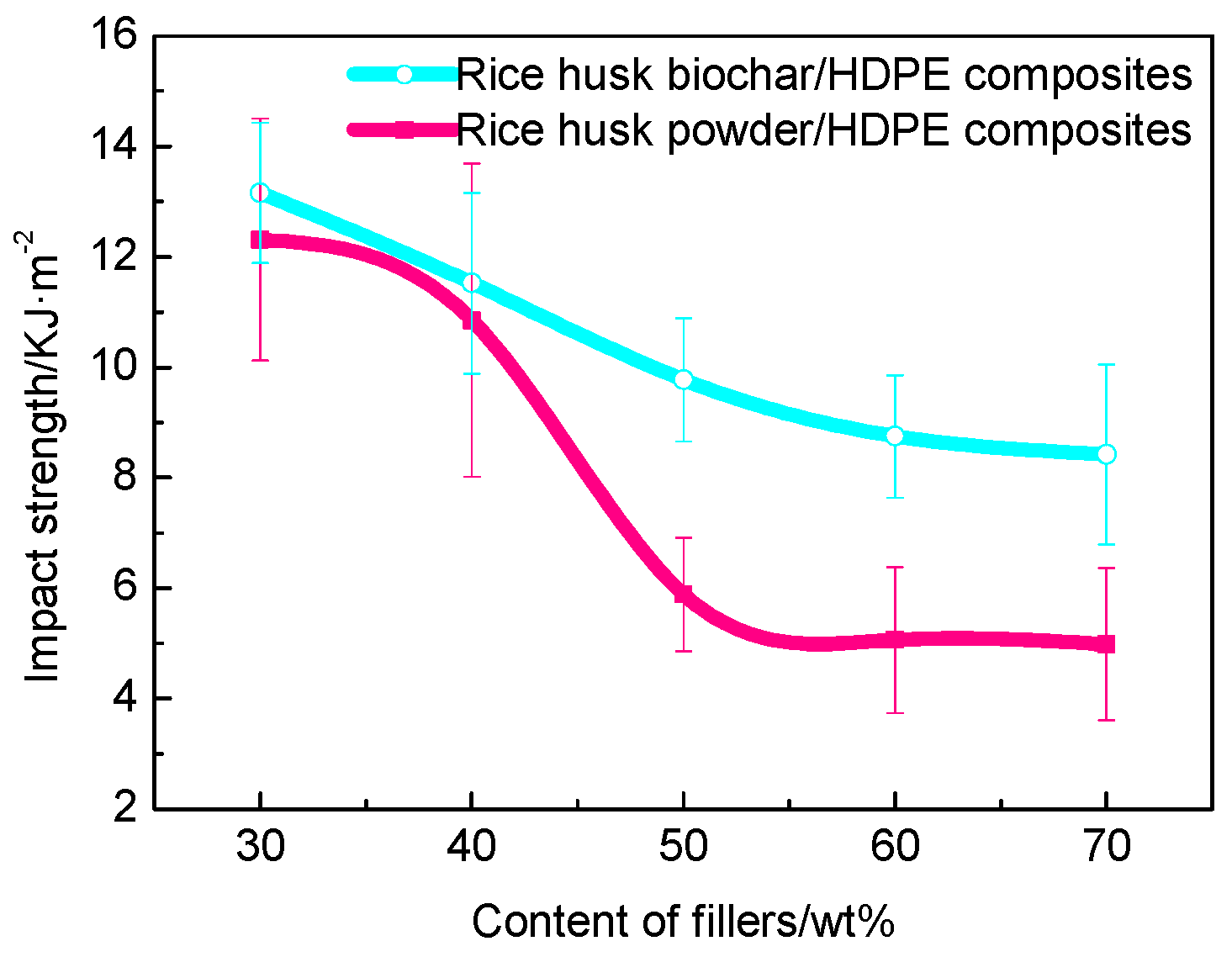

3.3. Mechanical Properties

3.3.1. Bending Strength

3.3.2. Tensile Strength

3.3.3. Impact Strength

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Cicala, G.; Saccullo, G.; Blanco, I.; Samal, S.; Battiato, S.; Dattilo, S.; Saake, B. Polylactide/lignin blends: Effects of processing conditions on structure and thermo-mechanical properties. J. Therm. Anal. Calorim. 2017, 130, 515–524. [Google Scholar] [CrossRef]

- Cicala, G.; Tosto, C.; Latteri, A.; La Rosa, A.D.; Blanco, I.; Elsabbagh, A.; Russo, P.; Ziegmann, G. Green Composites Based on Blends of Polypropylene with Liquid Wood Reinforced with Hemp Fibers: Thermomechanical Properties and the Effect of Recycling Cycles. Materials 2017, 10, 998. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Li, X.; Deng, Q.; Li, D. Three kinds of charcoal powder reinforced ultra-high molecular weight polyethylene composites with excellent mechanical and electrical properties. Mater. Des. 2015, 85, 54–59. [Google Scholar] [CrossRef]

- Nguila, I.G.; Petrissans, M.; Gerardin, P. Chemical reactivity of heat-treated wood. Wood Sci. Technol. 2007, 41, 157–168. [Google Scholar] [CrossRef]

- Hu, R.; Lim, J.-K. Fabrication and Mechanical Properties of Completely Biodegradable Hemp Fiber Reinforced PLA Composites. J. Compos. Mater. 2007, 41, 1655–1669. [Google Scholar] [CrossRef]

- Jayamani, E.; Bakri, M.K.B. Dielectric Properties of Lignocellulosic Fibers Reinforced Polymer Composites: Effect of Fiber Loading and Alkaline Treatment. Mater. Today Proc. 2015, 2, 2757–2766. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Gu, C.; Liu, J.; Liu, Y.; Li, M.; Lu, Y. Enhancement of the Mechanical Properties of Basalt Fiber-Wood-Plastic Composites via Maleic Anhydride Grafted High-Density Polyethylene (MAPE) Addition. Materials 2013, 6, 2483–2496. [Google Scholar] [CrossRef] [PubMed]

- Schirp, A.; Stender, J. Properties of extruded wood-plastic composites based on refiner wood fibres (TMP fibres) and hemp fibres. Eur. J. Wood Wood Prod. 2010, 68, 219–231. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. A novel approach in organic waste utilization through biochar addition in wood/polypropylene composites. Waste Manag. 2015, 38, 132–140. [Google Scholar] [CrossRef] [PubMed]

- Colantoni, A.; Evic, N.; Lord, R.; Retschitzegger, S.; Proto, A.R.; Gallucci, F.; Monarca, D. Characterization of biochars produced from pyrolysis of pelletized agricultural residues. Renew. Sustain. Energy Rev. 2016, 64, 187–194. [Google Scholar] [CrossRef] [Green Version]

- Srinivasan, P.; Sarmah, A.K. Characterisation of agricultural waste-derived biochars and their sorption potential for sulfamethoxazole in pasture soil: A spectroscopic investigation. Sci. Total Environ. 2015, 502, 471–480. [Google Scholar] [CrossRef] [PubMed]

- Krishnakumar, S.; Rajalakshmi, A.G.; Balaganesh, B.; Manikandan, P.; Vinoth, C.; Rajendran, V. Impact of Biochar on Soil Health. Int. J. Adv. Res. 2014, 2, 933–950. [Google Scholar]

- Sarmah, A.K.; Srinivasan, P.; Smernik, R.J.; Manleyharris, M.; Antal, M.J., Jr.; Downie, A.; Zwieten, L.V.; Krull, E.; Singh, B.; Joseph, S. Retention capacity of biochar-amended New Zealand dairy farm soil for an estrogenic steroid hormone and its primary metabolite. Aust. J. Soil Res. 2010, 48, 648–658. [Google Scholar] [CrossRef]

- Das, O.; Bhattacharyya, D.; Hui, D.; Lau, K.T. Mechanical and flammability characterisations of biochar/polypropylene biocomposites. Compos. Part B Eng. 2016, 106, 120–128. [Google Scholar] [CrossRef]

- Ikram, S.; Das, O.; Bhattacharyya, D. A parametric study of mechanical and flammability properties of biochar reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2016, 91, 177–188. [Google Scholar] [CrossRef]

- Zhang, Q.; Cai, H.; Ren, X.; Kong, L.; Liu, J.; Jiang, X. The Dynamic Mechanical Analysis of Highly Filled Rice Husk Biochar/High-Density Polyethylene Composites. Polymers 2017, 9, 628. [Google Scholar] [CrossRef]

- Khan, A.; Savi, P.; Quaranta, S.; Rovere, M.; Giorcelli, M.; Tagliaferro, A.; Rosso, C.; Jia, C. Low-Cost Carbon Fillers to Improve Mechanical Properties and Conductivity of Epoxy Composites. Polymers 2017, 9, 642. [Google Scholar] [CrossRef]

- Rao, A.K.; Ahmad, S.; Savi, P.; Tulliani, J.M.; Giorcelli, M.; Ferro, G.A. Improvement in electromagnetic interference shielding effectiveness of cement composites using carbonaceous nano/micro inerts. Constr. Build. Mater. 2015, 85, 208–216. [Google Scholar]

- Li, S.; Li, D. Carbon fiber reinforced highly filled charcoal powder/ultra high molecular weight polyethylene composites. Mater. Lett. 2014, 134, 99–102. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; He, L.; Lu, K.; Sarmah, A.; Li, J.; Bolan, N.S.; Pei, J.; Huang, H. Using biochar for remediation of soils contaminated with heavy metals and organic pollutants. Environ. Sci. Pollut. Res. 2013, 20, 8472–8483. [Google Scholar] [CrossRef] [PubMed]

- Mo, Z. A method for the non-isothermal crystallization kinetics of polymers. Acta Polym. Sin. 2008, 008, 656–661. [Google Scholar] [CrossRef]

- Huttepain, M.; Oberlin, A. Microtexture of nongraphitizing carbons and tem studies of some activated samples. Carbon 1990, 28, 103–111. [Google Scholar] [CrossRef]

- Kyotani, T. Control of pore structure in carbon. Carbon 2000, 38, 269–286. [Google Scholar] [CrossRef]

- Liou, T.H. Preparation and characterization of nano-structured silica from rice husk. Mater. Sci. Eng. A 2004, 364, 313–323. [Google Scholar] [CrossRef]

- You, Z.; Li, D. The dynamical viscoelasticity and tensile property of new highly filled charcoal powder/ultra-high molecular weight polyethylene composites. Mater. Lett. 2013, 112, 197–199. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A.; Scherzer, D. Mechanical properties of PLA composites with man-made cellulose and abaca fibres. Compos. Part A Appl. Sci. Manuf. 2009, 40, 404–412. [Google Scholar] [CrossRef]

- Sewda, K.; Maiti, S.N. Crystallization and melting behavior of HDPE in HDPE/teak wood flour composites and their correlation with mechanical properties. J. Appl. Polym. Sci. 2010, 118, 2264–2275. [Google Scholar] [CrossRef]

- Huang, L.; Wang, H.; Wang, Q. The non-isothermal crystallization kinetics analysis of polypropylene based wood plastic composite. Eng. Sci. 2014, 16, 21–24. [Google Scholar]

- Joshi, M.; Butola, B.S. Studies on nonisothermal crystallization of HDPE/POSS nanocomposites. Polymer 2004, 45, 4953–4968. [Google Scholar] [CrossRef]

- Ou, R.; Xie, Y.; Guo, C.; Wang, Q. Isothermal crystallization kinetics of Kevlar fiber-reinforced wood flour/high-density polyethylene composites. J. Appl. Polym. Sci. 2012, 126, E2–E9. [Google Scholar] [CrossRef]

- Shi, X.; Wang, J.; Jiang, B.; Yang, Y. Influence of nanofiller dimensionality on the crystallization behavior of HDPE/carbon nanocomposites. J. Appl. Polym. Sci. 2013, 128, 3609–3618. [Google Scholar] [CrossRef]

- Ahmad, I.; Chong, E.L.; Mohd, D.H.; Abdullah, I. Electron-beam-irradiated rice husk powder as reinforcing filler in natural rubber/high-density polyethylene (NR/HDPE) composites. Compos. Part B Eng. 2012, 43, 3069–3075. [Google Scholar] [CrossRef]

- Kord, B. Nanofiller reinforcement effects on the thermal, dynamic mechanical, and morphological behavior of hdpe/rice husk flour composites. Bioresources 2011, 6, 1351–1358. [Google Scholar]

- Lu, J.Z.; Wu, Q.; Negulescu, I.I. Wood-fiber/high-density-polyethylene composites: Coupling agent performance. J. Appl. Polym. Sci. 2010, 96, 93–102. [Google Scholar] [CrossRef]

- Nurshamila, S.B.; Ismail, H.; Othman, N. The effect of Rattan filler loading on properties of Rattan powder filled polypropylene composites. Bioresources 2012, 7, 5677–5690. [Google Scholar] [CrossRef]

| Cooling Rate °C/min | Maximum Crystallization Peak Temperature °C | |||||

|---|---|---|---|---|---|---|

| HDPE | Biochar—30% | Biochar—40% | Biochar—50% | Biochar—60% | Biochar—70% | |

| 5 | 120.22 | 119.19 | 119.44 | 119.53 | 119.49 | 119.39 |

| 10 | 119.33 | 118.25 | 118.59 | 118.55 | 118.54 | 118.62 |

| 20 | 118.31 | 117.37 | 117.69 | 117.65 | 117.78 | 117.71 |

| 30 | 117.23 | 116.68 | 116.32 | 117.01 | 117.45 | 116.98 |

| Relative Crystallinity | HDPE | BPC (Biochar—30 wt %) | BPC (Biochar—70 wt %) | |||

|---|---|---|---|---|---|---|

| a | F(T) | a | F(T) | a | F(T) | |

| 20% | 1.60 | 0.87 | 1.67 | 0.92 | 1.46 | 1.62 |

| 40% | 1.61 | 2.22 | 1.71 | 2.58 | 1.53 | 5.37 |

| 60% | 1.65 | 5.75 | 2.00 | 7.65 | 1.60 | 11.36 |

| 80% | 1.70 | 23.48 | 2.12 | 24.90 | 1.64 | 29.69 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Yi, W.; Li, Z.; Wang, L.; Cai, H. Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites. Polymers 2018, 10, 286. https://doi.org/10.3390/polym10030286

Zhang Q, Yi W, Li Z, Wang L, Cai H. Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites. Polymers. 2018; 10(3):286. https://doi.org/10.3390/polym10030286

Chicago/Turabian StyleZhang, Qingfa, Weiming Yi, Zhihe Li, Lihong Wang, and Hongzhen Cai. 2018. "Mechanical Properties of Rice Husk Biochar Reinforced High Density Polyethylene Composites" Polymers 10, no. 3: 286. https://doi.org/10.3390/polym10030286