Novel Bacterial Cellulose-Poly (Acrylic Acid) Hybrid Hydrogels with Controllable Antimicrobial Ability as Dressings for Chronic Wounds

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Synthesis of AM-Grafted BC-PAA Hydrogel Hybrid Composite

2.3. Morphological Characterisation

2.4. Mechanical Properties Test

2.5. Hygroscopicity Test

2.6. Drug Release Test

3. Results and Discussion

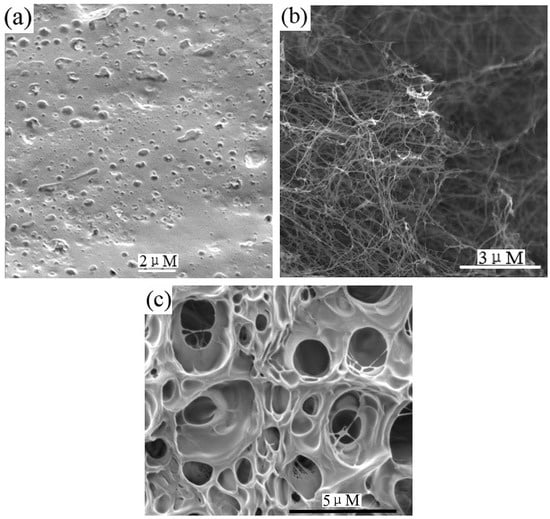

3.1. Morphological Characterization

3.2. FTIR Analysis

3.3. Mechanical Properties Test

3.4. Hygroscopicity Test

3.5. Drug Release Test

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mostoe, T.A.; O’Shaughnessy, K.; Kloeters, O. Chronic wound pathogenesis and current treatment strategies: A unifying hypothesis. Plast. Reconstr. Surg. 2006, 117, 35S–41S. [Google Scholar] [CrossRef] [PubMed]

- Werdin, F.; Tennenhaus, M.; Schaller, H.-E.; Rennekampff, H.-O. Evidence-based management strategies for treatment of chronic wounds. Eplasty 2009, 9, e19. [Google Scholar] [PubMed]

- Schneider, L.A.; Korber, A.; Grabbe, S.; Dissemond, J. Influence of pH on wound-healing: A new perspective for wound-therapy? Arch. Dermatol. Res. 2007, 298, 413–420. [Google Scholar] [CrossRef] [PubMed]

- Gupta, P.; Vermani, K.; Garg, S. Hydrogels: From controlled release to pH-responsive drug delivery. Drug Discov. Today 2002, 7, 569–579. [Google Scholar] [CrossRef]

- Karaaslana, M.A.; Tshabalalab, M.A.; Yelleb, D.J.; Buschle-Diller, G. Nanoreinforced biocompatible hydrogels from wood hemicelluloses and cellulose whiskers. Carb. Polym. 2011, 86, 192–201. [Google Scholar] [CrossRef]

- Iguchi, M.; Yamanaka, S.; Budhiono, A. Bacterial cellulose—A masterpiece of nature’s arts. J. Mater. Sci. 2002, 35, 261–270. [Google Scholar] [CrossRef]

- Klemm, D.; Schumann, D.; Udhardt, U.; Marsch, S. Bacterial synthesized cellulose–artificial blood vessels for microsurgery. Prog. Polym. Sci. 2001, 26, 1561–1603. [Google Scholar] [CrossRef]

- Svensson, A.; Nicklasson, E.; Harrah, T.; Panilaitis, B.; Kaplan, D.L.; Brittberg, M.; Gatenholm, P. Bacterial cellulose as a potential scaffold for tissue engineering of cartilage. Biomaterials 2005, 26, 419–431. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.-J.; Ahn, Y.; Kang, M.-S.; Jun, H.-K.; Kim, I.S.; Moon, S.-H. Preparation and characterization of acrylic acid-treated bacterial cellulose cation-exchange membrane. J. Chem. Technol. Biotechnol. 2004, 79, 79–84. [Google Scholar] [CrossRef]

- Amin, M.C.I.M.; Ahmad, N.; Halib, N.; Ahmad, I. Synthesis and characterization of thermos- and pH-responsive bacterial cellulose/acrylic acid hydrogels for drug delivery. Carb. Polym. 2012, 88, 465–473. [Google Scholar] [CrossRef]

- Mohamad, N.; Amin, M.C.I.M.; Pandey, M.; Ahmad, N.; Rajab, N.F. Bacterial cellulose/acrylic acid hydrogel synthesized via electron beam irradiation: Accelerated burn wound healing in an animal model. Carb. Polym. 2014, 114, 312–320. [Google Scholar] [CrossRef] [PubMed]

- Sofokleous, P.; Stride, E.; Edirisinghe, M. Preparation, Characterization, and Release of Amoxicillin from Electrospun Fibrous Wound Dressing Patches. Pharma Res. 2013, 30, 1926–1938. [Google Scholar] [CrossRef] [PubMed]

- Ye, S.; Jiang, L.; Wu, J.; Su, C.; Huang, C.; Lie, X.; Shao, W. Flexible Amoxicillin-Grafted Bacterial Cellulose Sponges for Wound Dressing: In Vitro and in Vivo Evaluation. ACS Appl. Mater. Interfaces 2018, 10, 5862–5870. [Google Scholar] [CrossRef] [PubMed]

- Shao, W.; Wu, J.; Liu, H.; Ye, S.; Jiang, L.; Liu, X. Novel bioactive surface functionalization of bacterial cellulose membrane. Carbohydr. Polym. 2017, 178, 270–276. [Google Scholar] [CrossRef] [PubMed]

- Punet, X.; Mauchauffe, R.; Giannotti, M.I.; Rodriquez-Cabello, J.C.; Sanz, F.; Engel, E.; Mateos-Timoneda, M.A.; Planell, J.A. Enhanced cell-material interactions through the biofunctionalization of polymeric surfaces with engineered peptides. Biomacromolecules 2013, 14, 2690–2702. [Google Scholar] [CrossRef] [PubMed]

- Mauchauffe, R.; Moreno-Couranjou, M.; Boscher, N.D.; Van De Weerdt, C.; Duwez, A.S.; Choquet, P. Robust bio-inspired antibacterial surfaces based on the covalent binding of peptides on functional atmospheric plasma thin films. J. Mater. Chem. B 2014, 2, 5168–5177. [Google Scholar] [CrossRef]

- Zu, S.Z.; Han, B.H. Aqueous dispersion of graphene sheets stabilized by pluronic copolymers: Formation of supramolecular hydrogel. J. Phys. Chem. C 2009, 113, 13651–13657. [Google Scholar] [CrossRef]

- Doillon, C.J.; Silver, F.H.; Berg, R.A. Fibroblast growth on a porous collagen sponge containing hyaluronic acid and fibronectin. Biomaterials 1987, 8, 195–200. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, X.; Shen, Y.; Yoshino, K.; Feng, W. A mechanically strong, flexible and conductive film based on bacterial cellulose/graphene nanocomposite. Carbohydr. Polym. 2012, 87, 644–649. [Google Scholar] [CrossRef]

- Shao, W.; Wang, S.; Wu, J.; Huang, M.; Liu, H.; Min, H. Synthesis and antimicrobial activity of copper nanoparticle loaded regenerated bacterial cellulose membranes. RSC Adv. 2016, 6, 65879–65884. [Google Scholar] [CrossRef]

- Aramwit, P.; Muangman, P.; Namviriyachote, N.; Srichana, T. In vitro evaluation of the antimicrobial effectiveness and moisture binding properties of wound dressings. Int. J. Mol. Sci. 2010, 11, 864–874. [Google Scholar] [CrossRef] [PubMed]

- Koetting, M.C.; Peters, J.T.; Steichen, S.D.; Peppas, N.A. Stimulus-responsive hydrogels: Theory, modern advances, and applications. Mater. Sci. Eng. R. Rep. 2015, 93, 1–49. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Akala, E.O.; Kopeckova, P.; Kopecek, J. Novel pH sensitive hydrogels with adjustable kinetics of sweeling. Biomaterials 1998, 19, 1037–1047. [Google Scholar] [CrossRef]

- Da Silva, R.; Ganzarolli de Oliveira, M. Effect of the cross-linking density on the morphology of poly(NIPAAm-co-Aac) hydrogels. Polymer 2007, 48, 4114–4122. [Google Scholar] [CrossRef]

- Maneerung, T.; Tokura, S.; Rujiravanit, R. Impregnation of silver nanoparticles into bacterial cellulose for antimicrobial wound dressing. Carbohydr. Polym. 2008, 72, 43–51. [Google Scholar] [CrossRef]

- Czaja, W.; Krystynowicz, A.; Bielecki, S.; Brown, M. Microbial cellulose—The natural power to heal wounds. Biomaterial 2006, 27, 145–151. [Google Scholar] [CrossRef] [PubMed]

- Tavakoli, J.; Tang, Y. Honey/PVA hybrid wound dressings with controlled release of antibiotics: Structural, physico-mechanical and in-vitro biomedical studies. Mater. Sci. Eng. 2017, 77, 318–325. [Google Scholar] [CrossRef] [PubMed]

- Tavakoli, J.; Mirzaei, S.; Tang, Y. Cost-Effective Double-Layer Hydrogel Composites for Wound Dressing Applications. Polymer 2018, 10, 305. [Google Scholar] [CrossRef]

- Mi, F.-L.; Shyu, S.-S.; Wu, Y.-B.; Lee, S.-T.; Shyong, J.-Y.; Huang, R.-N. Fabrication and characterization of a sponge-like asymmetric chitosan membrane as a wound dressing. Biomaterials 2001, 22, 165–173. [Google Scholar] [CrossRef]

- Jayakumar, R.; Prabaharan, M.; Sudheesh Kumar, P.T.; Nair, S.V.; Tamura, H. Biomaterials based on chitin and chitosan in wound dressing applications. Biotechnol. Adv. 2011, 29, 322–337. [Google Scholar] [CrossRef] [PubMed]

- Brazel, C.S.; Peppas, N.A. Mechanism of solute and drug transport in relaxing, swellable, hydrophilic gassy polymers. Polymer 1999, 40, 3383–3398. [Google Scholar] [CrossRef]

- Chiba, M.; Hanes, J.; Langer, R. Degradation of porous poly(anhydride-coimide) microspheres and implication for controlled macromolecule delivery. Biomaterials 1998, 18, 163–172. [Google Scholar]

| Specimens | Tensile Strength at Break (MPa) | Elongation at Break (%) |

|---|---|---|

| PAA | 0.06 ± 0.01 | 79.67 ± 7.13 |

| BC-PAA | 2.85 ± 0.23 | 57.00 ± 3.11 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chuah, C.; Wang, J.; Tavakoli, J.; Tang, Y. Novel Bacterial Cellulose-Poly (Acrylic Acid) Hybrid Hydrogels with Controllable Antimicrobial Ability as Dressings for Chronic Wounds. Polymers 2018, 10, 1323. https://doi.org/10.3390/polym10121323

Chuah C, Wang J, Tavakoli J, Tang Y. Novel Bacterial Cellulose-Poly (Acrylic Acid) Hybrid Hydrogels with Controllable Antimicrobial Ability as Dressings for Chronic Wounds. Polymers. 2018; 10(12):1323. https://doi.org/10.3390/polym10121323

Chicago/Turabian StyleChuah, Clarence, Jing Wang, Javad Tavakoli, and Youhong Tang. 2018. "Novel Bacterial Cellulose-Poly (Acrylic Acid) Hybrid Hydrogels with Controllable Antimicrobial Ability as Dressings for Chronic Wounds" Polymers 10, no. 12: 1323. https://doi.org/10.3390/polym10121323