Internal Relative Humidity, Autogenous Shrinkage, and Strength of Cement Mortar Modified with Superabsorbent Polymers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Test Methods

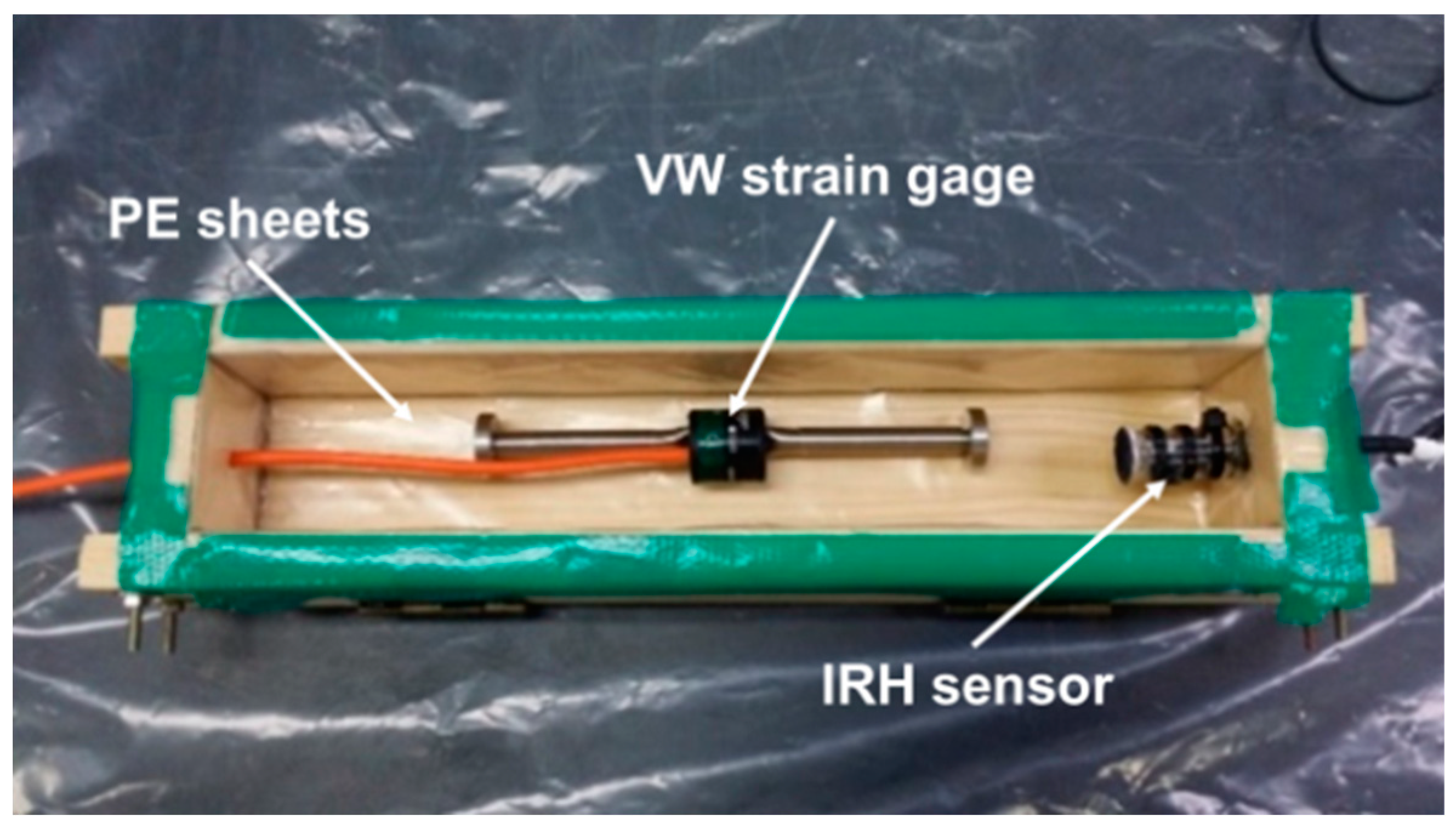

2.2.1. Autogenous Shrinkage and IRH Measurements

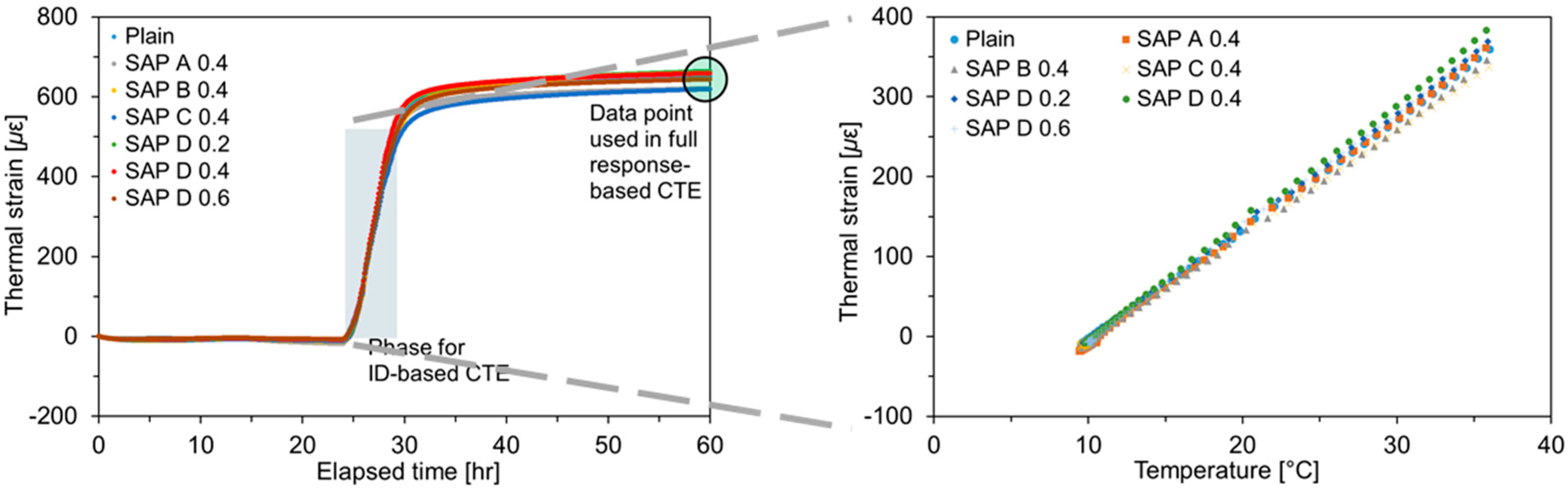

2.2.2. Coefficient of Thermal Expansion Test

2.2.3. Flexural and Compressive Strength Tests

3. Results and Discussion

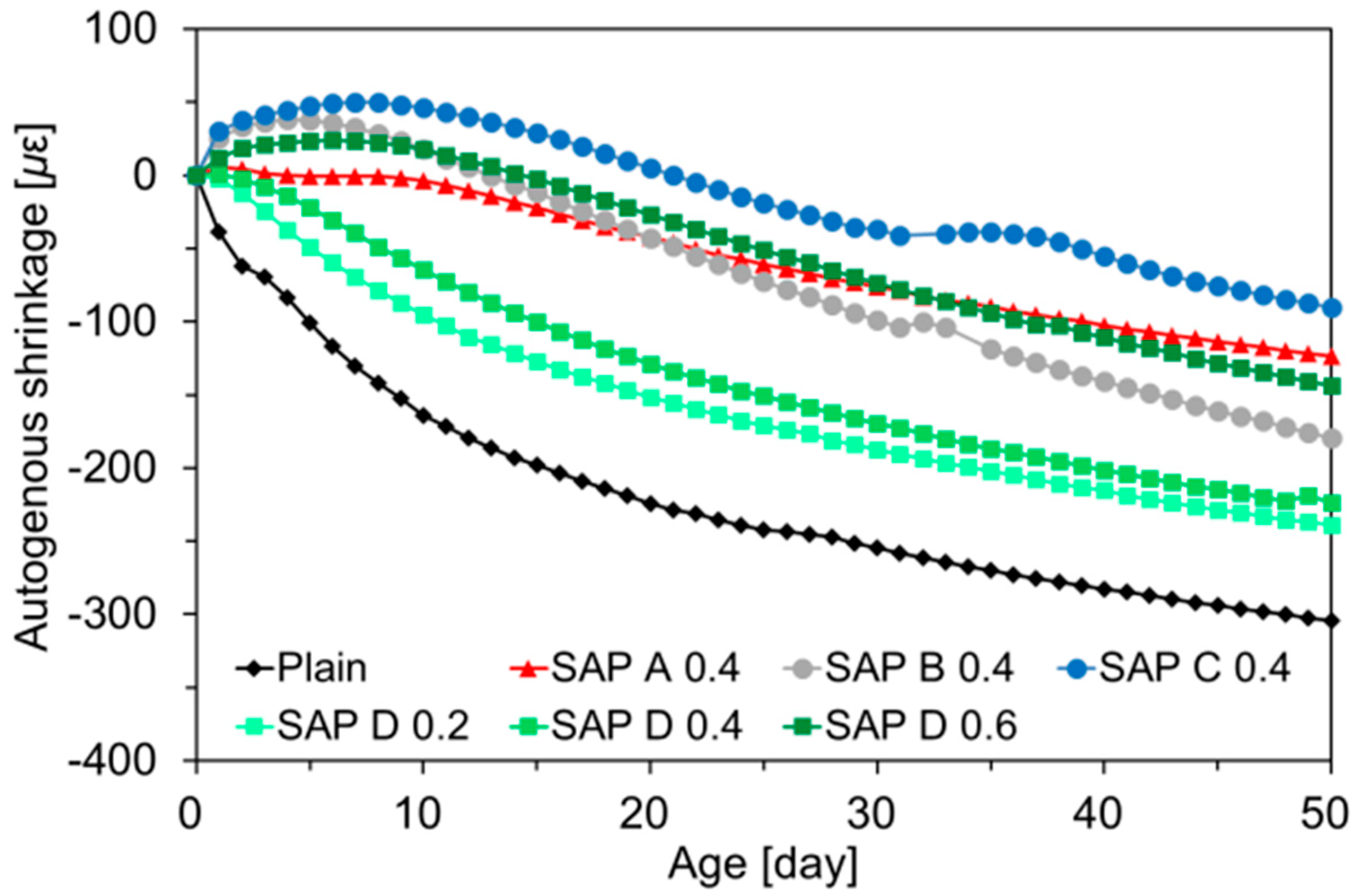

3.1. IRH Changes and Autogenous Shrinkage

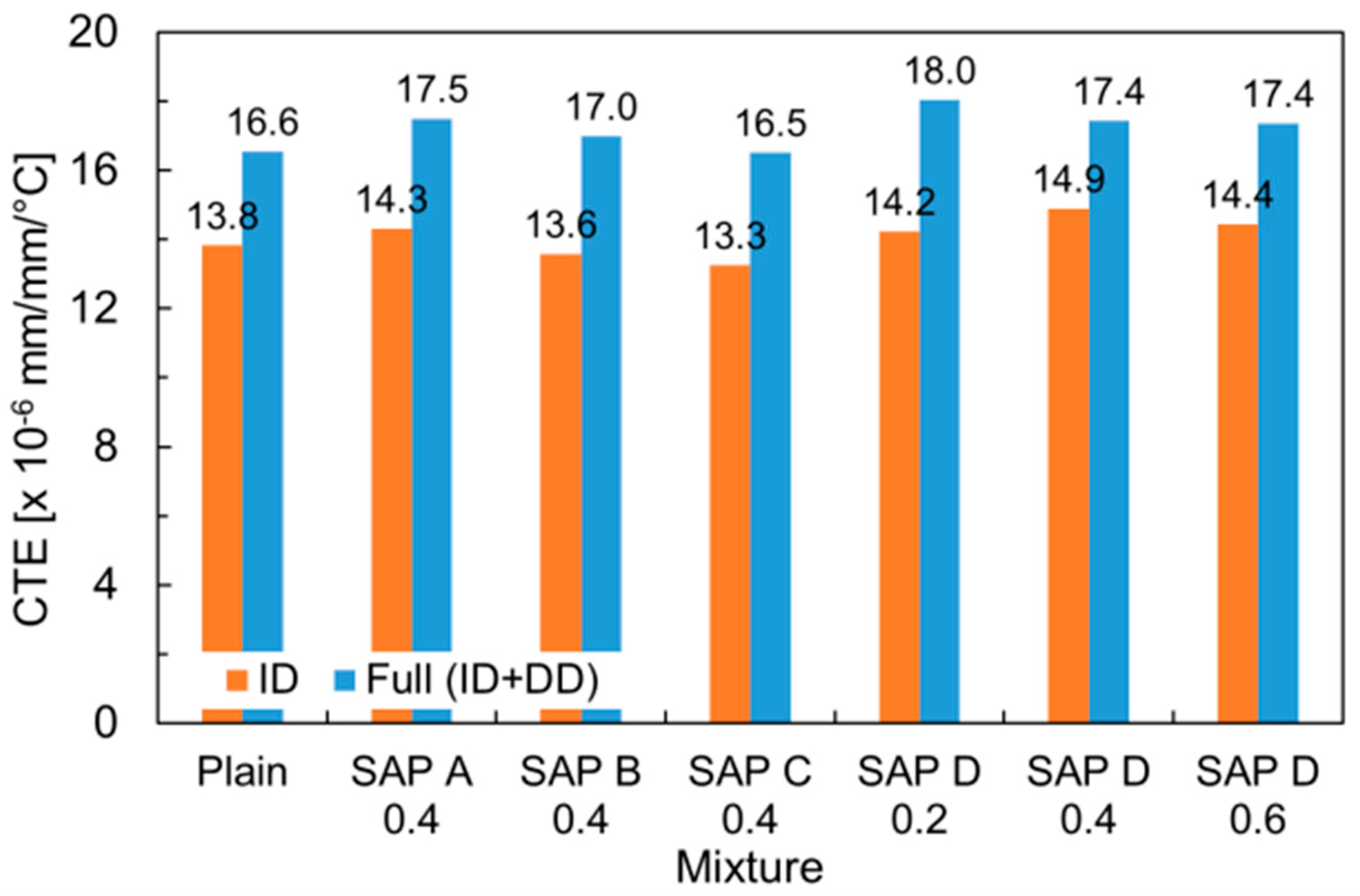

3.2. Coefficient of Thermal Expansion

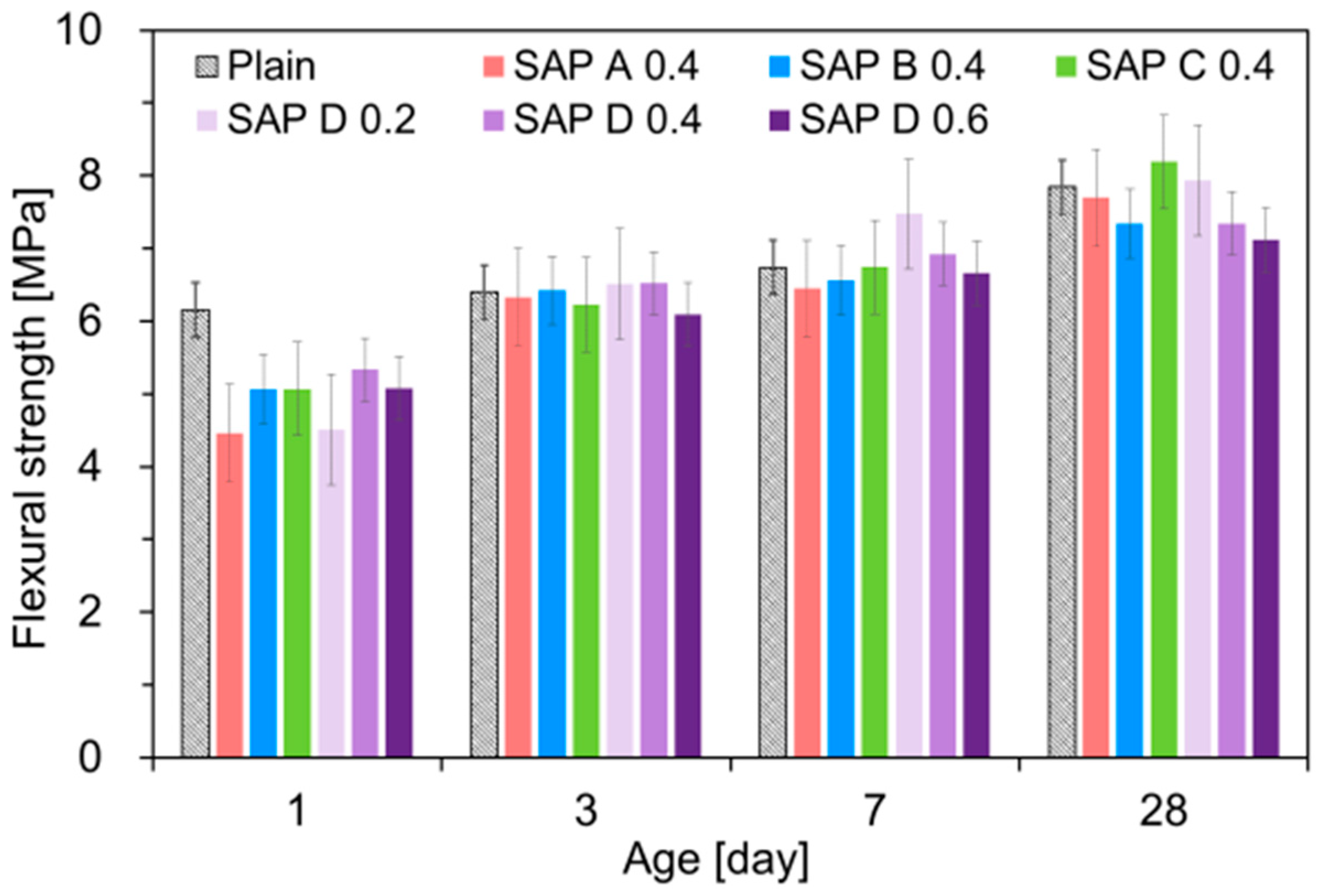

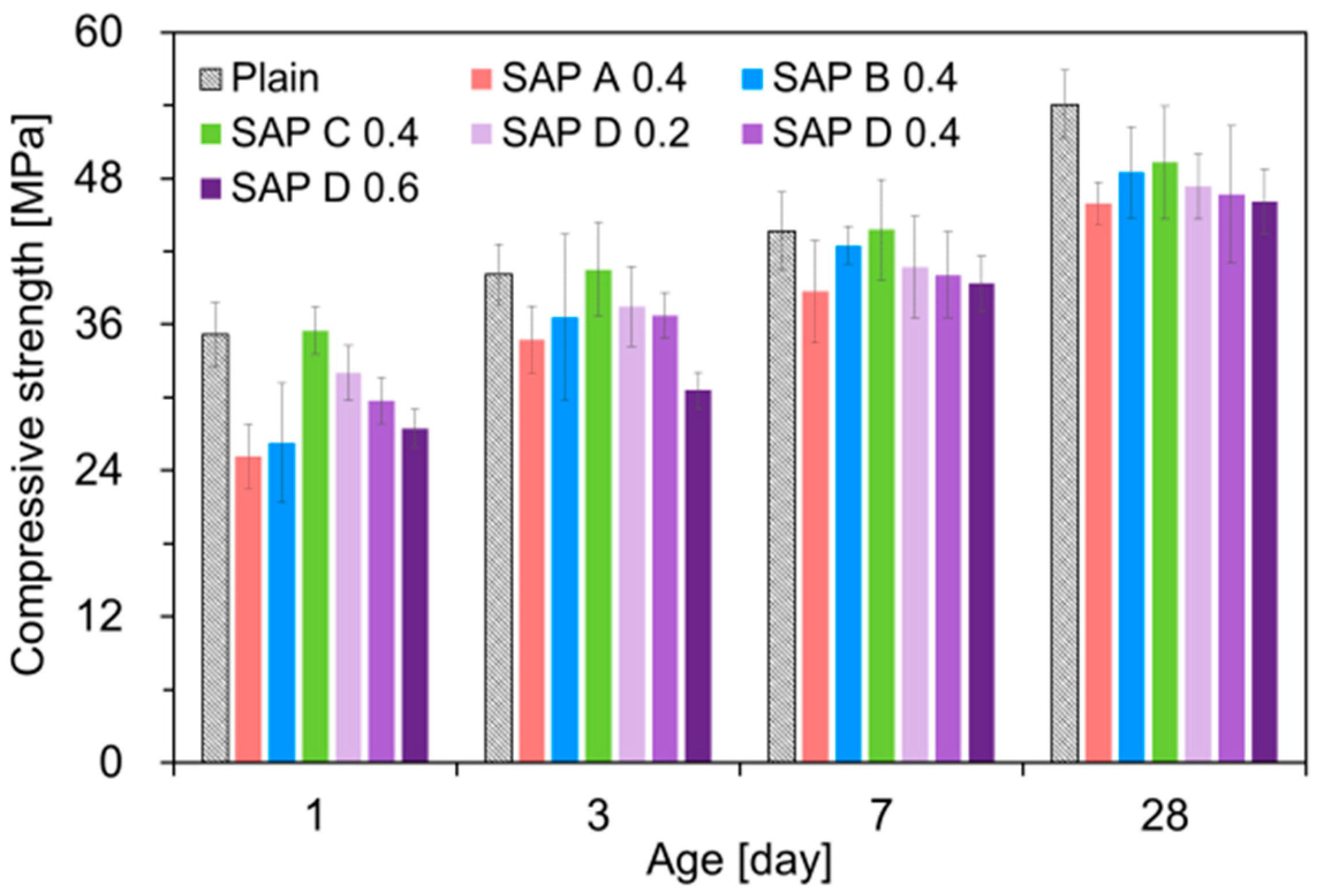

3.3. Flexural and Compressive Strengths

4. Concluding Remarks

- The inclusion of SAPs can be a viable option to alleviate IRH drops and corresponding autogenous shrinkage developments in cementitious composites with a low w/c.

- The effectiveness of autogenous shrinkage mitigation became greater as the dosage of the SAP increased.

- SAPs with higher cross-linking density and larger particle size worked more effectively in mitigating autogenous shrinkage.

- The trend of autogenous shrinkage was quite close to that of IRH changes. The autogenous shrinkage was almost a linear function of IRH with a coefficient of determination (R2) of more than 0.90.

- SAP additions had insignificant effects on both immediate deformation (ID)-based- and full response-based CTEs.

- SAP inclusions had minimal adverse effects on the flexural strength characteristics of low w/c mortars although the compressive strength was moderately reduced at all ages. Particularly for flexural strength, the SAP with greater moisture retention capacity resulted in even higher later-age strength gains than the plain mixture.

Author Contributions

Funding

Conflicts of Interest

References

- Wiegrink, K.; Marikunte, S.; Shah, S.P. Shrinkage cracking of high-strength concrete. ACI Mater. J. 1996, 93, 409–415. [Google Scholar]

- Tazawa, E.-I.; Miyazawa, S. Experimental study on mechanism autogenous shrinkage of concrete. Cem. Concr. Res. 1995, 25, 1633–1638. [Google Scholar] [CrossRef]

- Aitcin, P.-C. Demystifying autogenous shrinkage. Concr. Int. 1999, 21, 54–56. [Google Scholar]

- Yeon, J.H.; Choi, S.; Won, M.C. Effect of relative humidity on coefficient of thermal expansion of hardened cement paste and concrete. Transp. Res. Rec. 2009, 2113, 83–91. [Google Scholar] [CrossRef]

- Grasley, Z.C.; Lange, D.A. Thermal dilation and internal relative humidity of hardened cement paste. Mater. Struct. 2007, 40, 311–317. [Google Scholar] [CrossRef]

- Sellevold, E.J.; Bjøntegaard, Ø. Coefficient of thermal expansion of cement paste and concrete: Mechanisms of moisture interaction. Mater. Struct. 2006, 39, 809–815. [Google Scholar] [CrossRef]

- Lura, P.; Jensen, O.M.; van Breugel, K. Autogenous shrinkage in high-performance cement paste: An evaluation of basic mechanisms. Cem. Concr. Res. 2003, 33, 223–232. [Google Scholar] [CrossRef]

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford: London, UK, 1997. [Google Scholar]

- Nagataki, S.; Gomi, H. Expansive admixtures. Cem. Concr. Compos. 1998, 20, 163–170. [Google Scholar] [CrossRef]

- Folliard, K.J.; Berke, N.S. Properties of high-performance concrete containing shrinkage-reducing admixture. Cem. Concr. Res. 1997, 27, 1357–1364. [Google Scholar] [CrossRef]

- Swayze, M.A. Early concrete volume changes and their control. J. Am. Concr. Inst. 1942, 13, 425–440. [Google Scholar]

- Neville, A.M.; Brooks, J.J. Concrete Technology; Longman: Harlow, UK, 1987. [Google Scholar]

- Powers, T.C. Capillary continuity of discontinuity in Portland cement paste. PCA Bull. 1959, 10, 2–12. [Google Scholar]

- Liu, X.M.; Du, H.; Zhang, M.H. A model to estimate the durability performance of both normal and light-weight concrete. Constr. Build. Mater. 2015, 80, 255–261. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials I. Principles and theoretical background. Cem. Concr. Res. 2002, 31, 647–654. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.F. Water-entrained cement-based materials II. Experimental observations. Cem. Concr. Res. 2002, 32, 973–978. [Google Scholar] [CrossRef]

- Schröfl, C.; Mechtcherine, V.; Gorges, M. Relation between the molecular structure and the efficiency of superabsorbent polymers (SAP) as concrete admixture to mitigate autogenous shrinkage. Cem. Concr. Res. 2012, 42, 865–873. [Google Scholar] [CrossRef]

- Snoeck, D.; Jensen, O.M.; De Belie, N. The influence of superabsorbent polymers on the autogenous shrinkage properties of cement pastes with supplementary cementitious materials. Cem. Concr. Res. 2015, 74, 59–67. [Google Scholar] [CrossRef]

- Shen, D.; Wang, X.; Cheng, D.; Zhang, J.; Jiang, G. Effect of internal curing with super absorbent polymers on autogenous shrinkage of concrete at early age. Constr. Build. Mater. 2016, 106, 512–522. [Google Scholar] [CrossRef]

- Lam, H.; Hooton, R.D. Effects of internal curing methods on restrained shrinkage and permeability. In Proceedings of the 4th International Seminar on Self-Desiccation and Its Importance in Concrete Technology, Gaithersburg, MD, USA, 20 June 2005; Persson, B., Bentz, D., Nilsson, L.-O., Eds.; Lund University: Lund, Sweden, 2005; pp. 210–228. [Google Scholar]

- Lura, P.; Durand, F.; Loukili, A.; Kovler, K.; Jensen, O.M. Compressive strength of cement pastes and mortars with suberabsorbent polymers. In Volume Changes of Hardening Concrete: Testing and Mitigation, Proceedings of the RILEM Proceedings of PRO 52, Lyngby, Denmark, 20–23 August 2006; Jensen, O.M., Lura, P., Kovler, K., Eds.; RILEM Publications SARL: Bagneux, France, 2006; pp. 20–23. [Google Scholar]

- Esteves, L.P.; Cachim, P.; Ferreira, V.M. Mechanical properties of cement mortars with superabsorbent polymers. In Advances in Construction Materials; Grosse, C.U., Ed.; Springer: Berlin, Germany, 2007; pp. 451–462. [Google Scholar]

- Snoeck, D.; Schaubroeck, D.; Dubruel, P.; De Belie, N. Effect of high amounts of superabsorbent polymers and additional water on the workability, microstructure and strength of mortars with a water-to-cement ratio of 0.50. Constr. Build. Mater. 2014, 72, 148–157. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Secrieru, E.; Schröfl, C. Effect of superabsorbent polymers (SAPs) on rheological properties of fresh cement-based mortars—Development of yield stress and plastic viscosity over time. Cem. Concr. Res. 2015, 67, 52–65. [Google Scholar] [CrossRef]

- Secrieru, E.; Mechtcherine, V.; Schröfl, C.; Borin, D. Rheological characterisation and prediction of pumpability of strain hardening cement-based-composites (SHCC) with and without addition of superabsorbent polymers (SAP) at various temperatures. Constr. Build. Mater. 2016, 112, 581–594. [Google Scholar] [CrossRef]

- Bessaies-Bey, H.; Baumann, R.; Schmitz, M.; Radler, M.; Roussel, N. Effect of polyacrylamide on rheology of fresh cement pastes. Cem. Concr. Res. 2015, 76, 98–106. [Google Scholar] [CrossRef]

- Lee, H.X.D.; Wong, H.S.; Buenfeld, N. Potential of superabsorbent polymer for self-sealing cracks in concrete. Adv. Appl. Ceram. 2010, 109, 296–302. [Google Scholar] [CrossRef]

- Snoeck, D.; Steuperaert, S.; Van Tittelboom, K.; Dubruel, P.; De Belie, N. Visualization of water penetration in cementitious materials with superabsorbent polymers by means of neutron radiography. Cem. Concr. Res. 2012, 42, 1113–1121. [Google Scholar] [CrossRef]

- Lee, H.X.D.; Wong, H.S.; Buenfeld, N. Self-sealing of cracks in concrete using superabsorbent polymers. Cem. Concr. Res. 2016, 79, 194–208. [Google Scholar] [CrossRef] [Green Version]

- Hong, G.; Choi, S. Rapid self-sealing of cracks in cementitious materials incorporating superabsorbent polymers. Constr. Build. Mater. 2017, 143, 366–375. [Google Scholar] [CrossRef]

- Snoeck, D.; Van Tittelboom, K.; Steuperaert, S.; Dubruel, P.; De Belie, N. Self-healing cementitious materials by the combination of microfibres and superabsorbent polymers. J. Intell. Mater. Syst. Struct. 2014, 25, 13–24. [Google Scholar] [CrossRef] [Green Version]

- Shen, D.; Shi, H.; Tang, X.; Ji, Y.; Jiang, G. Effect of internal curing with super absorbent polymers on residual stress development and stress relaxation in restrained concrete ring specimens. Constr. Build. Mater. 2016, 120, 309–320. [Google Scholar] [CrossRef]

- Wyrzykowski, M.; Lura, P. Controlling the coefficient of thermal expansion of cementitious materials—A new application for superabsorbent polymers. Cem. Concr. Compos. 2013, 35, 49–58. [Google Scholar] [CrossRef]

- Mönnig, S.; Lura, P. Superabsorbent polymers—An additive to increase freeze-thaw resistance of high strength concrete. In Advances in Construction Materials; Grosse, C.U., Ed.; Springer: Berlin, Germany, 2007; pp. 351–358. [Google Scholar]

- Laustsen, S.; Hasholt, M.T.; Jensen, O.M. Void structure of concrete with superabsorbent polymers and its relation to frost resistance of concrete. Mater. Struct. 2015, 48, 357–368. [Google Scholar] [CrossRef]

- Snoeck, D.; Pel, L.; De Belie, L. The water kinetics of superabsorbent polymers during cement hydration and internal curing visualized and studied by NMR. Sci. Rep. 2017, 7, 9514. [Google Scholar] [CrossRef] [PubMed]

- Yun, K.-K.; Kim, K.-K.; Choi, W.; Yeon, J.H. Hygral behavior of superabsorbent polymers with various particle sizes and cross-linking densities. Polymers 2017, 9, 600. [Google Scholar] [CrossRef]

- Bazant, Z.P. Delayed thermal dilatations of cement paste and concrete due to mass transport. Nuclear Eng. Des. 1970, 14, 308–318. [Google Scholar] [CrossRef]

- AASHTO. Standard Test Method for the Coefficient of Thermal Expansion of Hydraulic Cement Concrete; TP60-00; AASHTO: Washington, DC, USA, 2000. [Google Scholar]

- Wang, F.; Yang, J.; Cheng, H.; Wu, J.; Liang, X. Study on mechanism of desorption behavior of saturated superabsorbent polymers in concrete. ACI Mater. J. 2015, 112, 463–470. [Google Scholar] [CrossRef]

- Justs, J.; Wyrzykowski, M.; Bajare, D.; Lura, P. Internal curing by superabsorbent polymers in ultra-high performance concrete. Cem. Concr. Res. 2015, 76, 82–90. [Google Scholar] [CrossRef]

- Esteves, L.P. Superabsorbent polymers: On their interaction with water and pore fluid. Cem. Concr. Compos. 2011, 33, 717–724. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, Y.; Peng, B.; Liu, Z.; Hu, S. Autogenous shrinkage of concrete with super-absorbent polymer. ACI Mater. J. 2009, 106, 123–127. [Google Scholar]

- Bazant, Z.P.; Xi, Y. Drying creep of concrete: Constitutive model and new experiments separating its mechanisms. Mater. Struct. 1994, 27, 3–14. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, Y.; Liu, Z.; Hu, S. Internal relative humidity and autogenous shrinkage of low water/binder ratio concrete. In Volume Changes of Hardening Concrete: Testing and Mitigation, Proceedings of the RILEM Conference on, Lyngby, Denmark, 20–23 August 2006; Jensen, O.M., Lura, P., Kovler, K., Eds.; RILEM Publications SARL: Bagneux, France, 2006; pp. 51–56. [Google Scholar]

- Ramazani-Harandi, M.J.; Zohuriaan-Mehr, M.J.; Yousefi, A.A.; Ershad-Langroudi, A.; Kabiri, K. Rheological determination of the swollen gel strength of superabsorbent polymer hydrogels. Polym. Test. 2006, 25, 470–474. [Google Scholar] [CrossRef]

- Meyers, S.L. Thermal expansion characteristics of hardened cement paste and of concrete. Highw. Res. Board 1951, 30, 193–203. [Google Scholar]

- Kada, H.; Lachemi, M.; Petrov, N.; Bonneau, O.; Aitcin, P.-C. Determination of the coefficient of thermal expansion of high performance concrete from initial setting. Mater. Struct. 2002, 35, 35–41. [Google Scholar] [CrossRef]

- Cusson, D.; Hoogeveen, T. Test method for determining coefficient of thermal expansion of high-performance concrete at early age. In Proceedings of the 12th International Congress on the Chemistry of Cement, Montreal, QC, Canada, 8–13 July 2007. [Google Scholar]

- Yeon, J.H.; Choi, S.; Won, M.C. In situ measurement of coefficient of thermal expansion in hardening concrete and its effect on thermal stress development. Constr. Build. Mater. 2013, 38, 306–315. [Google Scholar] [CrossRef]

- Laustsen, S.; Bentz, D.P.; Hasholt, M.T.; Jensen, O.M. CT measurement of SAP voids in concrete. In Proceedings of the International RILEM Conference on Use of Superabsorbent Polymers and Other New Additives in Concrete, Lyngby, Denmark, 15–18 August 2010; RILEM Publications SARL: Bagneux, France, 2010; pp. 153–162. [Google Scholar]

- Sarbapalli, D.; Dhabalia, Y.; Sarkar, K.; Bhattacharjee, B. Application of SAP and PEG as curing agents for ordinary cement-based systems: Impact on the early age properties of paste and mortar with water-to-cement ratio of 0.4 and above. Eur. J. Environ. Civ. Eng. 2017, 21, 1237–1252. [Google Scholar] [CrossRef]

- Wang, F.; Yang, J.; Hu, S.; Li, X.; Cheng, H. Influence of superabsorbent polymers on the surrounding cement paste. Cem. Concr. Res. 2016, 81, 112–121. [Google Scholar] [CrossRef]

- Trtik, P.; Muench, B.; Weiss, W.J.; Herth, G.; Kaestner, A.; Lehmann, E.; Lura, P. Neutron Tomography Measurements of Water Release from Superabsorbent Polymers in Cement Paste. In Proceedings of the International Conference on Material Science and 64th RILEM Annual Week, Aachen, Germany, 6–10 September 2010; RILEM Publications SARL: Aachen, Germany, 2010; pp. 175–185. [Google Scholar]

- Klemm, A.J.; Moriconi, G.; Trillini, G. Combined effect of polymeric fibres and SAP on the performance of repair mortars. In Proceedings of the 3rd International Conference on Sustainable Construction Materials and Technologies (SCMT3), Kyoto, Japan, 18–21 August 2013. [Google Scholar]

| Chemical Composition (%) | Fineness (m2/kg) | Specific Gravity | |||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | ||

| 19.7 | 5.33 | 2.90 | 61.5 | 3.81 | 2.54 | 0.86 | 0.18 | 370 | 3.15 |

| Chemical Nomenclature | Chemical Formula | Molar Mass (g/mol) | Constitutional Formula | Density (g/cm3) | Appearance |

|---|---|---|---|---|---|

| Poly (sodium prop-2-enoate) | (C3H3NaO2)n | Variable |  | 1.22 |  |

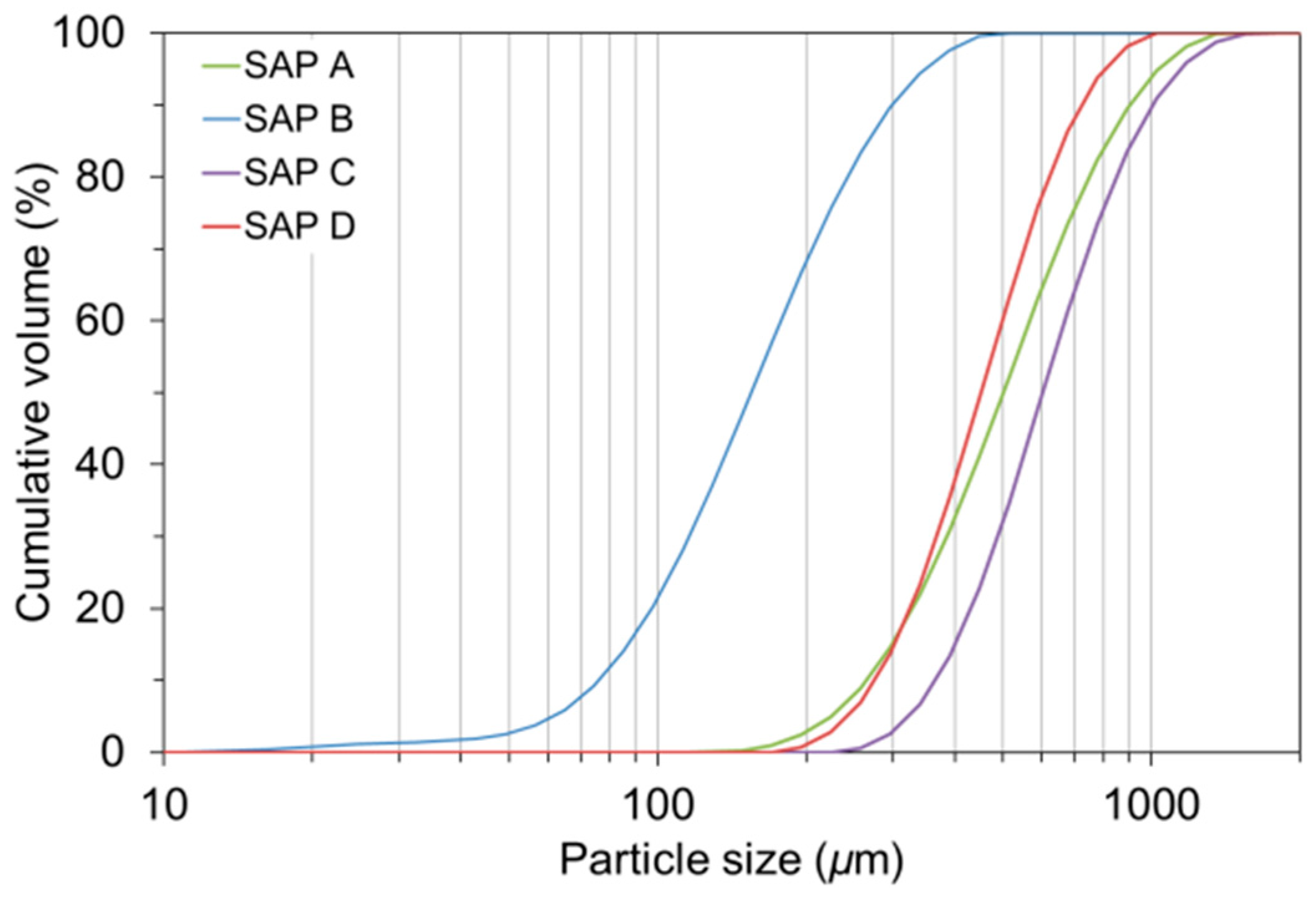

| Type of SAP | Dry particle Size (Diameter) | Cross-Linking Density | Rate of Moisture Uptake [36] | Free Absorption Capacity (in Cement Filtrate at 60 min) [36] | Absorption Capacity under Mixing Condition [36] |

|---|---|---|---|---|---|

| SAP A | #80–20 mesh (177–841 μm) | Low | Low | Medium-high (38.91 g/g SAP) | High (12.70 g/g SAP) |

| SAP B | #120–80 mesh (125–177 μm) | Medium | High | Medium (35.43 g/g SAP) | Medium (8.75 g/g SAP) |

| SAP C | #80–20 mesh (177–841 μm) | High | Low | Low (31.01 g/g SAP) | Low (4.82 g/g SAP) |

| SAP D | #100–40 mesh (149–400 μm) | Medium | Medium | High (42.71 g/g SAP) | Medium-high (10.99 g/g SAP) |

| Mixture | Weight per Unit Volume (kg/m3) | |||||

|---|---|---|---|---|---|---|

| Cement | Sand | Water | SAP | IC Water a | Water Reducer | |

| Plain | 604.2 | 1661.6 | 181.3 | - | - | 3.02 |

| SAP A 0.4 | 586.2 | 1612.1 | 175.9 | 2.35 | 29.8 | 2.93 |

| SAP B 0.4 | 591.7 | 1627.2 | 177.5 | 2.37 | 20.7 | 2.96 |

| SAP C 0.4 | 597.3 | 1642.6 | 179.2 | 2.39 | 11.5 | 2.99 |

| SAP D 0.4 | 588.6 | 1618.7 | 176.6 | 2.35 | 25.9 | 2.94 |

| SAP D 0.2 | 596.3 | 1639.8 | 178.9 | 1.19 | 13.1 | 2.98 |

| SAP D 0.6 | 581.1 | 1598.0 | 174.3 | 3.49 | 38.3 | 2.91 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Urgessa, G.; Choi, K.-B.; Yeon, J.H. Internal Relative Humidity, Autogenous Shrinkage, and Strength of Cement Mortar Modified with Superabsorbent Polymers. Polymers 2018, 10, 1074. https://doi.org/10.3390/polym10101074

Urgessa G, Choi K-B, Yeon JH. Internal Relative Humidity, Autogenous Shrinkage, and Strength of Cement Mortar Modified with Superabsorbent Polymers. Polymers. 2018; 10(10):1074. https://doi.org/10.3390/polym10101074

Chicago/Turabian StyleUrgessa, Girum, Ki-Bong Choi, and Jung Heum Yeon. 2018. "Internal Relative Humidity, Autogenous Shrinkage, and Strength of Cement Mortar Modified with Superabsorbent Polymers" Polymers 10, no. 10: 1074. https://doi.org/10.3390/polym10101074