Analysis of Waveguides on Lithium Niobate Thin Films

Abstract

:1. Introduction

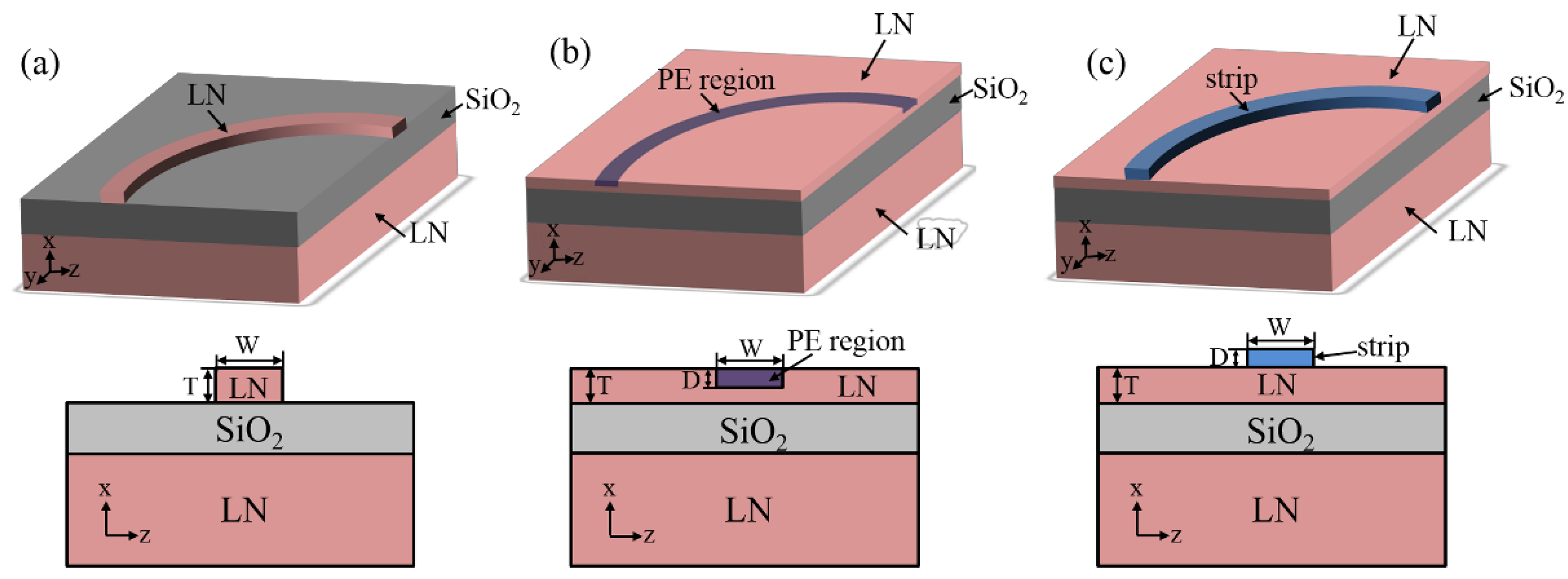

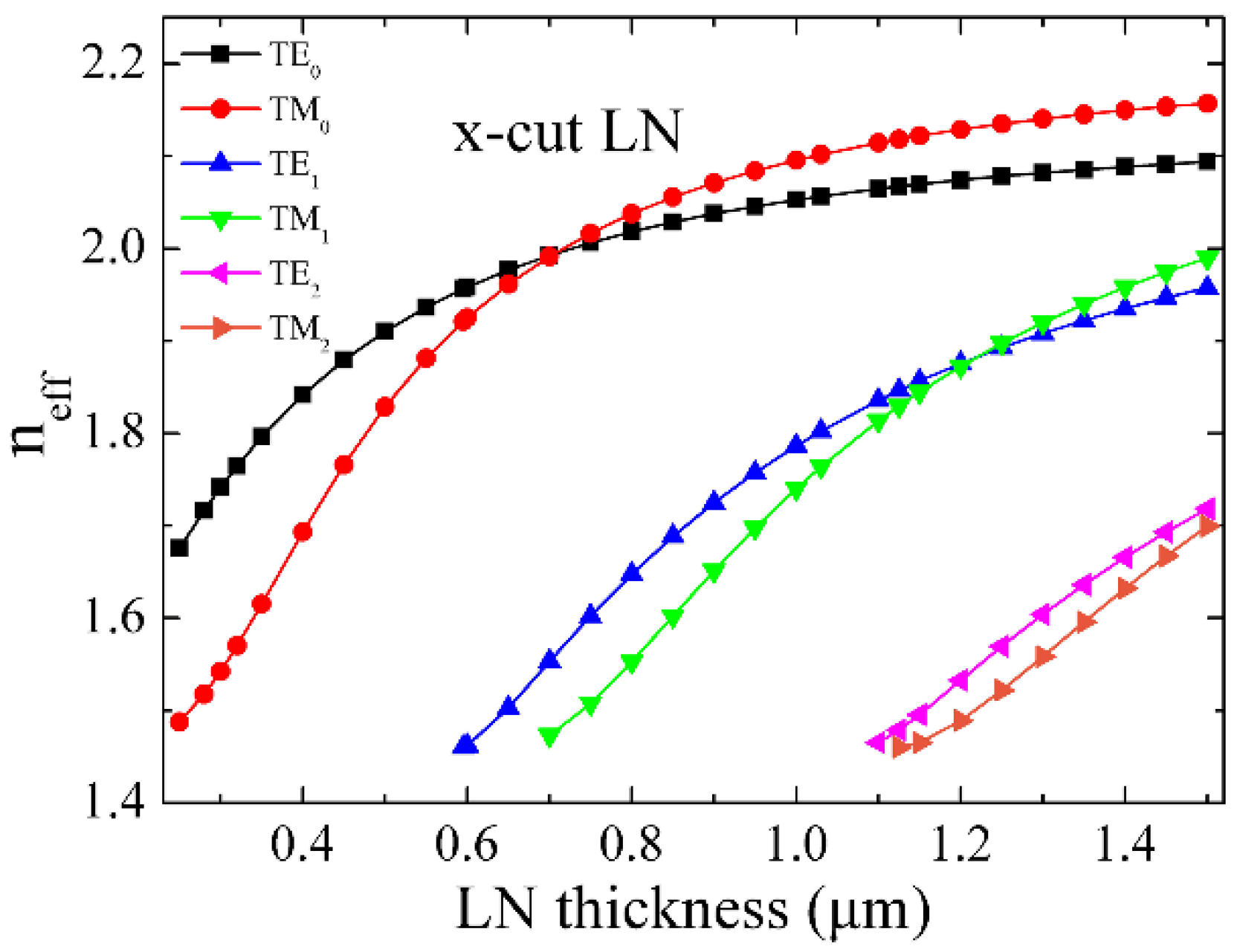

2. Design of Waveguide Geometry

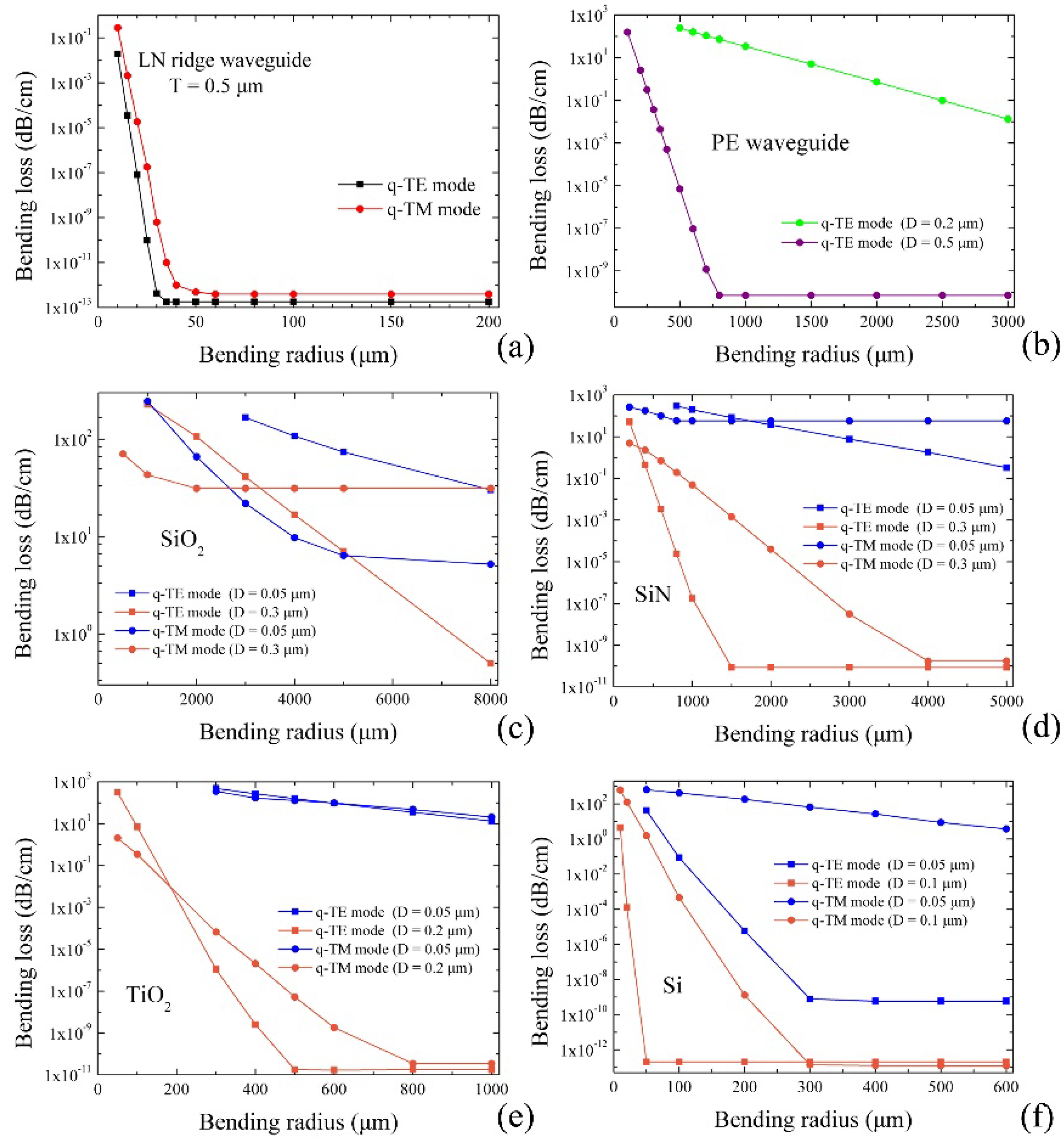

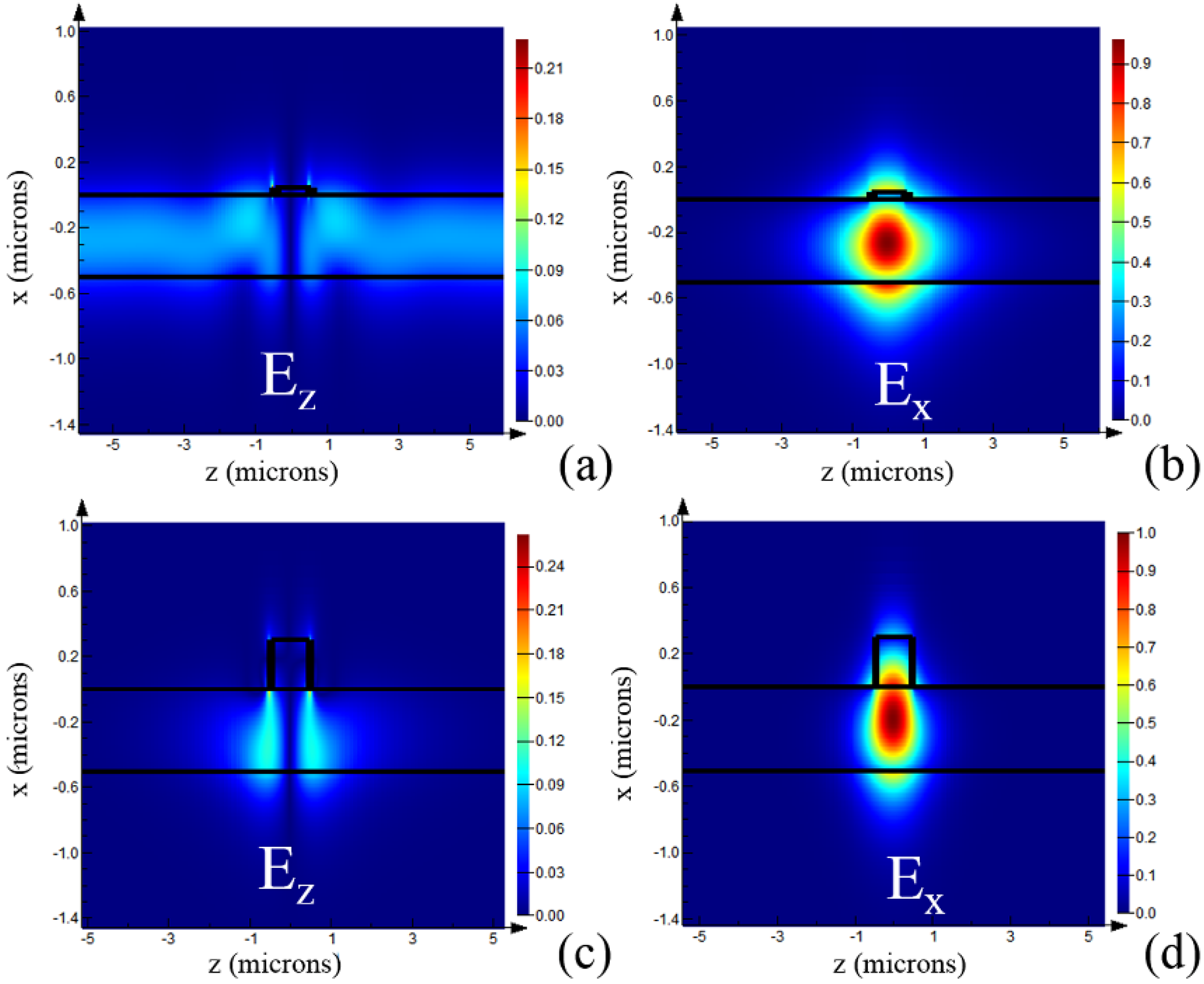

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Weis, R.S.; Gaylord, T.K. Lithium niobate: Summary of physical properties and crystal structure. Appl. Phys. A Mater. Sci. Process 1985, 37, 191–203. [Google Scholar] [CrossRef]

- Arizmendi, L. Photonic applications of lithium niobate crystals. Phys. Status Solidi A Appl. Res. 2004, 201, 253–283. [Google Scholar] [CrossRef]

- Poberaj, G.; Hu, H.; Sohler, W.; Gunter, P. Lithium niobate on insulator (LNOI) for micro-photonic devices. Laser Photonics Rev. 2012, 6, 488–503. [Google Scholar] [CrossRef]

- Rabiei, P.; Gunter, P. Optical and electro-optical properties of sub-micrometer lithium niobate slab waveguides prepared by crystal ion slicing and wafer bonding. Appl. Phys. Lett. 2004, 85, 4603–4605. [Google Scholar] [CrossRef]

- Liang, H.; Luo, R.; He, Y.; Jiang, H.; Lin, Q. High-quality lithium niobate photonic crystal nanocavities. Optica 2017, 4, 1251. [Google Scholar] [CrossRef]

- Kovalevich, T.; Ndao, A.; Suarez, M.; Tumenas, S.; Balevicius, Z.; Ramanavicius, A.; Baleviciute, I.; Häyrinen, M.; Roussey, M.; Kuittinen, M.; et al. Tunable Bloch surface waves in anisotropic photonic crystals based on lithium niobate thin films. Opt. Lett. 2016, 41, 5616–5619. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Sadani, B.; Courjal, N.; Ulliac, G.; Smith, N.; Stenger, V.; Collet, M.; Baida, F.I.; Bernal, M.P. Enhanced electro-optical lithium niobate photonic crystal wire waveguide on a smart-cut thin film. Opt. Express 2012, 20, 2974–2981. [Google Scholar] [CrossRef] [PubMed]

- Rao, A.; Fathpour, S. Compact lithium niobate electrooptic modulators. IEEE J. Sel. Top. Quant. 2018, 24, 3400114. [Google Scholar] [CrossRef]

- Rao, A.; Patil, A.; Rabiei, P.; Honardoost, A.; DeSalvo, R.; Paolella, A.; Fathpour, S. High-performance and linear thin-film lithium niobate Mach–Zehnder modulators on silicon up to 50 GHz. Opt. Lett. 2016, 41, 5700–5703. [Google Scholar] [CrossRef] [PubMed]

- Cai, L.; Kang, Y.; Hu, H. Electric-optical property of the proton exchanged phase modulator in single-crystal lithium niobate thin film. Opt. Express 2016, 24, 4640–4647. [Google Scholar] [CrossRef] [PubMed]

- Mian, Z.; Cheng, W.; Xi, C.; Maxime, B.; Amirhassan, S.A.; Sethumadhavan, C.; Peter, W.; Marko, L. Ultra-high bandwidth integrated lithium niobate modulators with record-low Vπ. In Proceedings of the Optical Fiber Communication Conference, San Diego, CA, USA, 11–15 March 2018. [Google Scholar] [CrossRef]

- Wolf, R.; Breunig, I.; Zappe, H.; Buse, K. Cascaded second-order optical nonlinearities in on-chip micro rings. Opt. Express 2017, 25, 29927–29933. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Li, Z.; Kim, M.; Xiong, X.; Ren, X.; Guo, G.; Yu, N.; Lončar, M. Metasurface-assisted phase-matching-free second harmonic generation in lithium niobate waveguides. Nat. Commun. 2017, 8, 2098. [Google Scholar] [CrossRef] [PubMed]

- Delfyett, P.; Fathpour, S. Second-harmonic generation in periodically-poled thin film lithium niobate wafer-bonded on silicon. Opt. Express 2016, 24, 29941–29947. [Google Scholar] [CrossRef]

- Cai, L.; Wang, Y.; Hu, H. Efficient second harmonic generation in χ(2) profile reconfigured lithium niobate thin film. Opt. Commun. 2017, 387, 405–408. [Google Scholar] [CrossRef]

- Rabiei, P.; Ma, J.; Khan, S.; Chiles, J.; Fathpour, S. Heterogeneous lithium niobate photonics on silicon substrates. Opt. Express 2013, 21, 25573–25581. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Chen, J.; Nagy, J.; Reano, R.M. Highly linear ring modulator from hybrid silicon and lithium niobate. Opt. Express 2015, 23, 13255–13264. [Google Scholar] [CrossRef] [PubMed]

- Witmer, J.D.; Valery, J.A.; Arrangoiz-Arriola, P.; Sarabalis, C.J.; Hill, J.T.; Safavi-Naeini, A.H. High-Q photonic resonators and electro-optic coupling using silicon-on-lithium-niobate. Sci. Rep.-UK 2017, 7, 46313. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Wang, C.; Cheng, R.; Shams-Ansari, A.; Lončar, M. Monolithic ultra-high-Q lithium niobate microring resonator. Optica 2017, 4, 1536. [Google Scholar] [CrossRef]

- Krasnokutska, I.; Tambasco, J.J.; Li, X.; Peruzzo, A. Ultra-low loss photonic circuits in lithium niobate on insulator. Opt. Express 2018, 26, 897–904. [Google Scholar] [CrossRef] [PubMed]

- Cai, L.; Kong, R.; Wang, Y.; Hu, H. Channel waveguides and y-junctions in x-cut single-crystal lithium niobate thin film. Opt. Express 2015, 23, 29211. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Chen, Z.; Cai, L.; Jiang, Y.; Zhu, H.; Hu, H. Amorphous silicon-lithium niobate thin film strip-loaded waveguides. Opt. Mater. Express 2017, 7, 4018. [Google Scholar] [CrossRef]

- Siew, S.Y.; Cheung, E.J.H.; Liang, H.; Bettiol, A.; Toyoda, N.; Alshehri, B.; Dogheche, E.; Danner, A.J. Ultra-low loss ridge waveguides on lithium niobate via argon ion milling and gas clustered ion beam smoothening. Opt. Express 2018, 26, 4421–4430. [Google Scholar] [CrossRef] [PubMed]

- Cai, L.; Wang, Y.; Hu, H. Low-loss waveguides in a single-crystal lithium niobate thin film. Opt. Lett. 2015, 40, 3013–3016. [Google Scholar] [CrossRef] [PubMed]

- Chang, L.; Li, Y.; Volet, N.; Wang, L.; Peters, J.; Bowers, J.E. Thin film wavelength converters for photonic integrated circuits. Optica 2016, 3, 531. [Google Scholar] [CrossRef]

- Jin, S.; Xu, L.; Zhang, H.; Li, Y. LiNbO3 thin-film modulators using silicon nitride surface ridge waveguides. IEEE Photonics Technol. Lett. 2016, 28, 736–739. [Google Scholar] [CrossRef]

- Chen, L.; Xu, Q.; Wood, M.G.; Reano, R.M. Hybrid silicon and lithium niobate electro-optical ring modulator. Optica 2014, 1, 112. [Google Scholar] [CrossRef]

- Weigel, J.P.O.; Savanier, M.; DeRose, C.T.; Pomerene, A.T.; Starbuck, A.L.; Lentine, A.L.; Stenger, V.; Mookherjea, S. Lightwave circuits in lithium niobate through hybrid waveguides with silicon photonics. Sci. Rep.-UK 2016, 6, 22301. [Google Scholar] [CrossRef] [PubMed]

- Changlui, R.; Pinliao, Y.; Seenwang, W. Bent waveguide with a high index reflector on LiNbO3. Opt. Quant. Electron. 2000, 32, 313–325. [Google Scholar] [CrossRef]

- Qian, Y.; Kim, S.; Song, J.; Nordin, G.P.; Jiang, J. Efficient and compact silicon-on-insulator rib waveguide 90° bends and splitters. Opt. Mater. 2017, 72, 136–139. [Google Scholar] [CrossRef]

- Wang, Q.; Farrell, G.; Wang, P.; Rajan, G.; Freir, T. Design of integrated wavelength monitor based on a Y-branch with an S-bend waveguide. Sens. Actuat. A-Phys. 2007, 134, 405–409. [Google Scholar] [CrossRef]

- Ogusu, K.; Kawakami, S.; Nishida, S. Optical strip waveguide: An analysis. Appl. Opt. 1979, 18, 908–914. [Google Scholar] [CrossRef] [PubMed]

- Saitoh, E.; Kawaguchi, Y.; Saitoh, K.; Koshiba, M. TE/TM-Pass polarizer based on lithium niobate on insulator ridge waveguide. IEEE Photonics J. 2013, 5, 6600610. [Google Scholar] [CrossRef]

- Qiu, W.; Bernal, M.P.; Ndao, A.; Guyot, C.; Hameed, N.M.; Courjal, N.; Maillotte, H.; Baida, F.I. Analysis of ultra-compact waveguide modes in thin film lithium niobate. Appl. Phys. B 2015, 118, 261–267. [Google Scholar] [CrossRef]

- Lumerical Solutions. Available online: http://www.lumerical.com/ (accessed on 5 April 2018).

- Zelmon, D.E.; Small, D.L. Infrared corrected Sellmeier coefficients for congruently grown lithium niobate and 5 mol. % magnesium oxide-doped lithium niobate. J. Soc. Am. B 1997, 14, 3319–3332. [Google Scholar] [CrossRef]

- Landsberger, L.M.; Tiller, W.A. Refractive index, relaxation times and the viscoelastic model in dry-grown SiO2 films on Si. Appl. Phys. Lett. 1987, 51, 1416–1418. [Google Scholar] [CrossRef]

- Li, S.; Cai, L.; Wang, Y.; Jiang, Y.; Hu, H. Waveguides consisting of single-crystal lithium niobate thin film and oxidized titanium stripe. Opt. Express 2015, 23, 24212–24219. [Google Scholar] [CrossRef] [PubMed]

- Ogusu, K.; Tanaka, I. Optical strip waveguide: An experiment. Appl. Opt. 1980, 19, 3322–3325. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Chen, Z.; Hu, H. Analysis of Waveguides on Lithium Niobate Thin Films. Crystals 2018, 8, 191. https://doi.org/10.3390/cryst8050191

Wang Y, Chen Z, Hu H. Analysis of Waveguides on Lithium Niobate Thin Films. Crystals. 2018; 8(5):191. https://doi.org/10.3390/cryst8050191

Chicago/Turabian StyleWang, Yiwen, Zhihua Chen, and Hui Hu. 2018. "Analysis of Waveguides on Lithium Niobate Thin Films" Crystals 8, no. 5: 191. https://doi.org/10.3390/cryst8050191