1. Introduction

Crystallographic texture plays a significant role in the mechanical response of structural materials [

1,

2]. In structural materials with hexagonal close-packed (

hcp) structure, especially in Ti, Zr, Mg and their alloys, the role of texture is even more significant [

3,

4,

5,

6,

7,

8]. Texture influences most of the mechanical, physical and chemical properties of polycrystalline materials, rendering these properties anisotropic [

1]. From the practical point of view, the anisotropy in these properties may or may not be a desirable feature [

2]. Improvement in the mechanical properties such as strength, ductility or toughness can often be achieved through microstructural control or texture optimization. Depending on the manufacturing procedure, the microstructure of the different texture components can be very different. Therefore, the quantitative analysis of the microstructural parameters prevailing in individual texture components is indispensable for a better understanding of the mechanical, physical and chemical properties of structural materials.

X-ray and neutron diffraction line profile analysis has proven to be a powerful tool for characterizing the microstructure of crystalline materials [

9,

10,

11,

12,

13]. Software packages have been developed to determine the microstructural parameters from the shape of the diffracted peaks using Marquardt–Levenberg (ML) optimization [

12,

13]. In the convolutional multiple whole profile (CMWP) procedure the measured diffraction patterns are matched by simulated diffraction patterns consisting of several convoluted defect-specific profile functions. The defect-related theoretical profile functions are tuned by the physically mandatory minimum number of parameters. These parameters are the median,

m, and the variance,

, of a log-normal size distribution function in the size profile, the dislocation density,

ρ, the dislocation arrangement parameter,

and, in case of

hcp materials, the fractions of prevailing slip systems in the strain profile and the fault density,

or

for stacking faults or twin boundaries in the planar defect profile [

13,

14]. In more complex cases like hexagonal materials or multiple phases the ML procedure alone may cause uncertainties. The CMWP method has been improved recently using a new approach in which the ML and a Monte-Carlo statistical method are combined in an alternating manner [

15]. The new CMWP procedure eliminates uncertainties and provides globally optimized parameters of the microstructure.

CMWP can be used for describing the microstructure of individual texture components separately, only if each diffraction peak originates from a single texture component only. There are two ways to achieve this: (1) create a texture-specific diffraction pattern (TSDP) for each texture component by cutting diffraction peaks corresponding to the same texture component from one or more measured patterns and putting them together, (2) grouping the peaks in a measured pattern and handling them as multiple quasi-phases where each quasi-phase corresponds to a separate texture component.

In our previous works we developed procedures to separate X-ray diffraction peaks belonging to both random and one major texture components. The microstructural parameters were determined in the random and major texture components in a strongly textured AZ31-type Mg alloy deformed at different temperatures by evaluating diffraction patterns of more than one quasi-phase [

16] and in tensile-deformed Zr by evaluating TSDPs [

17]. However, in the procedures described in [

16,

17] only one major texture component was considered and the identification of diffraction peaks corresponding to the same texture component is valid only in a close range around the 0° azimuth angle of the scattered beam. Therefore, if the measured data are collected by a two-dimensional detector, only a limited fraction of the Debye–Scherrer (DS) rings can be used in these evaluation schemes.

The characterization of the microstructure in four major texture components separately by neutron diffraction line profile analysis has been developed by Ungár et al. [

11]. Although that method provides the separation of diffraction peaks for multiple texture components in the case of neutron diffraction experiments, X-ray diffraction geometry is more complex from the point of view of the peak identification procedure. The neutron diffraction geometry in the SMARTS engineering diffractometer [

18], and in a number of other similar diffractometers at spallation neutron sources [

19,

20,

21] has two detectors positioned at angles +90° and −90° relative to the incoming neutron beam and the diffraction patterns are collected by the method of time of flight (TOF) in each detector. Since the diffraction angles are the same for all diffraction peaks, it is relatively simple to calculate the intensity contribution recorded by the detectors for the different texture components as detailed in [

11]. In the case of X-ray diffraction with a parallel beam geometry both in laboratory and synchrotron measurements, when the beam is monochromatic, the scattered intensity distribution depends on both the diffraction angle and the azimuth angle. In order to get a diffraction pattern, the intensity distribution is often integrated alongside the azimuth angle, especially in synchrotron measurements. If one wants to determine the contributions of different texture components for a diffraction peak in a measured pattern in general, one needs to calculate the intensity as a function of the diffraction and azimuth angles integrated over a certain azimuthal interval of the DS rings.

In this work we present the principles and the practice of a general method to determine the microstructural parameters in multiple texture components separately in the case of parallel-beam geometry X-ray diffraction setups. Based on the principles of the method a computer software package, X-TEX, has been developed. The present work aims to determine differences between the microstructures in different, coexisting texture components, in this manner, X-TEX differs from texture analysing software as MTEX [

22] or ATEX [

23]. The method will be tested and illustrated by determining the dislocation densities, dipole character, prevailing slip systems and subgrain sizes in tensile-deformed, textured, commercially pure Ti.

2. Principles of the X-TEX Method

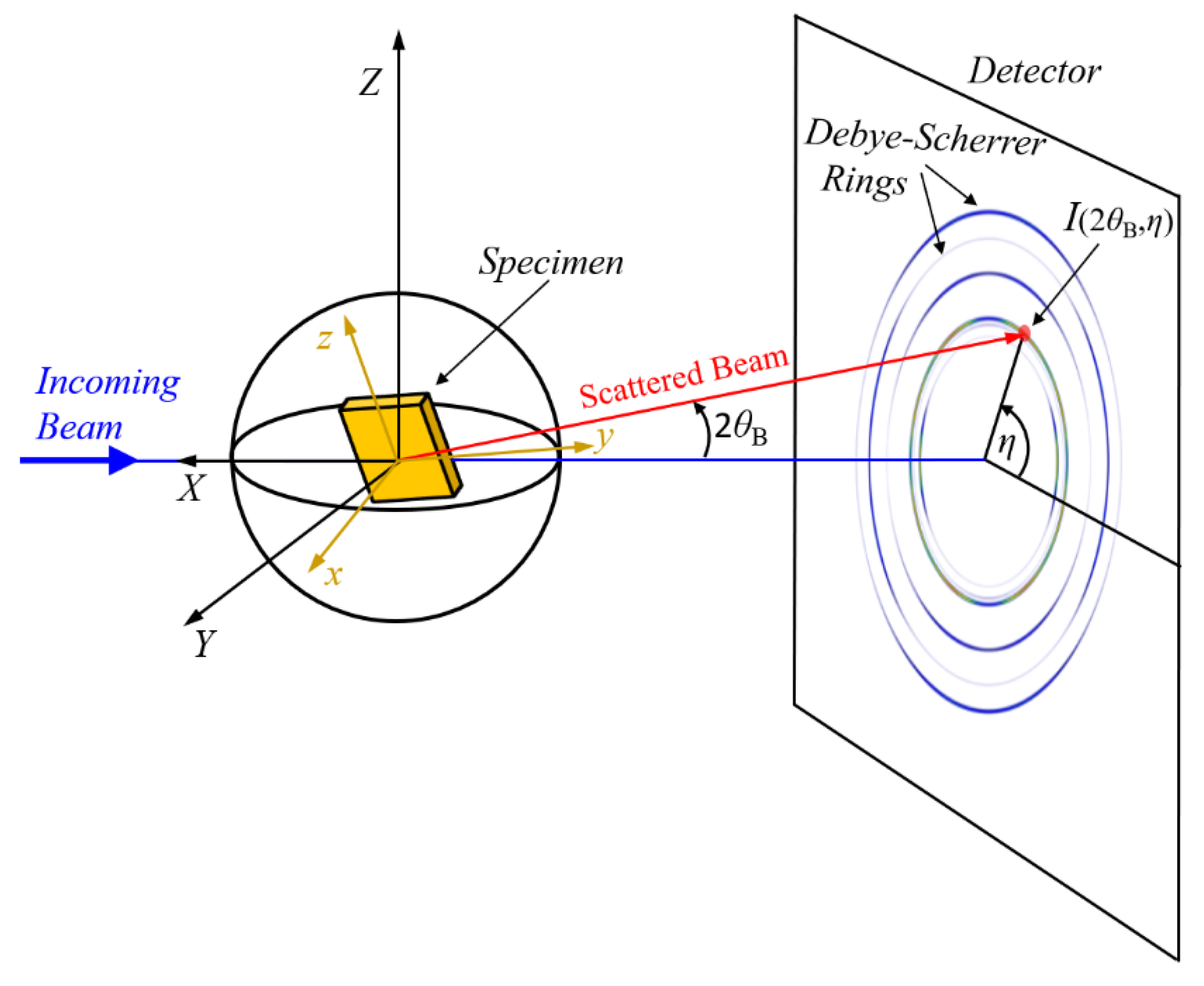

In the X-TEX procedure we simulate the texture using Gaussian distributions around the ideal orientations of specific texture components. With this method we calculate the scattered X-ray intensity contribution from each texture component at any point along the DS rings. The laboratory and the specimen Cartesian coordinate systems,

and

, are shown in

Figure 1. The laboratory coordinate system is defined so that the positive X-axis is parallel to the incoming X-ray beam showing toward the X-ray source, and the positive Z-axis is pointing upwards. Initially

and

coincide, i.e.,

x‖

X,

y‖

Y and

z‖

Z. In an orthogonal coordinate system, the unit vectors,

, normal to the crystallographic

hkl planes in cubic or

hcp crystals are:

where

is the spacing of

hkl planes and

and

are the lattice parameters in the

hcp crystal. In the case of

hcp crystals, the unit cell is positioned in the following manner: the

basis vector has an angle of 30° with the

-axis and

and

are parallel to the

- and

-axis, respectively.

The ideal orientation of a texture component,

is interpreted as a three-dimensional rotation matrix with

z-x-z convention:

where the Eulerian angles

,

and

describe the rotation between the crystallographic and the sample coordinate system

. The specimen orientation in

is described by another rotation matrix with

Z-X-Z convention:

where

,

and

are the Eulerian angles of the specimen rotation in

. Rotating the specimen by

,

and

angles, the normal vectors of the

hkl planes for an ideal orientation of the

ith texture component will be

Denote the unit vector in the direction of the diffraction vector in

as

:

where

is the diffraction angle of

hkl planes according to Bragg’s law and

η is the azimuth angle of the scattered beam as it can be seen in

Figure 1. The

hkl plane of a crystal will scatter the X-ray beam into

direction only if the normal vector of the plane is pointing in the

direction. This means that in the

direction the diffracted X-ray intensity is proportional to the volume fraction of grains oriented in this manner. Their relative volume fraction is obtained by assuming a Gaussian distribution of orientations around the ideal orientation of the

ith texture component:

where

is the variance of the distribution and

is a normalization factor taking into account the

volume fraction of grains belonging to the

ith texture component:

where

and

are polar coordinates. The total intensity of the

hkl reflection in the

direction including the contribution of the random texture component is:

where

is the volume fraction of the random texture component,

is a coefficient that includes the Lorentz-polarization and the absorption correction,

is the structure factor and the

summation goes over permutations of the

hkl indices. Experimental diffraction patterns for line profile analysis are obtained by integrating the intensity distribution measured with a two-dimensional detector along the

η azimuth angle. Therefore, one has to integrate the theoretical intensity distribution

of Equation (8) over an

interval as well:

the theoretical diffraction pattern produced by any modelled texture for any specimen orientation is given by Equation (9) and consists of several peaks.

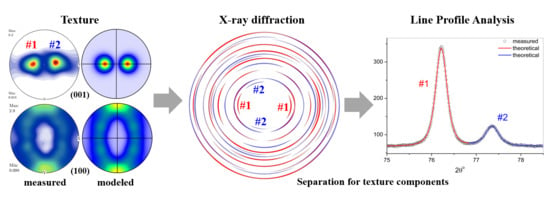

When a polycrystalline material is texture free, the intensity along DS rings is constant. Texture causes variations of the intensity along the rings and the diffracted intensity originates from different texture components as illustrated in

Figure 2.

Figure 2a shows the diffracted intensity resulting from two texture components

for which the intensities of the (100) reflection overlap.

Figure 2b, however, shows the diffracted intensity distribution resulting from the same two texture components for a different specimen orientation, where the intensities along the DS ring of the (100) reflection are well separated into sections consisting of contributions from the individual single texture components. Integration over the entire ring or partial

integration over an erroneously chosen

range causes mixed diffraction peaks consisting of contributions from different texture components. The goal is to find those specimen orientations which provide for as many as possible separated intensity distributions along the

hkl rings from which diffraction peaks corresponding to one single texture component only can be obtained. Since texture is usually not infinitely sharp, it is to be expected that peaks mainly corresponding to one texture component will also have some contribution from other texture components. The overlap of scattered intensity from different texture components can be considered by taking into account the angular spread and the volume fraction of grains of different texture components. The intensity contributions for

hkl peaks provided by grains belonging to the

ith texture component are described with the

intensity ratios. Peaks are considered to correspond to the investigated texture component, if their intensity ratio is larger than a chosen threshold value

.

There are two possibilities to evaluate the peaks belonging to the same texture component with the CMWP software. The first possibility is to put individually selected peaks (obtained from integrating the intensity distributions along an hkl ring over a specific interval) together creating a texture-specific diffraction pattern (TSDP). These peaks can be selected either from different measurements or from the same measurement by integrating the intensities over different intervals for each peak. The second possibility is to integrate the DS rings over the same range for each hkl ring and group the peaks into different quasi-phases in the CMWP procedure. The advantages of this (quasi) multiple-phase evaluation against the TSDP method are: (1) there is no need to cut out peaks, thus overlapping peaks can also be evaluated; and (2) the TSDP may require in general more than one measurement, where the second method does not. The disadvantage is that peaks have lower values, thus, the contributions of alien texture components will be higher. In this work both methods will be applied to tensile-deformed, textured titanium.

5. Evaluation of the X-Ray Diffraction Experiments

Prior to the line profile measurements with long sample-detector distance of 300 mm, the scattered X-ray intensity distribution was recorded using a shorter (100 mm) sample-detector distance for all specimens with ND-A sample orientation in order to measure larger parts of the DS rings. From these measurements, the parameters used to describe the texture in the X-TEX method were determined according to the intensity variation along the DS rings. IP readouts for the as-received and the 23% tensile-deformed specimen are shown in

Figure 5a,b, respectively. The two images are very similar because of the similar texture, however, small differences can be recognized in the case of some arcs. It will be shown later, that these differences have great importance in the separation procedure of the peaks. It is noted that in the case of the as-received image, intensity maxima are visible because of the large undistorted grains in this specimen. The strong line broadening toward the edge of the IPs in the vertical direction is an instrumental effect from the horizontal width of the beam, which occurs because of the relatively small specimen-IP distance. This problem automatically disappears at larger distances between specimen and IP. The texture parameters are determined from these measurements by dividing the images into several horizontal stripes. The measured intensity of the

hkl diffraction peak in the

Nth stripe,

is obtained by integrating the intensity distribution along the DS arc in the range of the stripe. The X-TEX software varies the texture parameters with a Monte-Carlo algorithm and calculates the intensity of diffraction peaks in each stripe with different texture parameters. The obtained results,

are compared with the measured intensities for all of the stripes and DS rings. The texture parameters are optimized by minimizing the sum of squared residuals (SSR):

Calculated detector images based on the optimized texture parameters for the as-received and the 23% tensile-deformed specimen are shown in

Figure 5c,d, respectively.

The texture parameters, i.e., the Eulerian angles

,

and

of the ideal orientation of each of the major texture components, the

volume fraction of the random texture component and the full width at half maximum (FWHM =

) of the Gaussian distribution defined in Equation (6), determined by X-TEX are listed in

Table 2.

The

volume fractions of the major texture components are considered equal for the symmetrical components with respect to RD according to the measured pole figures. Based on the measured pole figures, each of the two major texture components (one with positive

, the other with negative

) was produced from two subcomponents for more precise description of the texture. Calculated pole figures based on the texture parameters listed in

Table 2 are plotted in

Figure 6. It can be seen that the calculated pole figures based on texture parameters determined from X-ray diffraction measurements are in good agreement with pole figures measured by EBSD (if the slightly different frequency of the symmetrical components with respect to RD is ignored) and show, for instance, the replacement of the (110) direction by a (100) direction along RD.

Knowing the parameters of the texture, X-ray diffraction measurements were performed for line profile analysis with a larger (300 mm) sample-detector distance to achieve higher angular resolution and negligible instrumental effect. Line profiles were obtained by integrating the intensity distributions along the corresponding DS rings. The diffraction patterns were evaluated by the CMWP procedure [

15]. The measured diffraction pattern,

is matched by theoretically calculated and convoluted profile functions representing the effects of size,

, distortion,

and planar defects,

as well as instrumental effects,

:

where the asterisk stands for convolution and

is the background intensity. The instrumental contribution was deemed unnecessary, as the present instrumental conditions do not require the use of any corrections. The nature of line broadening caused by crystallite size, distortion and planar faults are essentially different, so fitting multiple whole measured profiles considering these physical effects simultaneously makes a powerful tool to characterize the microstructure. The size profile,

is determined by assuming a log-normal size distribution with median

m and logarithmic variance

[

10]. The area-weighted average crystallite size,

, was calculated from the median and variance of the distribution as

[

29].

represents the coherently scattering domain size which is closer to the subgrain or dislocation cell size than to crystallographic grain size. The strain profile,

is given by its Fourier transform [

30]:

where

is the absolute value of the diffraction vector and

L is the Fourier variable. The mean square strain caused by restrictedly random dislocation distributions in crystals is given by the Wilkens function

[

31]:

where

ρ,

b,

and

Re are the dislocation density, the absolute value of the Burgers vector, the

hkl dependent contrast factor and the effective outer cut-off radius of dislocations, respectively. Since the absolute value of

Re depends on the dislocation density

ρ, a dimension-free parameter,

was introduced to describe the dislocation arrangement. The smaller the value of

, the stronger is the correlation between dislocations of opposite sign. In this manner, smaller

indicates a stronger dipole character. If dislocations of all possible Burgers vectors in a particular slip mode are equally populated, the dislocation contrast factors can be averaged over the permutations of the corresponding

hkl indices. In the hexagonal system this is given as [

32]:

where

,

and

are parameters depending on the

ith slip plane family, the elastic properties of the material and the

c/

a ratio,

is the average contrast factor of the

ith slip plane family corresponding to the

hk0 type reflections, and

is the lattice constant in the basal plane. The CMWP procedure provides measured parameter values

and

. Matching of the measured

and theoretically calculated

values can provide the relative fractions

,

and

of the

,

and

type of dislocations as detailed in [

33]. The

planar defect profiles are parameterized as a function of fault probabilities for the different stacking faults and twin boundaries [

14]. In [

14], the effect of twinning on the diffraction patterns in hexagonal materials is worked out for the {101}<102> and {112}<113> compressive, and {102}<101> and {111}<116> tensile twin systems. Since the CMWP evaluation gave zero twin probability in all the specimens for all twinning modes, these values are not presented in this paper (note that this is not in conflict with the frequency of twin boundaries up to 30% reported in [

24] based on EBSD measurements. The latter twin boundary frequency refers to the fraction of twin boundaries of all high angle boundaries, whereas profile analysis determines the probability of twin boundaries occurring on all possible twinning planes). At room temperature, several twinning modes have been observed in commercially pure titanium, e.g., [

24,

34]. However, the effect of twinning cannot be seen in the X-ray line profiles unless the average distance between twin boundaries is smaller than about 2 μm corresponding to a twin probability of at most 0.01%.

In order to follow the microstructure evolution during deformation in the different texture components separately, two measurements were carried out on the ND surface for all specimens denoted as ND-A and ND-B. The A and B notation distinguishes pairs of measurements which are symmetrical from the point of view of texture and the separation procedure of the diffraction peaks. This means that the

values of the two major texture components become swapped between the two measurements of the pair, while the

values of the random texture component are the same. Using this method, particular

hkl peaks correspond to component #1 when measured on surface A, but to component #2 when measured on surface B, respectively. In this manner, several

hkl peaks are measured for both major texture components and the peaks for the random component are measured twice so better statistics for the microstructural parameters can be achieved during the CMWP evaluation. The ND-A and ND-B diffraction patterns were evaluated simultaneously in the fitting procedure with the same parameter values for the individual texture components. The

values of the two major and the random texture components for the

hkl peaks in the case of the as-received and the 23% tensile-deformed specimens in the ND-A measurement are listed in

Table 3. The

values in the case of the ND-B measurements are exactly the same except the swap between the two major components. The patterns were evaluated using the multiple phase option of CMWP, where the individual peaks were assigned to the three different quasi-phases according to their

values calculated by X-TEX. In

Table 3 it can be seen that peaks mainly correspond to one texture component, but also have some contribution from other texture components. Peaks are considered to belong to one of the major texture components if

and to the random component if

. These values are highlighted with bold numbers in the table. The limit of 40% intensity contribution for the random texture component may appear to be a low value, however for this limit the scattered intensity stems from grains tilted at least 30° from the ideal orientation of the major texture components.

Table 3 shows that the intensity contributions for some

hkl peaks are remarkably different between the as-received and the 23% tensile-deformed specimen; two peaks (201 and 203) are actually assigned to different texture components.

The diffraction patterns of the as-received and 23% tensile-deformed specimens corresponding to the ND-A measurement are shown in

Figure 7. The peaks in the patterns were grouped into multiple phases in the CMWP method according to their

values so that each quasi-phase corresponds to a single texture component. In order to reveal the shape of the peaks in the whole intensity range better, a logarithmic intensity scale is used. The peaks, which could not be unambiguously assigned to a phase, were fitted as a separate “mixed” phase as well, the results of which are not interpreted. This evaluation with multiple phases is an appropriate method to include overlapping peaks, such as 112 and 201 in

Figure 7 as well, even when they are attributed to different phases.

Higher χ values for individual peaks can be obtained by carrying out multiple measurements with different sample orientations. In this manner, texture-specific diffraction patterns (TSDPs) can be created by cutting and putting together peaks with high χ values for each texture component. In the case of the ND-A and ND-B measurements for the 23% tensile-deformed specimen, the average χ value of peaks belonging to the major texture components is 80%, but only 57% for peaks of the random texture component. In order to show the power of using TSDPs, eight measurements were performed for the 23% tensile-deformed specimen in different sample orientations denoted as illustrated in

Figure 4b. The χ values of the two major and the random texture components for the

hkl peaks in the case of the TSDP measured on different surfaces are listed in

Table 4. Using TSDPs, the average χ value was 85% for both the major and the random texture components. In

Figure 8, TSDPs for the major texture component #1 and the random texture component are plotted.

6. Results

The results of the CMWP evaluation are shown in

Figure 9. By combining the Marquardt–Levenberg optimization procedure with a statistical Monte Carlo method, robust optimized parameters are obtained [

15]. The resulting values for the microstructural parameters versus the true plastic strain are plotted for the different texture components separately. In addition, the results of the evaluation of the TSDPs for the 23% tensile-deformed specimen are shown in the figures as well. A significant difference was found between the dislocation densities in the random and major texture components (

Figure 9a). In the as-received state the dislocation density is the same for all texture components within experimental error. With increasing deformation, the dislocation density increases in all texture components, however, in the random component the increase is significantly, about 2–3 times higher than in the two major components. The difference between the dislocation densities in the random and the two major texture components is slightly higher in case of the TSDP evaluation that consists of peaks with higher

ratios, however, there is no significant difference between the two methods.

For all texture components, the arrangement parameter

is above 1 indicating rather low screening between the dislocations (

Figure 9b). The value of

remains between 1 and 2 during the whole deformation in the random texture component while

increases in the major texture components to about 4 indicating an even weaker screening. Again, the

values obtained from the TSDP evaluation differ slightly more. In the as-received state, there are mainly

type dislocations in the specimen, their fraction is over 80%. As a result of deformation, initially (during the first 2% tensile deformation) the fraction of

type dislocations increases and reaches even 40%, then with increasing plastic deformation the

type dislocations become more dominant again. There is no significant difference in this respect between the major and the random texture components (

Figure 9c). The area-weighted crystallite size remains almost constant during the first 2% of tensile deformation and decreases after 2% deformation in all components (

Figure 9d). The refinement is stronger in the random component, i.e., the crystallite size is under 60 nm in the random component while it is around 90 nm in the major texture components after 23% strain. The microstructural parameters of the two major texture components are equivalent within experimental error during the whole deformation.

7. Discussion

In order to deform a polycrystal homogeneously without producing cracks, at least five independent slip systems need to be activated. For

hcp metals this requirement cannot be fulfilled by only

type dislocations since they can provide only four independent slip systems [

35,

36], therefore twinning or deformation by

type dislocations are needed as well [

37]. From the CMWP evaluation a vanishing probability for twin boundaries (less than 0.01%) is concluded. This is, however, not in conflict with the observations [

24] that about 30% of all high angle boundaries (with mean chord length of 5 µm and above) were identified as twin boundaries. Further evidence from EBSD revealed the occurrence of 64.6° <100> compressive twinning after 2% tensile deformation and additional 84.8° <110> tensile twinning after 10% tensile deformation. Only during the first 2% tensile deformation, no twinning is observed at all. This may explain the observation of a strong increase in

type dislocations during the initial deformation stage to achieve compatible deformation during this stage. During later stages, twinning can accommodate part of the deformation and the increase in the density of

type dislocations is not as strong any longer. Nevertheless, dislocation accumulation of

type dislocations occurs continuously along with twinning.

A significant difference between the dislocation densities of the random and the major texture components can be revealed by plotting the densities of

and

type dislocations separately.

Figure 10a,b shows that while in the random component the amount of

type dislocations gradually increases with deformation, in the major texture components

type slip systems are not activated even at 10% strain, the density of

type dislocations increases only at higher, 23% strain. The reason for this may be the following: It is well known that in CP Ti the main slip systems are prismatic and basal

systems [

38], providing altogether four independent slip systems. Although pyramidal

slip can be present as a secondary slip system, the critical resolved shear stress (CRSS) value for this is higher than for pyramidal

system [

39]. In our case, the Schmid factor of basal

slip is zero for the ideal orientation of both major texture components in the as-received state as well as after 23% tensile deformation and has very small values for orientations close to these orientations. Consequently, the number of independent

type slip systems is higher in the random texture component than in both major texture components causing the development of larger dislocation densities of

type Burgers vectors in the random texture component. The almost constant density of

dislocations in the major texture components at the beginning of the tensile deformation, on the other hand, roots analogously in the vanishing Schmid factor for basal slip for these orientations. With proceeding tensile deformation, an increased activation of prismatic

slip may cause the observed increase in density of

dislocations in the major texture components. Despite the CRSS of

dislocations being much higher than that of

dislocations,

slip systems must be activated as an increase in the

dislocation density is observed during tensile deformation. The initial increase in their density is attributed to the requirement of compatible deformation: without activation of twinning modes, i.e., in the early stage of tensile deformation, compatibility can only be achieved by a certain contribution of

slip. With proceeding deformation, the increase in density of

dislocations becomes smaller, most likely due to a lower activation of

slip systems enabled by simultaneously occurring twinning.

From the arrangement parameters generally larger than 1, it is concluded that the deformation-induced dislocations do not create dislocation configurations with short screening length as narrow dislocation dipoles in either one of the texture components. There could be several reasons for that: (i) the dislocation density may not be large enough to force the dislocations into low energy configuration with small screening length like dipoles, (ii) the dislocations may not have enough three-dimensional mobility to acquire these configurations, or (iii) the dislocation annihilation might be insufficient to allow their ordering. In the major texture components the dislocation densities are lower than in the random texture component, they show even weaker screening and a larger arrangement parameter.

In order to connect microstructure with strength, the flow stress,

, is correlated with the dislocation densities,

, in

Figure 11. The dependence can be rationalized using Taylor’s relation [

40]:

where

is a friction stress required to move dislocations,

is an interaction coefficient describing the interactions between dislocations,

is the Taylor factor for dislocation slip,

= 44 GPa is the shear modulus and

is the length of the Burgers vector averaged according to the fractions of the different types of dislocations.

For the dislocation densities and Burgers vectors volume-averaged values are considered corresponding to the volume fractions of the major and random texture components. The flow stress values are taken from the stress-strain curve in [

24]. Using Equation (15),

, i.e., the intercept with the stress axis and the product

, i.e., the slope of the fitted straight line can be obtained as shown in

Figure 11. The result of

= 45 (±26) MPa from this linear fitting is close to the standard value of 78 MPa for well-annealed CP Ti [

41]. The

Taylor factor varies between 2.5 and 5.0 for Ti in literature [

42,

43]. By knowing the texture, it would be possible in principle to calculate

on the assumption of

and

slip, however it is beyond the scope of the present work. Using the 2.5 and 5.0 extremal values of the Taylor factor we get 0.21 and 0.41 as lower and upper bounds for the coefficient

in good correspondence with expected values from 0.1 to 0.5 in [

44]. The good description achieved by Taylor’s relation indicates that dislocations are mainly responsible for the observed work-hardening in spite of the concurrent twinning. This is in accordance with the successful description of the different work-hardening stages by stage wise Voce laws in [

24].