Visible Light Induced Nano-Photocatalysis Trimetallic Cu0.5Zn0.5-Fe: Synthesis, Characterization and Application as Alcohols Oxidation Catalyst

Abstract

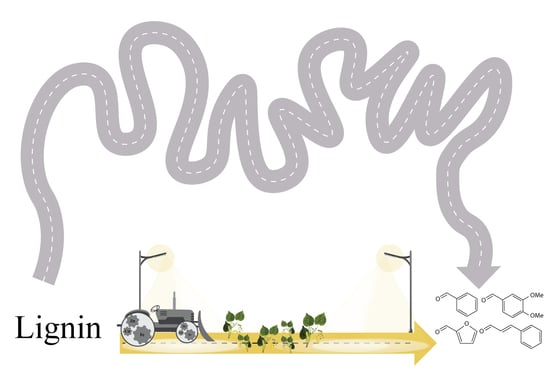

:1. Introduction

2. Results and Discussion

2.1. Trimetallic Nanoparticles

2.2. TGA

2.3. Benzyl Alcohol Oxidation

2.4. Recyclability

3. Experimental

3.1. Materials

3.2. Copper-Zinc Ferrite Cu0.5Zn0.5Fe2O4 NP Synthesis

3.3. Characterization

3.4. Photocatalytic Oxidation of Benzyl Alcohol to Benzaldehyde

3.5. Product Analysis

3.6. Experimental Procedure for the Reuse of the Catalyst

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ng, Y.H.; Lightcap, I.V.; Goodwin, K.; Matsumura, M.; Kamat, P.V. To What Extent Do Graphene Scaffolds Improve the Photovoltaic and Photocatalytic Response of TiO2 Nanostructured Films? J. Phys. Chem. Lett. 2010, 1, 2222–2227. [Google Scholar] [CrossRef]

- Zhang, H.; Lv, X.; Li, Y.; Wang, Y.; Li, J. P25-graphene Composite as a High Performance Photocatalyst. ACS Nano 2010, 4, 380–386. [Google Scholar] [CrossRef] [PubMed]

- Woan, K.; Pyrgiotakis, G.; Sigmund, W. Photocatalytic Carbon Nanotube TiO2 Composites. Adv. Mater. 2009, 21, 2233–2239. [Google Scholar] [CrossRef]

- Kumaresan, L.; Mahalakshmi, M.; Palanichamy, M.; Murugesan, V. Synthesis, Characterization, and Photocatalytic Activity of Sr2þ Doped TiO2 Nanoplates. Ind. Eng. Chem. Res. 2010, 49, 1480–1485. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Wang, W.Z.; Yin, W.Z.; Shang, M.; Wang, L.; Sun, S.M. Inducing Photocatalysis by Visible Light Beyond the Absorption Edge: Effect of Upconversion Agent on the Photocatalytic Activity of Bi2WO6. Appl. Catal. B 2010, 101, 68–73. [Google Scholar] [CrossRef]

- Liang, Y.Y.; Wang, H.L.; Casalongue, H.S.; Chen, Z.; Dai, H.J. TiO2 Nanocrystals Grown on Graphene as Advanced Photocatalytic Hybrid Materials. Nano Res. 2010, 3, 701–705. [Google Scholar] [CrossRef] [Green Version]

- Vijayan, B.K.; Dimitrijevic, N.M.; Wu, J.S.; Gray, K.A. The Effects of Pt Doping on the Structure and Visible Light Photoactivity of Titania Nanotubes. J. Phys. Chem. C 2010, 114, 21262–21269. [Google Scholar] [CrossRef]

- Romcevic, N.; Kostic, R.; Hazic, B.; Romcevic, M.; KuryliszynKudelska, I.; Dobrowolski, W.D.; Narkiewicz, U.; Sibera, D. Raman Scattering from ZnO Incorporating Fe Nanoparticles: Vibrational Modes and Low-Frequency Acoustic Modes. J. Alloys Compd. 2010, 507, 386–390. [Google Scholar] [CrossRef]

- Cai, L.; Liao, X.; Shi, B. Using Collagen Fiber as a Template to Synthesize TiO2 and Fex/TiO2 Nanofibers and Their Catalytic Behaviors on the Visible Light-Assisted Degradation of Orange II. Ind. Eng. Chem. Res. 2010, 49, 3194–3199. [Google Scholar] [CrossRef]

- Guo, R.Q.; Fang, L.A.; Dong, W.; Zheng, F.G.; Shen, M.R. Enhanced Photocatalytic Activity and Ferromagnetism in Gd Doped BiFeO3 Nanoparticles. J. Phys. Chem. C 2010, 114, 21390–21396. [Google Scholar] [CrossRef]

- Cai, W.D.; Chen, F.; Shen, X.X.; Chen, L.J.; Zhang, J.L. Enhanced Catalytic Degradation of AO7 in the CeO2-H2O2 System with Fe3þ Doping. Appl. Catal. B 2010, 101, 160–168. [Google Scholar] [CrossRef]

- Shu, X.; He, J.; Chen, D. Visible-Light-Induced Photocatalyst Based on Nickel Titanate Nanoparticles. Ind. Eng. Chem. Res. 2008, 47, 4750–4753. [Google Scholar] [CrossRef]

- Hirakawa, T.; Nosaka, Y. Properties of O2 and OH Formed in TiO2 Aqueous Suspensions by Photocatalytic Reaction and the Influence of H2O2 and Some Ions. Langmuir 2002, 18, 3247–3325. [Google Scholar] [CrossRef]

- Xu, S.H.; Feng, D.L.; Shangguan, W.F. Preparations and Photocatalytic Properties of Visible-Light-Active Zinc Ferrite-Doped TiO2 Photocatalyst. J. Phys. Chem. C 2009, 113, 2463–2467. [Google Scholar] [CrossRef]

- Laokul, P.; Amornkitbamrung, V.; Seraphin, S.; Maensiri, S. Characterization and Magnetic Properties of Nanocrystalline CuFe2O4, NiFe2O4, ZnFe2O4 Powders Prepared by the Aloe Vera Extract Solution. Curr. Appl. Phys. 2011, 11, 101–108. [Google Scholar] [CrossRef]

- Zhang, B.P.; Zhang, J.L.; Chen, F. Preparation and Characterization of Magnetic TiO2/ZnFe2O4 Photocatalysts by a sol-gel Method. Res. Chem. Intermed. 2008, 34, 375–380. [Google Scholar] [CrossRef]

- Gómez-Pastora, J.; Bringas, E.; Ortiz, I. Recent progress and future challenges on the use of high performance magnetic nano-adsorbents in environmental applications. Chem. Eng. J. 2014, 256, 187–204. [Google Scholar] [CrossRef]

- Al-Hunaiti, A.; Ghazzy, A.; Sweidan, N.; Mohaidat, Q.; Bsoul, I.; Mahmood, S.; Hussein, T. Nano-Magnetic NiFe2O4 and Its Photocatalytic Oxidation of Vanillyl Alcohol—Synthesis, Characterization, and Application in the Valorization of Lignin. Nanomaterials 2021, 11, 1010. [Google Scholar] [CrossRef]

- Al-Hunaiti, A.; Mohaidat, Q.; Bsoul, I.; Mahmood, S.; Taher, D.; Hussein, T. Synthesis and characterization of novel phyto-mediated catalyst, and its application for a selective oxidation of (VAL) into vanillin under visible light. Catalysts 2020, 10, 839. [Google Scholar] [CrossRef]

- Sharma, G.; Kumar, D.; Kumar, A.; Ala’a, H.; Pathania, D.; Naushad, M.; Mola, G.T. Revolution from monometallic to trimetallic nanoparticle composites, various synthesis methods and their applications: A review. Mater. Sci. Eng. C 2017, 71, 1216–1230. [Google Scholar] [CrossRef]

- Mondal, B.N.; Basumallick, A.; Chattopadhyay, P.P. Magnetic behavior of nanocrystalline Cu–Ni–Co alloys prepared by mechanical alloying and isothermal annealing. J. Alloys Compd. 2008, 457, 10–14. [Google Scholar] [CrossRef]

- Roshanghias, A.; Bernardi, J.; Ipser, H. An attempt to synthesize Sn-Zn-Cu alloy nanoparticles. Mater. Lett. 2016, 178, 10–14. [Google Scholar] [CrossRef]

- Lan, J.; Li, C.; Liu, T.; Yuan, Q. One-step synthesis of porous PtNiCu trimetallic nanoalloy with enhanced electrocatalytic performance toward methanol oxidation. J. Saudi Chem. Soc. 2019, 23, 43–51. [Google Scholar] [CrossRef]

- Venkatesan, P.; Santhanalakshmi, J. Designed synthesis of Au/Ag/Pd trimetallic nanoparticle-based catalysts for Sonogashira coupling reactions. Langmuir 2010, 26, 12225–12229. [Google Scholar] [CrossRef]

- Duan, H.; Wang, D.; Li, Y. Green chemistry for nanoparticle synthesis. Chem. Soc. Rev. 2015, 44, 5778–5792. [Google Scholar] [CrossRef]

- Iravani, S.; Varma, R. Plant-derived Edible Nanoparticles and miRNAs: Emerging Frontier for Therapeutics and Targeted Drug-delivery. ACS Sustain. Chem. Eng. 2019, 7, 8055–8069. [Google Scholar] [CrossRef]

- Imraish, A.; Al-Hunaiti, A.; Abu-Thiab, T.; Ibrahim, A.; Hwaitat, E.; Omar, A. Phyto-Facilitated Bimetallic ZnFe2O4 Nanoparticles via Boswellia carteri: Synthesis, Characterization, and Anti-Cancer Activity. Anti-Cancer Agents Med. Chem. 2021, 21, 1767–1772. [Google Scholar] [CrossRef]

- Iravani, S.; Varma, R.S. Plants and plant-based polymers as scaffolds for tissue engineering. Green Chem. 2019, 21, 4839–4867. [Google Scholar] [CrossRef]

- Pugh, S.; McKenna, R.; Halloum, I.; Nielsen, D.R. Engineering Escherichia coli for Renewable Benzyl Alcohol Production. Metab. Eng. Commun. 2015, 2, 39–45. [Google Scholar] [CrossRef]

- Pillai, U.R.; Sahle-Demessie, E. Oxidation of alcohols over Fe3+/montmorillonite-K10 using hydrogen peroxide. Appl. Catal. A-Gen. 2003, 245, 103–109. [Google Scholar] [CrossRef]

- O’Brien, P.; Lopez-Tejedor, D.; Benavente, R.; Palomo, J.M. Pd Nanoparticles-Polyethylenemine-Lipase Bionanohybrids as Heterogeneous Catalysts for Selective Oxidation of Aromatic Alcohols. ChemCatChem 2018, 10, 4992–4999. [Google Scholar] [CrossRef]

- Alshammari, H.M.; Alshammari, A.S.; Humaidi, J.R.; Alzahrani, S.A.; Alhumaimess, M.S.; Aldosari, O.F.; Hassan, H. Au-Pd Bimetallic Nanocatalysts Incorporated into Carbon Nanotubes (CNTs) for Selective Oxidation of Alkenes and Alcohol. Processes 2020, 8, 1380. [Google Scholar] [CrossRef]

- An, H.; Deng, C.; Sun, Y.; Lv, Z.; Cao, L.; Xiao, S.; Zhao, L.; Yin, Z. Design of Au@ Ag/BiOCl–OV photocatalyst and its application in selective alcohol oxidation driven by plasmonic carriers using O2 as the oxidant. CrystEngComm 2020, 22, 6603–6611. [Google Scholar] [CrossRef]

- Smit, J.; Wijn, H.P.J.; Ferrites; Mahmood, S.H. Properties and Synthesis of Hexaferrites. In Hexaferrite Permanent Magnetic Material; Wiley: New York, NY, USA, 1959; p. 54. [Google Scholar]

- Mahmood, S.H. Magnetic anisotropy in fine magnetic particles. J. Magn. Magn. Mater. 1993, 118, 359–364. [Google Scholar] [CrossRef]

- Narayanasamy, A.; Jeyadevan, B.; Chinnasamy, C.N.; Ponpandian, N.; Greneche, J.M. Structural, magnetic and electrical properties of spinel ferrite nanoparticles. In Proceedings of the Ninth International Conference on Ferrites, San Francisco, CA, USA, 3 January 2005; pp. 867–875. [Google Scholar]

- Rincón-Granados, K.L.; Vázquez-Olmos, A.R.; Vega-Jiménez, A.; Ruiz, F.; Garibay-Febles, V.; Ximénez-Fyvie, L. Preparation, characterization and photocatalytic activity of NiO, Fe2O3 and NiFe2O4. Materialia 2021, 15, 177–182. [Google Scholar]

- Marmisollé, W.A.; Azzaroni, O. Recent developments in the layer-by-layer assembly of polyaniline and carbon nanomaterials for energy storage and sensing applications. From synthetic aspects to structural and functional characterization. Nanoscale 2016, 8, 9890–9918. [Google Scholar] [CrossRef]

- Jiang, C.; Markutsya, S.; Tsukruk, V.V. Compliant, robust, and truly nanoscale free-standing multilayer films fabricated using spin-assisted layer-by-layer assembly. Adv. Mater. 2004, 16, 157–161. [Google Scholar] [CrossRef]

- Kroschwitz, J.I.; Howe-Grant, M. Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley and Sons: New York, NY, USA, 1991; p. 127. [Google Scholar]

- Al-Hunaiti, A.; Al-Said, N.; Halawani, L.; Haija, M.A.; Baqaien, R.; Taher, D. Synthesis of magnetic CuFe2O4 nanoparticles as green catalyst for toluene oxidation under solvent-free conditions. Arab. J. Chem. 2020, 13, 4945–4953. [Google Scholar] [CrossRef]

- Karimi, B.; Abedi, S.; Clark, J.; Budarin, V. Highly efficient aerobic oxidation of alcohols using a recoverable catalyst: The role of mesoporous channels of SBA-15 in stabilizing palladium nanoparticles. Angew. Chem. Int. Ed. 2006, 17, 4776–4779. [Google Scholar] [CrossRef]

- Wang, C.; Chen, W.; Chang, H.T. Enzyme Mimics of Au/Ag Nanoparticles for Fluorescent Detection of Acetylcholine. Anal. Chem. 2012, 84, 9706–9712. [Google Scholar] [CrossRef]

- Zhu, Z.; Liu, F.; Fan, J.; Li, Q.; Min, Y.; Xu, Q. C2 Alcohol Oxidation Boosted by Trimetallic PtPbBi Hexagonal Nanoplates. ACS Appl. Mater. Interfaces 2020, 12, 52731–52740. [Google Scholar] [CrossRef] [PubMed]

- Miedziak, P.; Sankar, M.; Dimitratos, N.; Lopez-Sanchez, J.A.; Carley, A.F.; Knight, D.W.; Brian, T.; Christopher, J.K.; Hutchings, G.J. Oxidation of benzyl alcohol using supported gold–palladium nanoparticles. Catal. Today 2011, 164, 315–319. [Google Scholar] [CrossRef]

- Higashimoto, S.; Kitao, N.; Yoshida, N.; Sakura, T.; Azuma, M.; Ohue, H.; Sakata, Y. Selective photocatalytic oxidation of benzyl alcohol and its derivatives into corresponding aldehydes by molecular oxygen on titanium dioxide under visible light irradiation. J. Catal. 2009, 266, 279–285. [Google Scholar] [CrossRef]

- Du, M.; Zeng, G.; Huang, J.; Sun, D.; Li, Q.; Wang, G.; Li, X. Green photocatalytic oxidation of benzyl alcohol over noble-metal-modified H2Ti3O7 nanowires. ACS Sustain. Chem. Eng. 2019, 7, 9717–9726. [Google Scholar] [CrossRef]

- Hong, Y.; Jing, X.; Huang, J.; Sun, D.; Odoom-Wubah, T.; Yang, F.; Li, Q. Biosynthesized bimetallic Au–Pd nanoparticles supported TiO2 for solvent-free oxidation of benzyl alcohol. ACS Sustain. Chem. Eng. 2014, 2, 1752–1759. [Google Scholar] [CrossRef]

- Veisi, H.; Hemmati, S.; Qomi, M. Aerobic oxidation of benzyl alcohols through biosynthesized palladium nanoparticles mediated by Oak fruit bark extract as an efficient heterogeneous nanocatalyst. Tetrahedron Lett. 2017, 58, 4191–4496. [Google Scholar] [CrossRef]

| Entry | Solvent | Yield * % |

|---|---|---|

| 1 | Acetonitrile | 74 |

| 2 | Isopropanol | 67 |

| 3 | Aceton | 7 |

| 4 | Water | 2 |

| Entry | Cu-Zn-Fe (mg) | H2O2 (µL) | Yield * % |

|---|---|---|---|

| 1 | 0 | 350 | 1 |

| 2 | 7 | 350 | 95 |

| 3 | 10 | 350 | 99 |

| 4 | 15 | 350 | 99 |

| 5 | 20 | 350 | 89 |

| 6 | 10 | 0 | 9 |

| 7 | 10 | 250 | 54 |

| 8 | 10 | 350 | 99 |

| 9 | 10 | 500 | 99 |

| Entry | Light Power (W) | Yield * % |

|---|---|---|

| 1 | 7 | 30.0 |

| 2 | 30 | 93.0 |

| 3 | 60 | 99 |

| 4 | 120 | 99 |

| Entry | Substrate | Alcohol | Aldehyde | Yield * % |

|---|---|---|---|---|

| 1 | 1-Octanol |  |  | 29.2 |

| 2 | 2-Octanol |  |  | 34.5 |

| 3 | Furfuryl alcohol |  |  | 99 |

| 4 | Cinnamyl alcohol |  |  | 61.4 |

| 5 | 3,4-dimethyl benzyl alcohol |  |  | 99 |

| 6 | Benzyl alcohol |  |  | 99 |

| Source | Metallic NPs | Reaction Conditions | Conversion % | Selectivity % | Ref. |

|---|---|---|---|---|---|

| Synthatic | Au-Pd/O-CNTs | 2 h, 120 °C, Solvent free | 28.3 | 96 | [42] |

| Synthatic | Au@Ag/BiOCl–OV | 1 h, Xenon 300 W, CH3CN | 92 | 99 | [43] |

| Synthatic | Trimetallic PtPbBi | Electrical | - | - | [44] |

| Synthatic | 2.5% Au + 2.5% Pd/TiO2DP2 | 140 °C, 10 bar O2 | 84 | 40 | [45] |

| Synthatic | Pd/H2Ti3O7 Nanowires | Halogen 150 W, 90 °C | 49.5 | 76 | [46] |

| Synthatic | TiO2 | LED 450 W, 36 h, O2 | 99 | 99 | [47] |

| Nature (Cacumen Platycladi) | Au−Pd/TiO2 | 6 h, 90 °C, O2 | 74.2 | 98 | [48] |

| Nature (Oak fruit bark) | Pd NPs | 12 h, 80 °C, K2CO3 | 95 | - | [49] |

| This work (Tilia) | Trimetallic Cu-Zn-Fe | 2 h, LED 60 W, H2O2 | 99 | 99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghazzy, A.; Yousef, L.; Al-Hunaiti, A. Visible Light Induced Nano-Photocatalysis Trimetallic Cu0.5Zn0.5-Fe: Synthesis, Characterization and Application as Alcohols Oxidation Catalyst. Catalysts 2022, 12, 611. https://doi.org/10.3390/catal12060611

Ghazzy A, Yousef L, Al-Hunaiti A. Visible Light Induced Nano-Photocatalysis Trimetallic Cu0.5Zn0.5-Fe: Synthesis, Characterization and Application as Alcohols Oxidation Catalyst. Catalysts. 2022; 12(6):611. https://doi.org/10.3390/catal12060611

Chicago/Turabian StyleGhazzy, Asma, Lina Yousef, and Afnan Al-Hunaiti. 2022. "Visible Light Induced Nano-Photocatalysis Trimetallic Cu0.5Zn0.5-Fe: Synthesis, Characterization and Application as Alcohols Oxidation Catalyst" Catalysts 12, no. 6: 611. https://doi.org/10.3390/catal12060611