Single-Atom Catalysts: Preparation and Applications in Environmental Catalysis

Abstract

:1. Introduction

2. Synthesis of SACs

2.1. The Atomic Layer Deposition (ALD) Method

2.2. The Wet-Chemistry Method

2.2.1. The Impregnation Method

2.2.2. The Co-Precipitation Method

2.2.3. The Deposition–Precipitation (DP) Method

2.3. The Pyrolysis Approach

2.4. The Electrochemical/Photochemical Method

2.5. Other Synthesis Methods

3. Catalytic Applications of SACs

3.1. CO Oxidation

3.2. Methane Combustion

3.3. Volatile Organic Compounds (VOCs) Oxidation

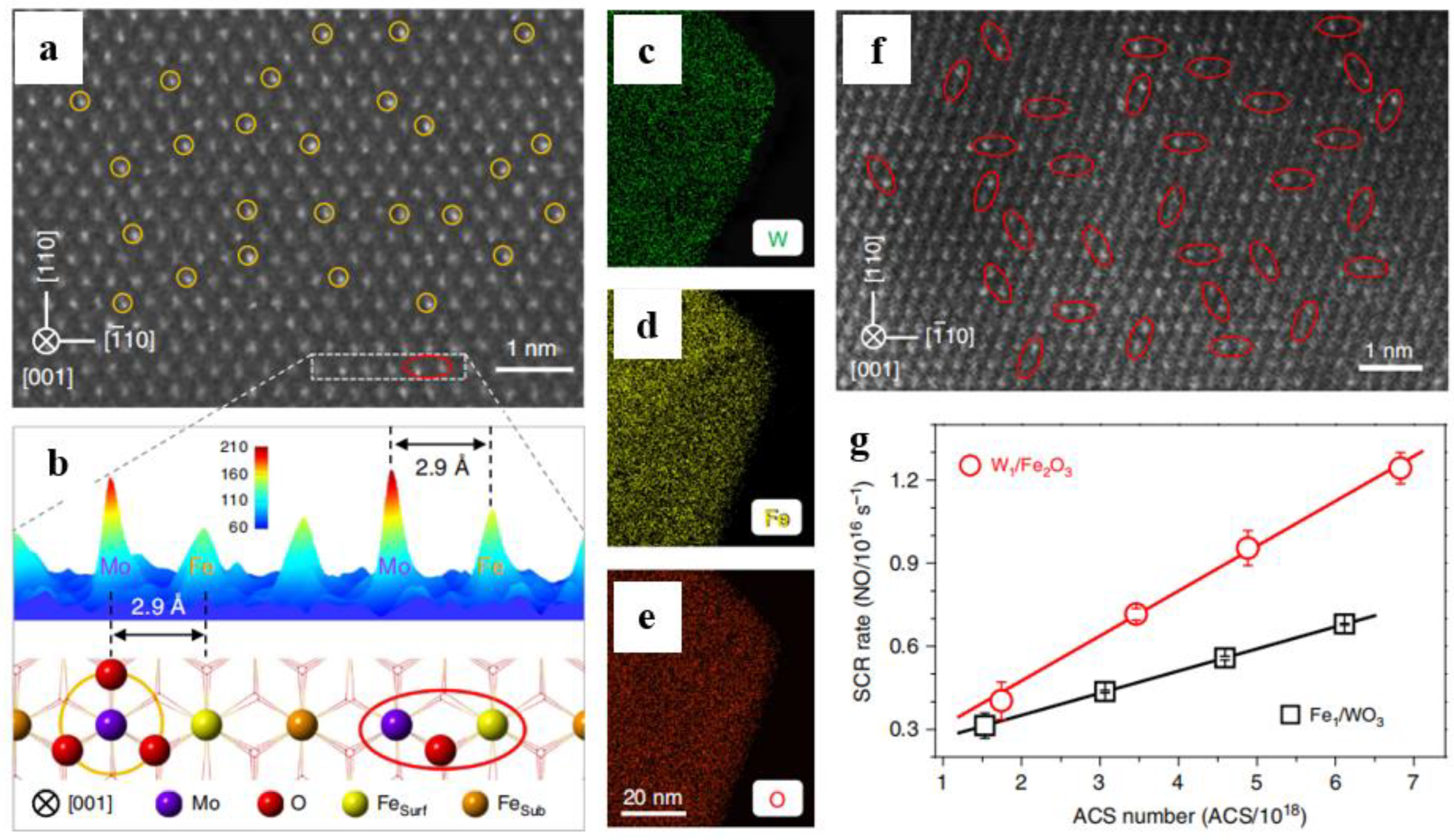

3.4. NOx Reduction

4. Conclusive Remarks and Perspectives

- (i)

- Efficiency: SACs have achieved the maximum atomic utilization efficiency and have made great progress in CO oxidation, methane oxidation, VOCs oxidation, and NOx reduction. In general, SACs are usually more active than their NPs catalysts, mainly due to the reducibility of the support (i.e., the number of oxygen vacancies, which is critical for anchoring single atoms) and the presence of OH groups on the support surface.

- (ii)

- Economy: The high atomic utilization reduces the amount of precious metal used in the catalyst and effectively reduces the cost.

- (iii)

- Uniqueness: The single active sites of SACs are helpful for further studying the active sites and catalytic mechanisms of various reactions.

- (i)

- At present, there are many strategies to synthesize SACs, such as the ALD, wet chemical, and pyrolysis methods. However, the loading of monatomic metals is limited, so it is necessary to explore a common strategy to achieve the scale-up production of SACs with high metal loadings, a satisfactory catalyst output, and good activity.

- (ii)

- The agglomeration of single atoms is still a common phenomenon, and the influence of inorganic molecules in the reaction atmosphere under actual industrial conditions should also be considered, such as the presence of H2O, CO2, SO2, and HCl. Selecting a suitable metal to dope into a support or form an alloy structure can effectively modify the electronic structure of SACs and enhance the single atoms–support interaction, which is a good pathway to maintain the stability of SACs.

- (iii)

- SACs are currently limited to traditional pollutants (e.g., VOCs) in the atmosphere and need to be further expanded to other fields, such as the synthesis of high-value chemicals, the dehydrogenation of VOCs, the resource utilization of CO2, the purification of water, and so on.

- (iv)

- Optimizing the catalyst structures to improve catalytic performance: Since the atomic structure has a direct effect on reactivity, it is highly desirable to use in situ characterization techniques to study the catalyst structures so as to design the catalysts rationally. The catalyst support with a high surface area has a complex nanostructure and abundant surface active sites, which is beneficial for improving the catalytic performance.

- (v)

- In addition to the development of in situ STM, STEM, and XAFS as well as the DFT theoretical calculations, more techniques need to be developed to recognize single atoms and further identify controversial active sites and mechanisms. The understanding of catalyst structures has a guiding role for the design of highly efficient catalysts. In addition, the current DFT calculations can only provide theoretical models of simple pollutant molecules, and more computational methods need to be explored to evaluate the reaction mechanisms of complex molecules.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, C.Z.; Du, D.; Eychmuller, A.; Lin, Y.H. Engineering ordered and nonordered porous noble metal nanostructures: Synthesis, assembly, and their applications in electrochemistry. Chem. Rev. 2015, 115, 8896–8943. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.Q.; Iocozzia, J.; Wang, Y.; Cui, X.; Chen, Y.H.; Zhao, S.Q.; Li, Z.; Lin, Z.Q. Noble metal−metal oxide nanohybrids with tailored nanostructures for efficient solar energy conversion, photocatalysis and environmental remediation. Energy Environ. Sci. 2017, 10, 402–434. [Google Scholar] [CrossRef]

- Cai, P.W.; Li, Y.; Wang, G.X.; Wen, Z.H. Alkaline-acid Zn-H2O fuel cell for the simultaneous generation of hydrogen and electricity. Angew. Chem. Int. Ed. 2018, 57, 3910–3915. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.Y.; Liu, H.T.; Liu, Y.; He, P.; Li, J.H. A room-temperature ionic liquid-templated proton-conducting gelatinous electrolyte. J. Phys. Chem. B 2004, 108, 17512–17518. [Google Scholar] [CrossRef]

- Furstner, A. Gold and platinum catalysis—A convenient tool for generating molecular complexity. Chem. Soc. Rev. 2009, 38, 3208–3221. [Google Scholar] [CrossRef]

- Zheng, N.F.; Zhang, T. Preface: Single-atom catalysts as a new generation of heterogeneous catalysts. Nat. Sci. Rev. 2018, 5, 625. [Google Scholar] [CrossRef]

- Zhang, S.R.; Nguyen, L.; Liang, J.X.; Shan, J.J.; Liu, J.Y.; Frenkel, A.I.; Patlolla, A.; Huang, W.X.; Li, J.; Tao, F. Catalysis on singly dispersed bimetallic sites. Nat. Commun. 2015, 6, 7938. [Google Scholar] [CrossRef] [Green Version]

- Youngs, T.G.A.; Manyar, H.; Bowron, D.T.; Gladden, L.F.; Hardacre, C. Probing chemistry and kinetics of reactions in heterogeneous catalysts. Chem. Sci. 2013, 4, 3484. [Google Scholar] [CrossRef] [Green Version]

- Bell, A.T. The impact of nanoscience on heterogeneous. Catal. Sci. 2003, 299, 1688. [Google Scholar]

- Hunt, S.T.; Román-Leshkov, Y. Principles and methods for the rational design of core–shell nanoparticle catalysts with ultralow noble metal loadings. Acc. Chem. Res. 2018, 51, 1054. [Google Scholar] [CrossRef]

- Qiao, B.T.; Wang, A.Q.; Yang, X.F.; Allard, L.F.; Jiang, Z.; Cui, Y.T.; Liu, J.Y.; Li, J.; Zhang, T. Single-atom catalysis of CO oxidation using Pt1/FeOx. Nat. Chem. 2011, 3, 634. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.Y. Catalysis by supported single metal atoms. ACS Catal. 2017, 7, 34–59. [Google Scholar] [CrossRef]

- Ji, S.F.; Chen, Y.J.; Wang, X.L.; Zhang, Z.D.; Wang, D.S.; Li, Y.D. Chemical synthesis of single atomic site catalysts. Chem. Rev. 2020, 120, 11900–11955. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Chen, W.X.; Zhang, L.; Yao, T.; Liu, W.; Lin, Y.; Ju, H.X.; Dong, J.C.; Zheng, L.R.; Yan, W.S.; et al. Uncoordinated amine groups of metal−organic frameworks to anchor single Ru sites as chemoselective catalysts toward the hydrogenation of quinoline. J. Am. Chem. Soc. 2017, 139, 9419–9422. [Google Scholar] [CrossRef] [PubMed]

- Li, P.S.; Wang, M.Y.; Duan, X.X.; Zheng, L.R.; Cheng, X.P.; Zhang, Y.F.; Kuang, Y.; Li, Y.P.; Ma, Q.; Feng, Z.X.; et al. Boosting oxygen evolution of single-atomic ruthenium through electronic coupling with cobalt iron layered double hydroxides. Nat. Commun. 2019, 10, 1711. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, J.L.; Uhlman, M.B.; Montemore, M.M.; Trimpalis, A.; Giannakakis, G.; Shan, J.J.; Cao, S.F.; Hannagan, R.T.; Sykes, E.C.H. Integrated catalysis-surface science-theory approach to understand selectivity in the hydrogenation of 1-hexyne to 1-hexene on PdAu single-atom alloy catalysts. ACS Catal. 2019, 9, 8757–8765. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, H.S.; Liu, S.H.; Banis, M.N.; Song, Z.X.; Li, J.J.; Yang, L.J.; Markiewicz, M.; Zhao, Y.; Li, R.Y.; et al. Pt/Pd single-atom alloys as highly active electrochemical catalysts and the origin of enhanced activity. ACS Catal. 2019, 9, 9350–9358. [Google Scholar] [CrossRef]

- He, Q.; Liu, D.B.; Lee, J.H.; Liu, Y.M.; Xie, Z.H.; Hwang, S.; Kattel, S.; Song, L.; Chen, J.C. Electrochemical conversion of CO2 to syngas with controllable CO/H2 ratios over Co and Ni single-atom catalysts. Angew. Chem. Int. Ed. 2020, 59, 3033–3037. [Google Scholar] [CrossRef]

- Kucheyev, S.O.; Biener, J.; Wang, Y.M.; Baumann, T.F.; Wu, K.J.; Buuren, T.V.; Hamza, A.V.; Satcher, J.H., Jr.; Elam, J.W.; Pellin, M.J. Atomic layer deposition of ZnO on ultralow-density nanoporous silica aerogel monoliths. Appl. Phys. Lett. 2005, 86, 083108. [Google Scholar] [CrossRef] [Green Version]

- Baumann, T.F.; Biener, J.; Wang, Y.M.M.; Kucheyev, S.O.; Nelson, E.J.; Satcher, J.H., Jr.; Elam, J.W.; Pellin, M.J.; Hamza, A.V. Atomic layer deposition of uniform metal coatings on highly porous aerogel substrates. Chem. Mater. 2006, 18, 6106–6108. [Google Scholar] [CrossRef]

- Biener, J.; Baumann, T.F.; Wang, Y.M.; Nelson, E.J.; Kucheyev, S.O.; Hamza, A.V.; Kemell, M.; Ritala, M.; Leskelä, M. Ruthenium/aerogel nanocomposites via atomic layer deposition. Nanotechnology. 2007, 18, 055303. [Google Scholar] [CrossRef]

- Kucheyev, S.O.; Biener, J.; Baumann, T.F.; Wang, Y.M.; Hamza, A.V.; Li, Z.; Lee, D.K.; Gordon, R.G. Mechanisms of atomic layer deposition on substrates with ultrahigh aspect ratios. Langmuir 2008, 24, 943–948. [Google Scholar] [CrossRef] [PubMed]

- King, J.S.; Wittstock, A.; Biener, J.; Kucheyev, S.O.; Wang, Y.M.; Baumann, T.F.; Giri, S.K.; Hamza, A.V.; Baeumer, M.; Bent, S.F. Ultralowloading Pt nanocatalysts prepared by atomic layer deposition on carbon aerogels. Nano Lett. 2008, 8, 2405–2409. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Wang, C.C.; Kei, C.C.; Hsueh, Y.C.; Perng, T.P. Atomic layer deposition of platinum nanoparticles on carbon nanotubes for application in proton-exchange membrane fuel cells. Small 2009, 5, 1535–1538. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Lee, H.B.R.; Johnson, R.W.; Tanskanen, J.T.; Liu, N.; Kim, M.G.; Pang, C.; Ahn, C.; Bent, S.F.; Bao, Z. Selective metal deposition at graphene line defects by atomic layer deposition. Nat. Commun. 2014, 5, 4781. [Google Scholar] [CrossRef] [Green Version]

- Yan, H.; Zhao, X.X.; Guo, N.; Lyu, Z.Y.; Du, Y.H.; Xi, S.B.; Guo, R.; Chen, C.; Chen, Z.X.; Liu, W.; et al. Atomic engineering of high-density isolated Co atoms on graphene with proximal-atom controlled reaction selectivity. Nat. Commun. 2018, 9, 3197. [Google Scholar] [CrossRef] [Green Version]

- Yan, H.; Lin, Y.; Wu, H.; Zhang, W.H.; Sun, Z.H.; Cheng, H.; Liu, W.; Wang, C.L.; Li, J.J.; Huang, X.H.; et al. Bottom-up precise synthesis of stable platinum dimers on graphene. Nat. Commun. 2017, 8, 1070. [Google Scholar] [CrossRef] [Green Version]

- Yan, H.; Cheng, H.; Yi, H.; Lin, Y.; Yao, T.; Wang, C.L.; Li, J.J.; Wei, S.Q.; Lu, J.J. Single-atom Pd1/graphene catalyst achieved by atomic layer deposition: Remarkable performance in selective hydrogenation of 1,3-butadiene. J. Am. Chem. Soc. 2015, 137, 10484–10487. [Google Scholar] [CrossRef]

- Sun, S.H.; Zhang, G.X.; Gauquelin, N.; Chen, N.; Zhou, J.G.; Yang, S.L.; Chen, W.F.; Meng, X.B.; Geng, D.S.; Banis, M.N.; et al. Single-stom catalysis using Pt/graphene achieved through atomic layer deposition. Sci. Rep. 2013, 3, 1775. [Google Scholar] [CrossRef] [Green Version]

- Cao, Y.J.; Chen, S.; Luo, Q.Q.; Yan, H.; Lin, Y.; Liu, W.; Cao, L.L.; Lu, J.L.; Yang, J.L.; Yao, T.; et al. Atomic-level insight into optimizing the hydrogen evolution pathway over a Co1-N4 single-site photocatalyst. Angew. Chem. Int. Ed. 2017, 56, 12191–12196. [Google Scholar] [CrossRef]

- Zhang, L.; Si, R.T.; Liu, H.S.; Chen, N.; Wang, Q.; Adair, K.; Wang, Z.Q.; Chen, J.T.; Song, Z.X.; Li, J.J.; et al. Atomic layer deposited Pt−Ru dual-metal dimers and identifying their active sites for hydrogen evolution reaction. Nat. Commun. 2019, 10, 4936. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.W.; Long, R.; Zhang, Y.M.; Duan, D.L.; Xiong, Y.J.; Zhang, Y.J.; Bi, Y.P. Direct observation of dynamic bond evolution in single atom Pt/C3N4 catalysts. Angew. Chem. Int. Ed. 2020, 59, 6224–6229. [Google Scholar] [CrossRef] [PubMed]

- Cheng, N.C.; Stambula, S.; Wang, D.; Banis, M.N.; Liu, J.; Riese, A.; Xiao, B.W.; Li, R.Y.; Sham, T.K.; Liu, L.M.; et al. Platinum single-atom and cluster catalysis of the hydrogen evolution reaction. Nat. Commun. 2016, 7, 13638. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.L.; Gu, X.K.; Yan, H.; Lin, Y.; Li, J.J.; Liu, D.D.; Li, W.X.; Lu, J.L. Water-mediated Mars−van Krevelen mechanism for CO oxidation on ceria-supported single-atom Pt1 catalyst. ACS Catal. 2017, 7, 887–891. [Google Scholar] [CrossRef]

- Cao, L.N.; Liu, W.; Luo, Q.Q.; Yin, R.T.; Wang, B.; Weissenrieder, J.; Soldemo, M.; Yan, H.; Lin, Y.; Sun, Z.H.; et al. Atomically dispersed iron hydroxide anchored on Pt for preferential oxidation of CO in H2. Nature 2019, 565, 631–635. [Google Scholar] [CrossRef] [PubMed]

- O’Neill, B.J.; Jackson, D.H.K.; Lee, J.; Canlas, C.; Stair, P.C.; Marshall, C.L.; Elam, J.M.; Kuech, T.F.; Dumesic, J.A.; Huber, G.W. Catalyst design with atomic layer deposition. ACS Catal. 2015, 5, 1804–1825. [Google Scholar] [CrossRef] [Green Version]

- Fonseca, J.; Lu, J.L. Single-atom catalysts designed and prepared by the atomic layer deposition technique. ACS Catal. 2021, 11, 7018–7059. [Google Scholar] [CrossRef]

- Liu, S.Z.; Wang, Y.J.; Wang, S.B.; You, M.M.; Hong, S.; Wu, T.S.; Soo, Y.L.; Zhao, Z.Q.; Jiang, G.Y.; Qiu, J.S.; et al. Photocatalytic fixation of nitrogen to ammonia by single Ru atom decorated TiO2 nanosheets. ACS Sustain. Chem. Eng. 2019, 7, 6813–6820. [Google Scholar] [CrossRef]

- Wan, J.W.; Chen, W.X.; Jia, C.Y.; Zheng, L.R.; Dong, J.C.; Zheng, X.S.; Wang, Y.; Yan, W.S.; Chen, C.; Peng, Q.; et al. Defect effects on TiO2 nanosheets: Stabilizing single atomic site Au and promoting catalytic properties. Adv. Mater. 2018, 30, 1705369. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, C.X.; Liu, H.X.; Sun, J.Q.; Xie, R.C.; Qiu, Y.; Lu, F.; Liu, Y.F.; Zhuo, L.C.; Liu, X.J.; et al. Amorphous MoOx-stabilized single platinum atoms with ultrahigh mass activity for acidic hydrogen evolution. Nano Energy 2020, 70, 104529. [Google Scholar] [CrossRef]

- Wang, H.; Xu, D.Y.; Guan, E.J.; Wang, L.; Zhang, J.; Wang, C.T.; Wang, S.; Xu, H.; Meng, X.J.; Yang, B.; et al. Atomically dispersed Ru on manganese oxide catalyst boosts oxidative cyanation. ACS Catal. 2020, 10, 6299–6308. [Google Scholar] [CrossRef]

- Chen, J.Y.; Wanyan, Y.J.; Zeng, J.X.; Fang, H.H.; Li, Z.J.; Dong, Y.D.; Qin, R.X.; Wu, C.Z.; Liu, D.Y.; Wang, M.Z.; et al. Surface engineering protocol to obtain an atomically dispersed Pt/CeO2 catalyst with high activity and stability for CO oxidation. ACS Sustain. Chem. Eng. 2018, 6, 14054–14062. [Google Scholar] [CrossRef]

- Guo, Y.; Mei, S.; Yuan, K.; Wang, D.J.; Liu, H.C.; Yan, C.H.; Zhang, Y.W. Low-temperature CO2 methanation over CeO2-supported Ru single atoms, nanoclusters, and nanoparticles competitively tuned by strong metal−support interactions and H-spillover effect. ACS Catal. 2018, 8, 6203–6215. [Google Scholar] [CrossRef]

- Feng, Y.; Dai, L.Y.; Wang, Z.W.; Peng, Y.; Duan, E.H.; Liu, Y.X.; Jing, L.; Wang, X.; Rastegarpanah, A.; Dai, H.X.; et al. Photothermal synergistic effect of Pt1/CuO-CeO2 single-atom catalysts significantly improving toluene removal. Environ. Sci. Technol. 2022, 56, 8722–8732. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Roh, C.W.; Sahoo, S.K.; Yang, S.; Bae, J.; Han, J.W.; Lee, H. Highly durable platinum single-atom alloy catalyst for electrochemical reactions. Adv. Energy Mater. 2018, 8, 1701476. [Google Scholar] [CrossRef]

- Hackett, S.F.J.; Brydson, R.M.; Gass, M.H.; Harvey, I.; Newman, A.D.; Wilson, K.; Lee, A.F. High-activity, single-site mesoporous Pd/Al2O3 catalysts for selective aerobic oxidation of allylic alcohols. Angew. Chem. Int. Ed. 2007, 46, 8593–8596. [Google Scholar] [CrossRef] [PubMed]

- Yang, K.; Liu, Y.X.; Deng, J.G.; Zhao, X.T.; Yang, J.; Han, Z.; Hou, Z.Q.; Dai, H.X. Three-dimensionally ordered mesoporous iron oxide-supported single-atom platinum: Highly active catalysts for benzene combustion. Appl. Catal. B 2019, 244, 650–659. [Google Scholar] [CrossRef]

- Kwak, J.H.; Kovarik, L.; Szanyi, J. CO2 reduction on supported Ru/Al2O3 catalysts: Cluster size dependence of product selectivity. ACS Catal. 2013, 3, 2449–2455. [Google Scholar] [CrossRef]

- Yu, W.Z.; Wang, W.W.; Li, S.Q.; Fu, X.P.; Wang, X.; Wu, K.; Si, R.; Ma, C.; Jia, C.J.; Yan, C.H. Construction of active site in a sintered copper-ceria nanorod catalyst. J. Am. Chem. Soc. 2019, 141, 17548–17557. [Google Scholar] [CrossRef]

- Zhang, D.; Luo, J.J.; Wang, J.J.; Xiao, X.; Liu, Y.F.; Qi, W.; Su, D.S.; Chu, W. Ru/FeOx catalyst performance design: Highly dispersed Ru species for selective carbon dioxide hydrogenation. Chin. J. Catal. 2018, 39, 157–166. [Google Scholar] [CrossRef]

- Millet, M.M.; Algara-Siller, G.; Wrabetz, S.; Mazheika, A.; Girgsdies, F.; Teschner, D.; Seitz, F.; Tarasov, A.; Leychenko, S.V.; Schloegl, R.; et al. Ni single atom catalysts for CO2 activation. J. Am. Chem. Soc. 2019, 141, 2451–2461. [Google Scholar] [CrossRef] [PubMed]

- Lin, J.; Wang, A.Q.; Qiao, B.T.; Liu, X.Y.; Yang, X.F.; Wang, X.D.; Liang, J.X.; Li, J.; Liu, J.Y.; Zhang, T. Remarkable performance of Ir1/FeOx single atom catalyst in water gas shift reaction. J. Am. Chem. Soc. 2013, 135, 15314–15317. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.S.; Liu, X.Y.; Wang, A.Q.; Zhang, L.L.; Qiao, B.T.; Yang, Y.F.; Huang, Y.Q.; Miao, S.; Liu, J.Y.; Zhang, T. FeOx-supported platinum single-atom and pseudo-single-atom catalysts for chemoselective hydrogenation of functionalized nitroarenes. Nat. Commun. 2014, 5, 5634. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, Z.Y.; Feng, X.B.; Deng, J.L.; He, C.; Douthwaite, M.; Yu, Y.K.; Liu, J.; Hao, Z.P.; Zhao, Z. Atomic-scale insights into the low-temperature oxidation of methanol over a single-atom Pt1-Co3O4 catalyst. Adv. Funct. Mater. 2019, 29, 1902041. [Google Scholar] [CrossRef]

- Lang, R.; Xi, W.; Liu, J.C.; Cui, Y.T.; Li, T.B.; Lee, A.F.; Chen, F.; Chen, Y.; Li, L.; Li, L.; et al. Non defect-stabilized thermally stable single-atom catalyst. Nat. Commun. 2019, 10, 234. [Google Scholar] [CrossRef] [Green Version]

- Qiao, B.T.; Liu, J.X.; Wang, Y.G.; Lin, Q.Q.; Liu, X.Y.; Wang, A.Q.; Li, J.; Zhang, T.; Liu, J.Y. Highly efficient catalysis of preferential oxidation of CO in H2-rich stream by gold single-atom catalysts. ACS Catal. 2015, 5, 6249–6254. [Google Scholar] [CrossRef]

- Wang, H.; Shen, J.H.; Huang, J.F.; Xu, T.J.; Zhu, J.R.; Zhu, Y.H.; Li, C.Z. Atomically dispersed Au catalysts supported on CeO2 foam: Controllable synthesis and CO oxidation reaction mechanism. Nanoscale 2017, 9, 16817–16825. [Google Scholar] [CrossRef]

- Guo, X.G.; Fang, G.Z.; Li, G.; Ma, H.; Fan, H.J.; Yu, L.; Ma, C.; Wu, X.; Deng, D.H.; Wei, M.M.; et al. Direct, nonoxidative conversion of methane to ethylene, aromatics, and hydrogen. Science 2014, 344, 616–619. [Google Scholar] [CrossRef]

- Qiao, B.T.; Lin, J.; Wang, A.Q.; Chen, Y.; Zhang, T.; Liu, J.Y. Highly active Au1/Co3O4 single-atom catalyst for CO oxidation at room temperature. Chin. J. Catal. 2015, 36, 1505–1511. [Google Scholar] [CrossRef]

- Gu, X.K.; Qiao, B.T.; Huang, C.Q.; Ding, W.C.; Sun, K.J.; Zhan, E.S.; Zhang, T.; Liu, J.Y.; Li, W.X. Supported single Pt1/Au1 atoms for methanol steam reforming. ACS Catal. 2014, 4, 3886–3890. [Google Scholar] [CrossRef]

- He, T.; Chen, S.M.; Ni, B.; Gong, Y.; Wu, Z.; Song, L.; Gu, L.; Hu, W.P.; Wang, X. Zirconium–porphyrin-based metal–organic framework hollow nanotubes for immobilization of noble-metal single atoms. Angew. Chem. Int. Ed. 2018, 57, 3493. [Google Scholar] [CrossRef] [PubMed]

- Vile, G.; Albani, D.; Nachtegaal, M.; Chen, Z.P.; Dontsova, D.; Antonietti, M.; Lopez, N.; Perez-Ramírez, J. A stable single-site palladium catalyst for hydrogenations. Angew. Chem. Int. Ed. 2015, 54, 11265–11269. [Google Scholar] [CrossRef] [PubMed]

- Fei, H.L.; Dong, J.C.; Arellano-Jimenez, M.J.; Ye, G.L.; Kim, N.D.; Samuel, E.L.; Peng, Z.W.; Zhu, Z.; Qin, F.; Bao, J.M.; et al. Atomic cobalt on nitrogen-doped graphene for hydrogen generation. Nat. Commun. 2015, 6, 8668. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xi, J.B.; Sung, H.Y.; Wang, D.; Zhang, Z.Y.; Duan, X.M.; Xiao, J.W.; Xiao, F.; Liu, L.M.; Wang, S. Confined-interface-directed synthesis of palladium single-atom catalysts on graphene/amorphous carbon. Appl. Catal. B 2018, 225, 291. [Google Scholar] [CrossRef] [Green Version]

- Yang, M.; Allard, L.F.; Flytzani-Stephanopoulos, M. Atomically dispersed Au−(OH)x species bound on titania catalyze the low temperature water-gas shift reaction. J. Am. Chem. Soc. 2013, 135, 3768–3771. [Google Scholar] [CrossRef]

- Ge, X.X.; Zhou, P.; Zhang, Q.H.; Xia, Z.H.; Chen, S.L.; Gao, P.; Zhang, Z.; Gu, L.; Guo, S.J. Palladium single atoms on TiO2 as a photocatalytic sensing platform for analyzing organophosphorus pesticide chlorpyrifos. Angew. Chem. Int. Ed. 2019, 131, 232–236. [Google Scholar]

- Liu, P.X.; Zhao, Y.; Qin, R.X.; Mo, S.G.; Chen, G.X.; Gu, L.; Chevrier, D.M.; Zhang, P.; Guo, Q.; Zang, D.D.; et al. Photochemical route for synthesizing atomically dispersed palladium catalysts. Science 2016, 352, 797–800. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.H.; Heo, J.S.; Kim, T.H.; Park, S.; Yoon, M.H.; Kim, J.; Oh, M.S.; Yi, G.R.; Noh, Y.Y.; Park, S.K. Flexible metal-oxide devices made by room-temperature photochemical activation of sol-gel films. Nature 2012, 489, 128–132. [Google Scholar] [CrossRef]

- Zhang, Z.R.; Feng, C.; Liu, C.X.; Zuo, M.; Qin, L.; Yan, X.P.; Xing, Y.L.; Li, H.L.; Si, R.; Zhou, S.M.; et al. Electrochemical deposition as a universal route for fabricating single-atom catalysts. Nat. Commun. 2020, 11, 1215. [Google Scholar] [CrossRef] [Green Version]

- Fan, L.; Liu, P.F.; Yan, X.C.; Gu, L.; Yang, Z.Z.; Yang, H.G.; Qiu, S.L.; Yao, X.D. Atomically isolated nickel species anchored on graphitized carbon for efficient hydrogen evolution electrocatalysis. Nat. Commun. 2016, 7, 10667. [Google Scholar] [CrossRef] [Green Version]

- Liu, P.X.; Zhao, Y.; Qin, R.X.; Gu, L.; Zhang, P.; Fu, G.; Zheng, N.F. A vicinal effect for promoting catalysis of Pd1/TiO2: Supports of atomically dispersed catalysts play more roles than simply serving as ligands. Sci. Bull. 2018, 63, 675–682. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.T.; Gao, W.B.; Wang, Q.Q.; Dou, M.; Zhang, Z.P.; Wang, F. Selective loading of atomic Pt on a RuCeOx support enables stable hydrogen evolution at high current densities. Angew. Chem. Int. Ed. 2020, 59, 20423–20427. [Google Scholar] [CrossRef] [PubMed]

- Wei, H.H.; Huang, K.; Wang, D.; Zhang, R.Y.; Ge, B.H.; Ma, J.Y.; Wen, B.; Zhang, S.; Li, Q.Y.; Lei, M.; et al. Iced photochemical reduction to synthesize atomically dispersed metals by suppressing nanocrystal growth. Nat. Commun. 2017, 8, 1490. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Heiz, U.; Sanchez, A.; Abbet, S.; Schneider, W.D. Catalytic oxidation of carbon monoxide on monodispersed platinum clusters: Each atom counts. J. Am. Chem. Soc. 1999, 121, 3214–3217. [Google Scholar] [CrossRef]

- Vajda, S.; White, M.G. Catalysis applications of size-selected cluster deposition. ACS Catal. 2015, 5, 7152–7176. [Google Scholar] [CrossRef]

- Li, X.N.; Yuan, Z.; He, S.G. CO oxidation promoted by gold atoms supported on titanium oxide cluster anions. J. Am. Chem. Soc. 2014, 136, 3617–3623. [Google Scholar] [CrossRef]

- Bilecka, I.; Niederberger, M. Microwave chemistry for inorganic nanomaterials synthesis. Nanoscale 2010, 2, 1358–1374. [Google Scholar] [CrossRef]

- Fei, H.L.; Dong, J.C.; Wan, C.Z.; Zhao, Z.P.; Xu, X.; Lin, Z.Y.; Wang, Y.L.; Liu, H.T.; Zang, K.T.; Luo, J.; et al. Microwave-assisted rapid synthesis of graphene-supported single atomic metals. Adv. Mater. 2018, 30, 1802146. [Google Scholar] [CrossRef]

- Yao, Y.G.; Huang, Z.N.; Xie, P.F.; Wu, L.P.; Ma, L.; Li, T.Y.; Pang, Z.Q.; Jiao, M.L.; Liang, Z.Q.; Gao, J.L.; et al. High temperature shockwave stabilized single atoms. Nat. Nanotechnol. 2019, 14, 851–857. [Google Scholar] [CrossRef]

- Cui, X.J.; Xiao, J.P.; Wu, Y.H.; Du, P.P.; Si, R.; Yang, H.X.; Tian, H.F.; Li, J.Q.; Zhang, W.H.; Deng, D.H.; et al. A graphene composite material with single cobalt active sites: A highly efficient counter electrode for dye-sensitized solar cells. Angew. Chem. Int. Ed. 2016, 55, 6708–6712. [Google Scholar] [CrossRef]

- Deng, D.H.; Chen, X.Q.; Yu, L.; Wu, X.; Liu, Q.F.; Liu, Y.; Yang, H.X.; Tian, H.F.; Hu, Y.F.; Du, P.P.; et al. A single iron site confined in a graphene matrix for the catalytic oxidation of benzene at room temperature. Sci. Adv. 2015, 1, e1500462. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, Y.X.; Li, Z.Y.; Yuan, Z.; Li, X.N.; He, S.G. Thermal methane conversion to formaldehyde promoted by single platinum atoms in PtAl2O4– cluster anions. Angew. Chem. Int. Ed. 2014, 53, 9482–9486. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.Y.; Jing, M.Z.; Feng, X.B.; Xiong, J.C.; He, C.; Douthwaitee, M.; Zheng, L.R.; Song, W.Y.; Liu, J.; Qu, Z.G. Stabilizing platinum atoms on CeO2 oxygen vacancies by metal-support interaction induced interface distortion: Mechanism and application. Appl. Catal. B 2020, 278, 119304. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Sui, S.H.; Zheng, X.M.; Cao, R.R.; Zhang, P.Y. One-pot synthesis of atomically dispersed Pt on MnO2 for efficient catalytic decomposition of toluene at low temperatures. Appl. Catal. B 2019, 257, 117878. [Google Scholar] [CrossRef]

- Huang, Z.W.; Gu, X.; Cao, Q.Q.; Hu, P.P.; Hao, J.M.; Li, J.H.; Tang, X.F. Catalytically active single-atom sites fabricated from silver particles. Angew. Chem. Int. Ed. 2012, 51, 4198–4203. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.B.; Liu, F.D.; Zhai, Y.P.; Ariga, H.; Yi, N.; Liu, Y.C.; Asakura, K.; Flytzani-Stephanopoulos, M.; He, H. Alkali-metal-promoted Pt/TiO2 opens a more efficient pathway to formaldehyde oxidation at ambient temperatures. Angew. Chem. Int. Ed. 2012, 51, 9628–9632. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, M.Z.; Xu, W.J.; Chen, J.; Hong, Z.X.; Jia, H.P. Incorporating Mn cation as anchor to atomically disperse Pt on TiO2 for low temperature removal of formaldehyde. Appl. Catal. B 2019, 259, 118013. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Zhu, Y.H.; Asakura, H.; Zhang, B.; Zhang, J.G.; Zhou, M.X.; Han, Y.; Tanaka, T.; Wang, A.Q.; Zhang, T.; et al. Thermally stable single atom Pt/m-Al2O3 for selective hydrogenation and CO oxidation. Nat. Commun. 2017, 8, 16100. [Google Scholar] [CrossRef] [Green Version]

- Lou, Y.; Cai, Y.F.; Hu, W.D.; Wang, L.; Dai, Q.G.; Zhan, W.C.; Guo, Y.L.; Hu, P.; Cao, X.M.; Liu, J.Y.; et al. Identification of active area as active center for CO oxidation over single Au atom catalyst. ACS Catal. 2020, 10, 6094–6101. [Google Scholar] [CrossRef]

- Kropp, T.; Mavrikakis, M. Transition metal atoms embedded in graphene: How nitrogen doping increases CO oxidation sctivity. ACS Catal. 2019, 9, 6864–6868. [Google Scholar] [CrossRef]

- Xiong, H.F.; Kunwar, D.; Jiang, D.; García-Vargas, C.E.; Li, H.Y.; Du, C.C.; Canning, G.; Pereira-Hernandez, X.I.; Wan, Q.; Lin, S.; et al. Engineering catalyst supports to stabilize PdOx two-dimensional rafts for water-tolerant methane oxidation. Nat. Catal. 2021, 4, 830–839. [Google Scholar] [CrossRef]

- Hou, Z.Q.; Dai, L.Y.; Deng, J.G.; Zhao, G.F.; Jing, L.; Wang, Y.S.; Yu, X.H.; Gao, R.Y.; Tian, X.R.; Dai, H.X.; et al. Electronically engineering water resistance in methane combustion with an atomically dispersed tungsten on PdO catalyst. Angew. Chem. Int. Ed. 2022, 61, e202201655. [Google Scholar] [CrossRef] [PubMed]

- Luo, L.H.; Luo, J.; Li, H.L.; Ren, F.N.; Zhang, Y.F.; Liu, A.D.; Li, W.X.; Zeng, J. Water enables mild oxidation of methane to methanol on gold single-atom catalysts. Nat. Commun. 2021, 12, 1218. [Google Scholar] [CrossRef] [PubMed]

- Fujiwara, K.; Pratsini, S.E. Single Pd atoms on TiO2 dominate photocatalytic NOx removal. Appl. Catal. B 2018, 226, 127–134. [Google Scholar] [CrossRef]

- Xie, S.H.; Tan, W.; Li, Y.J.; Ma, L.; Ehrlich, S.N.; Deng, J.G.; Xu, P.; Gao, F.; Dong, L.; Liu, F.D. Copper single atom-triggered niobia−ceria catalyst for efficient low-temperature reduction of nitrogen oxides. ACS Catal. 2022, 12, 2441–2453. [Google Scholar] [CrossRef]

- Qu, W.Y.; Liu, X.N.; Chen, J.X.; Dong, Y.Y.; Tang, X.F.; Chen, Y.X. Single-atom catalysts reveal the dinuclear characteristic of active sites in NO selective reduction with NH3. Nat. Commun. 2020, 11, 1532. [Google Scholar] [CrossRef] [Green Version]

- Luo, L.L.; Chen, S.Y.; Xu, Q.; He, Y.; Dong, Z.J.; Zhang, L.F.; Zhu, J.F.; Du, Y.G.; Yang, B.; Wang, C.M. Dynamic atom clusters on AuCu nanoparticle surface during CO oxidation. J. Am. Chem. Soc. 2020, 142, 4022–4027. [Google Scholar] [CrossRef]

- Yoo, M.; Yu, Y.S.; Ha, H.; Lee, S.; Choi, J.S.; Oh, S.; Kang, E.; Choi, H.; An, H.; Lee, K.S.; et al. A tailored oxide interface creates dense Pt single-atom catalysts with high catalytic activity. Energy Environ. Sci. 2020, 13, 1231–1239. [Google Scholar] [CrossRef]

- Ding, K.L.; Gulec, A.; Johnson, A.M.; Schweitzer, N.M.; Stucky, G.D.; Marks, L.D.; Stair, P.C. Identification of active sites in CO oxidation and water-gas shift over supported Pt catalysts. Science 2015, 350, 189. [Google Scholar] [CrossRef] [Green Version]

- Pereira-Hernández, X.I.; DeLaRiva, A.; Muravev, V.; Kunwar, D.; Xiong, H.F.; Sudduth, B.; Engelhard, M.; Kovarik, L.; Hensen, E.J.M.; Wang, Y.; et al. Tuning Pt-CeO2 interactions by high-temperature vapor-phase synthesis for improved reducibility of lattice oxygen. Nat. Commun. 2019, 10, 1358. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Liu, J.X.; Allard, L.F.; Lee, S.; Liu, J.L.; Li, H.; Wang, J.Q.; Wang, J.; Oh, S.H.; Li, W.; et al. Surpassing the single-atom catalytic activity limit through paired Pt−O−Pt ensemble built from isolated Pt1 atoms. Nat. Commun. 2019, 10, 3808. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maurer, F.; Jelic, J.; Wang, J.; Gänzler, A.; Dolcet, P.; Wöll, C.; Wang, Y.; Studt, F.; Casapu, M.; Grunwaldt, J.D. Tracking the formation, fate and consequence for catalytic activity of Pt single sites on CeO2. Nat. Catal. 2020, 3, 824–833. [Google Scholar] [CrossRef]

- Guo, L.W.; Du, P.P.; Fu, X.P.; Ma, C.; Zeng, J.; Si, R.; Huang, Y.Y.; Jia, C.J.; Zhang, Y.W.; Yan, C.H. Contributions of distinct gold species to catalytic reactivity for carbon monoxide oxidation. Nat. Commun. 2016, 7, 13481. [Google Scholar] [CrossRef] [PubMed]

- Tang, X.; Wang, L.; Yang, B.; Fei, C.; Yao, T.Y.; Liu, W.; Lou, Y.; Dai, Q.G.; Cai, Y.F.; Cao, X.M.; et al. Direct oxidation of methane to oxygenates on supported single Cu atom catalyst. Appl. Catal. B 2021, 285, 119827. [Google Scholar] [CrossRef]

- Lin, J.; Qiao, B.T.; Li, N.; Li, L.; Sun, X.C.; Liu, J.Y.; Wang, X.D.; Zhang, T. Little do more: A highly effective Pt1/FeOx single-atom catalyst for the reduction of NO by H2, Chem. Commun. 2015, 51, 7911–7914. [Google Scholar] [CrossRef]

- Chen, J.X.; Fang, X.; Ren, Z.H.; Qu, W.Y.; Hu, X.L.; Ma, Z.; Chen, L.W.; Liu, X.; Chen, Y.X.; Tang, X.F. Single Mo atoms paired with neighboring Ti atoms catalytically decompose ammonium bisulfate formed in low-temperature SCR. J. Mater. Chem. A 2022, 10, 6065. [Google Scholar] [CrossRef]

| Method | Catalyst | Loaded Metal | Support | Catalytic Reaction | Ref. | |

|---|---|---|---|---|---|---|

| The ALD method | Co1/graphene | Co (2.50 wt%) | Graphene | Hydrogenation of nitroarenes | [26] | |

| Pd1/Graphene | Pd (0.25 wt%) | Graphene | Selective hydrogenation of 1,3-butadiene | [28] | ||

| Co1-N4/g-C3N4 | Co (1.00 wt%) | g-C3N4 | Photocatalytic hydrogen production | [30] | ||

| Pt/C3N4 | Pt (0.14–0.32 wt%) | C3N4 | photocatalytic hydrogen production | [32] | ||

| Pt1/CeO2 | Pt (0.22 wt%) | CeO2 | CO oxidation | [34] | ||

| Fe−Pt/SiO2 | Fe (0–0.75 wt%) | SiO2 | Preferential oxidation of CO in hydrogen (PROX) | [35] | ||

| The impregnation method | Ru/TiO2 | Ru (1.00 wt%) | TiO2 | Photocatalytic fixation of nitrogen to ammonia | [38] | |

| Au-SA/TiO2 | Au (0.25 wt%) | TiO2 | CO oxidation | [39] | ||

| Pt-SA/α-MoOx | Pt (0.28 wt%) | α-MoOx | Hydrogen evolution reaction (HER) | [40] | ||

| Ru/MnO2-r | Ru (0.10 wt%) | MnO2-r | Oxidative cyanation of alcohols | [41] | ||

| Pt/CeO2 | Pt (1.00 wt%) | CeO2 | CO oxidation | [42] | ||

| Ru/CeO2 | Ru (0.89 wt%) | CeO2 | CO2 methanation | [43] | ||

| Pt1/CuO−CeO2 | Pt (0.39 wt%) | CuO−CeO2 | Photothermal catalytic oxidation of toluene | [44] | ||

| Pt1/ATO | Pt (1.0, 4.0, 8.0 wt%) | SnO2 | Formic acid oxidation reaction | [45] | ||

| Pd/Al2O3 | - | Al2O3 | Selective aerobic oxidation of allylic alcohols | [46] | ||

| Pt1/meso-Fe2O3 | Pt (0.15 wt%) | Fe2O3 | Benzene combustion | [47] | ||

| Ru/CoFe-LDHs | Ru (0.45 wt%) | CoFe-LDHs | Oxygen evolution reaction. | [15] | ||

| Ru/Al2O3 | Ru (0.1–5.0 wt%) | Al2O3 | CO2 reduction | [48] | ||

| The co-precipitation method | CuCe | Cu (1.00 wt%) | CeO2 | CO oxidation | [49] | |

| Ni/MgO | Ni (0–18.7 wt%) | MgO | Reverse water–gas shift (rWGS) | [51] | ||

| Ir1/FeOx | Ir (0.01 wt%) | FeOx | Water–gas shift reaction (WGS) | [52] | ||

| Pt1/FeOx | Ir (0.08 wt%) | FeOx | Chemoselective hydrogenation | [53] | ||

| Pt1-Co3O4 | Pt (0.02–0.30 wt%) | Co3O4 | Methanol oxidation | [54] | ||

| Pt/Fe2O3 | Pt (0.30 wt%) | Fe2O3 | Methane oxidation | [55] | ||

| The deposition–precipitation method | Au1/CeO2 | Au (0.05, 0.30 wt%) | CeO2 | Preferential oxidation of CO (PROX) | [56] | |

| Au1/Co3O4 | Au (0.05 wt%) | Co3O4 | CO oxidation | [59] | ||

| Pt1/ZnO Au1/ZnO | Pt (0.0125 wt%) Au (0.0125 wt%) | ZnO | Methanol steam reforming | [60] | ||

| The pyrolysis approach | Ru SAs/N−C | Ru (0.30 wt%) | N−C | Chemoselective hydrogenation | [14] | |

| HNTM-Ir/Pt | Ir (1.05 wt%), Pt (2.54 wt%) | MOF (HNTM) | Photocatalytic H2 evolution | [61] | ||

| Co-N-graphene | Co (0.57 at%) | N-graphene | Hydrogen generation | [63] | ||

| RGO@AC/Pd | Pd (0.43–0.87 wt%) | RGO@AC (carbon) | 4-Nitrophenol (4-NP) reduction | [64] | ||

| The electrochemical/photochemical method | Au–(OH)x/TiOx | Au (~1.0 wt%) | TiOx | WGS | [65] | |

| Pd SA/TiO2 | Pd (0.53 wt%) | TiO2 | HER | [66] | ||

| Pd1/TiO2 | Pd (1.50 wt%) | TiO2 | Hydrogenation of aldehydes | [67] | ||

| Ir1/Co(OH)2 | Ir (1.2, 2.0 wt%) | Co(OH)2 | HER | [69] | ||

| Ni−Carbon | Ni (1.50 wt%) | Carbon | HER | [70] | ||

| Pd1/TiO2 | Pd (1.20 wt%) | TiO2 | Toluene and methane oxidation | [71] | ||

| Pt/RuCeOx | Pt (0.49 wt%) | RuCeOx | HER | [72] | ||

| Pt1/MC | Pt (2.60 wt%) | Carbon | HER | [73] | ||

| Other synthesis methods | Microwave-assisted | Co-NG-MW | Co (1.10 wt%) | N-graphene | HER | [78] |

| Shock-heating | Pt-CA-CNF | Pt (0.24 wt%) | Carbon | CO oxidation, direct methane conversion | [79] | |

| Ball milling | CoN4/GN | Co (8.40%) | Graphene | Interconversion of the redox couple I−/I3− | [80] | |

| FeN4/GN | Fe (1.50 wt%) | Graphene | Benzene oxidation | [81] | ||

| Mass-selected | Aux(TiO2)yOz− | - | TiO2 | CO oxidation | [76] | |

| Laser ablation | PtAlxOy− | - | Pt/Al mixed metal | Thermal methane conversion to formaldehyde | [82] | |

| Reaction | SACs Catalyst | Catalytic Activity | Stability | Ref. |

|---|---|---|---|---|

| Photothermocatalytic oxidation of toluene | Pt1/CuO-CeO2 | Toluene conversion at 160−180 °C was increased by 48% after light illumination. | No obvious change in activity within 25 h of on-stream toluene oxidation at 185 °C. | [44] |

| Formic acid oxidation | Pt1/ATO | The Pt1/ATO catalyst showed activity and durability superior to those of the commercial Pt/C catalyst. | The structure was retained after a test of 1800 cycles. | [45] |

| Crotyl alcohol, cinnamyl alcohol, benzyl alcohol oxidation | Pd/meso-Al2O3 | TOF = 7080 h−1 at 60 °C in crotyl alcohol oxidation; the most active catalyst reported at present for cinnamyl alcohol oxidation (TOF = 4400 h−1); TOF = 4096 h−1 and more than 99% selectivity of benzaldehyde for benzyl alcohol oxidation. | − | [46] |

| Benzene oxidation | Pt1/meso-Fe2O3 | The TOFPt (2.69 s−1) over Pt1/meso-Fe2O3 was much higher than that (1.16 s−1) over 0.25 Pt NP/meso-Fe2O3 at 160 °C. | No significant change in activity after 40 h of on-stream reaction. | [47] |

| Methanol oxidation | Pt1-Co3O4 | The reaction rate at 70 °C (0.013 mol/(gPt s)) over Pt1-Co3O4 was over four times higher than that (0.03 mol/(gPt s)) over Pt/Co3O4. | After water-resistant tests, notable losses were observed; the Pt1-Co3O4 catalyst possessed a better CO2 (5 vol%) resistance. | [54] |

| Toluene oxidation | Pd1/TiO2 | Complete toluene removal was achieved at 190 oC (Pd/TiO2 required a much higher temperature at 250 °C). | − | [69] |

| Oxidation of benzene to phenol | FeN4/GN | The conversion was 23.4% and the yield was 18.7% at room temperature. | Benzene oxidation took place efficiently at 0 °C, with a phenol yield of 8.3% after 24 h of reaction. | [80] |

| Methanol oxidation | Pt1-CeO2{100} | The TOFPt was 0.68 s−1 at 50 °C (T50% = 33.7 °C, T90% = 51.9 °C). | Negligible deactivation can be observed for an extended 800 min at 52 °C in a mixture airflow. | [83] |

| Toluene oxidation | Pt/MnO2 | 100% conversions of 0.42 ppm and 10 ppm toluene were achieved at 28 and 80 °C, respectively. The complete oxidation of toluene into CO2 took place at 220 °C. | Kept stable at 220 °C within 10 h of reaction. | [84] |

| HCHO oxidation | Ag-HMO | The TOF at 80 °C (0.035 s−1) over Ag-HMO was about seven times higher than that (ca. 0.005 s−1) over Ag/HMO. | − | [85] |

| Alkali-Metal- Pt/TiO2 | A 100% conversion of HCHO was achieved at 40 °C over the 1% Na-Pt/TiO2 catalyst. | − | [86] | |

| Pt/Mn-TiO2 | The complete oxidation of 100 ppm HCHO was achieved at room temperature under the conditions of WHSV = 60,000 mL/(g h) and RH = 50%. | During the long-term activity test (>75 h), Pt/Mn-TiO2 displayed good stability, even at a WHSV of 120,000 mL/(g h). | [87] | |

| CO oxidation | 0.22Pt1/CeO2 | 100% CO conversion was obtained at 160 °C, and the temperature was remarkably decreased to 98 °C in the presence of water. | The activity was virtually preserved at 92 °C after 96 h. | [34] |

| 0.25Au/TiO2 | The full conversion temperature was 120 °C, which was significantly lower than that over Au/Per-TiO2. | Without an obvious decrease in catalytic activity after 600 min of reaction. | [39] | |

| CeO2-AA-Pt | The temperature of the CO complete conversion was 60 °C. | No activity losses in five cycle tests. | [42] | |

| CuCe | A CO consumption rate of 6100 μmolCO/(gCu s) was achieved at 120 °C, which was much higher than that over the other reported copper catalysts. | Possessed remarkable cyclic stability at 600 and 200 °C (5 mg of catalyst, GHSV = 240,000 mL/(g h)). | [49] | |

| Pt-HT-SAs | − | Kept the excellent stability in CO or methane conversion at 220 °C for 50 h. | [78] | |

| Pt/m-Al2O3 | TOF was 0.023 s−1 at 200 °C and steadily increased to 0.175 s−1 at 250 °C (GHSV = 4.8 × 107 mL/(g h)). | Kept the stable activity after 60 cycles within a month. | [88] | |

| Au1/Co3O4 | TOF was 3.1 s−1 at −75 °C, which was one of the most active Au catalysts for CO oxidation (T90% = −100 °C). | Kept stable after 10 cycle tests. | [89] | |

| CoOx/Pt/CeO2 | TOF was 0.88 s−1 at 25 °C, with a GHSV of 75,000 mL/(g h) (T50% = 6 oC, T90% = 20 °C). | Kept stable during 36 h of on-stream reaction. | [90] | |

| CH4 oxidation | Pt/Fe2O3 | The specific activity (2.01 molCH4/(gPt h)) over Pt/Fe2O3 was 4 times higher than that that (0.47 molCH4/(gPt h)) over Pt/Fe2O3-NP and 20 times higher than that over Pt/Al2O3. | Maintained a similar activity for over 16 h of on-stream reaction. | [55] |

| Pd1/TiO2 | The temperature (380 °C) for the complete oxidation of methane was substantially decreased. | − | [71] | |

| 1Pd/2Pt@CeO2 | At 300 °C, the reaction rate (3.27 mmolCH4/(molPd s)) was three times higher than that (0.91 mmolCH4/(molPd s)) of (1Pd + 2Pt)/CeO2. | A loss of 3.8% in reactivity in the presence of 4 v/v% water vapor and a loss of 15.7% in reactivity in the presence of 10 v/v% water. | [91] | |

| PdW1/Al2O3 | The TOF at 260 °C over PdW1/Al2O3 was much higher than that over Pd/Al2O3. | No deactivation during the 30 h reaction process. | [92] | |

| Cu1/ZSM-5 | The Cu1/ZSM-5 catalyst was highly active (C1 oxygenates productivity of 4800 μmol/gcat at 50 °C and 12,000 μmol/gcat at 70 °C within 30 min) and selective (C1 oxygenates selectivity of 99% at 50 °C). C1 oxygenate productivity of 4800 and 12,000 μmol/gcat was achieved at 50 and 70 °C, respectively. A C1 oxygenate selectivity of 99% was achieved at 50 °C. | − | [82] | |

| Au1/BP | The mass activity reached 113.5 μmol/gcat in the presence of water with 33 bar of mixed gas (CH4:O2 = 10:1) at 90 °C under light irradiation (1.2 W). | After 10 in situ cycles (20 h), about 205.2 μmol of methanol was generated. | [93] | |

| NOx reduction | Pd/TiO2 | The presence of Pd led to a drastic increase (4–5 times) in NOx removal efficiency after 5 h of reaction. | − | [94] |

| NbCuCe | 80% NOx conversion was achieved at 150 °C, and a high N2 selectivity was detected during the activity testing process. | Under the conditions of 5 vol% H2O, 5 vol% CO2, and 200 ppm C3H6, NbCuCe still exhibited a better catalytic performance than Cu-CHA and NbCe. | [95] | |

| Mo1/Fe2O3 | TOF at 270 °C over Mo1/Fe2O3 was ca. 1.7 × 10−3 s−1, comparable to TOF at 277 °C (1.3 × 10−3 s−1) and TOF at 323 °C (2.4 × 10−3 s−1) over V2O5/TiO2. | − | [96] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, X.; Deng, J.; Liu, Y.; Jing, L.; Hou, Z.; Pei, W.; Dai, H. Single-Atom Catalysts: Preparation and Applications in Environmental Catalysis. Catalysts 2022, 12, 1239. https://doi.org/10.3390/catal12101239

Yu X, Deng J, Liu Y, Jing L, Hou Z, Pei W, Dai H. Single-Atom Catalysts: Preparation and Applications in Environmental Catalysis. Catalysts. 2022; 12(10):1239. https://doi.org/10.3390/catal12101239

Chicago/Turabian StyleYu, Xiaohui, Jiguang Deng, Yuxi Liu, Lin Jing, Zhiquan Hou, Wenbo Pei, and Hongxing Dai. 2022. "Single-Atom Catalysts: Preparation and Applications in Environmental Catalysis" Catalysts 12, no. 10: 1239. https://doi.org/10.3390/catal12101239