A Review on the Pathways of the Improved Structural Characteristics and Photocatalytic Performance of Titanium Dioxide (TiO2) Thin Films Fabricated by the Magnetron-Sputtering Technique

Abstract

:1. Introduction

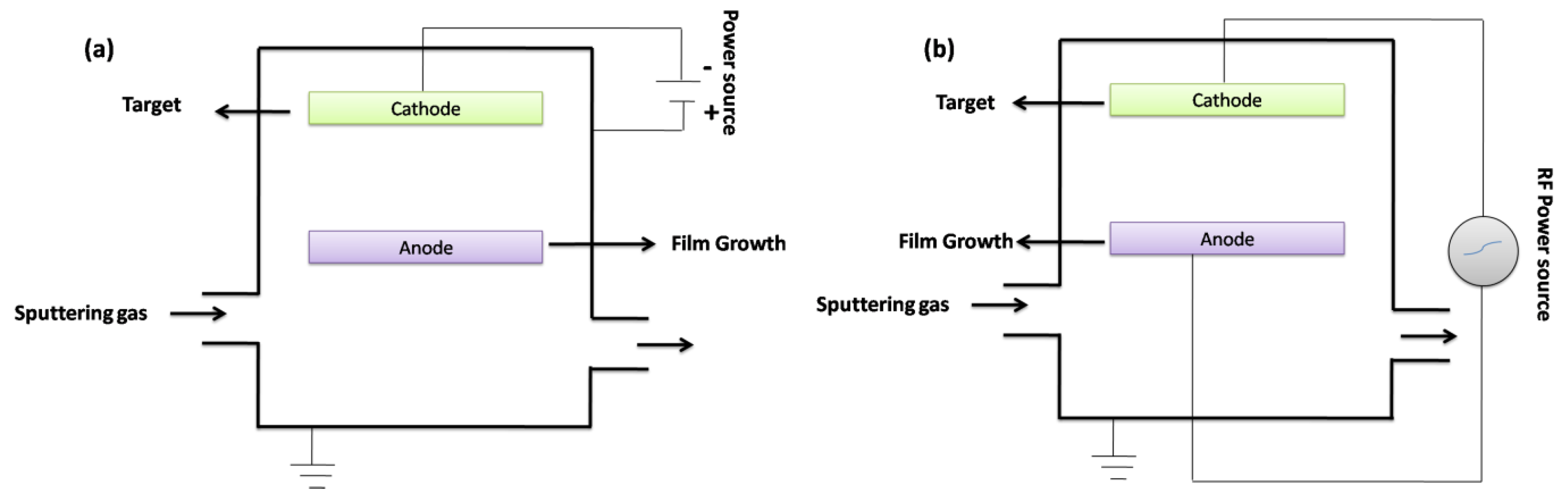

2. Working Principle of Magnetron Sputtering Technique

3. Effect of Deposition Conditions on Photocatalytic Thin Films

3.1. Substrate Type

3.2. Sputtering Power

3.3. Distance between Substrate and Target

3.4. Working Pressure

3.5. Argon/Oxygen Ratio

3.6. Deposition Time

3.7. Substrate Temperature

4. Metal Oxide Doping

5. Non-Metal Oxide Doping

6. Annealing Treatment

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kumar, T.S.; Bhuyan, R.K.; Pamu, D. Effect of post annealing on structural, optical and dielectric properties of MgTiO3 thin films deposited by RF magnetron sputtering. Appl. Surf. Sci. 2013, 264, 184–190. [Google Scholar] [CrossRef]

- Jeong, S.H.; Kim, J.K.; Kim, B.S.; Shim, S.H.; Lee, B.T. Characterization of SiO2 and TiO2 films prepared using RF magnetron sputtering and their application to anti-reflection coating. Vacuum 2004, 76, 507–515. [Google Scholar] [CrossRef]

- Hu, W.; Li, L.; Li, G.; Tang, C.; Sun, L. High-quality brookite TiO2 flowers: Synthesis, characterization, and dielectric performance. Cryst. Growth Des. 2009, 9, 3676–3682. [Google Scholar] [CrossRef]

- Tighineanu, A.; Ruff, T.; Albu, S.; Hahn, R.; Schmuki, P. Conductivity of TiO2 nanotubes: Influence of annealing time and temperature. Chem. Phys. Lett. 2010, 494, 260–263. [Google Scholar] [CrossRef]

- Lee, C.H.; Kim, K.H.; Choi, H.W. Enhancing Efficiency of Dye-Sensitized Solar Cells Using TiO2 Composite Films and RF-Sputtered Passivating Layer. Mol. Cryst. Liq. Cryst. 2012, 567, 9–18. [Google Scholar] [CrossRef]

- Pansila, P.; Witit-Anun, N.; Chaiyakun, S. Influence of sputtering power on structure and photocatalyst properties of DC magnetron sputtered TiO2 thin film. Procedia Eng. 2012, 32, 862–867. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Ma, W.; Zhao, J. Semiconductor-mediated photodegradation of pollutants under visible-light irradiation. Chem. Soc. Rev. 2010, 39, 4206–4219. [Google Scholar] [CrossRef]

- Zheng, S.K.; Xiang, G.; Wang, T.M.; Pan, F.; Wang, C.; Hao, W.C. Photocatalytic activity studies of TiO2 thin films prepared by RF magnetron reactive sputtering. Vacuum 2003, 72, 79–84. [Google Scholar] [CrossRef]

- Wang, Q.; Zhu, K.; Neale, N.R.; Frank, A.J. Constructing ordered sensitized heterojunctions: Bottom-up electrochemical synthesis of p-type semiconductors in oriented n-TiO2 nanotube arrays. Nano Lett. 2009, 9, 806–813. [Google Scholar] [CrossRef]

- Hanaor, D.A.; Sorrell, C.C. Review of the anatase to rutile phase transformation. J. Mater. Sci. 2011, 46, 855–874. [Google Scholar] [CrossRef] [Green Version]

- Yang, Z.; Choi, D.; Kerisit, S.; Rosso, K.M.; Wang, D.; Zhang, J.; Graff, G.; Liu, J. Nanostructures and lithium electrochemical reactivity of lithium titanites and titanium oxides: A review. J. Power Sour. 2009, 192, 588–598. [Google Scholar] [CrossRef]

- Yoo, D.; Kim, I.; Kim, S.; Hahn, C.H.; Lee, C.; Cho, S. Effects of annealing temperature and method on structural and optical properties of TiO2 films prepared by RF magnetron sputtering at room temperature. Appl. Surf. Sci. 2007, 253, 3888–3892. [Google Scholar] [CrossRef]

- Maeda, M.; Watanabe, T. Effects of crystallinity and grain size on photocatalytic activity of titania films. Surf. Coat. Technol. 2007, 201, 9309–9312. [Google Scholar] [CrossRef]

- Takabayashi, S.; Zeman, P. Effect of total and oxygen partial pressures on structure of photocatalytic TiO2 films sputtered on unheated substrates. Surf. Coat. Technol. 2002, 153, 93–99. [Google Scholar]

- Ogawa, H.; Higuchi, T.; Nakamura, A.; Tokita, S.; Miyazaki, D.; Hattori, T.; Tsukamoto, T. Growth of TiO2 thin film by reactive RF magnetron sputtering using oxygen radical. J. Alloys Compd. 2008, 449, 375–378. [Google Scholar] [CrossRef]

- Pelaez, M.; Nolan, N.T.; Pillai, S.C.; Seery, M.K.; Falaras, P.; Kontos, A.G.; Dunlop, P.S.; Hamilton, J.W.; Byrne, J.A.O.; Shea, K.; et al. A review on the visible light active titanium dioxide photocatalysts for environmental applications. Appl. Catal. B 2012, 125, 331–349. [Google Scholar] [CrossRef] [Green Version]

- Herrmann, J.M. Heterogeneous photocatalysis: State of the art and present applications In honor of Pr. RL Burwell Jr. (1912–2003), Former Head of Ipatieff Laboratories, Northwestern University, Evanston (Ill). Top. Catal. 2005, 34, 49–65. [Google Scholar] [CrossRef]

- Carneiro, J.O.; Teixeira, V.; Portinha, A.; Dupak, L.; Magalhaes, A.; Coutinho, P. Study of the deposition parameters and Fe-dopant effect in the photocatalytic activity of TiO2 films prepared by dc reactive magnetron sputtering. Vacuum 2005, 78, 37–46. [Google Scholar] [CrossRef]

- Subrahmanyam, A.; Biju, K.P.; Rajesh, P.; Kumar, K.J.; Kiran, M.R. Surface modification of sol gel TiO2 surface with sputtered metallic silver for Sun light photocatalytic activity: Initial studies. Sol. Energy Mater. Sol. Cell 2012, 101, 241–248. [Google Scholar] [CrossRef]

- Bersani, D.; Lottici, P.P.; Ding, X.Z. Phonon confinement effects in the Raman scattering by TiO2 nanocrystals. Appl. Phys. Lett. 1998, 72, 73–75. [Google Scholar] [CrossRef]

- Lee, S.H.; Yamasue, E.; Okumura, H.; Ishihara, K.N. Effect of oxygen and nitrogen concentration of nitrogen doped TiOx film as photocatalyst prepared by reactive sputtering. Appl. Catal. A-Gen. 2009, 371, 179–190. [Google Scholar] [CrossRef]

- Padmanabhan, S.C.; Pillai, S.C.; Colreavy, J.; Balakrishnan, S.; McCormack, D.E.; Perova, T.S.; Gun’ko, Y.; Hinder, S.J.; Kelly, J.M. A simple sol− gel processing for the development of high-temperature stable photoactive anatase titania. Chem. Mater. 2007, 19, 4474–4481. [Google Scholar] [CrossRef]

- Wiatrowski, A.; Mazur, M.; Obstarczyk, A.; Wojcieszak, D.; Kaczmarek, D.; Morgiel, J.; Gibson, D. Comparison of the physicochemical properties of TiO2 thin films obtained by magnetron sputtering with continuous and pulsed gas flow. Coatings 2018, 8, 412. [Google Scholar] [CrossRef] [Green Version]

- Veith, M.; Lee, J.; Miró, M.M.; Akkan, C.K.; Dufloux, C.; Aktas, O.C. Bi-phasic nanostructures for functional applications. Chem. Soc. Rev. 2012, 41, 5117–5130. [Google Scholar] [CrossRef] [PubMed]

- Su, J.; Boichot, R.; Blanquet, E.; Mercier, F.; Pons, M. Chemical vapor deposition of titanium nitride thin films: Kinetics and experiments. Cryst. Eng. Comm. 2019, 21, 3974–3981. [Google Scholar] [CrossRef]

- Henkel, B.; Neubert, T.; Zabel, S.; Lamprecht, C.; Selhuber-Unkel, C.; Raetzke, K.; Strunskus, T.; Vergöhl, M.; Faupel, F. Photocatalytic properties of titania thin films prepared by sputtering versus evaporation and aging of induced oxygen vacancy defects. Appl. Catal. B 2016, 180, 362–371. [Google Scholar] [CrossRef]

- Rodríguez, J.; Gómez, M.; Lu, J.; Olsson, E.; Granqvist, C.G. Reactively Sputter-Deposited Titanium Oxide Coatings with Parallel Penniform Microstructure. Adv. Mater. 2000, 12, 341–343. [Google Scholar] [CrossRef]

- Suzuki, M.; Ito, T.; Taga, Y. Photocatalysis of sculptured thin films of TiO2. Appl. Phys. Lett. 2001, 78, 3968–3970. [Google Scholar] [CrossRef]

- Merenda, A.; Kong, L.; Zhu, B.; Duke, M.C.; Gray, S.R.; Dumée, L.F. Functional nanoporous titanium dioxide for separation applications: Synthesis routes and properties to performance analysis. In Water Scarcity and Ways to Reduce the Impact; Springer: Cham, Switzerland, 2019; pp. 151–186. [Google Scholar]

- Henkel, B.; Vahl, A.; Aktas, O.C.; Strunskus, T.; Faupel, F. Self-organized nanocrack networks: A pathway to enlarge catalytic surface area in sputtered ceramic thin films, showcased for photocatalytic TiO2. Nanotechnology 2017, 29, 035703. [Google Scholar] [CrossRef]

- Mejia, M.I.; Marin, J.M.; Restrepo, G.; Pulgarin, C.; Mielczarski, E.; Mielczarski, J.; Arroyo, Y.; Lavanchy, J.C.; Kiwi, J. Self-cleaning modified TiO2–cotton pretreated by UVC-light (185 nm) and RF-plasma in vacuum and also under atmospheric pressure. Appl. Catal. B 2009, 91, 481–488. [Google Scholar] [CrossRef]

- Chen, D.Y.; Tsao, C.C.; Hsu, C.Y. Photocatalytic TiO2 thin films deposited on flexible substrates by radio frequency (RF) reactive magnetron sputtering. Curr. Appl. Phys. 2012, 12, 179–183. [Google Scholar] [CrossRef]

- Chiou, A.H.; Kuo, C.G.; Huang, C.H.; Wu, W.F.; Chou, C.P.; Hsu, C.Y. Influence of oxygen flow rate on photocatalytic TiO2 films deposited by rf magnetron sputtering. J. Mater. Sci.-Mater. Electron. 2012, 23, 589–594. [Google Scholar] [CrossRef] [Green Version]

- Wei, C.H.; Chang, C.M. Polycrystalline TiO2 thin films with different thicknesses deposited on unheated substrates using RF magnetron sputtering. Mater. Trans. 2011. [Google Scholar] [CrossRef] [Green Version]

- Yang, W.; Liu, Z.; Peng, D.L.; Zhang, F.; Huang, H.; Xie, Y.; Wu, Z. Room-temperature deposition of transparent conducting Al-doped ZnO films by RF magnetron sputtering method. Appl. Surf. Sci. 2009, 255, 5669–5673. [Google Scholar] [CrossRef]

- Nair, P.B.; Justinvictor, V.B.; Daniel, G.P.; Joy, K.; Ramakrishnan, V.; Thomas, P.V. Effect of RF power and sputtering pressure on the structural and optical properties of TiO2 thin films prepared by RF magnetron sputtering. Appl. Surf. Sci. 2011, 257, 10869–10875. [Google Scholar] [CrossRef]

- Laha, P.; Panda, A.B.; Mahapatra, S.K.; Barhai, P.K.; Das, A.K.; Banerjee, I. Development of RF plasma sputtered Al2O3–TiO2 multilayer broad band antireflecting coatings and its correlation with plasma parameters. Appl. Surf. Sci. 2012, 258, 2275–2282. [Google Scholar] [CrossRef]

- Shet, S.; Ahn, K.S.; Nuggehalli, R.; Yan, Y.; Turner, J.; Al-Jassim, M. Effects of substrate temperature and RF power on the formation of aligned nanorods in ZnO thin films. JOM-US 2010, 62, 25–30. [Google Scholar] [CrossRef]

- Jamuna-Thevi, K.; Bakar, S.A.; Ibrahim, S.; Shahab, N.; Toff, M.R. Quantification of silver ion release, in vitro cytotoxicity and antibacterial properties of nanostuctured Ag doped TiO2 coatings on stainless steel deposited by RF magnetron sputtering. Vacuum 2011, 86, 235–241. [Google Scholar] [CrossRef]

- Sun, H.; Wang, C.; Pang, S.; Li, X.; Tao, Y.; Tang, H.; Liu, M. Photocatalytic TiO2 films prepared by chemical vapor deposition at atmosphere pressure. J. Non-Cryst. Solids 2008, 354, 1440–1443. [Google Scholar] [CrossRef]

- Amadelli, R.; Samiolo, L.; Maldotti, A.; Molinari, A.; Valigi, M.; Gazzoli, D. Preparation, characterisation, and photocatalytic behaviour of Co-TiO2 with visible light response. Int. J. Photoenergy 2008, 2008, 853753. [Google Scholar] [CrossRef] [Green Version]

- Lei, Y.; Zhang, L.D.; Fan, J.C. Fabrication, characterization and Raman study of TiO2 nanowire arrays prepared by anodic oxidative hydrolysis of TiCl3. Chem. Phys. Lett. 2001, 338, 231–236. [Google Scholar] [CrossRef]

- Arconada, N.; Castro, Y.; Durán, A. Photocatalytic properties in aqueous solution of porous TiO2-anatase films prepared by sol–gel process. Appl. Catal. A-Gen. 2010, 385, 101–107. [Google Scholar] [CrossRef]

- Khoa, N.T.; Pyun, M.W.; Yoo, D.H.; Kim, S.W.; Leem, J.Y.; Kim, E.J.; Hahn, S.H. Photodecomposition effects of graphene oxide coated on TiO2 thin film prepared by electron-beam evaporation method. Thin Solid Films 2012, 520, 5417–5420. [Google Scholar] [CrossRef]

- Liao, C.H.; Huang, C.W.; Wu, J.C. Novel dual-layer photoelectrode prepared by RF magnetron sputtering for photocatalytic water splitting. Int. J. Hydrog. Energy 2012, 37, 11632–11639. [Google Scholar] [CrossRef]

- Yang, W.J.; Hsu, C.Y.; Liu, Y.W.; Hsu, R.Q.; Lu, T.W.; Hu, C.C. The structure and photocatalytic activity of TiO2 thin films deposited by dc magnetron sputtering. Superlattice Microstruct. 2012, 52, 1131–1142. [Google Scholar] [CrossRef]

- Garlisi, C.; Scandura, G.; Palmisano, G.; Chiesa, M.; Lai, C.Y. Integrated nano-and macroscale investigation of photoinduced hydrophilicity in TiO2 thin films. Langmuir 2016, 32, 11813–11818. [Google Scholar] [CrossRef]

- Haseeb, A.S.; Hasan, M.M.; Masjuki, H.H. Structural and mechanical properties of nanostructured TiO2 thin films deposited by RF sputtering. Surf. Coat. Technol. 2010, 205, 338–344. [Google Scholar] [CrossRef]

- Lee, K.S.; Lee, S.H. Influence of SiO2 interlayer on the hydrophilicity of TiO2/SiO2/glass produced by RF-magnetron sputtering. Mater. Lett. 2007, 61, 3516–3518. [Google Scholar] [CrossRef]

- Meng, F.; Xiao, L.; Sun, Z. Thermo-induced hydrophilicity of nano-TiO2 thin films prepared by RF magnetron sputtering. J. Alloys Compd. 2009, 485, 848–852. [Google Scholar] [CrossRef]

- Ohsaki, H.; Andou, R.; Kinbara, A.; Watanabe, T. Crystallization of ITO and TiO2 by RF plasma treatment. Vacuum 2013, 87, 145–149. [Google Scholar] [CrossRef]

- Choi, W.J.; Kwak, D.J.; Park, C.S.; Sung, Y.M. Characterization of transparent conductive ITO, ITiO, and FTO Films for application in photoelectrochemical cells. J. Nanosci. Nanotechnol. 2012, 12, 3394–3397. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Yang, T.; Li, Y.; Pang, Z.; Lin, L.; Lv, M.; Han, S. Structural, electrical and optical properties of ITO films with a thin TiO2 seed layer prepared by RF magnetron sputtering. Vacuum 2009, 83, 1091–1094. [Google Scholar] [CrossRef]

- Rhee, S.W.; Kim, K.H.; Choi, H.W. Effect of ZnO Passivating Layer Using RF-Sputtered for Dye-Sensitized Solar Cells. Mol. Cryst. Liq. Cryst. 2012, 565, 131–137. [Google Scholar] [CrossRef]

- Chen, C.C.; Yang, W.J.; Hsu, C.Y. Investigation into the effects of deposition parameters on TiO2 photocatalyst thin films by rf magnetron sputtering. Superlattice Microstruct. 2009, 46, 461–468. [Google Scholar] [CrossRef]

- Wenbin, X.; Shurong, D.; Demiao, W.; Gaochao, R. Investigation of microstructure evolution in Pt-doped TiO2 thin films deposited by RF magnetron sputtering. Physica B 2008, 403, 2698–2701. [Google Scholar] [CrossRef]

- Jung, J.M.; Wang, M.; Kim, E.J.; Hahn, S.H. Photocatalytic properties of Au/TiO2 thin films prepared by RF magnetron co-sputtering. Vacuum 2008, 82, 827–832. [Google Scholar] [CrossRef]

- Lin, S.S. The optical properties of Ti-doped TiO2 nanoceramic films deposited by simultaneous RF and DC magnetron sputtering. Ceram. Int. 2012, 38, 3129–3134. [Google Scholar] [CrossRef]

- Huang, H.H.; Huang, C.C.; Huang, P.C.; Yang, C.F.; Hsu, C.Y. Preparation of rutile and anatase phases titanium oxide film by RF sputtering. J. Nanosci. Nanotechnol. 2008, 8, 2659–2664. [Google Scholar] [CrossRef]

- Su, Y.F.; Chou, T.C.; Ling, T.R.; Sun, C.C. Photocurrent performance and nanostructure analysis of TiO2/ITO electrodes prepared using reactive sputtering. J. Electrochem. Soc. 2004, 151, A1375–A1382. [Google Scholar] [CrossRef] [Green Version]

- Lin, S.S.; Wu, D.K. Effect of RF deposition power on the properties of Al-doped TiO2 thin films. Surf. Coat. Technol. 2010, 204, 2202–2207. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, X.; Zhao, Q.; Li, C.; He, X. The effect of O2 partial pressure on the structure and photocatalytic property of TiO2 films prepared by sputtering. Mater. Chem. Phys. 2005, 90, 207–212. [Google Scholar] [CrossRef]

- Magyari-Köpe, B.; Park, S.G.; Lee, H.D.; Nishi, Y. First principles calculations of oxygen vacancy-ordering effects in resistance change memory materials incorporating binary transition metal oxides. J. Mater. Sci. 2012, 47, 7498–7514. [Google Scholar] [CrossRef]

- Sirisuk, A.; Klansorn, E.; Praserthdam, P. Effects of reaction medium and crystallite size on Ti3+ surface defects in titanium dioxide nanoparticles prepared by solvothermal method. Catal. Commun. 2008, 9, 1810–1814. [Google Scholar] [CrossRef]

- Chow, L.L.; Yuen, M.M.; Chan, P.C.; Cheung, A.T. Reactive sputtered TiO2 thin film humidity sensor with negative substrate bias. Sens. Actuators B-Chem. 2001, 76, 310–315. [Google Scholar] [CrossRef]

- Huang, C.H.; Tsao, C.C.; Hsu, C.Y. Study on the photocatalytic activities of TiO2 films prepared by reactive RF sputtering. Ceram. Int. 2011, 37, 2781–2788. [Google Scholar] [CrossRef]

- Eufinger, K.; Poelman, D.; Poelman, H.; De Gryse, R.; Marin, G.B. Photocatalytic activity of dc magnetron sputter deposited amorphous TiO2 thin films. Appl. Surf. Sci. 2007, 254, 148–152. [Google Scholar] [CrossRef]

- Hou, Y.Q.; Zhuang, D.M.; Zhang, G.; Zhao, M.; Wu, M.S. Influence of annealing temperature on the properties of titanium oxide thin film. Appl. Surf. Sci. 2003, 218, 98–106. [Google Scholar] [CrossRef]

- Miao, L.; Jin, P.; Kaneko, K.; Terai, A.; Nabatova-Gabain, N.; Tanemura, S. Preparation and characterization of polycrystalline anatase and rutile TiO2 thin films by rf magnetron sputtering. Appl. Surf. Sci. 2003, 212, 255–263. [Google Scholar] [CrossRef]

- Zhang, T.J.; Li, S.Z.; Zhang, B.S.; Pan, R.K.; Jiang, J.; Ma, Z.J. Optical properties of RF-sputtered Ba0.65Sr0.35TiO3 thin films. J. Electroceram. 2008, 21, 174–177. [Google Scholar] [CrossRef]

- Ye, Q.; Liu, P.Y.; Tang, Z.F.; Zhai, L. Hydrophilic properties of nano-TiO2 thin films deposited by RF magnetron sputtering. Vacuum 2007, 81, 627–631. [Google Scholar] [CrossRef]

- Hasan, M.M.; Haseeb, A.S.; Saidur, R.; Masjuki, H.H.; Hamdi, M. Influence of substrate and annealing temperatures on optical properties of RF-sputtered TiO2 thin films. Opt. Mater. 2010, 32, 690–695. [Google Scholar] [CrossRef]

- Heo, C.H.; Lee, S.B.; Boo, J.H. Deposition of TiO2 thin films using RF magnetron sputtering method and study of their surface characteristics. Thin Solid Films 2005, 475, 183–188. [Google Scholar] [CrossRef]

- Lin, W.S.; Huang, C.H.; Yang, W.J.; Hsu, C.Y.; Hou, K.H. Photocatalytic TiO2 films deposited by RF magnetron sputtering at different oxygen partial pressure. Curr. Appl. Phys. 2010, 10, 1461–1466. [Google Scholar] [CrossRef]

- Kang, S.H.; Lim, J.W.; Kim, H.S.; Kim, J.Y.; Chung, Y.H.; Sung, Y.E. Photo and electrochemical characteristics dependent on the phase ratio of nanocolumnar structured TiO2 films by RF magnetron sputtering technique. Chem. Mater. 2009, 21, 2777–2788. [Google Scholar] [CrossRef]

- Zhao, X.T.; Sakka, K.; Kihara, N.; Takata, Y.; Arita, M.; Masuda, M. Hydrophilicity of TiO2 thin films obtained by RF magnetron sputtering deposition. Curr. Appl. Phys. 2006, 6, 931–933. [Google Scholar] [CrossRef]

- Song, P.K.; Yamagishi, M.; Odaka, H.; Shigesato, Y. Photoinduced hydrophilicity of epitaxially grown TiO2 films by RF magnetron sputtering. Jpn. J. Appl. Phys. 2003, 42, L1529. [Google Scholar] [CrossRef]

- Shibata, A.; Okimura, K.; Yamamoto, Y.; Matubara, K. Effect of heating probe on reactively sputtered TiO2 film growth. Jpn. J. Appl. Phys. 1993, 32, 5666. [Google Scholar] [CrossRef]

- Kasemanankul, P.; Witit-Anan, N.; Chaiyakun, S.; Limsuwan, P.; Boonamnuayvitaya, V. Low-temperature deposition of (1 1 0) and (1 0 1) rutile TiO2 thin films using dual cathode DC unbalanced magnetron sputtering for inducing hydroxyapatite. Mater. Chem. Phys. 2009, 117, 288–293. [Google Scholar] [CrossRef]

- Ngaruiya, J.M.; Kappertz, O.; Mohamed, S.H.; Wuttig, M. Structure formation upon reactive direct current magnetron sputteringof transition metal oxide films. Appl. Phys. Lett. 2004, 85, 748–750. [Google Scholar] [CrossRef]

- Sundaram, K.B.; Khan, A. Characterization and optimization of zinc oxide films by RF magnetron sputtering. Thin Solid Films 1997, 295, 87–91. [Google Scholar] [CrossRef]

- Barnes, M.C.; Gerson, A.R.; Kumar, S.; Hwang, N.M. The mechanism of TiO2 deposition by direct current magnetron reactive sputtering. Thin Solid Films 2004, 446, 29–36. [Google Scholar] [CrossRef]

- Barnes, M.C.; Kim, D.Y.; Ahn, H.S.; Lee, C.O.; Hwang, N.M. Deposition mechanism of gold by thermal evaporation: Approach by charged cluster model. J. Cryst. Growth 2000, 213, 83–92. [Google Scholar] [CrossRef]

- Shah, S.I.; Li, W.; Huang, C.P.; Jung, O.; Ni, C. Study of Nd3+, Pd2+, Pt4+, and Fe3+ dopant effect on photoreactivity of TiO2 nanoparticles. Proc. Natl. Acad. Sci. USA 2002, 99 (Suppl. 2), 6482–6486. [Google Scholar] [CrossRef] [Green Version]

- Lin, W.S.; Kao, L.M.; Li, W.P.; Hsu, C.Y.; Hou, K.H. Fabricating TiO2 photocatalysts by RF reactive magnetron sputtering at varied oxygen partial pressures. J. Mater. Eng. Perform. 2011, 20, 1063–1067. [Google Scholar] [CrossRef]

- Xu, Y.; Shen, M. Fabrication of anatase-type TiO2 films by reactive pulsed laser deposition for photocatalyst application. J. Mater. Process. Technol. 2008, 202, 301–306. [Google Scholar] [CrossRef]

- Chaoumead, A.; Joo, B.H.; Kwak, D.J.; Sung, Y.M. Structural and electrical properties of sputtering power and gas pressure on Ti-dope In2O3 transparent conductive films by RF magnetron sputtering. Appl. Surf. Sci. 2013, 275, 227–232. [Google Scholar] [CrossRef]

- Jin, Y.S.; Kim, K.H.; Kim, W.J.; Jang, K.U.; Choi, H.W. The effect of RF-sputtered TiO2 passivating layer on the performance of dye sensitized solar cells. Ceram. Int. 2012, 38. S505–S509. [Google Scholar] [CrossRef]

- Wang, T.M.; Zheng, S.K.; Hao, W.C.; Wang, C. Studies on photocatalytic activity and transmittance spectra of TiO2 thin films prepared by rf magnetron sputtering method. Surf. Coat. Technol. 2002, 155, 141–145. [Google Scholar] [CrossRef]

- Choi, Y.L.; Kim, S.H.; Song, Y.S.; Lee, D.Y. Photodecomposition and bactericidal effects of TiO2 thin films prepared by a magnetron sputtering. J. Mater. Sci. 2004, 39, 5695–5699. [Google Scholar] [CrossRef]

- Zhu, H.; Hüpkes, J.; Bunte, E.; Gerber, A.; Huang, S.M. Influence of working pressure on ZnO: Al films from tube targets for silicon thin film solar cells. Thin Solid Films 2010, 518, 4997–5002. [Google Scholar] [CrossRef]

- Drüsedau, T.P.; Löhmann, M.; Garke, B. Decay length of the pressure dependent deposition rate for magnetron sputtering. J. Vac. Sci. Technol. A 1998, 16, 2728–2732. [Google Scholar] [CrossRef]

- Zhang, C.; Ding, W.; Wang, H.; Chai, W.; Ju, D. Influences of working pressure on properties for TiO2 films deposited by DC pulse magnetron sputtering. J. Environ. Sci. 2009, 21, 741–744. [Google Scholar] [CrossRef]

- Zuo, J. Deposition of Ag nanostructures on TiO2 thin films by RF magnetron sputtering. Appl. Surf. Sci. 2010, 256, 7096–7101. [Google Scholar] [CrossRef]

- Barreca, D.; Gasparotto, A.; Tondello, E.; Bruno, G.; Losurdo, M. Influence of process parameters on the morphology of Au/SiO2 nanocomposites synthesized by radio-frequency sputtering. J. Appl. Phys. 2004, 96, 1655–1665. [Google Scholar] [CrossRef]

- Okimura, K.; Shibata, A. Mass and Energy Analyses of Substrate-incident Ions in TiO2 Deposition by RF Magnetron Sputtering. Jpn. J. Appl. Phys. 1997, 36, 313. [Google Scholar] [CrossRef]

- Šícha, J.; Musil, J.; Meissner, M.; Čerstvý, R. Nanostructure of photocatalytic TiO2 films sputtered at temperatures below 200 C. Appl. Surf. Sci. 2008, 254, 3793–3800. [Google Scholar] [CrossRef]

- El Akkad, F.; Paulose, T.A. Optical transitions and point defects in F: SnO2 films: Effect of annealing. Appl. Surf. Sci. 2014, 295, 8–17. [Google Scholar] [CrossRef]

- Mardare, D.; Tasca, M.; Delibas, M.; Rusu, G.I. On the structural properties and optical transmittance of TiO2 RF sputtered thin films. Appl. Surf. Sci. 2000, 156, 200–206. [Google Scholar] [CrossRef]

- Vorontsov, A.V.; Savinov, E.N.; Zhensheng, J. Influence of the form of photodeposited platinum on titania upon its photocatalytic activity in CO and acetone oxidation. J. Photochem. Photobiol. A 1999, 125, 113–117. [Google Scholar] [CrossRef]

- Zhang, W.; Li, Y.; Zhu, S.; Wang, F. Influence of argon flow rate on TiO2 photocatalyst film deposited by DC reactive magnetron sputtering. Surf. Coat. Technol. 2004, 182, 192–198. [Google Scholar] [CrossRef]

- Tomaszewski, H.; Poelman, H.; Depla, D.; Poelman, D.; De Gryse, R.; Fiermans, L.; Reyniers, M.F.; Heynderickx, G.; Marin, G.B. TiO2 films prepared by DC magnetron sputtering from ceramic targets. Vacuum 2002, 68, 31–38. [Google Scholar] [CrossRef]

- Huang, C.L.; Hsu, C.H. Properties of reactively radio frequency-magnetron sputtered (Zr, Sn) TiO4 dielectric films. J. Appl. Phys. 2004, 96, 1186–1191. [Google Scholar] [CrossRef]

- Zhang, W.J.; Zhu, S.L.; Li, Y.; Wang, F.H. Photocatalytic property of TiO2 films deposited by pulsed DC magnetron sputtering. J. Mater. Sci. Technol. 2004, 20, 31–34. [Google Scholar]

- Pradhan, S.S.; Pradhan, S.K.; Bhavanasi, V.; Sahoo, S.; Sarangi, S.N.; Anwar, S.; Barhai, P.K. Low temperature stabilized rutile phase TiO2 films grown by sputtering. Thin Solid Films 2012, 520, 1809–1813. [Google Scholar] [CrossRef]

- Water, W.; Chu, S.Y. Physical and structural properties of ZnO sputtered films. Mater. Lett. 2002, 55, 67–72. [Google Scholar] [CrossRef]

- Toku, H.; Pessoa, R.S.; Maciel, H.S.; Massi, M.; Mengui, U.A. The effect of oxygen concentration on the low temperature deposition of TiO2 thin films. Surf. Coat. Technol. 2008, 202, 2126–2131. [Google Scholar] [CrossRef]

- Jeong, S.H.; Kim, B.S.; Lee, B.T.; Kim, J.K.; Park, H.R. Structural and optical properties of TiO2 films prepared using reactive RF magnetron sputtering. J. Korean Phys. Soc. 2002, 41, 67–71. [Google Scholar]

- Tavares, C.J.; Vieira, J.; Rebouta, L.; Hungerford, G.; Coutinho, P.; Teixeira, V.; Carneiro, J.O.; Fernandes, A.J. Reactive sputtering deposition of photocatalytic TiO2 thin films on glass substrates. Mater. Sci. Eng. B 2007, 138, 139–143. [Google Scholar] [CrossRef]

- Xiong, J.; Das, S.N.; Kim, S.; Lim, J.; Choi, H.; Myoung, J.M. Photo-induced hydrophilic properties of reactive RF magnetron sputtered TiO2 thin films. Surf. Coat. Technol. 2010, 204, 3436–3442. [Google Scholar] [CrossRef]

- Rahman, K.H.; Kar, A.K. Effect of precursor concentration of microstructured titanium-di-oxide (TiO2) thin films and their photocatalytic activity. Mater. Res. Express 2019, 6, 096436. [Google Scholar] [CrossRef]

- Tondare, R.S.; Shivaraj, B.W.; Narasimhamurthy, H.N.; Krishna, M.; Subramanyam, T.K. Effect of deposition time on structural, electrical and optical properties of Aluminium doped ZnO thin films by RF magnetron sputtering. Mater. Today-Proc. 2018, 5, 2710–2715. [Google Scholar] [CrossRef]

- Abdallah, B.; Jazmati, A.K.; Refaai, R. Oxygen effect on structural and optical properties of ZnO thin films deposited by RF magnetron sputtering. Mater. Res. 2017, 20, 607–612. [Google Scholar] [CrossRef]

- Nakajima, A.; Hashimoto, K.; Watanabe, T.; Takai, K.; Yamauchi, G.; Fujishima, A. Transparent superhydrophobic thin films with self-cleaning properties. Langmuir 2000, 16, 7044–7047. [Google Scholar] [CrossRef]

- Vancoppenolle, V.; Jouan, P.Y.; Wautelet, M.; Dauchot, J.P.; Hecq, M. Dc magnetron sputtering deposition of TiO2 films in argon–oxygen gas mixtures: Theory and experiments. Surf. Coat. Technol. 1999, 116, 933–937. [Google Scholar] [CrossRef]

- Alnama, K.; Abdallah, B.; Kanaan, S. Deposition of ZnS thin film by ultrasonic spray pyrolysis: Effect of thickness on the crystallographic and electrical properties. Compos. Interface 2017, 24, 499–513. [Google Scholar] [CrossRef]

- Abdallah, B.; Ismail, A.; Kashoua, H.; Zetoun, W. Effects of deposition time on the morphology, structure, and optical properties of PbS thin films prepared by chemical bath deposition. J. Nanomater. 2018, 2018, 1826959. [Google Scholar] [CrossRef] [Green Version]

- Abdallah, B.; Kakhia, M.; Abou Shaker, S. Deposition of Na2WO4 films by ultrasonic spray pyrolysis: Effect of thickness on the crystallographic and sensing properties. Compos. Interface 2016, 23, 663–674. [Google Scholar] [CrossRef]

- Abbas, M.M.; Shehab, A.A.; Al-Samuraee, A.K.; Hassan, N.A. Effect of deposition time on the optical characteristics of chemically deposited nanostructure PbS thin films. Energy Procedia 2011, 6, 241–250. [Google Scholar] [CrossRef] [Green Version]

- Daghrir, R.; Drogui, P.; Robert, D. Modified TiO2 for environmental photocatalytic applications: A review. Ind. Eng. Chem. Res. 2013, 52, 3581–3599. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, X.; Zhang, N.; Zhao, Q.; He, X.; Feng, J. Photocatalytic mechanism of TiO2–CeO2 films prepared by magnetron sputtering under UV and visible light. Surf. Sci. 2005, 595, 203–211. [Google Scholar] [CrossRef]

- Ananthakumar, R.; Subramanian, B.; Yugeswaran, S.; Jayachandran, M. Effect of substrate temperature on structural, morphological and optical properties of crystalline titanium dioxide films prepared by DC reactive magnetron sputtering. J. Mater. Sci.-Mater. Electron. 2012, 23, 1898–1904. [Google Scholar] [CrossRef]

- Metin, H.; Esen, R. Kimyasal Depolama Yöntemi Teknigiyle Büyütülen cds Filimlerinde Fotoiletkenlik Çalismalari. Erciyes Üniversitesi Fen Bilimleri Enstitüsü Fen Bilimleri Dergisi 2003, 19, 96–102. [Google Scholar]

- Purniawan, A.; Hermastuti, R.; Purwaningsih, H.; Atmono, T.M. Effect of deposition time of sputtering Ag-Cu thin film on mechanical and antimicrobial properties. In AIP Conference Proceedings 2018; AIP Publishing LLC: Melville, NY, USA, 2018; Volume 1945, p. 020008. [Google Scholar]

- Zheng, X.W.; Li, Z.Q. Structural and electrical transport properties of Nb-doped TiO2 films deposited on LaAlO3 by rf sputtering. Appl. Surf. Sci. 2009, 255, 8104–8109. [Google Scholar] [CrossRef]

- Singh, S.; Srinivasa, R.S.; Major, S.S. Effect of substrate temperature on the structure and optical properties of ZnO thin films deposited by reactive rf magnetron sputtering. Thin solid films. 2007, 515, 8718–8722. [Google Scholar] [CrossRef]

- Lin, S.S.; Huang, J.L. Effect of thickness on the structural and optical properties of ZnO films by rf magnetron sputtering. Surf. Coat. Technol. 2004, 185, 222–227. [Google Scholar] [CrossRef] [Green Version]

- Yan, B.X.; Luo, S.Y.; Mao, X.G.; Shen, J.; Zhou, Q.F. Unusual photoelectric behaviors of Mo-doped TiO2 multilayer thin films prepared by RF magnetron co-sputtering: Effect of barrier tunneling on internal charge transfer. Appl. Phys. A 2013, 110, 129–135. [Google Scholar] [CrossRef]

- Zuo, J.; Keil, P.; Grundmeier, G. Synthesis and characterization of photochromic Ag-embedded TiO2 nanocomposite thin films by non-reactive RF-magnetron sputter deposition. Appl. Surf. Sci. 2012, 258, 7231–7237. [Google Scholar] [CrossRef]

- Sato, Y.; Akizuki, H.; Kamiyama, T.; Shigesato, Y. Transparent conductive Nb-doped TiO2 films deposited by direct-current magnetron sputtering using a TiO2− x target. Thin Solid Films 2008, 516, 5758–5762. [Google Scholar] [CrossRef]

- Takeuchi, M.; Sakai, S.; Matsuoka, M.; Anpo, M. Preparation of the visible light responsive TiO2 thin film photocatalysts by the RF magnetron sputtering deposition method. Res. Chem. Intermed. 2009, 35, 973. [Google Scholar] [CrossRef]

- Ievtushenko, A.I.; Karpyna, V.A.; Lazorenko, V.I.; Lashkarev, G.V.; Khranovskyy, V.D.; Baturin, V.A.; Karpenko, O.Y.; Lunika, M.M.; Avramenko, K.A.; Strelchuk, V.V.; et al. High quality ZnO films deposited by radio-frequency magnetron sputtering using layer by layer growth method. Thin Solid Films 2010, 518, 4529–4532. [Google Scholar] [CrossRef]

- Zhang, W.; Li, Y.; Zhu, S.; Wang, F. Copper doping in titanium oxide catalyst film prepared by dc reactive magnetron sputtering. Catal. Today 2004, 93, 589–594. [Google Scholar] [CrossRef]

- Laird, R.; Belkind, A. Cosputtered films of mixed TiO2/SiO2. J. Vac. Sci. Technol. A 1992, 10, 1908–1912. [Google Scholar] [CrossRef]

- Matsuoka, M.; Kitano, M.; Takeuchi, M.; Anpo, M.; Thomas, J.M. Photocatalytic water splitting on visible light-responsive TiO2 thin films prepared by a RF magnetron sputtering deposition method. Top. Catal. 2005, 35, 305–310. [Google Scholar] [CrossRef]

- Anpo, M.; Takeuchi, M. The design and development of highly reactive titanium oxide photocatalysts operating under visible light irradiation. J. Catal. 2003, 216, 505–516. [Google Scholar] [CrossRef]

- Trupina, L.; Miclea, C.; Amarande, L.; Cioangher, M. Growth of highly oriented iridium oxide bottom electrode for Pb (Zr, Ti) O3 thin films using titanium oxide seed layer. J. Mater. Sci. 2011, 46, 6830–6834. [Google Scholar] [CrossRef]

- Kamisaka, H.; Mizuguchi, N.; Yamashita, K. Electron trapping at the lattice Ti atoms adjacent to the Nb dopant in Nb-doped rutile TiO2. J. Mater. Sci. 2012, 47, 7522–7529. [Google Scholar] [CrossRef]

- Diebold, U. The surface science of titanium dioxide. Surf. Sci. Rep. 2003, 48, 53–229. [Google Scholar] [CrossRef]

- Gillispie, M.A.; van Hest, M.F.; Dabney, M.S.; Perkins, J.D.; Ginley, D.S. rf magnetron sputter deposition of transparent conducting Nb-doped TiO2 films on SrTiO3. J. Appl. Phys. 2007, 101, 033125. [Google Scholar] [CrossRef]

- Jun, T.H.; Lee, K.S. Cr-doped TiO2 thin films deposited by RF-sputtering. Mater. Lett. 2010, 64, 2287–2289. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, F.; Zhang, J.; Chen, H.; Anpo, M. Fe3+-TiO2 photocatalysts prepared by combining sol–gel method with hydrothermal treatment and their characterization. J. Photochem. Photobiol. A 2006, 180, 196–204. [Google Scholar] [CrossRef]

- Seong, S.G.; Kim, E.J.; Kim, Y.S.; Lee, K.E.; Hahn, S.H. Influence of deposition atmosphere on photocatalytic activity of TiO2/SiOx double-layers prepared by RF magnetron sputtering. Appl. Surf. Sci. 2009, 256, 1–5. [Google Scholar] [CrossRef]

- Ohko, Y.; Tatsuma, T.; Fujii, T.; Naoi, K.; Niwa, C.; Kubota, Y.; Fujishima, A. Multicolour photochromism of TiO2 films loaded with silver nanoparticles. Nat. Mater. 2003, 2, 29–31. [Google Scholar] [CrossRef] [PubMed]

- Warren, S.C.; Thimsen, E. Plasmonic solar water splitting. Energy Environ. Sci. 2012, 5, 5133–5146. [Google Scholar] [CrossRef]

- Dionne, J.A.; Atwater, H.A. Plasmonics: Metal-worthy methods and materials in nanophotonics. Mrs Bull. 2012, 37, 717–724. [Google Scholar] [CrossRef] [Green Version]

- Lee, M.K.; Kim, T.G.; Kim, W.; Sung, Y.M. Surface plasmon resonance (SPR) electron and energy transfer in noble metal− zinc oxide composite nanocrystals. J. Phys. Chem. C 2008, 112, 10079–10082. [Google Scholar] [CrossRef]

- Tian, Y.; Tatsuma, T. Mechanisms and applications of plasmon-induced charge separation at TiO2 films loaded with gold nanoparticles. J. Am. Chem. Soc. 2005, 127, 7632–7637. [Google Scholar] [CrossRef] [PubMed]

- Furube, A.; Du, L.; Hara, K.; Katoh, R.; Tachiya, M. Ultrafast plasmon-induced electron transfer from gold nanodots into TiO2 nanoparticles. J. Am. Chem. Soc. 2007, 129, 14852–14853. [Google Scholar] [CrossRef]

- Yin, P.; Chen, L.; Wang, Z.; Qu, R.; Liu, X.; Ren, S. Production of biodiesel by esterification of oleic acid with ethanol over organophosphonic acid-functionalized silica. Bioresour Technol. 2012, 110, 258–263. [Google Scholar] [CrossRef]

- Nishijima, Y.; Ueno, K.; Kotake, Y.; Murakoshi, K.; Inoue, H.; Misawa, H. Near-infrared plasmon-assisted water oxidation. J. Phys. Chem. Lett. 2012, 3, 1248–1252. [Google Scholar] [CrossRef]

- Chen, M.H.; Chen, C.K.; Chen, C.J.; Cheng, L.C.; Wu, C.P.; Cheng, B.H.; Ho, Z.Y.; Tseng, L.M.; Hsu, Y.Y.; Chan, T.S. Plasmon inducing effects for enhanced photoelectrochemical water splitting X-ray absortpion approach to electronic structrures. ACS Nano 2012, 6, 7362–7372. [Google Scholar] [CrossRef]

- Khan, M.R.; Chuan, T.W.; Yousuf, A.; Chowdhury, M.N.; Cheng, C.K. Schottky barrier and surface plasmonic resonance phenomena towards the photocatalytic reaction: Study of their mechanisms to enhance photocatalytic activity. Catal. Sci. Technol. 2015, 5, 2522–2531. [Google Scholar] [CrossRef] [Green Version]

- György, E.; del Pino, A.P. Tunable optical and nano-scale electrical properties of WO3 and Ag-WO3 nanocomposite thin films. J. Mater. Sci. 2011, 46, 3560–3567. [Google Scholar] [CrossRef]

- Liu, S.X.; Qu, Z.P.; Han, X.W.; Sun, C.L. A mechanism for enhanced photocatalytic activity of silver-loaded titanium dioxide. Catal. Today 2004, 93, 877–884. [Google Scholar] [CrossRef]

- Nooke, A.; Beck, U.; Hertwig, A.; Krause, A.; Krüger, H.; Lohse, V.; Negendank, D.; Steinbach, J. On the application of gold based SPR sensors for the detection of hazardous gases. Sensor Actuators B-Chem. 2010, 149, 194–198. [Google Scholar] [CrossRef]

- Atabaev, T.S.; Hossain, M.A.; Lee, D.; Kim, H.K.; Hwang, Y.H. Pt-coated TiO2 nanorods for photoelectrochemical water splitting applications. Results Phys. 2016, 6, 373–376. [Google Scholar] [CrossRef] [Green Version]

- Sadeghi, M.; Liu, W.; Zhang, T.G.; Stavropoulos, P.; Levy, B. Role of photoinduced charge carrier separation distance in heterogeneous photocatalysis: Oxidative degradation of CH3OH vapor in contact with Pt/TiO2 and cofumed TiO2−Fe2O3. J. Phys. Chem.-US 1996, 100, 19466–19474. [Google Scholar] [CrossRef]

- Meng, F.; Sun, Z. Enhanced photocatalytic activity of silver nanoparticles modified TiO2 thin films prepared by RF magnetron sputtering. Mater. Chem. Phys. 2009, 118, 349–353. [Google Scholar] [CrossRef]

- Singh, J.; Khan, S.A.; Shah, J.; Kotnala, R.K.; Mohapatra, S. Nanostructured TiO2 thin films prepared by RF magnetron sputtering for photocatalytic applications. Appl. Surf. Sci. 2017, 422, 953–961. [Google Scholar] [CrossRef]

- Li, H.; Li, Z.; Yu, Y.; Ma, Y.; Yang, W.; Wang, F.; Yin, X.; Wang, X. Surface-plasmon-resonance-enhanced photoelectrochemical water splitting from Au-nanoparticle-decorated 3D TiO2 nanorod architectures. J. Phys. Chem. C 2017, 121, 12071–12079. [Google Scholar] [CrossRef]

- Vahl, A.; Veziroglu, S.; Henkel, B.; Strunskus, T.; Polonskyi, O.; Aktas, O.C.; Faupel, F. Pathways to Tailor Photocatalytic Performance of TiO2 Thin Films Deposited by Reactive Magnetron Sputtering. Materials 2019, 12, 2840. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.F.; Koshy, P.; Adler, L.; Sorrell, C.C. Photocatalytic activity of V-doped TiO2 thin films for the degradation of methylene blue and rhodamine B dye solutions. J. Aust. Ceram. Soc. 2017, 53, 569–576. [Google Scholar] [CrossRef]

- Bensouici, F.; Bououdina, M.; Dakhel, A.A.; Tala-Ighil, R.; Tounane, M.; Iratni, A.; Souier, T.; Liu, S.; Cai, W. Optical, structural and photocatalysis properties of Cu-doped TiO2 thin films. Appl. Surf. Sci. 2017, 395, 110–116. [Google Scholar] [CrossRef]

- Gomes, J.; Lincho, J.; Domingues, E.; Quinta-Ferreira, R.M.; Martins, R.C. N–TiO2 photocatalysts: A review of their characteristics and capacity for emerging contaminants removal. Water 2019, 11, 373. [Google Scholar] [CrossRef] [Green Version]

- Banerjee, S.; Pillai, S.C.; Falaras, P.; O’shea, K.E.; Byrne, J.A.; Dionysiou, D.D. New insights into the mechanism of visible light photocatalysis. J. Phys. Chem. Lett. 2014, 5, 2543–2554. [Google Scholar] [CrossRef] [Green Version]

- El-Sheikh, S.M.; Zhang, G.; El-Hosainy, H.M.; Ismail, A.A.; O’Shea, K.E.; Falaras, P.; Kontos, A.G.; Dionysiou, D.D. High performance sulfur, nitrogen and carbon doped mesoporous anatase–brookite TiO2 photocatalyst for the removal of microcystin-LR under visible light irradiation. J. Hazard. Mater. 2014, 280, 723–733. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Zhao, Y.; Sun, C.; Li, F.; Lu, G.Q.; Cheng, H.M. Synergistic effects of B/N doping on the visible-light photocatalytic activity of mesoporous TiO2. Angew. Chem. Int. Ed. 2008, 47, 4516–4520. [Google Scholar] [CrossRef]

- Xu, J.H.; Li, J.; Dai, W.L.; Cao, Y.; Li, H.; Fan, K. Simple fabrication of twist-like helix N, S-codoped titania photocatalyst with visible-light response. Appl. Catal. B-Environ. 2008, 79, 72–80. [Google Scholar] [CrossRef]

- Liu, G.; Han, C.; Pelaez, M.; Zhu, D.; Liao, S.; Likodimos, V.; Kontos, A.G.; Falaras, P.; Dionysiou, D.D. Enhanced visible light photocatalytic activity of CN-codoped TiO2 films for the degradation of microcystin-LR. J. Mol. Catal. A-Chem. 2013, 372, 58–65. [Google Scholar] [CrossRef]

- Katsanaki, A.V.; Kontos, A.G.; Maggos, T.; Pelaez, M.; Likodimos, V.; Pavlatou, E.A.; Dionysiou, D.D.; Falaras, P. Photocatalytic oxidation of nitrogen oxides on NF-doped titania thin films. Appl. Catal. B-Environ. 2013, 140, 619–625. [Google Scholar] [CrossRef]

- Cavalcante, R.P.; Dantas, R.F.; Bayarri, B.; González, O.; Giménez, J.; Esplugas, S.; Junior, A.M. Synthesis and characterization of B-doped TiO2 and their performance for the degradation of metoprolol. Catal. Today 2015, 252, 27–34. [Google Scholar] [CrossRef]

- Wieslander, G.; Norbäck, D.; Björnsson, E.; Janson, C.; Boman, G. Asthma and the indoor environment: The significance of emission of formaldehyde and volatile organic compounds from newly painted indoor surfaces. Int. Arch. Occup. Environ. Health 1996, 69, 115–124. [Google Scholar] [CrossRef]

- Wu, K.R.; Hung, C.H. Characterization of N, C-codoped TiO2 films prepared by reactive DC magnetron sputtering. Appl. Surf. Sci. 2009, 256, 1595–1603. [Google Scholar] [CrossRef]

- Fujishima, A.; Zhang, X.; Tryk, D.A. TiO2 photocatalysis and related surface phenomena. Surf. Sci. Rep. 2008, 63, 515–582. [Google Scholar] [CrossRef]

- Periyat, P.; Pillai, S.C.; McCormack, D.E.; Colreavy, J.; Hinder, S.J. Improved high-temperature stability and sun-light-driven photocatalytic activity of sulfur-doped anatase TiO2. J. Phys. Chem. C 2008, 112, 7644–7652. [Google Scholar] [CrossRef] [Green Version]

- Prabakar, K.; Takahashi, T.; Nezuka, T.; Takahashi, K.; Nakashima, T.; Kubota, Y.; Fujishima, A. Visible light-active nitrogen-doped TiO2 thin films prepared by DC magnetron sputtering used as a photocatalyst. Renew. Energy 2008, 33, 277–281. [Google Scholar] [CrossRef]

- Parker, J.C.; Siegel, R.W. Raman microprobe study of nanophase TiO2 and oxidation-induced spectral changes. J. Mater. Res. 1990, 5, 1246–1252. [Google Scholar] [CrossRef]

- Sathish, M.; Viswanathan, B.; Viswanath, R.P.; Gopinath, C.S. Synthesis, characterization, electronic structure, and photocatalytic activity of nitrogen-doped TiO2 nanocatalyst. Chem. Mater. 2005, 17, 6349–6353. [Google Scholar] [CrossRef]

- Di-Valentin, C.; Pacchioni, G.; Selloni, A. Origin of the different photoactivity of N-doped anatase and rutile TiO2. Phys. Rev. B. 2004, 70, 1–4. [Google Scholar] [CrossRef]

- Lindgren, T.; Mwabora, J.M.; Avendano, E.; Jonsson, J.; Hoel, A.; Granqvist, C.G.; Lindquist, S.E. Photoelectrochemical and optical properties of nitrogen doped titanium dioxide films prepared by reactive DC magnetron sputtering. J. Phys. Chem. B 2003, 107, 5709–5716. [Google Scholar] [CrossRef]

- Li, Q.; Shang, J.K. Heavily Nitrogen-Doped Dual-Phase Titanium Oxide Thin Films by Reactive Sputtering and Rapid Thermal Annealing. J. Am. Ceram. Soc. 2008, 91, 3167–3172. [Google Scholar] [CrossRef]

- Hamal, D.B.; Klabunde, K.J. Synthesis, characterization, and visible light activity of new nanoparticle photocatalysts based on silver, carbon, and sulfur-doped TiO2. J. Colloid Interface Sci. 2007, 311, 514–522. [Google Scholar] [CrossRef] [PubMed]

- Hsu, S.W.; Yang, T.S.; Chen, T.K.; Wong, M.S. Ion-assisted electron-beam evaporation of carbon-doped titanium oxide films as visible-light photocatalyst. Thin Solid Films 2007, 515, 3521–3526. [Google Scholar] [CrossRef]

- Matsunaga, T.; Inagaki, M. Carbon-coated anatase for oxidation of methylene blue and NO. Appl. Catal. B-Environ. 2006, 64, 9–12. [Google Scholar] [CrossRef]

- Lee, M.K.; Park, Y.C. Super-hydrophilic anatase TiO2 thin film in-situ deposited by DC magnetron sputtering. Thin Solid Films 2017, 638, 9–16. [Google Scholar] [CrossRef]

- Meng, F.; Lu, F. Characterization and photocatalytic activity of TiO2 thin films prepared by RF magnetron sputtering. Vacuum. 2010, 85, 84–88. [Google Scholar] [CrossRef]

- Sakatani, Y.; Grosso, D.; Nicole, L.; Boissière, C.; de AASoler-Illia, G.J.; Sanchez, C. Optimised photocatalytic activity of grid-like mesoporous TiO2 films: Effect of crystallinity, pore size distribution, and pore accessibility. J. Mater. Chem. 2006, 16, 77–82. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, X.; Wang, B.; Liu, Q. Preparation and super-hydrophilic properties of TiO2/SnO2 composite thin films. Mater. Res. Bull. 2002, 37, 2255–2262. [Google Scholar] [CrossRef]

- Khadar, M.A.; Shanid, N.M. Nanoscale fine-structure evaluation of RF magnetron sputtered anatase films using HRTEM, AFM, micro-Raman spectroscopy and fractal analysis. Surf. Coat. Technol. 2010, 204, 1366–1374. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.-H.; Rahman, K.H.; Wu, C.-C.; Chen, K.-C. A Review on the Pathways of the Improved Structural Characteristics and Photocatalytic Performance of Titanium Dioxide (TiO2) Thin Films Fabricated by the Magnetron-Sputtering Technique. Catalysts 2020, 10, 598. https://doi.org/10.3390/catal10060598

Wang Y-H, Rahman KH, Wu C-C, Chen K-C. A Review on the Pathways of the Improved Structural Characteristics and Photocatalytic Performance of Titanium Dioxide (TiO2) Thin Films Fabricated by the Magnetron-Sputtering Technique. Catalysts. 2020; 10(6):598. https://doi.org/10.3390/catal10060598

Chicago/Turabian StyleWang, Yu-Hsiang, Kazi Hasibur Rahman, Chih-Chao Wu, and Kuan-Chung Chen. 2020. "A Review on the Pathways of the Improved Structural Characteristics and Photocatalytic Performance of Titanium Dioxide (TiO2) Thin Films Fabricated by the Magnetron-Sputtering Technique" Catalysts 10, no. 6: 598. https://doi.org/10.3390/catal10060598