Microstructure-Enhanced Liquid–Liquid Extraction in a Real-Time Fluorescence Detection Microfluidic Chip †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Apparatus

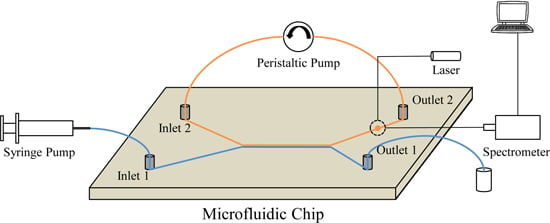

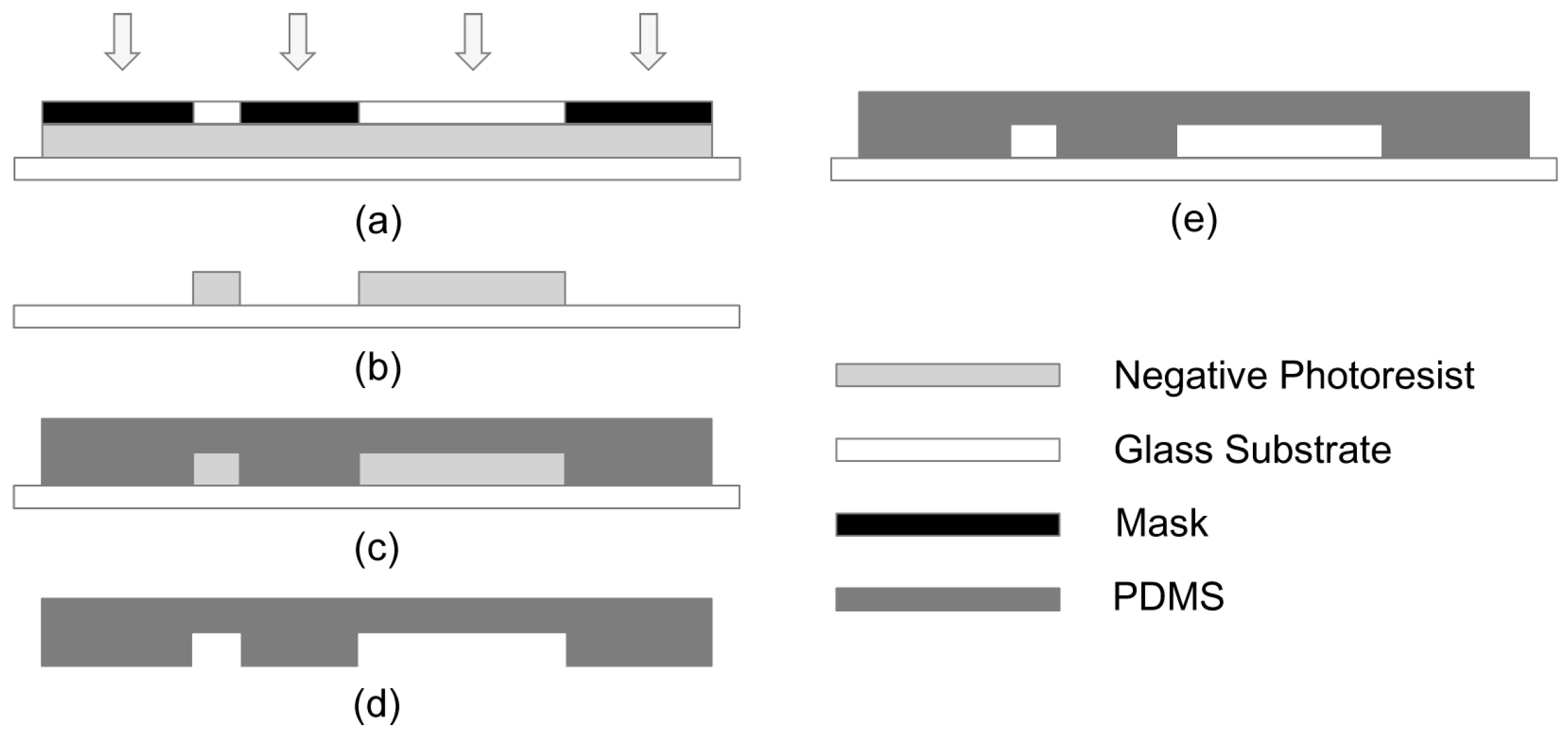

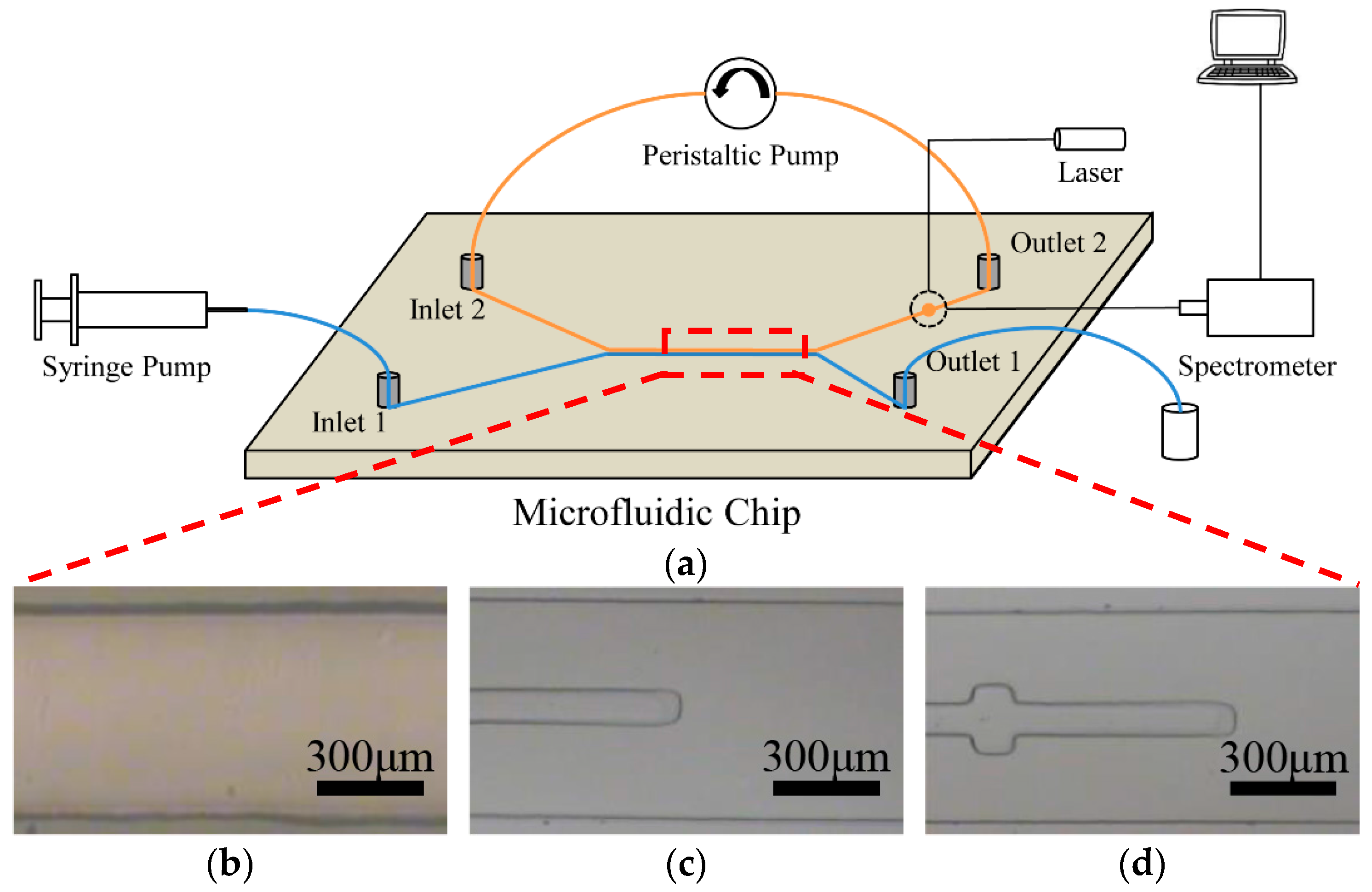

2.2. Design and Fabrication

2.3. Procedures

3. Results and Discussion

3.1. Selection of Flow Rate

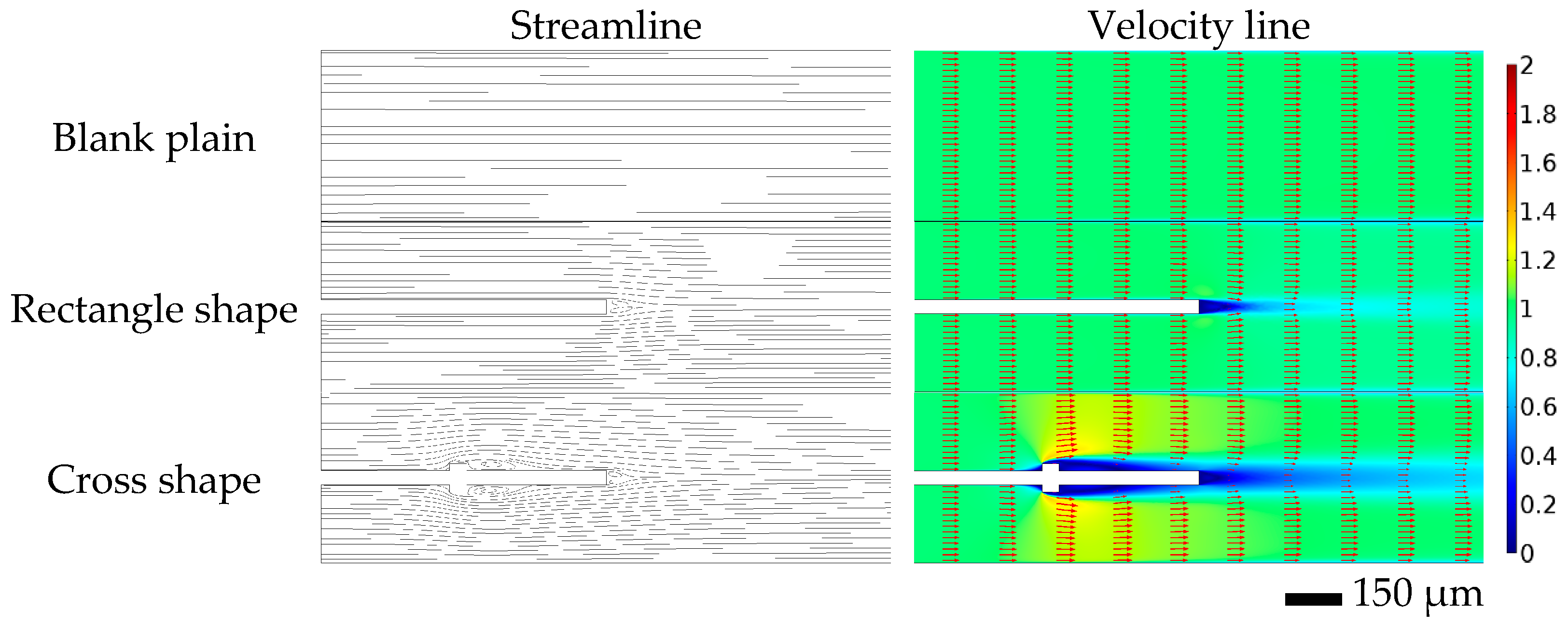

3.2. Simulation of Flow Flied

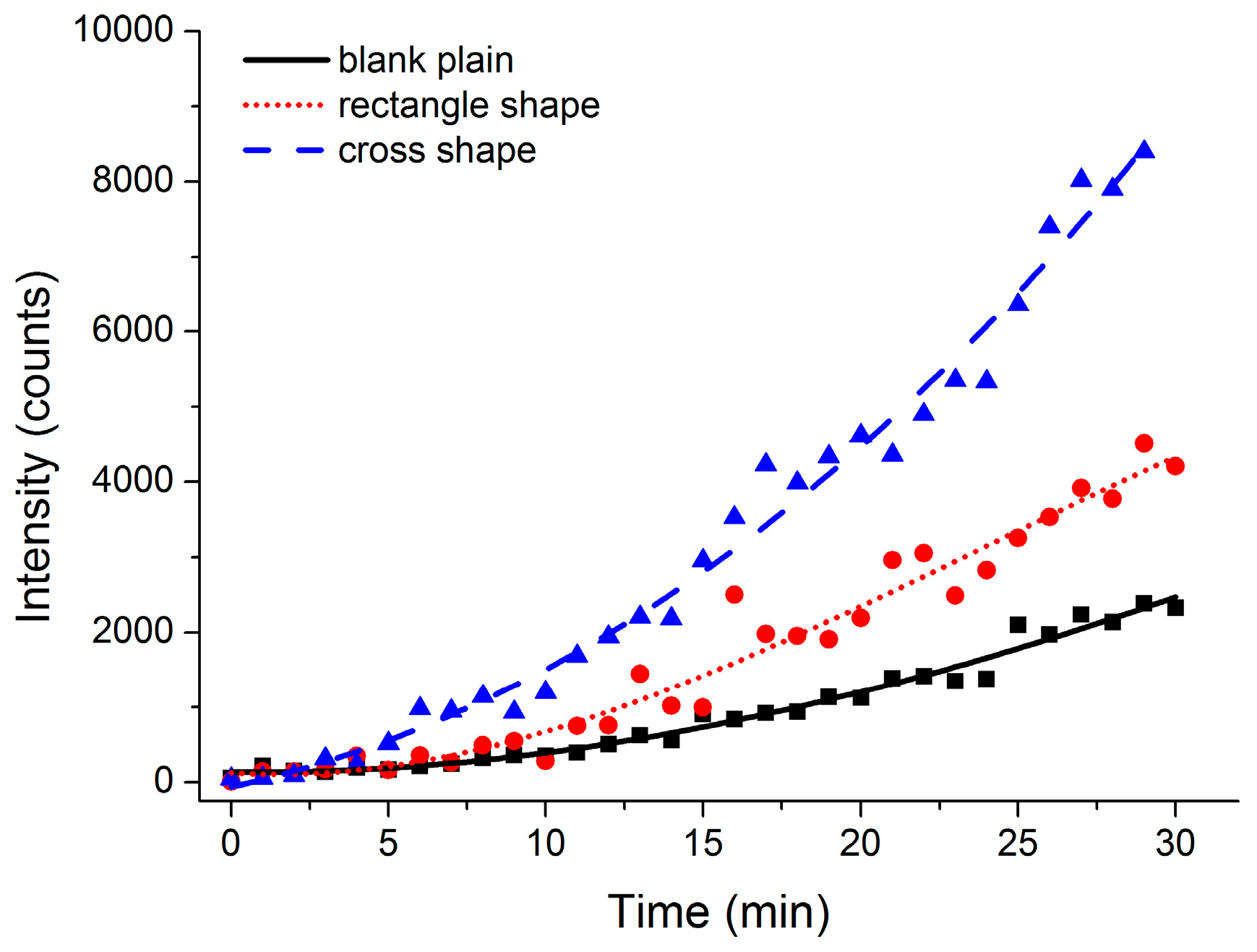

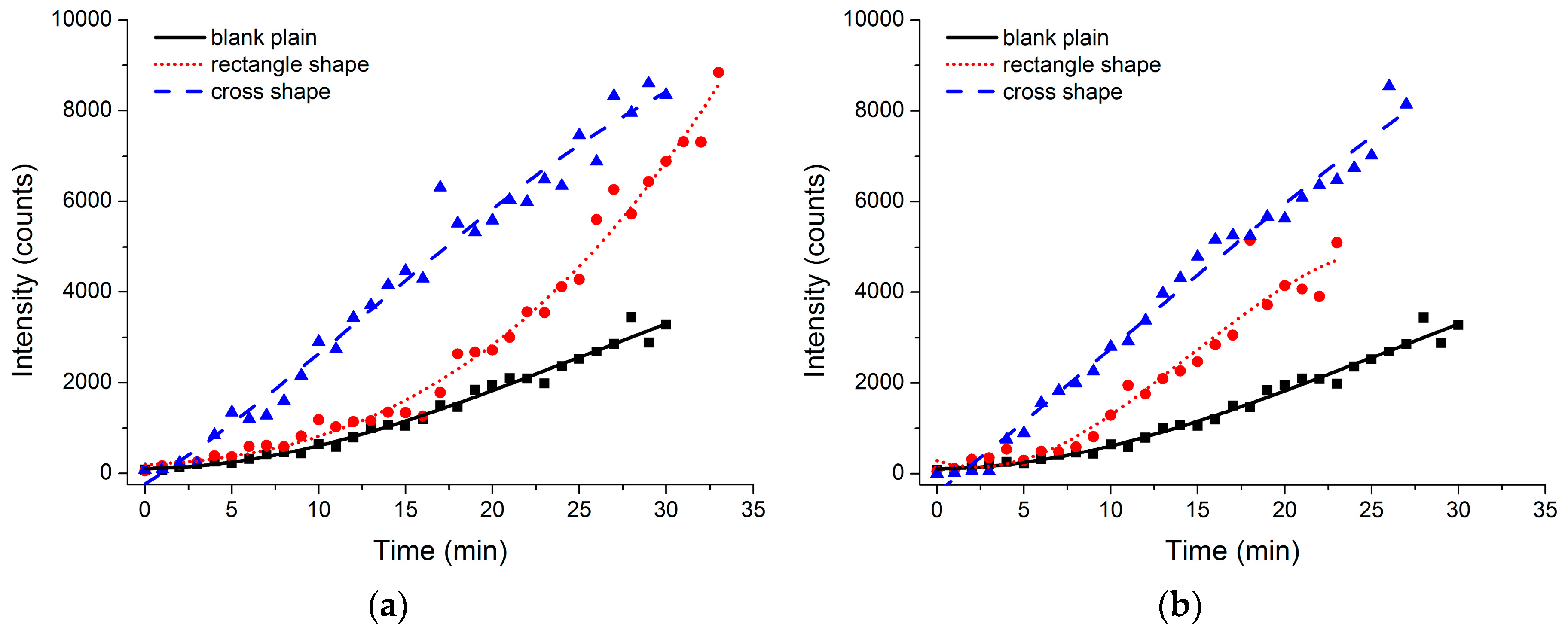

3.3. Performance of Microfluidic Chip

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- DeMello, A.J. Control and detection of chemical reactions in microfluidic systems. Nature 2006, 442, 394–402. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; Song, F.C.; Seo, S.W. A multilayered integrated sensor for three-dimensional, micro total analysis systems. J. Micromech. Microeng. 2013, 23, 095022. [Google Scholar] [CrossRef]

- Kovarik, M.L.; Ornoff, D.M.; Melvin, A.T.; Dobes, N.C.; Wang, Y.L.; Dickinson, A.J.; Gach, P.C.; Shah, P.K.; Allbritton, N.L. Micro total analysis systems: Fundamental advances and applications in the laboratory, clinic, and field. Anal. Chem. 2013, 85, 451–472. [Google Scholar] [CrossRef] [PubMed]

- Culbertson, C.T.; Mickleburgh, T.G.; Stewart-James, S.A.; Sellens, K.A.; Pressnall, M. Micro total analysis systems: Fundamental advances and biological applications. Anal. Chem. 2014, 86, 95–118. [Google Scholar] [CrossRef] [PubMed]

- Watts, P.; Wiles, C.; Haswell, S.J.; Pombo-Villar, E. Solution phase synthesis of β-peptides using micro reactors. Tetrahedron 2002, 58, 5427–5439. [Google Scholar] [CrossRef]

- Burns, M.A.; Johnson, B.N.; Brahmasandra, S.N.; Handique, K.; Webster, J.R.; Krishnan, M.; Sammarco, T.S.; Man, P.M.; Jones, D.; Heldsinger, D.; et al. An integrated nanoliter DNA analysis device. Science 1998, 282, 484–487. [Google Scholar] [CrossRef] [PubMed]

- Fu, A.Y.; Chou, H.P.; Spence, C.; Arnold, F.H.; Quake, S.R. An integrated microfabricated cell sorter. Anal. Chem. 2002, 74, 2451–2457. [Google Scholar] [CrossRef] [PubMed]

- Anderson, C.R.; Rupp, H.S.; Wu, W.H. Complexities in tetracycline analysis-chemistry, matrix extraction, cleanup, and liquid chromatography. J. Chromatogr. A 2005, 1075, 23–32. [Google Scholar] [CrossRef] [PubMed]

- Strehle, K.R.; Cialla, D.; Rosch, P.; Henkel, T.; Kohler, M.; Popp, J. A reproducible surface-enhanced raman spectroscopy approach. Online SERS measurements in a segmented microfluidic system. Anal. Chem. 2007, 79, 1542–1547. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.X.; Choo, J.B. Recent advances in surface-enhanced raman scattering detection technology for microfluidic chips. Electrophoresis 2008, 29, 1815–1828. [Google Scholar] [CrossRef] [PubMed]

- Henderson, R.K.; Baker, A.; Murphy, K.R.; Hamblya, A.; Stuetz, R.M.; Khan, S.J. Fluorescence as a potential monitoring tool for recycled water systems: A review. Water Res. 2009, 43, 863–881. [Google Scholar] [CrossRef] [PubMed]

- Rezaee, M.; Yamini, Y.; Faraji, M. Evolution of dispersive liquid-liquid microextraction method. J. Chromatogr. A 2010, 1217, 2342–2357. [Google Scholar] [CrossRef] [PubMed]

- Brody, J.P.; Yager, P. Diffusion-based extraction in a microfabricated device. Sens. Actuators A Phys. 1997, 58, 13–18. [Google Scholar] [CrossRef]

- Fleming, K.K.; Longmire, E.K.; Hubei, A. Numerical characterization of diffusion-based extraction in cell-laden flow through a microfluidic channel. J. Biomech. Eng. 2007, 129, 703–711. [Google Scholar] [PubMed]

- Huh, Y.S.; Jeon, S.J.; Lee, E.Z.; Park, H.S.; Hong, W.H. Microfluidic extraction using two phase laminar flow for chemical and biological applications. Korean J. Chem. Eng. 2011, 28, 633–642. [Google Scholar] [CrossRef]

- Lin, B. Microfluidics: Technologies and Applications; Springer: Berlin/Heidelberg, Germany, 2011; Volume 304. [Google Scholar]

- Xiao, H.; Liang, D.; Liu, G.; Guo, M.; Xing, W.; Cheng, J. Initial study of two-phase laminar flow extraction chip for sample preparation for gas chromatography. Lab Chip 2006, 6, 1067–1072. [Google Scholar] [CrossRef] [PubMed]

- Maruyama, T.; Kaji, T.; Ohkawa, T.; Sotowa, K.-I.; Matsushita, H.; Kubota, F.; Kamiya, N.; Kusakabe, K.; Goto, M. Intermittent partition walls promote solvent extraction of metal ions in a microfluidic device. Analyst 2004, 129, 1008–1013. [Google Scholar] [CrossRef]

- Marschewski, J.; Jung, S.; Ruch, P.; Prasad, N.; Mazzotti, S.; Michel, B.; Poulikakos, D. Mixing with herringbone-inspired microstructures: Overcoming the diffusion limit in co-laminar microfluidic devices. Lab Chip 2015, 15, 1923–1933. [Google Scholar] [CrossRef] [PubMed]

- Tagawa, T.; Aljbour, S.; Matouq, M.; Yamada, H. Micro-channel reactor with guideline structure for organic–aqueous binary system. Chem. Eng. Sci. 2007, 62, 5123–5126. [Google Scholar] [CrossRef]

- Iaccarino, G.; Ooi, A.; Durbin, P.A.; Behnia, M. Reynolds averaged simulation of unsteady separated flow. Int. J. Heat Fluid Flow 2003, 24, 147–156. [Google Scholar] [CrossRef]

- Friend, J.; Yeo, L. Fabrication of microfluidic devices using polydimethylsiloxane. Biomicrofluidics 2010, 4, 026502. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y. A Fluorescence Oil Detection Device; Louisiana State University: Baton Rouge, LA, USA, 2013. [Google Scholar]

- Huang, Y.S.; Meng, T.; Guo, T.; Li, W.; Yan, W.L.; Li, X.R.; Wang, S.; Tong, Z.P. Aqueous two-phase extraction for bovine serum albumin (BSA) with co-laminar flow in a simple coaxial capillary microfluidic device. Microfluid. Nanofluid. 2014, 16, 483–491. [Google Scholar] [CrossRef]

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, P.; Chen, X.; Xiong, Y.; Liu, G.; Tian, Y. Microstructure-Enhanced Liquid–Liquid Extraction in a Real-Time Fluorescence Detection Microfluidic Chip . Micromachines 2016, 7, 46. https://doi.org/10.3390/mi7030046

Xiong P, Chen X, Xiong Y, Liu G, Tian Y. Microstructure-Enhanced Liquid–Liquid Extraction in a Real-Time Fluorescence Detection Microfluidic Chip . Micromachines. 2016; 7(3):46. https://doi.org/10.3390/mi7030046

Chicago/Turabian StyleXiong, Penghui, Xiangyu Chen, Ying Xiong, Gang Liu, and Yangchao Tian. 2016. "Microstructure-Enhanced Liquid–Liquid Extraction in a Real-Time Fluorescence Detection Microfluidic Chip " Micromachines 7, no. 3: 46. https://doi.org/10.3390/mi7030046